Page 1

August 1997

CDP68HC68T1

CMOS Serial Real-Time Clock With

RAM and Power Sense/Control

Features

• SPI (Serial Peripheral Interface)

• Full Clock Features

- Seconds, Minutes, Hours (12/24, AM/PM), Day of

Week, Date, Month, Year (0-99), Automatic Leap Year

• 32 Word x 8-Bit RAM

• Seconds, Minutes, Hours Alarm

• Automatic Power Loss Detection

• Low Minimum Standby (Timekeeping) Voltage. . . 2.2V

• Selectable Crystal or 50/60Hz Line Input

• Buffered Clock Output

• Battery Input Pin that Powers Oscillator and also

Connects to V

Pin When Power Fails

DD

• Three Independent Interrupt Modes

- Alarm

- Periodic

- Power-Down Sense

Description

The CDP68HC68T1 Real-Time Clock provides a

time/calendar function, a 32 byte static RAM, and a 3 wire

Serial Peripheral Interface (SPI Bus). The primary function of

the clock is to divide down a frequency input that can be

supplied by the on-board oscillator in conjunction with an

external crystal or by an external clock source. The internal

oscillator can operate with a 32KHz, 1MHz, 2MHz, or 4MHz

crystal. An external clock source with a 32KHz, 1MHz,

2MHz, 4MHz, 50Hz or 60Hz frequency can be used to drive

the CDP68HC68T1. The time registers hold seconds,

minutes, and hours, while the calendar registers hold day-ofweek, date, month, and year information. The data is stored

in BCD format. In addition, 12 or 24 hour operation can be

selected. In 12 hour mode, an AM/PM indicator is provided.

The T1 has a programmable output which can provide one

of seven outputs for use elsewhere in the system.

Computer handshaking is controlled with a “wired-OR”

interrupt output. The interrupt can be programmed to provide

a signal as the result of: 1) an alarm programmed to occur at

a predetermined combination of seconds, minutes, and

hours; 2) one of 15 periodic interrupts ranging from subsecond to once per day frequency; 3) a power fail detect.

The PSE output and the V

power control. The

CPUR output is available to reset the

processor under power-down conditions.

under software control and can also be activated via the

CDP68HC68T1’s watchdog. If enabled, the watchdog

requires a periodic toggle of the CE pin without a serial

transfer.

input are used for external

SYS

CPUR is enabled

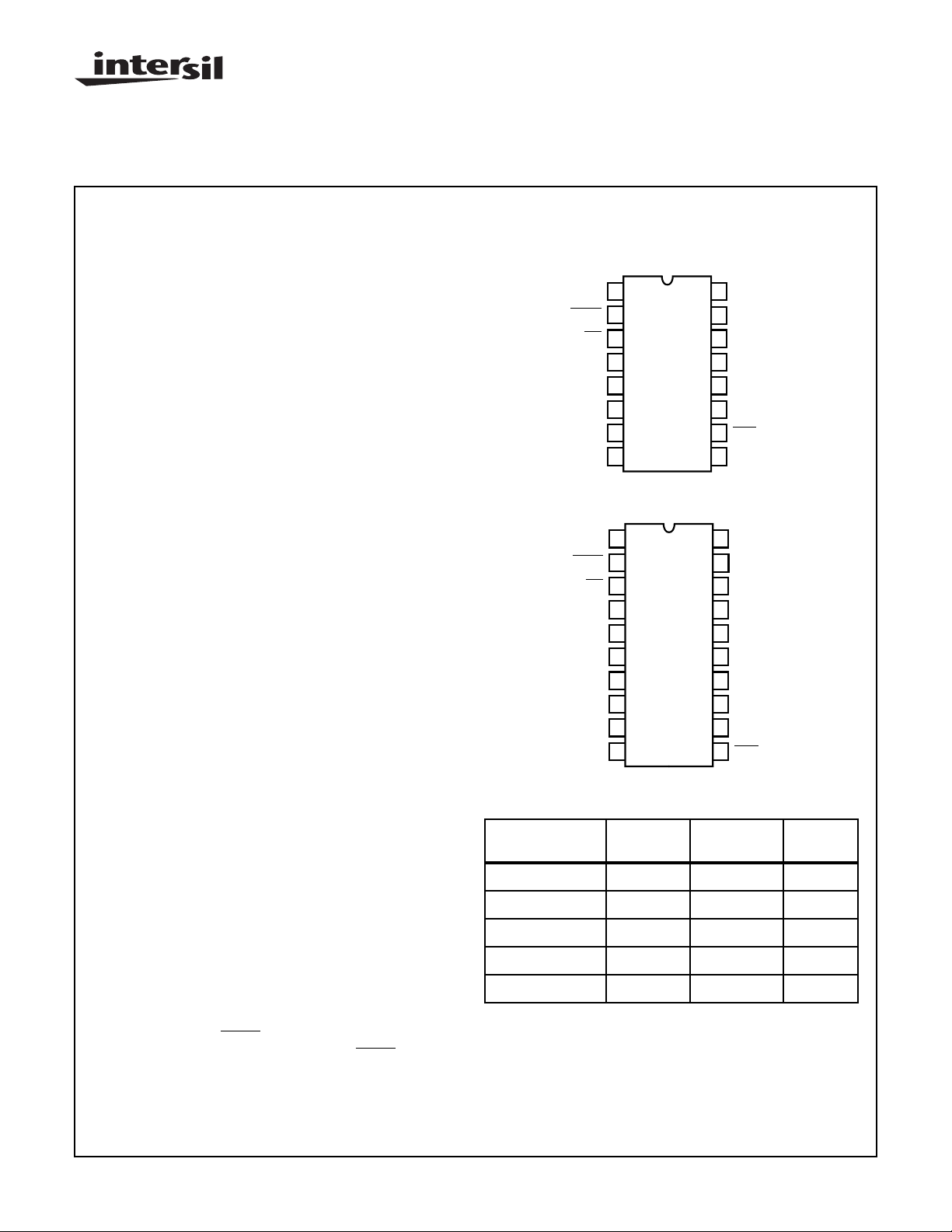

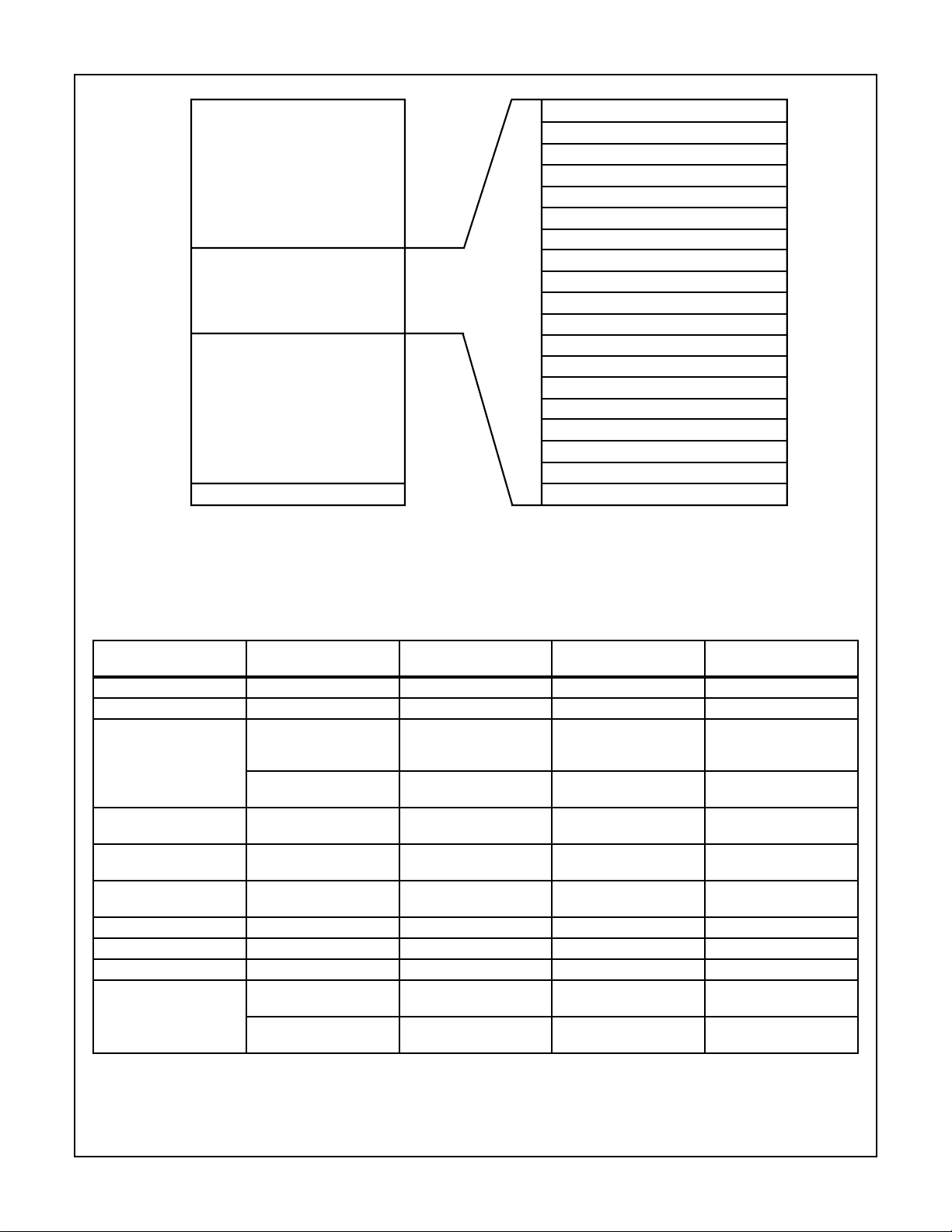

Pinouts

CDP68HC68T1 (PDIP, SBDIP, SOIC)

TOP VIEW

CLKOUT

CPUR

INT

SCK

MOSI

MISO

CE

V

SS

CLK OUT

CPUR

INT

NC

SCK

MOSI

MISO

CE

V

SS

PSE

1

2

3

4

5

6

7

8

CDP68HC68T1 (SOIC)

TOP VIEW

1

2

3

4

5

6

7

8

9

10

16

V

XTAL OUT

15

XTAL IN

14

V

13

V

12

LINE

11

POR

10

PSE

9

20

19

18

17

16

15

14

13

12

11

DD

BATT

SYS

VDD

XTAL OUT

XTAL IN

NC

V

BATT

V

SYS

NC

NC

LINE

POR

Ordering Information

TEMP.

PART NUMBER

CDP68HC68T1E -40 to 85 16 Ld PDIP E16.3

CDP68HC68T1D -40 to 85 16 Ld SBDIP D16.3

CDP68HC68T1M -40 to 85 20 Ld SOIC M20.3

CDP68HC68T1M2 -40 to 85 16 Ld SOIC M16.3

CDP68HC68T1W -40 to 85 DIE

NOTE: Pin number references throughout this specification refer to

the 16 lead PDIP/SBDIP/SOIC. See pinouts for cross reference.

RANGE (oC) PACKAGE

PKG.

NO.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

1

File Number 1547.3

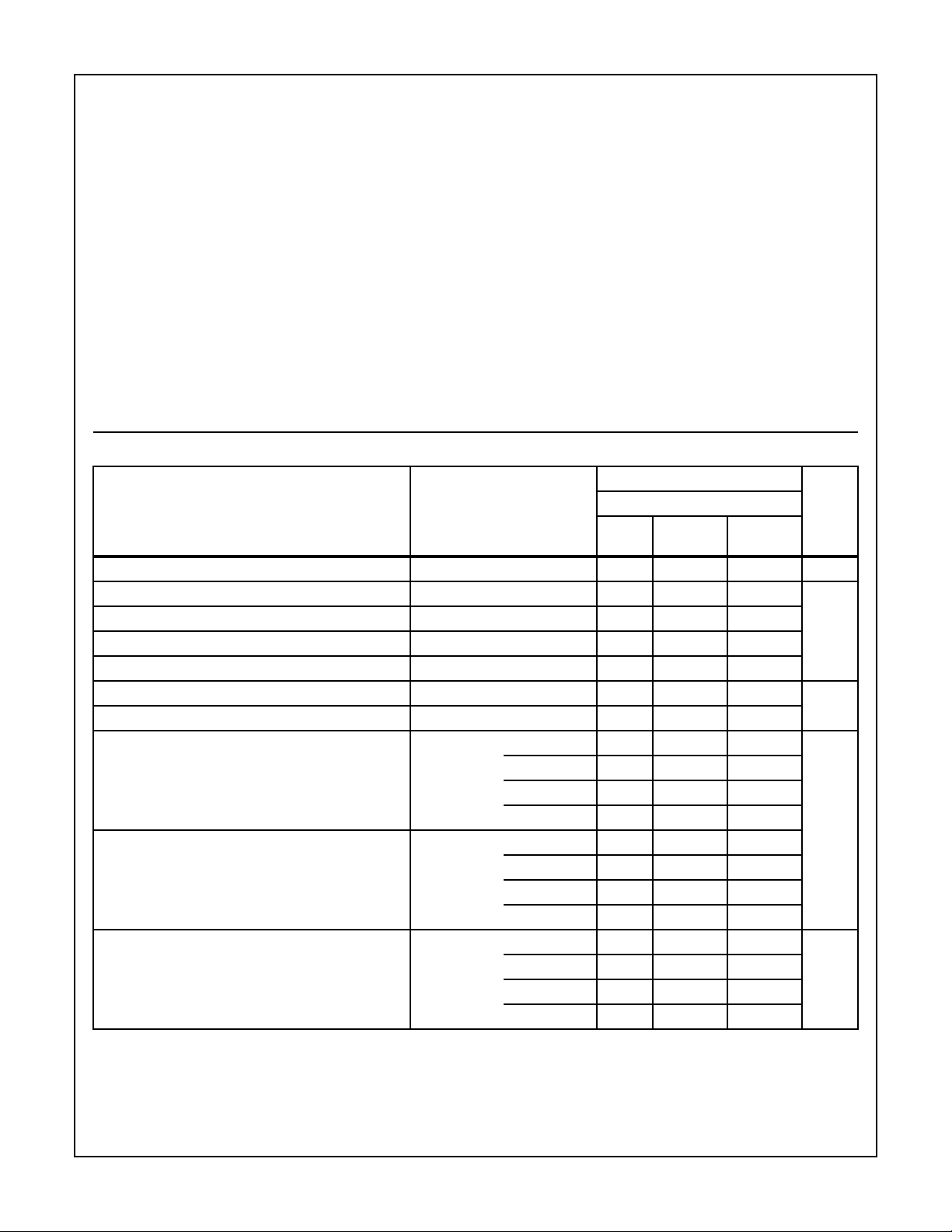

Page 2

CDP68HC68T1

Absolute Maximum Ratings Thermal Information

Supply Voltage, VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7V

Input Voltage, VIN. . . . . . . . . . . . . . . . . . . . VSS -0.3V to VDD +0.3V

Current Drain Per Input Pin Excluding VDD and VSS, I . . . . . .10mA

Current Drain Per Output Pin, I. . . . . . . . . . . . . . . . . . . . . . . . .40mA

Operating Conditions

Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +3.0V to +6.0V

Standby (Timekeeping) Voltage . . . . . . . . . . . . . . . . +2.2V to +6.0V

Temperature Range

CDP68HC68T1D (SBDIP Package). . . . . . . . . . . -55oC to 125oC

CDP68HC68T1E (PDIP Package) . . . . . . . . . . . . . -40oC to 85oC

CDP68HC68T1M/M2 (SOIC Packages). . . . . . . . . -40oC to 85oC

Input High Voltage . . . . . . . . . . . . . . . . . . . . . . . (0.7 x VDD) to V

Input Low Voltage. . . . . . . . . . . . . . . . . . . . . . . . . .0V to (0.3 x VDD)

Serial Clock Frequency (f

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

) . . . . . . . . . . . . . . . . . +3.0V to +6.0V

SCK

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

16 Ld PDIP . . . . . . . . . . . . . . . . . . . . . 90 N/A

16 Ld SOIC . . . . . . . . . . . . . . . . . . . . . 100 N/A

20 Ld SOIC . . . . . . . . . . . . . . . . . . . . . 100 N/A

16 Ld SBDIP . . . . . . . . . . . . . . . . . . . . 75 24

Maximum Junction Temperature (Hermetic) . . . . . . . . . . . . . . . 175oC

Maximum Junction Temperature (Plastic) . . . . . . . . . . . . . . . 150oC

Maximum Storage Temperature Range (T

) . . . .-65oC to 150oC

STG

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300oC

(SOIC, Lead Tips Only)

DD

Static Electrical Specifications At T

PARAMETER CONDITIONS

Quiescent Device Current I

Output Voltage High Level V

Output Voltage Low Level V

Output Voltage High Level V

Output Voltage Low Level V

Input Leakage Current I

Three-State Output Leakage Current I

Operating Current (Note 3)

(ID + IB) VDD = VB = 5V

Crystal Operation

Pin 14

External Clock (Squarewave) (Note 3)

(ID + IB) VDD= VS = 5V

Standby Current (Note 3) I

VS = 3V

Crystal Operation

= -40oC to +85oC, VDD = V

A

DD

OH

OL

OH

OL

IN

OUT

B

IOH = -1.6mA, VDD = 4.5V 3.7 - IOL = 1.6mA, VDD = 4.5V

IOH≤ 10µA, VDD = 4.5V 4.4 - IOL≤ 10µA, VDD = 4.5V

= 5V ±5%, except as noted.

BATT

LIMITS

CDP68HC68T1

(NOTE 2)

MIN

TYP MAX

-1 10µA

-

-

- 0.4

- 0.1

-- ±1

--±10

32kHz - 0.08 0.01

1MHz - 0.5 0.6

2MHz - 0.7 0.84

4MHz - 1 1.2

32kHz - 0.02 0.024

1MHz - 0.1 0.12

2MHz - 0.2 0.24

4MHz - 0.4 0.5

32kHz - 20 25

1MHz - 200 250

2MHz - 300 360

4MHz - 500 600

UNITS

V

µA

mA

µA

2

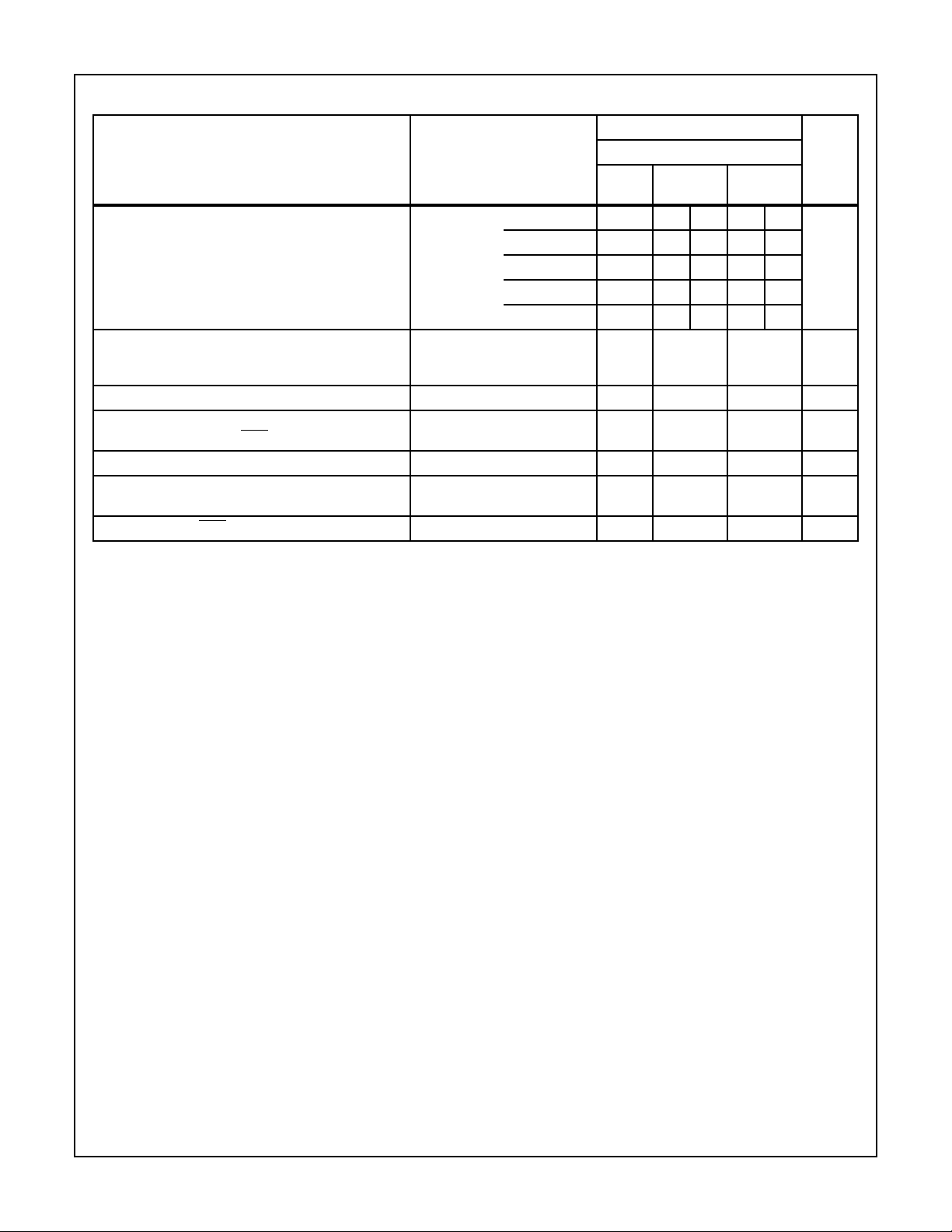

Page 3

CDP68HC68T1

Static Electrical Specifications At T

PARAMETER CONDITIONS

Operating Current (Note 3)

VDD = 5V, VB = 3V

Crystal Operation

Standby Current (Note 3) I

VB = 2.2V

Crystal Operation

Input Capacitance C

Maximum Rise and Fall Times tr, t

(Except XTAL Input and POR Pin 10)

Input Voltage (Line Input Pin Only, Power Sense Mode) 0 10 12 V

V

> V

SYS

(For VB Not Internally Connected to VDD)

Power-On Reset (POR) Pulse Width 100 75 - ns

NOTES:

2. Typical values are for TA = 25oC and nominal VDD.

3. Clock out (Pin 1) disabled, outputs open circuited. No serial access cycles.

B

= -40oC to +85oC, VDD = V

A

B

IN

f

V

T

VIN = 0, TA = 25oC--2pF

= 5V ±5%, except as noted. (Continued)

BATT

LIMITS

CDP68HC68T1

(NOTE 2)

MIN

32kHz - 25 15 30 20

1MHz - 0.08 0.15 0.1 0.18

2MHz - 0.15 0.25 0.18 0.3

4MHz - 0.3 0.4 0.36 0.5

32kHz - 10 12 µA

-- 2µs

- 0.7 - V

TYP MAX

I

DIBIDIS

UNITS

mA

3

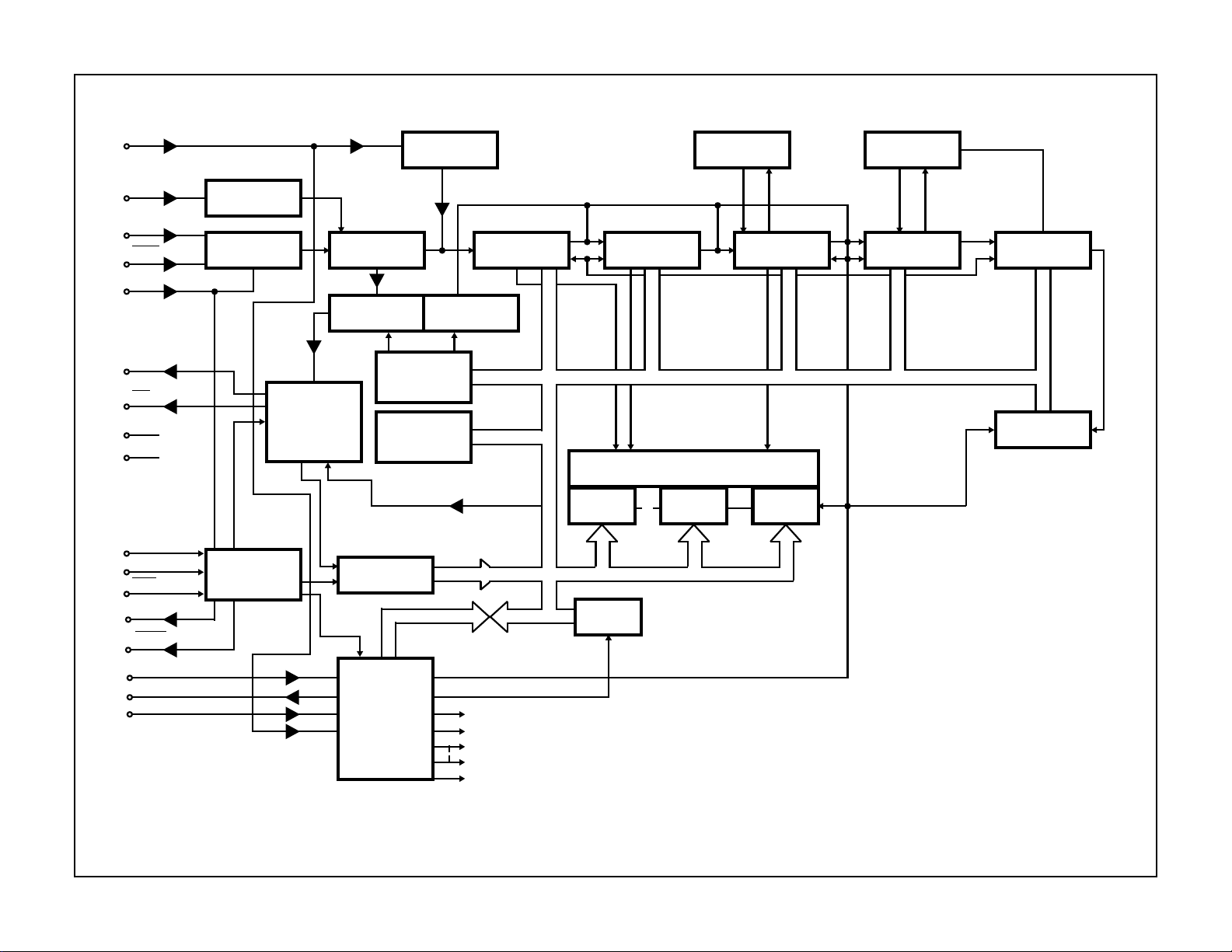

Page 4

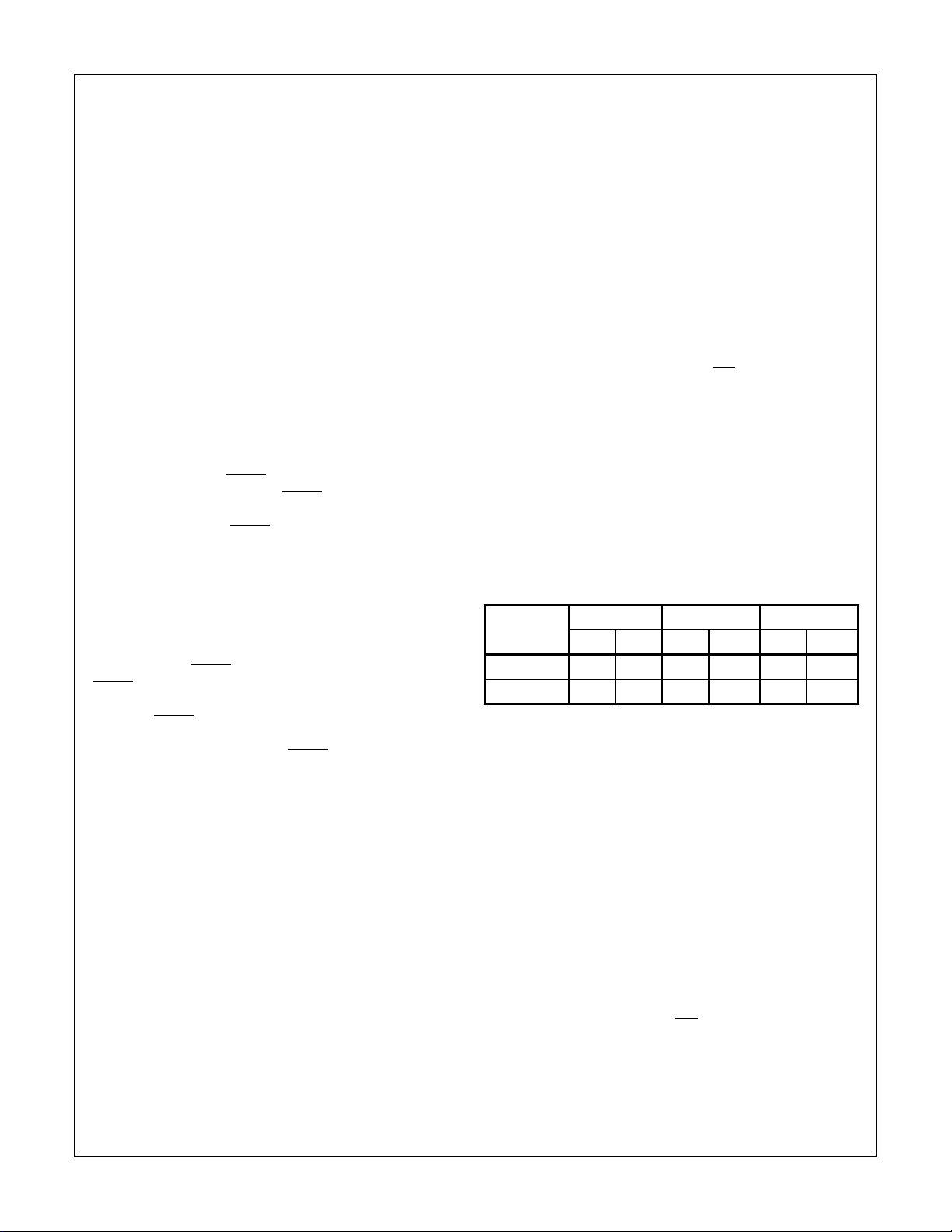

Functional Block Diagram

CE

LINE

50/60Hz

XTAL IN

XTAL OUT

V

BATT

CLOCK

OUT

INT

V

DD

V

SS

OSCILLATOR

CLOCK

LOGIC

PRESCALE SECOND MINUTE HOUR

PRESCALE

SELECT

AND

INT

4

LINE

V

SYS

POR

PSE

CPUR

POWER

SENSE

CONTROL

INT STATUS

REGISTER

FREEZE

CIRCUIT

CLOCK

CONTROL

REGISTER

INTERRUPT

CONTROL

REGISTER

CLOCK

SELECT

SECOND

LATCH

32 X 8

RAM

AM - PM AND

HOUR LOGIC

COMPARATOR

MINUTE

LATCH

8-BIT DATA BUS

HOUR

LATCH

CALENDAR

LOGIC

DAY/DAY

OF WEEK

MONTH

CDP68HC68T1

YEAR

SCK

MISO

MOSI

SERIAL

INTERFACE

FIGURE 1. REAL TIME CLOCK FUNCTIONAL DIAGRAM

Page 5

CDP68HC68T1

0

32 RAM LOCATIONS

31

32

CLOCK/CALENDAR

50

51

13 BYTES UNUSED

63

TEST MODE

R = READABLE W = WRITABLE

$00

$1F

$20

$32

$33

$3F

$5585

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FIGURE 2. ADDRESS MAP

SECONDS

MINUTES

HOURS

DAY OF WEEK

DATE

MONTH

YEARS

NOT USED

SEC ALARM

MIN ALARM

HRS ALARM

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

STATUS REGISTER

CONTROL REGISTER

INTERRUPT CONTROL REGISTER

R, W

R, W

R, W

R, W

R, W

R, W

R, W

R, W

R, W

$20

$21

$22

$23

$24

$25

$26

$27

$28

W

$29

W

$2A

W

$2B

$2C

$2D

$2E

$2F

$30

R

$31

$32

TABLE 1. CLOCK/CALENDAR AND ALARM DATA MODES

ADDRESS LOCATION

(H) FUNCTION DECIMAL RANGE BCD DATA RANGE

(NOTE 4)

BCD DATE EXAMPLE

20 Seconds 0-59 00-59 18

21 Minutes 0-59 00-59 49

22 Hours

12 Hour Mode

1-12 81-92 (AM)

A1-B2 (PM)

A3

(Note 5)

Hours

0-23 00-23 15

24 Hour Mode

23 Day of the Week

1-7 01-07 03

(Sunday = 1)

24 Day of the Month

1-31 01-31 29

(Date)

25 Month

1-12 01-12 10

Jan = 1, Dec = 12

26 Years 0-99 00-99 85

28 Alarm Seconds 0-59 00-59 18

29 Alarm Minutes 0-59 00-59 49

2A Alarm Hours (Note 6)

12 Hour Mode

Alarm Hours

1-12 01-12 (AM)

23

21-32 (PM)

0-23 00-23 15

24 Hour Mode

NOTES:

4. Example: 3:49:18, Tuesday. Oct. 29,1985.

5. Most significant Bit, D7, is “0” for 24 hours, and “1” for 12 hour mode. Data Bit D5 is “1” for P.M. and ‘0” for A.M. in 12 hour mode.

6. Alarm hours. Data Bit D5 is “1” for P.M. and “0” for A.M. in 12 hour mode. Data Bits D7 and D6 are DON’T CARE.

5

Page 6

CDP68HC68T1

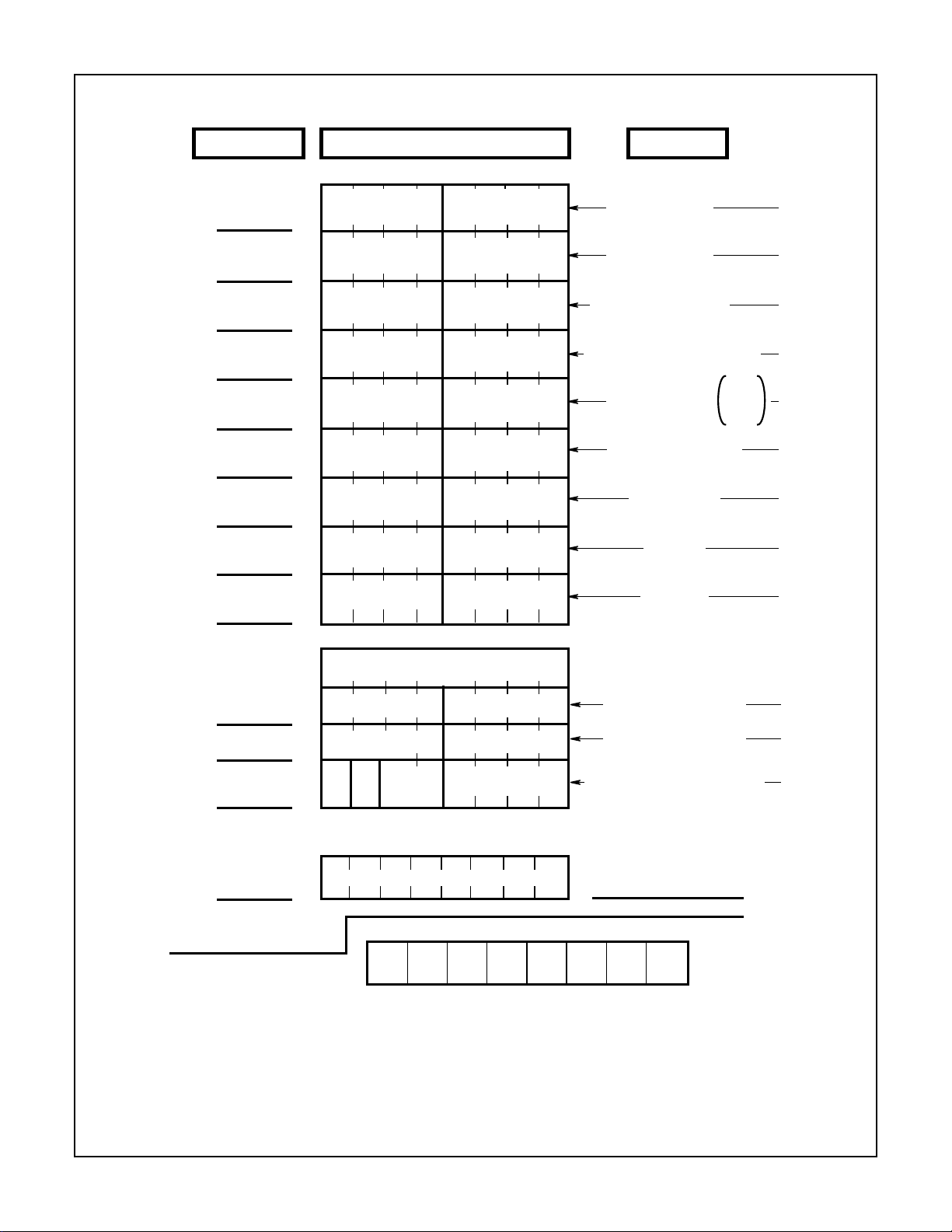

Programmers Model - Clock Registers

NAMEWRITE/READ REGISTERSHEX ADDRESS

DB7

20

21

22

23

24

25

26

31

32

TENS 0-5

TENS 0-5

12

HR

24

XXXX

76543210

76543210

PM/AM

X

TENS 0-2

TENS 0-3

TENS 0-1

TENS 0-9

X

UNITS 0-9

UNITS 0-9

UNITS 0-9

UNITS 1-7

UNITS 0-9

UNITS 0-9

UNITS 0-9

DB0

SECONDS (00-59)

MINUTES (00-59)

DB7, 1 = 12 HR., 0 = 24 HR.

DB = 1 PM, 0 = AM

HOURS (01-12 OR 00-23

DAY OF WK (01-07) SUNDAY = 1

01-28

DATE

DAY OF MONTH

MONTH (01-12) JAN = 1

DEC = 12

YEARS (00-99)

CONTROL

INTERRUPT

29

30

31

28

29

2A

30

RAM DATA BYTE

XX

765 432 1 0

NOTE: X = Don’t care writes, X = 0 when read.

WRITE ONLY REGISTERS

TENS 0-5

TENS 0-5

PM/AM

TENS 0-2

READ ONLY REGISTERS

7654321 0

D7 D6 D5 D4 D3 D2 D1 D0

HEX ADDRESS 00-1F

UNITS 0-9

UNITS 0-9

UNITS 0-9

BIT

ALARM SECONDS (00-59)

ALARM MINUTES (00-59)

ALARM HOURS (01-12 OR 00-23)

PLUS AM/PM IN 12 HR. MODE

PM = 1, AM = 0

STATUS

6

Page 7

Functional Description

CDP68HC68T1

The SPI real-time clock consists of a clock/calendar and a

32 x 8 RAM. Communications is established via the SPI

(Serial Peripheral Interface) bus. In addition to the clock/calendar data from seconds to years, and system flexibility provided by the 32-byte RAM, the clock features computer

handshaking with an interrupt output and a separate squarewave clock output that can be one of 7 different frequencies.

An alarm circuit is available that compares the alarm latches

with the seconds, minutes and hours time counters and activates the interrupt output when they are equal. The clock is

specifically designed to aid in power-down/up applications

and offers several pins to aid the designer of battery backup

systems.

Mode Select

The voltage level that is present at the V

input pin at the

SYS

end of power-on-reset selects the device to be in the single

supply or battery backup mode.

Single-Supply Mode

If V

CLK OUT, PSE and

will be completely operational.

logic level at the V

CLK OUT, PSE and

down instruction, V

is a logic high when power-on-reset is completed,

SYS

CPUR will be enabled and the device

CPUR will be placed low if the

pin goes low. If the output signals

SYS

CPUR are disabled due to a power-

brought to a logic low and then to a

SYS

logic high will re-enable these outputs. An example of the

single-supply mode is where only one supply is available

and V

DD

, V

BATT

and V

are tied together to the supply.

SYS

Battery Backup Mode

If V

OUT, PSE and

CPUR low). This condition will be held until V

threshold (about 0.7V) above V

PSE and

operational. If V

outputs CLK OUT, PSE and

example of battery backup operation occurs if V

V

connected to the V

is a logic low at the end of power-on-reset, CLK

SYS

CPUR will be disabled (CLK OUT, PSE and

rises to a

. The outputs CLK OUT,

BATT

SYS

CPUR will then be enabled and the device will be

falls below a threshold above V

SYS

BATT

CPUR will be disabled. An

is tied to

and VDD is not connected to a supply when a battery is

DD

pin. (See Pin Functions, V

BATT

SYS

BATT

the

for

Battery Backup Operation.)

Clock/Calendar (See Figure 1 and Figure 2)

The clock/calendar portion of this device consists of a long

string of counters that is toggled by a 1Hz input. The 1Hz

input is generated by a prescaler driven by an on-board

oscillator that utilizes one of four possible external crystals or

that can be driven by an external clock source. The 1Hz trigger to the counters can also be supplied by a 50Hz or 60Hz

input source that is connected to the LINE input pin.

The time counters offer seconds, minutes and hours data in

12 hour or 24 hour format. An AM/PM indicator is available

that once set, toggles every 12 hours. The calendar counters

consist of day (day of week), date (day of month), month and

years information. Data in the counters is in BCD format.

The hours counter utilizes BCD for hour data plus bits for

12/24 hour and AM/PM. The 7 time counters are accessed

serially at addresses 20H through 26H. (See Table 1).

RAM

The real-time clock also has a static 32 x 8 RAM that is

located at addresses 00-1FH. Transmitting the address/control word with bit-5 low selects RAM access. Bits 0 through 4

select the RAM location.

Alarm

The alarm is set by accessing the three alarm latches and

loading the required data. The alarm latches consist of seconds, minutes and hours registers. When their outputs equal

the values in the seconds, minutes and hours time counters,

an interrupt is generated. The interrupt output will go low if

the alarm bit in the Interrupt Control Register is set high. The

alarm interrupt bit in the Status Register is set when the

interrupt occurs (see Pin Functions,

INT Pin). To preclude a

false interrupt when loading the time counters, the alarm

interrupt bit should be set low in the Interrupt Control Register. This procedure is not required when the alarm time is

set.

Watchdog Function (See Figure 6)

When bit 7 in the Interrupt Control Register is set high, the

Clock’s CE (chip enable) pin must be toggled at a regular

interval without a serial data transfer. If the CE is not toggled,

the clock will supply a CPU reset pulse and bit 6 in the Status Register will be set. Typical ser vice and reset times are

listed below.

50Hz 60Hz XTAL

MIN MAX MIN MAX MIN MAX

Service Time - 10ms - 8.3ms - 7.8ms

Reset Time 20 40ms 16.7 33.3ms 15.6 31.3ms

Clock Out

The value in the 3 least significant bits of the Clock Control

Register selects one of seven possible output frequencies.

(See Clock Control Register). This squarewave signal is

available at the CLK OUT pin. When Power-Down operation

is initiated, the output is set low.

Control Registers and Status Registers

The operation of the Real-Time Clock is controlled by the

Clock Control and Interrupt Control Registers. Both registers

are Read-Write Registers. Another register, the Status Register, is available to indicate the operating conditions. The

Status Register is a Read only Register.

Power Control

Power control is composed of two operations, Power Sense

and Power Down/Up. Two pins are involved in power sensing, the LINE input pin and the

INT output pin. Two additional

pins are utilized during power-down/up operation. They are

the PSE (Power Supply Enable) output pin and V

SYS

input

pin.

7

Page 8

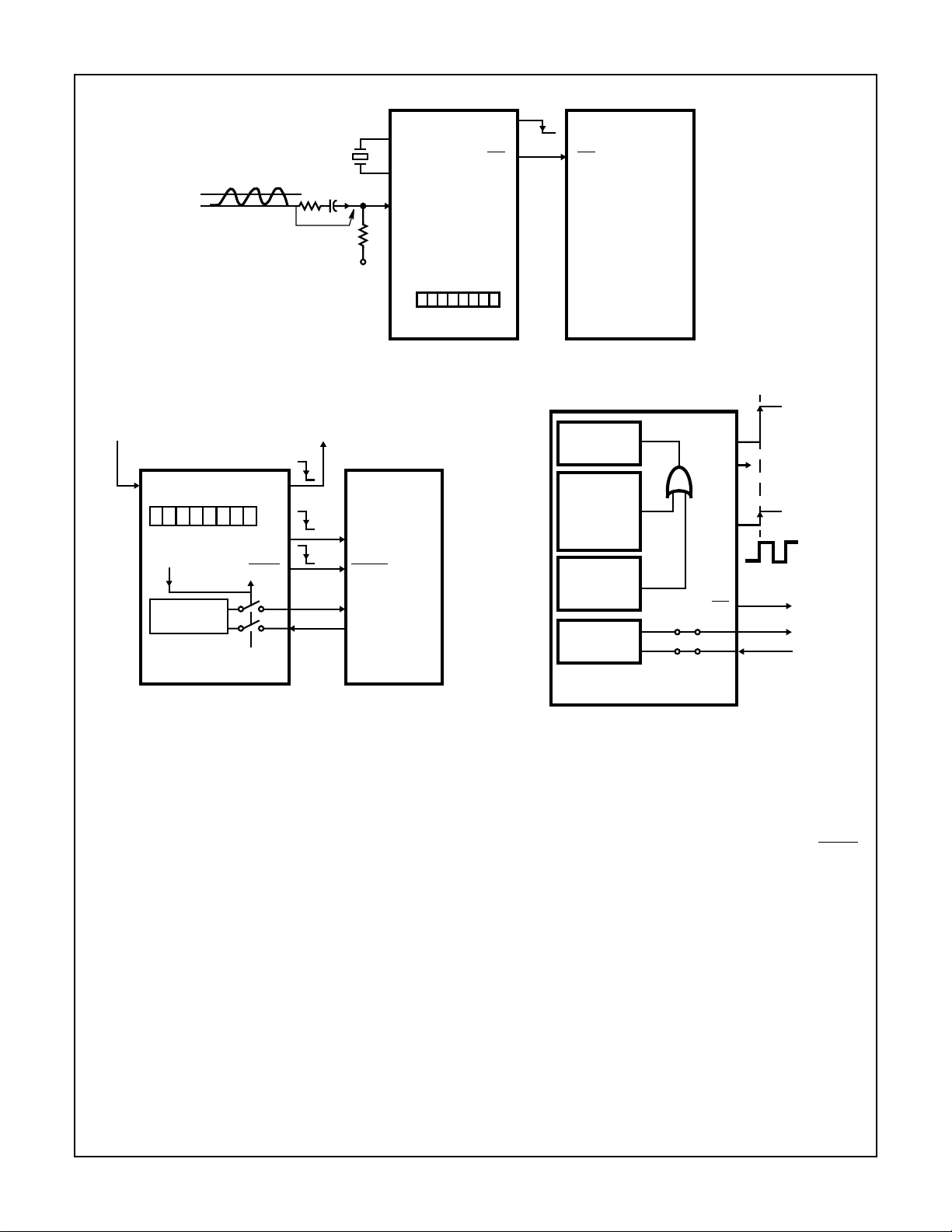

CDP68HC68T1

XTAL IN

INT INT

V

DD

0V

XTAL OUT

LINE

CPU

CDP68HC05C16B

V

REAL-TIME CLOCK

DD

STATUS REGISTER

CDP68HC68T1

I

FIGURE 3. POWER-SENSING FUNCTIONAL DIAGRAM

FROM SYSTEM

POWER

V

SYS

I

INTERRUPT

CONTROL

REGISTER

SERIAL

INTERFACE

REAL-TIME CLOCK

CDP68HC68T1

TO SYSTEM

POWER CONTROL

PSE

CLK

OUT

CPUR

MISO

MOSI

OSC

RESET

CPU

CDP68HC05C4B

POWER

UP

POWER

SENSE

OR

ALARM

CIRCUIT

PERIODIC

INTERRUPT

SIGNAL

SERIAL

INTERFACE

REAL-TIME CLOCK

CDP68HC68T1

PSE

CPUR

CLK

OUT

INT

MISO

MOSI

FIGURE 4. POWER-DOWN FUNCTIONAL DIAGRAM FIGURE 5. POWER-UP FUNCTIONAL DIAGRAM (INITIA TED

BY INTERRUPT SIGNAL

Power Sensing (See Figure 3)

When Power Sensing is enabled (Bit 5 = 1 in Interrupt Control Register), AC transitions are sensed at the LINE input pin.

Threshold detectors determine when transitions cease. After

a delay of 2.68ms to 4.64ms, plus the external input circuit RC

time constant, an interrupt is generated and a bit is set in the

Status Register. This bit can then be sampled to see if system

power has turned back on. See PIN FUNCTIONS, LINE PIN.

The power-sense circuitry operates by sensing the lev el of the

voltage presented at the line input pin. This voltage is centered around V

threshold (about 1V) from V

and as long as it is either plus or minus a

DD

a power-sense failure will not

DD

be indicated. With an AC signal present, remaining in this

V

window longer than a minimum of 2.68ms will activate

DD

the power-sense circuit. The larger the amplitude of the AC

signal, the less time it spends in the V

likely a power failure will be detected. A 60Hz, 10V

window, and the less

DD

P-P

sinewave voltage is an applicable signal to present at the LINE

input pin to setup the power sense function.

Power Down (See Figure 4)

Power down is a processor-directed operation. A bit is set in

the Interrupt Control Register to initiate operation. 3 pins are

affected. The PSE (Power Supply Enable) output, normally

high, is placed low. The CLK OUT is placed low. The

CPUR

output, connected to the processors reset input is also

placed low. In addition, the Serial Interface is disabled.

Power Up (See Figure 5 and Figure 6)

Two conditions will terminate the Power-Down mode. The

first condition (See Figure 5) requires an interrupt. The interrupt can be generated by the alarm circuit, the programmable periodic interrupt signal, or the power sense circuit.

The second condition that releases Power Down occurs

when the level on the V

level at the V

V

(See Figure 6) in the Battery Backup Mode or V

BATT

input, after previously falling to the level of

BATT

pin rises about 0.7V above the

SYS

falls to logic low and returns high in the Single Supply Mode.

8

SYS

Page 9

CDP68HC68T1

V

SS

The negative power-supply pin that is connected to ground.

V

BATT

V

SYS

SERIAL

INTERFACE

REAL-TIME CLOCK

CDP68HC68T1

FIGURE 6. POWER-UP FUNCTIONAL DIAGRAM (INITIATED BY

A RISE IN VOLTAGE ON THE “V

PSE

CPUR

CLK

OUT

SYS

MISO

MOSI

” PIN)

CLK OUT

Clock output pin. One of seven frequencies can be selected

(or this output can be set low) by the levels of the three

LSB’s in the Clock-Control Register. If a frequency is

selected, it will toggle with a 50% duty cycle except 2Hz in

the 50Hz time base mode. (Ex, if 1Hz is selected, the output

will be high for 500ms and low for the same period). During

power-down operation (bit 6 in Interrupt Control Register set

to “1”), the clock-output pin will be set low.

CPUR

CPU reset output pin. This pin functions as an N-Channel

only, open-drain output and requires an external pull-up

resistor.

INT

Interrupt output pin. This output is driven from a single NFET

pulldown transistor and must be tied to an external pull-up

resistor. The output is activated to a low level when:

1. Power-sense operation is selected (B5 = 1 in Interrupt

Control Register) and a power failure occurs.

2. A previously set alarm time occurs. The alarm bit in the

Status Register and interrupt-out signal are delayed

30.5µs when 32kHz operation is selected and 15.3µs for

2MHz and 7.6µs for 4MHz.

3. A previously selected periodic interrupt signal activates.

The Status Register must be read to set the Interrupt output

high after the selected periodic interval occurs. This is also

true when conditions 1 and 2 activate the interrupt. If power

down had been previously selected, the interrupt will also

reset the power-down functions.

PSE

Power-supply enable output pin. This pin is used to control

power to the system. The pin is set high when:

1. V

rises above the V

SYS

voltage after V

BATT

SYS

was

placed low by a system failure.

2. An interrupt occurs.

3. A power-on reset (if V

is a logic high).

SYS

The PSE pin is set low by writing a high into bit 6 (powerdown bit) in the Interrupt Control Register.

POR

Power-on reset. A Schmitt-trigger input that generates a

power-on internal reset signal using an external R-C network. Both control registers and frequency dividers for the

oscillator and line input are reset. The Status Register is

reset except for the first time up bit (B4), which is set.

Single supply or battery backup operation is selected at the

end of POR.

LINE

This input is used for two functions. When not used it

should be connected to V

via a 10kΩ resistor. The first

DD

function utilizes the input signal as the frequency source for

the timekeeping counters. This function is selected by

setting bit 6 in the Clock Control Register. The second

function enables the line input to sense a power failure.

Threshold detectors operating above and below V

DD

sense

an AC voltage loss. Bit 5 must be set to “1” in the Interrupt

Control Register and crystal or external clock source

operation is required. Bit 6 in the Clock Control Register

must be low to select XTAL operation.

Oscillator Circuit

The CDP68HC68T1 has an on-board 150K resistor that is

switched in series with its internal inverter when 32kHz is

selected via the Clock Control Register. Note: When first

powered up the series resistor is not part of the oscillator

circuit. (The CDP68HC68T1 sets up for a 4MHz oscillator).

SCK, MOSI, MISO

See Serial Peripheral Interface (SPI) section in this data sheet.

CE

A positive chip-enable input. A low level at this input holds the

serial interface logic in a reset state. This pin is also used for

the watchdog function.

9

Page 10

CDP68HC68T1

R (NOTE 8)

5 - 30pF

C1

CRYSTAL

10 - 40pF

XTAL

IN

T1

NOTES:

7. All frequencies recommended oscillator circuit. C1, C2 values

crystal dependent.

8. R used for 32KHz operation only. 100K - 300K range as specified

by crystal manufacturer.

FIGURE 7. OSCILLATOR CIRCUIT

V

SYS

22M

XTAL

OUT

C2

This input is connected to the system voltage. After the CPU

initiates power down by setting bit 6 in the Interrupt Control

Register to “1”, the level on this pin will terminate power

down if it rises about 0.7V above the level at the V

pin after previously falling below V

+0.7V. When power

BATT

BATT

input

down is terminated, the PSE pin will return high and the

Clock Output will be enabled. The

CPUR output pin will also

return high. The logic level present at this pin at the end of

POR determines the CDP68HC68T1’s operating mode.

V

BATT

The oscillator power source. The positive terminal of the battery should be connected to this pin. When the level on the

V

pin falls below V

SYS

internally connected to the V

V

rises a threshold above (0.7V) the voltage on V

SYS

the connection from V

the “LINE” input is used as the frequency source, V

be tied to V

V

BATT

or VSS. The “XTAL IN” pin must be at VSS if

DD

is at VSS. If V

IN” pin can be tied to V

+0.7V, the V

BATT

BATT

BATT

SS

pin. When the voltage on

DD

to the VDDpin is opened. When

is connected to VDD, the “XTAL

or VDD.

pin will be

BATT

BATT

BATT

may

XTAL IN, XTAL OUT

These pins are connected to a 32,768Hz. 1.048576MHz,

2.097152MHz or 4.194304MHz crystal. If an external clock

is used, it should be connected to “XTAL IN” with ‘XTAL

OUT” left open.

V

DD

The positive power-supply pin.

Clock Control Register

START-STOP

A high written into this bit will enable the counter stages of

the clock circuitry. A low will hold all bits reset in the divider

chain from 32Hz to 1Hz. A clock out selected by bits 0, 1 and

2 will not be affected by the stop function e xcept the 1Hz and

2Hz outputs.

LlNE-XTAL

When this bit is set high, clock operation will use the 50 or

60-cycle input present at the LINE input pin. When the bit is

low, the crystal input will generate the 1Hz time update.

XTAL Select

One of 4 possible crystals is selected by value in these two

bits:

0 = 4.194304MHz 2 = 1.048576MHz

1 = 2.097152MHz 3 = 32,768Hz

50-60Hz

50Hz is selected as the line input frequency when this bit is

set high. A low will select 60Hz. The power-sense bit in the

Interrupt Control Register must be set low for line frequency

operation.

Clock Out

The three bits specify one of the 7 frequencies to be used as

the squarewave clock output:

0 = XTAL 4 = Disable (low output)

1 = XTAL/2 5 = 1Hz

2 = XTAL/4 6 = 2Hz

3 = XTAL/8 7 = 50Hz or 60Hz

,

All bits are reset by a power-on reset. Therefore, the XTAL is

XTAL Operation = 64Hz

selected as the clock output at this time.

Interrupt Control Register

Watchdog

When this bit is set high, the watchdog operation will be

enabled. This function requires the CPU to toggle the CE pin

periodically without a serial-transfer requirement. In the

event this does not occur, a CPU reset will be issued. Status

Register must be read before re-enabling watchdog.

Power Down

A high in this location will initiate a power down. A CPU reset

will occur, the CLK OUT and PSE output pins will be set low

and the serial interface will be disabled.

CLOCK CONTROL REGISTER (Write/Read) - Address 31H

D7 D6 D5 D4 D3 D2 D1 D0

START LINE XTAL XTAL 50Hz CLK OUT CLK OUT CLK OUT

SEL SEL

STOP XTAL 1 0 60Hz 2 1 0

10

Page 11

CDP68HC68T1

Power Sense

This bit is used to enable the line input pin to sense a power

failure. It is set high for this function. When power sense is

selected, the input to the 50Hz to 60Hz prescaler is disconnected. Therefore, crystal operation is required when power

sense is enabled. An interrupt is generated when a power

failure is sensed and the power sense and Interrupt True bit

in the Status Register are set. When power sense is activated, a “0” must be written to this location followed by a “1”

to re-enable power sense.

The output of the alarm comparator is enabled when this bit

is set high. When a comparison occurs between the seconds, minutes and hours time and alarm counters, the interrupt output is activated. When loading the time counters, this

bit should be set low to avoid a false interrupt. This is not

required when loading the alarm counters. See Pin Functions,

INT for explanation of alarm delay.

Periodic Select

The value in these 4 bits will select the frequency of the periodic output. (See Table 2).

Alarm

INTERRUPT CONTROL REGISTER (Write/Read) - Address 32H

D7 D6 D5 D4 D3 D2 D1 D0

WATCHDOG POWER

DOWN

NOTE: All bits are reset by power-on reset.

D0 - D3 VALUE

0 Disable

1 2048Hz X

2 1024Hz X

3 512Hz X

4 256Hz X

5 128Hz X

6 64Hz X

7 32Hz X

8 16Hz X

9 8Hz X

10 4Hz X

11 2Hz X X

12 1Hz X X

13 Minute X X

14 Hour X X

15 Day X X

POWER

SENSE

TABLE 2. PERIODIC INTERRUPT OUTPUT

PERIODIC INTERRUPT

OUTPUT FREQUENCY

50 or 60Hz X

ALARM

PERIODIC SELECT

FREQUENCY TIME BASE

XTAL LINE

11

Page 12

CDP68HC68T1

STATUS REGISTER (Read Only) - Address 30H

D7 D6 D5 D4 D3 D2 D1 D0

0 WATCHDOG TEST

MODE

MODE

DISABLE

RESET

WRITE H CPOL = 1

READ H CPOL = 1

NOTES:

9. When interfacing to CDP68HC05 microcontrollers, serial clock phase bit, CPHA, must be set = 1 in the microcomputer’s Control Register.

10. MISO remains at a high Z until 8-bits of data are ready to be shifted out during a READ. It remains at a high Z during the entire WRITE

cycle.

CE SCK (Note 9) MOSI MISO

L INPUT DISABLED INPUT DISABLED HIGH Z

FIRST

TIME

UP

TRUTH TABLE

CPOL = 0

CPOL = 0

INTERRUPT

TRUE

SIGNAL

POWER

SENSE

INTERRUPT

DATA BIT LATCH HIGH Z

X NEXT DATA BIT

ALARM

INTERRUPT

CLOCK

INTERRUPT

SHIFTED OUT

(Note 10)

WATCHDOG

If this bit is set high, the watchdog circuit has detected a

CPU failure.

TEST MODE

When this bit is set high, the device is in the TEST MODE.

FIRST-TIME UP

Power-on reset sets this bit high. This signifies that data in

the RAM and Clock is not valid and should be initialized.

INTERRUPT TRUE

A high in this bit signifies that one of the three interrupts

(Power Sense, Alarm, and Clock) is valid.

POWER-SENSE INTERRUPT

This bit set high signifies that the power-sense circuit has

generated an interrupt.

ALARM INTERRUPT

When the seconds, minutes and hours time and alarm

counter are equal, this bit will be set high. Status Register

must be read before loading Interrupt Control Register for

valid alarm indication after alarm activates.

CLOCK INTERRUPT

A periodic interrupt will set this bit high.

All bits are reset by a power-on reset except the “FIRST-

TIME UP” which is set. All bits except the power-sense bit

are reset after a read of this register.

Pin Signal Description

SCK (Serial Clock Input, Note 11)

This input causes serial data to be latched from the MOSI

input and shifted out on the MISO output.

MOSI (Master Out/Slave In, Note 11)

Data bytes are shifted in at this pin, most significant bit

(MSB) first.

MISO (Master In/Slave Out)

Data bytes are shifted out at this pin, most significant bit

(MSB) first.

CE (Chip Enable, Note 12)

A positive chip-enable input. A low level at this input holds

the serial interface logic in a reset state, and disables the

output driver at the MISO pin.

NOTES:

11. These inputs will retain their previous state if the line driving

them goes into a High-Z state.

12. The CE input has as internal pull down device, if the input is in a

low state before going to High Z, the input can be left in a High Z.

Functional Description

The Serial Peripheral Interface (SPI) utilized by the

CDP68HC68T1 is a serial synchronous bus for address and

data transfers. The clock, which is generated by the microcomputer is active only during address and data transfers. In

systems using the CDP68HC05C4 or CDP68HC05D2, the

12

Page 13

CDP68HC68T1

inactive clock polarity is determined by the CPOL bit in the

microcomputer’s Control Register. A unique feature of the

CDP68HC68T1 is that it automatically determines the level

of the inactive clock by sampling SCK when CE becomes

active (see Figure 8). Input data (MOSI) is latched internally

on the internal strobe edge and output data (MISO) is shifted

out on the shift edge, as defined by Figure 8. There is one

clock for each data bit transferred (address, as well as data

bits are transferred in groups of 8).

CE

CPOL = 1

SCK

CE

CPOL = 0

SCK

MOSI MSB MSB -1

NOTE: “CPOL” is a bit that is set in the microcomputer’s Control

Register.

FIGURE 8. SERIAL RAM CLOCK (SCK) AS A FUNCTION OF

MCU CLOCK POLARITY (CPOL)

SHIFT

SHIFT

INTERNAL

STROBE

INTERNAL

STROBE

Address And Data Format

There are three types of serial transfer:

1. Address Control - Figure 9.

2. READ or WRITE Data - Figure 10.

3. Watchdog Reset (actually a non-transfer) Figure 11.

The Address/Control and Data bytes are shifted MSB first,

Into the serial data input (MOSI) and out of the serial data

output (MISO).

Any transfer of data requires an Address/Control byte to

specify a Write or Read operation and to select a Clock or

RAM location, followed by one or more bytes of data.

Data is transferred out of MISO for a Read and into MOSI for

a Write operation.

Address/Control Byte - Figure 9

It is always the first byte received after CE goes true. To

transmit a new address, CE must first go false and then true

again. Bit 5 is used to select between Clock and RAM locations.

BIT 7 6 5 4 3 2 1 0

R 0 CLK RAM A4 A3 A2 A1 A0

W/

04 A0-A4 Selects 5-Bit HEX Address of RAM or specifies Clock Register. Most Significant Address

5 CLK RAM

60

7 W/R

CE

SCK (NOTE)

RMOSI

NOTE: SCK can be either polarity.

FIGURE 9. ADDRESS/CONTROL BYTE-TRANSFER WAVEFORMS

Bit. If equal to “1”, A0 through A4 selects a Clock Register. If equal to “0”, A0 through A4

selects one of 32 RAM locations. Must be set to ”0” when not in Test Mode 7W/R W/R = “1”

initiates one or more WRITE cycles.W/R = “0”, initiates one or more READ cycles.

CLOCK

0W/

RAM

A2

A1 A0A3A4

13

Page 14

Read/Write Data (See Figure 10)

Read/Write data follows the Address/Control byte.

76543210BIT

D7 D6 D5 D4 D3 D2 D1 D0

CE

SCK (NOTE)

CDP68HC68T1

MOSI

MISO

NOTE: SCK can be either polarity.

FIGURE 10. READ/WRITE DATA TRANSFER WAVEFORMS

Watchdog Reset - (See Figure 11)

When watchdog operation is selected, CE must be toggled

periodically or a CPU reset will be outputted.

SERVICE

TIME

CE

SCK

CPUR

FIGURE 11. WATCHDOG OPERATION WAVEFORMS

SERVICE

TIME

D2

D2

D1 D0D3D4D5D6D7

D1 D0D3D4D5D6D7

Address And Data

Data transfers can occur one byte at a time (Figure 12) or in

a multibyte burst mode (Figure 13). After the Real-Time

Clock enabled, an Address/Control word is sent to set the

CLOCK or RAM and select the type of operation (i.e., Read

or Write). For a single-byte Read or Write, one byte is transferred to or from the Clock Register or RAM location specified in the Address/Control byte and the Real-Time Clock is

then disabled. Write cycle causes the latched Clock Register

or RAM address to automatically increment. Incrementing

continues after each transfer until the device is disabled.

After incrementing to 1FH the address will “wrap” to 00H and

continue. Therefore, when the RAM is selected the address

will “wrap” to 00H and when the clock is selected the

address will “wrap” 20H.

14

Page 15

CE

SCK

CDP68HC68T1

READ

WRITE

CE

SCK

MOSI

MOSIWRITE

MOSI

MISO

ADDRESS BYTE WRITE DATA

ADDRESS BYTE

READ DATA

FIGURE 12. SINGLE-BYTE TRANSFER WAVEFORMS

DATA BYTEADDRESS BYTE

DATA BYTE

DATA BYTE

READ

MOSI

MISO

W/

R ADDRESS

ADDRESS BYTE

DATA BYTEDATA BYTEDATA BYTE

DATA BYTE

DATA BYTE +1

DATA BYTE + (n-1)

FIGURE 13. MULTIPLE-BYTE TRANSFER WAVEFORMS

15

Page 16

CDP68HC68T1

Dynamic Electrical Specifications Bus Timing V

IDENT. NO PARAMETER

1 Chip Enable Setup Time t

2 Chip Enable After Clock Hold Time t

3 Clock Width High t

4 Clock Width Low t

5 Data In to Clock Setup Time t

7 Clock to Data Propagation Delay t

8 Chip Disable to Output High Z t

11 Output Rise Time t

12 Output Fall Time t

A Data in After Clock Hold Time t

B Clock to Data Out Active t

C Clock Recovery Time t

±10%, VSS = 0VDC, TA = 40oC to 85oC

DD

LIMITS (ALL TYPES)

VDD = 3.3V VDD = 5V

MIN MAX MIN MAX

EVCV

CVEX

WH

WL

DVCV

CVDV

EXQZ

r

f

CVDX

CVQX

REC

200 - 100 - ns

250 - 125 - ns

400 - 200 - ns

400 - 200 - ns

200 - 100 - ns

- 200 - 100 ns

- 200 - 100 ns

- 200 - 100 ns

- 200 - 100 ns

200 - 100 - ns

- 200 - 100 ns

200 - 200 - ns

UNITS

16

Page 17

Timing Diagrams

CDP68HC68T1

5 A 5

MOSI

CE

SCK

MOSI

MISO

CE

SCK

W/R

I

A6

34

A0

D7

D6OD1

O

C

DO

N

N

2

FIGURE 14. WRITE-CYCLE TIMING WAVEFORMS

A5

W/R

A6 A0

D7

D6ODI

O

7 8

DO

N

2CI

12118

N

4 3

FIGURE 15. READ-CYCLE TIMING WAVEFORMS

System Diagrams

AC

LINE

NOTE: Example of a system in which power is always on. Clock circuit driven by line input frequency.

BRIDGE

REGULATOR

FIGURE 16. POWER-ON ALWAYS SYSTEM DIAGRAM

PORV

DD

INT

V

LINE

CDP68HC68T1

V

BATT

XTAL IN

SYS

CPUR

CE

SCK

MOSI

MISO

V

DD

IRQ

V

DD

CDP68HC05C8B

RESET

PORT

SCK

MOSI

MISO

17

Page 18

CDP68HC68T1

System Diagrams

AC

LINE

(Continued)

BRIDGE

GENERATOR

V

CDP68HC68T1

LINE

V

DD

BATT

V

DD

POR

V

SYS

INT

CPUR

CLK OUT

CE

MISO

MOSI

SCK

V

DD

IRQ

CDP68HC05C8B

RESET

OSC 1

PORT (e.g., PCO)

MISO

MOSI

SCK

V

DD

NOTE: Example of a system in which the power is controlled by an external source. The LINE input pin can sense when the switch opens by use

of the POWER-SENSE INTERRUPT. The CDP68HC68T1 crystal drives the clock input to the CPU using the CLK OUT pin. On power down when

V

SYS

< V

BATT

+ 0.7V. V

will power the CDP68HC68T1. A threshold detect activates a P-Channel switch, connecting V

BATT

BATT

to VDD. V

BATT

always supplies power to the oscillator, keeping voltage frequency variation to a minimum.

FIGURE 17. EXTERNALLY CONTROLLED POWER SYSTEM DIAGRAM

A Procedure for P o wer-Do wn Operation might consist of the following:

1. Set power sense operation b y writing bit 5 high in the Interrupt Control Register .

2. When an interrupt occurs, the CPU reads the Status Register to determine the interrupt source.

3. Sensing a power f ailure , the CPU does the necessary housekeeping to prepare f or shutdown.

4. The CPU reads the Status Register again after sev eral milliseconds to determine validity of po w er f ailure .

5. The CPU sets power-down bit 6 and disables all interrupts in the Interrupt Control Register when power down is verified. This

causes the CPU reset and clock out to be held low and disconnects the serial interface.

6. When power returns and V

rises above V

SYS

, power down is terminated. The CPU reset is released and serial communi-

BATT

cation is established.

18

Page 19

CDP68HC68T1

System Diagrams

0.047

20k

AC

LINE

1k

RTC

V

DD

REGULATOR

CHARGE

(Continued)

R

0.1

22M

100k

POR V

V

BATT

XTAL

LINE

DDVSYS

CPUR

V

SS

PSE

INT

CLK

OUT

CE

SPI

NC

(EPS)

ENABLED

POWER

SUPPLY

V

DD

V

DD

3

RESET

CDP68HC05C4B

IRQ

OSC1

PORT

SPI

V

SS

FIGURE 18. EXAMPLE OF A SYSTEM WITH A BATTERY BACKUP

19

Page 20

CDP68HC68T1

System Diagrams

CLOCK BUTTON

IGNITION

5V

REG

+

12V

-

(Continued)

LINE V

V

BATT

POR

XTAL

2MHz

DD

T1

V

SS

V

SYS

PSE

CPUR

CLK OUT

INT

SPI

CE

ENABLED POWER

V

DD

PORT

RESET

CDP68HC05C4B

OSC1

IRQ

3

SPI

PORT

V

SS

Example of an automotive system. The V

and LINE inputs can be used to sense the ignition turning on and off. An external

SYS

switch is included to activate the system without turning on the ignition. Also, the CMOS CPU is not po wered down with the system

V

, but is held in a low power reset mode during power down. When restoring power the CDP68HC68T1 will enable the CLK

DD

OUT pin and set the PSE and

CPUR high.

Important Application Note: Those units with a code of 6PG have delayed alarm interrupts of 8.3ms regardless of

CDP68HC68T1’s operating frequency. (See Pin Functions, INT.) In addition, reading the Status Register before delayed alarm activates will disable alarm signal.

FIGURE 19. AUTOMOTIVE SYSTEM DIAGRAM

20

Page 21

Dual-In-Line Plastic Packages (PDIP)

CDP68HC68T1

E

C

L

e

A

C

e

B

BASE

PLANE

SEATING

PLANE

D1

B1

D

A2

A1

A

L

e

C

S

-C-

D1

e

B

0.010 (0.25) C AMB

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English and

Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpendic-

e

A

ular to datum .

-C-

7. eB and eC are measured at the lead tips with the leads unconstrained.

eC must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

E16.3 (JEDEC MS-001-BB ISSUE D)

16 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N16 169

NOTESMIN MAX MIN MAX

Rev. 0 12/93

21

Page 22

CDP68HC68T1

Ceramic Dual-In-Line Metal Seal Packages (SBDIP)

LEAD FINISH

c1

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

S

-A-

-B-

D

A

A

S S

e

S S

D

-D-

E

S2

-C-

BASE

METAL

M

SECTION A-A

Q

A

L

eA/2

aaa C A - B

M

b1

M

(b)

eA

S S

c

D

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, a nd N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. Dimension Q shall be measured from the seating plane to the

base plane.

6. Measure dimension S1 at all four corners.

7. Measure dimension S2 from the top of the ceramic body to the

nearest metallization or lead.

8. N is the maximum number of terminal positions.

9. Braze fillets shall be concave.

10. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

11. Controlling dimension: INCH.

D16.3 MIL-STD-1835 CDIP2-T16 (D-2, CONFIGURATION C)

16 LEAD CERAMIC DUAL-IN-LINE METAL SEAL PACKAGE

(c)

SYMBOL

A - 0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 0.840 - 21.34 -

E 0.220 0.310 5.59 7.87 -

e 0.100 BSC 2.54 BSC eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 5

S1 0.005 - 0.13 - 6

S2 0.005 - 0.13 - 7

α

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2

N16 168

INCHES MILLIMETERS

90

o

105

o

90

o

105

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

22

Page 23

CDP68HC68T1

6

4

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

0.25(0.010) B

E

SEATING PLANE

D

-C-

H

-B-

A

M

L

h x 45

M

o

α

e

B

0.25(0.010) C AMB

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.00

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater above

the seating plane, shall not exceed a maximum value of 0.61mm (0.02

inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are

not necessarily exact.

A1

0.10(0.004)

S

C

M16.3 (JEDEC MS-013-AA ISSUE C)

16 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.3977 0.4133 10.10 10.50 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC -

H 0.394 0.419 10.00 10.65 -

h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N16 167

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

23

Page 24

CDP68HC68T1

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

0.25(0.010) B

E

SEATING PLANE

D

-C-

H

-B-

A

M

L

h x 45

M

o

α

e

B

0.25(0.010) C AMB

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

A1

0.10(0.004)

S

C

M20.3 (JEDEC MS-013-AC ISSUE C)

20 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.4961 0.5118 12.60 13.00 3

E 0.2914 0.2992 7.40 7.60 4

e 0.050 BSC 1.27 BSC -

H 0.394 0.419 10.00 10.65 -

h 0.010 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N20 207

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

24

Loading...

Loading...