Page 1

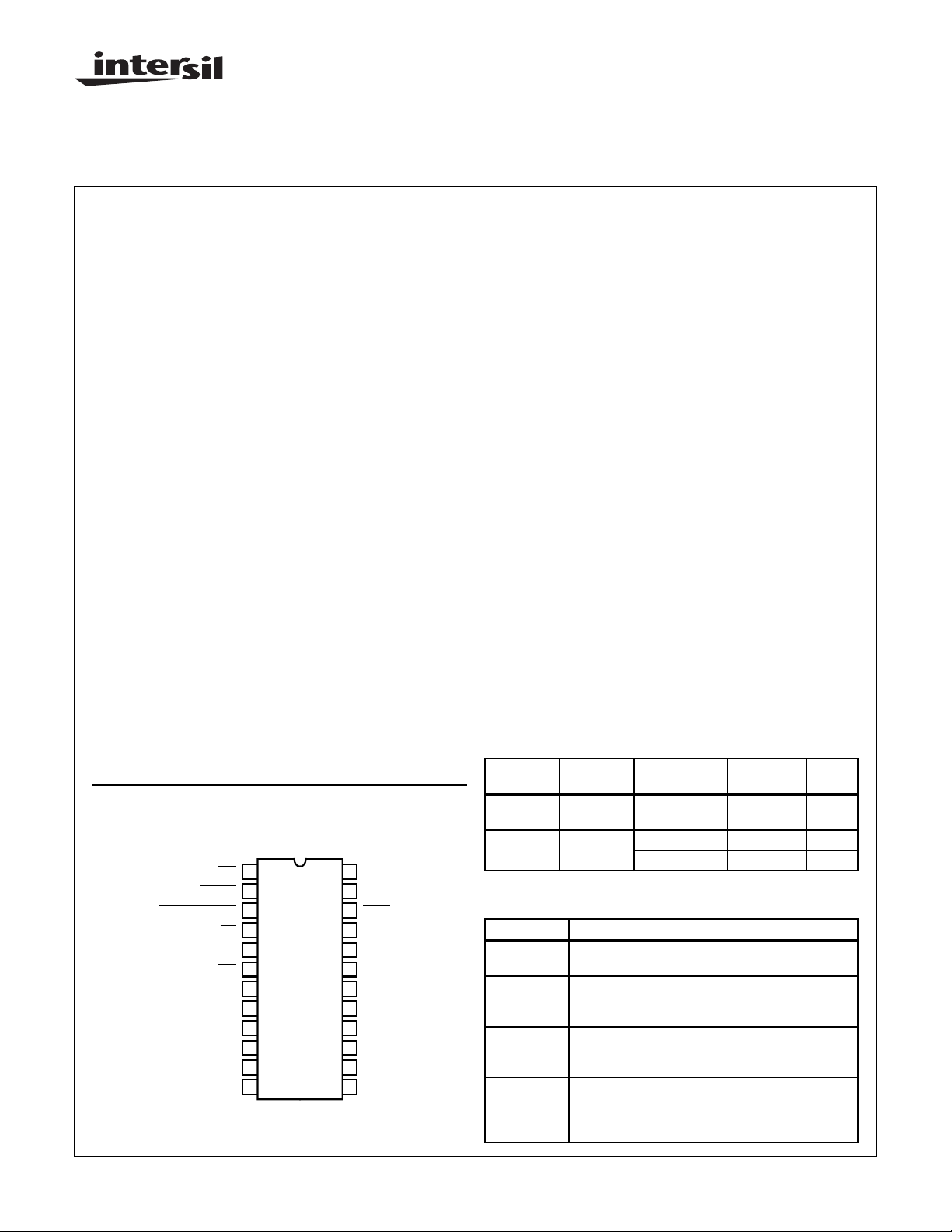

CDP1879,

CDP1879C-1

March 1997

Features

• CPU Interface for Use with General-Purpose

Microprocessors

• Time Of Day/Calendar

• Reads Seconds, Minutes, Hours

• Reads Day of Month and Month

• Alarm Circuit With Seconds, Minutes or Hours

Operation

• Power Down Mode

• Separate Clock Output Selects 1 of 15 Square Wave

Signals

• Interrupt Output Activated By Clock Output and/or

Alarm Circuit

• Date Integrity Sampling for Clock Rollover Eliminated

• On-Board Oscillator:

- Crystal Operation CDP1879 at 10V. . . . . . . 4.19MHz,

2.09MHz or 1.048MHz

- Crystal Operation CDP1879C-1 at 5V . . . . . 4.19MHz,

2.09MHz or 1.048MHz or 32kHz

- External Clock Operation at 10V or 5V. . . . 4.19MHz,

2.09MHz, 1.048MHz or 32kHz

• Addressable in Memory Space or CDP1800 Series I/O

Mode

• Low Standby (Timekeeping) Voltage with External Clock

• Related Literature

- AN7275, Guide to the Use of CD1879 and

CDP1879C1 Real Time Clock

Pinout

CDP1879, CDP1879C-1 (PDIP, SBDIP)

TOP VIEW

INT

RESET

POWER DOWN

RD

MEM

IO/

TPB/

WR

TPA

CS

A2

A1

A0

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

24

V

DD

XTAL

23

22

XTAL

CLK

21

OUT

DB7

20

DB6

19

DB5

18

DB4

17

DB3

16

DB2

15

DB1

14

DB0

13

CMOS Real-Time Clock

Description

The CDP1879 real-time clock supplies time and calendar information

from seconds to months in BCD format. It consists of 5 separately

addressable and programmable counters that divide down an oscillator

input. The clock input can have any one of 4 possible frequencies,

allowing flexibility in the choice of crystal or external clock sources.

Using an external 32kHz clock source, timekeeping can be performed

down to 2.5V (see Standby (Timekeeping)Voltage Operation).

The device can be memory-mapped for use with any general-purpose

microprocessor and has the additional capability of operating in the

CDP1800 series input/output mode.

The real-time clock functions as a time-of-day/calendar with an alarm

capability that can be set for combinations of seconds, minutes or

hours. Alarm time is configured by loading alarm latches that activate

an interrupt output through a comparator when the counter and alarm

latch v alues are equal.

Fifteen selectable square-wave signals are available as a separate

clock output signal and can also activate the interrupt output. A status

register is available to indicate the interrupt source. The value in an 8 bit

control register determines the operational characteristics of the de vice,

by selecting the prescaler divisor and the clock output, and controls the

load and alarm functions.

A transparent “freeze” circuit preclude clock rollover during counter and

latch access times to assure stable and accurate values in the counters

and alarm latches.

The CDP1879 is functionally identical to the CDP1879C-1. The

CDP1879 has a recommended operating voltage range of 4V to 10.5V,

and the CDP1879C-1 has a recommended operating voltage range of

4V to 6.5V . The CDP1879 and the CDP1879C-1 are supplied in 24 lead

hermetic dual-in-line side-brazed ceramic packages (D suffix) and 24

lead dual-in-line plastic packages (E suffix

Ordering Information

TEMP

P A CKAGE

PDIP -40oC to

SBDIP -40oC to

Burn-In CDP1879CD1X - D24.6

RANGE 5V 10V

CDP1879CE1 CDP1879E E24.6

+85oC

CDP1879CD1 - D24.6

+85oC

CDP1879 Modes of Operation

OPERATION FUNCTION

Read 1. Seconds, minutes, hours, date and month counters

Write 1. Control register to set device operation

Power Down 1. Three-state interrupt output with active alarm or

Interrupt 1. Clock out as source

2. Status register to identify interrupt source

2. Seconds, minutes, hours, date and month counters

3. Alarm latches for alarm time

clock out circuitry for wake-up control

2. Data bus and address inputs are “DON’T CARE”

2. Alarm time as source

3. Either interrupt can occur during normal or power

down mode

).

PKG.

NO.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

4-104

File Number

1360.2

Page 2

CDP1879, CDP1879C-1

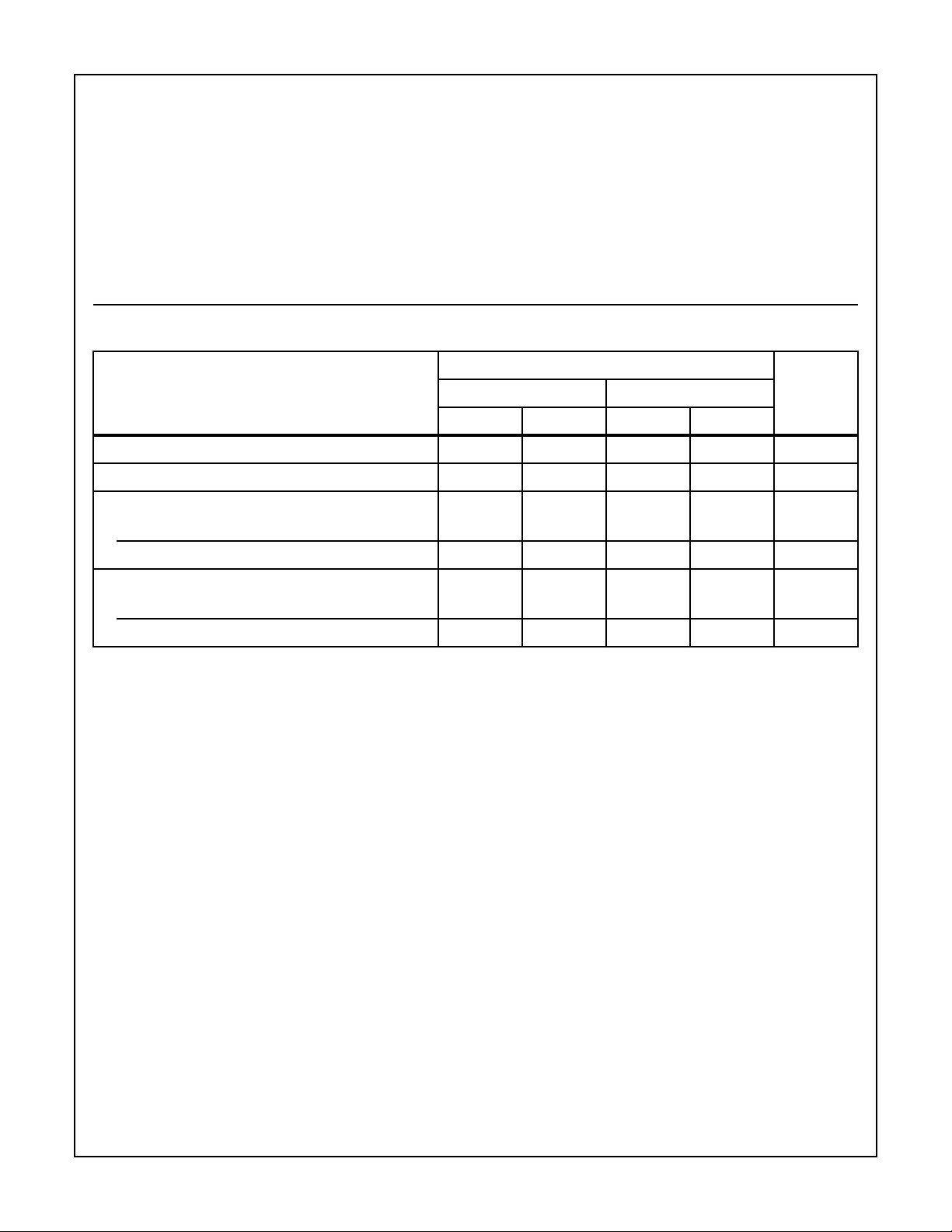

Absolute Maximum Ratings Thermal Information

DC Supply Voltage Range, V

(Voltage referenced to VSS Terminal)

CDP1879 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +11V

CDP1879C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7V

Input Voltage Range, All Inputs . . . . . . . . . . . . . . -0.5 to VDD +0.5V

DC Input Current, Any One Input . . . . . . . . . . . . . . . . . . . . . . ±10mA

Device Dissipation Per Output Transistor. . . . . . . . . . . . . . . . 40mW

For TA = Full Package Temperature Range

(All Package Types)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

DD

Thermal Resistance (Typical) θJA (oC/W) θJC (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . 60 N/A

SBDIP Package. . . . . . . . . . . . . . . . . . 50 12

Operating Temperature Range (TA)

Package Type D, H . . . . . . . . . . . . . . . . . . . . . . .-55oC to +125oC

Package Type E. . . . . . . . . . . . . . . . . . . . . . . . . . .-40oC to +85oC

Storage Temperature Range (T

Lead Temperature (During Soldering). . . . . . . . . . . . . . . . . .+265oC

At Distance 1/16 ±1/32 in. (1.59± 0.79mm) From Case for 10s Max

). . . . . . . . . . . .-65oC to +150oC

STG

Operating Conditions at T

PARAMETER

DC Operating Voltage Range 4 10.5 4 6.5 V

Input Voltage Range V

DC Standby (Timekeeping) Voltage (Note 1), V

TA = -40oC to +85oC (Note 2) 3 - 3 - V

TA = 0o to +70oC 2.5 - 2.5 V

Clock Input Rise or Fall Time, tR, t

VDD = 5V - 10 - 10 µs

VDD = 10V - 1 - - µs

NOTES:

1. Timekeeping function only, no READ/WRITE accesses, 32kHz external frequency source only, no crystal operation.

2. See Standby (Timekeeping) Voltage Operation.

= FuIl Package-Temperature Range, Unless Otherwise specified. For maximum reliability, operating con-

A

ditions should be selected so that operation Is always within the following ranges:

LIMITS

CDP1879 CDPl879C-1

MIN MAX MIN MAX

SS

STBY

F

V

DD

V

SS

V

DD

UNITS

V

4-105

Page 3

CDP1879, CDP1879C-1

XTAL

OSCILLATOR SECOND

XTAL

CLOCK OUT

INT

RESET

V

DD

V

SS

DB0-DB7

A0

A1

A2

TPA

MEM

I-O

TPB/WR

RD

CS

POWER DOWN

PRESCALE

PRESCALE

SELECT

CLOCK AND

INT. LOGIC

INT. STATUS

REGISTER

I/O

INTERFACE

ADDRESS DECODE

AND

CONTROL LOGIC

FREEZE

CIRCUIT

CONTROL

REGISTER

CLOCK

SELECT

AM - PM

AND

HOUR LOGIC

MINUTE HOUR DAY MONTH

8-BIT DATA BUS

COMPARATOR

SECOND

LATCH

MINUTE

LATCH

HOUR

LATCH

CALENDAR

LOGIC

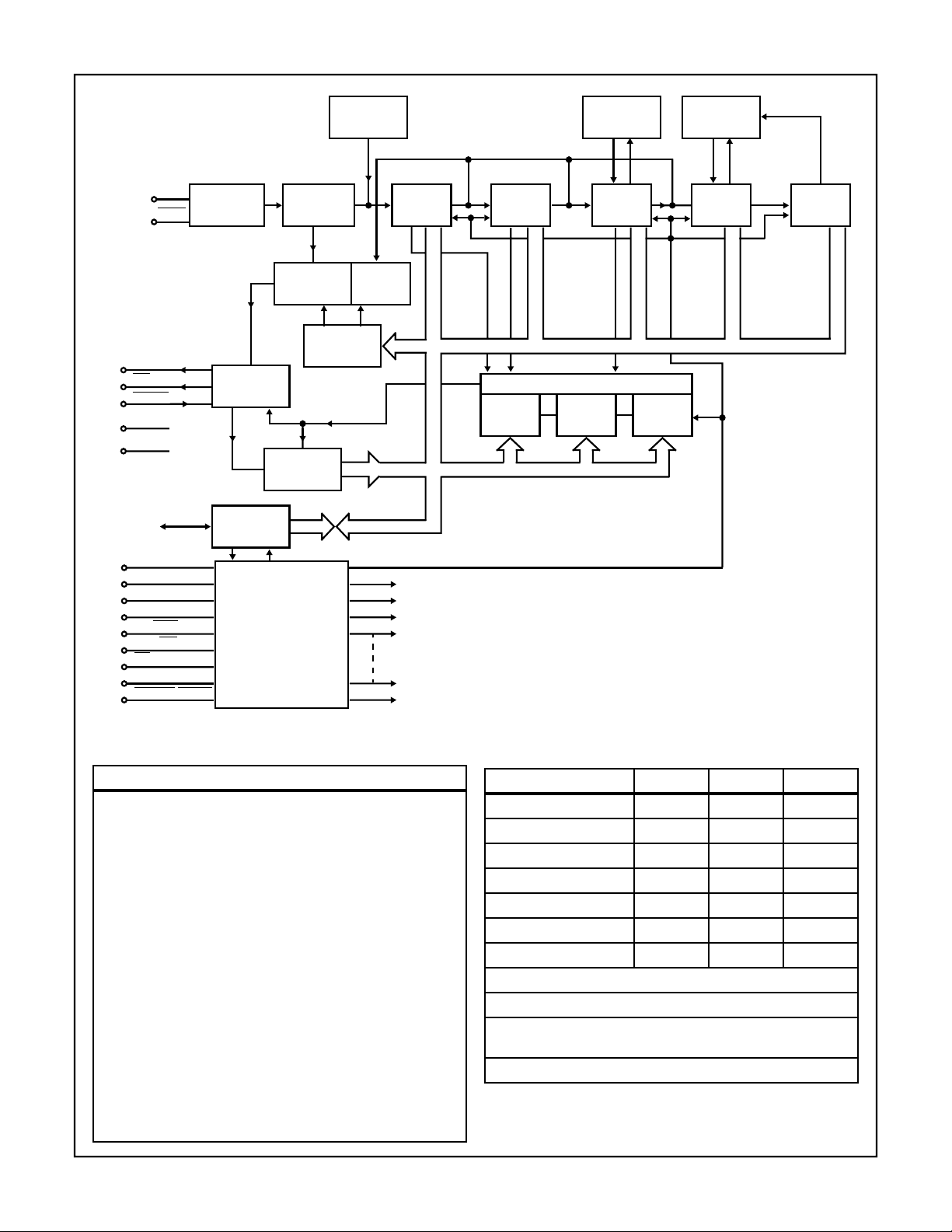

FIGURE 1. REAL-TIME CLOCK FUNCTIONAL DIAGRAM

TABLE 1.

CONTROL REGISTER BIT ASSIGNMENT

Bit 1, 0

Frequency 00

Select 01

10

11

32768Hz

1.048576MHz

2.097152MHz

4.194304MHz

Bit 2

Start/Stop 1 = Start

0 = Stop

Bit 3

Counter/Latch Control

“0” = Write to Counter and disable alarm

“1” = Write to and enable alarm Clock Select

Bit 7, 6, 5, 4

0000 - disableµs

0001 - 488.2µs

0010 - 976.5µs

0011 - 1953.1µs

0100 - 3906.2µs

0101 - 7812.5µs

0110 - 15.625ms

0111 - 31.25ms

1000 - 62.5ms

1001 - 125ms

1010 - 250ms

1011 - 500ms

1100 - sec.

1101 - min.

1110 - hour

1111 - day

TABLE 2.

ADDRESSES A2 A1 A0

Latch, Counter Seconds 0 1 0

Latch, Counter Minutes 0 1 1

Latch, Counter Hours 1 0 0

Counter, Day 1 0 1

Counter, Month 1 1 0

Control, Register 1 1 1

Status Register 1 1 1

MSB of Hours Counters (Bit 7) is an AM-PM Bit. 0 = AM; 1 = PM

Bit 6 of Hours Counter Controls 12/24 hr. 1 = 12 Hr: 0 = 24 Hr.

Status Register: Bit 7 MSB = Alarm

Interrupt Source: Bit 6 = Clock.

MSB of Month Counter (Bit 7) is a Leap Year Bit 0 = No, 1 = Yes.

4-106

Page 4

CDP1879, CDP1879C-1

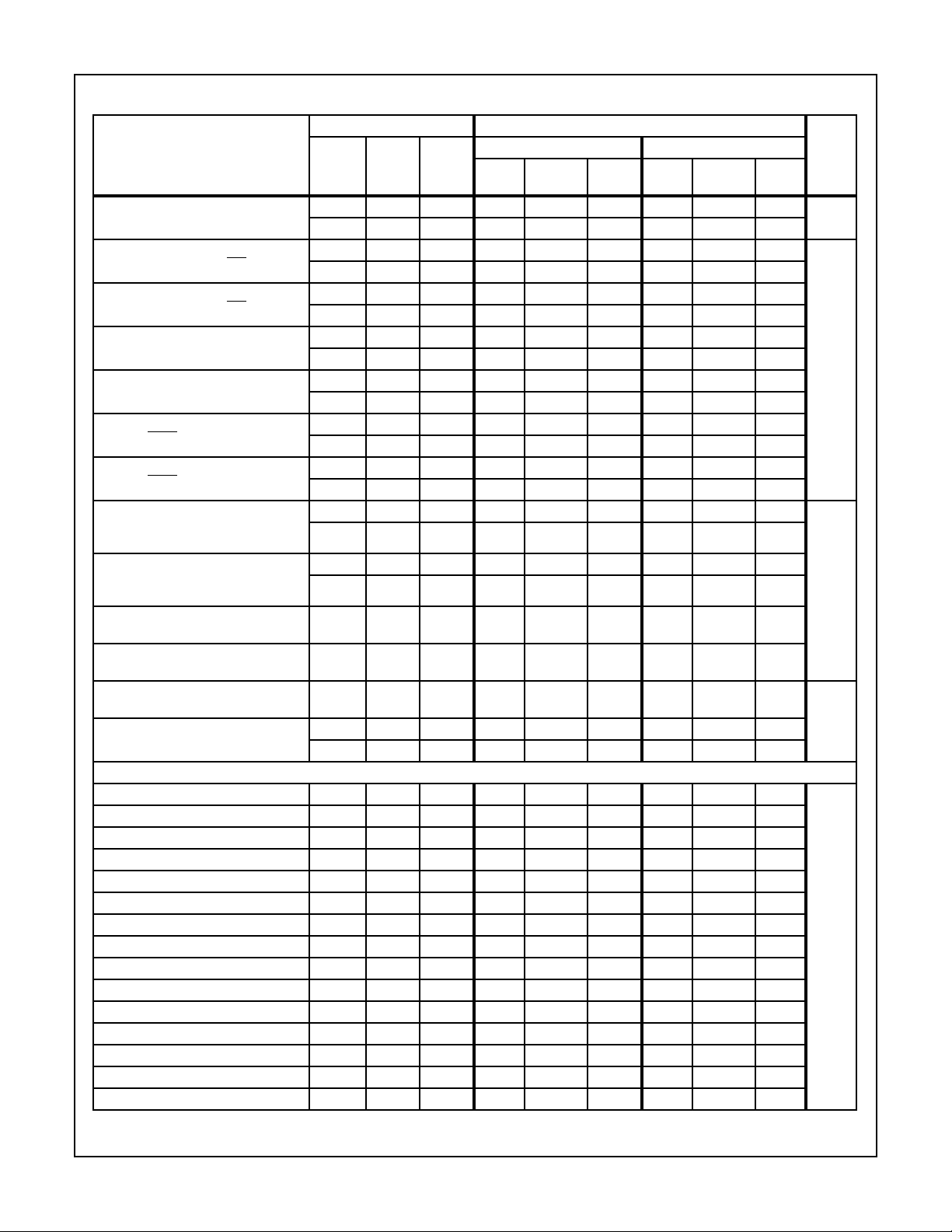

Static Electrical Specifications at T

-40oC to +85oC VDD± 5%, Unless Otherwise Specified

A

CONDITIONS LIMITS

CDP1879 CDPl879C-1

PARAMETER

Ouiescent Device Current I

V

(V)

DD

V

O

(V)

V

IN

DD

(V)

MIN

(NOTE 1)

TYP MAX MIN

(NOTE 1)

TYP MAX

0, 5 5 - 0.01 50 - 0.02 200 µA

0, 10 10 - 1 200 - - -

Output Low Drive (Sink)

Current, Data Bus and INT l

Output High Drive (Source)

Current, Data Bus and INT I

Output Low Drive (Sink)

Current, Clock Out l

Output High Drive (Source)

Current, Clock Out I

Output Low Drive (Sink)

Current, XTAL Out l

Output High Drive (Source)

Current, XTAL Out I

Output Voltage

Low-Level V

(Note 2)

Output Voltage

High Level V

(Note 2)

Input Low Voltage V

Input High Voltage V

Input Leakage Current I

Three-State Output

Leakage Current I

OL

OH

OL

OH

OL

OH

OL

OH

IL

IH

IN

OUT

0.4 0, 5 5 1.8 4 - - - -

0.5 0,10 10 3.6 7 - - - -

4.6 0, 5 5 -1.1 -2.3 - -1.1 -2.3 -

9.5 0,10 10 -2.6 -4.4 - - - -

0.4 0, 5 5 0.6 1.4 - 0.6 1.4 -

0.5 0,10 10 1.2 3 - - - -

4.6 0, 5 5 -1.1 -2.3 - -1.1 -2.3 -

9.5 0,10 10 -2.6 -4.4 - - - -

0.4 0, 5 5 0.2 0.9 - 0.2 0.9 -

0.5 0,10 10 0.4 2 - - - -

4.6 0, 5 5 -0.15 -0.4 - -0.15 -0.4 -

9.5 0,10 10 -0.3 -0.7 - - - -

- 0, 5 5 - 0 0.1 - 0 0.1

- 0,10 10 - 0 0.1 - - -

- 0, 5 5 4.9 5 - 4.9 5 -

- 0, 10 10 9.9 10 - - - -

0.5, 4.5

0.5, 9.5

0.5, 4.5

0.5, 9.5

Any

Input

-

-

-

-

0, 5

0, 10

10

10

10

5

5

5

3.5

-

-

7

-

-

-

-

-

-

-

-

1.5

±1

±2

-

3

-

-

-

3.5

-

-

-

-

-

-

-

-

-

0, 5 0,5 5 - - ±1- - ±1

0,10 0,10 10 - - ±1--Operating Current (Note 3)

External Clock 32kHz - - 5 - 0.01 0.15 - 0.01 0.15

External Clock 1MHz - - 5 - 0.2 1 - 0.2 1

External Clock 2MHz - - 5 - 0.35 1.5 - 0.35 1.5

External Clock 4MHz - - 5 - 0.7 2 - 0.7 2

External Clock 32kHz - - 10 - 0.03 0.25 - - External Clock 1MHz - - 10 - 0.4 2 - - External Clock 2MHz - - 10 - 0.8 3 - - External Clock 4MHz - - 10 - 1.6 4.5 - XTAL Oscillator (Note 4) 32kHz - - 5 - 0.1 0.25 - 0.1 0.25

XTAL Oscillator (Note 4) 1MHz - - 5 - 0.3 0.5 - 0.3 0.5

XTAL Oscillator (Note 4) 2MHz - - 5 - 0.4 0.6 - 0.4 0.6

XTAL Oscillator (Note 4) 4MHz - - 5 - 0.6 0.8 - 0.6 0.8

XTAL Oscillator (Note 4) 1MHz - - 10 - 1.6 3 - - XTAL Oscillator (Note 4) 2MHz - - 10 - 1.8 3.5 - - XTAL Oscillator (Note 4) 4MHz - - 10 - 2 5 - - -

UNITS

mA

V

1.5

-

-

-

±1

µA

mA

4-107

Page 5

CDP1879, CDP1879C-1

Static Electrical Specifications at T

-40oC to +85oC VDD± 5%, Unless Otherwise Specified (Continued)

A

CONDITIONS LIMITS

PARAMETER

Input Capacitance C

Output Capacitance C

IN

OUT

Maximum Clock Rise tR, t

and Fall Times

V

(V)

- - - - 5 7.5 - 5 7.5 pF

- - - - 10 15 - 10 15

F

--5--10--10µs

--10--1---

V

O

(V)

V

IN

DD

(V)

NOTES:

1. Typical values are for TA = 25oC and nominal VDD.

2. IOL = IOH = 1µA.

3. Operating current measured with clockout = 488.2µs and no load.

4. See Table 3 and Figure 6 for oscillator circuit information.

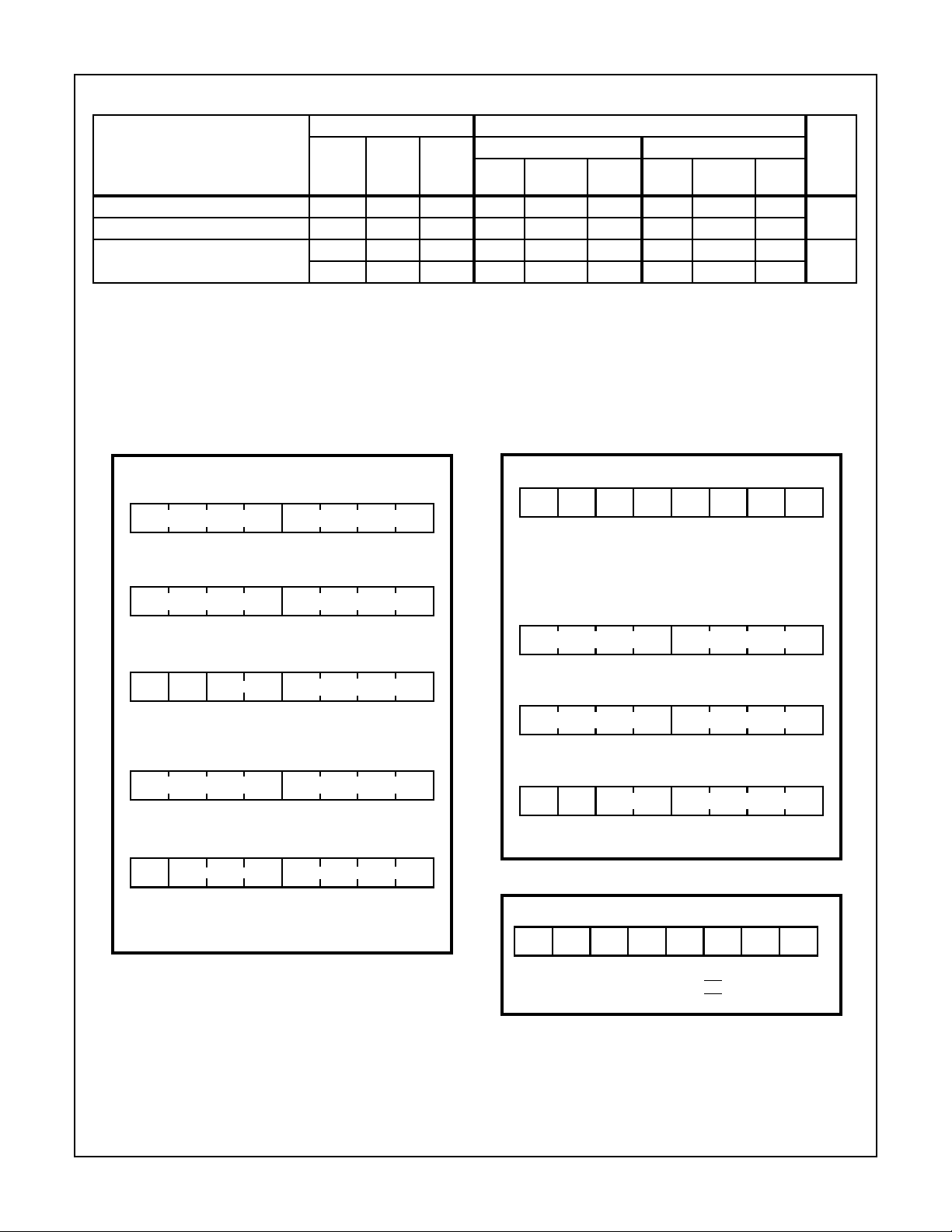

Programming Model

WRITE AND READ REGISTERS WRITE ONLY REGISTERS

BCD FORMAT

DB7 DB0

TENS 0-5 UNITS 0-9

SECONDS COUNTER (00-59)

DB7 DB0

TENS 0-5

MINUTES COUNTER (00-59)

DB7 DB0

DB6

X X TENS 0-2

HOURS COUNTER (01 - 12 OR 00-23)

DB7 0=AM, 1=PM

DB6 0=24 HR, 1=12 HR

DB7 DB0

TENS 0-3 UNITS 0-9

DAY OF MONTH COUNTER

(01-28, 29, 30, 31)

DB7 DB0

X TENS 0 OR 1

MONTH COUNTER

(JAN=1 DEC=12)

DB7 0=NO LEAP YEAR

1=LEAP YEAR

UNITS 0-9

UNITS 0-9

UNITS 0-9

CDP1879 CDPl879C-1

(NOTE 1)

MIN

TYP MAX MIN

DB7 DB0

7

6543210

CONTROL REGISTER

DB0-DB1 - FREQUENCY SELECT

DB2 - START/STOP

DB3 - COUNTER/ALARM LATCH CONTROL

DB4-DB7 - CLOCK OUTPUT SELECT

DB7 DB0

TENS 0-5 UNITS 0-9

SECONDS ALARM LATCH (00-59)

DB7 DB0

TENS 0-5 UNITS 0-9

MINUTES ALARM LATCH (00-59)

DB6

DB7 DB0

TENS 0-2 UNITS 0-9XX

HOURS ALARM LATCH (01-12 OR 00-23

12 HR, DB7=0 AM, 1=PM

24 HR, DB7=X

(NOTE 1)

TYP MAX

READ ONLY REGISTER

DB7 DB0

DB6

X

X000000

UNITS

4-108

INTERRUPT STATUS REGISTER

DB7=1 ALARM CIRCUIT ACTIVATED INT.

DB6=1 CLOCK OUTPUT ACTIVATED

INT.

Page 6

CDP1879, CDP1879C-1

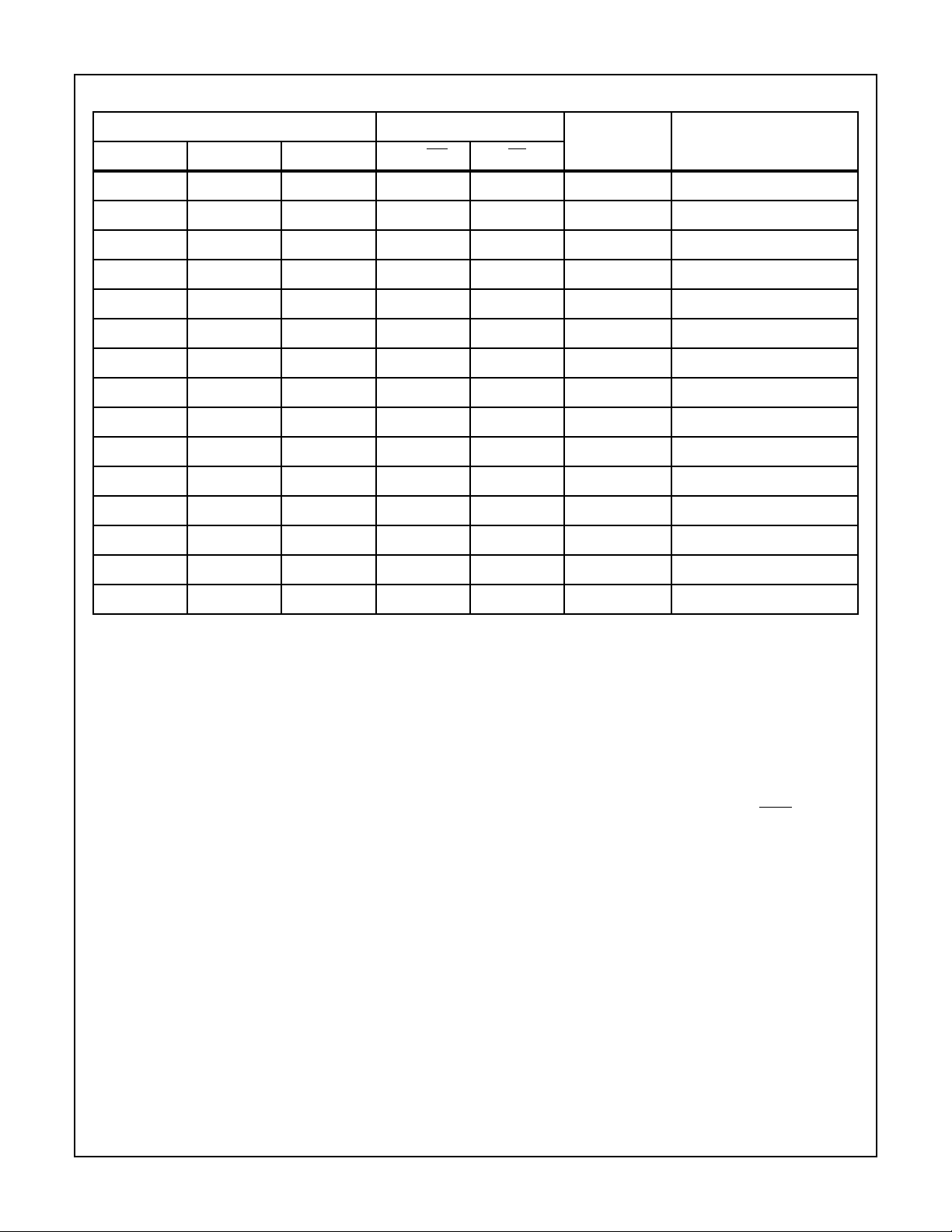

REGISTER TRUTH TABLE

ADDRESS ACTIVE SIGNAL

0 1 0 X - 0 Write Seconds Counter

0 1 0 - X 0 Read Seconds Counter

0 1 1 X - 0 Write Minutes Counter

0 1 1 - X 0 Read Minutes Counter

1 0 0 X - 0 Write Hours Counter

1 0 0 - X 0 Read Hours Counter

1 0 1 X - 0 Write Date Counter

1 0 1 - X 0 Read Date Counter

1 1 0 X - 0 Write Month Counter

1 1 0 - X 0 Read Month Counter

0 1 0 X - 1 Write Seconds Alarm Latch

0 1 1 X - 1 Write Minutes Alarm Latch

1 0 0 X - 1 Write Hours Alarm Latch

1 1 1 X - - Write Control Register

BIT 3 CONTROL

REGISTER REGISTER OPERATIONA2 A1 AO TPB/WR RD

1 1 1 - X - Read Int. Status Register

General Operation

The real-time clock contains seconds, minutes, and hours,

date and month counters that hold time of day/calendar

information (see Figure 2). The frequency of an intrinsic

oscillator is divided down to supply a once-a-second signal

to the counter series string. The counters are separately

addressable and can be written to or read from.

The real-time clock contains seconds, minutes and hour

write-only alarm latches that store the alarm time (see Figure 3). When the value of the alarm latches and counters are

equal, the interrupt output is activated. The interrupt output

can also be activated by a clock output transition. The clock

output is derived from the prescaler and counters and can

be one of 15 square-wave signals. The value in the readonly interrupt status register identifies the interrupt source.

Operational control of the real-time clock is determined by

the byte in a write-only control register. The 8-bit v alue in this

register determines the correct divisor for the prescaler, a

data direction and alarm enable bit, clock output select, and

start/stop control (see Figure 4).

Data transfer and addressing are accomplished in two

modes of operation, memory mapping and I/O mapping

using the CDP1800-series microprocessors. The mode is

selected by the level on an input pin. (IO/

mapping implies use of the address lines as chip selects and

address inputs during linear selection or partial or full decoding methods. I/O mapping with the CDP1800-series microprocessors involves use of the N line outputs in conjunction

with input and output instructions to transfer data to and from

memory.

MEM). Memory

4-109

Page 7

CDP1879, CDP1879C-1

XTAL

OSCILLATOR SECOND

XTAL

CLOCK OUT

INT

RESET

V

DD

V

SS

DB0-DB7

A0

A1

A2

TPA

IO/

MEM

TPB/

WR

RD

CS

POWER DOWN

PRESCALE

PRESCALE

SELECT

CLOCK AND

INT. LOGIC

INT. STATUS

REGISTER

I/O

INTERFACE

ADDRESS DECODE

AND

CONTROL LOGIC

FREEZE

CIRCUIT

CONTROL

REGISTER

CLOCK

SELECT

AM - PM

AND

HOUR LOGIC

MINUTE HOUR DAY MONTH

8-BIT DATA BUS

COMPARATOR

SECOND

LATCH

MINUTE

LATCH

HOUR

LATCH

CALENDAR

LOGIC

FIGURE 2. FUNCTIONAL DIAGRAM - TIME COUNTERS HIGHLIGHTED

4-110

Page 8

CDP1879, CDP1879C-1

XTAL

OSCILLATOR SECOND

XTAL

CLOCK OUT

INT

RESET

V

DD

V

SS

DB0-DB7

A0

A1

A2

TPA

MEM

IO/

TPB/

WR

RD

CS

POWER DOWN

PRESCALE

PRESCALE

SELECT

CLOCK AND

INT. LOGIC

INT. STATUS

REGISTER

I/O

INTERFACE

ADDRESS DECODE

AND

CONTROL LOGIC

FREEZE

CIRCUIT

CONTROL

REGISTER

CLOCK

SELECT

AM - PM

AND

HOUR LOGIC

MINUTE HOUR DA Y MONTH

8-BIT DATA BUS

COMPARATOR

SECOND

LATCH

MINUTE

LATCH

LATCH

HOUR

CALENDAR

LOGIC

FIGURE 3. FUNCTIONAL DIAGRAM - ALARM CIRCUIT, CLOCK OUTPUT, INTERRUPT, AND STATUS REGISTERS HIGHLIGHTED

Operational Sequence

Power is applied and the real-time clock is reset. This sets

the interrupt output pin high. After the CS pin is set high and

with address 7 on the address input lines, the control register

is loaded via the data bus to configure the clock.

With selective addressing, the seconds through month

counters are then written to and loaded to set the current time.

The real-time clock will now hold the current “wall clock” time,

with an accuracy determined by the crystal or external clock

used. If the alarm function is desired, the control register is

accessed and loaded again. This new byte will allow subsequent time data to be entered into the seconds, minutes and

hours alarm latches. This sequence is also used when selecting one of the 15 available cloc k-out signals.

If the alarm function was selected, the interrupt output pin

will be set low when the values in the seconds, minutes and

hour alarm latches match those in the seconds, minutes and

hour counters.

If one of the 15 sub second-to-day clock outputs is selected

by the byte in the control register, the clock output pin toggles at that frequency (50% duty cycle) The interrupt output

will also be set low on the first clock out negative transition.

The interrupt source (alarm or clock out) can be determined

by reading the interrupt status register. The clock output can

be deselected by placing zero in the upper nibble of the control register if the alarm function is selected as the only interrupt source.

Counters

The counter section consists of an on-board oscillator, a

prescaler and 5 counters that hold the time of day/calendar

information (see Figure 2).

1 of 4 possible external crystals determine the frequency of the

on-board oscillator (32,768Hz, 1.048576MHz, 2.097152MHz,

4.194304MHz). The oscillator output is divided down by a pres-

4-111

Page 9

CDP1879, CDP1879C-1

caler that supplies a once-a-second pulse to the counters. The

seconds counter divide the pulse by 60 and its output clocks

the minute counter every 60 seconds Further division by the

minutes, hours, day of month and month counters result in 5

counters holding data that reflect the time/calendar from seconds to months. The counters are addressed separately and

BCD data is transferred to and from via the data bus. The most

significant bit of the hours counter (Bit 7) is user programmed to

FREEZE

CIRCUIT

XTAL

XTAL

CLOCK OUT

INT

RESET

V

DD

V

SS

OSCILLATOR SECOND

CLOCK AND

INT. LOGIC

PRESCALE

PRESCALE

SELECT

CONTROL

REGISTER

INT. STATUS

REGISTER

CLOCK

SELECT

indicate AM or PM and will be inverted every 12th hour . (0=AM,

1=PM). Bit 6 of the hours counter is user programmed to

enable the hours counter for 12 or 24 hour operation.

(0=24,1=12). If 24-hour operation is selected, the AM-PM bit is

“don't care”, but still toggles ev ery 12th hour . Writing to the seconds counter resets the last 7 stages of the prescaler, allowing

time accuracy to approximately 1/100 of a second.

AM - PM

AND

HOUR LOGIC

MINUTE HOUR DAY MONTH

8-BIT DATA BUS

COMPARATOR

SECOND

LATCH

MINUTE

LATCH

HOUR

LATCH

CALENDAR

LOGIC

I/O

DB0-DB7

A0

A1

A2

TPA

MEM

IO/

TPB/WR

RD

CS

POWER DOWN

INTERFACE

ADDRESS DECODE

AND

CONTROL LOGIC

FIGURE 4. FUNCTIONAL DIAGRAM - CONTROL REGISTER HIGHLIGHTED

The most significant bit of the month counter is a Leap Year

bit. If it is set to “1”, the counter will count to February 29,

then roll to March 1. If set to “0” it will go to March 1st after

February 28th.

Alarm And Interrupt Status Register

The alarm circuit consists of 1) seconds, minutes and hour

alarm latches that hold the alarm time, 2) the outputs of the

seconds, minutes and hour counters, and 3) a comparator

that drives an interrupt output. The comparator senses the

counter and alarm latch values and activates the interrupt

output (active low) when they are equal (see Figure 3).

The write-only alarm latches have the same addresses as

their comparable counters. Bit 3 in the control register determines data direction to the latches or counters and alarm

enabling. For example, during a write cycle, if bit-3 in the

control register is a “1”, addressing the seconds counter or

alarm latch will load the seconds alarm latch from the data

bus and will enable the alarm function. Conversely, if bit-3 in

the control register is a “0”, addressing the seconds counter

or alarm latch during a write cycle will place the value on the

data bus into the seconds counter and will disable the alarm

function. The interrupt output can be activated by the alarm

circuit or the clock output. When an interrupt occurs, the

4-112

Page 10

CDP1879, CDP1879C-1

upper two bits of the interrupt status register identify the

interrupt source. The interrupt status register has the same

address as the control register. Addressing the interrupt status register with the

RD line active will place these register

bits on the data bus. Bits 0-5 are held low. A “1” in bit-6 represents a clock output transition as the interrupt source. A

“1” in bit-7 will identify the alarm circuit as the interrupt

source.

Activating the reset pin (active low) resets the hour latch to

“30” which prevents a match between alarm and time registers during an initialization procedure. Activating the reset

pin or writing to the control register resets the interrupt output (high) and clears the interrupt status register

Clock Output

One of 15 counter and prescaler overflows can be selected

as a 50% duty cycle output signal that is available at the

“clock out” pin. The frequency is selected by the upper nibble

in the control register. For example, selecting a one-second

clock output will result in a repetitive signal that will be high

for 500ms and low f or the same period. The high-to-low tr ansition of the output signal will set the clock bit in the status

register and activate the interrupt output. The level of the

“clock out” signal is derived from the value in the counter.

Example - if hours clock is selected and the minutes counter

holds 4 minutes, the clock out will be low for 26 minutes and

high for 30 minutes Thereafter, the clock out will toggle at a

50% duty cycle rate (see Table 1 and Figure 3).

CONTROL REGISTER (SEE TABLE 1 AND FIGURE 4)

BIT

7

6543210

CONTROL REGISTER BYTE

The 8-bit value in the control register determines the following:

1. Bit 0 and 1 - Frequency Select - Since there are one of 4

possible crystals the oscillator in the real-time clock can

operate with, these bit levels determine the prescaler divisor so that an accurate one second pulse is supplied to

the counter series string.

BIT 1 BIT 0 FREQUENCY

0 0 32,768Hz

0 1 1.048576MHz

1 0 2.097152MHz

1 1 4.194304MHz

2. Bit 2 - Start-Stop Control - Counter enabling is controlled

by the value at this location. A “1” will allow the counters

to function and a “0” in this location will disable the

counters.

3 Bit 3 - Counter/Latch Control - The level at this location

controls two functions. It is required since the counters

and alarm latches have the same addresses.

BIT

1) A “0” in bit-3 will direct subsequent data to or from

the counter selected and the alarm function will be

disabled.

2) A “1” in bit-3 will direct subsequent data to or from

the alarm latch and will enable the alarm.

4. Bits 4 to 7 - Clock Select - These bits select one of 15

square-wave signals that will be present at the “clockout” pin. If bit-4 to bit-7 are zero's, the clock output pin will

be high. If a clock is selected, the first high-to-low clock

out transition will activate the interrupt pin (active low) and

place a “1” in bit-6 of the status register. Writing to the

control register or activating the reset pin will set the interrupt pin high and reset the interrupt status register.

Normal operation requires the control register to be written

to and loaded first with a control word. However, subsequent

writing to a counter if a “clock out” is selected may cause an

interrupt out signal. Therefore, “clock-out” should be deselected by writing zero's into bit-4 through bit-7 if the interrupt

is used. When the counters are loaded, the control register

is again written to with the value in the upper nibble selecting

the “clock out” signal. See Table 1.

Read And Write Signals

When the IO/MEM pin is low, the real-time clock is enabled

for memory mapped operation. Data on the bus is placed in,

or read from a counter, alarm latch or register by 1) placing

the CS pin high, 2) selective addressing, 3) placing the

TPB/

WR pin low during a write cycle with the RD pin high or

4) setting the

TPB/

WR pin high.

RD pin low during a read cycle with this

The I/O mapping mode used with the CDP1800 series

microprocessor is selected by setting the IO/

The TPB/

WR pin on the real-time clock is connected to the

MEM pin high.

TPB output pin of the microprocessor. Data on that bus is

written to or read from the counters, latches and registers by

1) placing the CS pin high, 2) selective addressing utilizing

the microprocessor N lines and I/O instructions, 3) placing

the TPB/

WR pin high with the RD pin low during an output or

write operation (data is latched on TPB's trailing edge), 4)

setting the

RD line high during an input or read operation.

Data is placed on the bus by the real-time clock between the

trailing edges of TPA and TPB.

Freeze Circuit

Since writing to or reading from the counters or alarm

latches is performed asynchronously, the once-a-second

signal from the prescaler may pulse the counter series string

during these operations. This can result in erroneous data.

To avoid this occurring, a transparent “freeze” circuit' is incorporated into the real-time clock. This circuit is designed to

trap and hold the one-second input clock transition if it

occurs during access times. When the operations are completed, it is inserted into the counter series string. To utilize

the “freeze” circuit, address “1” (A0 = 1, A1 = 0, A2 = 0) is

selected first while performing a write operation. Read or

write accesses may now be performed with assurance the

data is stable. All operations must be concluded within

4-113

Page 11

CDP1879, CDP1879C-1

250ms of the address “1” access. In memory mapping any

dummy write operation after selecting address “1” will set the

“freeze” circuit. If using the I/O mode, a 61 output instruction

will perform the same function. There is no time restriction

on subsequent accesses as long as the read or write operations are preceded by selecting address “1”.

Power Down

Power down operation is initiated with a low signal on the

"POWER DOWN” input pin. In conjunction with the interrupt

output, it is used to supply external control circuits with a 3

level control signal. The operating current is not appreciably

reduced during “POWER DOWN” operation. When power

down is initiated, any inputs on the address or data bus are

ignored. The clock output is set low. The interrupt output is

three-stated. If enabled previously, the alarm circuitry is

active and will set the interrupt output pin low when alarm

time occurs. The interrupt output will also go low if a clock

was selected and an internal high-to-low transition occurs

during power down. The clock output pin will remain low. If

power down is initiated in the middle of a read or write

sequence, it will not become activated until the read or write

cycle is completed.

Pin Functions

VDD, VSS - Power and ground for device.

DB0 - DB7 - DATA BUS - 8-bit bidirectional bus that trans-

fers BCD data to and from the counters, latches and registers.

A0, A1, A2 - Address inputs that select a counter, latch or

register to read from or write to.

TPA - Strobe input used to latch the value on the chip select

pin. CS is latched on the trailing edge of TPA. During memory mapping, it is used to latch the high order address bit

used for the chip select. When the real-time clock is used

with other microprocessors, or when the high order address

of the CDP1800 series microprocessor is externally latched,

it is connected to V

gate the N lines.

IO/MEM - Tied low during memory mapping and high when

the input/output mode of the CDP1800 series microprocessor is used.

. In the input/output mode, it is used to

DD

Microprocessor Real-Time Clock

MRD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RD

TPB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TPB/WR

TPA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TPA

N LINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ADDRESS LINES

IO/MEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

CS - CHIP SELECT - Used to enable or disable the inputs

and outputs. TPA is used to strobe and latch a positive level

on this pin to enable the device.

XTAL AND XTAL - The frequency of the internal oscillator is

determined by the value of the crystal connected to these

pins. “XTAL” may be driven directly by an external frequency

source.

Clock Out - 1 of 15 square wave frequencies will appear at

this pin when selected. During power down, this pin will be

placed low, and will be high during normal operation when

the clock is deselected.

Power Down - Power Down Control - A low on this pin will

place the device in the power down mode.

INT - Interrupt Output - A low on this pin indicates an active

alarm time or high-to-low transition of the “clock out” signal.

RESET - A low on this pin clears the status register and

places the interrupt output pin high.

DD

Frequency Input Requirements

The Real-Time Clock operates with the following frequency

input sources:

1. An external crystal that is used with the on-board oscilla-

tor. The oscillator is biased by a large feedback resistor

and oscillates at the crystal frequency (see Figure 6,

Table 3).

2. An external frequency input that is supplied at the XTAL

input.

XTAL is left open (see Figure 5). A typical external

oscillator circuit is shown in Figure 7 in section, “Standby

(Timekeeping) Voltage Operation”.

RD, TPB/WR - Direction Signals - Active signals that determine data direction flow. In the memory mapped mode, data

is placed on the bus from the counters or status register

when

RD pin is active.

Data is transferred to a counter, latch or the control register

when

RD is high and TPB/WR is active and latched on the

trailing edge (low to high) of the TPB/

In the input/output mode, data is placed on the bus from a

counter or status register when RD is not active between the

trailing edges of TPA and TPB. Data on the bus is written to a

counter, latch, or the control register during TPB when

active and latched on TPB's trailing edge. The following connections are required between the microprocessor and realtime clock in the CDP1800 series I/O mode.

WR signal.

RD is

4-114

Page 12

CDP1879, CDP1879C-1

TABLE 3. TYPICAL OSCILLATOR CIRCUIT PARAMETERS FOR SUGGESTED OSCILLATOR CIRCUIT, SEE FIGURE 6

PARAMETER 4.197MHz 2.097MHz 1.049MHz 32768Hz (NOTE) UNITS

R

F

C

0

C

1

R

S

C

L

Crystal Impedance 73 200 200 50K (max.) Ω

NOTE: CDP1879C-1 only.

Design Considerations for Stable Crystal Oscillation

1. Stray capacitances should be minimized for best oscillator performance. Circuit board traces should be kept to a

maximum of 1 inch, and there should be no parallel

traces.

2. A signal line or power source line must not cross or go

near the oscillator circuit line.

3. It is advisable to put a 0.1µF capacitor between V

V

of the CDP1879.

SS

22 22 22 22 MΩ

39 39 39 39 pF

5555pF

- - - 200 kΩ

- - - 91 pF

CDP1879

PIN 23

XTAL

PARALLEL

RESONANT

CRYSTAL

C

O

DD

and

XTAL

PIN 22

R

F

R

S

C

L

C

I

CDP1879

XTAL

XTAL

PIN 23

PIN 22

EXTERNAL

FREQUENCY

SOURCE

FIGURE 5. CONNECTIONS FOR AN EXTERNAL FREQUENCY

SOURCE APPLIED TO REAL-TIME CLOCK

5PF

39PF

R

22 MEG.

200K

L

1

R

F

2

3

FIGURE 6. SUGGESTED OSCILLAT OR CIRCUIT APPLIED T O

REAL-TIME CLOCK (SEE TABLE 3)

Standby (Timekeeping) Voltage Operation

When any one of the four specified crystals is used with the

on-board oscillator, the Real-Time Clock can operate at a

minimum of 4V V

(timekeeping only, no device READ/WRITE accesses) down

to 3V at -40

o

C to +85oC and 2.5V at 0o to +70oC.

To achieve this low voltage operation, an external 32kHz clock

source must be supplied at the XTAL input (see Figure 7). The

standby requirements for CHIP SELECT/DESELECT are

listed in Table 4, and Figure 8 indicates the timing waveforms.

Figure 9 illustrates the typical timekeeping curve over the full

temperature range.

+3V

14

4

. However, at 32kHz the clock will run

DD

24

23

22

1/3 CD54/74HC04 CDP1879

FIGURE 7. TYPICAL EXTERNAL CLOCK-SOURCE CIRCUIT

4-115

Page 13

CDP1879, CDP1879C-1

STANDBY (TIMEKEEPING) CHARACTERISTICS AT FULL TEMPERATURE RANGE

LIMITS

V

t

RC

V

IH

V

IL

DD

(V)

5

10

5

10

t

F (NOTE 1)

PARAMETER

Chip Deselect to Standby t

(Timekeeping) Voltage Time

Recovery to Normal t

Operation Time

STANDBY

VOLTAGE MODE

0.95 V

V

DD

t

STBY

V

CS

IH

V

IL

DD

V

t

R (NOTE 1)

CSTBY

RC

STBY

0.95 V

DD

NOTE:

1. tR, tF ≥ 1µs

FIGURE 8. STANDBY (TIMEKEEPING) V OLTAGE AND TIMING

WAVEFORMS

V

STBY

(V)

2.5, 3

2.5, 3

2.5, 3

2.5, 3

MIN MAX MIN MAX

2

1

2

1

EXTERNAL CLOCK SOURCE OF 32kHz

TYPICAL STANDBY (TIMEKEEPING) VOLTAGE

3V (-40

2.5V (-0oC ≤ T ≤ +70oC

5

4

)

DD

3

+ V

2

STBY

(V

1

STANDBY (TIMEKEEPING VOLTAGE (V)

0

-40 -20 0 20 40 60 80 100

-

-

-

-

o

C ≤ T ≤ +85oC)

FULL TEMPERATURE RANGE -oC

2

-

2

-

-

-

-

-

FIGURE 9. TYPICAL STANDBY (TIMEKEEPING) V OLTA GE vs

FULL TEMPERATURE RANGE

CDP1879 CDP1879C-1

UNITS

µs

Applications

A typical application for this real-time clock is as a wake-up

control to a CPU to reduce total system power in intermittent-use systems. A hookup diagram illustrating this feature

is shown in Figure 10. In this configuration, the alarm and

power-down features of the CDP1879 are utilized in the control of the sleep and wake-up states of the CPU. A typical

shut-down/start-up sequence for this system could proceed

as follows:

1. The CPU has finished a current task and will be inactive

for the next six hours.

2. The CPU loads the CDP1879 alarm registers with the

desired wake-up time.

3. The CDP1800 Q output is set high, which stops the CPU

oscillator (as an alternative, in an NMOS system, power

to all components except the clock chip could be shut off).

4. This Q output signal is received by the CDP1879 as a

power-down signal.

5. The CDP1879 three-states the interrupt output pin.

6. The CDP1879 eventually times out, and sets an alarm by

driving the

INT output low.

7. The alarm signal resets the CPU (to avoid oscillator startup problems) and flags the processor for a warm-start

routine.

8. The CPU, once into its normal software sequence, writes

to the CDP1879 control register to reset the interrupt

request.

4-116

Page 14

CDP1879, CDP1879C-1

XTALXTAL

A0

A1

A2

IO/MEM

CDP1879

PD

INT

XTAL

XTAL

CDP1800

CLEAR

N0

N1

N2

EFI

V

DD

1/2

V

DD

CD40107

CD40107

1/2

V

DD

V

DD

Q

FIGURE 10. CPU WAKE-UP CIRCUIT USING THE CDP1879 REAL-TIME CLOCK

ADDRESS

LINES

CLEAR

MWR

MRD

TPA

INTERRUPT

MA0

MA1

MA2

MA7

CDP1802MEMORY

XTAL

RESET

TPB/

RD

TPA

INTERRUPT

A0

A1

A2

CS V

CLOCK

WR

IO/

CDP1879

DB0 - DB7

XTAL

OUT

MEM

SS

DATA BUS

FIGURE 11. TYPICAL CDP1802 MEMORY MAPPED SYSTEM

4-117

Page 15

CDP1879, CDP1879C-1

LATCH HIGH-ORDER

TPA

ADDRESS FOR CS

ADDRESS

TPB/

WR

DATA FROM CPU

TO REAL TIME CLOCK

HIGH BYTE LOW BYTE

DATA LATCHED

VALID DATA

FIGURE 12. CDP1800 SERIES MEMORY MAPPED WRITE CYCLE TIMING WAVEFORMS

TPA

ADDRESS

RD

DATA FROM

REAL TIME CLOCK

TO CPU

HIGH BYTE LOW BYTE

OUTPUT DRIVERS

ENABLED DISABLED

VALID DATA

FIGURE 13. CDP1800 SERIES MEMORY MAPPED READ CYCLE TIMING WAVEFORMS

ADDRESS

LINES

CLEAR

TPA

MRD

TPB

INTERRUPT

N0

N1

N2

CDP1802MEMORY

XTAL

RESET

TPA

RD

TPB/

INTERRUPT

A0

A1

A2

CLOCK

OUT

WR

IO/

CDP1879

DB0 - DB7

XTAL

MEM

CS

FIGURE 14. TYPICAL CDP1802 INPUT/OUTPUT MAPPED SYSTEM

V

DD

4-118

Page 16

CDP1879, CDP1879C-1

TPA

RD

N LINES

TPB/

WR

DATA FROM MEMORY

TO REAL-TIME CLOCK

FIGURE 15. CDP1800 SERIES INPUT/OUTPUT MAPPING TIMING WAVEFORMS WITH OUTPUT INSTRUCTION

TPA

RD

TPB/

WR

N LINES

DATA FROM

REAL-TIME CLOCK

TO MEMORY

FIGURE 16. CDP1800 SERIES INPUT/OUTPUT MAPPING TIMING WAVEFORMS WITH INPUT INSTRUCTION

Dynamic Electrical Specifications at T

PARAMETER

-40oC to +85oC, Input tR, tF = 10ns, CL = 50pF

A

V

DD

(V)

Read Cycle Times (See Figure 17)

Data Access from Address t

DA

5 - 400 - 400

10 - 190 - -

Read Pulse Width t

RD

5 270 - 270 -

10 160 - - -

Data Access from Read t

DR

5 - 375 - 375

10 - 170 - -

Address Hold after Read t

RH

50-0 -

10 0 - - -

Output Hold after Read t

DH

5 50 230 50 230

10 40 130 - -

Chip Select Setup to TPA t

CS

5 50 - 50 -

10 30 - - -

NOTE:

1. Time required by a limit device to allow for the indicated function.

DATA LATCHED

VALID DATA

OUTPUT DRIVERS ENABLED

OUTPUT DRIVERS

DISABLED

VALID DATA

LIMITS

CDP1879 CDP1879C-1

(NOTE 1)

MIN MAX

(NOTE 1)

MIN MAX

UNITS

ns

4-119

Page 17

TPA

ADDRESS/CHIP SELECT

READ

DATA TO CPU

CDP1879, CDP1879C-1

t

CS

t

RD

t

DR

t

DA

FIGURE 17. READ CYCLE TIMING WAVEFORMS

t

RH

t

DH

Dynamic Electrical Specifications at T

PARAMETER

-40oC to +85oC, Input tR, tF = 10ns, CL = 50 pF

A

V

DD

(V)

Write Cycle Times (See Figure 18)

Address Setup to Write t

AS

5

10

Write Pulse Width t

WR

5

10

Data Setup to Write t

DS

5

10

Address Hold after Write t

AH

5

10

Data Hold after Write t

WH

5

10

Chip Select Setup to TPA t

CS

5

10

NOTE:

1. Time required by a limit device to allow for the indicated function.

LIMITS

CDP1879 CDP1879C-1

(NOTE 1)

MIN MAX

225

110

150

70

65

30

0

0

150

80

50

30

-

-

-

-

-

-

-

-

-

-

-

-

(NOTE 1)

MIN MAX

225

150

65

150

50

UNITS

-

-

-

-

-

-

-

-

ns

0

-

-

-

-

-

-

-

-

-

4-120

Page 18

TPA

ADDRESS/CHIP SELECT

CDP1879, CDP1879C-1

t

CS

t

AH

WRITE

DATA TO REAL-TIME CLOCK

t

AS

t

WR

t

DS

t

WH

FIGURE 18. WRITE CYCLE TIMING WAVEFORM

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Cor poration reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

4-121

ASIA

Intersil (Taiwan) Ltd.

Taiwan Limited

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...