Page 1

CD-G15000/CP-G15000S

In the interests of user-safety the set should be restored to its

origina

l condition and only parts identical to those specified be

used

.

SERVICE MANUAL

No.S2605CDG15000

MINI COMPONENT SYSTEM

CONTENTS

PRECAUTIONS FOR USING LEAD FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Important service notes ................................1-1

[2] Specifications.................................................1-2

[3] Names of parts ..............................................1-3

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section........................................2-1

[2] Test mode ......................................................2-2

[3] CD section .....................................................2-4

[4] CD Changer mechanism section ...................2-5

CHAPTER 3. MECHANISM BLOCKS

[1] Caution on disassembly ................................3-1

Removing and reinstalling the main parts ........3-4

[2]

CHAPTER 4. DIAGRAMS

[1] CD Block diagrams........................................4-1

[2] Main Block diagrams .....................................4-2

[3] Sub Woofer Block diagram............................4-3

MODEL

CD-G15000

SPEAKER SYSTEM

CP-G15000SMODEL

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes on schematic diagram.......................... 6-1

[2] Types of transistor and LED.......................... 6-1

[3] Schematic diagram ........................................ 6-2

[4] Wiring side of PWB ...................................... 6-10

CHAPTER 7. FLOWCHART

[1] Troubleshooting ............................................. 7-1

CHAPTER 8. OTHERS

[1] Function table of IC ........................................ 8-1

[2] FL Display ...................................................... 8-8

Parts Guide (CD-G15000)

ts Guide (CP-G15000S)

Par

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms of CD circuit ................................5-1

[2] Voltage...........................................................5-2

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

!

– 1

This document has been published to be used

fo

r after sales service only.

Th

e contents are subject to change without notice.

Page 2

CD-G15000/CP-G15000S

AudioXL-MP150Service ManualXLMP150MarketE

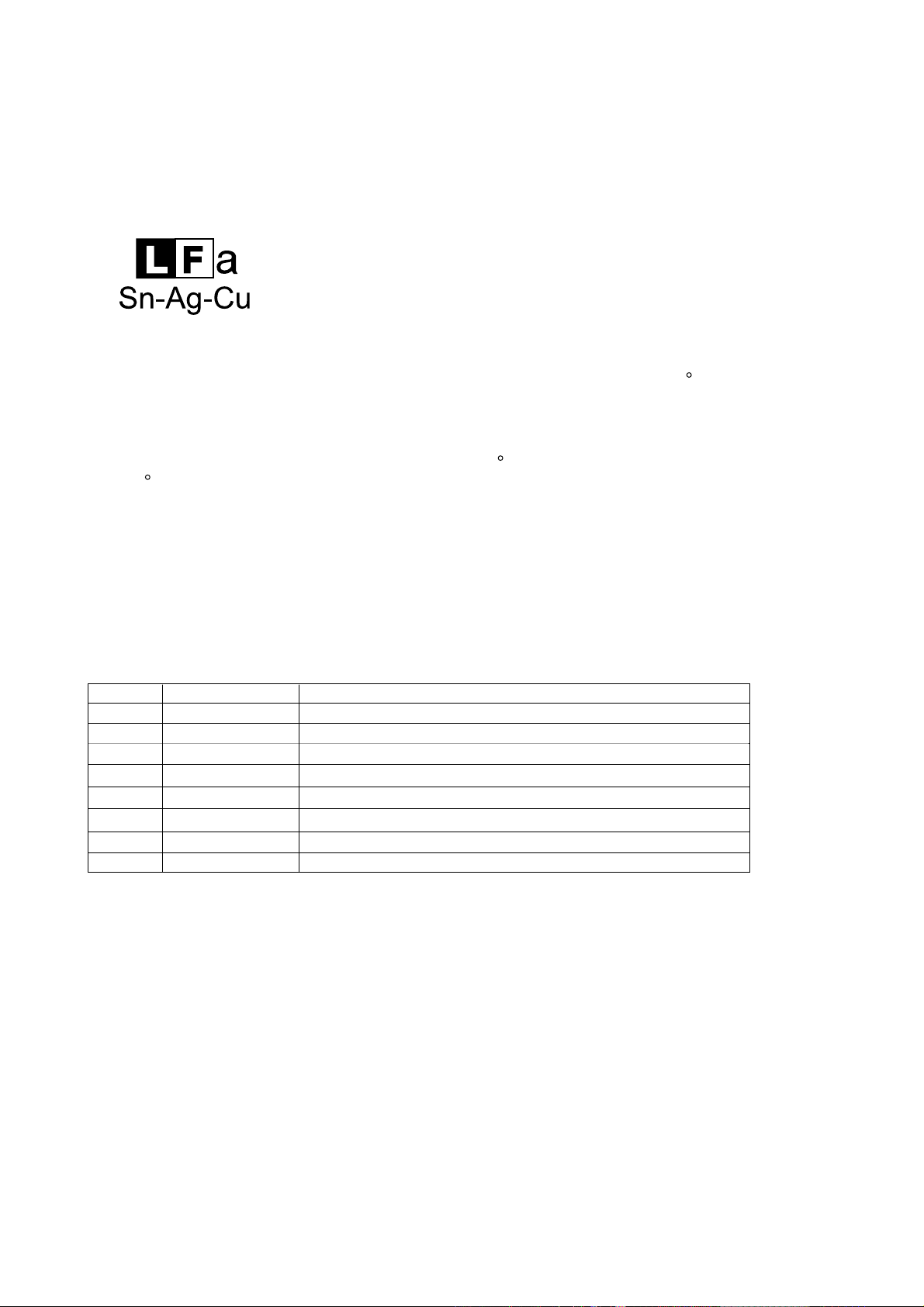

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN,DISPLAY,POWER,GAME INPUT,SPEAKER,CD SERVO,CD MOTOR(PWB ONLY),CD CHANGER MOTOR

B ONLY), SUB WOOFER SPEAKER LED,SUB WOOFER AMP,PRIMARY POWER,LED

(PW

FLASHING,JACK,VOLUME,POWE

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals.The alphabetical

characte

Example:

r following LF shows the type of lead-free solder.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with

conventiona

l lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, were

commen

solderin

d you to use a dedicated soldring bit,if you are not familiar with how to obtain lead-free wire solder or

g bit,contact our service station or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead

r by 40 C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

solde

B for extended period of time. However, since the land may be peeled off or the maximum heat-resistance

PW

temperatur

solderin

Lead-fre

e of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

g condition.

e solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn

on and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder.Clean the bit

r every use of it.

afte

Whe

n the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-fre

PWB-A 92LPWB6529MANS

PWB-B 92LPWB6529DPLS

PWB-

PWB-

PWB-

PWB-

e wire solder for servicing

Ref No.

C

D

E

F

Parts No.

92LPWB6514CDU

92LPWB6230LED

QPWBF0027AWZZ

QPWBF1055AWZ

PWB6512AMPSPWB-H

PWB6512CTRSPWB-J

R SWITCH PWB"of this model employs lead-free solder.

Indicates lead-free solder of tin,silver and copper.

MAIN (A1), POWER (A2)

DISPLAY (B1), GAME INPUT (B2), SPEAKER (B3)

S

CD SERVO

SU

S

CD MOTOR (PWB ONLY)

CD CHANGER MOTOR (PWB ONLY)

Z

SUB WOOFER AMP(H1),PRIMARY POWER(H2),LED FLASHING(H3),JACK(H4)

VOLUME (J1),POWER SWITCH (J2)

Description

B WOOFER SPEAKER LED

– 2

i

Page 3

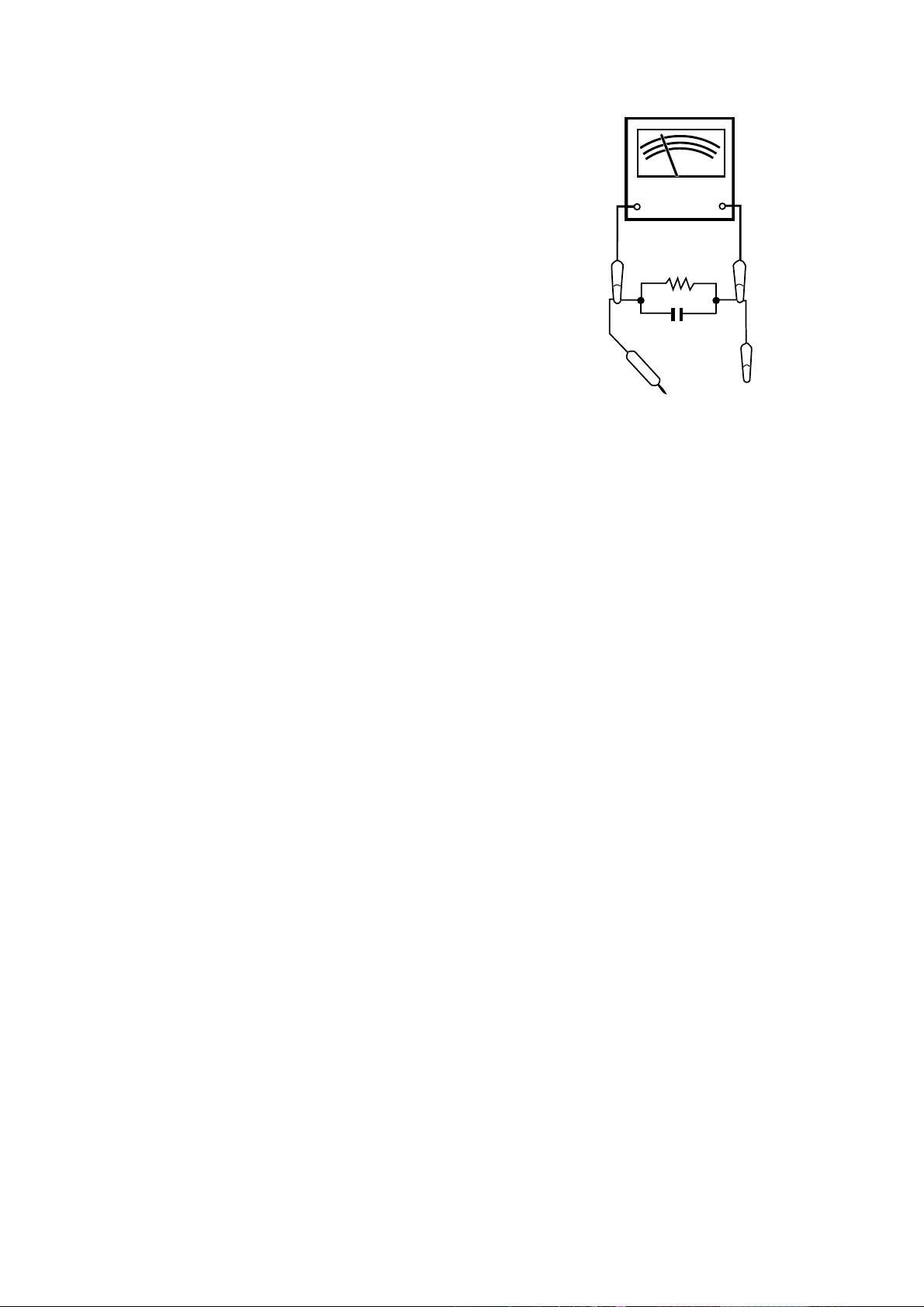

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

TEST PROBE

0.15 mF

1.5 kohms

10 W

VTVM

AC SCALE

CHAPTER 1: GENERAL DESCRIPTION

[1] Important service notes

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the use r, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the audio product.

2. Inspect all protective devices such as insulating

materials, cabinet, terminal board, adjustment and

compartment covers or shields, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

* Plug the AC line cord directly into a 120 volt AC out-

let.

* Using two clip leads, connect a 1.5 kohm, 10 watt

resistor paralleled by a 0.15 µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as conduit or electrical ground

connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or

higher, sensitivity to measure the AC voltage drop

across the resistor (See diagram).

* Connect the resistor connection to all exposed metal

parts having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control

shafts, escutcheon, etc.) and measure the AC voltage drop across the resistor.

CD-G15000/CP-G15000S

All check must be repeated with the AC line cord plug

connection reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected

before returning the audio product to the owner.

1 – 1

– 3

Page 4

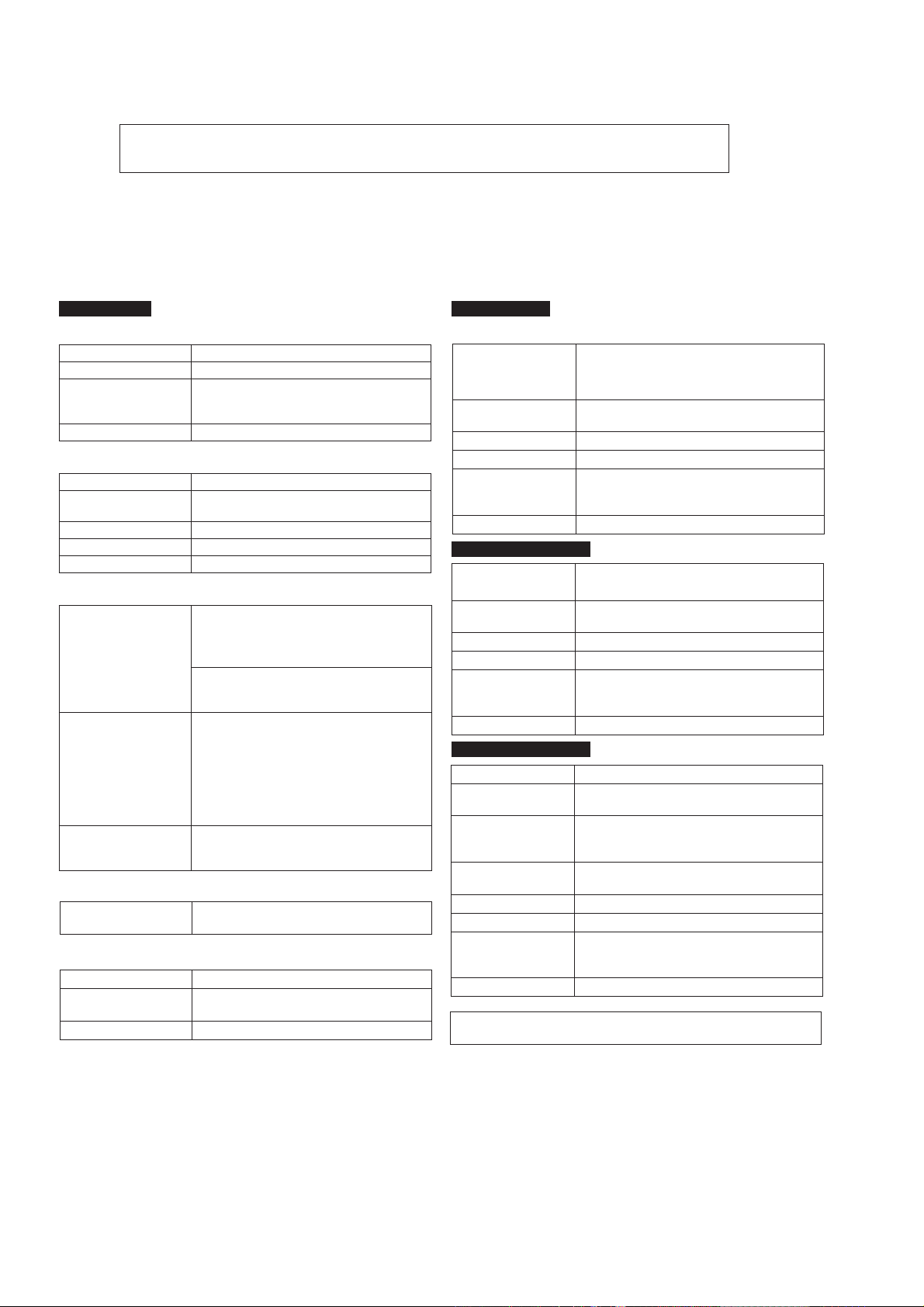

CD-G15000/CP-G15000S

[2] Specifications

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

As part of our policy of continuous improvement,

SHARP reserves the right to make design and

specifcation changes for product improvement

without prior notice. The performance specification

figures indicated are nominal values of production

units .There maybe some deviations from these

values in individual units.

CD-G15000 CP-G15000

■ General

Power source AC 120 V, 60 Hz

Power consumption 175 W

Dimensions Width: 10-1/4" (260 mm)

Height: 13" (330 mm)

Depth: 12-7/8" (322 mm)

Weight 21.35 lbs. (9.67 kg)

■ CD player

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

pickup

D/A converter 1-bit D/A converter

Frequency response 20 - 20,000 Hz

Dynamic range 90 dB (1 kHz)

■ Amplifier

Output power

Front speakers 150 watts minimum RMS per channel into

8 ohms from 100 Hz to 20 kHz, 10% total

harmonic distortion

Rear speakers 75 watts minimum RMS per channel into

16 ohms from 5 kHz to 20 kHz, 10% total

harmonic distortion

Output terminals Front speakers: 8 ohms

Rear speakers: 16 ohms

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

Video output: 1Vp-p (75 ohms)

Input terminals Game/Auxiliary (audio signal):

500 mV/47 k ohms

Game/Video: 1Vp-p (75 ohms)

■ Tuner

Frequency range FM: 87.5 - 108.0 MHz

AM: 530 - 1,720 kHz

■ Cassette deck

Frequency response 50 - 14,000 Hz (normal tape)

Signal/noise ratio 55 dB (TAPE-1 playback)

50 dB (TAPE-2 recording/playback)

Wow and flutter 0.3 % (WRMS)

Type 2-way type speaker system

Maximum input

power

Rated input power 150 W

Impedance 8 ohms

Dimensions Width: 7-11/16" (195 mm)

Weight 10.8 lbs. (4.9 kg)/each

Type Full-range speaker system

Maximum input

power

Rated input power 75 W

Impedance 16 ohms

Dimensions Width: 5-11/16" (145 mm)

Weight 6.4 lbs. (2.9 kg)/each

Power source AC 120 V, 60 Hz

Power

consumption

Output power 400 watts minimum RMS into 6 ohms from

Input terminals Subwoofer input (audio signal):

Speaker type 10" (25 cm) woofer

Impedance 6 ohms

Dimensions Width: 18-1/8" (460 mm)

Weight 46.2 lbs. (21 kg)

Specifications for this model are subject to change without prior

notice.

2" (5 cm) tweeter x 1

5-1/8" (13 cm) woofer x 2

300 W

Height: 15-3/4" (400 mm)

Depth: 9-5/8" (244 mm)

GBOXSA133AWM1

4" (10 cm) speaker x 2

150 W

Height: 15-3/4" (400 mm)

Depth: 9-1/8" (231 mm)

CP-SW15000

120 W

50 Hz to 120 Hz, 10% total harmonic

distortion

200mV / 10 k ohms at 70 Hz

Height: 15-3/4" (400 mm)

Depth: 15-13/16" (402 mm)

– 3

1 – 2

Page 5

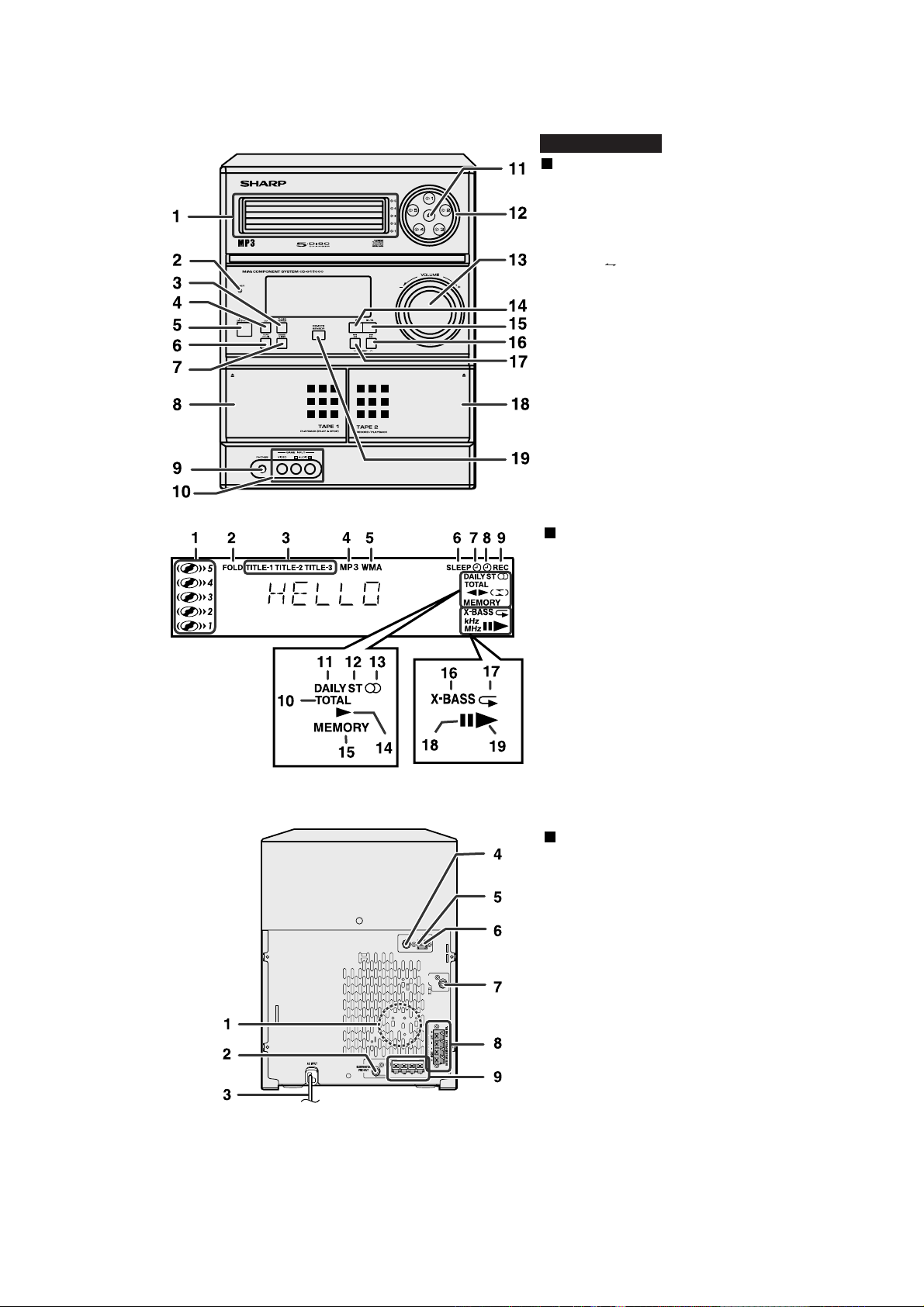

[3] Names of parts

CD-G15000/CP-G15000S

CD-G15000

Front panel

1. Disc Trays

2. Timer Indicator

3. Tuner (Band) Button

4. CD Button

5. Power On/Stand-by Button

6. Tape (1 2) Button

7. Game/Video Button

8. Tape 1 Cassette Compartment

9. Headphone Jack

10. Game/Video Input Jacks

11. Disc Tray Open/Close Button

12. Disc Number Select Buttons

13. Volume Control

14. CD or Tape Stop Button

15. CD Play or Repeat, Tape Play Button

16. CD Track Up or Fast Forward, Tape 2 Fast Forward,

Tuner Preset Up, Time Up Button

17. CD Track Down or Fast Reverse, Tape 2 Rewind,

Tuner Preset Down, Time Down Button

18. Tape 2 Cassette Compartment

19. Remote Sensor

FM GND AM

75OHMS

ANTENNA

Display

1. Disc Number Indicators

2. MP3/WMA Folder Indicator

3. MP3/WMA Title Indicators

4. MP3 Indicator

5. WMA Indicator

6. Sleep Indicator

7. Timer Play Indicator

8. Timer Recording Indicator

9. Tape 2 Record Indicator

10. MP3/WMA Total Indicator

11. Daily Timer Indicator

12. FM Stereo Mode Indicator

13. FM Stereo Receiving Indicator

14. Tape Forward Play Indicator

15. Memory Indicator

16. Extra Bass Indicator

17. Disc Repeat Play Indicator

18. Disc Pause Indicator

19. Disc Play Indicator

Rear panel

1. Cooling Fan

2. Subwoofer Pre-output Jack

3. AC Power Cord

4. FM 75 Ohms Antenna Jack

5. AM Antenna Ground Terminal

6. AM Loop Antenna Terminal

7. Video Output Jack

8. Front Speaker Terminals

VIDEO

OUT

9. Rear Speaker Terminals

REARSPEAKERS

RIGHT

LEFT

RATEDSPEAKERIMPEDANCE:16OHMSMIN.

1 – 3

–2

Page 6

CD-G15000/CP-G15000S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

26

27

28

29

21

22

23

24

25

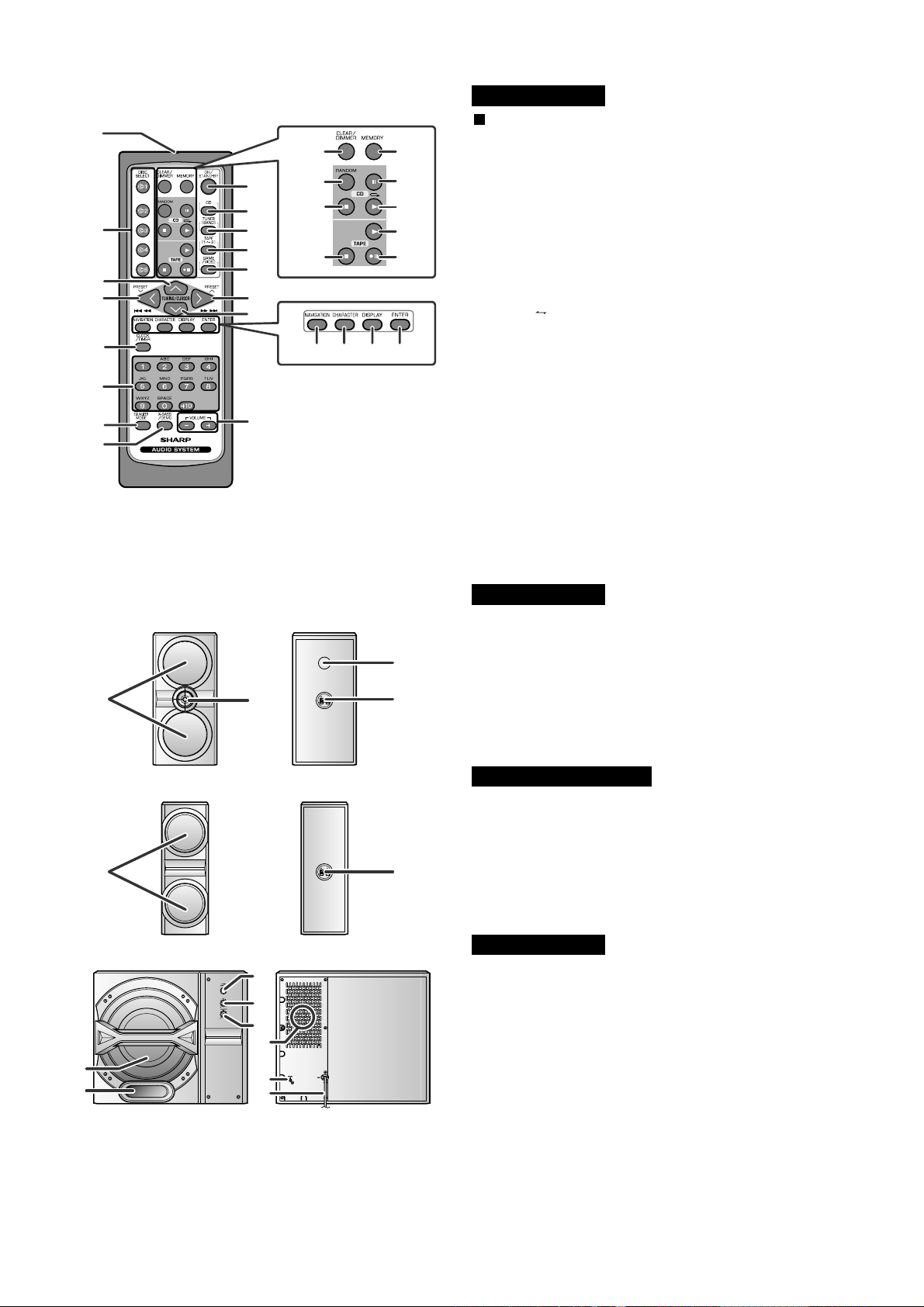

CD-G15000

Remote control

1. Remote Contr ol Transmitter

2. Disc Number Select Buttons

3. Tuning Up, Cursor Up Button

4. Disc Track Down or Fast Reverse, Tape 2 Rewind,

Tuner Preset Down, Time Down, Cursor Left Button

5. Clock/Timer Button

6. Character Input/Disc Direct Search Buttons

7. Equaliz er Mode Select Button

8. Extra Bass Button

9. On/Stand-by Button

10. CD Button

11. Tuner (Band) Button

12. Tape (1 2) Button

13. Game/Video Button

14. Disc Track Up or Fast Forward, Tape 2 Fast Forward,

Tuner Preset Up, Time Up, Cursor Right Button

15. Tuning Down, Cursor Down Button

16. Volume Up and Down Buttons

17. Clear/Dimmer Button

18. Disc Random Button

19. Disc Stop Button

20. Tape Stop Button

21. Memory Button

22. Disc Pause Button

23. Disc Play or Repeat Button

24. Tape Play Button

25. Tape 2 Record Pause Button

26. MP3/WMA Navigation Mode Select Button

27. Character Button

28. MP3/WMA Display Button

29. Enter Button

CP-G15000

1. Woofers

2. Tweeter

3. Bass Reflex Duct

3

1

2

4

4. Speaker Terminals

GBOXSA133AWM1

1. Full-range Speakers

2. Speaker Terminals

1

2

CP-SW15000

3

4

5

6

1

2

7

8

1. Subwoofer

2. Bass Reflex Duct

3. Power Switch

4. Volume Control

5. Crossover Frequency Control

6. Cooling Fan

7. Subwoofer Input jack

8. AC Power Cord

1 – 4

– 3

Page 7

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

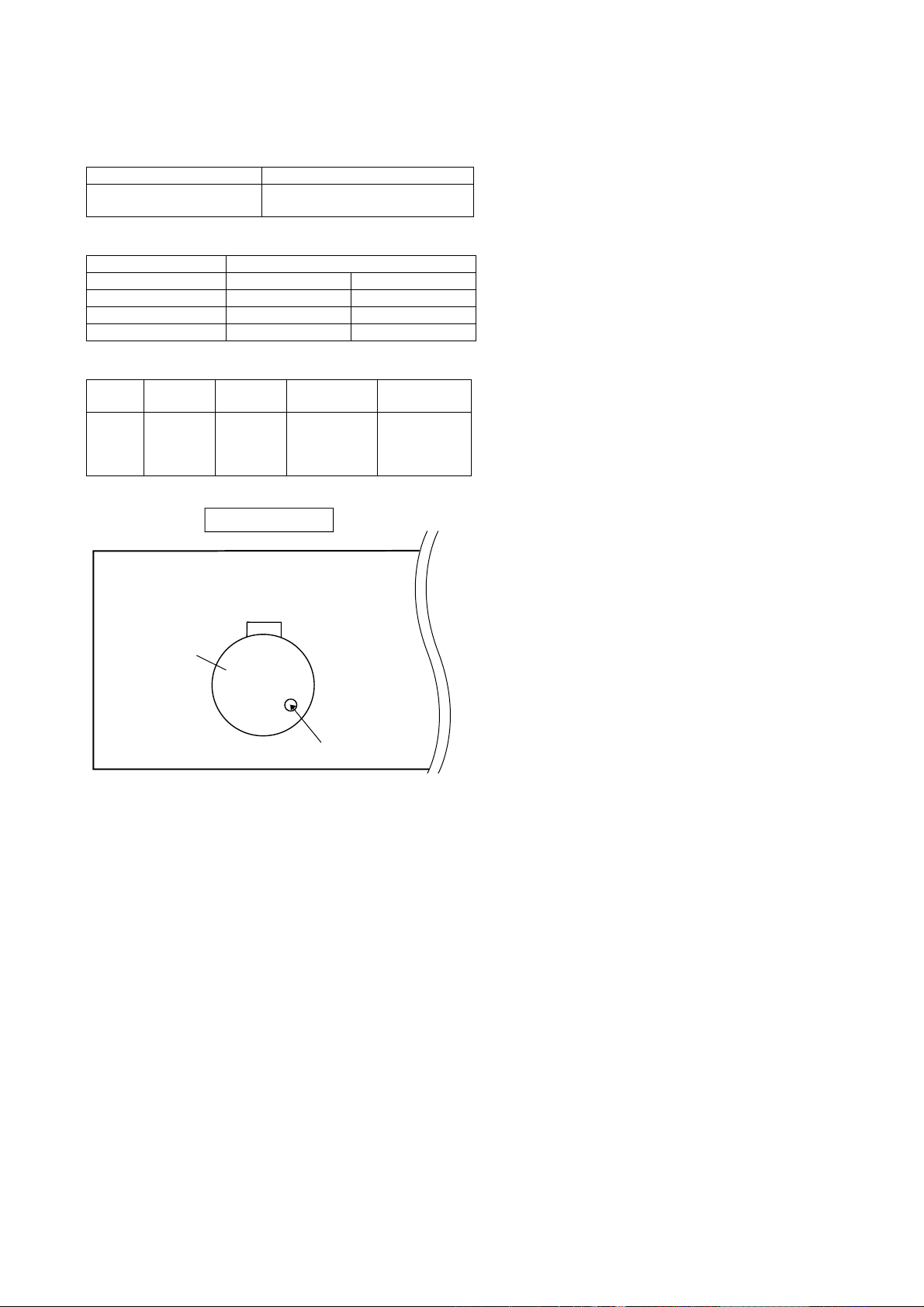

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Tape 1: Over 80 g

Tape 2: Over 80 g

• Torque Check

Torque Meter Specified Value

Tape 1 Tape 2

Play: TW-2111 30 to 80 g.cm 30 to 80 g.cm

Fast forward: TW-2231 — 70 to 180 g.cm

— 70 to 180 g.cm

• Tape Speed

CD-G15000/CP-G15000S

Test Tape Adjust-

ing Point

Normal

speed

Figure 1

MTT-111 Variable

Resistor in

motor.

TAPE MECHANISM

Tape

Motor

Specified

Value

3,000 ± 30 Hz

Speaker

Variable Resistor in motor

Instrument

Connection

Speaker Terminal (Load

resistance: 6

ohms)

2 – 1

Page 8

CD-G15000/CP-G15000S

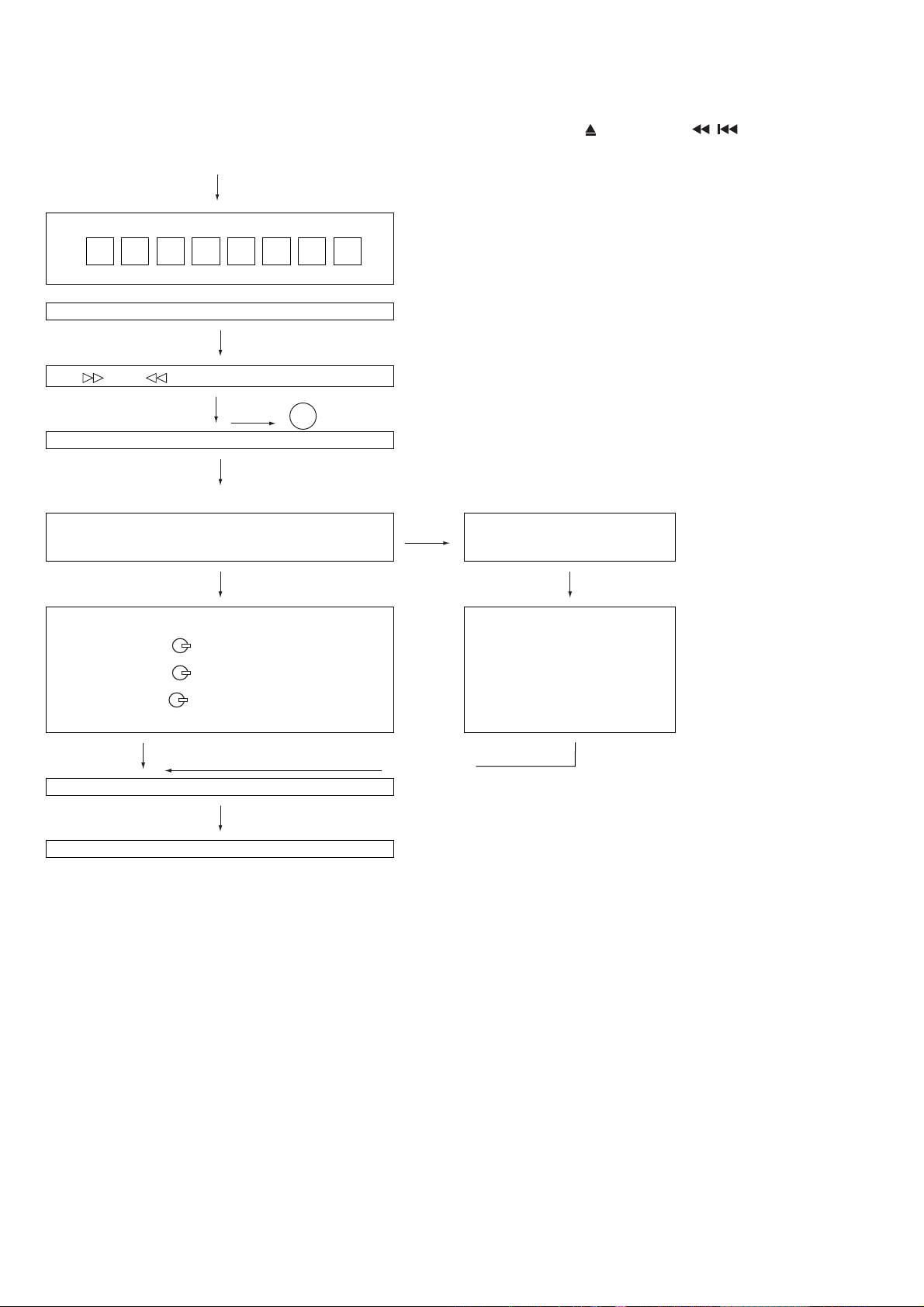

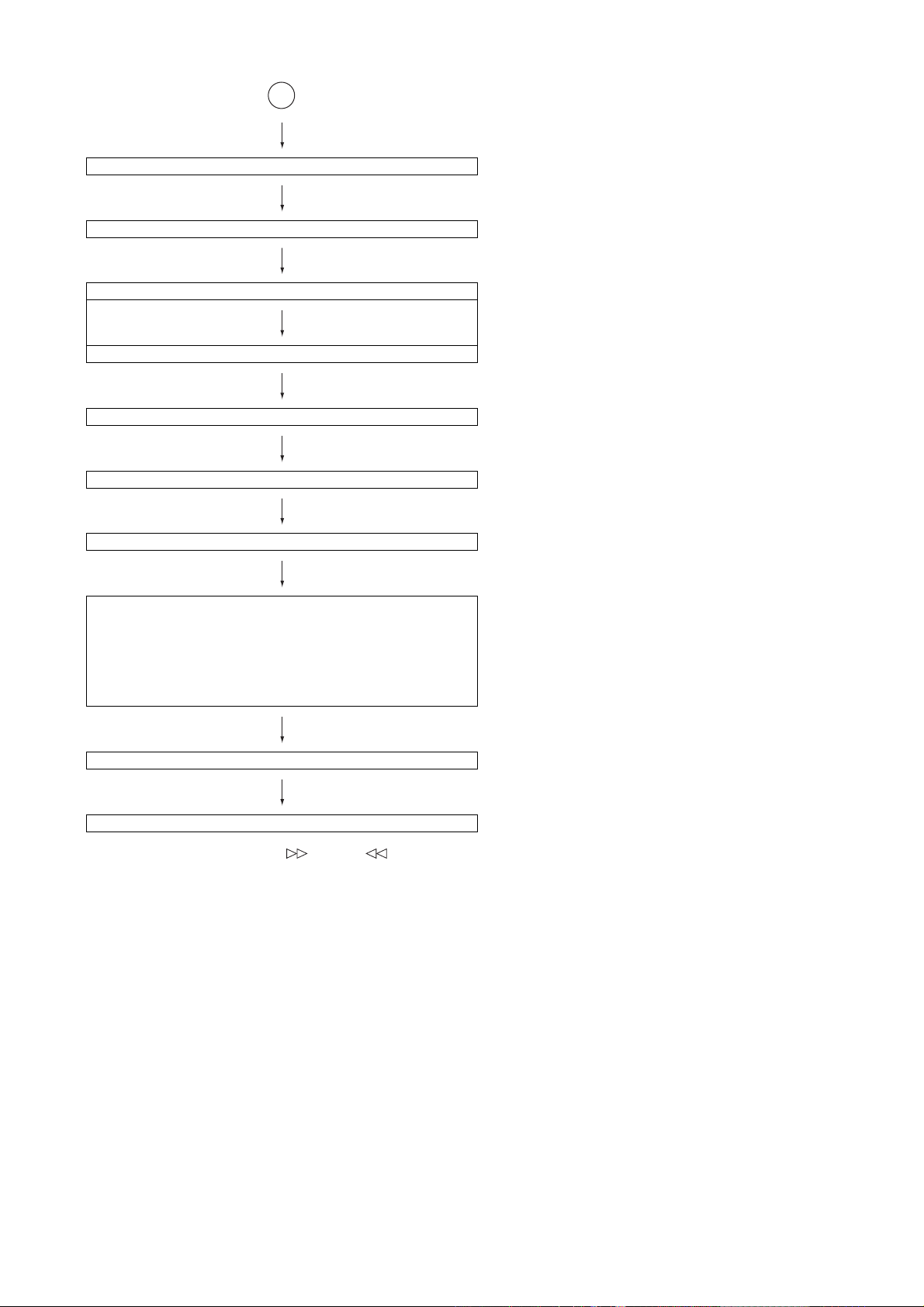

[2] Test mode

• Setting the test mode

During stand-by mode, press GAME/VIDEO button while pressing down the button and button. then,

press the CD button to enter the test mode.

C D T E S T

OPEN/CLOSE operation is using manual. IL isn’t done

<< >>,<< >>buttons make pick's slide possible.

to page 2-3

<<PLAY>> key input.

Do TOC IL. Do normal play.

When these following key is input into PLAY key, track number can be appoint directly.

<< 1>> key: Track 4

<< 2>> key: Track 9

<< 3>> key: Track 15

A

IL isn’t done

IL isn’t done

<<MEMORY>>

key input.

Adjustment result automatically will

display as below for each 2 sec:

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

––––––––

2 – 2

Page 9

A

<<MEMORY>> key input.

Laser ON.

<<MEMORY>> key input.

Tracking OFF play at that specific point.

<<MEMORY>> key input.

Tracking ON play from that specific point.

CD-G15000/CP-G15000S

<<MEMORY>> key input.

Adjustment result automatically will display as below for each 2 sec :

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

Sliding the PICKUP with<< >>, << >> button

must only be in STOP mode.

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

2 – 3

Page 10

CD-G15000/CP-G15000S

[3] CD section

CD Error code description

Error Explanation

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize pro-

cess.

20* TRAY error. Can't detect TRAY switch when TRAY is mov-

ing.

21* When it detect TRAY operation error during initialize pro-

cess.

31 When it change to CD function, DSP cannot read initial

data.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed

instead of 'ER-CD**'. 'ER-CD**' display will only be

displayed when error had been detected for the 5

times.

Standard Specification of Stereo System Error Message Display Contents

Error Contents Display Notes

CD CD Changer Mechanism Error. 'ER-CD**' (*) 10: CAM SW Detection NG during normal operation

CD DSP Communication Error. 'ER-CD31' DSP COMMUNICATION ERROR.

Focus Not Match/IL Time Over. 'NO DISC'

TUNER PLL Unlock. PLL Unlock.

th

11: CAM SW Detection NG during initialize process

20:TRAY SW Detection NG during normal operation

21:TRAY SW Detection NG during initialize process

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**'

display will only be display when error had been

detected for the 5

th

times.

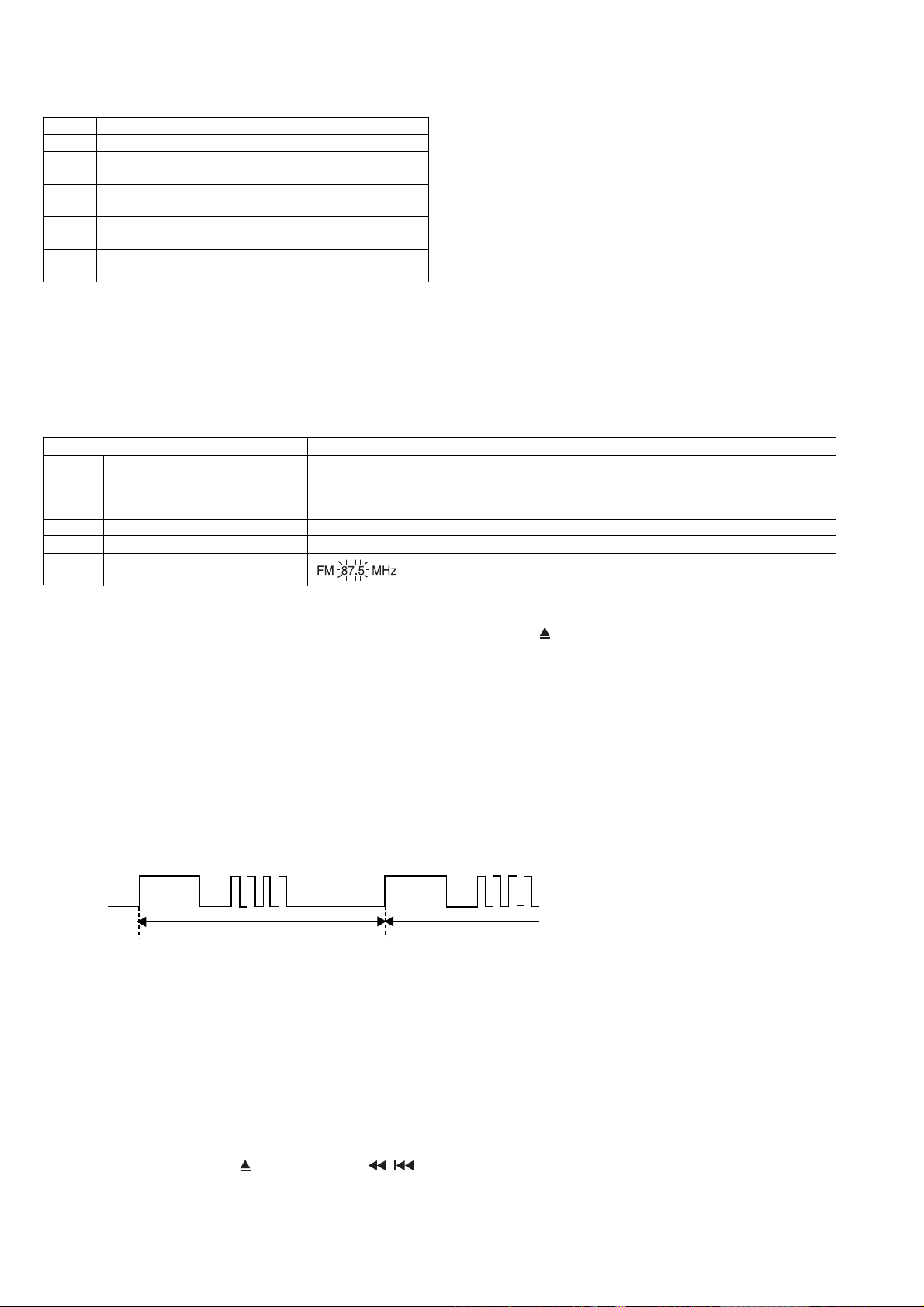

Speaker abnormal detection and +B PROTECTION

display

In case speaker abnormal detection or +B PROTECTION had occurred, the unit will automatically enter to

stand - by mode and Timer indicator will be flashing as

below.

Example : In case of speaker abnormal

TIMER

LED

ON

OFF

NO. 1

NO.1 : +B Protection

NO.2 : Speaker abnormal

OFF

FLASHING

NO. 2

1 FRAME

OFF

NO. 1

+B PROTECTION is condition when irregular process

occur on power supply line.

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set taper-

ing/parts replacement.

ON

3. Press button until "WAIT"→ "FINISHED"

appears.

4. Unplug the AC cord and the unit is ready for transporting.

FLASHING

OFF

NO. 2

(REPEAT)

1. Press the ON/STAND-BY button to enter stand-by

mode.

2. While pressing down the button and the

button, press the GAME/VIDEO button. The Micro

Computer version number will be displayed as

"CM*****".

2 – 4

Page 11

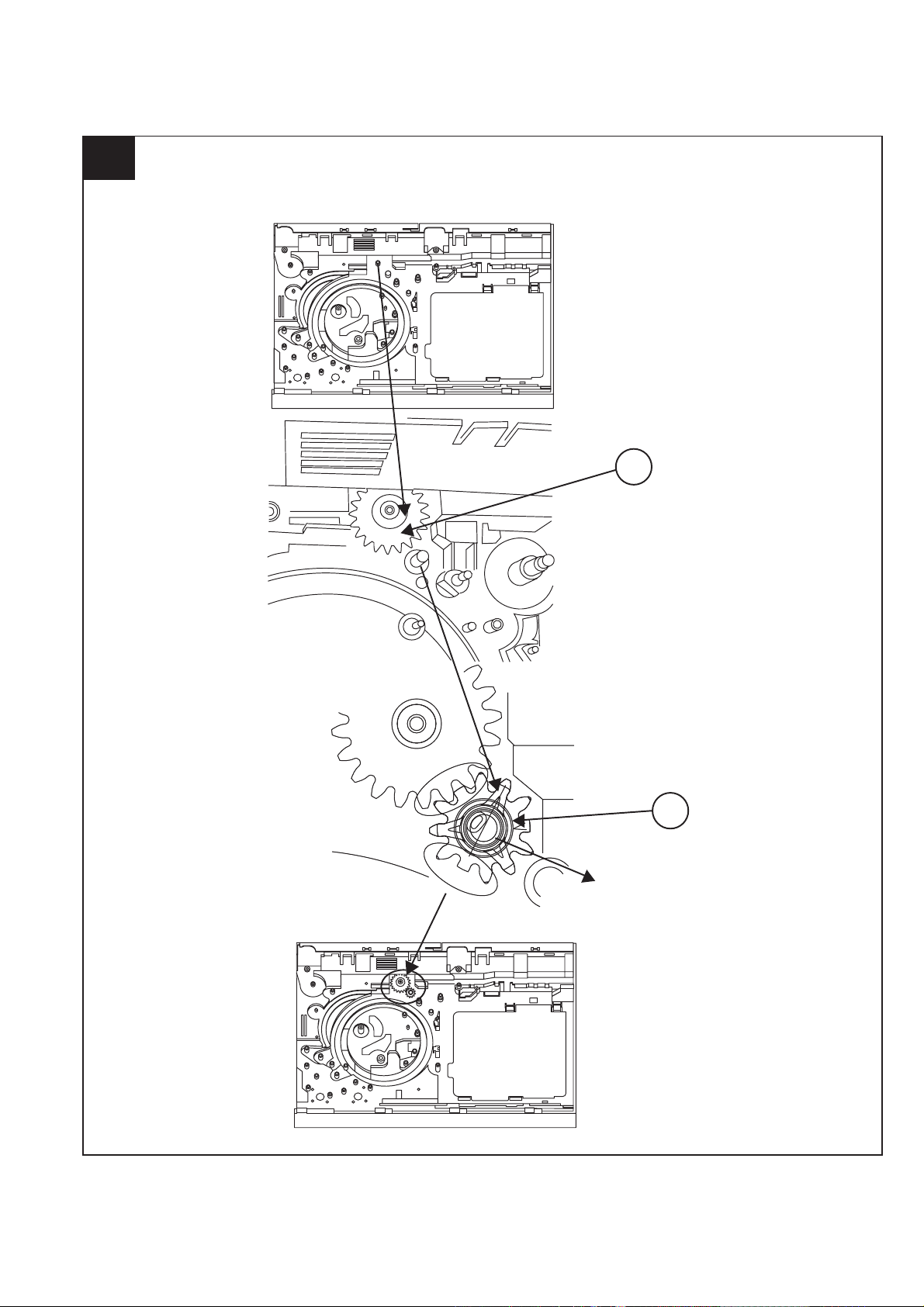

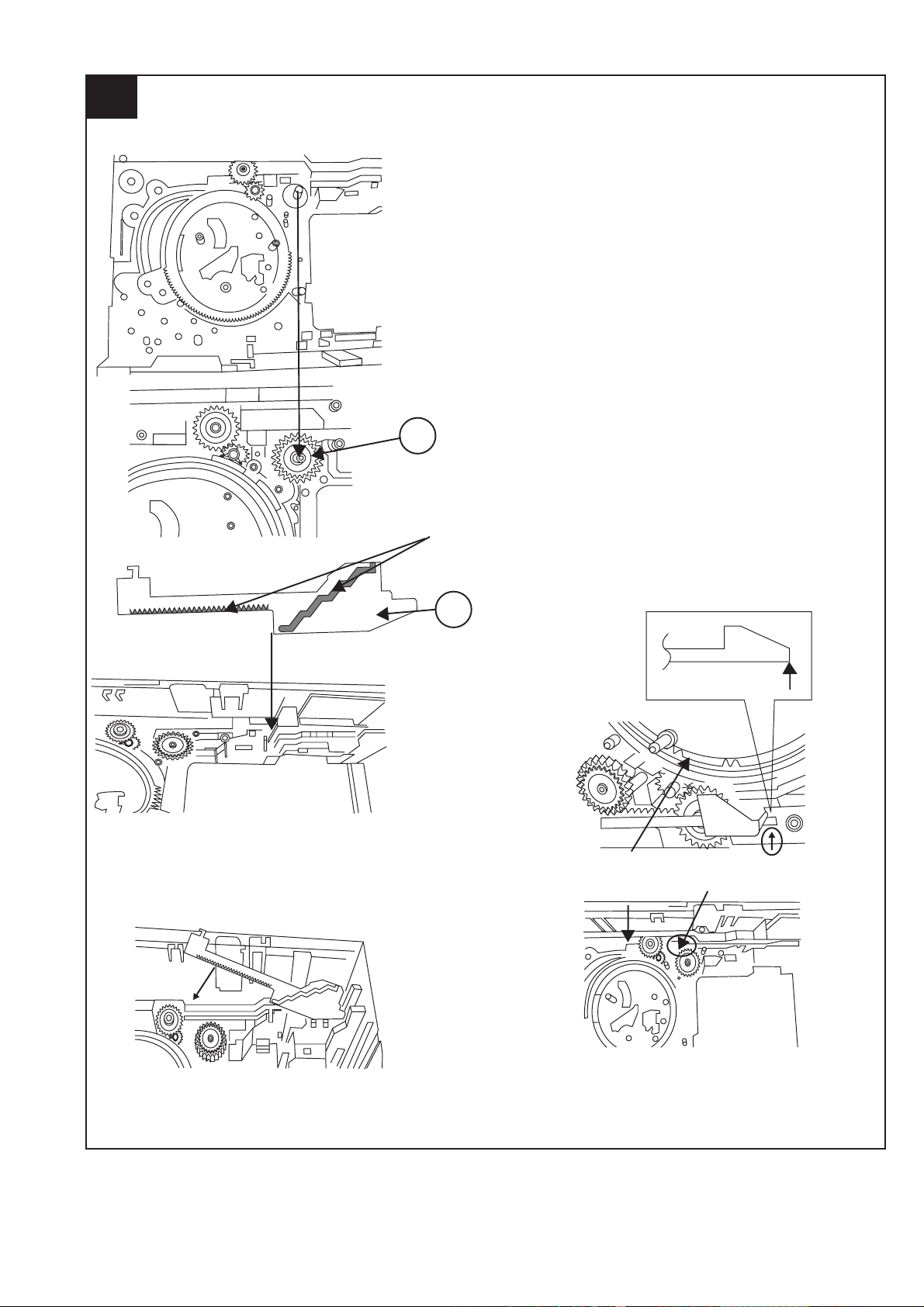

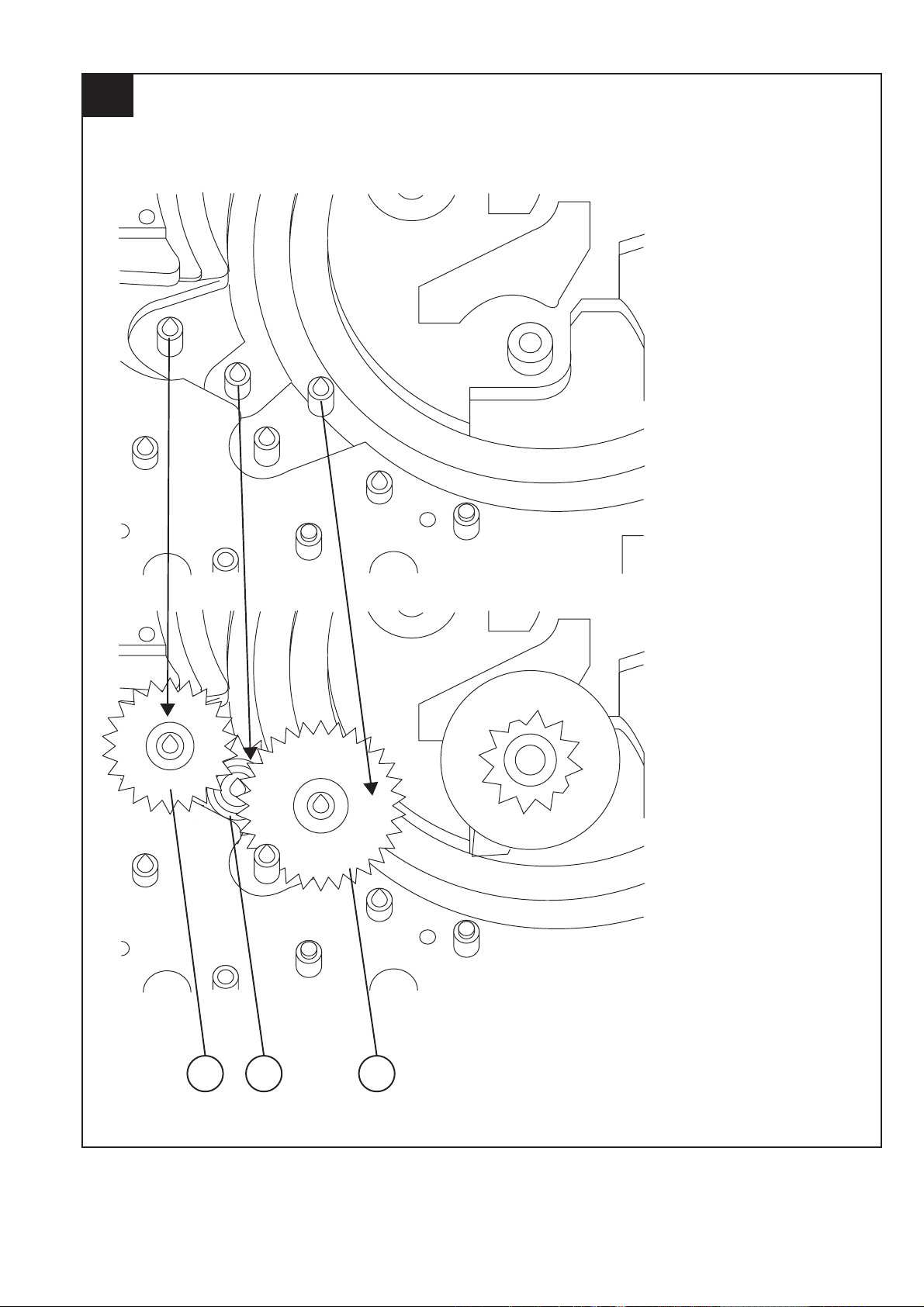

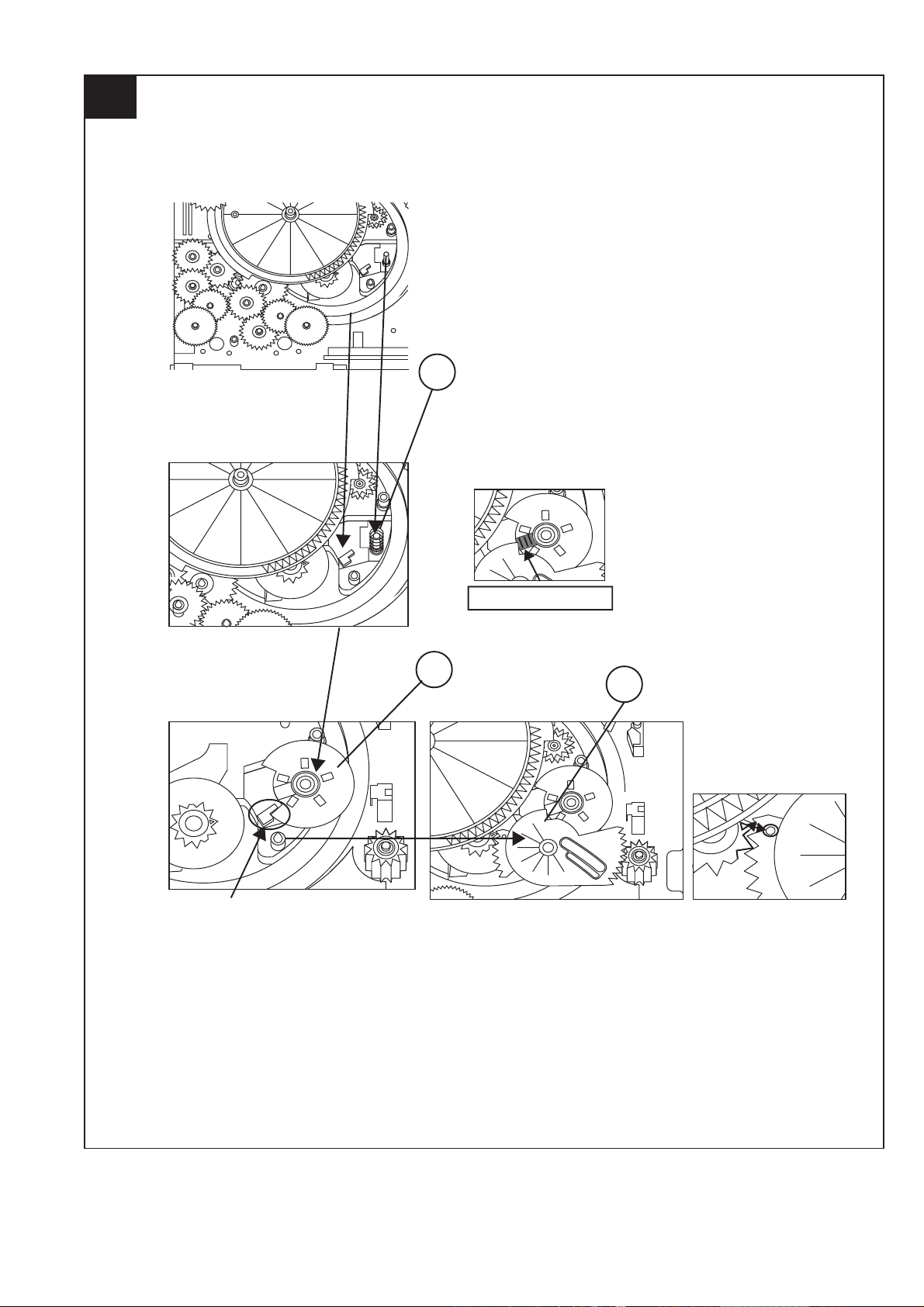

[4] CD Changer mechanism section

• All numbers in the drawing correspond to those in

parts guide (CHANGER MECHANISM PARTS).

1

CD-G15000/CP-G15000S

141

2 – 5

140

HALF GEAR

MUST BE ARRANGED AS SHOWN

Page 12

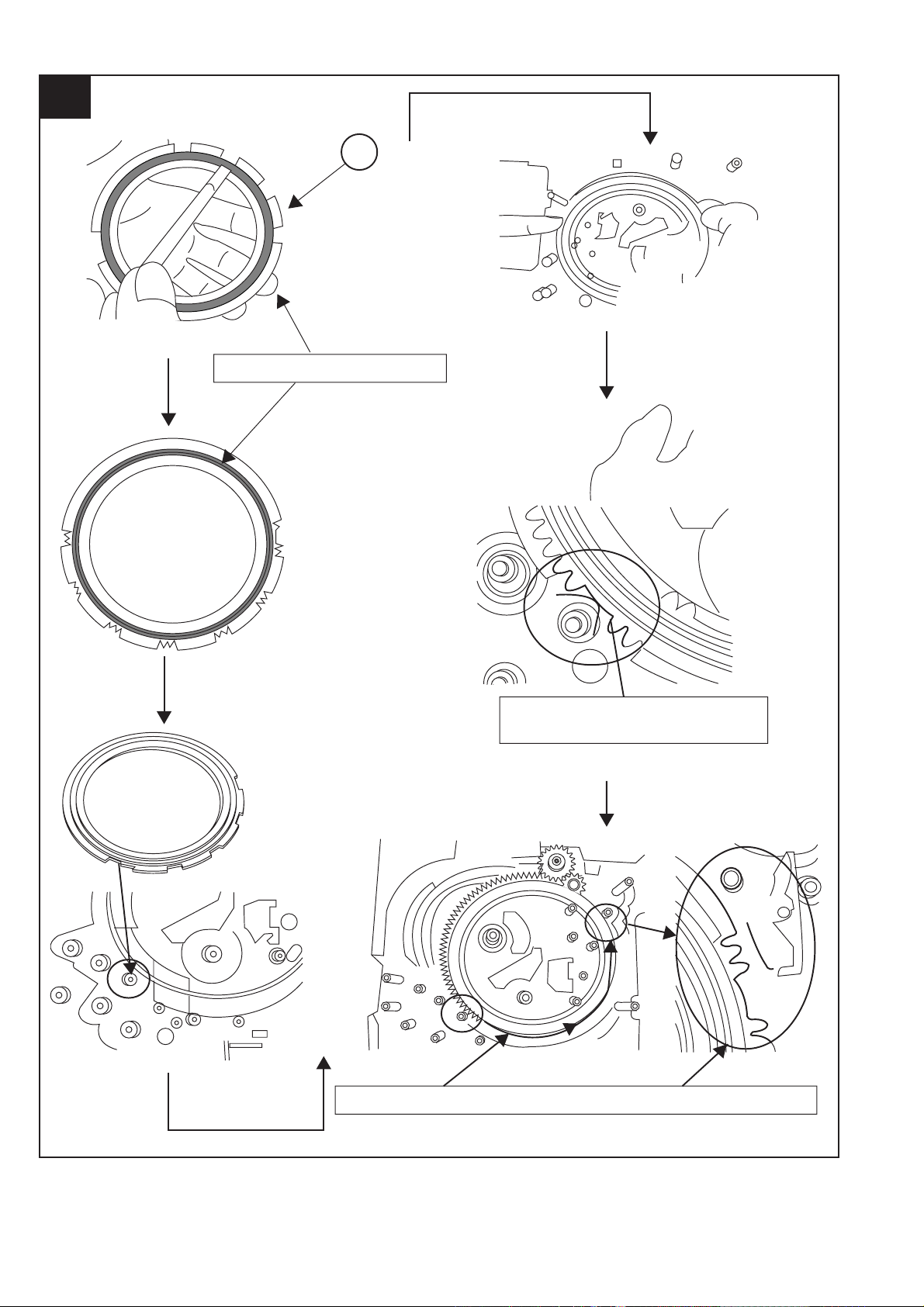

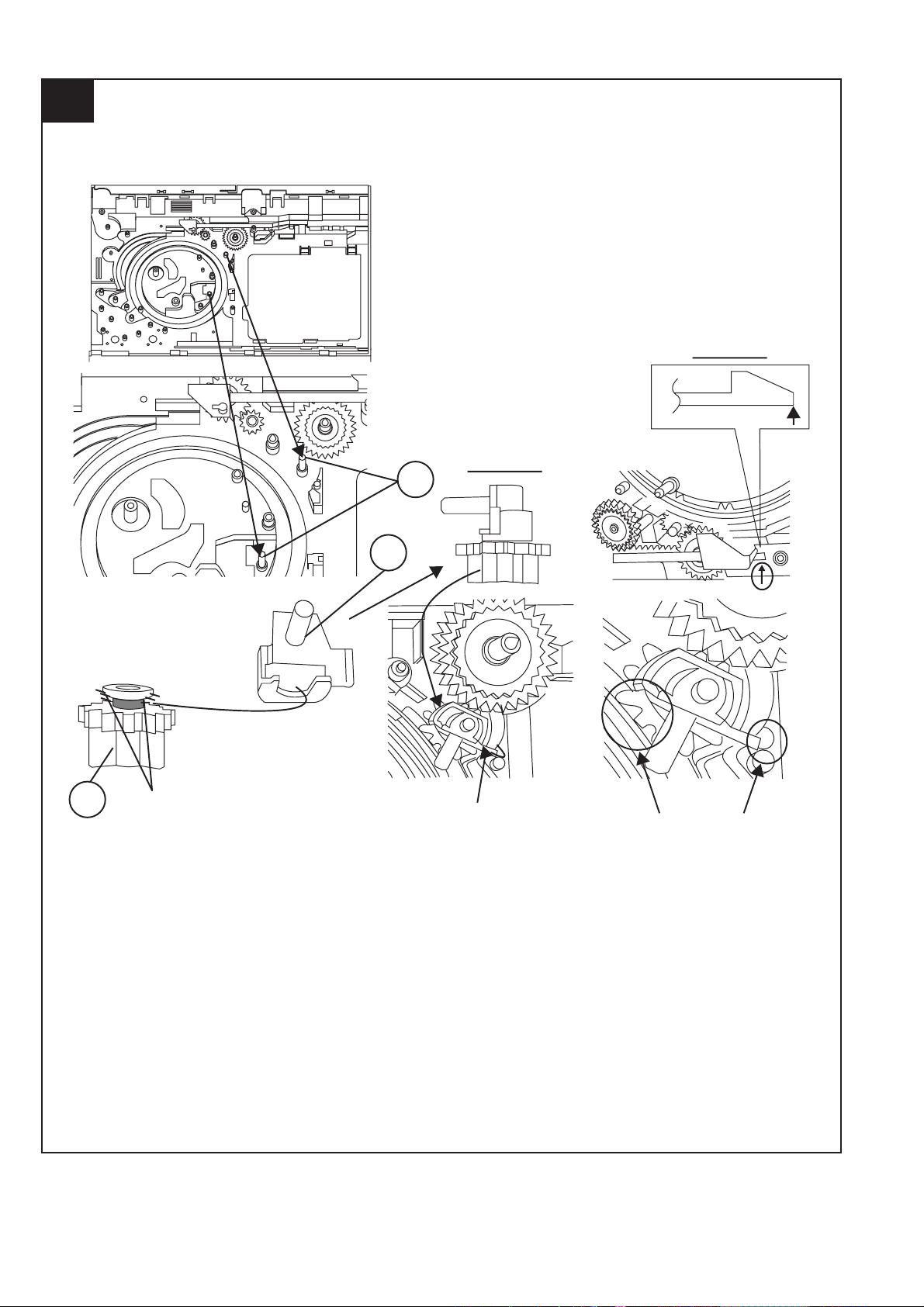

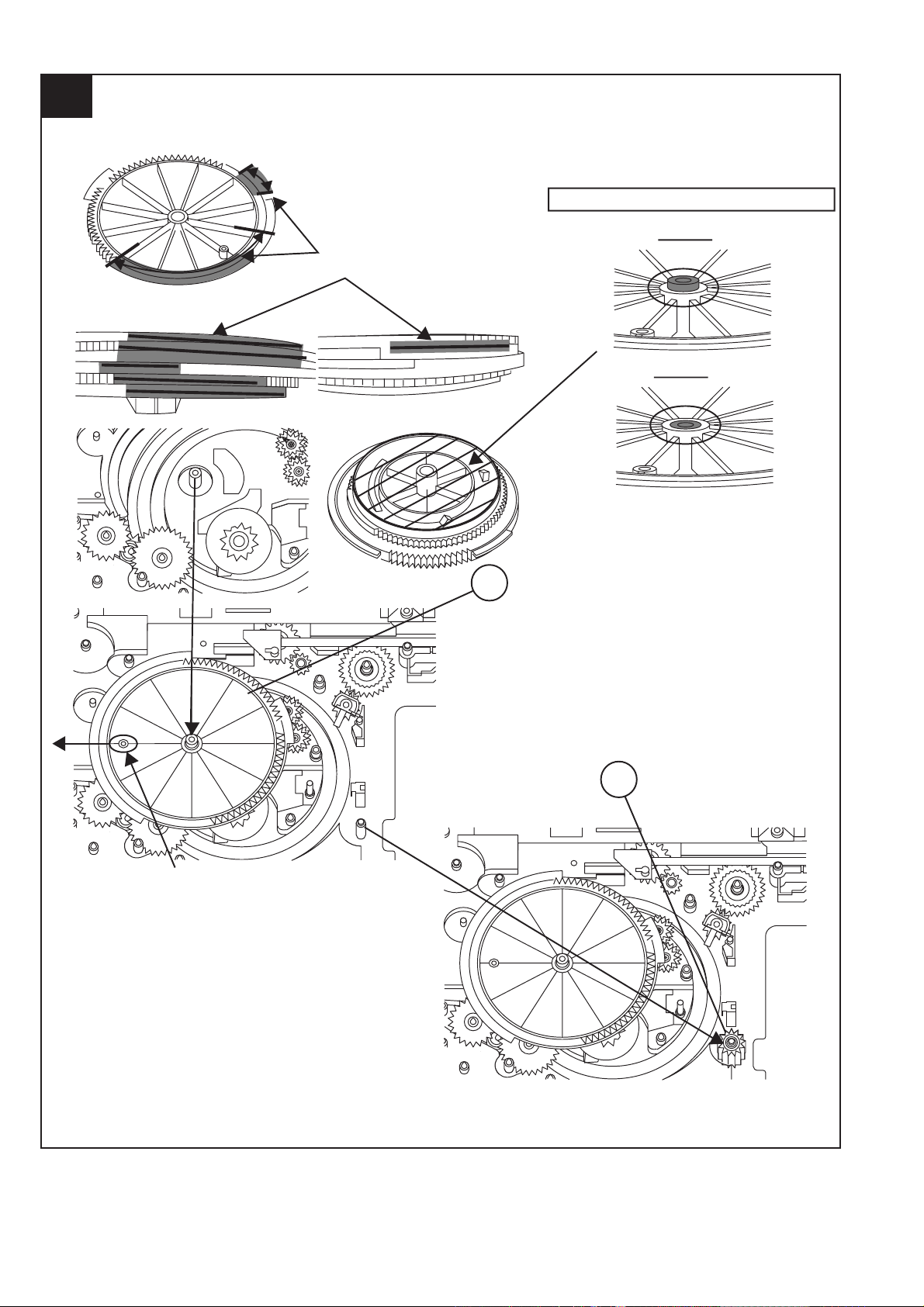

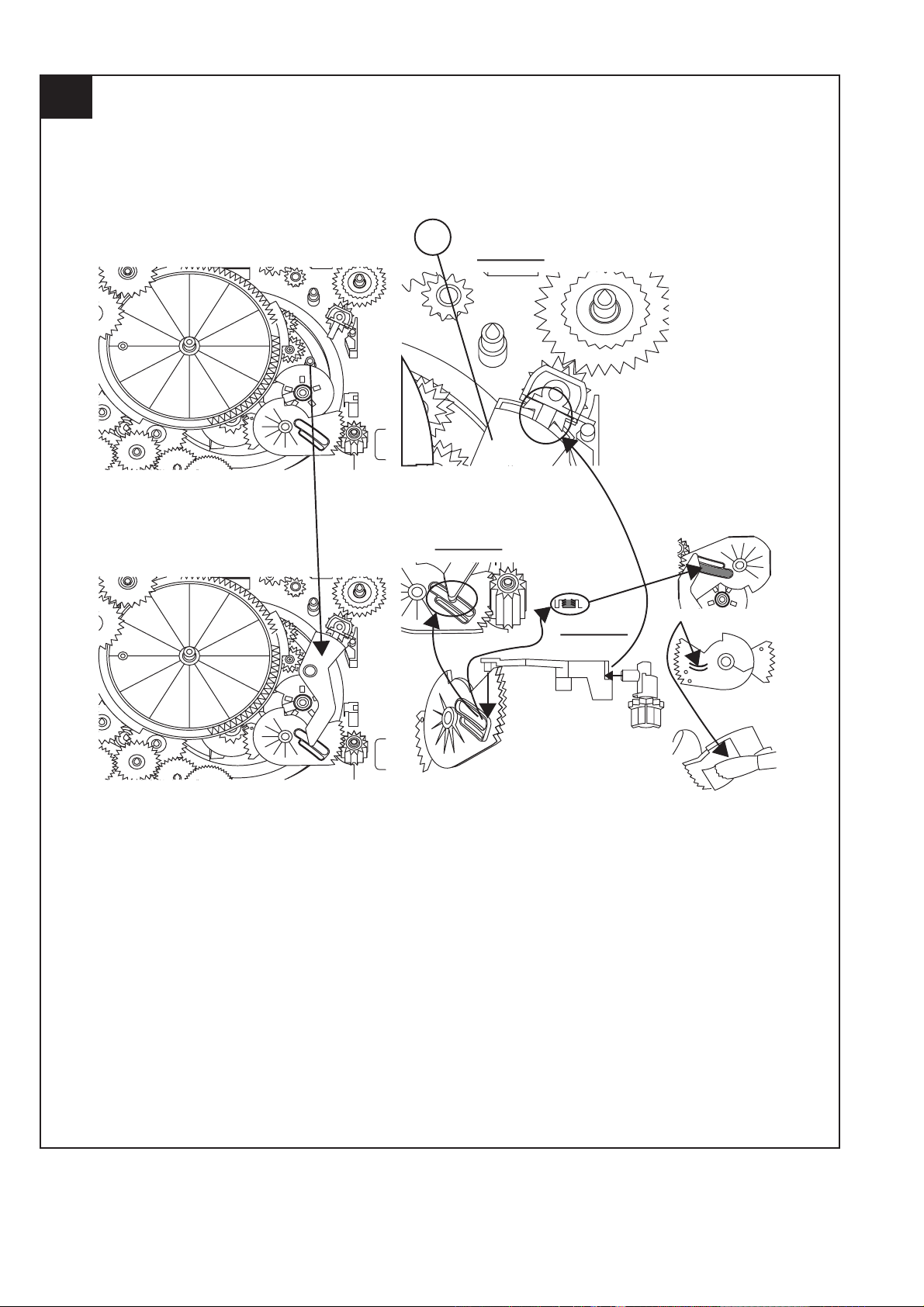

CD-G15000/CP-G15000S

2

APPLY SANKOL SHS1001 BEFORE FIX

139

FIX ITEM 139 ACCORDING TO THE

PICTURE AS SHOWN ABOVE

ROTATE MODE BIG GEAR UNTIL REACH AS SHOWN IN PICTURE

2 – 6

Page 13

APPLY GREASE SC141

PULL THE LEVER UNITIL

REACH THE ARROW MARK

143

112

3

CD-G15000/CP-G15000S

2 – 7

Page 14

CD-G15000/CP-G15000S

4

FIGURE 2

FIGURE 1

152

142

APPLY GREASE SC141

118

SLOT CLAMP

SWITCH ARM INSIDE BASE SLOT

HALF GEAR MUST BE

ARRANGED AS SHOWN

2 – 8

Page 15

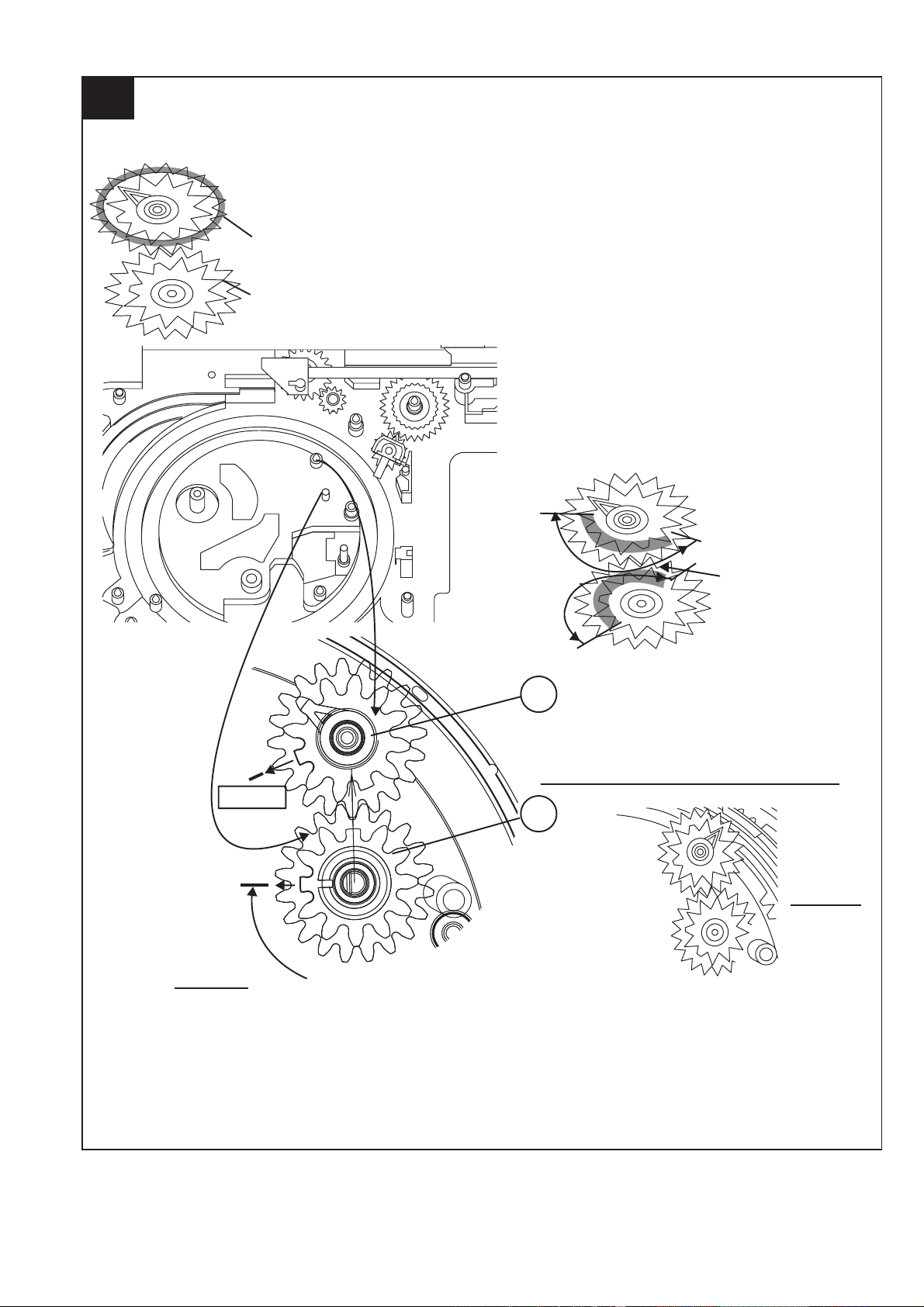

5

CD-G15000/CP-G15000S

APPLY GREASE SC141 AT BOTTOM SIDE

OF GEAR FOLLOW MARKING (REFER TO GRAY AREA)

NO NEED TO APPLY GREASE AT BOTTOM

SIDE

FIGURE 1

APPLY GREASE SC141

AT TOP SIDE OF GEAR

FOLLOW MARKING

(REFER TO GRAY AREA)

127

IF DIRECTION IS OTHER THAN DIRECTION

SHOWN IN FIGURE 1, IT IS INCORRECT

CORRECT

128

INCORRECT

BLACK MARK

2 – 9

Page 16

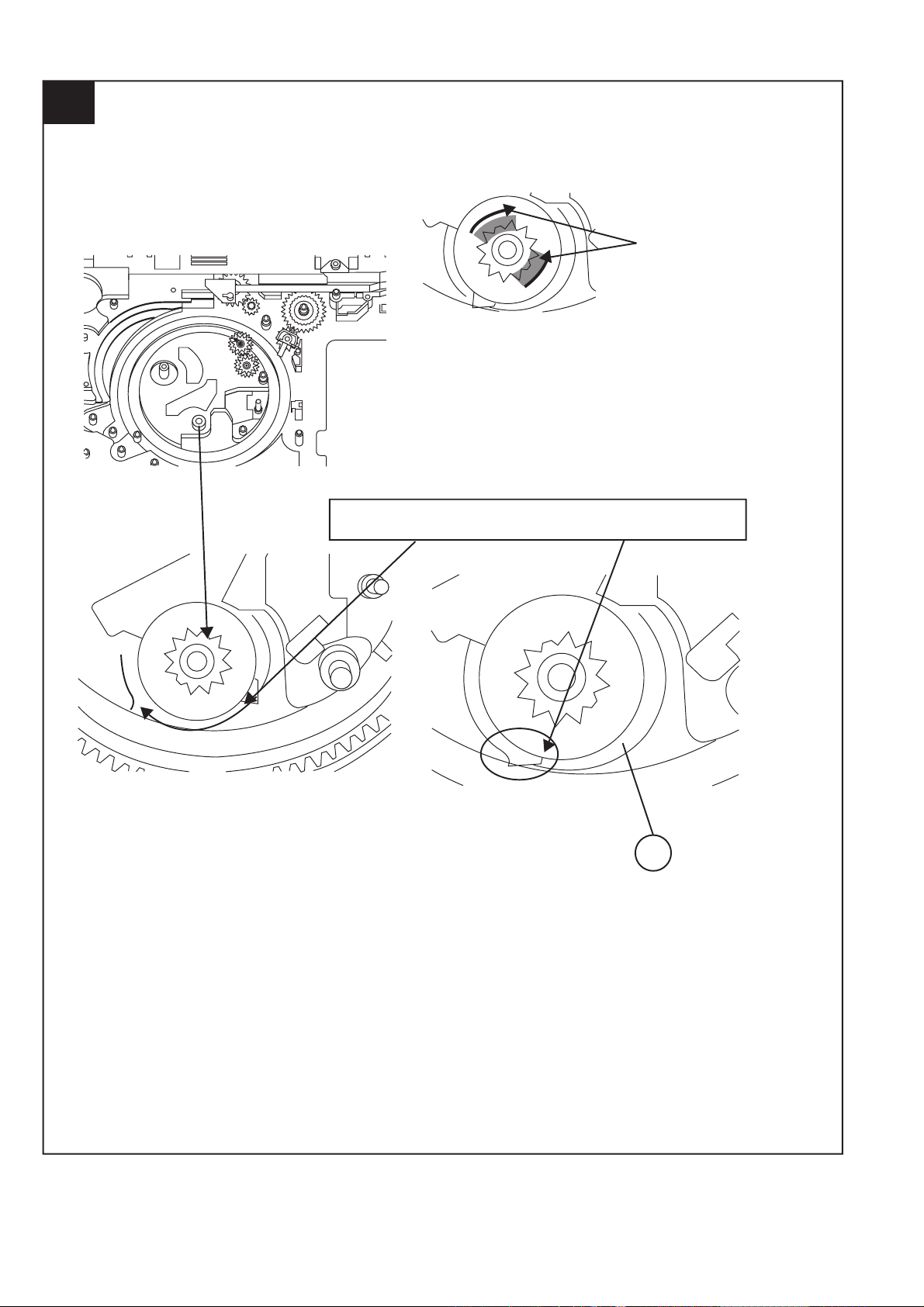

CD-G15000/CP-G15000S

6

APPLY GREASE SC141 AT

HALF GEAR AREA

ROTATE CLOCKWISE UNTIL REACH HERE (MAXIMUM)

129

2 – 10

Page 17

7

CD-G15000/CP-G15000S

151150149

2 – 11

Page 18

CD-G15000/CP-G15000S

8

THE SHOW N AREA MUST FREE FROM GREASE

CORRECT

GREASE SC141 APPLICATION LENGTH

GREASE APPLICATION PORTION

INCORRECT

SHOWN HOLE MUST FACING ARROW DIRECTION

124

131

2 – 12

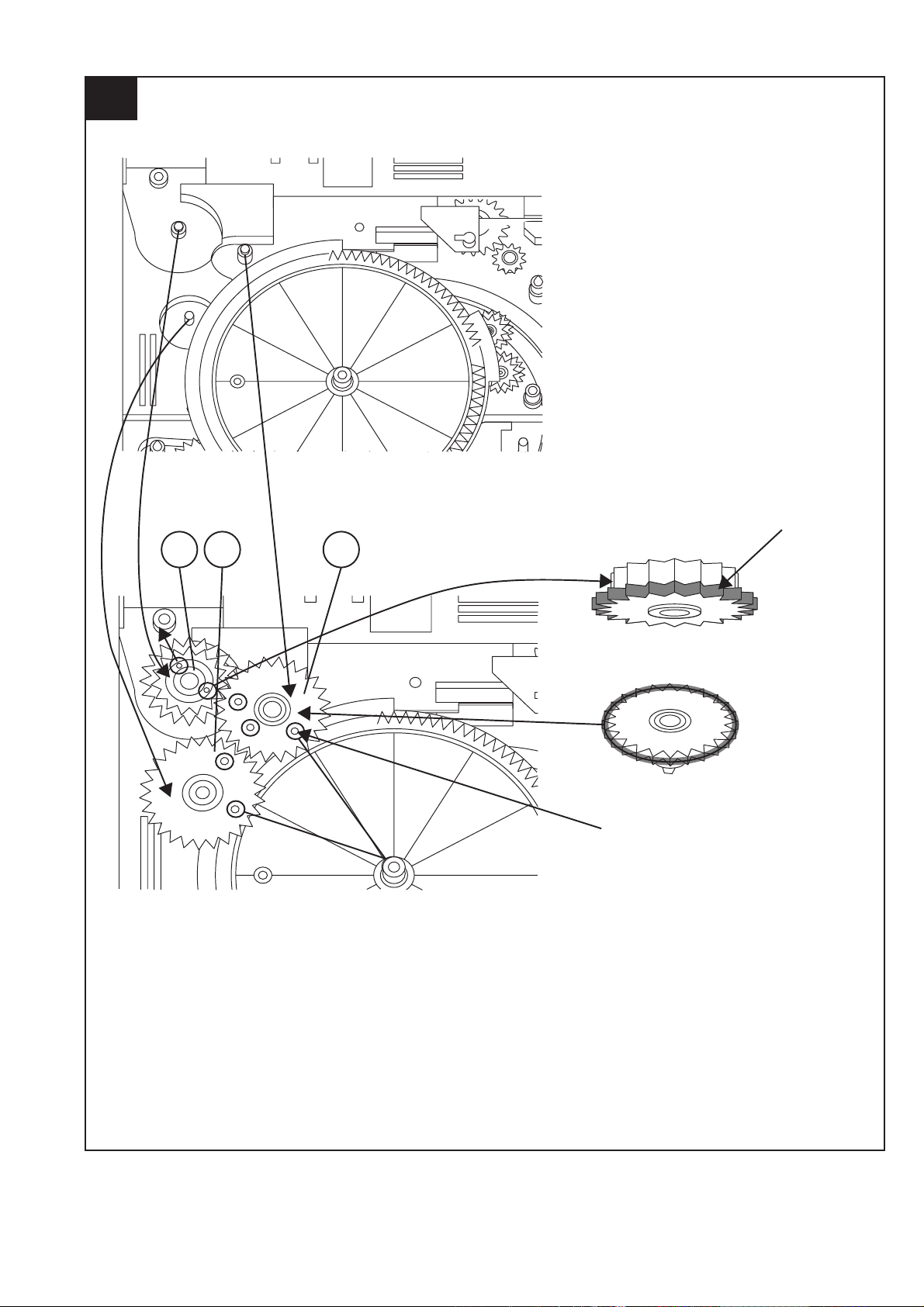

Page 19

9

138 126 125

CD-G15000/CP-G15000S

APPLY GREASE SC141

AT BOTTOM SIDE

ONLY

TR-RE JOINT GEAR C

APPLY GREASE SC141 ONLY AT TOP SIDE GEAR

MUST BE FIXED ACCORDINGLY TO

THE HOLE'S

2 – 13

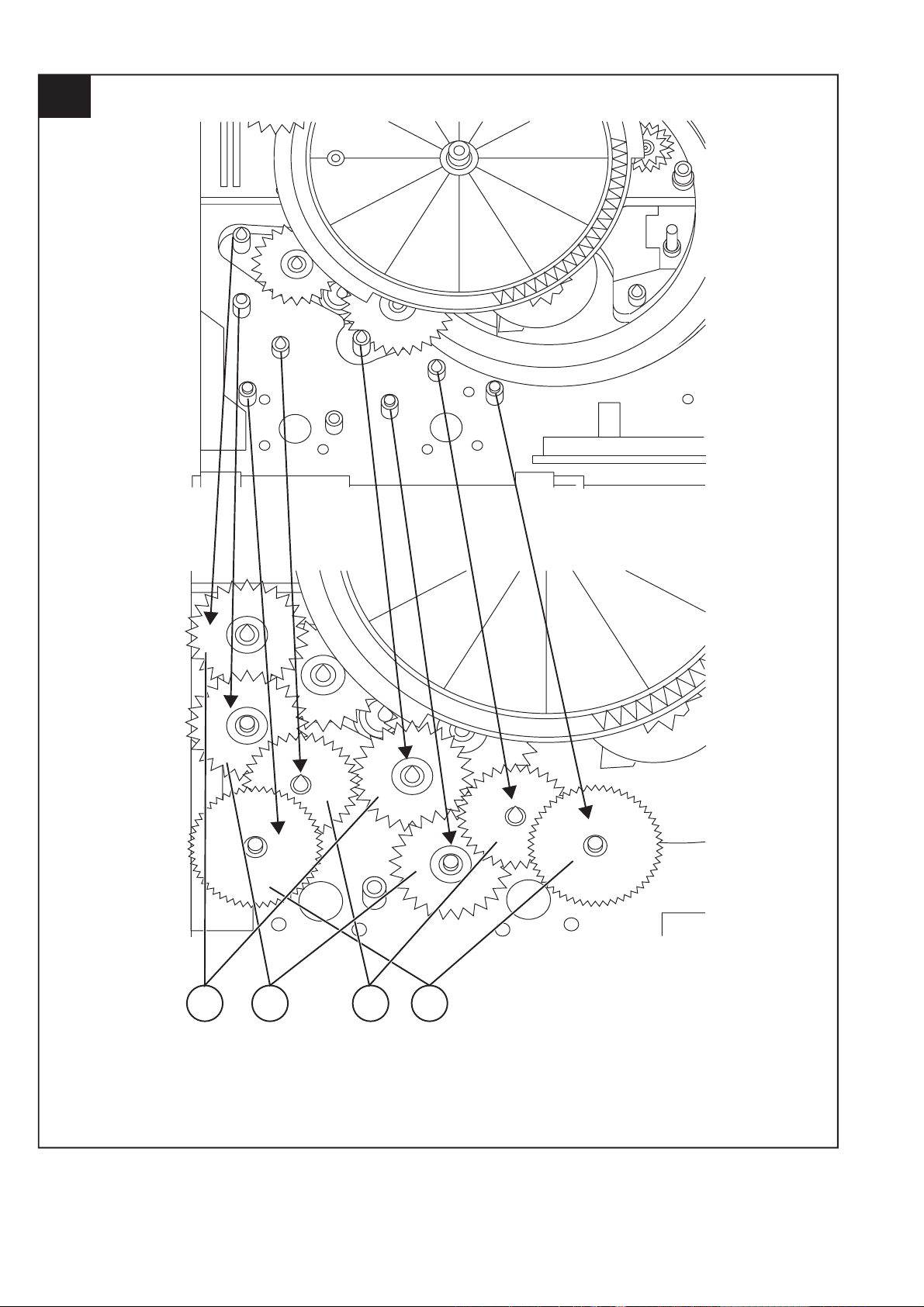

Page 20

CD-G15000/CP-G15000S

10

148 147 146 145

2 – 14

Page 21

11

CD-G15000/CP-G15000S

121

144

WHEN FIXING ITEM 144 MUST FOLLOW AS SHOWN

APPLY GREASE SC141

130

2 – 15

Page 22

CD-G15000/CP-G15000S

12

117

FIGURE 2

FIGURE 1

APPLY GREASE

SC141

FIGURE 3

APPLY GREASE SC141

2 – 16

Page 23

13

CD-G15000/CP-G15000S

ITEM 133 , 134 MUST APPLY GREASE SC141

ON TOP SIDE GEAR ONLY

134

GEAR 112 GEAR 112

133

132

CORRECT

TOP VIEW AFTER

BEING ASSEMBLED

INCORRECT

IT IS INCORRECT TO

FIX IT IN REVERSED

DIRECTION

2 – 17

Page 24

CD-G15000/CP-G15000S

14

APPLY GREASE SC141

BEFORE FIX

MOVE 112 UNTIL TOUCH THE WALL

A

B

DURING GEAR A ROTATE

MUST PRESS SHOWN AREA

AND LEVER B WILL MOVE

ARROW DIRECTION THEN

FIX PART 108

SCREW TORQUE

+0.5

2 kgf-cm

-0

108 803 x6

APPLY GREASE SC141

CONFIRM WHETHER

FIXED

PROPELY OR NOT

2 – 18

Page 25

15

CD-G15000/CP-G15000S

APPLY GREASE SC141

113

BEHIND THE LEVER NEED TO APPLY GREASE SC141

PULL IT THEN LEVER WILL

MOVE IN

2 – 19

Page 26

CD-G15000/CP-G15000S

16

123

115

APPLY GREASE SC141

APPLY GREASE SC141 BEFORE FIX

APPLY GREASE

SC141 AT BOSS

SPRING MUST BE ARRANGED UNDER THE HOOK

CORRECT LR JOINT LEV

BOARD R

BOARD R

LR JOINT LEV

INCORRECT

2 – 20

Page 27

17

CD-G15000/CP-G15000S

IT IS INCORRECT IF ASSEMBLED IN

REVERSED DIRECTION

103 137 136

APPLY GREASE SC141

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS.

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

2 – 21

Page 28

CD-G15000/CP-G15000S

18

IT IS INCORRECT IF ASSEMBLED IN

REVERSED DIRECTION

APPLY GREASE SC141

104

135

136

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

CONFIRM BOTH GEARS SIT PROPERLY AND LOCKED

2 – 22

Page 29

AFTER FIX OUTER UP/DOWN LEVER HOLD AS SHOWN PORTION AND

MOVE UP/DOWN THEN CONFIRM WHETHER LEVER GO INSIDE THE HOLE OR NOT

IT IS INCORRECT IF THE LEVER HOLD DOES NOT

ENTER THE HOLE

IT IS CORRECT IF THE LEVER HOLD

ENTERS THE HOLE

19

ALL OF THIS 135 AND 137 GEAR FIX TOGETHER WITH 119

AND 120 LEVER ( MOVE TOGETHER )

BIGGER SLOT FACING OUT

119

135

BIGGER SLOT FACING OUT

120

137

CD-G15000/CP-G15000S

2 – 23

Page 30

CD-G15000/CP-G15000S

20

BIGSLOTFACINGOUT

110

2 – 24

Page 31

21

CD-G15000/CP-G15000S

PUSH THE LEVER ACCORDING TO ARROW

DIRECTION THEN FIX

WHEN FIXING MAIN BASE ASSEMBLY FOLLOW ACCORDING TO PICTURE 1

PICTURE 1

CORRECT INCORRECT INCORRECT

MAKE SURE MECHA HOLDER SHAFT FIX PROPERLY TO LEVER

PICTURE 3

PICTURE 2

2 – 25

Page 32

CD-G15000/CP-G15000S

22

APPLY SANKOL (SHS1001)

101

102

APPLY SANKOL

(SHS1001) ON TOP

APPLY SANKOL (SHS1001) INSIDE

THE SLOT & OTHER SHOWN PORTION

APPLY SANKOL

(SHS1001)

APPLY SANKOL (SHS1001) AT

TRAY SLIDING PORTION

FIX TRAY NO 1 FIRST THAN

FOLLOW OTHER

APPLY SANKOL (SHS1001) AT BACK PORTION

COSMO GUIDE TRAY HAVE

MARKING AS SHOWN

2 – 26

Page 33

AFTER ASSEMBLY GEAR UP/DOWN BOARD

APPLY GREASE SC141 AT INNER & OUTER GEAR SLIDING PORTION

WHEN FIX GEAR UP/

DOWN BOARD THE

TWO LEVER MUST AT

PARALLEL LINE AND

POSITIONED AT TOP

MAX SIDE

111

23

GEAR UP/DOW N BOARD

CD-G15000/CP-G15000S

2 – 27

Page 34

CD-G15000/CP-G15000S

24

SCREW TORQUE

+0.5

3 kgf-cm

-0

ROTATE THE GEAR TO MOVE UP 111 GEAR

UP AND DOWN BOARD BEFORE SCREW

804

2 – 28

Page 35

25

CD-G15000/CP-G15000S

AFTER ASSEMBLY TOP PLATE

FIX THE FFC

FFC4

AFTER PUSH, MAKE SURE SNAP PROPERLY

AFTER FIX, PUSH FOLLOW ARROW DIRECTION

BEFORE LOCK

AFTER LOCK

BACK

PORTION

107

122

BEFORE LOCK

PRESS IN

SLOT IN

BEFORE LOCK

AFTER LOCK

AFTER LOCK

MUST CONFIRM

MUST CONFIRM

2 – 29

Page 36

CD-G15000/CP-G15000S

26

CORRECT

INCORRECT

CAUTION

1. MAKE SURE NO PWB CHIP INSIDE SET .( BEFORE FIX MAKE

SURE PW B IS FREE FROM DUST , GREASE & ETC )

803

2 – 30

Page 37

27

THE TW O SLOT MUST FREE

FROM GREASE SC141

APPLY GREASE SC141

BELOW THE MARKING

FOR BOTH PORTION

CD-G15000/CP-G15000S

ASSEMBLY SEQUENCE

1. APPLY GREASE SC141 TO MAIN BASE

GREASE SC141 APPLICATION AREA

ALL BOSS

APPLY GREASE SC141

APPLY GREASE

SC141

CAUTION

TRAY SLIDING

AREA MUST

FREE FROM

GREASE SC141

APPLY GREASE

SC141

APPLY GREASE

APPLY GREASE SC141 AT WALL

APPLY GREASE

SC141

SC141

105

APPLY GREASE SC141

AT BOTH SLOT

APPLY GREASE SC141 AT 3 HALF MOON

1 RIB ONLY

APPLY GREASE

SC141

APPLY GREASE SC141

INSIDE SLOT

2 – 31

Page 38

CD-G15000/CP-G15000S

28

REFERENCE ONLY

MOTOR GEAR HEIGHT FROM

MAIN BASE 12.2

+

0.1

-

0.1

-

+

12.2

MOTOR SCREWING HOLE

MUST HAVE GAP

M1,2

801

-0

13.8 + 0.2

APPLY GREASE SC141

SCREW TORQUE

1.5 + 0.5

-0

AFTER SCREW MOTOR, CONFIRM THE

ARRANGEMENT AS IN FIGURE 2

FIGURE 2

2 – 32

Page 39

29

APPLY SANKOL (SHS1001)

CD-G15000/CP-G15000S

3.1 + 0.1

SHAFT X 3 DIM AFTER INSERTION

MUST CONFIRM EVERYDAY

109-2

APPLY GREASE AT THE SLIDING PORTION

114

116

UP / DOWN

HOLDER CHANGE

TO NATURE

COLOR

SANKOL

APPLICATION AREA

(SHS1001)

APPLY GREASE SC141

2 – 33

Page 40

CD-G15000/CP-G15000S

30

BEFORE MELT IT

AFTER MELT IT ( MUST FLAT )

CHANGE COLOR

TO NATURE

WHEN FITTING STABILIZER PLATE TO STABILIZER,

ROTATE STABILIZER ANTI CLOCKW ISE BY JIG

( ! STRICLY CANNOT FIT USING HAND )

AFTER ASSEMBLED TO

HOLDER, STABILIZER

NEED TO BE CLEANED

WITH ALCOHOL DISC

TOUCHING SURFACE

BELOW

2 – 34

Page 41

31

CD-G15000/CP-G15000S

106

APPLY GREASE SC141

MUST MAKE SURE SNAP PROPERLY BOTH SIDE

ALL SURFACE MUST TOUCH

CORRECT INCORRECT

GAP

INCORRECT

2 – 35

Page 42

CD-G15000/CP-G15000S

32

NO GAP HAVE GAP

CORRECT INCORRECT

2 – 36

Page 43

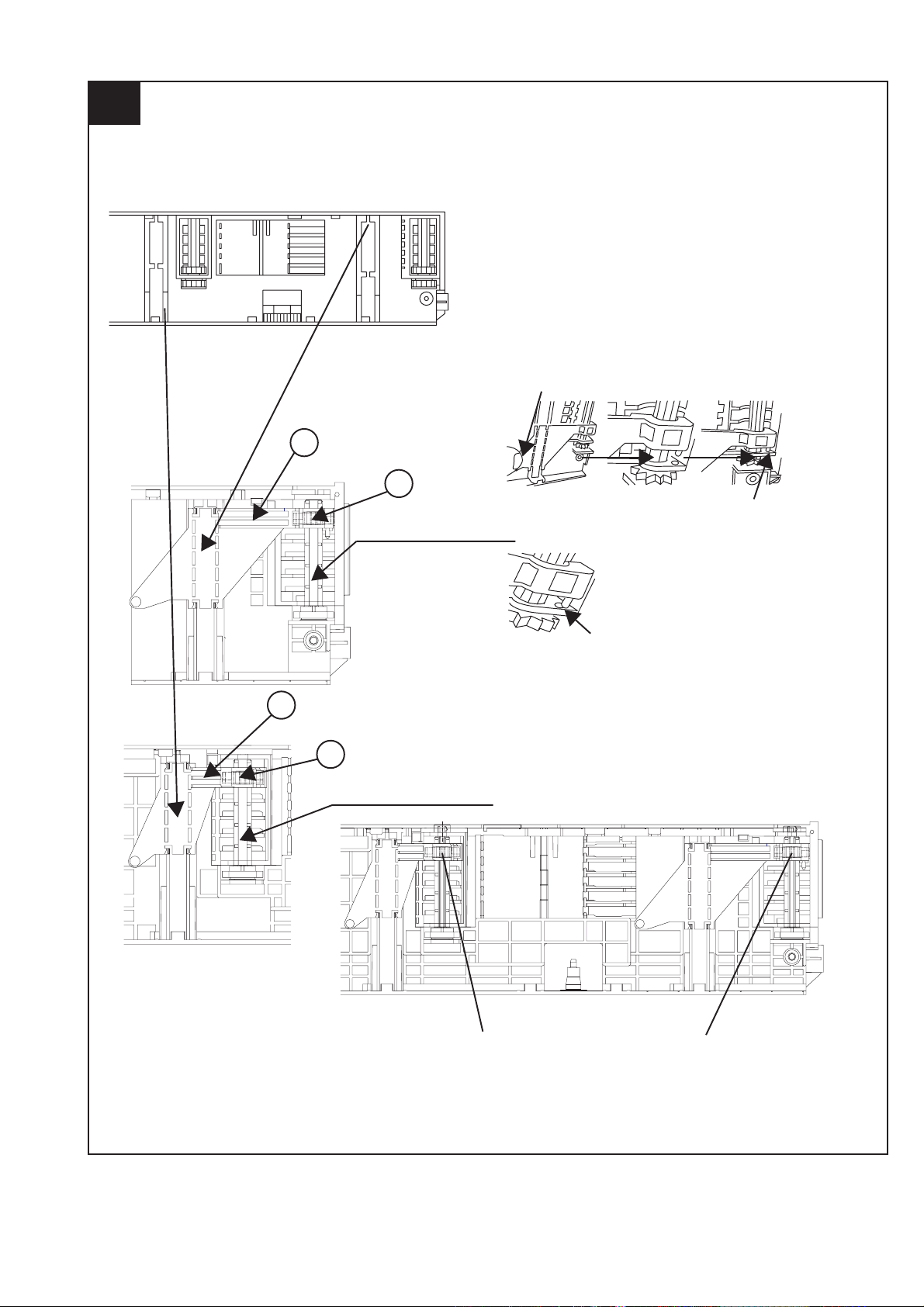

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the front end

of the connector so as to protect the optical pickup from electrostatic damage.

Figure 2

Figure 1

Figure 3

(C1)x1

PULL

PULL

Lug wire

(E1)x1

3x10mm

Fan Motor

Rear Panel

(C1)x1

Hook

Hook

3x10mm

(D1)x9

3x10mm

(E2)x1

(E3)x1

Power PWB

Main PWB

Front Panel

(F1)x1

O

O

O

(C2) x1

(C3) x1

CD Changer

Unit

CD Servo PWB

(A1)x1

3x12mm

Rear Panel

3x12mm

(Left)

(B1)x2

3x10mm

(B1)x2

3x10mm

(B1)x2

3x10mm

(B1)x2

3x10mm

Side Panel

(Right)

(A1)x2

3x12mm

Side Panel

(A1)x2

Front Panel

Top Cabinet

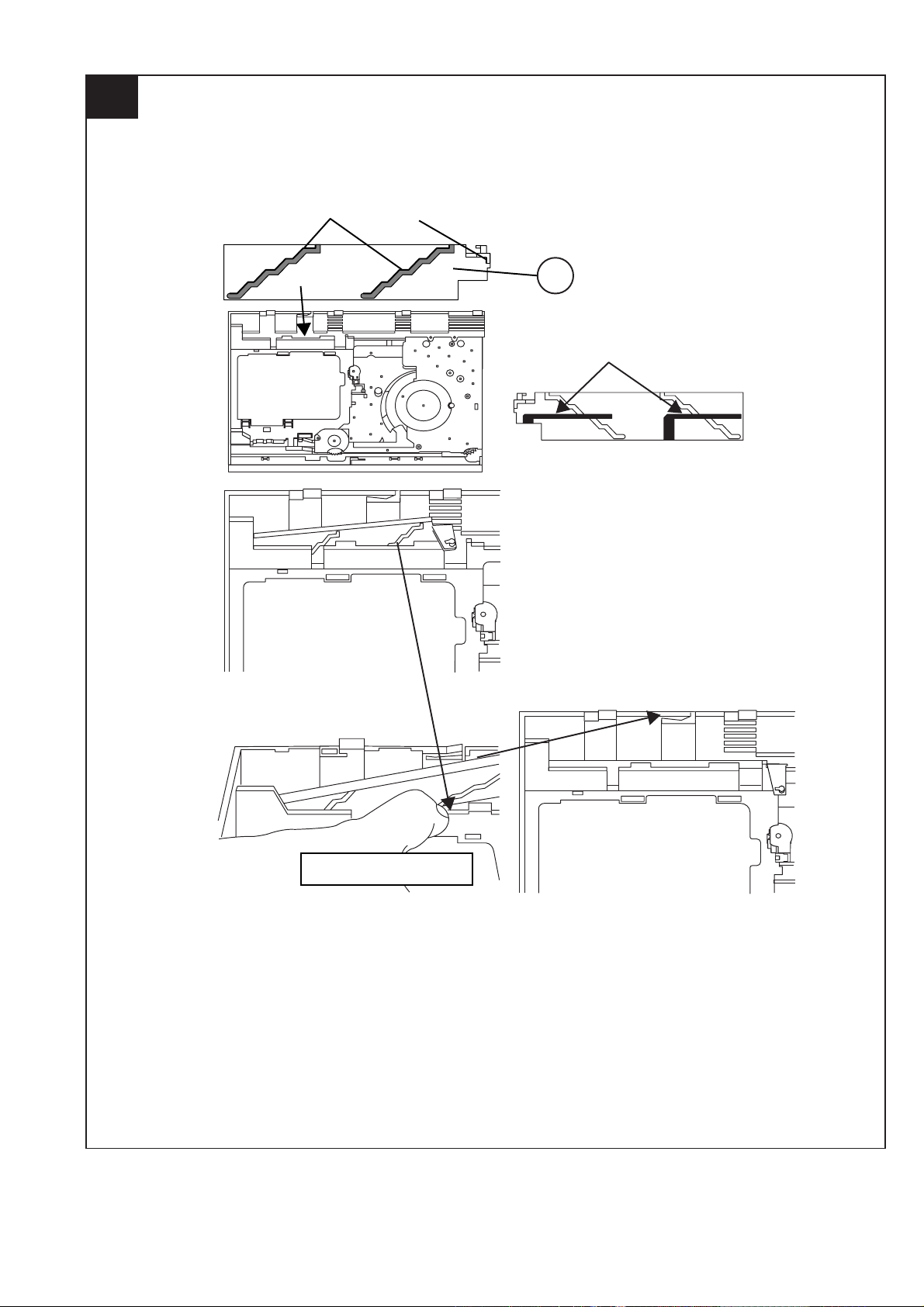

STEP REMOVAL PROCEDURE FIGURE

1

Top Cabinet

1. Screw…………..……….(A1) X 5 1

2

Side Panel (Left/

2. Screw……….…………..(B1) X 8

1

Right)

3 CD Changer unit 1. Hook ……………………(C1) X 2 2

2. Socket………………..…(C2) X 1

3. Flat Cable ……… …….(C3) X 1

4 Rear Panel with

1. Screw………..………….(D1) X 9 2

Fan motor

5 Front Panel

1. Screw………………..….(E1) X 3 2,3

2. Flat Cable ………..…….(E2) X 1 2

3. Socket……..……………(E3) X 1 2

4. Hook …………….…...…(E4) X 2 3

6 Main PWB 1. Screw………………..….(F1) X 5

2,3

2. Socket……..……………(F2) X 4 3

3. Flat Cable ……………...(F3) X 1

3

7 Power PWB 1. Screw………………..….(G1) X 4 3

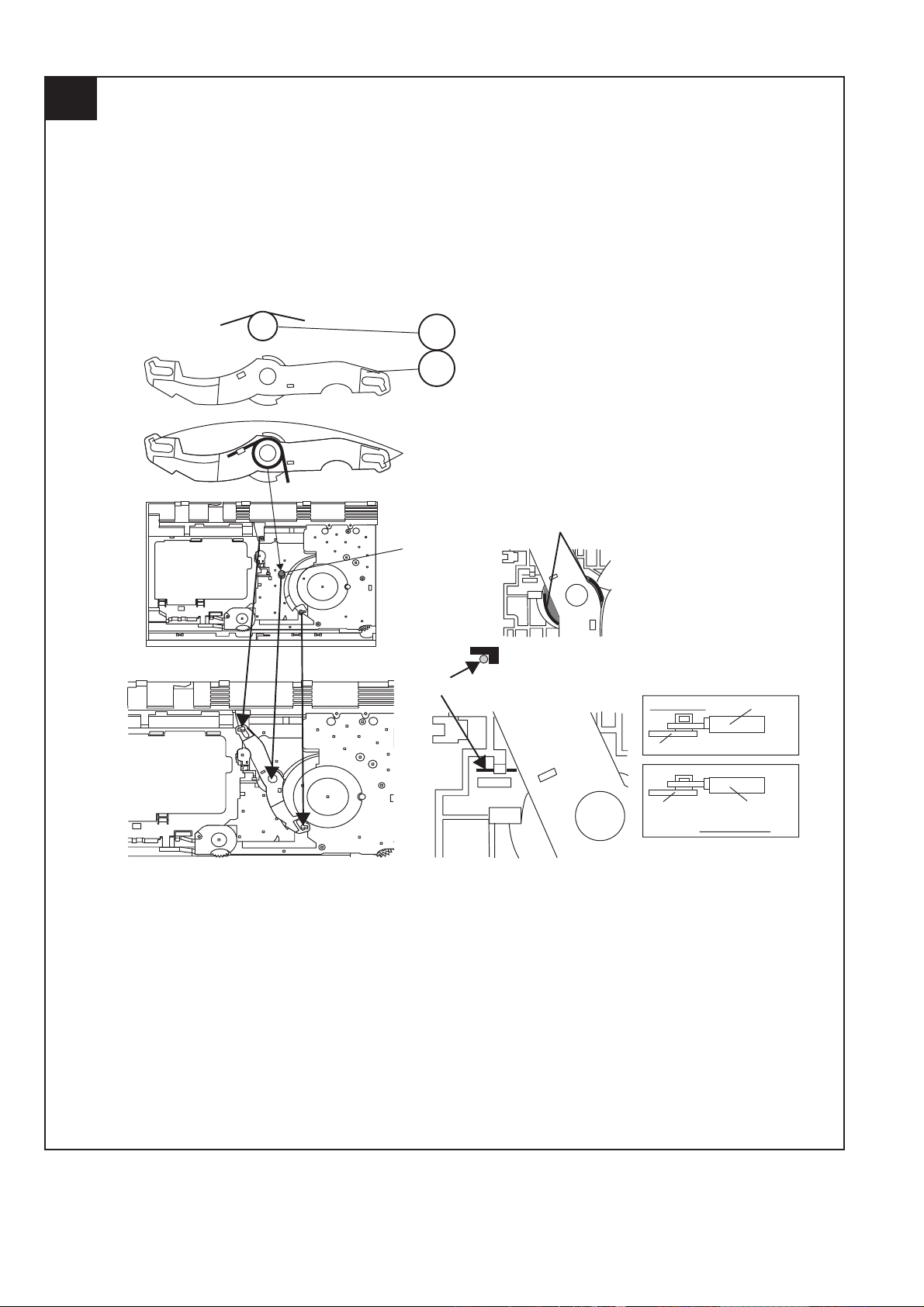

8 Tape Mechanism 1. Screw…….…………..….(H1) X 6 4

2. Flat Cable ………..…….(H2) X 1

9 Game Input PWB 1. Screw………………..….(J1) X 2 5

10 Display PW B 1. Knob……..…………..….(K1) X 1

2. Nut……………..……..….(K2) X 1 5

3. W asher……..….………..(K3) X 1

4. Screw……..……………..(K4) X 6

11 Speaker PWB 1. Screw………………..….(L1) X 3 6

12 CD Servo PWB

1. Screw…….………….….(M1) X 3

7

2. Flat Cable ………..…….(M2) X 2

3. Socket……..……………(M3) X 1

13

Changer 1. Screw…….………….….(N1) X 4 8

Mechanism Unit

2. Changer Chassis………(N2) X 1

14 CD Mechanism 1. Screw…….………….….(P1) X 4 9

PULL

PULL

Hoo k

(E4)x1

4x8mm

(G1)x4

Power PWB

(F2)x1

(F2)x2

(F3)x1

Front Panel

(F2)x1

3x8mm

(E1)x2

3x6mm

(F1)x4

(E4)x1

CD-G15000/CP-G15000S

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

CHAPTER 3. MECHANISM BLOCKS

CHAPTER 3.

[1] Caution on disassembly

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to b e remove d when disassemb ling the unit. After servicing

the unit, be sure to rearrange the leads where they were before disassembling.

3 – 1

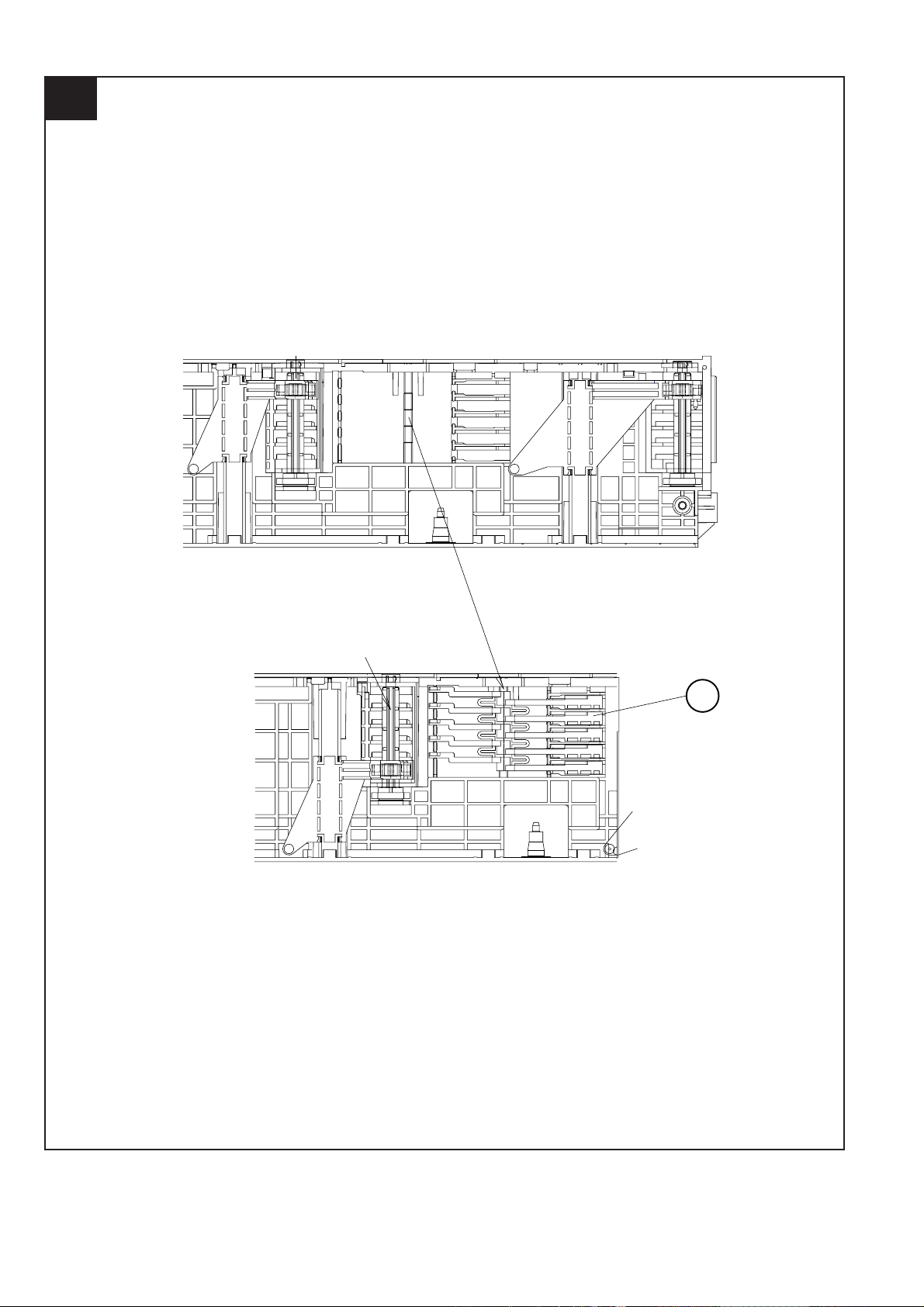

Page 44

CD-G15000/CP-G15000S

O

(H1)x6

3x10mm

Figure 4

Tape

Mechanism

(K4)x6

2.6x10mm

(H2)x1

Lug wire

Front Panel

Front Panel

Display PWB

(K2)x1

(K1)x1

(K3)x1

(M2)x1

Figure 7

(M1)x3

3x10mm

(N1)x4

3x10mm

(M3)x1

CD Servo

PWB

(M2)x1

Changer

Mechanism

Unit

Figure 5

(J1)x2

Special

(L1)x3

Ø3x10mm

Figure 6

Game Input

PWB

Speaker PWB

Figure 8

(P1)x4

2.6x10mm

CD Mechanism

(N2)x1

Changer

Mechanism

Unit

Changer

Mechanism

Unit

3 – 2

Figure 9

Page 45

STEP

1 Woofer 1. Front Panel Ass'y…..(A1) X 1 10

Tweeter 1. Screw……...….....….(B1) X 2 12

2. Screw.…….……...…(A2) X 8 11

1 Woofer 1. Front Panel Ass'y…..(A1) X 1 13

2. Screw.…….……...…(A2) X 8 14

2

REMOVAL PROCEDURE FIGURE STEP REMOVAL PROCEDURE FIGURE

CP-G15000 GBOXSA133AWM1

(A1)x1

Speaker Box Assembly

Driver should

be pried away

from Speaker Box.

Figure 13

Screwdriver

Ø3.5x16mm

Ø3.5x16mm

(A2)x4

(A2)x4

Speaker Box Assembly

WOOFER

WOOFER

Figure 14

Figure 12

(A1)x1

Speaker Box Assembly

from Speaker Box.

be pried away

Driver should

Figure 10

Screwdriver

Ø4x16mm

Ø4x16mm

WOOFER

WOOFER

(A2)x4

(A2)x4

Speaker Box Assembly

Figure 11

Ø3x10mm

TWEETER

(B1)x2

Front Panel Assembly

CD-G15000/CP-G15000S

3 – 3

Page 46

CD-G15000/CP-G15000S

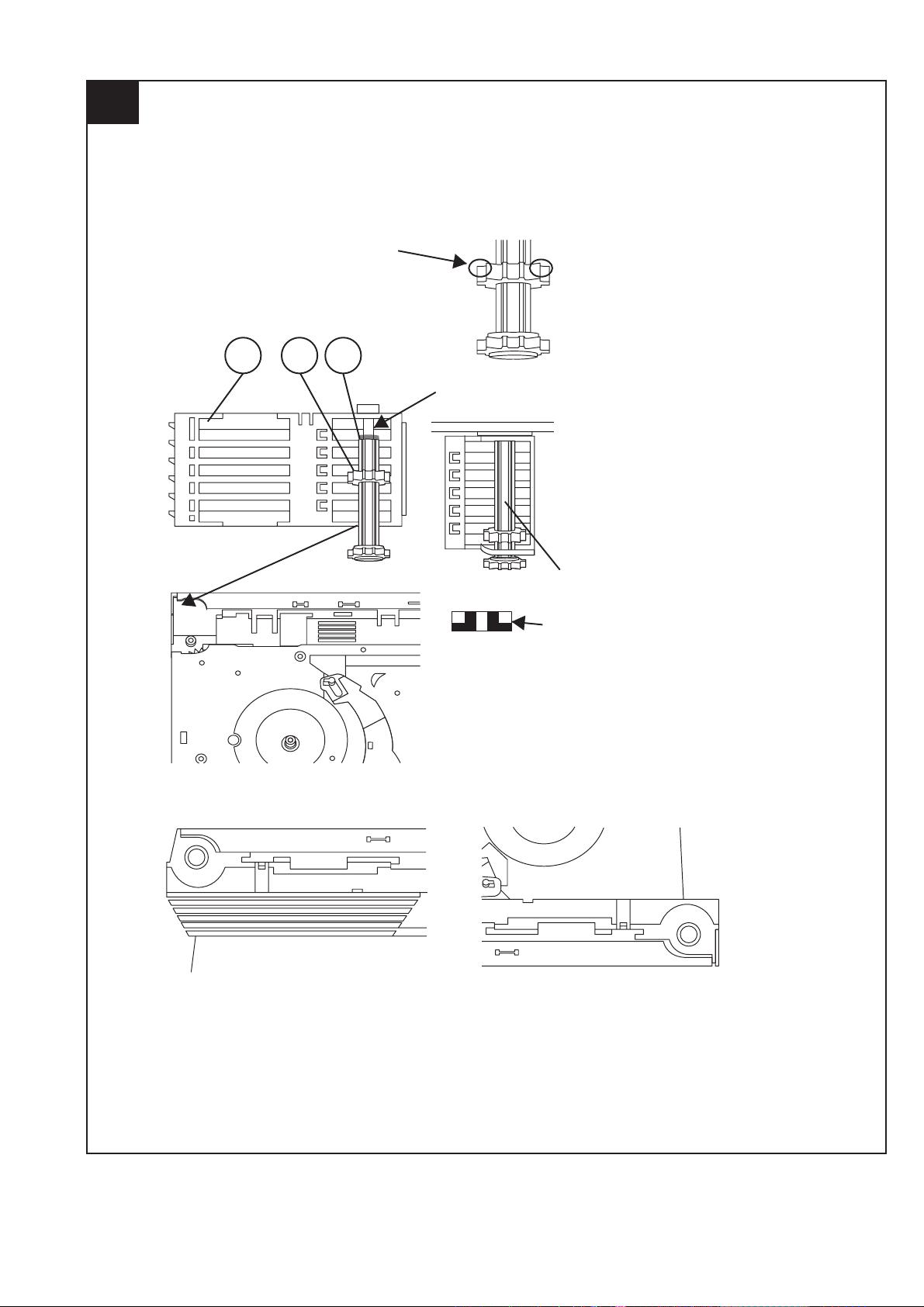

CP-SW15000

STEP PROCEDURE FIGURE

REMOVAL

Subwoofer Panel

1 1. Screw Cover……. ……..(A1) X 4 15

2. Catching Holder……..…(A2) X 4

3. Screw …………………..(A3) X 4

4. Socket ………………….(A4) X 1

2 1. Screw Cover……. ……..(B1) X 4 15

AMP Front Panel

2. Catching Holder……..…(B2) X 4

3. Screw …………………..(B3) X 4

4. Socket ………………….(B4) X 3

Rear Plate

3 1. Screw …………………..(C1) X 8 15

Subwoofer Speaker

4 1. Screw …………………..(D1) X 2 16

LED PWB

Power Switch PWB

5 1. Screw …………………..(E1) X 2 17

Volume PWB

6 1. Screw …………………..(F1) X 4 17

LED Flashing PW B

7 1. Screw …………………..(G1) X 2 17

Subwoofer

8 1. Screw …………………..(H1) X 8 18

AMP Chassis Assembly

9 1. Screw …………………...(J1) X 8 18

10 1. Screw …………………..(K1) X 2 19

Fan Assembly

11 1. Screw …………………...(L1) X 1 19

Jack PWB

12 Subwoofer AMP PWB 1. Screw …………………..(M1) X 9 20

13 1. Screw …………………..(N1) X 2 20

Primary Power PW B

(A1)x4

2. Screw …………………..(C2) X 1

2. Socket ………………….(G2) X 1

2. Screw …………………...(J2) X 2

3. Screw …………………...(J3) X 6

2. Socket …………….…….(K2) X 1

2. Socket …………….…….(L2) X 1

2. Socket …………….…….(M2) X 4

2. Socket ………………….(N2) X 3

(A2)x4

(A3)x4

M4x40mm

Subwoofer Panel

Figure 17

Subwoofer Panel

Figure 16

AMP Front Panel

Power switch PWB

(F1)x4

M3x10mm

Volume PWB

(G2)x1

LED Flashing PWB

(G1)x2

M3x10mm

Subwoofer speaker

LED PWB

(D1)x2

M2.6x8mm

(E1)x2

Washer Screw

(B1)x4

(B2)x4

(B3)x4

M4x40mm

AMP Front Panel

(B4)x3

Rear Plate

Figure 15

(A4)x1

Speaker Box Assembly

(C1)x8

M4x16mm

(C2)x1

M3x10mm

(H1)x8

M4x16mm

M4x16mm

(J1)x8

Subwoofer

(J2)x2

Washer Screw

Figure 18

Speaker Box Assembly

AMP Chassis

Assembly

(J3)x6

M4x16mm

3 – 4

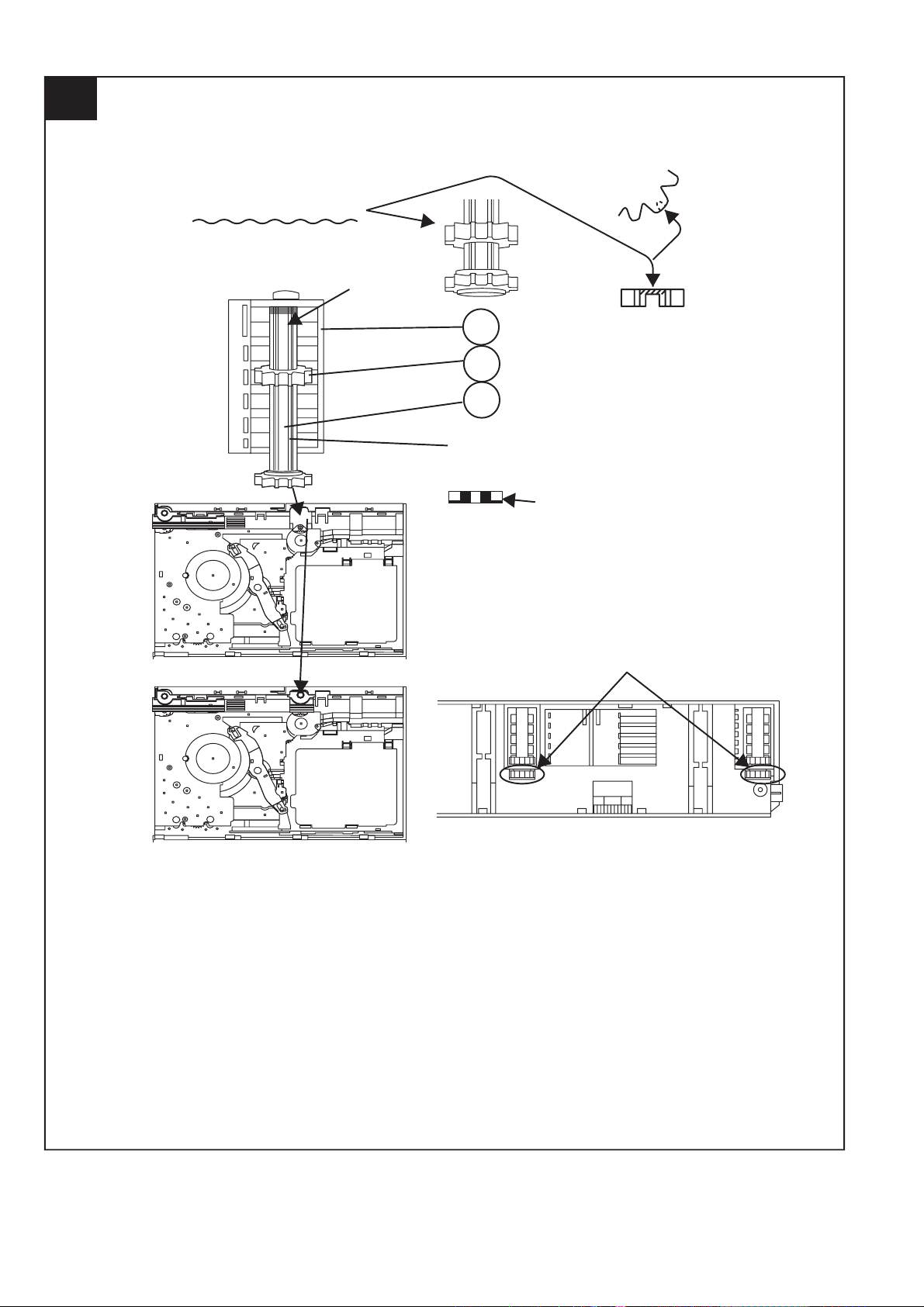

Page 47

CD-G15000/CP-G15000S

(M2)x3

(M2)x1

AMP PWB

Subwoofer

(K1)x2

(K2)x1

Fan

Assembly

AMP Chassis

Assembly

Washer Screw

(L2)x1

M3x8mm

(L1)x1

Jack PWB

Figure 19

Figure 20

(M1)x9

M3x8mm

M3x8mm

Primary

Power PWB

(N2)x3

(N1)x2

3 – 5

Page 48

CD-G15000/CP-G15000S

[2] Removing and reinstalling the main parts

1. TAPE MECHANISM SECTION

Perform steps 1 to 5 and 6 of the disassembly method

to remove the tape mechanism.

1.1. How to remove the record/playback and erase

heads (TAPE 2) (See Fig. 1)

1. When you remove the screws (A1) x 2 pcs., the

recording/playback head and three-dimensional

head of the erasing head can be removed.

Erase Head

(A1)x2

φ2x9mm

TAPE 2

Clutch Ass'y

Record/Playback

Head

Figure 1

1.2. How to remove the playback head (TAPE

1)(See Fig. 2)

1. When you remove the screws (B1) x 2 pcs., the

playback head can be removed.

TAPE 1

Clutch Ass'y

Playback

Head

Pinch

Pinch Roller

(C1)x1

Pull

<B>

<A>

Roller

Pawl

Figure 3

1.4. How to remove the belt (TAPE 2) (See Fig. 4)

1. Remove the main belt (D1) x 1 pc., from the motor

side.

2. Remove the FF/REW belt (D2) x 1 pc.

1.5. How to remove the belt (TAPE 1) (See Fig. 4)

1. Remove the main belt (E1) x 1 pc., from the motor

side.

2. Remove the FF/REW belt (E2) x 1 pc.

Tape

Motor

TAPE 2

Main Belt

(D1)x1

TAPE 1

Main Belt

(E1)x1

TAPE 1

FF/REW

Belt

(E2)x1

TAPE 2

FF/REW

Belt

(D2)x1

Main Belt

(D1)x1

Main Belt

(E1)x1

Tape

Motor

Figure 4

1.6. How to remove the motor (See Fig. 5)

1. Remove the screws (F1) x 2 pcs., to remove the

motor.

Tape

Motor

(B1)x2

φ2x9mm

Figure 2

1.3. How to remove the pinch roller (TAPE 1/2) (See

Fig. 3)

1. Carefully bend the pinch roller pawl in the direction

of the arrow <A>, and remove the pinch roller (C1) x

1 pc., in the direction of the arrow <B>.

Note:

When installing the pinch roller, pay attention to the

spring mounting position.

Clutch Ass'y

(F1)x2

φ2.6x5mm

Figure 5

2. CD MECHANISM SECTION

Perform steps 1, 2, 9, 10, 11 and 12 of the disassembly method to remove the CD mechanism.

3 – 6

Page 49

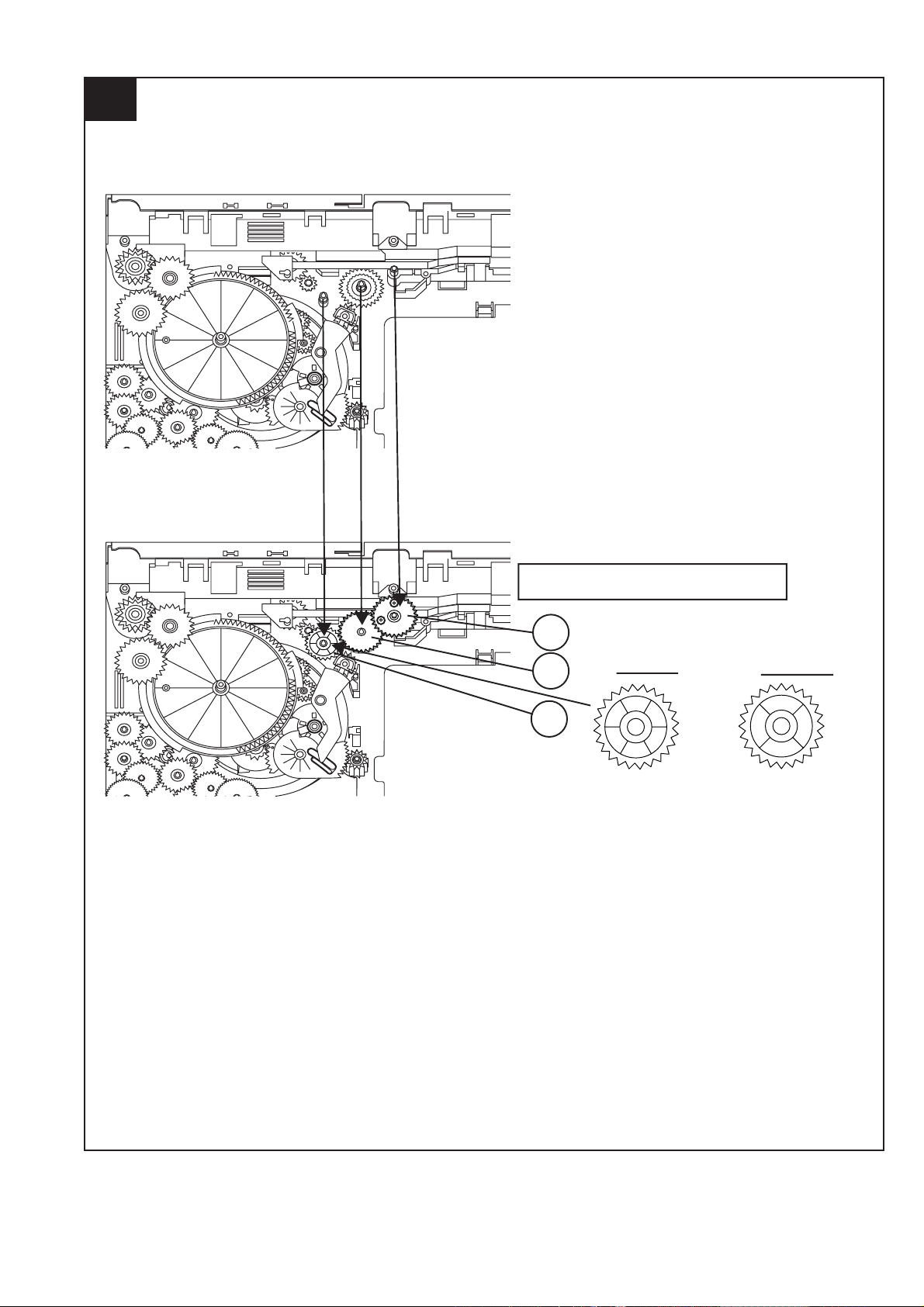

2.1. Remove the pickup. (See Fig. 1)

Mark 1

(DISC 1)

(DISC 2)

(DISC 3)

(DISC 4)

(DISC 5)

Gear up down board

Mark 3 Mark 5

Mark 2 Mark 4

1. Remove the stop washer (A1) x 1 pc., to remove the

gear (A2) x 1 pc.

2. Remove the screws (A3) x 2 pcs., to remove the

shaft (A4) x 1 pc.

3. Remove the pickup.

Note:

After removing the connector for the optical pickup

from the connector wrap the conductive aluminium foil

around the front end of connector so as to protect the

optical pickup from electrostatic damage.

(A3)x2

φ2.6x6mm

CD Mechanism

Shaft

(A4)x1

Gear

(A2)x1

Stop Washer

(A1)x1

CD-G15000/CP-G15000S

Reduction gear C

Front Rear

Figure 3

2. In another case, if CD mechanism is at tray No.1

play position and to remove CD located in tr ay No.3,

the procedure is as follows:

If the gear up down board is located at tray No.1

position, then rotate gear clock-wise until it at stock

position. Rotate reduction gear D clockwise (Figure

4) to move the CD mechanism to tray No.3 position.This is confirmed by checking the gear up down

board position by the marking as indicated on the

main chassis as shown in Figure 5.

Reduction gear D

Pickup Unit

Figure 1

3. CHANGER MECHANISM SECTION

Perform steps 1, 2, 9 and 10 of the disassembly

method to remove the CD changer mechanism.

3.1. How to remove CD Disc (See Fig. 2~5)

1. When CD is at play position (Figure 2), rotate r eduction gear C clock-wise as shown in Figure 3 Until

disc tray is at stock position, then rotate further to

eject the disc tray so that CD can be removed from

the tray.

CD Disc

Disc Tray

Guide Tray

CD At play position.

CD Disc

Up Down

Figure 4

Figure 5

CD At stalk position.

Figure 2

3 – 7

Page 50

CD-G15000/CP-G15000S

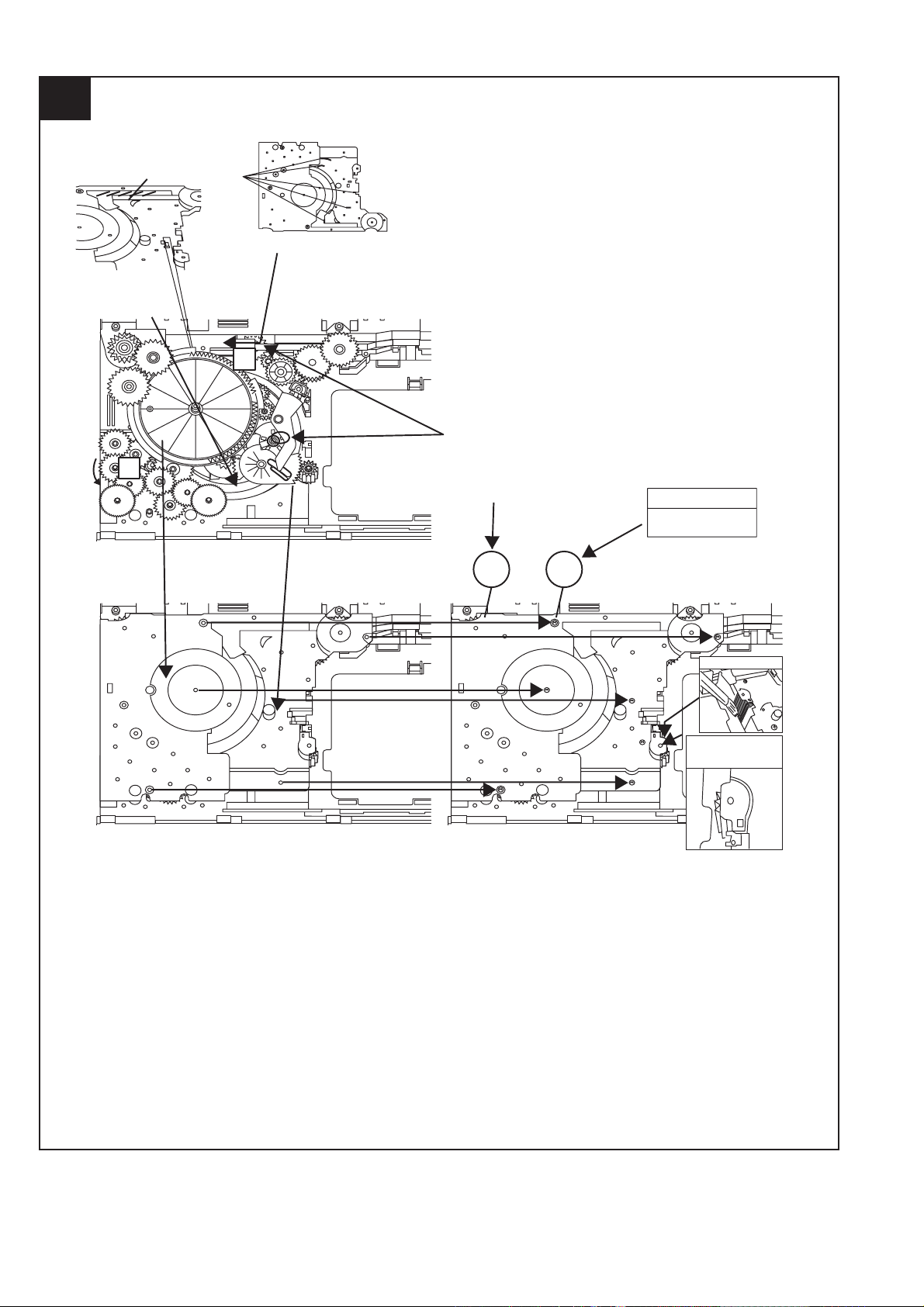

3.2. How to Remove the tray motor/main cam

motor/5-Changer Motor PWB (See Fig. 1)

1. Remove the screws (A1)x 2 pcs., to remove tray

motor/main cam motor/5-Changer Motor PWB.

Changer Mechanism Unit

Main Cam Motor

(A1)X2

φ2x10mm

Figure 1

Tray Motor

5-Changer

Motor PWB

NOTE:There are 2 more screws tighten the motors at

the bottom of main chassis. Before performing

procedure 1 above, disc stop spring, top plate

sear up down board and trays must be

removed, then only the 2 screws can be

untighten.

3 – 8

Page 51

CHAPTER 4. DIAGRAMS

CHAPTER 4. DIAGRAMS

[1] CD Block diagrams

CD-G15000/CP-G15000S

XL1

16.9344 MHz

+3.3V

CONSTANT

VOLTAGE

TO MAIN SECTION

R-CH

AGND

L-CH

CE

43

CL

44

DI

45

DO

46

RESB

47

INTB0

48

INTB1

49

XOUT

72

XIN

73

DVDD

AVDD

36 41

+3.3V

D_+5V(+B5)

DGND

7875

LCHO

+8V(+B7)

MGND

7123 456

CNP3

RCHO

LC78690E

CD SERVO

XVDD

74

LRVDD

76 876521

IC1

Q1

TO DISPLAY SECTION

+B6

GND

PHOTO

MO_A-

BIN

CIN

AIN

LASER

DRIVER

MO_A+

DIN

EIN

CD_RESB

CD_DI

CD_CLK

5251

CONT1

CONT0

FIN

1413

CD_DO

10

SLDO

SPDO

LDS

181968

CD_CE

PUIN

FDO

TDO

LDD

MP3_INT11CD_INT12TRAY SW1/SW2

DISC/CLAMP

13

14319876524

77

71

67

57

56

55

54

53

42

40

37

26

20

32

24

25

22

23

CNP7

+5V

SW3 TRAY SW2

SW2 TRAY SW1

SW1 CLAMP

SW4 DISC

RX1

GND

17151311

22

23

VIN4

VIN3

VIN2

28

VIN1

PVCC2

REV6

IC2

FWD6

LA6261

FOCUS/TRACKING/

9

27

SPIN/SLIDE

DRIVER

M1

M1

MAIN CAM

TRAY MOTOR

M

M

+

+

--

10 11319876524

32 3331 34

VO6-

VO6+

VO5+

FWD5

REV5

MOTOR

CNP4

VO5-

19

20

30

7

26

PICKUP UNIT

+3.3V

COIL

TRACKING

FOCUS COIL

Figure 4-1: BLOCK DIAGRAM (1/5)

4 – 1

NM1

SPINDLE

MOTOR

NM2

SLED

MOTOR

M

M

4

3363521

56

NSW 1

PICKUP

IN

Page 52

CD-G15000/CP-G15000S

IC101

AN7345K

PLAYBACK AND RECORD/

PLAYBACK AMP.

AUX

VIDEO

R

L

R

L

JK690

GAME INPUT

JK691

VIDEO OUT

-20dB

ATT

Q101~

Q104

Q107

Q108

Q601

Q602

Q603

Q604

REC/PLAY

CLK

CE

DI

+B4

L

R

BIAS

T1/T2

MUTING

P.B.

REC.

AC BIAS

L

L

R

R

R

L

TAPE

TUNER

CD

PB

CNP2

FROM CD SECTION

HEAD

ERASE

SWITCHING

SWITCHING

SWITCHING

BIAS

Q113

Q114

Q112

Q110

LED

DRIVER

Q710

Q706

Q711

Q712

Q707

Q708

Q714~

Q717

SWITCHING

Q109

BIAS

OSC

Q111

L103

Q105

Q106

REC./P.B.

HEAD

TAPE 2

P.B. HEAD

TAPE 1

R-CH

L-CH

R-CH

L-CH

IC601

LC75341

AUDIO PROCESSOR

TUNER

PACK

UNIT

RTUNSA007AWZZ

+B4

R

L

RECRL

ALC

R REC

L REC

POP REDUCE

SWITCHING

L(T2)

R(T2)

R(T1)

L(T1)

21

4

24

2

1

18

11

16

3

15

10

9

1

2

3

4

5

6

7

8

9

10

11

7

23

14

12

13

19

7

18

10

58

30

48

13

21

4

2

24

23

6

9

16

12

11

15

1

H/N

P.B

REC

T1/T2

T1/T2

NOR/

HIGH

+B4

+B4

+B4

SYSTEM

TAPE

MECHANISM

ASS'Y

MOTOR

DRIVER

SOLENOID

DRIVER

+B7

+B7

LED703

JOG701

VOLUME

IC701

IXA092AW

SYSTEM

MICROCOMPUTER

(2/2)

BI601CNS601

CHASIS_GND

FM_DETNC

NO USE TUN_SM

R_CH

+9V

L_CH

CHASIS_GND

DO

CL

D1

CE

CNP 303

1

3

4

1

3

2

[2] Main Block diagrams

Figure 4-2: BLOCK DIAGRAM (2/5)

4 – 2

Page 53

T

FL701

FL DISPLAY

812 45

~

27

26

CD-G15000/CP-G15000S

+B5

5150

TAPE

MECHANISM

ASS'Y

47

~

603

604

Y

MUTE

SYSTEM

SP DET.

D905~D907

IC901

STK41244

POWER AMP.

18

L

14

R

7

1

5

2

6

+B1

-B1

38 28 26

~

VLOAD

~

MICROCOMPUTER

VDD

12345 67

L-OUT

R-OUT

80

100

+B5

11

8

58

78

79

97

99

IC701

IXA092AW

SYSTEM

(1/2)

RESET

Q709

Q901~

Q904

59

40

46

47

RESET

XL701

4.19 MHz

VDD

11 1210 16 21 24 20 17 18 19

+B5

+B5

SP RELAY

ON-OFF

D801

VDD

~

25 13 27

AVDD

CLK

CEDIDO

Q905

39

+B5

34

33

~~

31

53

56

15

41

FAN MOTOR

DRIVER

RL914

RX701

REMOTE

3

SENSOR

2

KEY

SW701-SW705

SW707-SW716

TO CD

SECTION

Q906

MAIN POWER

TRANSFORMER

1

+B5

+B8

M901

M

FAN

MOTOR

SO901

SPEAKER

TERMINAL

PT801

SO901

REAR

SPEAKER

TERMINAL

D803,

D804

D842~

D845

F802

5A/125V

F801

5A/125V

Q801

F804

2A/125V

F803

2A/125V

VOLTAGE

REGULATOR

T.F.

F805

6A/125V

RL841

AC POWER

SUPPLY CORD

AC 120 V, 60 Hz

-B2

+B2

LD+8V

+B3

M+13V

1/T2

VF2

VF1

BIAS

R

ÐVF

+B5

+B7

+B4

+B9

+B6

+B8

AC_RLY

UNSW_5.6V

A+10V

A_+5V

SW5V

D+5V

RELAY

DRIVER

Q841

IC854

31

AN78L05

IC851

AN80T53

MULTI REGULATOR

7

2

6

+5V

1

D802

3

D863

VOLTAGE REGULATOR

PT841

SUB POWER

TRANSFORMER

Figure 4-3: BLOCK DIAGRAM (3/5)

4 – 3

Page 54

CD-G15000/CP-G15000S

L

D

8

9

[3] Sub Woofer Block Diagrams

+

-

VR502

VOLUME

-

+

1114151718

GND

VH-

VL-

Q902

Q901

VL+

D902

D901

IC901

STK41244

POWER AMP.

VH+

125678

VL-

VH-

VL+

D903

VH+

Q907

Q903

Q904

D910

D911

L902

L901

Q90

Q90

LED502

IC502

KIA4558P

OPE AMP.

IC501

KIA4558P

OPE AMP.

LED501

Q501

1

7

5

VR501

CROSSOVER

FREQUENCY

32

5

4

+12V

7

4

SO501

SUBWOOFER

INPUT

IC801

KIA7812AP

VOLTAGE

REGULATOR

31

2

8

32

1

8

VH-

VH+

VL-

VL+

D803~D806

D801

D802

Figure 4-4: BLOCK DIAGRAM (4/5)

4 – 4

Page 55

L902

0

CD-G15000/CP-G15000S

M401

FAN MOTOR

+

M

D908

RL901

L

R

L1_OUT

R1_OUT

-

D906

Q905

Q906

L901

L

D912

Q908

11

Q909

F805

T6.3A L 250V

D907

Q401

D909

R401

Q403

Q402

CNP901

1

2

3

4

SW802

POWER

CNS901

1

2

3

4

SP1

SUBWOOFER

F804

T6.3A L 250V

F806

800mA L 250V

T.F.

PT801

POWER

TRANSFORMER

Figure 4-5: BLOCK DIAGRAM (5/5)

4 – 5

F801

T6.3A L 250V

212

AC POWER SUPPLY CORD

120 V, 60Hz

1

Page 56

CD-G15000/CP-G15000S

CHAPTER 5. CIRCUIT DISCRIPTION

CHAPTER 5.

[1] Waveforms of CD circuit

1

3

1

2

IC1 22

IC1 23

IC1 22

IC1 16

Stopped

CH1=500 mV

DC 10:1

T

FDO

1

TDO

3

Smoothing : ON CH1 : 0.000 V

BW : FULL

Stopped

1

T

2

3

-3 div -1 div 0 div +1 div +3 div

Smoothing : ON CH1 : 0.000 V

BW : FULL

CH1=500 mV

DC 10:1

FDO

TE

CH2 : 0.0 V

CH3 : 0.000 V

CH4 : 0.00 V

CH2=10 V

DC 10:1

CH Position To

CH2 : 0.0 V

CH3 : 0.00 V

CH4 : 0.00 V

CH3=500 mV

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2K

CH3=1 V

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2K

500 ms/div

(500 ms/div)

NORM:20 kS/s

CH1

v/DIV

500 mV

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0 ns

Hold off : 0.2 µs

500 ms/div

(500 ms/div)

NORM:20 kS/s

CH2

Position

0.20 div

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0 ns

Hold off : 0.2 µs

1

5

6

7

1

IC1 22

IC1 25

IC1 28

IC1 27

IC1 22

Stopped

CH1=200 mV

DC 10:1

T

FDO

2

SPDO

1

=Filter= =Offset=

Smoothing : ON CH1 : 0.000 V

BW : FULL

Stopped

CH1=500 mV

DC 10:1

PD00

3

4

PD01

T

FDO

1

Smoothing : ON CH1 : 0.000 V

BW : FULL

T

CH2=500 mV

DC 10:1

CH2 : 0.000 V

CH3 : 0.00 V

CH4 : 0.00 V

CH2 : 0.0 V

CH3 : 0.00 V

CH4 : 0.00 V

=Record Length=

Main : 100 K

Zoom : 2K

CH3=1 V

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2K

1999/04/07 09:51:15

500 ms/div

(500 ms/div)

NORM:20 kS/s

=Trigger=

Mode : NORMAL

Type : EDGE CH2

Delay : 2.924 ms

Hold off : 0.2 µs

1999/04/05 17:33:17

CH4=1 V

500 ms/div

(500 ms/div)

DC 10:1

NORM:20 kS/s

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH2

Delay : 0.0 ns

Hold off : 0.2 µs

CH1

v/DIV

500 mV

IC1 2

4

Vp-p=1.0 V~1.3 V

0.5 mV/div,0.5 µsec/div

5 – 1

Page 57

[2] Voltage

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

CD-G15000

IC1

VOLTAGE

3.20 V

1.61V

1.61 V

1.60 V

1.61 V

3.08 V

1.65 V

1.65 V

1.65 V

1.65 V

1.48 V

0V

1.65 V

0V

1.65 V

1.47 V

1.48 V

0V

0V

0V

1.60 V

0V

1.61 V

1.61 V

0V

0V

3.20 V

0V

3.20 V

0V

0V

1.59 V

1.60 V

3.20 V

0V

0V

0V

0V

0V

0V

3.61 V

0V

0V

1.80 V

3.60 V

0V

1.45 V

1.49 V

3.19 V

3.79 V

0V

0V

0V

0V

0V

0V

0V

0V

0V

3.20 V

0V

0V

0.53 V

0V

5.16 V

5.18 V

4.68 V

0V

0V

0V

0V

0V

0V

4.86 V

4.86 V

3.01 V

0V

1.12 V

0V

3.20 V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

IC2

VOLTAGE

2.10 V

2.20 V

2.10 V

2.20 V

2.10 V

2.20 V

0V

4.37 V

5.02 V

3.20 V

1.62 V

1.65 V

1.62 V

1.65 V

1.62 V

0V

1.62 V

1.64 V

4.71 V

4.71 V

3.92 V

3.11 V

3.10 V

2.50 V

1.65 V

0V

5.02 V

8.68 V

5.02 V

0.59 V

0.71 V

0V

0V

0V

2.11 V

2.20 V

IC101

VOLTAGE

0V

0V

0.57 V

2.03 V

0.44 V

0V

0V

0.58 V

3.45 V

3.35 V

0V

0V

6.97 V

4.16 V

0V

3.42 V

0.57 V

0V

0V

0.41 V

2.03 V

0.57 V

0V

0V

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

IC301

VOLTAGE

0V

0V

0.29 V

0.20 V

0V

0.29 V

0.26 V

0.29 V

0.29 V

IC302

VOLTAGE

2.57 V

0V

0V

0V

0V

5.22 V

10.18 V

4.76 V

0V

0V

5.23 V

0V

5.23 V

0V

0V

2.59 V

5.24 V

0V

0V

10.18 V

0V

2.57 V

IC303

VOLTAGE

1.97 V

5.15 V

1.97 V

1.96 V

0V

0V

5.21 V

3.59 V

5.15 V

0V

2.01 V

1.25 V

2.27 V

1.13 V

1.10 V

1.96 V

0V

1.29 V

2.08 V

1.29 V

1.95 V

1.95 V

5.15 V

3.65 V

IC851

VOLTAGE

5.22 V

13.11 V

20.66 V

0V

19.72 V

10.22 V

8.67 V

IC601

PIN

VOLTAGE

NO.

0V

1

0V

2

0V

3

5.10 V

4

5.10 V

5

5.10 V

6

5.10 V

7

5.11 V

8

5.10 V

9

5.10 V

10

5.10 V

11

5.10 V

12

5.10 V

13

5.10 V

14

5.10 V

15

5.10 V

16

5.10V

17

5.10 V

18

5.10 V

19

5.10 V

20

5.10 V

21

5.10 V

22

10.20 V

23

0V

24

IC901

PIN

VOLTAGE

NO.

52.80 V

1

21.60 V

2

9.60 V

3

-9.70 V

4

-21.60V

5

-48.80 V

6

0V

7

-19.70 V

8

-22.90 V

9

-22.10 V

10

-18.60 V

11

-51.30 V

12

51.40V

13

-0.14 V

14

-0.13 V

15

-50.04 V

16

-0.14 V

17

-0.14 V

18

CP-G15000

IC901

PIN

VOLTAGE

NO.

50.1 V

1

21.83 V

2

9.94 V

3

-22.64 V

4

-21.84V

5

-49.6 V

6

0V

7

-18 mV

8

-23 mV

9

-47.6 V

10

-47.5 V

11

-48 V

12

49.2 V

13

-136.6 mV

14

-140 mV

15

-47.8 V

16

-120.9 mV

17

-135.5 mV

18

IC501

PIN

VOLTAGE

NO.

15.2 mV

1

1.6 mV

2

1.1 mV

3

9.18 V

4

3.7 mV

5

3.8 mV

6

108.8 mV

7

10.6 V

8

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

1

2

3

E

C

B

E

C

B

PIN

VOLTAGE

NO.

4.74 V

1

4.65 V

2

0V

3

4.70 V

4

4.72V

5

4.72 V

6

0V

7

0V

8

9

0V

4.83 V

10

11

2.27 V

1.99 V

12

13

0V

14

4.73 V

15

0V

16

4.74 V

17

0V

18

0V

19

5.22 V

20

0V

21

0V

22

4.68 V

23

0V

24

0V

25

0V

26

5.20 V

27

0V

28

5.01 V

29

5.01 V

30

2.64 V

31

5.01 V

32

5.01 V

33

0V

34

0V

35

5.01 V

36

1.67 V

37

5.20 V

38

5.01 V

39

4.87 V

40

0V

41

2.02 V

42

0V

43

13.10 V

44

0V

45

0V

46

4.74 V

47

0V

48

4.61 V

49

0V

50

0V

IC502

VOLTAGE

6.5 mV

6.5 mV

7.5 mV

4.0 V

7.5 mV

7.5 mV

7.5 mV

4.0 V

IC801

VOLTAGE

19.5 V

0.5 mV

12.0 V

Q901

VOLTAGE

18.2 mV

6.3 V

18.2 mV

Q902

VOLTAGE

17.7 mV

6.3 V

17.7 mV

IC701

PIN

NO.

E

C

B

PIN

NO.

E

C

B

PIN

NO.

E

C

B

PIN

NO.

E

C

B

PIN

VOLTAGE

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Q903

VOLTAGE

11.4 mV

6.3 V

1.5 mV

Q904

VOLTAGE

1.5 mV

6.3 V

11.4 mV

Q905

VOLTAGE

2.2 mV

0.8 V

0.7 V

Q906

VOLTAGE

0.7 V

0.8 V

1.5 V

CD-G15000/CP-G15000S

0V

0V

0V

0V

5.17 V

5.17 V

-29.70 V

0V

-0.26 V

-0.24 V

-0.22 V

-0.20 V

-0.19 V

-0.19 V

-0.18 V

-0.17 V

-0.16 V

0V

-29.90 V

-29.90 V

-29.90 V

-29.90 V

-29.90 V

-19.76 V

-27.40 V

-24.87 V

-22.29 V

-22.30 V

-30.13 V

-27.43 V

-14.50 V

-27.20 V

-19.30 V

-6.08 V

-21.85 V

-27.22 V

-21.89 V

-17.00 V

-27.38 V

-27.10 V

-27.07 V

-27.00 V

-27.00 V

-27.35 V

-26.27 V

-27.11 V

-27.00 V

-27.07 V

-27.07 V

-26.83 V

Q401

PIN

VOLTAGE

NO.

5.5 V

E

12.0 V

C

16.2 mV

B

Q402

PIN

VOLTAGE

NO.

0.7 mV

E

6.0 V

C

0.7 mV

B

Q403

PIN

VOLTAGE

NO.

5.5 V

E

187.5 mV

C

3.7 V

B

5 – 2

Page 58

CD-G15000/CP-G15000S

-MEMO-

5 – 3

Page 59

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes on schematic diagram

• Resistor:

To differentiate the units of resistors, such symbol

as K and M are used: the symbol K means 1000

ohm and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for improvement without prior notice.

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ “ ( ) are impor-

tant for maintaining the safety of the set. Be sure to

replace these parts with specified ones for maintaining the safety and performance of the set.

CD-G15000/CP-G15000S

REF. NO DESCRIPTION POSITION

JOG701 VOLUME MAX—MIN

SW701 POWER ON /STAND-BY ON—OFF

SW702 CD ON—OFF

SW703 TUNER (BAND) ON—OFF

SW704 GAME/VIDEO ON—OFF

SW705 TAPE ON—OFF

SW707 PLAY/PAUSE ON—OFF

SW708 FAST FORWARD/PRESET UP ON—OFF

[2] Types of transistor and LED

(S)(G)(D)

(1)(2)(3)

KTA1271 Y

KTA1273 Y

KTA1274 Y

TOP VIEW

KDS184

KDS160

FRONT

VIEW

ECB

KTC3199 GR

KTC3200 GR

KTC3203 Y

KTC3205 Y

(3)

(1)

B

E

KRA107 S

KRC102 S

KRC104 S

KTA1504 Y

KTC3875 GR

KTA1504 GR

FRONT

VIEW

AC AC

TS10B05G

D10XB60

REF. NO DESCRIPTION POSITION

SW709 FAST REWIND/PRESET DOWN ON—OFF

SW710 STOP ON—OFF

SW711 DISC 1 ON—OFF

SW712 DISC 2 ON—OFF

SW713 DISC 3 ON—OFF

SW714 DISC 4 ON—OFF

SW715 DISC 5 ON—OFF

SW716 OPEN/CLOSE ON—OFF

TOP VIEW

TOP

VIEW

(2)

C

1N404S

1N4148H

DSRL204F

503BC2E30

503BC2E12

SLR342VC

SDPB40F2BC

D1SS119

FRONT

VIEW

6 – 1

Page 60

CD-G15000/CP-G15000S

[3] SCHEMATIC DIAGRAM

MAIN PWB-A1 (1/2)

FM SIGNAL

CD SIGNAL

VIDEO SIGNAL

AUDIO SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

Figure 6-2: SCHEMATIC DIAGRAM (1/10)

6 – 2

Page 61

CD-G15000/CP-G15000S

Figure 6-3: SCHEMATIC DIAGRAM (2/10)

6 – 3

Page 62

CD-G15000/CP-G15000S

FM SIGNAL

MAIN PWB - A1 (2/2)

Figure 6-4: SCHEMATIC DIAGRAM (3/10)

6 – 4

Page 63

SPEAKER PWB - B3

CD-G15000/CP-G15000S

POWER PWB - A2

Figure 6-5: SCHEMATIC DIAGRAM (4/10)

6 – 5

5

6

7

8

9

1

2

3

4

Page 64

CD-G15000/CP-G15000S

DISPLAY PWB - B1

TAPE MECHANISM PWB-G

Figure 6-6: SCHEMATIC DIAGRAM (5/10)

6 – 6

1

2

3

Page 65

CD-G15000/CP-G15000S

Figure 6-7: SCHEMATIC DIAGRAM (6/10)

6 – 7

Page 66

CD-G15000/CP-G15000S

Figure 6-8: SCHEMATIC DIAGRAM (7/10)

6 – 8

Page 67

CD-G15000/CP-G15000S

Figure 6-9 :SCHEMATIC DIAGRAM (8/10)

6 – 9

Page 68

CD-G15000/CP-G15000S

SUB WOOFER AMP PWB - H1

VOLUME PWB - J1

JACK

PWB-H4

LED FLASHING

PWB -

H3

VOLTAGE

REGU

LATOR

SUB WOOFER SPEAKER LED PWB - D

Figure 6-9 :SCHEMATIC DIAGRAM (9/10)

6 – 10

Page 69

CD-G15000/CP-G15000S

POWER SWITCH

PWB-J2

PRIMARY POWER PWB - H2

Figure 6-9 :SCHEMATIC DIAGRAM (10/10)

6 – 11

Page 70

CD-G15000/CP-G15000S

[4] Wiring side of PWB

Figure 6-10: WIRING SIDE OF PWB (1/18)

6 – 12

Page 71

CD-G15000/CP-G15000S

Figure 6-11: WIRING SIDE OF PWB (2/18)

6 – 13

Page 72

CD-G15000/CP-G15000S

Figure 6-12: WIRING SIDE OF PWB (3/18)

6 – 14

56789101112131415161718

Page 73

CD-G15000/CP-G15000S

123456789

Figure 6-13: WIRING SIDE OF PWB (4/18)

6 – 15

Page 74

CD-G15000/CP-G15000S

-MEMO-

6 – 16

Page 75

CD-G15000/CP-G15000S

Figure 6-14: WIRING SIDE OF PWB (5/18)

6 – 17

Page 76

CD-G15000/CP-G15000S

A

B

C

D

E

F

1 2 3

G

H

1

23456

Figure 6-15: WIRING SIDE OF PWB (6/18)

6 – 18

Page 77

CD-G15000/CP-G15000S

7

8 9 10 11 12

Figure 6-16: WIRING SIDE OF PWB (7/18)

6 – 19

Page 78

CD-G15000/CP-G15000S

Figure 6-17: WIRING SIDE OF PWB (8/18)

6 – 20

Page 79

CD-G15000/CP-G15000S

Figure 6-18: WIRING SIDE OF PWB (9/18)

6 – 21

Page 80

CD-G15000/CP-G15000S

Figure 6-19: WIRING SIDE OF PWB (10/18)

6 – 22

GY

BK

Page 81

-MEMO-

CD-G15000/CP-G15000S

6 – 23

Page 82

CD-G15000/CP-G15000S

A

B

C

D

E

F

G

H

1

23456

Figure 6-20: WIRING SIDE OF PWB (11/18)

6 – 24

Page 83

CD-G15000/CP-G15000S

7

8 9 10 11 12

Figure 6-21: WIRING SIDE OF PWB (12/18)

6 – 25

Page 84

CD-G15000/CP-G15000S

Figure 6-22: WIRING SIDE OF PWB (13/18)

6 – 26

Page 85

-MEMO-

CD-G15000/CP-G15000S

6 – 27

Page 86

CD-G15000/CP-G15000S

Figure 6-23: WIRING SIDE OF PWB (14/18)

6 – 28

Page 87

CD-G15000/CP-G15000S

Figure 6-24: WIRING SIDE OF PWB (15/18)

6 – 29

Page 88

CD-G15000/CP-G15000S

Figure 6-25: WIRING SIDE OF PWB (16/18)

6 – 30

Page 89

COLOR TABLE

BK BLACK

WH WHITE

RD(R) RED

CD-G15000/CP-G15000S

VOLUME

123

13

8

1

34567

CNS505

123

RD(R)

1234567

CNP506

12

CNS803

Lead-free solder indication

Lead-free solder is used in the JACK, VOLUME, POWER SWITCH PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

Figure 6-26: CONTROL PWB TOP VIEW (17/18)

6 – 31

12

CNS802

TO

PRIMARY POWER

PWB-H2

Page 90

CD-G15000/CP-G15000S

Figure 6-27: WIRING SIDE OF PWB (18/18)

6 – 32

Page 91

CD-G15000/CP-G15000S

CHAPTER 8. OTHERS

[1] Function table of IC

IC1 VHiLC78690E-1: CD Servo (LC78690E) (1/2)

Pin No. Terminal Name In put/Output Setting in Reset Function

1 EFMIN Input INPUT RF signal input pin.

2 RFOUT Output UNSTABLE RF signal output pin.

3 LPF Output UNSTABLE RF signal DC level detection. LPF capacitor connection pin.

4 PHLPF Output UNSTABLE LPF capacitor pin for detection problem.

5 AIN Input INPUT A signal input pin.

6 CIN Input INPUT C signal input pin.

7 BIN Input INPUT B signal input pin.

8 DIN Input INPUT D signal input pin.

9 FEC Output UNSTABLE FE signal LPF capacitor connection pin.

10* RFMON Output UNSTABLE Built in analog signal for monitoring LSI pin.

11 VREF Output AVDD/2 VREF voltage output pin.

12 JITTC Output UNSTABLE Jitter detection capacitor connection pin.

13 EIN Input INPUT E signal input pin.

14 FIN Input INPUT F signal input pin.

15 TEC Output UNSTABLE TE signal LPF capacitor connection pin.

16 TE Output UNSTABLE TE signal output pin.

17 TEIN Input INPUT TES signal generation TE signal input pin.

18 LDD Output UNSTABLE Laser power control signal output pin.

19 LDS Input INPUT Laser power control signal input pin.

20 AVSS — — Analog GND pin. This pin must always be connected to 0V.

21 AVDD — — Analog power supply pin.

22 FDO Output AVDD/2 Focus control output pin. D/A converter output.

23 TDO Output AVDD/2 Tracking control output pin. D/A converter output.

24 SLDO Output AVDD/2 SLED control output pin. D/A converter output.

25 SPDO Output AVDD/2 SPINDLE control output pin. D/A converter output.

26 VVSS1 — — For use

27 PDOUT1 Output UNSTABLE Phase comparison output pin 1 to control built in VCO.

28 PDOUT0 Output UNSTABLE Phase comparison output pin 0 to control built in VCO.

29 PCKIST Input INPUT Resistor connection pin to set current for PDOUT 0 and 1 output.

30 VVDD1 — — Built_in VCO power supply pin 1.

by the

EFM

PLL

Circuit

Built-in VCO GND pin. This pin must always be connected to 0V.

31* DMUTEB Output L DMUTEB output pin.

32 PUIN Input/Output INPUT PUIN input pin. (built-in pull-up resistor)

33* DEFECT Output L DEFECT signal output pin.

34* FSEQ Output L Detected sync signal output. This signal is high when the sync signal

35* C2F Output L C2 error flag monitor output pin.

36 DVDD — — Digital power supply pin.

37 DVSS — — Digital GND pin. This pin must always be connected to 0V.

38 DVDD1.8 Output H Supply voltage connect to capacitor for digital circuit.

39 VDD3 — — Built-in VCO power supply pin 3.

40 VVSS3 — — Built-in VCO GND pin 3. This pin must always be connected to 0V.

41 DVDD — — Digital power supply pin.

42 DVSS — — Digital GND pin. This pin must always be connected to 0V.

43 CE Input INPUT Micro44 CL Input INPUT Data transfer clock input pin.

45 DI Input INPUT Data input pin.

46 DO Output H Data output pin. (TRI-State Output)

47 RESB Input — Reset input pin for LSI. This pin must set to low briefly after power is

48 INTB0 Output H Interrupt signal output pin 0. (SERVO Section)

49 INTB1 Output H Interrupt signal output pin 1. (DECODER Section)

50 ICONT2 Input/Output INPUT General Purpose I/O pin 2 Controlled by command from the microproces-

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

detected from the EFM signal and the internally generated sync signal

agree.

Chip enable signal input pin.

Computer

Interface

applied.

sor. Any of these that are unused must be

either set up as input pin ports and connected

to 0V, or set up as output pin ports and left

open.

8 – 1

Page 92

CD-G15000/CP-G15000S

IC1 VHiLC78690E-1: CD Servo (LC78690E) (2/2)

Pin No. Terminal Name Input/Output Setting in Reset Function

51 CONT1 Input/Output INPUT General Purpose I/O pin 1 Controlled by command from the microproces52 CONT0 Input/Output INPUT General Purpose I/O pin 0

53 TEST0 Input L Test input pin 1. This pin must always be connected to 0V.

54 STREQ Input/Output INPUT Stream data request output pin.

55 STCK Input/Output INPUT Stream data bit clock usage input pin.

56 STDATA Input/Output INPUT Stream data input pin.

57 TEST1 Input L Test input pin 0. This pin must always be connected to 0V.

58* DATA Output L Left/Right clock output pin.

59* DATACK Output L Bit clock output pin.

60* LRSY Output L Left/Right channel data output pin.

61 VVDD2 — — For use by

62 VPREF2 Input INPUT Built-in VCO control oscillator range setting input pin.

63 VCOC2 Input INPUT Built-in VCO control voltage setting input pin.

64 VPDOUT2 Output UNSTABLE Built-in VCO control output pin 2.

65 VVSS2 — — Built-in VCO GND pin. This pin must always be connected to

66 DVDD1.8 Output H Supply voltage connect to condenser for digital circuit.

67 DVSS — — Digital GND pin. This pin must always be connected to 0V.

68 DVDD — — Digital power supply pin.

69* DOUT Output Input Digital output pin. EIAJ format.

70* AMUTEB Output L GAMUTEB output pin.

71 XVSS — — Digital GND pin. This pin must always be connected to 0V.

72 XOUT Output OSCILLATING Crystal

73 XIN Input OSCILLATING

74 XVDD — — Digital power supply pin.

75 LCHO Output LRVDD/2 D/A con76 LRVDD — — LR channel power supply pin.

77 LRVSS — — LR channel GND pin. This pin must always be connected to

78 RCHO Output LRVDD/2 Right channel input supply pin.

79 AVDD — — Analog power supply pin.

80 SLCO — — Slice level control output pin.

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

the EFM

PLL Circuit

oscillator

verter

Built-in VCO power supply pin 2.

0V.

Connections for a 16.9344 MHZ oscillator element.

Left channel output supply pin.

0V.

sor. Any of these that are unused must be

either set up as input pin ports and connected

to 0V, or set up as output pin ports and left

open.

8 – 2

Page 93

IC1 VHiLC78690E-1: CD Servo (LC78690E)

AVD D

SLC0