Page 1

INTEGRATED CIRCUITS

FB2031

9-bit latched/registered/pass-thru

Futurebus+ transceiver

Product specification

IC19 Data Handbook

1995 May 25

Page 2

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

FEA TURES

•Latched, registered or straight through in

either A to B or B to A path

•Drives heavily loaded backplanes with

equivalent load impedances down to 10Ω.

•High drive 100mA BTL open collector

drivers on B-port

•Allows incident wave switching in heavily

loaded backplane buses

•Reduced BTL voltage swing produces less

noise and reduces power consumption

•Built-in precision band-gap reference

provides accurate receiver thresholds and

improved noise immunity

•Compatible with IEEE Futurebus+ or

proprietary BTL backplanes

•Each BTL driver has a dedicated Bus GND

for a signal return

•Controlled output ramp and multiple GND

pins minimize ground bounce

•Glitch-free power up/power down operation

•Low I

current

CC

•Tight output skew

•Supports live insertion

QUICK REFERENCE DATA

SYMBOL PARAMETER TYPICAL UNIT

t

PLH

t

PHL

t

PLH

t

PHL

C

I

I

O

OL

CC

Propagation delay

An to Bn

Propagation delay

Bn to An

2.7 ns

4.4

4.2

Output capacitance (B0 – Bn only) 6 pF

Output current (B0 – Bn only) 100 mA

Supply current

AIn to Bn

(outputs Low or High)

Bn to AOn (outputs Low) 50 mA

17 mA

Bn to AOn (outputs High) 25

ORDERING INFORMATION

PACKAGE

COMMERCIAL RANGE

VCC = 5V±10%; T

= 0°C to +70°C

amb

VCC = 5V±10%; T

52-pin Plastic Quad Flat Pack (QFP) FB2031BB CD3206BB SOT379-1

INDUSTRIAL RANGE

= –40°C to +85°C

amb

DRAWING

NUMBER

ns

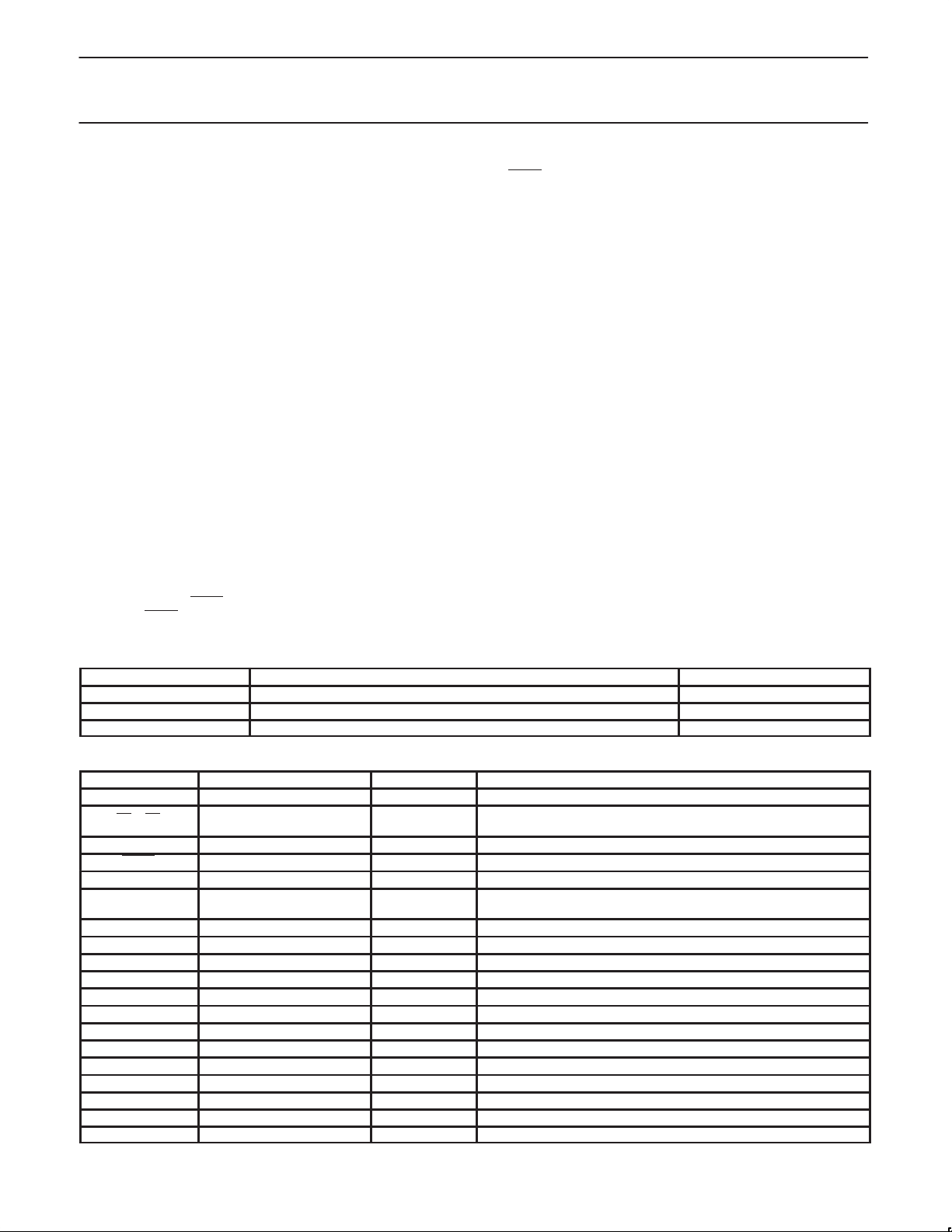

PIN CONFIGURATION

LOGIC GND

LOGIC GND

LOGIC GND

LOGIC GND

LOGIC GND

LOGIC GND

LOGIC GND

CC

V

LOGIC GND

A1

A0

52 51 50 49 48 47 46 45 44 43 42 41 40

1

2

A2

3

4

A3

A4

A5

A6

A7

9-Bit latched/registered transceiver

5

6

7

8

9

10

11

12

13

14 15 16 17 18 19 20 21 22 23 24 25 26

A8

SEL1

LCBA

OEA

BIAS V

OEB0

FB2031

52-lead PQFP

CC

BG V

LCAB

SEL0

BG GND

CC

TCK (option)

V

OEB1

CC

V

TDI (option)

TDO (option)

TMS (option)

B0

BUS GND

39

38

37

36

35

34

33

32

31

30

29

28

27

B8

B7

BUS GND

BUS GND

B1

BUS GND

B2

BUS GND

B3

BUS GND

B4

BUS GND

B5

BUS GND

B6

BUS GND

SG00060

1995 May 25 853-1714 15279

2

Page 3

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

DESCRIPTION

The FB2031 is a 9-bit latched/registered

transceiver featuring a latched, registered or

pass-thru mode in either the A-to-B or B-to-A

direction. The FB2031 is intended to provide

the electrical interface to a high performance

wired-OR bus.

The TTL-level side (A port) has a common

I/O. The common I/O, open collector B port

operates at BTL signal levels. The logic

element for data flow in each direction is

controlled by two mode select inputs (SEL0

and SEL1). A “00” configures latches in both

directions. A “10” configures thru mode in

both directions. A “01” configures register

mode in both directions. A “11” configures

register mode in the A-to-B direction and

latch mode in the B-to-A direction.

When configured in the buffer mode, the

inverse of the input data appears at the

output port. In the register mode, data is

stored on the rising edge of the appropriate

clock input (LCAB or LCBA). In the latch

mode, clock pins serve as transparent-Low

latch enables. Regardless of the mode, data

is inverted from input to output.

The 3-State A port is enabled by asserting a

High level on OEA. The B port has two output

enables, OEB0 and OEB1

is High and OEB1

enabled.

. Only when OEB0

is Low is the output

When either OEB0 is Low or OEB1

the B port is inactive and is pulled to the level

of the pullup voltage. New data can be

entered in the register and latched modes or

can be retained while the associated outputs

are in 3-State (A port) or inactive (B port).

The B-port drivers are Low-capacitance open

collectors with controlled ramp and are

designed to sink 100mA. Precision band gap

references on the B-port insure very good

noise margins by limiting the switching

threshold to a narrow region centered at

1.55V.

The B-port interfaces to “Backplane

Transceiver Logic” (see the IEEE 1194.1 BTL

standard). BTL features low power

consumption by reducing voltage swing (1V

p-p, between 1V and 2V) and reduced

capacitive loading by placing an internal

series diode on the drivers. BTL also

provides incident wave switching, a necessity

for high performance backplanes.

Output clamps are provided on the BTL

outputs to further reduce switching noise.

The “V

effects during a Low-to-High transition. The

“V

clamp, the “trapped reflection” clamp, clamps

out ringing below the BTL 0.5V V

This clamp remains active for approximately

100ns after a High-to-Low transition.

” clamp reduces inductive ringing

OH

” clamp is always active. The other

OH

is High,

level.

OL

To support live insertion, OEB0 is held Low

during power on/off cycles to insure glitchfree B port drivers. Proper bias for B port

drivers during live insertion is provided by the

BIAS V pin when at a 5V level while V

Low. The BIAS V pin is a low current input

which will reverse-bias the BTL driver series

Schottky diode, and also bias the B port

output pins to a voltage between 1.62V and

2.1V. This bias function is in accordance with

IEEE BTL Standard 1194.1. If live insertion is

not a requirement, the BIAS V pin should be

tied to a V

The LOGIC GND and BUS GND pins are

isolated inside the package to minimize noise

coupling between the BTL and TTL sides.

These pins should be tied to a common

ground external to the package.

Each BTL driver has an associated BUS

GND pin that acts as a signal return path and

these BUS GND pins are internally isolated

from each other. In the event of a ground

return fault, a “hard” signal failure occurs

instead of a pattern dependent error that may

be infrequent and impossible to troubleshoot.

As with any high power device, thermal

considerations are critical. It is

recommended that airflow (300Ifpm)

and/or thermal mounting be used to

ensure proper junction temperature.

CC

pin.

CC

is

P ACKAGE THERMAL CHARACTERISTICS

PARAMETER CONDITION 52-PIN PLASTIC QFP

θja Still air 80°C/W

θja 300 Linear feet per minute air flow 58°C/W

θjc Thermally mounted on one side to heat sink 20°C/W

PIN DESCRIPTION

SYMBOL PIN NUMBER TYPE NAME AND FUNCTION

A0 – A8 50, 52, 2, 4, 6, 8, 10, 12, 14 I/O BiCMOS data inputs/3-State outputs (TTL)

B0 – B8

OEB0 46 Input Enables the B outputs when High

OEB1 45 Input Enables the B outputs when Low

OEA 47 Input Enables the A outputs when High

BUS GND

LOGIC GND 51, 1, 3, 5, 7, 9, 11, 13 GND Logic ground (0V)

V

CC

BIAS V 48 Power Live insertion pre-bias pin

BG V

CC

BG GND 19 GND Band Gap threshold voltage reference ground

SEL0 20 Input Mode select

SEL1 15 Input Mode select

LCAB 18 Input A to B clock/latch enable (transparent latch when Low)

LCBA 16 Input B to A clock/latch enable (transparent latch when Low)

TMS 42 Input Test Mode Select (optional, if not implemented then no connect)

TCK 44 Input Test Clock (optional, if not implemented then no connect)

TDI 22 Input Test Data In (optional, if not implemented then no connect)

TDO 21 Output Test Data Out (optional, if not implemented then shorted to TDI)

40, 38, 36, 34, 32,

30, 28, 26, 24

25, 27, 29, 31, 33,

35, 37, 39, 41

23, 43, 49 Power Positive supply voltage

17 Power Band Gap threshold voltage reference

I/O Data inputs/Open Collector outputs, High current drive (BTL)

GND Bus ground (0V)

1995 May 25

3

Page 4

Philips Semiconductors Product specification

MODE

An to Bn thru mode

An to Bn transparent latch

An to Bn latch and read

An to Bn register

Bn to An thru mode

Bn to An transparent latch

Bn to An latch and read

Bn to An register

Disable Bn outputs

Latch mode (Bn to An)

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

FUNCTION TABLE

INPUTS OUTPUTS

An Bn* OEB0 OEB1 OEA LCAB LCBA SEL0 SEL1 An Bn

L — H L L X X H L input H**

H — H L L X X H L input L

p

Bn outputs latched and read

(preconditioned latch)

p

An outputs latched and read

(preconditioned latch)

p

Disable An outputs X X X X L X X X X Z X

L — H L L L X L L input H**

H — H L L L X L L input L

l — H L L ↑ X L L input H**

h — H L L ↑ X L L input L

data

data

latched

data

X

X

X — H L X H X L L X

l — H L L ↑ X X H input H**

h — H L L ↑ X X H input L

— L Disable H X X H L H input

— H Disable H X X H L L input

— L Disable H X L L L H input

— H Disable H X L L L L input

— L Disable H X L H H H input

— H Disable H X L H H L input

— l Disable H X ↑ L L H input

— h Disable H X ↑ L L L input

— l Disable H X ↑ H H H input

— h Disable H X ↑ H H L input

— X X X H X H L L

— X X X H X H H H

— l Disable H X ↑ L H H input

— h Disable H X ↑ L H L input

X X L X X X X X X X H**

X X X H X X X X X X H**

latched

latched

FUNCTION SELECT TABLE

NOTES:

H = High voltage level

L = Low voltage level

l = Low voltage level one set-up time

prior to the Low-to-High LCXX transition

h = High voltage level one set-up time

prior to the Low-to-High LCXX transition

1995 May 25

MODE SELECTED SEL0 SEL1

Thru mode H L

Register mode (An to Bn) X H

Latch mode (An to Bn) L L

Register mode (Bn to An) L H

L L

H H

X = Don’t care

Z = High-impedance (OFF) state

— = Input not externally driven

↑ = Low-to-High transition

H** = Goes to level of pull-up voltage

4

Bn

* = Precaution should be taken to

ensure B inputs do not float. If they do, they

are equal to Low state.

Disable = OEB0 is Low or OEB1

is High.

Page 5

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

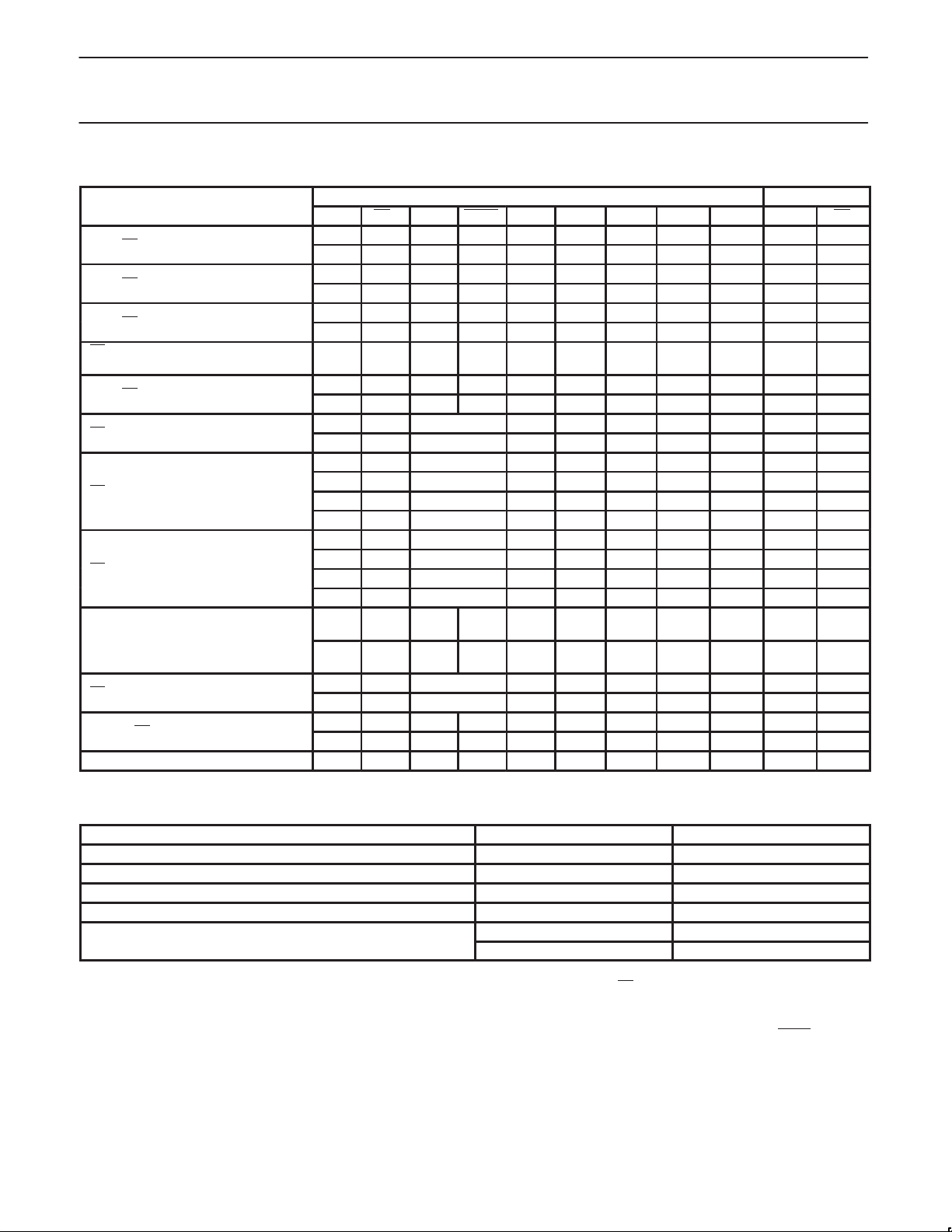

LOGIC DIAGRAM

46

OEB0

45

OEB1

47

OEA

DQ

E

DQ

14

A8

Clk

MUX

A ⇒ B

24

B8

TTL

MUX

A ⇐ B

DQ

E

DQ

12

A7

10

8

6

4

2

52

A1

50

A0

Clk

DQ

E

DQ

Clk

DQ

E

DQ

Clk

MUX

A ⇒ B

MUX

A ⇐ B

MUX

A ⇒ B

MUX

A ⇐ B

MUX

A ⇒ B

DQ

QD

E

DQ

Clk

DQ

E

DQ

Clk

DQ

E

DQ

Clk

26

B7

28

30

32

BTL

34

36

38

B1

40

B0

1995 May 25

LCAB

SEL0

SEL1

LCBA

TMS

TCK

TDI

TDO

18

20

15

16

42

(JTAG Boundary Scan pins)

44

22

21

Decode

OutIn

MUX

A ⇐ B

DQ

E

DQ

Clk

LOGIC GND = 1, 3, 5, 7, 9, 11, 13, 51

BUS GND = 25, 27, 29, 31, 33, 35, 37, 39, 41

BIAS V = 48

V

CC

BG V

BG GND = 19

CC

= 23, 43, 49

=17

SG00061

5

Page 6

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

ABSOLUTE MAXIMUM RATINGS

Operation beyond the limits set forth in this table may impair the useful life of the device.

Unless otherwise noted these limits are over the operating free-air temperature range.

SYMBOL

V

T

V

V

I

OUT

I

OUT

STG

CC

IN

IN

Supply voltage -0.5 to +7.0 V

Input voltage All inputs except B0 – B8 -1.2 to +7.0 V

Input current -40 to +5.0 mA

Voltage applied to output in High output state -0.5 to +V

Current applied to output in Low output state A0 – A8 48 mA

Storage temperature -65 to +150 °C

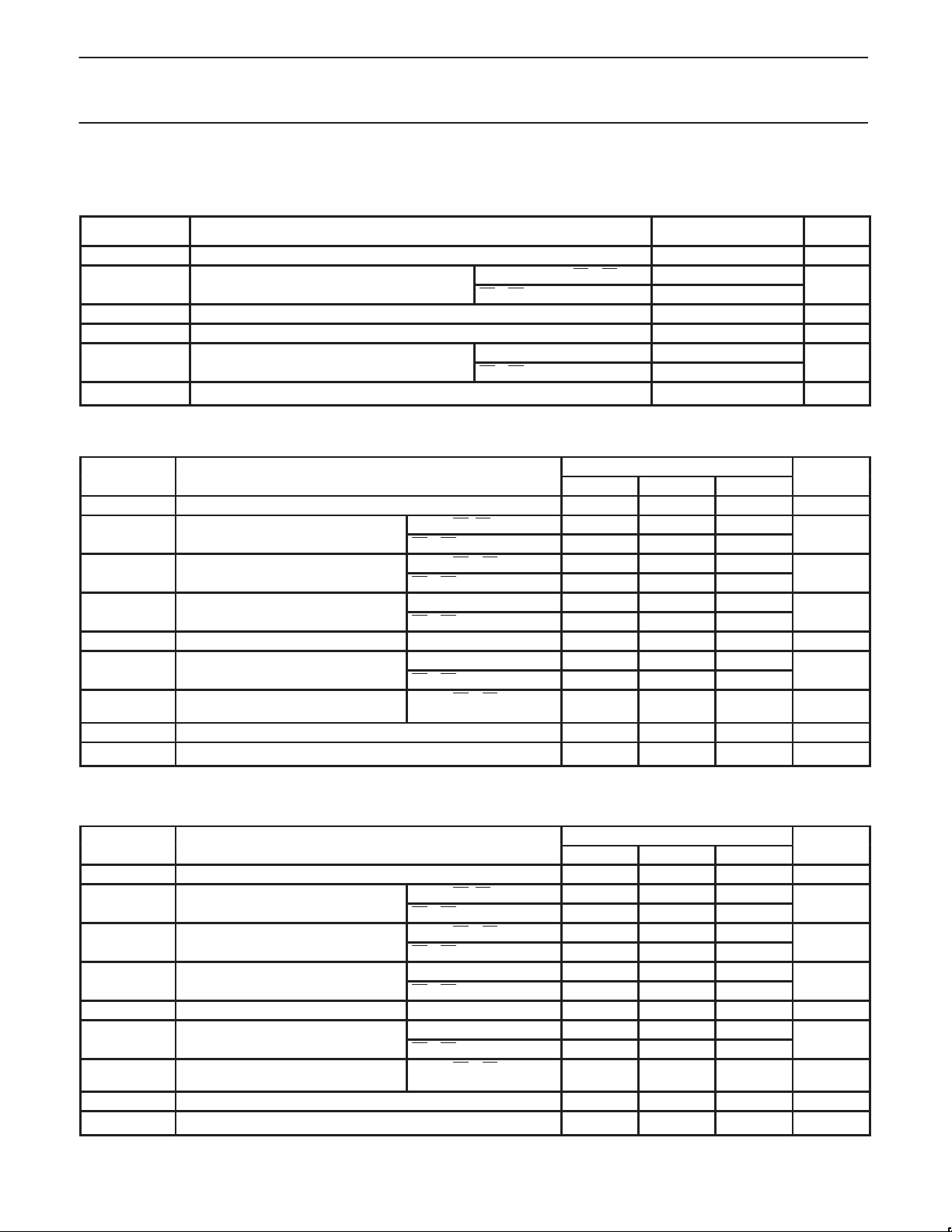

RECOMMENDED OPERATING CONDITIONS (Industrial)

SYMBOL PARAMETER LIMITS UNIT

V

C

T

V

V

I

I

OH

I

I

amb

CC

IH

IL

IK

OL

IA

OB

Supply voltage 4.5 5.0 5.5 V

High-level input voltage Except B0–B8 2.0 V

Low-level input voltage Except B0 – B8 0.8 V

Input clamp current Control inputs -40 mA

High-level output current A0 – A8 -3 mA

Low-level output current A0 – A8 24 mA

Off device input current Except B0 – B8,

Output capacitance of B port 6 7 pF

Operating free-air temperature range –40 +85 °C

PARAMETER RATING UNIT

B0 – B8 -1.2 to +3.5

CC

V

B0 – B8 200

MIN TYP MAX

B0 – B8 1.62 1.55

B0 – B8 1.47

B0 – B8 & A0 – A8 -18

B0 – B8 100

100 µA

VI = 0 to 5.5V, VCC = 0V

RECOMMENDED OPERATING CONDITIONS (Commercial)

SYMBOL PARAMETER LIMITS UNIT

MIN TYP MAX

V

CC

V

IH

V

IL

I

IK

I

OH

I

OL

I

IA

C

OB

T

amb

1995 May 25

Supply voltage 4.5 5.0 5.5 V

High-level input voltage Except B0–B8 2.0 V

B0 – B8 1.62 1.55

Low-level input voltage Except B0 – B8 0.8 V

B0 – B8 1.47

Input clamp current Control inputs -40 mA

B0 – B8 & A0 – A8 -18

High-level output current A0 – A8 -3 mA

Low-level output current A0 – A8 24 mA

B0 – B8 100

Off device input current Except B0 – B8,

100 µA

VI = 0 to 5.5V, VCC = 0V

Output capacitance of B port 6 7 pF

Operating free-air temperature range 0 +70 °C

6

Page 7

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

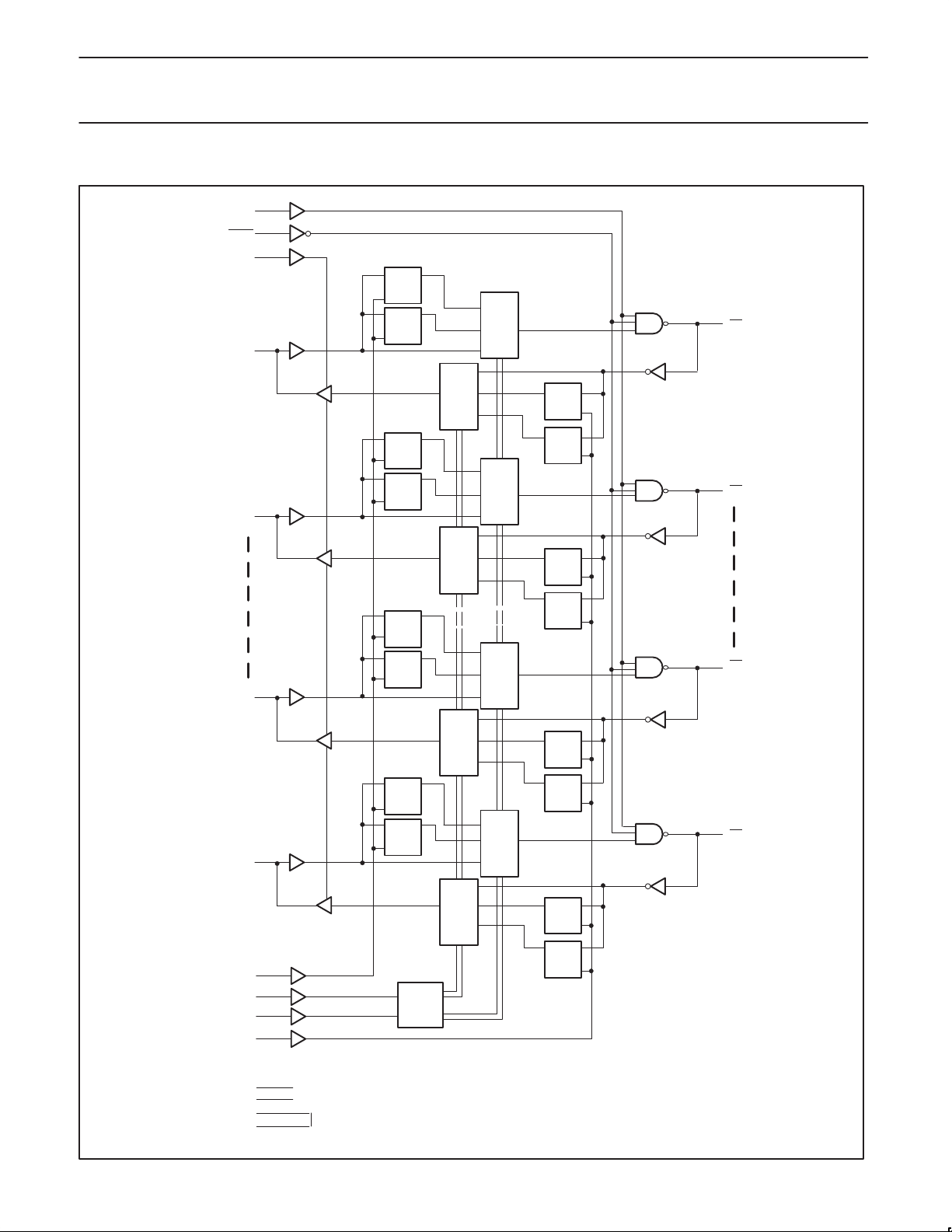

DC ELECTRICAL CHARACTERISTICS (Industrial)

Over recommended operating free-air temperature range unless otherwise noted.

SYMBOL

I

OH

I

OFF

V

OH

High level output current B0 – B8 VCC = MAX, VIL = MAX, VIH = MIN, VOH = 1.9V 100 µA

Power-off output current B0 – B8 VCC = 0.0V, VIL = MAX, VIH = MIN, VOH = 1.9V 200 µA

High-level output voltage A0 – A8

PARAMETER TEST CONDITIONS

4

VCC = MIN, VIL = MAX, VIH = MIN, IOH = -24mA 2.0 V

VCC = MIN, VIL = MAX, VIH = MIN, IOH = -3mA 2.5 2.85

A0 – A8

V

Low-level output voltage B0 – B8 VCC = MIN, VIL = MAX, VIH = MIN, IOL = 80mA .75 1.0 1.1 V

OL

4

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 24mA 0.5

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 100mA 1.15

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 80mA 1.15

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 4mA 0.5

V

Input clamp voltage Control pins VCC = MIN, II = I

IK

A0 – A8

IK

VCC = MIN, II = -18mA -1.2 V

B0 – Bn

I

Input current at maximum

I

input voltage

I

High-level input current

IH

Except

B0–B8

Except

B0

–B8

VCC = MAX, VI = 0.5V or 5.5V ±50 µA

VCC = MAX, VI = 2.7V 20

B0 – B8 VCC = MAX, VI = 1.9V 100

5

I

Low-level input current

IL

Except

B0

–B8

VCC = MAX, VI = 3.5V

VCC = MAX, VI = 0.5V -20

B0 – B8 VCC = MAX, VI = 0.75V -100

IIH + I

IIL + I

I

Off-state I/O High current A0 – A8 VCC = MAX, VO = 2.7V 50 µA

OZH

Off-state I/O Low current A0 – A8 VCC = MAX, VO = 0.5V -50 µA

OZL

OS

Short-circuit output

3

current

A0 – A8

only

VCC = MAX, VO = 0.0V -45 -150 mA

An to Bn VCC = MAX, outputs Low or High 17 30

Bn to An VCC = MAX, outputs Low 50 78

I

Supply current (total) Bn to An VCC = MAX, outputs High 25 45 mA

CC

I

CCZ

VCC = MAX, outputs 3-State 28 50

Worst case VCC = MAX, all A and B outputs on 50 78

NOTES:

1. For conditions shown as MIN or MAX, use the appropriate value specified under recommended operation conditions for the applicable type.

2. All typical values are at V

3. Not more than one output should be shorted at a time. For testing I

= 5V, T

CC

techniques are preferable in order to minimize internal heating and more accurately reflect operational values. Otherwise, prolonged shorting

amb

= 25°C.

, the use of high-speed test apparatus and/or sample-and-hold

OS

of a High output may raise the chip temperature well above normal and thereby cause invalid readings in other parameter tests. In any

sequence of parameter tests, IOS tests should be performed last.

4. Due to test equipment limitations, actual test conditions are V

5. For B port input voltage between 3 and 5 volts I

6. B0

– B8 clamps remain active for a minimum of 80ns following a High-to-Low transition.

will be greater than 100µA, but the parts will continue to function normally.

IH

= 1.8V and VIL = 1.3V for the B side.

IH

7. T emperature range: 0 to +85°C.

8. T emperature range: –40 to 0°C.

1

LIMITS UNIT

MIN TYP2MAX

-0.5

µA

100 mA

µA

1995 May 25

7

Page 8

Philips Semiconductors Product specification

SYMBOL

PARAMETER

TEST CONDITIONS

1

UNIT

VOHHigh-level output voltage

A0

4

V

VOLLow-level output voltage

V

A

B0

B8

µ

IL

µ

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

DC ELECTRICAL CHARACTERISTICS (Commercial)

Over recommended operating free-air temperature range unless otherwise noted.

LIMITS

MIN TYP2MAX

I

I

OFF

V

I

IIH + I

IIL + I

I

I

NOTES:

1. For conditions shown as MIN or MAX, use the appropriate value specified under recommended operation conditions for the applicable type.

2. All typical values are at V

3. Not more than one output should be shorted at a time. For testing I

techniques are preferable in order to minimize internal heating and more accurately reflect operational values. Otherwise, prolonged shorting

of a High output may raise the chip temperature well above normal and thereby cause invalid readings in other parameter tests. In any

sequence of parameter tests, I

4. Due to test equipment limitations, actual test conditions are V

5. For B port input voltage between 3 and 5 volts I

6. B0

High level output current B0 – B8 VCC = MAX, VIL = MAX, VIH = MIN, VOH = 1.9V 100 µA

OH

Power-off output current B0 – B8 VCC = 0.0V, VIL = MAX, VIH = MIN, VOH = 1.9V 100 µA

p

– A8

A0 – A8

p

B0 – B8 VCC = MIN, VIL = MAX, VIH = MIN, IOL = 100mA 1.15

VCC = MIN, VIL = MAX, VIH = MIN, IOH = -24mA 2.0

VCC = MIN, VIL = MAX, VIH = MIN, IOH = -3mA 2.5 2.85

4

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 24mA 0.5

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 80mA .75 1.0 1.1

VCC = MIN, VIL = MAX, VIH = MIN, IOL = 4mA 0.5

Input clamp voltage

IK

Input current at maximum

I

I

input voltage

High-level input current

IH

I

Low-level input current

IL

Control pins VCC = MIN, II = I

A0 – A8

B0 – Bn

Except

B0–B8

Except

B0–B8

–

Except

B0–B8

VCC = MIN, II = -18mA -1.2

VCC = MAX, VI = 0.0V or 5.5V ±50 µA

VCC = MAX, VI = 2.7V 20

VCC = MAX, VI = 1.9V 100

VCC = MAX, VI = 3.5V

VCC = MAX, VI = 0.5V -20

IK

5

100 mA

B0 – B8 VCC = MAX, VI = 0.75V -100

Off-state I/O High current A0 – A8 VCC = MAX, VO = 2.7V 50 µA

OZH

Off-state I/O Low current A0 – A8 VCC = MAX, VO = 0.5V -50 µA

OZL

OS

Short-circuit output

3

current

A0 – A8

only

VCC = MAX, VO = 0.0V -45 -150 mA

An to Bn VCC = MAX, outputs Low or High 17 30

Bn to An VCC = MAX, outputs Low 50 78

Supply current (total) Bn to An VCC = MAX, outputs High 25 45 mA

CC

I

CCZ

VCC = MAX, outputs 3-State 28 50

Worst case VCC = MAX, all A and B outputs on 50 78

= 5V, T

CC

OS

– B8 clamps remain active for a minimum of 80ns following a High-to-Low transition.

= 25°C.

amb

tests should be performed last.

will be greater than 100µA, but the parts will continue to function normally.

IH

IH

, the use of high-speed test apparatus and/or sample-and-hold

OS

= 1.8V and VIL = 1.3V for the B side.

-0.5

V

µ

A

1995 May 25

8

Page 9

Philips Semiconductors Product specification

SYMBOL

PARAMETER

UNIT

I

Bias in DC current

IOLOFF

Power u current

µA

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

LIVE INSERTION SPECIFICA TIONS

LIMITS

MIN NOM MAX

V

BIASV

BIASV

V

I

I

IBnPEAK

t

Bias pin voltage VCC = 0 to 5.25V, Bn = 0 to 2.0V 4.5 5.5 V

VCC = 0 to 4.75V, Bn = 0 to 2.0V,

p

Bias V = 4.5 to 5.5V

VCC = 4.5 to 5.5V, Bn = 0 to 2.0V,

Bias V = 4.5 to 5.5V

Bus voltage during prebias B0 – B8 = 0V, Bias V = 5.0V 1.62 2.1 V

Bn

Fall current during prebias B0 – B8 = 2V, Bias V = 4.5 to 5.5V 1 µA

LM

Rise current during prebias B0 – B8 = 1V, Bias V = 4.5 to 5.5V -1 µA

HM

Peak bus current during

insertion

p

Input glitch rejection VCC = 5.0V 1.35 1.0 ns

GR

VCC = 0 to 5.25V, B0 – B8 = 0 to 2.0V,

Bias V = 4.5 to 5.5V, OEB0 = 0.8V, tr = 2ns

V

= 0 to 5.25V, OEB0 = 0.8V 100

CC

V

= 0 to 2.2V, OEB0 = 0 to 5V 100

CC

1 mA

10 µA

10 mA

AC ELECTRICAL CHARACTERISTICS (Industrial)

A PORT LIMITS

T

= –40 to +85°C,

SYMBOL PARAMETER

TEST

CONDITION

T

= +25°C, VCC = 5V,

amb

CL = 50pF, RL = 500Ω

MIN TYP MAX MIN MAX

f

MAX

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PZH

t

PZL

t

PHZ

t

PLZ

t

TLH

t

THL

tSK(o)

tSK(p)

Maximum clock frequency Waveform 4 120 150 100 MHz

Propagation delay (thru mode)

Bn to An

Propagation delay (transparent latch)

Bn to An

Propagation delay

LCBA to An

Propagation delay

SEL0 or SEL1 to An

Output enable time from High or Low

OEA to An

Output disable time to High or Low

OEA to An

Output transition time, An Port

10% to 90%, 90% to 10%

Output to output skew for multiple

channels

Pulse skew

t

PHL

– t

1

PLH

2

MAX

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 5, 6

Waveform 5, 6

Test Circuit and

Waveforms

Waveform 3 0.5 1.0 1.5 ns

Waveform 2 0.5 1.0 1.0 ns

2.5

2.4

2.9

2.8

2.6

2.4

1.5

1.7

2.1

2.0

1.9

1.7

4.4

4.2

4.6

4.3

4.1

4.7

3.8

3.9

3.5

3.8

3.4

3.2

5.9

5.5

6.2

5.9

5.5

6.1

5.2

6.0

4.8

5.3

4.8

4.8

NOTES:

1. For conditions shown as MIN or MAX, use the appropriate value specified under recommended operation conditions for the applicable type.

2. All typical values are at V

3. Not more than one output should be shorted at a time. For testing I

techniques are preferable in order to minimize internal heating and more accurately reflect operational values. Otherwise, prolonged shorting

= 5V, T

CC

amb

= 25°C.

, the use of high-speed test apparatus and/or sample-and-hold

OS

of a High output may raise the chip temperature well above normal and thereby cause invalid readings in other parameter tests. In any

sequence of parameter tests, IOS tests should be performed last.

4. Due to test equipment limitations, actual test conditions are V

5. For B port input voltage between 3 and 5 volts I

6. B0

– B8 clamps remain active for a minimum of 80ns following a High-to-Low transition.

will be greater than 100µA, but the parts will continue to function normally.

IH

= 1.8V and VIL = 1.3V for the B side.

IH

amb

VCC = 5V±10%,

CL = 50pF, RL = 500Ω

2.3

2.4

2.7

2.5

2.0

2.0

1.2

1.5

1.8

1.7

1.6

1.5

3.0

1.7

7.0

6.2

7.1

7.0

6.2

6.8

6.2

6.5

6.0

6.3

5.5

5.5

7.5

4.0

UNIT

ns

ns

ns

ns

ns

ns

ns

1995 May 25

9

Page 10

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

AC ELECTRICAL CHARACTERISTICS (Industrial)

B PORT LIMITS

T

= –40 to +85°C,

SYMBOL PARAMETER

TEST

CONDITION

T

= +25°C, VCC = 5V,

amb

CD = 30pF, RU = 16.5Ω

MIN TYP MAX MIN MAX

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PZH

t

PZL

t

TLH

t

THL

t

SK(o)

tSK(p)

Propagation delay (thru mode)

An to Bn

Propagation delay (transparent latch)

An to Bn

Propagation delay

LCAB to Bn

Propagation delay

SEL0 or SEL1 to Bn

Enable/disable time

OEB0 or OEB1 to Bn

Output transition time, Bn Port

(1.3V to 1.8V)

Output to output skew for multiple

channels

Pulse skew

t

PHL

– t

1

PLH

2

MAX

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Test Circuit and

Waveforms

1.0

1.0

1.0

1.0

2.0

1.5

2.0

1.5

1.5

1.2

1.0

0.6

3.0

2.7

3.2

3.1

4.0

4.0

3.5

2.3

3.0

2.4

5.0

4.0

5.0

4.2

5.5

5.5

5.5

4.5

5.0

4.5

2.0

3.0

Waveform 3 1.0 0.4 1.6 1.6 ns

Waveform 2 0.3 1.0 1.5 ns

NOTES:

actual – tPMactual for any data input to output path compared to any other data input to output path where N and M are either LH or

1. t

PN

HL. Skew times are valid only under same test conditions (temperature, V

(p) is used to quantify duty cycle characteristics. In essence it compares the input signal duty cycle to the corresponding output signal

2. t

SK

duty cycle (50MHz input frequency and 50% duty cycle, tested on data paths only).

, loading, etc.).

CC

amb

VCC = 5V±10%,

CD = 30pF, RU = 16.5Ω

1.5

1.5

1.5

1.5

1.5

1.5

2.0

1.0

1.0

1.0

0.9

0.6

5.7

4.5

5.5

5.0

6.5

6.0

6.1

5.5

5.7

5.5

3.0

3.0

UNIT

ns

ns

ns

ns

ns

ns

1995 May 25

10

Page 11

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

AC ELECTRICAL CHARACTERISTICS (Commercial)

A PORT LIMITS

T

= 0 to +70°C,

SYMBOL PARAMETER

TEST

CONDITION

T

= +25°C, VCC = 5V,

amb

CL = 50pF, RL = 500Ω

MIN TYP MAX MIN MAX

f

MAX

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PZH

t

PZL

t

PHZ

t

PLZ

t

TLH

t

THL

tSK(o)

tSK(p)

Maximum clock frequency Waveform 4 120 150 100 MHz

Propagation delay (thru mode)

Bn to An

Propagation delay (transparent latch)

Bn to An

Propagation delay

LCBA to An

Propagation delay

SEL0 or SEL1 to An

Output enable time from High or Low

OEA to An

Output disable time to High or Low

OEA to An

Output transition time, An Port

10% to 90%, 90% to 10%

Output to output skew for multiple

channels

Pulse skew

t

PHL

– t

1

PLH

2

MAX

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 5, 6

Waveform 5, 6

Test Circuit and

Waveforms

Waveform 3 0.5 1.0 1.5 ns

Waveform 2 0.5 1.0 1.0 ns

2.5

2.4

2.9

2.8

2.6

2.4

1.5

1.7

2.1

2.0

1.9

1.7

4.4

4.2

4.6

4.3

4.1

4.7

3.8

3.9

3.5

3.8

3.4

3.2

5.9

5.5

6.2

5.9

5.5

6.1

5.2

6.0

4.8

5.3

4.8

4.8

NOTES:

actual – tPMactual for any data input to output path compared to any other data input to output path where N and M are either LH or HL.

1. t

PN

Skew times are valid only under same test conditions (temperature, V

(p) is used to quantify duty cycle characteristics. In essence it compares the input signal duty cycle to the corresponding output signal

2. t

SK

duty cycle (50MHz input frequency and 50% duty cycle, tested on data paths only).

, loading, etc.).

CC

amb

VCC = 5V±10%,

CL = 50pF, RL = 500Ω

2.3

2.4

2.7

2.5

2.0

2.0

1.2

1.5

1.8

1.7

1.6

1.5

2.0

1.0

6.6

5.9

7.0

6.5

6.0

6.5

6.0

6.5

5.8

6.0

5.4

5.4

7.5

3.5

UNIT

ns

ns

ns

ns

ns

ns

ns

1995 May 25

11

Page 12

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

AC ELECTRICAL CHARACTERISTICS (Commercial)

B PORT LIMITS

T

= 0 to +70°C,

SYMBOL PARAMETER

TEST

CONDITION

T

= +25°C, VCC = 5V,

amb

CD = 30pF, RU = 16.5Ω

MIN TYP MAX MIN MAX

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PLH

t

PHL

t

PZH

t

PZL

t

TLH

t

THL

t

SK(o)

tSK(p)

Propagation delay (thru mode)

An to Bn

Propagation delay (transparent latch)

An to Bn

Propagation delay

LCAB to Bn

Propagation delay

SEL0 or SEL1 to Bn

Enable/disable time

OEB0 or OEB1 to Bn

Output transition time, Bn Port

(1.3V to 1.8V)

Output to output skew for multiple

channels

Pulse skew

t

PHL

– t

1

PLH

2

MAX

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Waveform 1, 2

Test Circuit and

Waveforms

1.0

1.0

1.0

1.0

2.0

1.5

2.0

1.5

1.5

1.5

1.0

0.6

3.0

2.7

3.2

3.1

4.0

4.0

3.5

2.3

3.0

2.4

5.0

4.0

5.0

4.2

5.5

5.5

5.5

4.5

5.0

4.5

2.0

3.0

Waveform 3 0.4 1.0 1.6 ns

Waveform 2 0.3 1.0 1.5 ns

NOTES:

actual – tPMactual for any data input to output path compared to any other data input to output path where N and M are either LH or

1. t

PN

HL. Skew times are valid only under same test conditions (temperature, V

(p) is used to quantify duty cycle characteristics. In essence it compares the input signal duty cycle to the corresponding output signal

2. t

SK

duty cycle (50MHz input frequency and 50% duty cycle, tested on data paths only).

, loading, etc.).

CC

amb

VCC = 5V±10%,

CD = 30pF, RU = 16.5Ω

1.0

0.5

1.0

0.8

1.5

1.0

2.0

1.0

1.0

0.8

1.0

0.6

5.5

4.5

5.5

4.5

6.0

6.0

6.0

5.0

5.5

5.5

2.3

2.3

UNIT

ns

ns

ns

ns

ns

ns

AC SETUP REQUIREMENTS (Industrial)

SYMBOL PARAMETER

ts(H)

ts(L)

th(H)

th(L)

ts(H)

ts(L)

th(H)

th(L)

tw(H)

tw(L)

Setup time

An to LCAB

Hold time

An to LCAB

Setup time

Bn to LCBA

Hold time

Bn to LCBA

Pulse width, High or Low

LCAB or LCBA

TEST

CONDITION T

amb

MIN TYP MAX MIN MAX

Waveform 4 1.0

1.0

Waveform 4 1.0

1.0

Waveform 4 2.0

2.0

Waveform 4 0.0

0.0

Waveform 4 3.0

3.0

LIMITS

T

= –40 to +85°C,

= +25°C, VCC = 5V,

amb

VCC = 5V±10%, UNIT

CL = 50pF (A side) / CD = 30pF (B side)

RL = 500Ω (A side) / RU = 16.5Ω (B side)

1.5

1.0

2.0

1.0

3.0

3.0

0.0

0.0

3.0

3.0

ns

ns

ns

ns

ns

1995 May 25

12

Page 13

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

AC SETUP REQUIREMENTS (Commercial)

LIMITS

SYMBOL PARAMETER

ts(H)

ts(L)

th(H)

th(L)

ts(H)

ts(L)

th(H)

th(L)

tw(H)

tw(L)

Setup time

An to LCAB

Hold time

An to LCAB

Setup time

Bn to LCBA

Hold time

Bn to LCBA

Pulse width, High or Low

LCAB or LCBA

TEST

CONDITION T

Waveform 4 1.0

Waveform 4 1.0

Waveform 4 2.0

Waveform 4 0.0

Waveform 4 3.0

amb

MIN TYP MAX MIN MAX

1.0

1.0

2.0

0.0

3.0

= +25°C, VCC = 5V,

CL = 50pF (A side) / CD = 30pF (B side)

RL = 500Ω (A side) / RU = 16.5Ω (B side)

T

= 0 to +70°C,

amb

VCC = 5V±10%, UNIT

1.5

1.0

2.0

1.0

3.0

3.0

0.0

0.0

3.0

3.0

ns

ns

ns

ns

ns

1995 May 25

13

Page 14

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

AC WAVEFORMS

Input

Output

V

M

t

PLH

V

M

t

PHL

V

M

V

M

Waveform 1. Propagation Delay for Data

or Output Enable to Output

An, Bn

An, Bn

V

M

tSK(o)

V

M

Waveform 3. Output to Output Skew

OEA

V

M

t

PZH

An

V

M

t

PHZ

V

M

VOH -0.3V

OV

Waveform 5. 3-State Output Enable Time to High Level

and Output Disable Time from High Level

NOTE: V

= 1.55V for Bn, V

M

The shaded areas indicate when the input is permitted to change for predictable output performance.

= 1.5V for all others.

M

Input

Output

V

M

t

(input)

w

t

PHL

V

M

t

(output)

w

V

M

t

PLH

V

M

Waveform 2. Propagation Delay for Data

or Output Enable to Output

V

An, Bn

LCAB, LCBA

M

t

t

s

h

V

M

t

(H)

w

1/f

MAX

tst

h

t

(L)

w

V

M

Waveform 4. Setup and Hold Times,

Pulse Widths and Maximum Frequency

OEA

V

M

t

PZL

An

V

M

t

PLZ

V

M

VOL +0.3V

Waveform 6. 3-State Output Enable Time to Low Level

and Output Disable Time from Low Level

SG00062

1995 May 25

14

Page 15

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

TEST CIRCUIT AND WAVEFORMS

V

CC

PULSE

GENERATOR

V

IN

R

T

D.U.T.

V

OUT

Test Circuit for 3-State Outputs on A Port

SWITCH POSITION

TEST SWITCH

t

PLZ,

All other

PULSE

GENERATOR

t

PZL

V

IN

Test Circuit for Outputs on B Port

BIAS

V

R

closed

open

D.U.T.

T

V

CC

V

OUT

R

L

R

C

L

L

2.0V (for RU = 9 Ω)

2.1V (for RU = 16.5 Ω)

R

U

C

D

7.0V

NEGATIVE

PULSE

POSITIVE

PULSE

Family

FB+

A Port

90%

10%

V

M

10%

t

THL

t

TLH

90%

V

M

VM = 1.55V for Bn, VM = 1.5V for all others.

INPUT PULSE REQUIREMENTS

Low V

0.0V

1.0VB Port

DEFINITIONS:

RL= Load Resistor; see AC CHARACTERISTICS for value.

CL= Load capacitance includes jig and probe capacitance; see AC

CHARACTERISTICS for value.

R

= Termination resistance should be equal to Z

T

CD= Load capacitance includes jig and probe capacitance; see AC

CHARACTERISTICS for value.

RU= Pull up resistor; see AC CHARACTERISTICS for value.

t

W

10%

(tf)

(tr)

90%

t

W

Input Pulse Definitions

Rep. RateAmplitude t

1MHz3.0V

t

W

500ns

1MHz2.0V

OUT

AMP (V)

90%

V

M

LOW V

t

(tr)

TLH

t

(tf)

THL

AMP (V)

V

M

10%

LOW V

TLHtTHL

2.5ns

2.0ns500ns

2.5ns

2.0ns

of pulse generators.

SG00063

1995 May 25

15

Page 16

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

QFP52: plastic quad flat package; 52 leads (lead length 1.6 mm); body 10 x 10 x 2.0 mm SOT379-1

1995 May 25

16

Page 17

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

NOTES

1995 May 25

17

Page 18

Philips Semiconductors Product specification

FB20319-bit latched/registered/pass-thru Futurebus+ transceiver

Data sheet status

Data sheet

status

Objective

specification

Preliminary

specification

Product

specification

Product

status

Development

Qualification

Production

Definition

This data sheet contains the design target or goal specifications for product development.

Specification may change in any manner without notice.

This data sheet contains preliminary data, and supplementary data will be published at a later date.

Philips Semiconductors reserves the right to make chages at any time without notice in order to

improve design and supply the best possible product.

This data sheet contains final specifications. Philips Semiconductors reserves the right to make

changes at any time without notice in order to improve design and supply the best possible product.

[1]

[1] Please consult the most recently issued datasheet before initiating or completing a design.

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Philips Semiconductors

811 East Arques Avenue

P.O. Box 3409

Sunnyvale, California 94088–3409

Telephone 800-234-7381

Copyright Philips Electronics North America Corporation 1998

All rights reserved. Printed in U.S.A.

print code Date of release: 08-98

Document order number:

1995 May 25

18

Loading...

Loading...