Page 1

®

BYW98-200

HIGH EFFICI EN CY FAST RECO VE RY REC T IFIER DIODES

MAIN PRODUCT CHARACTERISTICS

I

F(AV)

V

RRM

3A

200 V

Tj (max) 150 °C

(max) 0.85 V

V

F

trr (max) 35 ns

FEATURES AND BE NE F ITS

VERY LOW CONDUCTION LOS SES

NEGLIGIBLE SWIT CHING LOS SE S

LOW FORWARD AND REVERSE RECOVERY

TIMES

DESCRIPTION

Low voltage drop and rectifier suited for switching

mode base drive and transistor circuits.

ABSOLUTE RATINGS

(limiting values)

DO-201AD

(Plastic)

Symbol Parameter Value Unit

V

I

RRM

FRM

Repetitive peak reverse voltage

Repetitive peak forward current *

tp=5 µs

200 V

110 A

F=1KHz

I

F (AV)

I

FSM

Average forward current*

Surge non repetitive forward current

Ta = 75°C

δ

= 0.5

= 10ms

t

p

3A

70 A

Sinusoidal

T

stg

Tj

T

L

Storage temperature range

Maximum operating junction temperature

Maximum lead temperature for soldering during 10s at

- 65 to + 150

150

230

4mm from cas e

* On infinite heatsink with 10mm lead length.

October 1999 - Ed: 4C

°

C

°

C

°

C

1/5

Page 2

BYW98-200

THERMAL RE SISTA NC E

Symbol Parameter Value Unit

Rth (j-a)

* On infinite heatsink with 10mm lead length.

Junction-ambient *

25

STATIC ELECTRICAL CHARACTERISTICS

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

*

R

Reverse leakage

T

= 25°CV

j

current

= 100°C

T

j

V

**

F

Pulse test : * tp = 5 ms, δ < 2 %

To evaluate the conduction losses use the following equations:

P = 0.75 x I

Forward voltage drop T

** tp = 380 µs, δ < 2 %

+ 0.04 I

F(AV)

F2(RMS)

= 25°CI

j

= 100°CI

T

j

= V

R

= 9A

F

= 3A

F

RRM

10

0.5 mA

1.2 V

0.78 0.85

RECOVERY CHARACTE RISTIC S

°

C/W

µ

A

Symbol Test Conditions Min. Typ. Max. Unit

t

rr

Q

rr

t

fr

V

FP

Tj = 25°CI

V

= 30V

R

Tj = 25°CI

V

≤ 30V

R

Tj = 25°CI

= 1A dIF/dt = - 50A/µs

F

= 3A dIF/dt = - 20A/µs

F

= 3A dIF/dt = - 50A/µs

F

Measured at 1.1 x V

Tj = 25°CI

= 3A dIF/dt = - 50A/µs

F

max

F

35 ns

15 nC

20 ns

5V

2/5

Page 3

BYW98-200

Fig. 1:

Average forward power dissipation versus

average forward current.

PF(av)(W)

3.5

3.0

δ = 0.05

δ = 0.1

δ = 0.2

2.5

2.0

1.5

1.0

0.5

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Fig. 3:

90

Thermal resistance versus lead length.

Rth(°C/W)

80

IF(av) (A)

Rth(j-a)

δ

70

60

50

40

30

Rth(j-l)

20

10

0

5 10152025

Lleads(mm)

δ = 0.5

=tp/T

δ = 1

T

tp

Fig. 2:

Average forward current versus ambient

temperature (δ=0.5).

IF(av)(A)

3.5

3.0

Rth(j-a)=Rth(j-l)

2.5

2.0

Rth(j-a)=75°C/W

1.5

1.0

0.5

0.0

0 25 50 75 100 125 150

Fig. 4:

T

δ

=tp/T

tp

Tamb(°C)

Variation of thermal impedance junction t o

ambient versus pulse duration (recommended pad

layout, epoxy FR4, e(Cu)=35µm).

Zth(j-a)/Rth(j-a)

1.00

δ = 0.5

δ = 0.2

δ = 0.1

0.10

T

Single pulse

0.01

tp(s)

1E-1 1E+0 1E+1 1E+2 5E+2

δ

=tp/T

tp

Fig. 5:

Forward voltage drop versus forward

current (maximum values).

IFM(A)

70.00

Tj=100°C

(Typical values)

10.00

Tj=25°C

1.00

0.10

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

Tj=100°C

VFM(V)

Fig. 6:

Junction capacitance versus reverse

voltage applied (typical values).

C(pF)

100

50

20

10

1 10 100 200

VR(V)

F=1MHz

Tj=25°C

3/5

Page 4

BYW98-200

Fig. 7:

Reverse recovery time versus dI

trr(ns)

100

80

Tj=100°C

/dt.

F

IF=3A

90% confidence

Tj=100°C

60

40

Tj=25°C

20

dIF/dt(A/µs)

0

1 10 100

Fig. 9:

Dynamic parameters versus junction

temperature.

%

250

200

IF=3A

dIF/dt=50A/µs

VR=30V

Qrr

Fig. 8:

dI

2.5

2.0

1.5

Peak reverse recovery current versus

/dt.

F

IRM(A)

IF=3A

90% confidence

Tj=100°C

Tj=100°C

1.0

0.5

Tj=25°C

0.0

1 10 100

dIF/dt(A/µs)

IRM

150

100

25 50 75 100 125 150

Tj(°C)

trr

4/5

Page 5

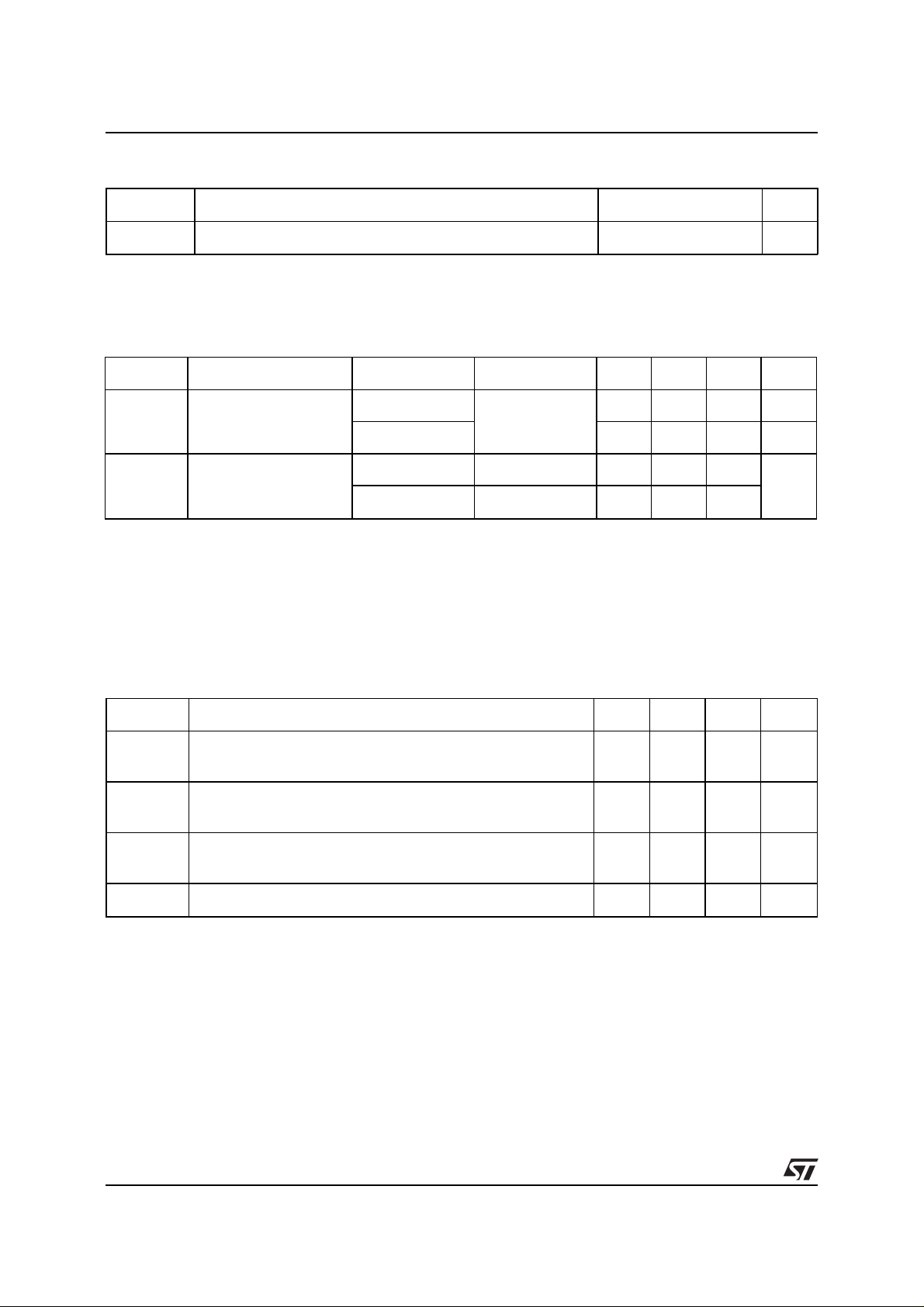

PACKAGE MECHANICAL DATA

DO-201AD

BYW98-200

BA

note 1

ØD ØD

DIMENSIONS

REF.

Millimeters Inches

Min. Max. Min. Max.

A 9.50 0.374

B 25.40 1.000

∅ C 5.30 0.209

∅ D 1.30 0.051

E 1.25 0.049

E

note 2

B

note 1

E

ØC

NOTES

1 - The lead diameter ∅ D is not controlled over zone E

2 - The minimum axial length within which the device may be

placed with its leads bent at right angles is 0.59"(15 mm)

Ordering code Marking Package Weight Base qty Delivery mode

BYW98-200 BYW98-200 DO-201AD 1.16 g. 600 Box

BYW98-200RL BYW98-200 DO-201AD 1.16 g. 1900 Tape and reel

White band indicates cathode

Epoxy meets UL94,V0

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherwi se un der any pat ent or patent rights of STMic roelec tronics. S pecifications ment ioned in t his publ ication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in li fe s upport devices or systems wi thou t ex press written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroe lectronics

© 1999 STMicroelectronics - Printed in Italy - All rights reser ved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

5/5

Loading...

Loading...