Page 1

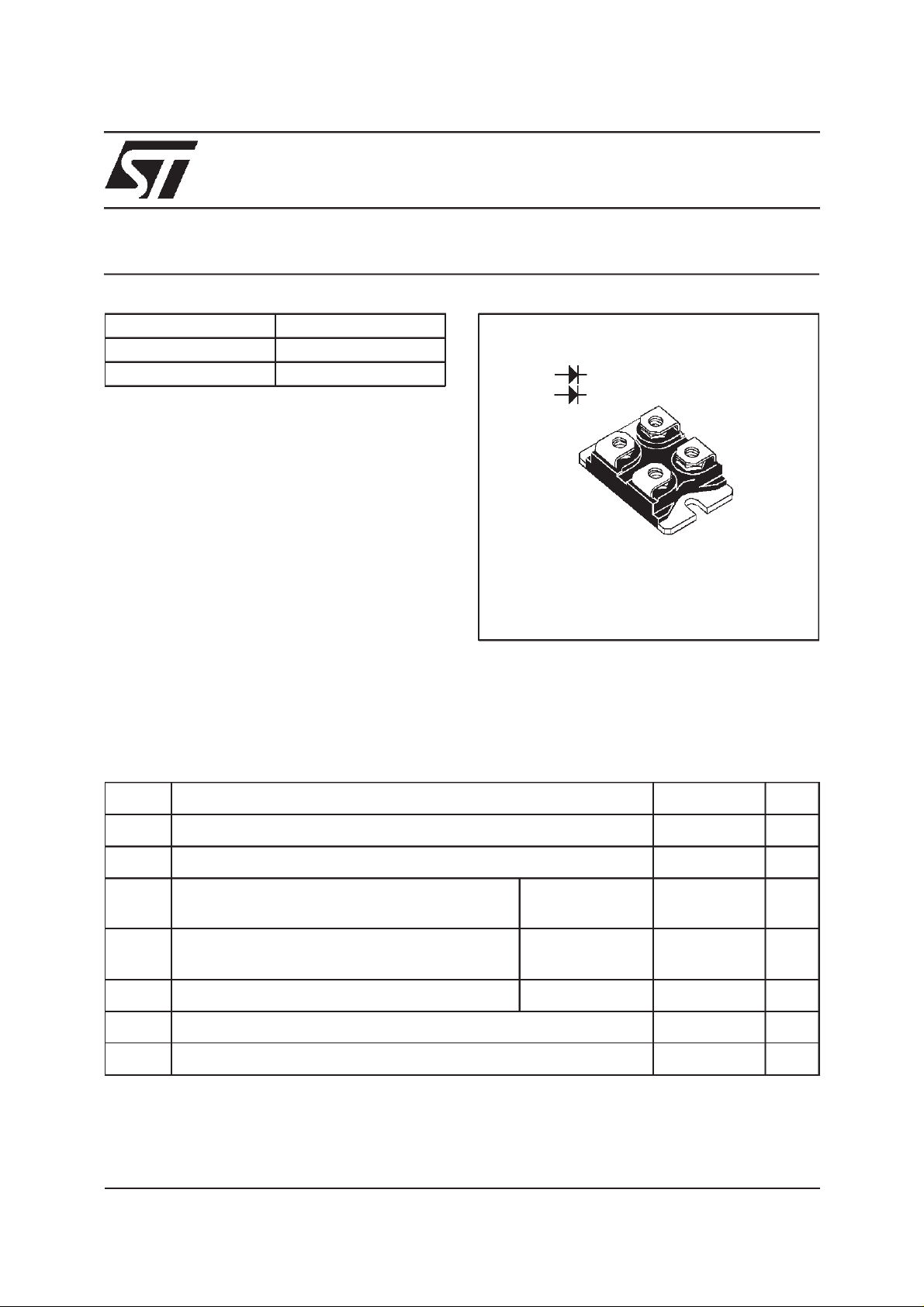

ULTRAFAST POWER RECTIFIER DIODE

MAIN PRODUCT CHARACTERISTICS

BYT200PIV-400

I

F(AV)

V

RRM

2 x100 A

400 V

VF(max) 1.4 V

FEATURES AND BENEFITS

n LOW CONDUCTION LOSSES

n NEGLIGIBLE SWITCHING LOSSES

n HIGH AVALANCHE CAPABILITY

n ISOLATED PACKAGE :

2500 V

DC

CAPACITANCE 42pF

DESCRIPTION

High current power rectifier diode suited for

Switched Mode Power Supply and high frequency

DC to DC converters.

Packaged in ISOTO P, this devic e is intended

for use in a medi um v olt age hig h c ur rent applications such as welding equipment and

Telecom supplies.

ABSOLUTE MAXIMUM RATING

A1 K1

A2 K2

4

ISOTOP

1=A1

2

3

TM

2=K1

3=A2

4=K2

1

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

F(AV)

Repetitive peak reverse voltage 400 V

RMS forward current 150 A

Average forward current Tc = 80°C

100 A

δ = 0.5

I

FSM

Surge non repetitive forward current tp = 10 ms

600 A

Sinusoidal

I

FRM

T

stg

Repetitive peak forward current tp 10 µs 800 A

Storage temperature range - 40 to + 150 °C

Tj Maximum junction temperature 150 °C

ISOTOP is atrademark of STMicroelectronics

May 2000 - Ed: 3C

1/5

Page 2

BYT200PIV-400

THERMAL RESISTANCES

Symbol Parameter Value Unit

R

th (j-c)

R

th (c)

STATIC ELECTRICAL CHARACTERISTICS (per diode)

Symbol Parameter Tests Conditions Min. Typ. Max. Unit

IR* Reverse leakage current Tj = 25°CV

VF** Forward voltage drop Tj = 25°CI

Pulse test : * tp = 5 ms, duty cycle < 2 %

RECOVERY CHARACTERISTICS

Junction to case Per leg 0.55 °C/W

Total 0.33

Coupling 0.1

R=VRRM

120 µA

Tj = 100°C 4 12 mA

= 100 A 1.6 V

F

Tj = 125°CI

** tp = 380 µs, duty cycle < 2%

= 100 A 0.95 1.4

F

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

rr

Reverse recovery time IF=0.5A IR=1A Irr=0.25A

IF=1A dI/dt= -50A/µs

55

100

Vr=30V

I

RM

Reverserecoverycurrent dIF/dt=-200A/µs Tj=125°C

40 A

VR=400V IF=100A

S factor Softness factor dIF/dt=-200A/µs Tj=125°C

0.25

VR=400V IF=100A

t

fr

Forward recovery time IF=100A dIF/dt=500A/µs

500 ns

Measured at 1.1 x VFmax.

V

FP

Peak forward voltage 12 V

Tj=25°C

To evaluate the conduction losses use the following equation :

P = 0.8 x I

+ 0.00228 x I

F(AV)

F2(RMS)

ns

2/5

Page 3

BYT200PIV-400

Fig. 1: Average forward power dissipation versus

average forward current (per diode).

PF(av)(W)

140

120

100

80

δ = 0.2

δ= 0.1

δ = 0.05

δ = 0.5

δ =1

60

40

20

0

0 102030405060708090100110120130

IF(av)(A)

Fig. 3: Average forward current versus ambient

temperature (δ = 0.5, per diode).

IF(av)(A)

120

100

80

60

40

20

0

0 25 50 75 100 125 150

Rth(j-a)=Rth(j-c)

Rth(j-a)=2°C/W

Tamb(°C)

Fig. 2:Peak currentversus form factor(perdiode).

IM(A)

500

400

300

200

P=75W

P=100W

P=125W

P=150W

100

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

δ

Fig. 4: Non repetitive surge peak forward current

versus overload duration (per diode).

IM(A)

700

600

500

400

300

200

100

0

1E-3 1E-2 1E-1 1E+0

t(s)

Tc=50°C

Tc=75°C

Tc=100°C

Fig. 5: Relative variation of thermal impedance

junction to case versus pulse duration (per diode).

K=[Zth(j-c)/Rth(j-c)]

1.0

δ = 0.5

0.5

δ = 0.2

δ = 0.1

0.2

Single pulse

0.1

1E-3 1E-2 1E-1 1E+0

tp(s)

Fig. 6: Forwardvoltage drop versus forward current

(maximumvalues,perdiode).

IFM(A)

500

100

10

1

0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50

Tj=125°C

Tj=25°C

VFM(V)

3/5

Page 4

BYT200PIV-400

Fig. 7: Junctioncapacitance versusreversevoltage

applied(typicalvalues, perdiode).

C(pF)

500

450

F=1MHz

Tj=25°C

400

350

300

250

200

150

100

1 10 100 200

VR(V)

Fig. 9:Recovery current versusdIF/dt(perdiode).

IRM(A)

50

IF=IF(av)

90% confidence

45

Tj=125°C

40

35

30

25

20

15

10

5

0

0 100 200 300 400 500

dIF/dt(A/µs)

Fig. 8: Recoverycharges versusdIF/dt(perdiode).

Qrr(µC)

3.0

2.5

IF=IF(av)

90% confidence

Tj=125°C

2.0

1.5

1.0

0.5

0.0

0 100 200 300 400 500

dIF/dt(A/µs)

Fig. 10: Transient peak forward voltage versus

dIF/dt (per diode).

VFP(V)

14

IF=IF(av)

90% confidence

12

Tj=125°C

10

8

6

4

2

0

0 100 200 300 400 500 600 700 800

dIF/dt(A/µs)

Fig. 11: Dynam ic parameters versus junction

temperature.

Qrr;IRM[Tj] / Qrr;IRM[Tj=125°C]

1.25

1.00

0.75

0.50

0.25

0.00

0 25 50 75 100 125 150

4/5

IRM

Qrr

Tj(°C)

Page 5

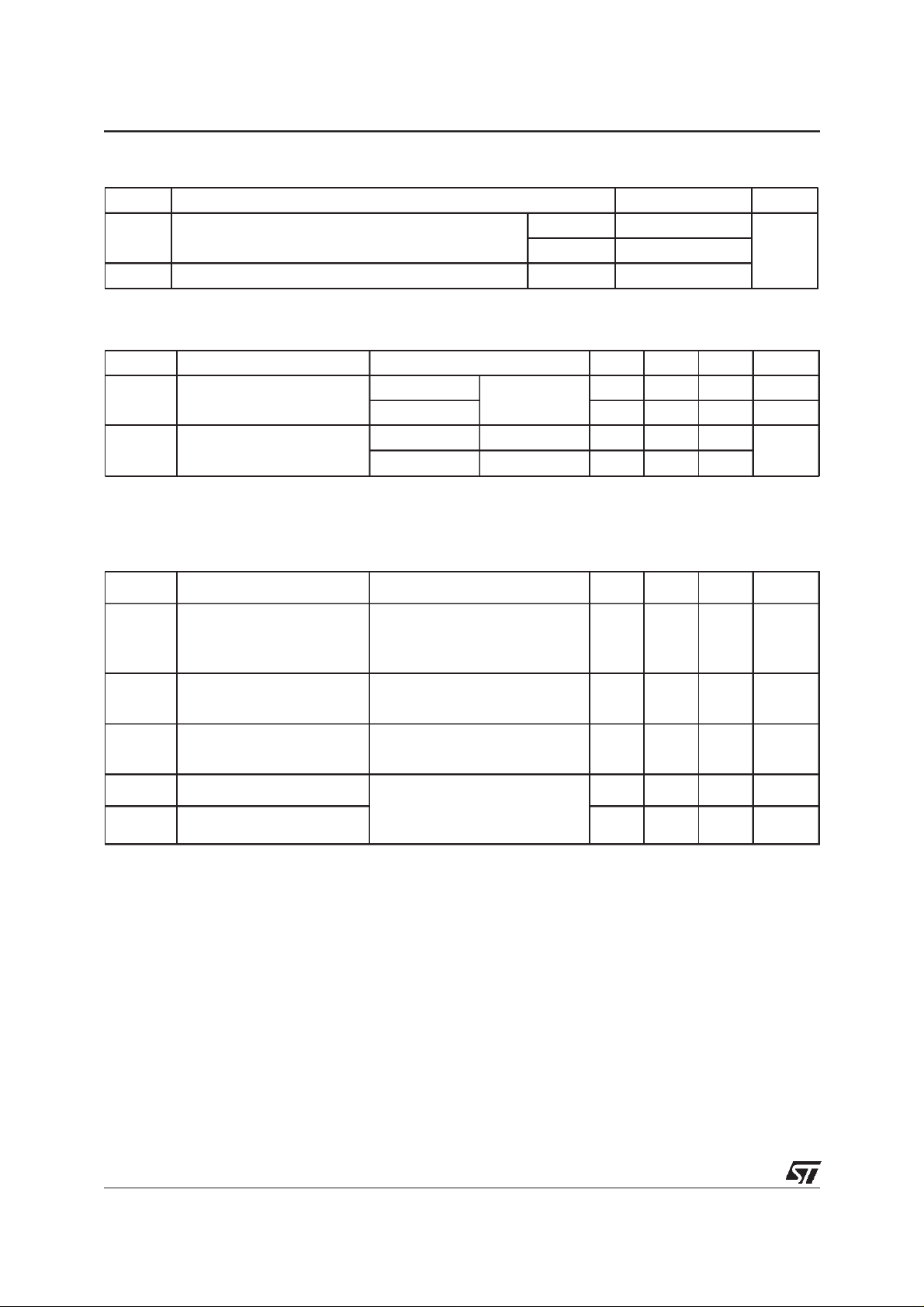

PACKAGE MECHANICAL DATA

ISOTOP

BYT200PIV-400

DIMENSIONS

REF.

A 11.80 12.20 0.465 0.480

A1 8.90 9.10 0.350 0.358

B 7.8 8.20 0.307 0.323

C 0.75 0.85 0.030 0.033

C2 1.95 2.05 0.077 0.081

D 37.80 38.20 1.488 1.504

D1 31.50 31.70 1.240 1.248

E 25.15 25.50 0.990 1.004

E1 23.85 24.15 0.939 0.951

E2 24.80 typ. 0.976 typ.

G 14.90 15.10 0.587 0.594

G1 12.60 12.80 0.496 0.504

G2 3.50 4.30 0.138 0.169

F 4.10 4.30 0.161 0.169

F1 4.60 5.00 0.181 0.197

P 4.00 4.30 0.157 0.69

P1 4.00 4.40 0.157 0.173

S 30.10 30.30 1.185 1.193

Millimeters Inches

Min. Max. Min. Max.

n Epoxy meets UL94, V0

Information furnished is believed to beaccurate andreliable. However, STMicroelectronicsassumes noresponsibilityfor the consequencesof

use ofsuch information norfor any infringementof patentsorother rights of thirdparties whichmay result from its use. Nolicenseis grantedby

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice.This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical componentsin life support devices orsystems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

5/5

Loading...

Loading...