Page 1

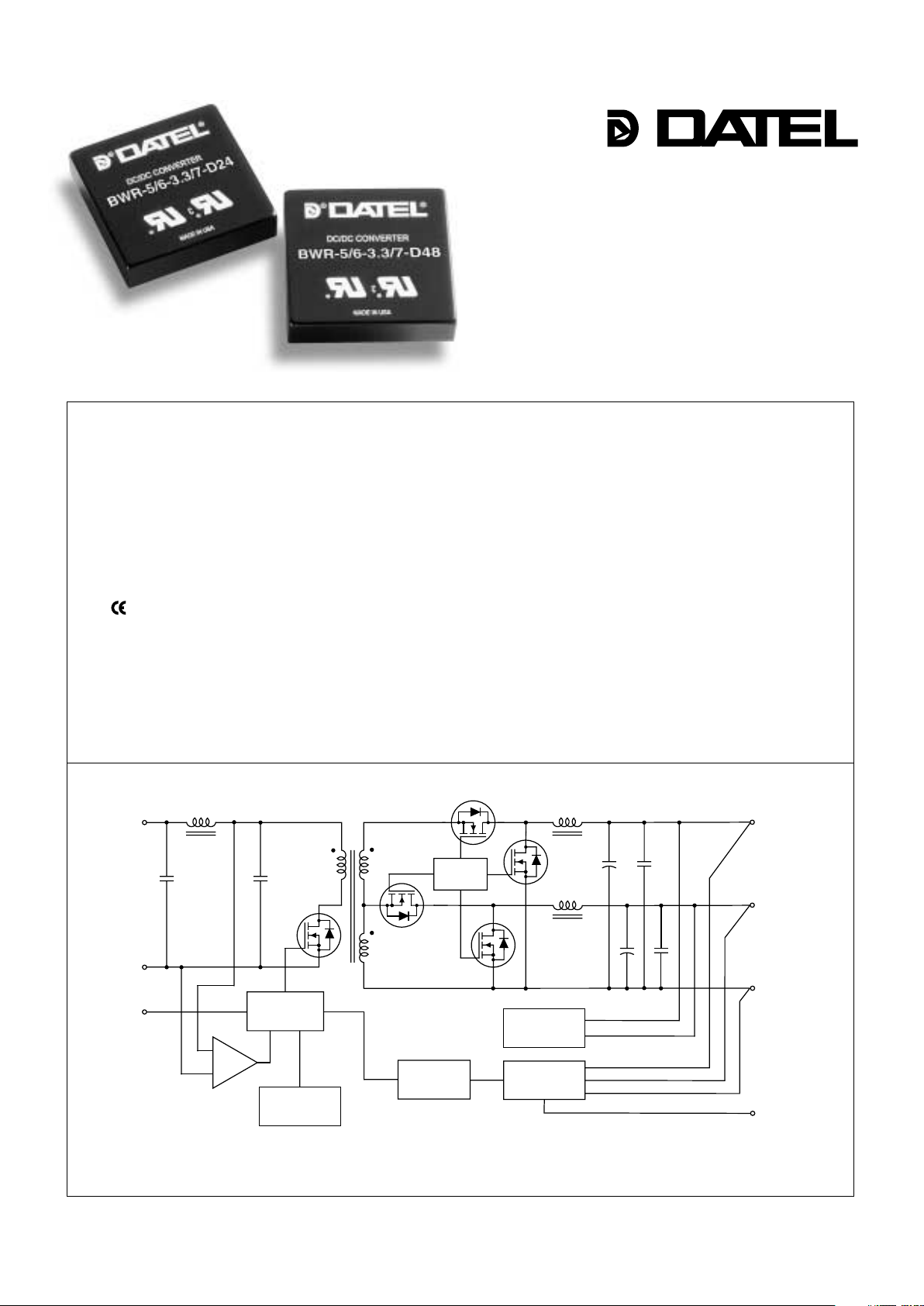

5V and 3.3V, 2" x 2"

33 Watt, DC/DC Converters

Dual Output

Mixed Voltage, BWR Models

Features

Figure 1. Simplifi ed Schematic

INNOVATION and EX C ELL E N C

E

®

®

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Regulated 3.3V and 5V outputs

5V @ 6Amps/3.3V @ 7 Amps capability

33 Watts total output power

No-load operation

Available input voltage ranges:

10-18V, 18-36V or 36-75V

Small 2" x 2" x 0.45" package

UL1950 and EN60950 safety approvals

mark available (75V-input models)

Continuous short-circuit protection

Fully isolated, 1500Vdc guaranteed

–40 to +100°C operating temperature

Input under and overvoltage shutdown

Output overvoltage protection

Thermal shutdown

DATEL, Inc., Mansfi eld, MA 02048 (USA) · Tel: (508)339-3000, (800)233-2765 Fax: (508)339-6356 · Email: sales@datel.com · Internet: www.datel.com

+INPUT

–INPUT

SWITCH

CONTROL

+5V OUTPUT

+3.3V OUTPUT

OUTPUT

RETURN

TRIM

PWM

CONTROLLER

REFERENCE &

ERROR AMP

OPTO

ISOLATION

ON/OFF

CONTROL

(SYNC)

UV & OV

COMPARATORS

ACTIVE

BLEEDER

THERMAL

SHUTDOWN

For applications requiring 33 Watts of power from 5V and 3.3V, DATEL offers a

new power sharing DC/DC converter capable of meeting your output current requirements. The BWR-5/6-3.3/7-D48 (36-75V input), BWR-5/6-3.3/7-D24 (18-36V input)

and BWR-5/6-3.3/7-D12 (10-18V input) are fully isolated DC/DC converters capable

of delivering any combination of 5V and 3.3V loading up to a combined total of 33

Watts of output power.

Housed in a standard 2" x 2" x 0.45" metal package coated with electrically nonconductive fi nish, these conv erters utilize a shared control-loop system to assure load

regulation of ±1% for 3.3V output and ±1.5% for 5V output. All models include input

Pi fi ltering, input overvoltage and undervoltage shutdown circuitry, output overvoltage

protection, output short-circuit and current limiting protection, and thermal shutdown.

Each design also provides trim capability, on/off control function, or an optional sync

control. Fully synchronous output rectifi cation renders high effi ciency and no-load

operation.

BWR power sharing modules offer low ripple and noise performance, high

effi ciency (88%), 1500Vdc of isolation voltage, and are fully specifi ed for –40

to +100°C operation. These devices meet IEC950, UL1950 and EN6950 safety

standards, including BASIC insulation requirements for "D48" models. CB reports

are available on request. "D48" models are CE marked (meet LVD requirements).

Page 2

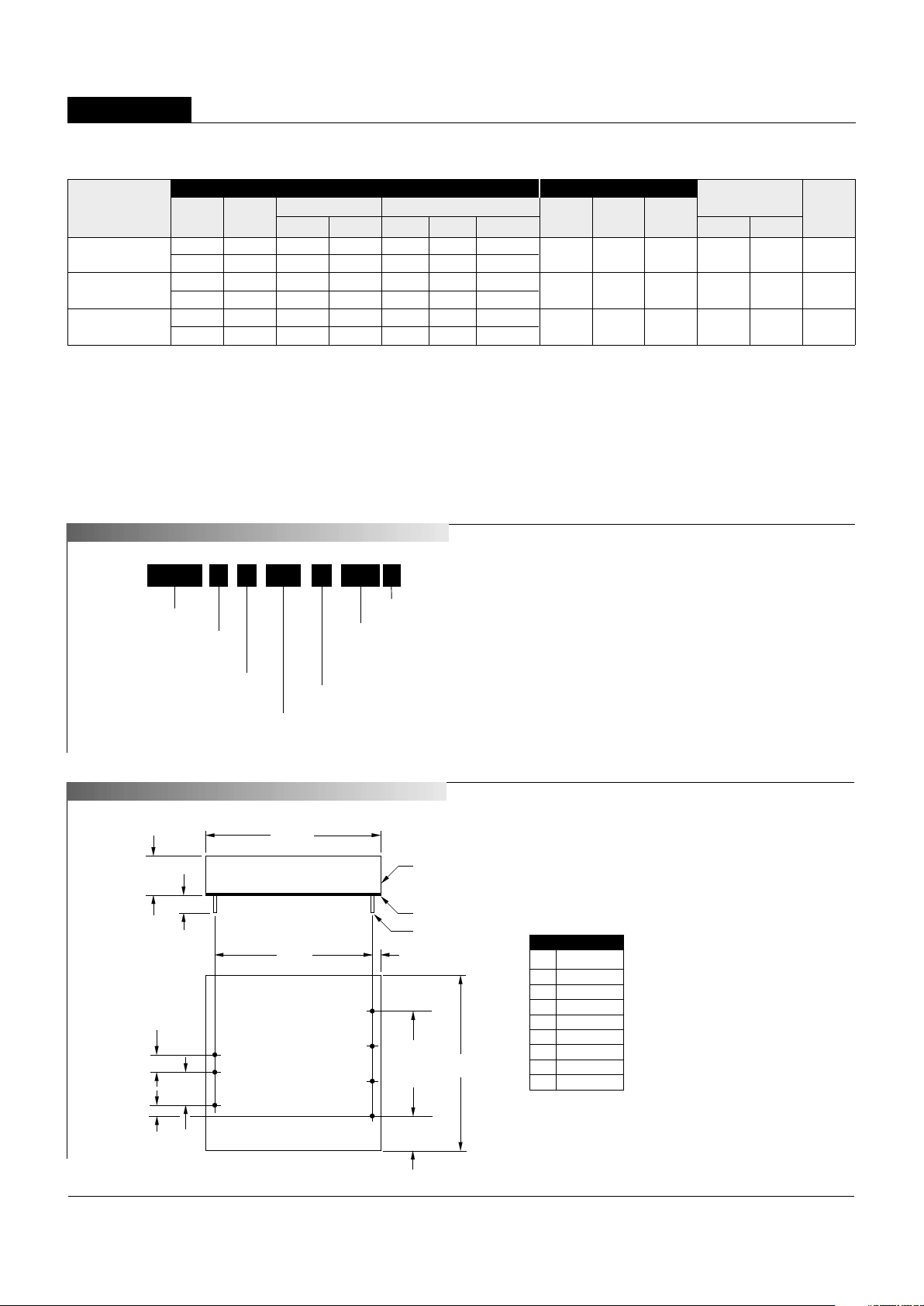

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

XWR Series

Performance Specifi cations and Ordering Guide

➀

PART NUMBER STRUCTURE

V1 Nominal Output Voltage:

5 Volts

5

BWR

6-

/

D48-

Input Voltage Range:

D12 = 10-18 Volts (12V nominal)

D24 = 18-36 Volts (24V nominal)

D48 = 36-75 Volts (48V nominal)

I

1 Maximum Output Current:

6 Amps

Dual Output/

Mixed-Voltage Series

3.3 7

/

-

S

V2 Nominal Output Voltage:

3.3 Volts

I2 Maximum Output Current:

7 Amps

Add "S" suffi x as desired

Part Number Suffi xes

BWR 33 Watt DC/DC's are designed so an On/Off Control function

with positive polarity (no suffi x) or a Sync function ("S" suffi x) can be

added in the pin 4 position.

No Suffi x On/Off Control function (positive polarity) on pin 4

S Suffi x Sync function on pin 4

BWR-5/6-3.3/7-D12

5 6 40 100 ±1% ±1.5% ±2.5%

12 10-18 70/3308 83% 86% C4, P33

3.3 7 95 140 ±0.5% ±1% ±1.5%

BWR-5/6-3.3/7-D24

5 6 40 100 ±1% ±1.5% ±2.5%

24 18-36 50/1615 85% 88% C4, P33

3.3 7 95 140 ±0.5% ±1% ±1.5%

BWR-5/6-3.3/7-D48

5 6 40 100 ±1% ±1.5% ±2.5%

48 36-75 25/780 85% 88% C4, P33

3.3 7 95 140 ±0.5% ±1% ±1.5%

➀ Typical at TA = +25°C under nominal line voltage and balanced "full-load" conditions (5V @ 3.3A/3.3V @ 5A).

➁ Any combination of 5V/3.3V rated I

OUT current, not to exceed 33 Watts of output power. (See derating graphs.)

➂ Ripple/Noise (R/N) measured over a 20MHz bandwidth. All models are specifi ed with 1µF ceramic

output capacitors.

Output

Input

➃ Tested from 10% load to 100% load (other output at 10% load).

➄ Nominal line voltage, no load/balanced full-power condition.

➅ Tested from no-load to 100% load (other output at no-load).

➆ Output trim may impact 5V load regulation.

R/N (mVp-p) ➂ Regulation (Max.)

➆

Effi ciency

Packag e

V

OUT IOUT ➁ VIN Nom. Range IIN ➄ (Case,

Model (Volts) (Amps) Typ. Max. Line Load ➃ No Load ➅ (Volts) (Volts) (mA) Min. Typ. Pinout)

MEC ANICAL SPECIFI CATIONS

2

BOTTOM VIEW

1.800

(45.72)

0.10

(2.54)

2.00

(50.80)

8

5

6

7

0.40

(10.16)

0.200

(5.08)

0.400

(10.16)

0.100

(2.54)

1

2

4

METAL CASE

INSULATED BAS

E

0.040 ±0.002 DIA.

(1.016 ±0.051)

2.00

(50.80)

0.20 MIN

(5.08)

0.45

(11.43)

1.200

(30.48)

3 EQ. SP. @

0.400 (10.16)

I/O Connections

Pin Function P33

1 +Input

2 –Input

3 No Pin

4 On/Off Control

5 +5V Output

6 Output Return

7 +3.3V Output

8 Trim

Notes:

For "D12" and "D24" models

the case is connected to

pin 2 (–Input).

For "D48" models, the case

is connected to pin 1 (+Input).

Case C4

Page 3

BWR Models

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

Performance/Functional Specifi cations

Typical @ TA = +25°C under nominal line voltage, balanced "full-load" conditions, unless noted. ➀

Input

Input Voltage Range:

D12 Models 10-18 Volts (12V nominal)

D24 Models 18-36 Volts (24V nominal)

D48 Models 36-75 Volts (48V nominal)

Overvoltage Shutdown:

➁

D12 Models 19-23 Volts (21V nominal)

D24 Models 37-42 Volts (40V nominal)

D48 Models 77-81 Volts (79V nominal)

Start-Up Threshold:

➁

D12 Models 9-10 Volts (9.3V nominal)

D24 Models 16.5-18 Volts (17V nominal)

D48 Models 34-36 Volts (35V nominal)

Undervoltage Shutdown:

➁

D12 Models 8.5-9.6 Volts (9.3V nominal)

D24 Models 16-17 Volts (16.5V nominal)

D48 Models 32.5-35 Volts (34V nominal)

Input Current:

Normal Operating Conditions See Ordering Guide

Standby Mode:

Off, OV, UV, Thermal Shutdown 10mA typical

Input Refl ected Ripple Current:

Source Impedance <0.1Ω, no external input fi ltering

D12 Models 200mAp-p (150mAp-p typical)

D24/D48 Models 250mAp-p (225mAp-p typical)

Internal Input Filter Type Pi (0.022µF - 4.7µH - 2.46µF)

Reverse-Polarity Protection:

➁

D12 Models 1 minute duration, 6A maximum

D24 Models 1 minute duration, 4A maximum

D48 Models 1 minute duration, 2A maximum

On/Off Control (Pin 4):

➁ ➂ ➃ ➅

D12, D24 & D48 Models On = open or 13V - +V

IN, IIN = 50µA max.

Off = 0-0.8V, I

IN = 1mA max.

Sync (Option, Pin 4): ➁ ➂ ➃

Input Threshold (Rising Edge Active) 1-2.7 Volts

Input Voltage Low 0-0.9 Volts

Input Voltage High 2.8-5 Volts

Input Resistance 35kΩ minimum

Output High Voltage (100µA load) 3.5-4.8 Volts

Output Drive Current 35mA

Input/Output Pulse Width 160-360nsec

Output

VOUT Accuracy

5V Output ±3% maximum

3.3V Output ±1.5% maximum

Minimum Loading Per Specifi cation No load, see Performance Specifi cations

Ripple/Noise (20MHz BW)

➁ ➄ See Ordering Guide

Line/Load Regulation

➁ See Ordering Guide

Effi ciency See Ordering Guide / Effi ciency Cur ves

Cross Regulation:

➁

5V Output (5V@0.6A, 3.3V@0.7-7A) ±6% maximum

3.3V Output (3.3V@0.7A, 5V@0.6-6A) ±0.5% maximum

Trim Range

➁ ±5%

Isolation Voltage:

Input-to-Output 1500Vdc minimum

Isolation Capacitance 470pF

Isolation Resistance 100MΩ

Temperature Coeffi cient ±0.02%/per°C

Output (continued)

Current Limit Inception: ➁

5V @ 95% VOUT (3.3V @ 0A) 7.6 -9.0 Amps

3.3V @ 98.5% V

OUT (5V @ 0A) 11.3 -12.7 Amps

Short Circuit Current:

➁

5V Output 5 Amps average, continuous

3.3V Output 6 Amps average, continuous

Overvoltage Protection:

➁ Magnetic feedback

5V Output 6.8 volts

3.3V Output 4.5Volts

Maximum Capacitive Loading

D12 Models 3.3V 1000µF

5V 470µF

D24, D48 Models 3.3V 2000µF

5V 1000µF

Dynamic Characteristics

Dynamic Load Response: ➁

5V (50-100% load step to 4% V

OUT) 300µsec maximum

3.3V (50-100% load step to 2.5% V

OUT) 300µsec maximum

Start-Up Time: ➁

V

IN to VOUT 20msec maximum

On/Off to V

OUT 15msec maximum

Switching Frequency 285kHz (±15kHz)

Environmental

MTBF ➆ Bellcore, ground fi xed, full power, +25°C

operating ambient temperature

D12 Models 1.3 million hours

D24/D48 Models 1.67 million hours

Operating Temperature (Ambient):

➁

Without Derating:

D12 Models –40 to +50°C

D24 Models –40 to +60°C

D48 Models –40 to +68°C

With Derating To +100°C (See Derating Curves)

Case Temperature:

Maximum Operational +100°C

For Thermal Shutdown

➁ +110°C minimum, +117°C maximum

Storage Temperature –40 to +120°C

Physical

Dimensions 2" x 2" x 0.45" (50.8 x 50.8 x 11.43mm)

Internal Case Connection:

D12/D24 Models –Input (Pin 2)

D48 Models +Input (Pin 1)

Case Material Corrosion resistant steel with

non-conductive, epoxy-based, black

enamel fi nish and plastic baseplate

Pin Material Brass, solder coated

Weight: 2.7 ounces (76.5 grams)

Primary to Secondary Insulation Level

D12/D24 Models Operational

D48 Models Basic

➀ Balanced "full-load" is 5V @ 3.3A/3.3V @ 5A. All models are specifi ed with external

1µF ceramic output capacitors.

➁ See Technical Notes/Graphs for details.

➂ Devices may be ordered with On/Off Control function or a Sync function.

See Part Number Suffi xes and Technical Notes for details.

➃ Applying a voltage to On/Off Control (pin 4) when no input power is applied to the

converter may cause permanent damage.

➄ Output noise may be further reduced with the installation of additional external output

capacitors. See Technical Notes.

➅ On/Off control is designed to be driven with open collector or by appropriate voltage

levels. Voltages must be referenced to the input return pin (–Input).

➆ Demonstrated MTBF available on request.

3

Page 4

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

XWR Series

4

Absolute Maximum Ratings

Input Voltage:

Continuous: "D12" Models 23 Volts

"D24" Models 42 Volts

"D48" Models 81 Volts

Transient (100msec): "D12" Models 25 Volts

"D24" Models 50 Volts

"D48" Models 100 Volts

Input Reverse-Polarity Protection

➁ Input Current must be limited. 1 minute

duration. Fusing recommended.

"D12" Models 6 Amps

"D24" Models 4 Amps

"D48" Models 2 Amps

Output Current

➁ Current limited. Devices can withstand

an indefi nite output short circuit.

On/Off Control (Pin 4) Max. Voltages

Referenced to –Input (pin 2)

No Suffi x +V

IN

"S" Suffi x +5.7 Volts

Storage Temperature –40 to +120°C

Lead Temperature (Soldering, 10 sec.) +300°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifi cations Table is not implied, nor recommended.

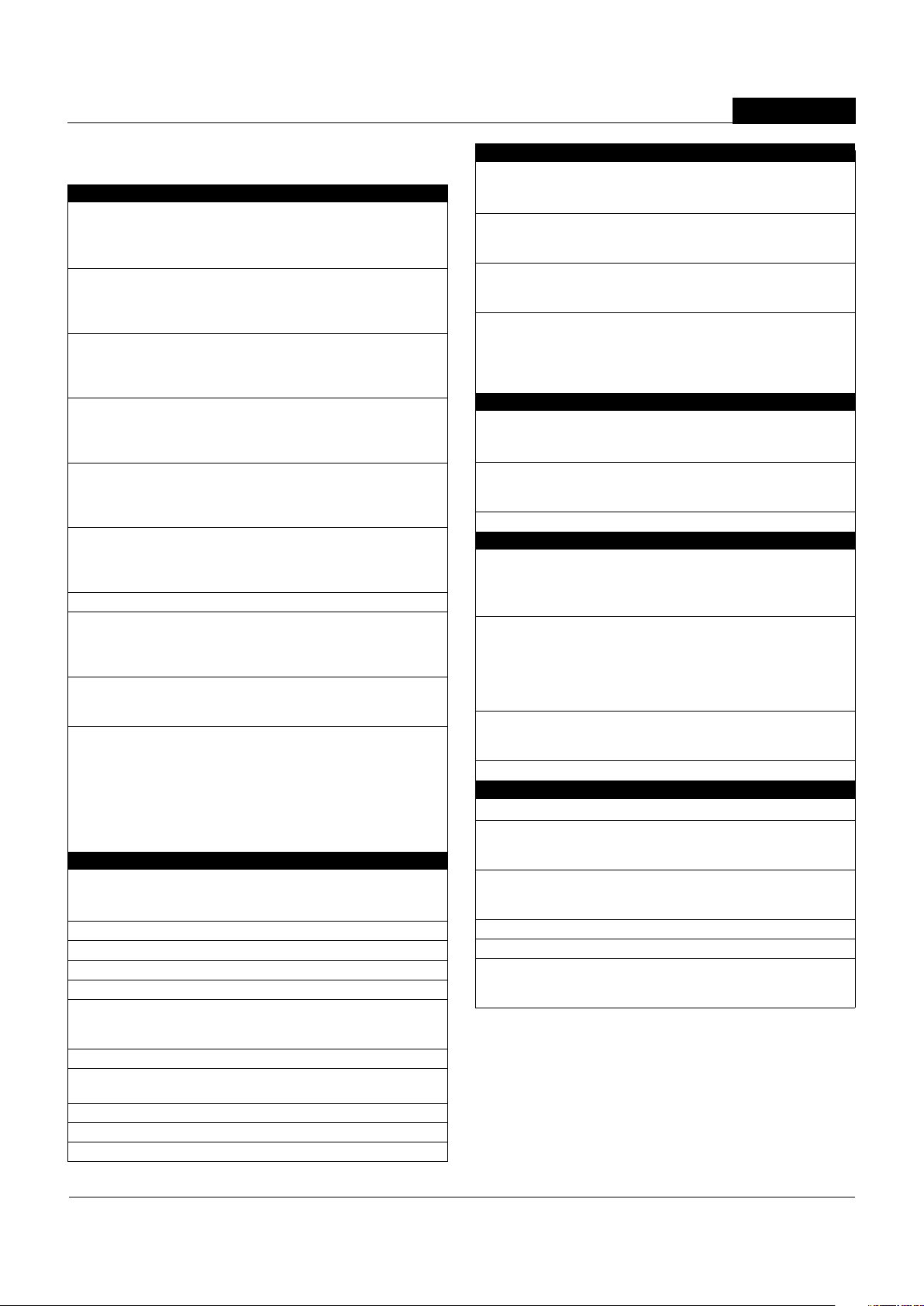

TECHNICAL NOTES

5V & 3.3V Regulation

The BWR 33 Watt Series converters are designed such that both the 5V and

3.3V outputs share a common regulation feedback control loop. Though the

feedback loop is infl uenced by both outputs, the 3.3 Volt output is dominant.

As a result, the 3.3 Volt regulation (1%) is superior to the 5 Volt regulation (4%).

The converters are specifi ed for load regulation of 10% to 100% loading and

for no-load to 100% loading. Operation below 10% of full load mandates

an increase in the regulation tolerance of ±0.5% for 3.3 Volt output and an

increase of ±1% for the 5 Volt output. A slight increase in switching noise

may also be observed for operation below 10% loading.

Operation with a full load on 3.3 Volt output and light to no load on 5 Volt

output is the most demanding for +5V regulation. Under such conditions the

internal "bleeder" circuit is activated to provide an internal load thereby keep-

ing regulation within the published specifi cations. The bleeder is activated

gradually so as not to cause any erratic behavior on the converters outputs. A

slight degradation in effi ciency will occur while this internal load is activated.

Filtering and Noise Reduction

The BWR 33 Watt Series Converters achieve their rated ripple and noise

specifi cations with the use of 1µF output capacitors. In critical applications,

input/output noise may be further reduced by installing additional external

I/O capacitors. Input capacitors should be selected for bulk capacitance,

low ESR and high rms-ripple-current ratings. Output capacitors should be

selected for low ESR and appropriate frequency response. All caps should

have appropriate voltage ratings and be located as close to the converter

as possible.

Start-Up Time

The V

IN to VOUT start-up time is the interval of time where the input voltage

crosses the turn-on threshold point, and the fully loaded output voltage enters

and remains within its specifi ed accuracy band. Actual measured times will

vary with input source impedance, external input/output capacitance, and the

slew rate of the input voltages. The BWR-5/6-3.3/7 Series implements a

soft start circuit that limits the duty cycle of the PWM controller at power up,

thereby limiting the Input Inrush current.

The On/Off Control to V

OUT start-up time assumes the converter has its

nominal input voltage applied but is turned off via the On/Off Control pin.

The specifi cation defi nes the interval between the time at which the converter

is turned on and the fully loaded output voltage enters and remains within

its specifi ed accuracy band. Similar to the V

IN to VOUT start-up, the On/Off

Control to V

OUT start-up time is also governed by the internal soft start

circuitry and external load capacitance.

Input Overvoltage/Undervoltage Shutdown and Start-Up Threshold

Under normal start-up conditions, devices will not begin to regulate until

the ramping-up input voltage exceeds the Start-Up Threshold Voltage (35V

for "D48" models). Once operating, devices will not turn off until the input

voltage drops below the Undervoltage Shutdown limit (34V for "D48" models).

Subsequent re-start will not occur until the input is brought back up to the

Start-Up Threshold. This built in hysteresis prevents any unstable on/off

situations from occurring at a single input voltage.

Input voltages exceeding the input overvoltage shutdown specifi cation listed

in the Performance/Functional Specifi cations will cause the device to shut-

down. A built-in hysteresis of 0.6 to 1.6 Volts for all models will not allow the

converter to restart until the input voltage is suffi ciently reduced.

On/Off Control

The On/Off Control (pin 4) may be used for remote on/off operation. As

shown in Figure 1, the control pin is referenced to the –Input (pin 2) and will

be internally pulled to a high state. The standard BWR model (no suffi x) is

designed so that it is enabled when the control pin is left open and disabled

when the control pin is pulled low (less than +0.8V relative to –Input).

Dynamic control of the on/off function is best accomplished with a mechanical

relay or an open-collector/open-drain circuit (optically isolated if appropriate).

The drive circuit should be able to sink approximately 1 mA for logic low.

The on/off control function is designed such that the converter can be

disabled while the input power is ramping up, and then "released" once the

input has stabilized.

Figure 1. Internal Circuitry for No Suffi x Models

4

2

1

R

A

RB

+INPUT

–INPUT

ON/OFF

CONTROL

D12 RA = 34.8kΩ, RB = 6.83kΩ

D24 R

A = 100kΩ, RB = 9.74kΩ

D48 R

A = 100kΩ, RB = 4.53kΩ

Page 5

BWR Models

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

5

Sync Function (Optional)

In critical applications employing multiple switching DC/DC converters, it

may be necessary to synchronize the switching of selected converters.

These BWR converters offer an optional Sync function ("S" suffi x) in place

of the On/Off Control on pin 4. The Sync pin will self confi gure as either

a slave or master, depending on the application. If the Sync pin detects

the appropriate input signal it will confi gure itself as a slave, if no signal is

detected it will generate master Sync pulses.

Synchronization of converters requires that the master switching frequency

exceed the slave frequency by a minimum of 60kHz. At the start of each

DC/DC converter switching cycle, an internally generated 160-360ns pulse

will be present at the Sync pin. If, however, the unit receives an external

Sync pulse, the DC/DC converter’s switching cycle will be reset, and a new

cycle initiated. Since the master frequency is higher than the slave’s switching

frequency, the slave cycles are always terminated prematurely, thereby never

allowing internal Synch pulses to be generated. The external signal’s rising

edge initiates the slave Sync process. External signals must adhere to min./

max. limits stated in Performance/Functional Specifi cations.

Operating these BWR converters at higher switching frequencies via the

external Sync function will result in a slight degradation of effi ciency.

Contact the DATEL for further information.

Current Limiting

When power demands from either output fall within 126% to 181% of the rated

output current, the DC/DC converter will go into a current limiting mode. In

this condition both output voltages will decrease proportionately with increases

in output current, thereby maintaining a somewhat constant power dissipa-

tion. This is commonly referred to as power limiting (see Figures 2a and

2b). Current limit inception is defi ned as the point where the full-power output

voltage falls below the specifi ed tolerance. If the load current being drawn

from the converter is signifi cant enough, the unit will go into a short circuit

condition. See "Short Circuit Condition."

Short Circuit Condition

When a converter is in current limit mode the output voltages will drop as the

output current demand increases (see fi gures 2a and 2b). If the output volt-

age drops too low, the magnetically coupled voltage used to develop primary

side voltages will also drop, thereby shutting down the PWM controller.

Following a time-out period of 5 to 15 milliseconds, the PWM will restart,

causing the output voltages to begin ramping to their appropriate values. If

the short-circuit condition persists, another shutdown cycle will be initiated.

This on/off cycling is referred to as "hiccup" mode. The hiccup cycling

reduces the average output current, thereby preventing internal temperatures

from rising to excessive levels. The BWR is capable of enduring an indefi nite

short circuit output condition.

Thermal Shutdown

These BWR converters are equipped with Thermal Shutdown Circuitry. If

the internal temperature of the DC/DC converter rises above the designed

operating temperature, a precision temperature sensor will power down the

unit. When the internal temperature decreases below the threshold of the

temperature sensor the unit will self start.

Output Overvoltage Protection

Both output voltages are monitored for an overvoltage condition via magnetic

coupling to the primary side. If either output voltage should rise to a level

which could be damaging to the load circuitry, the sensing circuitry will power

down the PWM controller causing the output voltages to decrease. Following

a time-out of 5 to 15 milliseconds the PWM will restart, causing the output

voltages to ramp to their appropriate values. If the fault condition persists,

and the output voltages again climb to excessive levels, the overvoltage

circuitry will initiate another shutdown cycle. This on/off cycling is referred

to as "hiccup" mode.

Figure 2a. Current Limiting Characteristics for 3.3V Output

Figure 2b. Current Limiting Characteristics for 5V Output

4

3

2

1

0

0 2 4 6 8 101214

3.3 V

OUT Average Ouput Current (Amps)

Typical Current Limiting Characteristics for 3.3V Output

(5V Output @ 600mA)

Ouput Voltages (Volts)

VIN NOM, VIN LO All Models

VIN HI D12, D24 Models

V

IN HI

D48 Models

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0123456789

5 V

OUT Average Ouput Current (Amps)

Ouput Voltages (Volts)

VIN NOM, VIN LO

All Models

V

IN HI D12, D24

Models

V

IN HI

D48 Models

Typical Current Limiting Characteristics for 5V Output

(3.3V Output @ 700mA)

Page 6

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

XWR Series

Isolation / Case Connection

The BWR 33 Watt Series’ 5V and 3.3V outputs (pins 5 & 7) and return (pin

6) are isolated from the +V

IN and –VIN inputs (pins 1 & 2) via a transformer

and an opto-coupled transistor. Case connections are made internal to the

DC/DC converter. "D12 & D24" cases are connected to –Input (pin 2), "D48"

to +Input (pin 1).

Input Reverse-Polarity Protection

Upon applying a reverse-polarity voltage to the DC/DC converter, an internal

diode will be forward biased, drawing excessive current from the power

source. Therefore, it is required that the input current be limited be either an

appropriately rated input fuse or a current limited power source.

Input Fusing

Certain applications and/or safety agencies may require the installation of

fuses at the inputs of power conversion components. Fuses should also

be used if the possibility of a sustained, non-current-limited, input-voltage

polarity reversal exists. For DATEL BWR 33 Watt Series Converters, slow

blow fuses are recommended with values no greater than the following.

V

IN Range Fuse Value

"D12" Models 6 Amps

"D24" Models 4 Amps

"D48" Models 2 Amps

It is recommended that fuses be installed in the +Input line.

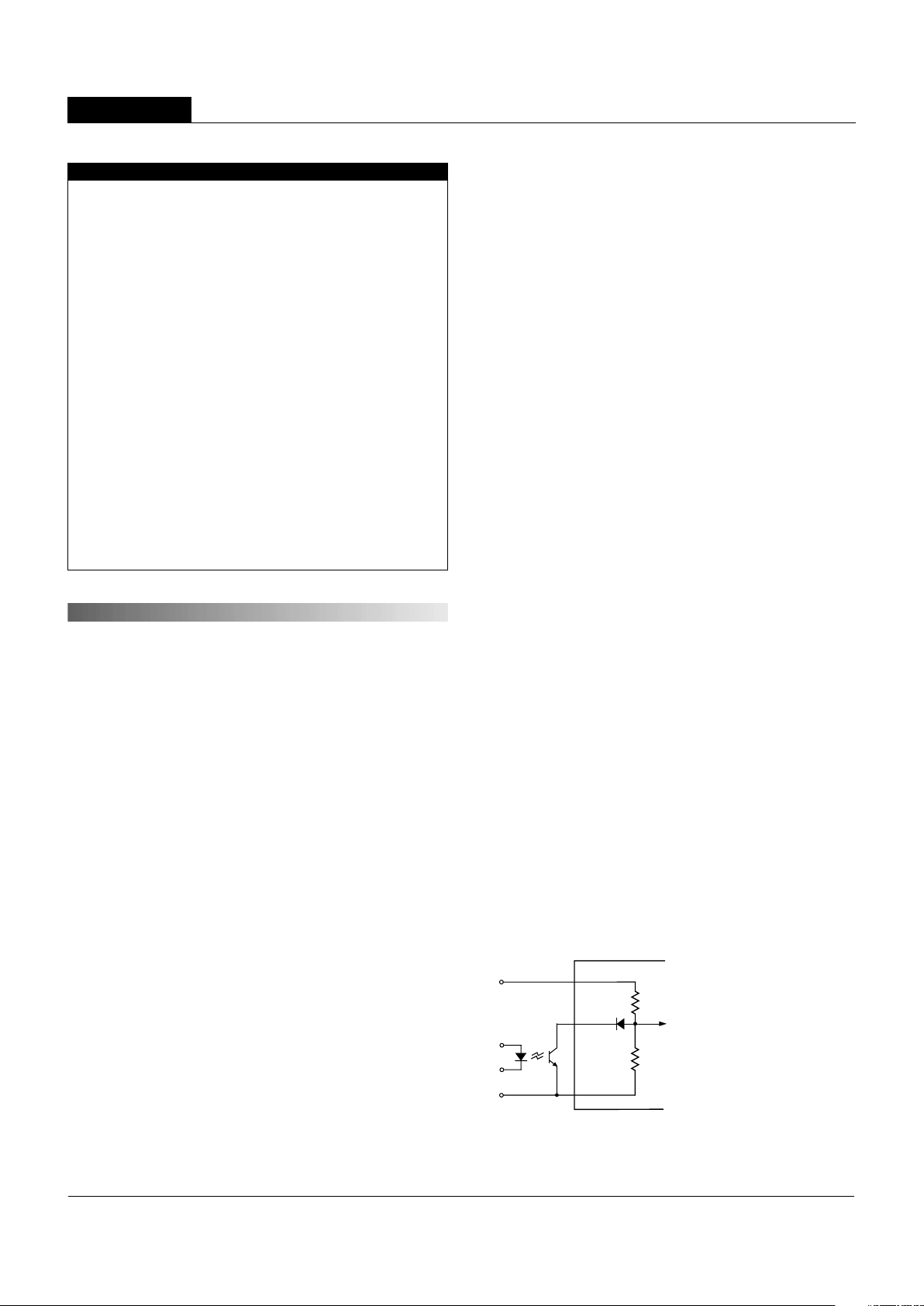

Trimming Output Voltages

These BWR converters have a trim capability (pin 8) that allow users to

adjust the output voltages ±5%. A trim adjustment will cause an equal

percentage of change in both outputs. Adjustments to the output voltages

can be accomplished via a trim pot Figure 3 or a single fi xed resistor as

shown in Figures 4 and 5. A single fi xed resistor can increase or decrease

the output voltage depending on its connection. Fixed resistors should

be metal-fi lm types with absolute TCR’s less than 100ppm/°C to minimize

sensitivity to changes in temperature.

A single resistor connected from the Trim Pin (pin 8) the +3.3V Output (pin

7), see Figure 4, will decrease the output voltages. A resistor connected

from the Trim Pin (pin 8) to Output Return (pin 6) will increase the output

voltages.

Table 1 shows the typical Trim Resistor values for output voltage changes

of 1 through 5%.

Trim adjustment greater than 5% can have an adverse affect on the convert-

er’s performance and is not recommended.

20kΩ

5-22

Turns

+INPUT

+5V OUTPUT

+3.3V OUTPUT

TRIM

OUTPUT

RETURN

–INPUT

ON/OFF

CONTROL

1

2

4

5

8

6

+5V LOAD

+3.3V LOAD

7

+INPUT

+5V OUTPUT

+3.3V OUTPUT

TRIM

OUTPUT

RETURN

–INPUT

ON/OFF

CONTROL

1

2

4

5

8

6

+5V LOAD

+3.3V LOAD

R TRIM

DOWN

7

+INPUT

+5V OUTPUT

+3.3V OUTPUT

TRIM

OUTPUT

RETURN

–INPUT

ON/OFF

CONTROL

1

2

4

5

8

6

+5V LOAD

+3.3V LOAD

R TRIM

UP

7

Figure 5. Increase Output Voltage Trim Connections

Using A Fixed Resistor

Figure 3. Trim Connections using a Trimpot

Figure 4. Decrease Output Voltage Trim Connections

Using A Fixed Resistor

Trim Down Trim Up

0% – –

1% 153k 178.9k

2% 79.1k 67k

3% 50k 37.5k

4% 34.5k 23.9k

5% 24.8k 16k

Table 1. Percentage of Output Voltage Change vs Trim Resistor Value (Ohms)

Trim Down

–13

DOWN

VO – 1.275

R

T (kΩ) =

–0.242

je

0.624 – 0.04VO

1

L

N

O

Q

VO =

R

T + 13

DOWN

je

+ 0.282

1

RT + 13

DOWN

je

0.993 +

1.275

VO =

4.523

R

T + 13

UP

–13

+3.308

UP

1

0.190(V

O – 1.275) + 0.031VO – 0.489

j

e

RT (kΩ) =

Trim Up

Note: Accuracy of adjustment is subject to the tolerances of resistor

values, reference accuracy and factory-adjusted output accuracy.

V

O = desired output voltage.

6

Page 7

BWR Models

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

D12 Model D12, D24, D48 Models

Typical Performance Curves

7

D24 Model

D48 Model

Input Ripple Current (VIN = 18V, 5V @ 3A, 3.3V@ 4.5A,

no external filtering, source impedance <0.1Ω.)

50mA/div

1µsec/div

Input Ripple Current (VIN = 36V, 5V @ 3A, 3.3V@ 4.5A,

no external filtering, source impedance <0.1Ω.)

50mA/div

1µsec/div

Input Ripple Current (VIN = 75V, 5V @ 3A, 3.3V@ 4.5A,

no external filtering, source impedance <0.1Ω.)

50mA/div

1µsec/div

Output Ripple and Noise (PARD)

(

VIN = nominal, 5V@3A, 3.3V @ 4.5A, external 1µF output capacitors.)

3.3V Output

Ripple/Noise

50mV/div

20MHz BW

5V Output

Ripple/Noise

50mV/div

20MHz BW

1µsec/div

Output Ripple and Noise (PARD)

(VIN = nominal, 5V@0A, 3.3V @ 7A, external 1µF output capacitors.)

3.3V Output

Ripple/Noise

50mV/div

20MHz BW

5V Output

Ripple/Noise

50mV/div

20MHz BW

1µsec/div

Output Ripple and Noise (PARD)

(VIN = nominal, 5V@ 6A, 3.3V @ 0A, external 1µF output capacitors.)

3.3V Output

Ripple/Noise

50mV/div

20MHz BW

5V Output

Ripple/Noise

50mV/div

20MHz BW

1µsec/div

Page 8

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

XWR Series

8

D12, D24, D48 Models

Typical Performance Curves

D12, D24, D48 Models

5V Output Half-Load to Full-Load Transient Response

(VIN = nominal, 3.3V@ 700mA, external 1µF output capacitors.)

5V Output

100mV/div

Output

Current

2A/div

100µsec/div

6A

3A

5V Output Full-Load to Half-Load Transient Response

(VIN = nominal, 3.3V@ 700mA, external 1µF output capacitors.)

5V Output

100mV/div

Output

Current

2A/div

100µsec/div

6A

3A

3.3V Output Half-Load to Full-Load Transient Response

(VIN = nominal, 5V@ 600mA, external 1µF output capacitors.)

3.3V Output

100mV/div

Output

Current

2A/div

100µsec/div

7A

3.5A

3.3V Output Full-Load to Half-Load Transient Response

(VIN = nominal, 5V@ 600mA, external 1µF output capacitors.)

3.3V Output

100mV/div

Output

Current

2A/div

100µsec/div

3.5A

7A

Percentage of Change on 3.3 VOUT (%)

5 Volt Output Current (Amps)

Cross Regulation Effects on +3.3VOUT

(Reference Point 5V @ 3.9A, 3.3V @ 4A)

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

0123456

3.3V @ 2A

3.3V @ 4A

3.3V @ 7A

3.3V @ 0A

3.3V @ 6A

Percentage of Change in +5 VOUT (%)

3.3 Volt Current (Amps)

Cross Regulation Effects On +5VOUT

(Reference Point 5V @ 4A, 3.3V @ 3.9A)

4.0

3.0

2.0

1.0

0

–1.0

–2.0

–3.0

–4.0

0123 4567

5V @ 0A

5V @ 2A

5V @ 4A

5V @ 6A

Page 9

BWR Models

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

9

D12, D24, D48 Models

Typical Performance Curves

Start-Up from VIN

(VIN = nominal, 5V@ 3A, 3.3V @ 4.5A, external 1µF output capacitors.)

2msec/div

3.3V

Output

2V/div

5V

Output

2V/div

V

IN

Start-Up from Remote On/Off Control

(VIN = nominal, 5V@ 3A, 3.3V @ 4.5A, external 1µF output capacitors.)

2msec/div

3.3V

Output

2V/div

5V

Output

2V/div

Remote

On/Off

(Pin 4)

D12, D24, D48 Models

D12 Models D24, D48 Models

90

85

80

75

70

65

60

D12 - 3.3 Volt Output Efficiency vs. Line and Load

(+5V @ 600mA)

0.70 1.40 2.10 2.80 3.50 4.20 4.90 5.60 6.30 7.00

+3.3V Output Current (Amps)

Efficiency (%)

V

IN

= 18V

V

IN

= 12V

V

IN

= 10V

90

85

80

75

70

65

60

D12 - 5 Volt Output Efficiency vs. Line and Load

(+3.3V @ 700mA)

0.60 1.20 1.80 2.40 3.00 3.60 4.20 4.80 5.40 6.00

+5V Output Current (Amps)

Efficiency (%)

V

IN

= 10V

V

IN

= 18V

V

IN

= 12V

95

90

85

80

75

70

65

60

55

50

D24/D48 - 3.3 Volt Output Efficiency vs. Line and Load

(+5V @ 600mA)

0 0.78 1.56 2.33 3.11 3.89 4.67 5.44 6.22 7.00

+3.3V Output Current (Amps)

Efficiency (%)

V

IN

= MAX

V

IN

= NOMINAL

V

IN

= MIN

95

90

85

80

75

70

65

60

55

50

D24/D48 - 5 Volt Output Efficiency vs. Line and Load

(+3.3V @ 700mA)

0 0.67 1.33 2.00 2.67 3.33 4.00 4.67 5.33 6.00

+5V Output Current (Amps)

Efficiency (%)

V

IN

= MAX

V

IN

= NOMINAL

V

IN

= MIN

Page 10

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

XWR Series

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.33A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 12V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.33A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 18V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Natural Convection Air FlowLoading

150lfm Air Flow

300lfm Air Flow

Output Power vs. Ambient Temperature

V

IN = Nominal, 5V @ 3.74A/3.3V @ 4.33A

10

Temperature Derating and Electrical Performace Curves

D24 ModelsD12 Models

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.3A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 24V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.3A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 36V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Natural Convection Air FlowLoading

150lfm Air Flow

300lfm Air Flow

Output Power vs. Ambient Temperature

V

IN = Nominal, 5V @ 3.74A/3.3V @ 4.33A

Page 11

BWR Models

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

DA TEL mak es no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein do

not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifi cations are subject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-6354-2025

DATEL, Inc. 11 Cabot Boulevard, Mansfi eld, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

ISO 9001 REGISTERED

INNOVATION and EX C ELL E N C

E

®

®

DS-0481A 1/01

11

Temperature Derating and Electrical Performace Curves

D48 Models D48 Models

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.33A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 48V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Loading (5V @ 1.98A, 3.3V @ 7A)

Loading (5V @ 3.74A, 3.3V @ 4.33A)

Loading (5V @ 5.1A, 3.3V @ 2.33A)

Loading (5V @ 6A, 3.3V @ 0.7A)

Output Power vs. Ambient Temperature

V

IN = 75V, Natural Convection Air flow

Output Power (Watts)

Ambient Temperature (˚C)

–400 15202530354045505560657075 80 85 90 95 100

35

30

25

20

15

10

5

0

Natural Convection Air FlowLoading

150lfm Air Flow

300lfm Air Flow

Output Power vs. Ambient Temperature

V

IN = Nominal, 5V @ 3.74A/3.3V @ 4.33A

Loading...

Loading...