Page 1

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

■

Features

Driver Features

■

Produces a logic zero in third state

■

400 mV difference voltage in third state

■

Two line drivers per package

■

Logic to convert TTL input logic levels to differential, pseudo-emmiter coupled logic (ECL) output

logic levels

■

No line loading when VCC = 0 V

■

High output driver for 50 Ω loads

■

200 mA short-circuit current (typical)

■

2.0 ns maximum propagation delay

■

<0.2 ns output skew (typical)

Receiver Features

■

Two line receivers per package

■

High input impedance ≅ 8 kΩ

■

Logic that converts differential input logic levels to

TTL output logic levels

■

4.0 ns maximum propagation delay

■

<0.20 V input sensitivity (typical)

−1.2 V to +7.2 V common-mode range

■

Common Device Features

■

Common enable for each driver/receiver pair

■

Operating temperature range: –40 °C to +125 °C

(wider than the 41 Series)

Electrostatic discharge (ESD) performance better

than the 41 Series

■

Lower power requirement than the 41 Series

Description

The BTF1A device is a dual differential transceiver

circuit that transmits and receives digital data over

balanced transmission lines and is compatible with

Lucent Technologies Microelectronics Group differential drivers and receivers. It is designed to provide

a strong logic zero when in the third state. The minimum difference voltage in the third state is 400 mV. It

is designed specifically for bus applications where a

well-defined logic state is needed when the bus is

idle. The driver puts out a logic

state mode, which is easily overriden by an active

buffer on the bus. When all the buffers on the bus are

inactive (third state), the signal on the bus is a

indicating that the bus is idle.

The dual drivers translate input TTL logic levels to differential pseudo-ECL output levels. The dual receiver

converts differential input logic levels to TTL output

levels. Each driver/receiver pair has its own common

enable control allowing serial data and a control clock

to be transmitted and received on a single integrated

circuit. The BTF1A tr ansceiv er re quires the customer

to supply termination resistors on the circuit board.

The powerdown loading characteristics of the

receiver input circuit are approximately 8 kΩ relative

to the power supplies; hence, it will not load the

transmission line when the circuit is powered down.

For those circuits with termination resistors, the line

will remain impedance matched when the circuit is

powered down. The driver does not load the line

when it is powered down.

Data Sheet

March 2001

when in the third

zero

zero

■

Single 5.0 V ± 5% supply

■

400 Mbits/s maximum data rate

■

Meets enhanced small device interface (ESDI)

standards

Page 2

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

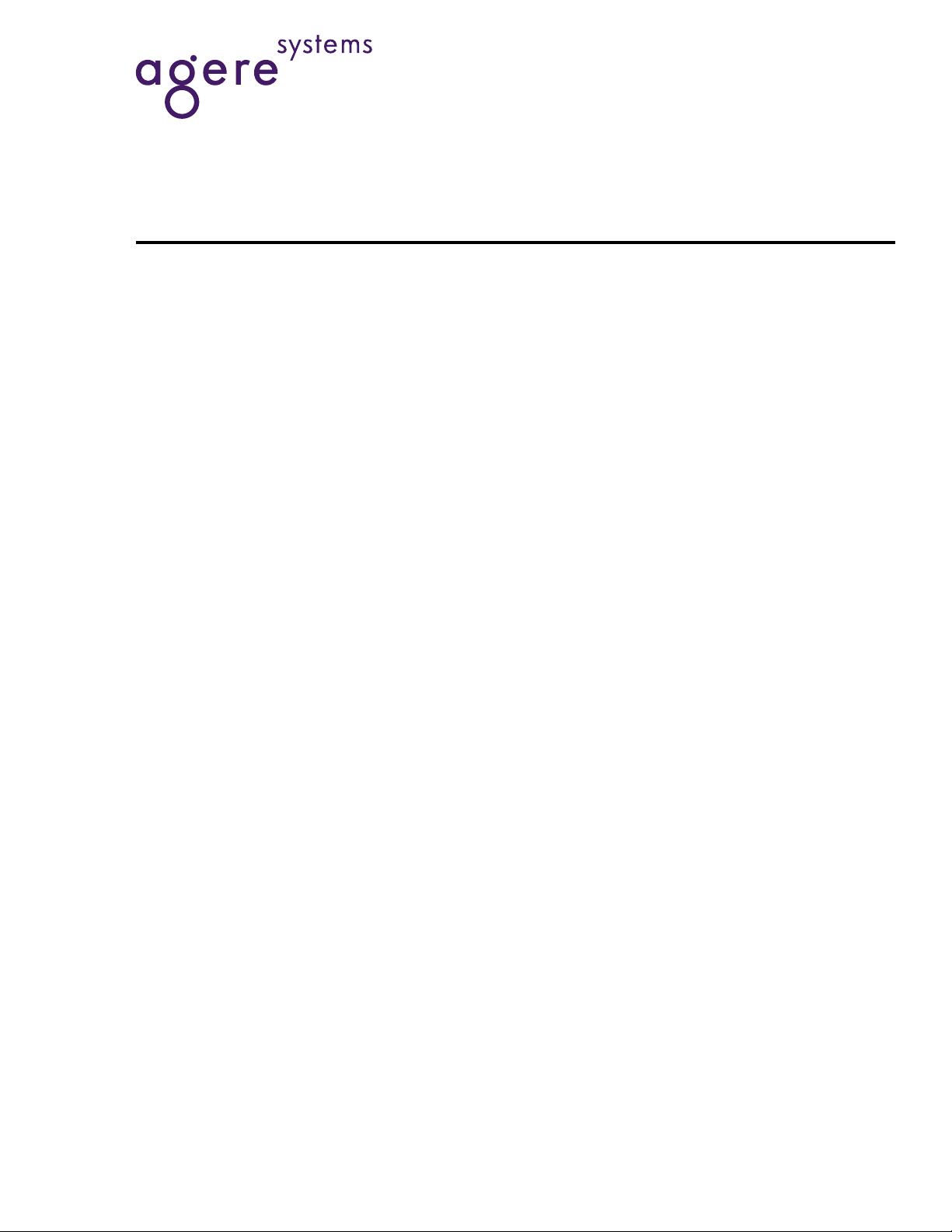

Pin Information

Data Sheet

March 2001

RO1

DI1

V

ED

ER

GND

DI2

RO2

1

2

CC

3

4

5

6

7

8

R1

D1

D2

R2

BTF1A

RI1

16

RI1

15

DO1

14

DO1

13

DO2

12

DO2

11

RI2

10

RI2

9

Figure 1. Differential Transceiver Logic Diagram

Table 1. Enable Truth Table

ED ER D1 D2 R1 R2

0 0 Active Active Active Active

1 0 Disabled Disabled Active Active

0 1 Active Active Disabled Disabled

1 1 Disabled Disabled Disabled Disabled

12-2747.a(F)

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operational sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Table 2. Absolute Maximum Ratings

Parameter Symbol Min Max Unit

Power Supply Voltage V

Ambient Operating Temperature T

Storage Temperature T

CC

A

stg

—6.5V

−40 125 °C

−55 150 °C

2 Agere Systems Inc.

Page 3

Data Sheet

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

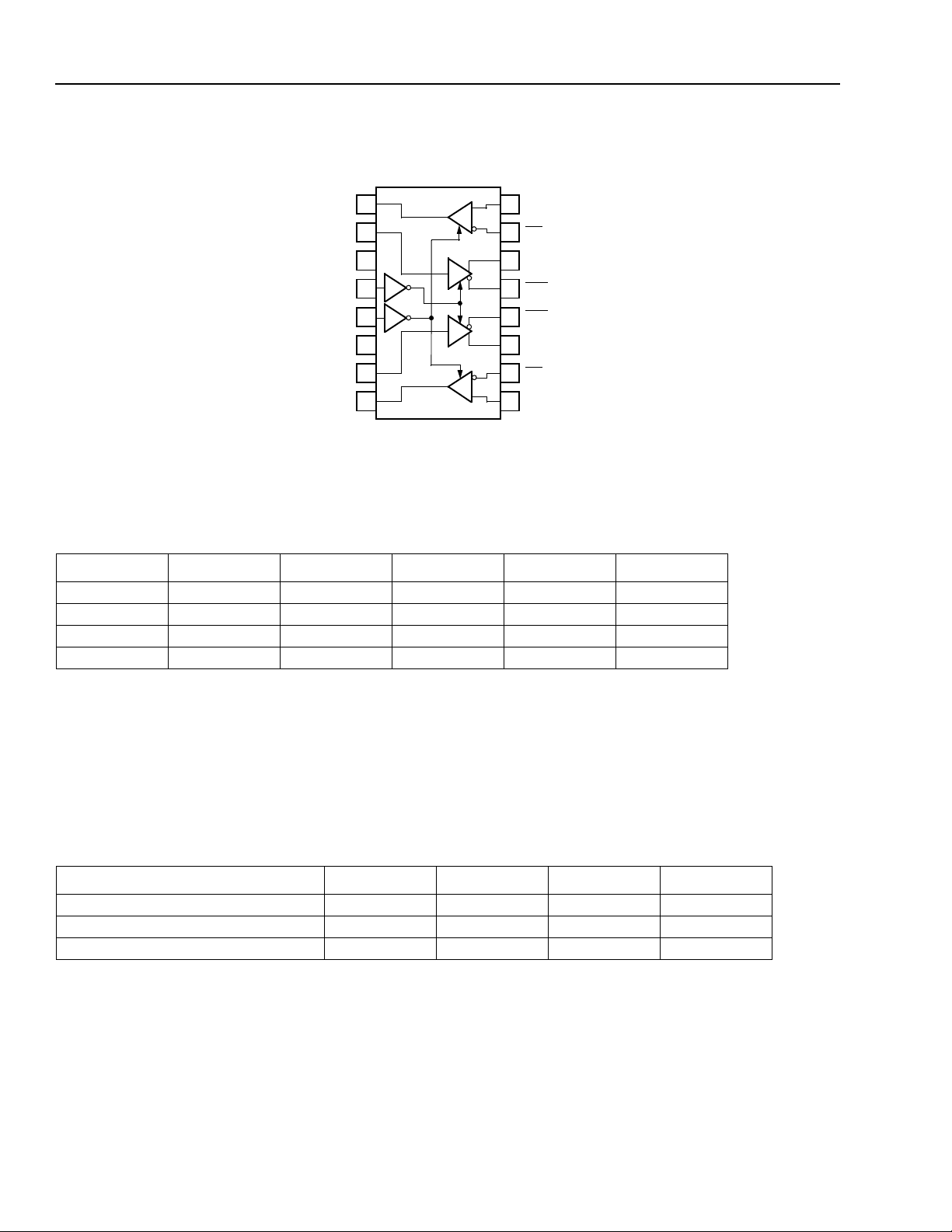

Electrical Characteristics

For variations in electrical characteristics over the temperature range, see Figure 10 through Figure 12.

Table 3. Power Supply Current Characteristics

A

= −40 °C to +125 °C, V

T

CC

= 5 V ± 0.25 V.

Parameter Symbol Min Typ Max Unit

Power Supply Current (V

All Outputs Disabled

All Outputs Enabled

CC

= 5.5 V)

I

I

CC

CC

—

—

40

20

65

35

mA

mA

Third State

The BTF1A driver produces pseudo-ECL levels, and has a third-state mode, which is different than a conventional

TTL device. When a driver is placed in the third state, the base of the output transistors are pulled low, bringing the

outputs below the active-low level. The BTF1A is unique because it provides a logic zero at its output when in the

third state. If all the buffers on the bus are in the third state, the BTF1A is designed to deliver a logic zero to the bus

to act as an indicator that the bus is idle. The guaranteed zero level, Vdo

– Vdo, is 0.4 V.

Agere Systems Inc. 3

Page 4

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Data Sheet

March 2001

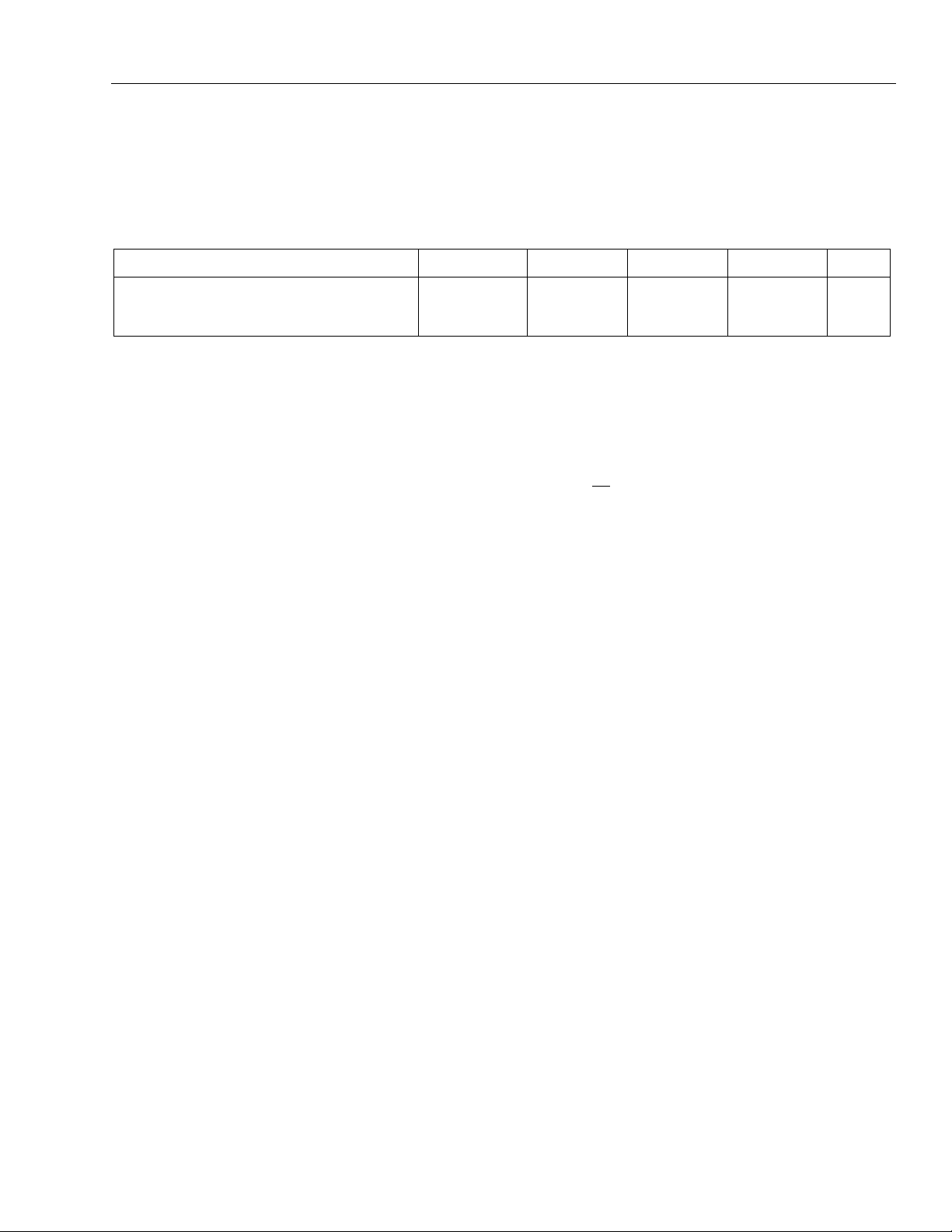

Electrical Characteristics

(continued)

Table 4. Driver Voltage and Current Characteristics

A

For variations in output voltage over the temperature range, see Figure 10 and Figure 11. T

= −40 °C to +125 °C.

Parameter Symbol Min Typ Max Unit

Output Voltages:

1

Low

1

High

:V

Differential Voltage (V

OH

– VOL)V

V

DIFF

OL

OH

OH –

V

1.4 V

CC

− 1.8 V

V

OH

− 1.1 V

CC

− 1V

OH

− 0.65 V

CC

− 0.8 V

0.65 1.1 1.4 V

Output Voltage Third State:

Difference Voltage Vdo

Third State, I

Output Voltages (T

1

Low

1

High

:V

OH

= –1.0 mA, VCC = 4.75 V V

A

Differential Voltage (V

- Vdo V

= 0 °C to 85 °C):

OH

– VOL)V

DIFZ

V

DIFF

OZ

OL

OH

0.4 0.6 — V

OL

——V

OH –

V

1.4 V

CC

− 1.5 V

V

OH

− 1.1 V

CC

− 1V

− 0.2 V

OH

− 0.8 V

CC

− 0.8 V

0.8 1.1 1.4 V

Input Voltages:

IH

OS

IH

IH

2

IL

3

IL

3

IL

2

IK

——0.8V

——0.8V

——0.7V

2.0 — — V

——−1.0 V

–100 — — mA

IL

——−400 µA

——20 µA

— — 100 µA

CC

Low, V

= 5.25 V: V

Data Input V

Enable Input V

High, V

Clamp, V

Short-circuit Output Current, V

Input Currents, V

Low, V

High, V

Reverse, V

1. Values are with terminations as per Figure 7.

2. The input levels and diff erence voltage provide zero noise immunity and should be tested only in a static, noise-free environment.

3. Test must be performed one lead at a time to prevent damage to the devi ce .

CC

= 4.75 V V

CC

= 4.75 V, II = –5.0 mA V

CC

= 5.25 V I

CC

= 5.25 V:

I

= 0.4 V I

I

= 2.7 V I

I

= 5.25 V I

4 Agere Systems Inc.

Page 5

Data Sheet

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

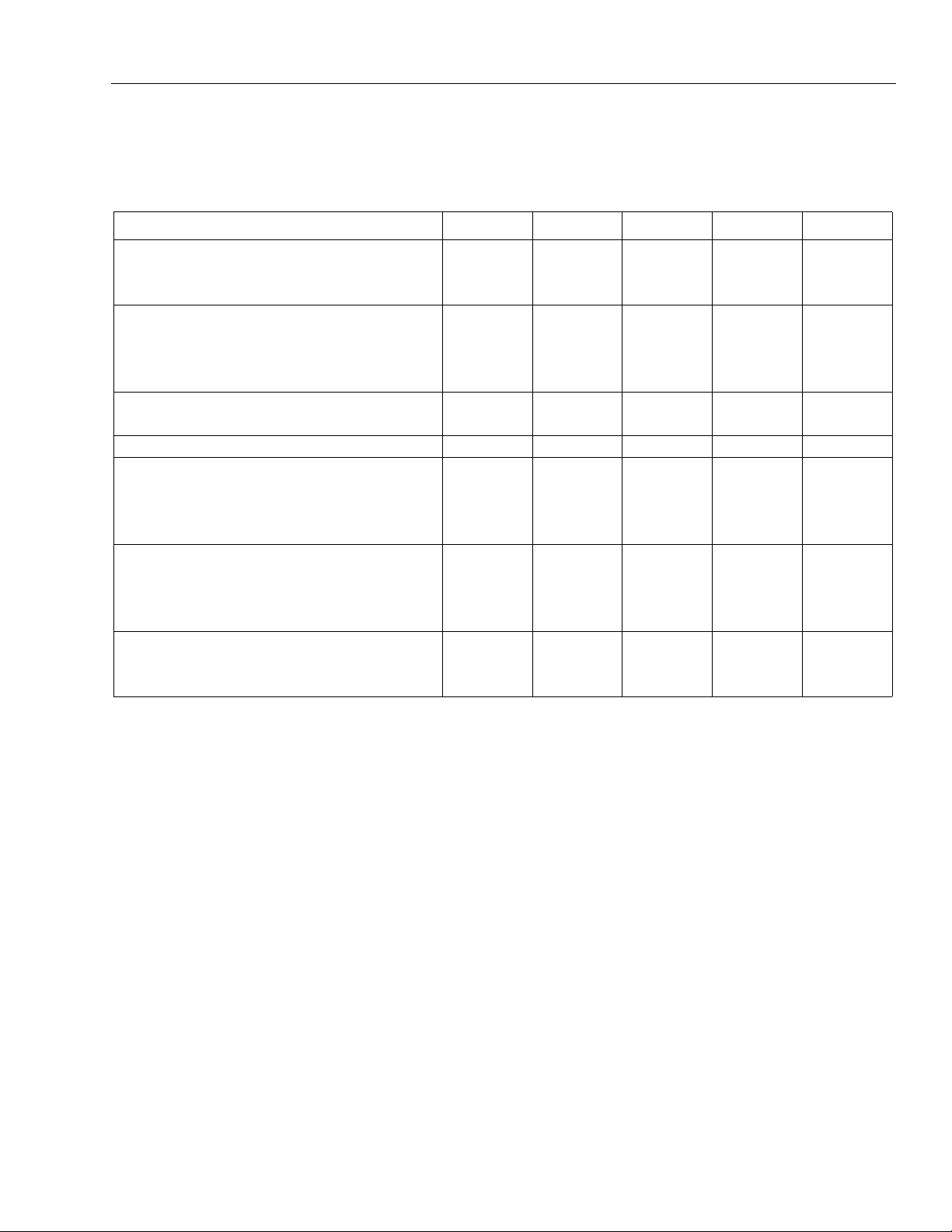

Electrical Characteristics

(continued)

Table 5. Receiver Voltage and Current Characteristics

OH

For variation in minimum V

and maximum VOL over the temperature range, see Figure 10. TA = –40 °C to +125 °C.

Parameter Symbol Min Typ Max Unit

CC

Output Voltages V

OL

Low, I

High, I

= 8.0 mA

OH

= −400 µA V

= 4.75 V:

1

OL

V

OH

——0.5V

2.4 — — V

Enable Input Voltages:

CC

Low, V

High, V

Clamp, V

Minimum Differential Input Voltages, V

−0.80 V < V

= 5.25 V V

CC

= 4.75 V V

CC

= 4.75 V, II = –5.0 mA V

IH – VIL

IH

< 7.2 V, −1.2 V < VIL < 6.8 V V

2

:

Input Offset Voltage V

Output Currents, V

Off-state (high Z), V

Off-state (high Z), V

CC

= 5.25 V:

O

= 0.4 V I

O

= 2.4 V I

Short Circuit I

Enable Input Currents, V

IN

Low, V

High, V

Reverse, V

= 0.4 V I

IN

= 2.7 V I

IN

= 5.5 V I

CC

= 5.25 V:

IL

IH

IK

TH

OFF

OZL

OZH

OS

IL

IH

IH

1

1

——0.7V

2.0 — — V

——−1.0 V

1

—0.10.20V

0.03 0.05 V

——–20µA

——20µA

3

–25 — –100 mA

— — –400 µA

——20µA

——100µA

Differential Input Currents:

IN

Low, V

High, V

1. The input levels and difference voltage provide zero noise immunity and should be tested only in a static, noise-free environment.

2. Outputs of unused receivers assume a logic 1 level when the inputs are left open. (It is recommended that all unused positive inputs

be tied to the positive power supply. No external series resistor is required.)

3. Test must be performed one lead at a time to prevent damage to the device.

= –1.2 V I

IN

= 7.2 V I

IL

IH

——−1.0 mA

——1.0mA

Agere Systems Inc. 5

Page 6

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Timing Characteristics

Data Sheet

March 2001

Table 6. Driver Timing Characteristics

P1

For t

and tP2 propagation delays over the temperature range, see Figure 13. Propagation delay test circuit con-

nected to output is shown in Figure 7. T

(See Figure 3 and Figure 4.)

A

= −40 °C to +125 °C, V

CC

= 5 V ± 0.25 V.

Parameter Symbol Min Typ Max Unit

Propagation Delay:

Input High to Output

Input Low to Output

1

1

2

P1

t

2

P2

t

0.8 1.2 2.0 ns

0.8 1.2 2.0 ns

Capacitive Delay ∆tp — 0.02 0.03 ns/pF

Disable Time (either E1 or E2):

High-to-High Impedance t

Low-to-High Impedance t

PHZ

PLZ

4812ns

4812ns

Enable Time (either E1 or E2):

High Impedance to High t

High Impedance to Low t

PZH

PZL

4812ns

4812ns

Output Skew:

P1

|t

– tP2|t

PHH – tPHL

|t

|, |t

PLH

PLL

– t

|t

Difference Between Drivers ∆t

Rise Time (20%—80%) t

Fall Time (80%—20%) t

1. CL = 5 pF. Capacitor is connected from each output to ground.

2. tP1 and tP2 are measured from the 1.5 V point of the input to the crossover point of the outputs (see Figure 3).

skew1

skew2

skew

tLH

tHL

—0.10.3ns

—0.20.5ns

——0.3ns

—0.7 2ns

—0.7 2ns

Table 7. Receiver Timing Characteristics

For propagation delays (t

PLH

and t

PHL

) over the temperature range, see Figure 14 and Figure 15. Propagation delay

test circuit connected to output is shown in Figure 8. T

(See Figure 5 and Figure 6.)

A

= −40 °C to +125 °C, V

CC

= 5 V ± 0.25 V.

Parameter Symbol M in Typ Ma x Unit

Propagation Delay:

Input to Output High t

Input to Output Low t

PLH

PHL

1.5 2.5 4.0 ns

1.5 2.5 4.0 ns

Pulse Width Distortion, ltpHL-tpLHI:

Load Capacitance (C

Load Capacitance (C

L

) = 15 pF tskew1 — — 0.7 ns

L

) = 150 pF tskew1 — — 4.0 ns

Output Waveform Skews:

Part-to-Part Skew, T

Part-to-Part Skew, T

A

= 75 °C ∆tskew1p-p — 0.8 1.4 ns

A

= –40 °C to +125 °C ∆tskew1p-p — — 1.5 ns

Same Part Skew ∆tskew — — 0.3 ns

Disable Time, C

High-to-high Impedance t

Low-to-high Impedance t

L

= 5 pF:

PHZ

PLZ

— 5 12 ns

— 5 12 ns

Enable Time:

High Impedance to High t

High Impedance to Low t

Rise Time (20%—80%) t

Fall Time (80%—20%) t

PZH

PZL

tLH

tHL

— 8 12 ns

— 8 12 ns

——3.0ns

——3.0ns

6 Agere Systems Inc.

Page 7

Data Sheet

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Timing Characteristics

(continued)

7

(ns)

P

6

5

4

PLH

t

(TYP)

3

2

PHL

t

(TYP)

1

0

EXTRINSIC PROPAGATION DELAY, t

25 50 75 100 125 150

LOAD CAPACITANCE, C

L

(pF)

175 2000

12-3462(F)

Note: This graph is included as an aid to the system designers. Total circuit delay varies with load capacitance. The total delay is the sum of the

delay due to the external capacitance and the intrinsic delay of the device.

Figure 2. Typical Extrinsic Propagation Delay Versus Load Capacitance at 25 °C

INPUT

TRANSITION

OUTPUTS

OUTPUT

OUTPUT

OUTPUT

PHH

t

t

PHL

P1

t

80%

t

PLL

t

PLH

t

80%

20%

tLH

t

Figure 3. Driver Propagation Delay Timing

2.4 V

1.5 V

0.4 V

P2

OH

V

OL

V

OH

V

(VOH + VOL)/2

OL

V

OH

V

(VOH + VOL)/2

OL

V

OH

V

20%

tHL

t

OL

V

12-2677(F)

Agere Systems Inc. 7

Page 8

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Data Sheet

March 2001

Timing Characteristics

(continued)

ED

PHZ

OUTPUT

OUTPUT

– 0.4 V

t

OUTPUT

PLZ

t

Note: In the third state, OUTPUT is 0.4 V more negative than OUTPUT.

Figure 4. Driver Enable and Disable Timing

t

t

PZH

PZL

3.0 V

1.5 V

0.0 V

OH

V

OL

V

+ 0.2 V

OL

V

VOL – 0.1 V

OL

V

VOL – 0.1 V

12-2268.d(F)

INPUT

INPUT

OUTPUT

PHL

t

80%

20%

tHL

t

20%

Figure 5. Receiver Propagation Delay Timing

PLH

t

80%

3.7 V

3.2 V

2.7 V

OH

V

1.5 V

OL

V

tLH

t

12-2251.b(F)

8 Agere Systems Inc.

Page 9

Data Sheet

TO OUTPUT OF

DEVICE UNDER

TEST

C

L

15 pF*

5 k

Ω

2 k

Ω

+5 V

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Timing Characteristics

E1*

†

E2

PHZ

t

OH

V

OUTPUT

OL

V

* E2 = 1 while E1 changes state.

†E1 = 0 while E2 changes state.

Test Conditions

(continued)

∆

V = 0.5 V

t

PZH

∆

V = 0.5 V

t

PLZ

∆

V = 0.5 V

Figure 6. Receiver Enable and Disable Timing

t

PZL

∆

V = 0.5 V

3 V

1.5 V

0 V

3 V

1.5 V

0 V

12-2538.b(F)

Parametric values specified under the Electrical Characteristics and Timing Characteristics sections for the

data transmission driver devices are measured with the

following output load circuits.

Ω

100

DO DO

200

Ω

200

Ω

12-2271.a(F)

Figure 7. Driver Propagation Delay Test Circuit

12-2249(F)

* Includes probe and jig capacitances.

Note: All 458E, IN4148, or equivalent diodes.

Figure 8. Receiver Propagation Delay Test Circuit

Agere Systems Inc. 9

Page 10

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Data Sheet

March 2001

Output Characteristics

Figure 9 illustrates typical driver output characteristics.

Included are load lines for two typical termination configurations.

OUTPUT VOLTAGE (V)

VCC – 2 V VCC – 1 V V

OH

V

Y LOAD

OL

V

π

LOAD

A. Output Current vs. Output Voltage for Loads

Shown in B and C

DO

60

Ω

90

60

Ω

DO

Ω

B. Y Load

CC

OUTPUT CURRENT (mA)

10

20

30

40

12-2269(F)

12-2270(F)

Temperature Characteristics

0

CC

–0.5

–1.0

–1.5

–2.0

OUTPUT VOLTAGE RELATIVE TO V

–2.5

Figure 10. V

1.2

1.0

0.8

0.6

VOH MAX

VOH MIN

VOL MAX

–25 0 25 50 75 100

TEMPERATURE (°C)

OL

and V

OH

Extremes for Drivers vs.

Temperature for 100 Ω Load

VOH – VOL TYP

VOH – VOL MIN

VOL MIN

125 150–50

2-3467(F)

Ω

100

DO DO

200

Ω

π

C.

Load

200

Ω

12-2271.a(F)

0.4

DIFFERENTIAL VOLTAGE (V)

0

–25 0 25 50 75 100

TEMPERATURE (°C)

Figure 11. Differential Voltage (VOH – VOL) for

125 150–50

12-3468(F)

Drivers vs. Temperature

Figure 9. Driver Output Current vs. Voltage

Characteristics

1010 Agere Systems Inc.

Page 11

Data Sheet

3.8

–25 0 25 50 75 100

1.00

3.00

TEMPERATURE (°C)

2.00

1.50

2.50

4.00

125 150

3.50

MAX

TYP

MIN

PROPAGATION DELAY (ns)

–50

–25 0 25 50 75

1.00

1.50

2.00

4.00

125 150–50

2.50

3.00

3.50

MAX

TYP

MIN

PROPAGATION DELAY (ns)

TEMPERATURE (°C)

100

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Temperature Characteristics

3.6

3.2

2.8

2.4

2.0

1.6

VOLTAGE (V)

1.2

0.8

0.4

0.0

–25 0 25 50 75 100

–50

Figure 12. Minimum V

Temperature at V

Receiver

IOH MIN

IOL MAX

TEMPERATURE (°C)

OH

and Maximum V

CC

= 4.5 V for the

(continued)

125 150

12-3464.a(F)

OL

vs.

12-3465(F)

Figure 14. Propagation Delay for a High Output

PLH

(t

) vs. Temperature at VCC = 5.0 V for

the Receivers

2.3

2.1

PROPAGATION DELAY (ns)

1.9

1.7

1.5

1.3

1.1

0.9

0.7

0.5

0.3

RANGE FOR tP1 AND t

MAX

MIN

–25 0 25 50 75 100

TEMPERATURE (°C)

P2

125 150–50

12-3469.a(F)

Figure 13. Min and Max for tP1 and tP2 Propagation

Delays vs. Temperature for the Driver

12-3466(F)

Figure 15. Propagation Delay for a Low Output

PHL

(t

) vs. Temperature at VCC = 5.0 V for

the Receivers

Agere Systems Inc. 11

Page 12

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Data Sheet

March 2001

Handling Precautions

CAUTION: This device is susceptible to damage as a result of ESD. Take proper precautions during both

handling and testing. Follow guidelines such as JEDEC Publication No. 108-A (Dec. 1988).

When handling and mounting line driver products, proper precautions should be taken to avoid exposure to ESD.

The user should adhere to the following basic rules for ESD control:

1. Assume that all electronic components are sensitive to ESD damage.

2. Never touch a sensitive component unless properly grounded.

3. Never transport, store, or handle sensitive components except in a static-safe environment.

ESD Failure Models

Lucent employs two models for ESD events that can cause device damage or failure:

1. A human body model (HBM) that is used by most of the industry for ESD-susceptibility testing and protectiondesign evaluation. ESD voltage thresholds are dependent on the critical parameters used to define the model.

A standard HBM (resistance = 1500 Ω, capacitance = 100 pF) is widely used and, therefore, can be used for

comparison purposes.

2. A charged-device model (CDM), which many believe is the better simulator of electronics manufacturing exposure.

Table 8 and Table 9 illustrate the role these two models play in the overall prevention of ESD damage. HBM ESD

testing is intended to simulate an ESD event from a charged person. The CDM ESD testing simulates charging and

discharging events that occur in production equipment and processes, e.g., an integrated circuit sliding down a

shipping tube.

The HBM ESD threshold voltage presented here was obtained by using these circuit parameters.

Table 8. Typical ESD Thresholds for Data Transmission Transceivers

Device HBM Threshold CDM Threshold

Differential Inputs >800 >1000

All Other Pins >2000 >1000

Table 9. ESD Damage Protection

ESD Threat Controls

Personnel Processes

Control

Model

Wrist straps

ESD shoes

Antistatic flooring

Human body model (HBM) Charged-device model (CDM)

Static-dissipative materials

Air ionization

12 Agere Systems Inc.

Page 13

Data Sheet

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Latch Up

Latch up evaluation has been performed on the data transmission receivers. Latch up testing determines if the

power-supply current exceeds the specified maximum due to the application of a stress to the device under test. A

device is considered susceptible to latch up if the power supply current exceeds the maximum level and remains at

that level after the stress is removed.

Lucent performs latch up testing per an internal test method which is consistent with JEDEC Standard No. 17 (previously JC-40.2)

Latch up evaluation involves three separate stresses to evaluate latch up susceptibility levels:

1. dc current stressing of input and output pins.

2. Power supply slew rate.

3. Power supply overvoltage.

Table 10. Latch Up Test Criteria and Test Results

CMOS Latch Up Standardized Test Procedure

.

Data Transmission

Receiver ICs

Minimum Criteria

Test Results

dc Current Stress

of I/O Pins

≥150 mA ≤1 µs ≥1.75 x Vmax

≥250 mA ≤100 ns ≥2.25 x Vmax

Power Supply

Slew Rate

Power Supply

Overvoltage

Agere Systems Inc. 13

Page 14

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Outline Diagrams

16-Pin SOIC (SONB/SOG)

Dimensions are in millimeters.

L

N

1

PIN #1 IDENTIFIER ZONE

Data Sheet

March 2001

B

W

H

SEATING PLANE

1.27 TYP

Package

Description

Small-Outline,

0.10

Number of

Pins

(N)

0.51 MAX

Maximum Length

(L)

0.28 MAX

Package Dimensions

Maximum Width

Without Leads

Maximum Width

Including Leads

(B)

16 10.49 7.62 10.64 2.67

(W)

0.61

5-4414(F)

Maximum Height

Above Board

(H)

Gull-Wing

(SOG)

Note: The dimensions in this oultine diagram are intended for informational purposes only . For detailed schematics to assist your design efforts,

please contact your Lucent Technologies sales representative.

14 Agere Systems Inc.

Page 15

Data Sheet

DIP

SOIC/NB

J-LEAD SOIC/GULL WING

AIRFLOW (ft/min)

200 400 600 800 1000 12000

40

50

60

70

80

90

100

110

120

130

140

THERMAL RESISTANCE

Θ

ja

(

°

C/W)

March 2001

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Power Dissipation

System designers incorporating Lucent data transmission drivers in their applications should be aware of

package and thermal information associated with these

components.

Proper thermal management is essential to the longterm reliability of any plastic encapsulated integrated

circuit. Thermal management is especially important

for surface-mount devices, given the increasing circuit

pack density and resulting higher thermal density. A

key aspect of thermal management involves the junction temperature (silicon temperature) of the integrated

circuit.

Several factors contribute to the resulting junction temperature of an integrated circuit:

■

Ambient use temperature

■

Device power dissipation

■

Component placement on the board

■

Thermal properties of the board

■

Thermal impedance of the package

Thermal impedance of the package is referred to as

ja

Θ

and is measured in °C rise in junction temperature

per watt of power dissipation. Thermal impedance is

also a function of airflow present in system application.

The following equation can be used to estimate the

junction temperature of any device:

The power dissipated in the output is a function of the:

■

Termination scheme on the outputs

■

Termination resistors

■

Duty cycle of the output

Package thermal impedance depends on:

■

Airflow

■

Package type (e.g., DIP, SOIC, SOIC/NB)

The junction temperature can be calculated using the

previous equation, after power dissipation levels and

package thermal impedances are known.

Figure 16 illustrates the thermal impedance estimates

for the various package types as a function of airflow.

This figure shows that package thermal impedance is

higher for the narrow-body SOIC package. Particular

attention should, therefore, be paid to the thermal management issues when using this package type.

In general, system designers should attempt to maintain junction temperature below 125 °C. The following

factors should be used to determine if specific data

transmission drivers in particular package types meet

the system reliability objectives:

■

System ambient temperature

■

Power dissipation

■

Pac kage type

■

Airflow

j

T

= TA + PD

Θ

ja

where:

j

T

is device junction temperature (°C).

A

T

is ambient temperature (°C).

D

P

is power dissipation (W).

ja

Θ

is package thermal impedance (junction to

ambient

—

°C/W).

The power dissipation estimate is derived from two factors:

■

Internal device power

■

Power associated with output terminations

Multiplying I

CC

times VCC provides an estimate of

12-2753(F)

internal power dissipation.

Agere Systems Inc. 15

Figure 16. Power Dissipation

Page 16

Dual Differential Transceiver BTF1A

With Idle Bus Indicator

Ordering Information

Data Sheet

March 2001

Part Number Driver

Terminating

1

Receiver

Terminating

2

Package Type Comcode

BTF1A16G None None 16-pin, Plastic SOIC 108648861

BTF1A16G-TR None None Tape and Reel SOIC 108698887

1. Indicates on-chip output terminating resistors from each driver output to ground.

2. Indicates on-chip input terminations across receiver inputs.

For additional information, contact your Agere Systems Account Ma na ger or the following:

INTERNET:

E-MAIL:

N. AMERICA: Agere Systems Inc., 555 Union Boulevard, Room 30L-15P-BA, Allentown, PA 18109-3286

ASIA PACIFIC: Agere Systems Singapore Pte. Ltd., 77 Science Park Drive, #03-18 Cintech III, Singapore 118256

CHINA: Agere Systems (Shanghai) Co., Ltd., 33/F Jin Mao Tower, 88 Century Boulevard Pudong, Shanghai 200121 PRC

JAPAN: Agere Systems Japan Ltd., 7-18, Higashi-Gotanda 2-chome, Shinagawa-ku, Tokyo 141, Japan

EUROPE: Data Requests: DATALINE:

Agere Systems Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application.

Copyright © 2001 Agere Systems Inc.

All Rights Reserved

Printed in U.S.A.

http://www.agere.com

docmaster@micro.lucent.com

1-800-372-2447

Tel. (65) 778 8833

Tel. (86) 21 50471212

Tel. (81) 3 5421 1600

Tech ni cal Inquiries:GERMANY:

, FAX 610-712-4106 (In CANADA:

, FAX (65) 777 7495

, FAX (86) 21 50472266

, FAX (81) 3 5421 1700

Tel. (44) 7000 582 368

FRANCE:

(39) 02 6608131

ITALY:

(49) 89 95086 0

(33) 1 40 83 68 00

(Milan), SPAIN:

1-800-553-2448

, FAX (44) 1189 328 148

(Munich), UNITED KINGDOM:

(Paris), SWEDEN:

, FAX 610-712-4106)

(46) 8 594 607 00

(34) 1 807 1441

(Madrid)

(44) 1344 865 900

(Stockholm), FINLAND:

(Ascot),

(358) 9 3507670

(Helsinki),

March 2001

DS01-068ANET-1 (Replaces DS01-068ANET)

Loading...

Loading...