Page 1

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

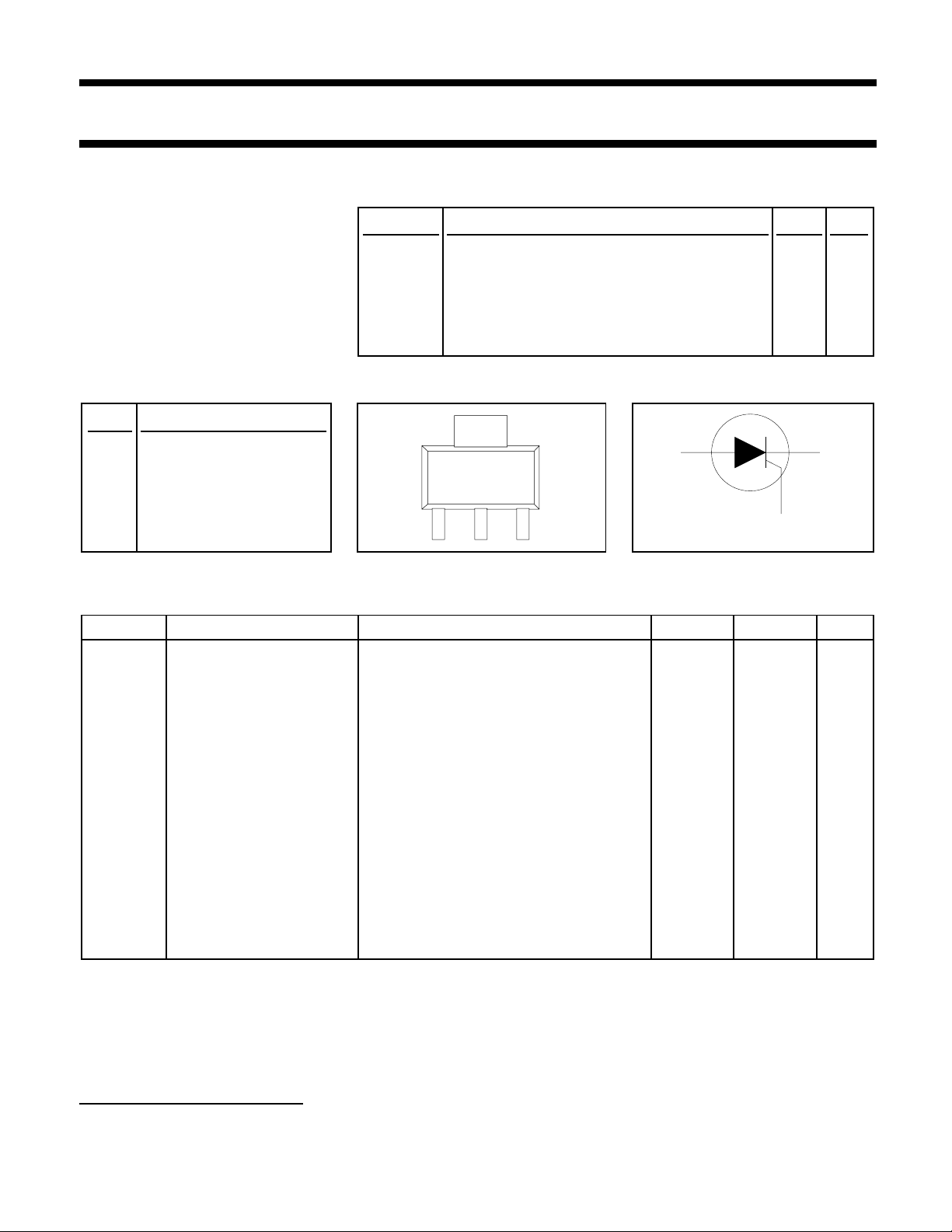

GENERAL DESCRIPTION QUICK REFERENCE DATA

Glass passivated, sensitive gate SYMBOL PARAMETER MAX. UNIT

thyristorinaplasticenvelope,suitable

forsurfacemounting,intended foruse V

in general purpose switching and V

phase control applications. This I

device is intended to be interfaced I

directly to microcontrollers, logic I

integrated circuits and other low

power gate trigger circuits.

PINNING - SOT223 PIN CONFIGURATION SYMBOL

, Repetitive peak off-state voltages 400 V

DRM

RRM

T(AV)

T(RMS)

TSM

Average on-state current 0.6 A

RMS on-state current 1 A

Non-repetitive peak on-state current 8 A

PIN DESCRIPTION

1 cathode

4

ak

2 anode

3 gate

tab anode

23

1

g

LIMITING VALUES

Limiting values in accordance with the Absolute Maximum System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DRM

. V

Repetitive peak off-state - 400

RRM

voltages

I

T(AV)

I

T(RMS)

I

TSM

I2tI

Average on-state current half sine wave; Tsp ≤ 112 ˚C - 0.63 A

RMS on-state current all conduction angles - 1 A

Non-repetitive peak half sine wave; Tj = 125 ˚C prior to surge;

on-state current with reapplied V

t = 10 ms - 8 A

2

t for fusing t = 10 ms - 0.32 A2s

t = 8.3 ms - 9 A

DRM(max)

dIT/dt Repetitive rate of rise of ITM = 2 A; IG = 10 mA; dIG/dt = 100 mA/µs - 50 A/µs

on-state current after

triggering

I

V

V

P

P

T

T

GM

GM

RGM

GM

G(AV)

stg

j

Peak gate current - 1 A

Peak gate voltage - 5 V

Peak reverse gate voltage - 5 V

Peak gate power - 2 W

Average gate power over any 20 ms period - 0.1 W

Storage temperature -40 150 ˚C

Operating junction - 125 ˚C

temperature

1

V

1 Although not recommended, off-state voltages up to 800V may be applied without damage, but the thyristor may

switch to the on-state. The rate of rise of current should not exceed 15 A/µs.

February 1996 1 Rev 1.100

Page 2

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

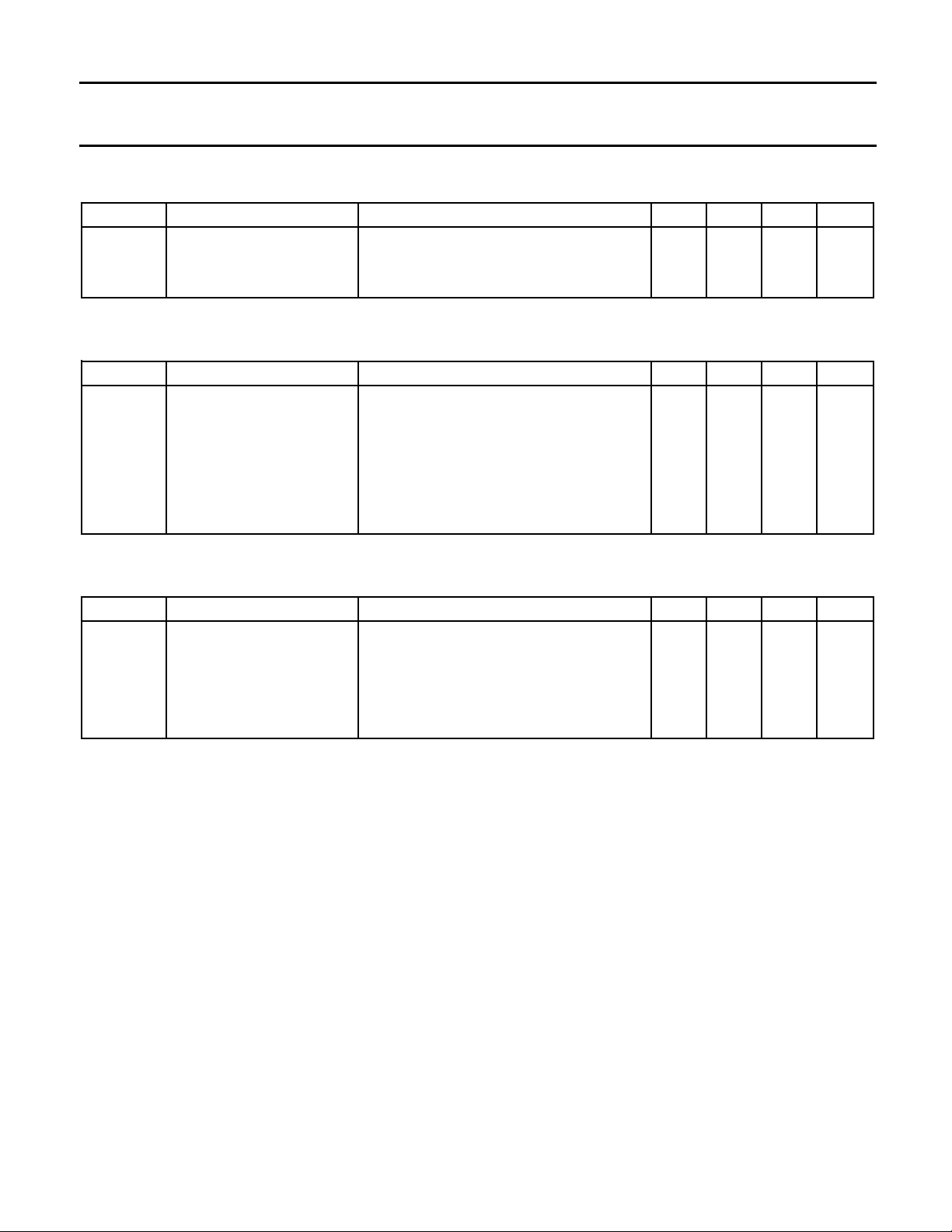

THERMAL RESISTANCES

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

R

th j-sp

R

th j-a

STATIC CHARACTERISTICS

Tj = 25 ˚C unless otherwise stated

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

GT

I

L

I

H

V

T

V

GT

ID, I

R

Thermal resistance - - 15 K/W

junction to solder point

Thermal resistance pcb mounted, minimum footprint - 156 - K/W

junction to ambient pcb mounted; pad area as in fig:14 - 70 - K/W

Gate trigger current VD = 12 V; IT = 10 mA; gate open circuit - 50 200 µA

Latching current VD = 12 V; IGT = 0.5 mA; RGK = 1 kΩ -26mA

Holding current VD = 12 V; IGT = 0.5 mA; RGK = 1 kΩ -25mA

On-state voltage IT = 2 A - 1.35 1.5 V

Gate trigger voltage VD = 12 V; IT = 10 mA; gate open circuit - 0.5 0.8 V

VD = V

gate open circuit

Off-state leakage current VD = V

; IT = 10 mA; Tj = 125 ˚C; 0.2 0.3 - V

DRM(max)

DRM(max)

; VR = V

; Tj = 125 ˚C; - 0.05 0.1 mA

RRM(max)

RGK = 1 kΩ

DYNAMIC CHARACTERISTICS

Tj = 25 ˚C unless otherwise stated

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

dVD/dt Critical rate of rise of VDM =67% V

off-state voltage exponential waveform; RGK = 1k Ω

t

gt

Gate controlled turn-on ITM = 2 A; VD = V

time dIG/dt = 0.1 A/µs

t

q

Circuit commutated VD = 67% V

turn-off time ITM = 1.6 A; VR = 35 V; dITM/dt = 30 A/µs;

dVD/dt = 2 V/µs; RGK = 1 kΩ

DRM(max)

; Tj = 125 ˚C; - 25 - V/µs

DRM(max)

; IG = 10 mA; - 2 - µs

DRM(max)

; Tj = 125 ˚C; - 100 - µs

February 1996 2 Rev 1.100

Page 3

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

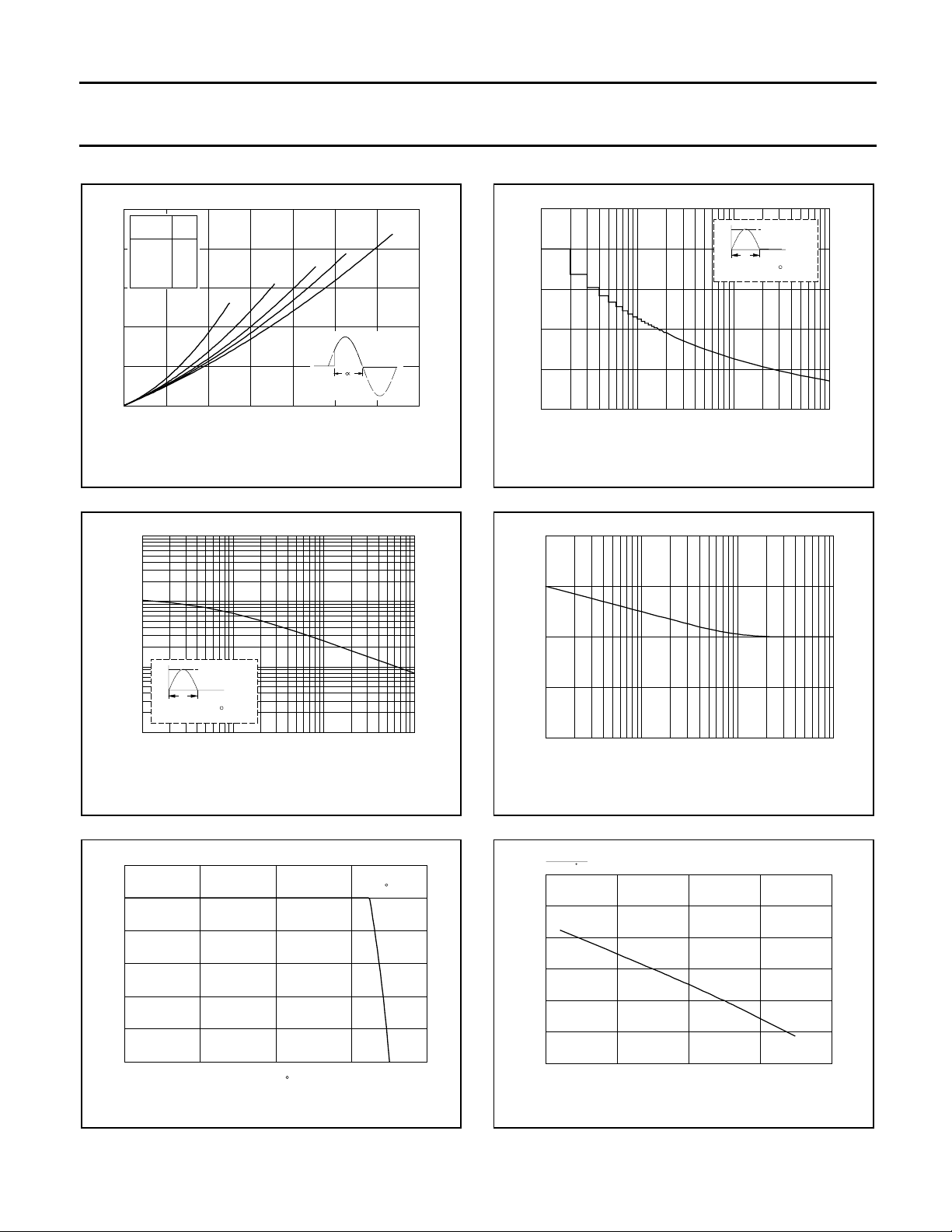

Ptot / W

1

conduction

form

angle

factor

degrees

0.8

0.6

0.4

0.2

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

a

30

4

60

2.8

90

2.2

120

1.9

180

1.57

BT169W

2.2

2.8

4

IF(AV) / A

Fig.1. Maximum on-state dissipation, P

average on-state current, I

factor = I

ITSM / A

1000

100

T(RMS)

BT169

T(AV)

/ I

T(AV)

Tsp(max) / C

a = 1.57

1.9

, where a = form

tot

.

110

113

116

119

122

125

, versus

ITSM / A

10

8

6

4

2

0

1 10 100 1000

Number of half cycles at 50Hz

BT169

I

I

Tj initial = 125 C max

TSM

T

time

T

Fig.4. Maximum permissible non-repetitive peak

on-state current I

sinusoidal currents, f = 50 Hz.

IT(RMS) / A

2

1.5

1

, versus number of cycles, for

TSM

BT134W

10

I

1

10us 100us 1ms

I

T

Tj initial = 125 C max

TSM

time

T

T / s

10ms

Fig.2. Maximum permissible non-repetitive peak

on-state current I

, versus pulse width tp, for

TSM

sinusoidal currents, tp ≤ 10ms.

IT(RMS) / A

1.2

1

0.8

0.6

0.4

0.2

0

-50 0 50 100 150

Fig.3. Maximum permissible rms current I

versus solder point temperature Tsp.

BT134W

Tsp / C

112 C

T(RMS)

,

0.5

0

0.01 0.1 1 10

surge duration / s

Fig.5. Maximum permissible repetitive rms on-state

current I

, versus surge duration, for sinusoidal

T(RMS)

currents, f = 50 Hz; Tsp ≤ 112˚C.

VGT(Tj)

VGT(25 C)

1.6

1.4

1.2

1

0.8

0.6

0.4

-50 0 50 100 150

BT151

Tj / C

Fig.6. Normalised gate trigger voltage

VGT(Tj)/ VGT(25˚C), versus junction temperature Tj.

February 1996 3 Rev 1.100

Page 4

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

IGT(Tj)

IGT(25 C)

3

2.5

2

1.5

1

0.5

0

-50 0 50 100 150

BT169

Tj / C

Fig.7. Normalised gate trigger current

IGT(Tj)/ IGT(25˚C), versus junction temperature T

IL(Tj)

IL(25 C)

3

2.5

2

1.5

1

0.5

0

-50 0 50 100 150

BT169

Tj / C

.

j

Fig.8. Normalised latching current IL(Tj)/ IL(25˚C),

versus junction temperature Tj, RGK = 1 kΩ.

IT / A

5

Tj = 125 C

Tj = 25 C

4

Vo = 1.0 V

Rs = 0.27 Ohms

3

2

1

0

0 0.5 1 1.5 2 2.5

BT169W

typ max

VT / V

Fig.10. Typical and maximum on-state characteristic.

Zth j-sp (K/W)

100

10

1

0.1

0.01

10us 0.1ms 1ms 10ms 0.1s 1s 10s

Fig.11. Transient thermal impedance Z

BT169W

P

D

tp / s

pulse width tp.

t

p

t

, versus

th j-sp

IH(Tj)

IH(25 C)

3

2.5

2

1.5

1

0.5

0

-50 0 50 100 150

BT169

Tj / C

Fig.9. Normalised holding current IH(Tj)/ IH(25˚C),

versus junction temperature T

,

RGK = 1 kΩ.

j

Fig.12. Typical, critical rate of rise of off-state voltage,

dVD/dt (V/us)

1000

100

10

1

0 50 100 150

Tj / C

RGK = 1 kohms

dVD/dt versus junction temperature Tj.

February 1996 4 Rev 1.100

Page 5

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

MOUNTING INSTRUCTIONS

Dimensions in mm.

3.8

min

1.5

min

1.5

min

(3x)

1.5

min

Fig.13. soldering pattern for surface mounting

SOT223.

2.3

4.6

6.3

PRINTED CIRCUIT BOARD

Dimensions in mm.

36

18

60

4.6

9

10

7

50

15

Fig.14. PCB for thermal resistance and power rating

for SOT223.

PCB: FR4 epoxy glass (1.6 mm thick), copper

laminate (35 µm thick).

4.5

February 1996 5 Rev 1.100

Page 6

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

MECHANICAL DATA

Dimensions in mm

Net Mass: 0.11 g

0.32

0.24

6.7

6.3

3.1

2.9

4

0.10

0.02

16

max

1.8

max

Notes

1. For further information, refer to surface mounting instructions for SOT223 envelope.

2. Epoxy meets UL94 V0 at 1/8".

13

10

max

1.05

0.85

1

2.3

23

0.80

0.60

4.6

Fig.15. SOT223 surface mounting package.

B

A

7.3

6.7

M

B

0.1

3.7

3.3

(4x)

AM0.2

February 1996 6 Rev 1.100

Page 7

Philips Semiconductors Product specification

Thyristor BT169DW

logic level

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values are given in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and

operation of the device at these or at any other conditions above those given in the Characteristics sections of

this specification is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Philips Electronics N.V. 1996

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the

copyright owner.

The information presented in this document does not form part of any quotation or contract, it is believed to be

accurate and reliable and may be changed without notice. No liability will be accepted by the publisher for any

consequence of its use. Publication thereof does not convey nor imply any license under patent or other

industrial or intellectual property rights.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices or systems where malfunction of these

products can be reasonably expected to result in personal injury. Philips customers using or selling these products

for use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting

from such improper use or sale.

February 1996 7 Rev 1.100

Loading...

Loading...