Page 1

September 1996

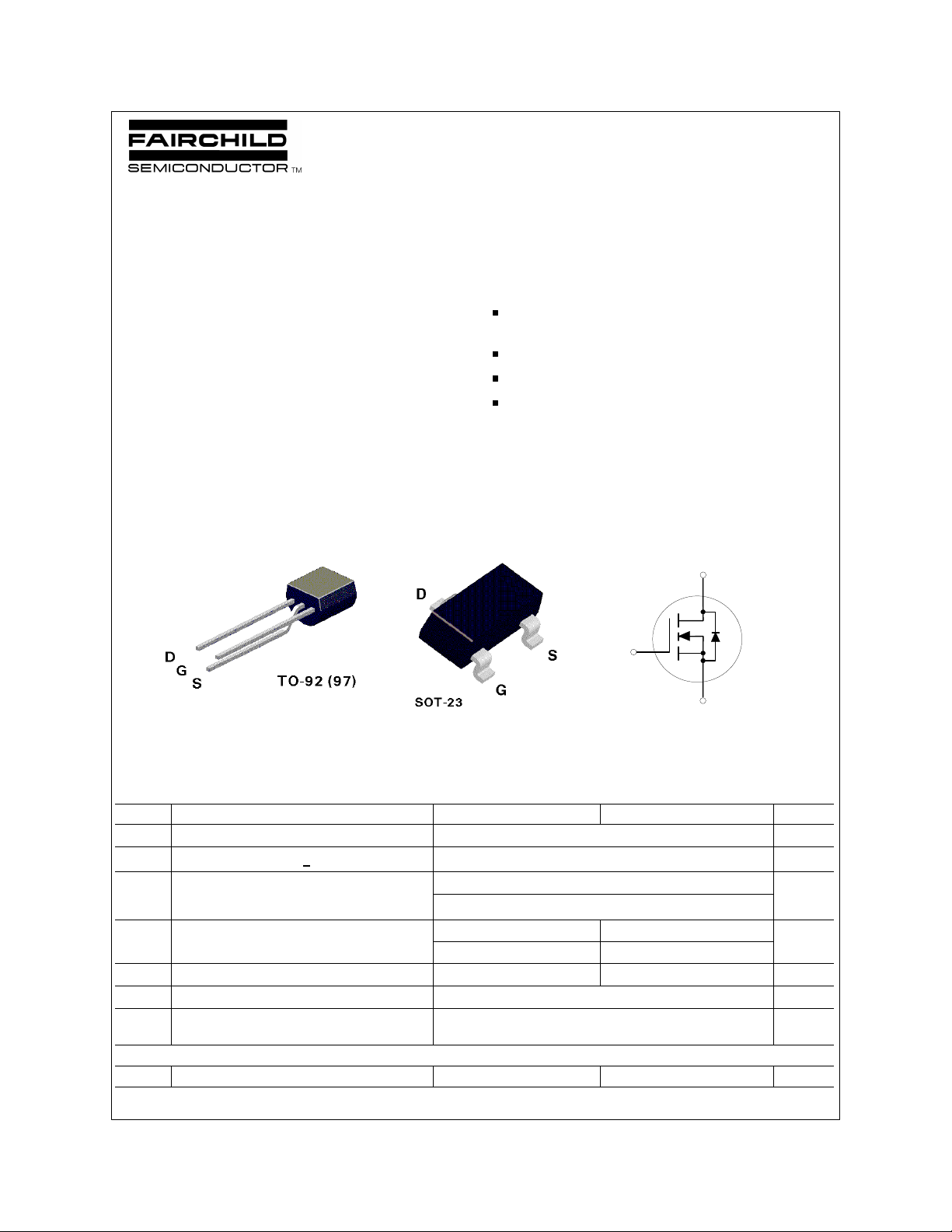

BSS100 / BSS123

N-Channel Logic Level Enhancement Mode Field Effect Transistor

General Description Features

These N-Channel logic level enhancement mode power

field effect transistors are produced using Fairchild's

proprietary, high cell density, DMOS technology. This

very high density process has been especially tailored to

minimize on-state resistance, provide superior switching

performance. This product is particularly suited to low

voltage, low current applications, such as small servo

motor controls, power MOSFET gate drivers, and other

switching applications.

_______________________________________________________________________________

BSS100: 0.22A, 100V. R

BSS123: 0.17A, 100V. R

DS(ON)

DS(ON)

= 6Ω @ V

= 6Ω @ V

GS

GS

High density cell design for extremely low R

Voltage controlled small signal switch.

Rugged and reliable.

D

= 10V.

= 10V

DS(ON)

.

G

BSS100

Absolute Maximum Ratings T

BSS123

= 25°C unless otherwise noted

A

S

Symbol Parameter BSS100 BSS123 Units

V

DSS

V

DGR

V

GSS

I

D

Drain-Source Voltage 100 V

Drain-Gate Voltage (RGS < 20KΩ)

100 V

Gate-Source Voltage - Continuous ± 14 V

- Non Repetitive (TP < 50 µS)

± 20

Drain Current - Continuous 0.22 0.17 A

- Pulsed 0.9 0.68

P

TJ,T

T

D

L

Total Power Dissipation @ TA = 25°C 0.63 0.36 W

Operating and Storage Temperature Range -55 to 150 °C

STG

Maximum Lead Temperature for Soldering

300 °C

Purposes, 1/16" from Case for 10 Seconds

THERMAL CHARACTERISTICS

R

JA

θ

Thermal Resistacne, Junction-to-Ambient 200 350 °C/W

© 1997 Fairchild Semiconductor Corporation

BSS100 Rev. F1 / BSS123 Rev. F1

Page 2

Electrical Characteristics (T

= 25°C unless otherwise noted)

A

Symbol Parameter Conditions Type Min Typ Max Units

OFF CHARACTERISTICS

BV

I

DSS

I

GSSF

DSS

Drain-Source Breakdown Voltage VGS = 0 V, ID = 250 µA All 100 V

Zero Gate Voltage Drain Current VDS = 100 V, V

VDS = 100 V, V

VDS = 100 V, V

VDS = 60 V, V

VDS = 20 V, V

= 0 V

GS

= 0 V

GS

= 0 V TJ=125oC All 60 µA

GS

= 0 V

GS

= 0 V

GS

Gate - Body Leakage, Forward VGS = 20 V, VDS = 0 V

VGS = 20 V, VDS = 0 V

BSS100

BSS123

BSS100

BSS123

BSS100

BSS123

15 µA

1 µA

10 nA

10 nA

10 nA

50 nA

ON CHARACTERISTICS (Note 1)

V

R

g

GS(th)

DS(ON)

FS

Gate Threshold Voltage VDS = VGS, ID = 1 mA All 0.8 1.4 2 V

Static Drain-Source On-Resistance VGS = 10 V, ID = 0.22 A

VGS = 10 V, ID = 0.17 A

VGS = 4.5 V, ID = 0.22 A

VGS = 4.5 V, ID = 0.17 A

Forward Transconductance VDS = 10 V, ID = 0.22 A

VDS = 10 V, ID = 0.17 A

BSS100

BSS123

BSS100

BSS123

BSS100

BSS123

2.8 6

2.8 6

3.2 10

3.2 10

0.08 0.4 S

0.08 0.4

DYNAMIC CHARACTERISTICS

C

iss

C

oss

C

rss

Input Capacitance VDS = 25 V, VGS = 0 V,

Output Capacitance All 10 15 pF

f = 1.0 MHz

All 29 60 pF

Reverse Transfer Capacitance All 2 6 pF

SWITCHING CHARACTERISTICS (Note 1)

t

t

t

t

Q

Q

Q

D(on)

r

D(off)

f

g

gs

gd

Turn - On Delay Time VDD = 30 V, ID = 0.28 A,

Turn - On Rise Time All 8 ns

VGS = 10 V, R

GEN

= 50 Ω

All 8 ns

Turn - Off Delay Time All 13 ns

Turn - Off Fall Time All 16 ns

Totall Gate Charge VDS = 10 V, ID = 0.22 A,

Gate-Source Charge All 0.15 0.25 nC

VGS = 10 V,

All 1.4 2 nC

Gate-Drain Charge All 0.2 0.4 nC

DRAIN-SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

I

S

I

SM

V

SD

Note:

1. Pulse Test: Pulse Width < 300 µs, Duty Cycle < 2.0%.

Maximum Continuous Source Current

Maximum Pulse Source Current (Note 1)

Drain-Source Diode Forward Voltage VGS = 0 V, IS = 0.44 A

VGS = 0 V, IS = 0.34 A

BSS100

BSS123

BSS100

BSS123

BSS100

BSS123

0.22 A

0.17

0.9 A

0.68

0.9 1.3 V

0.9 1.3

Ω

BSS100 Rev. F1 / BSS123 Rev. F1

Page 3

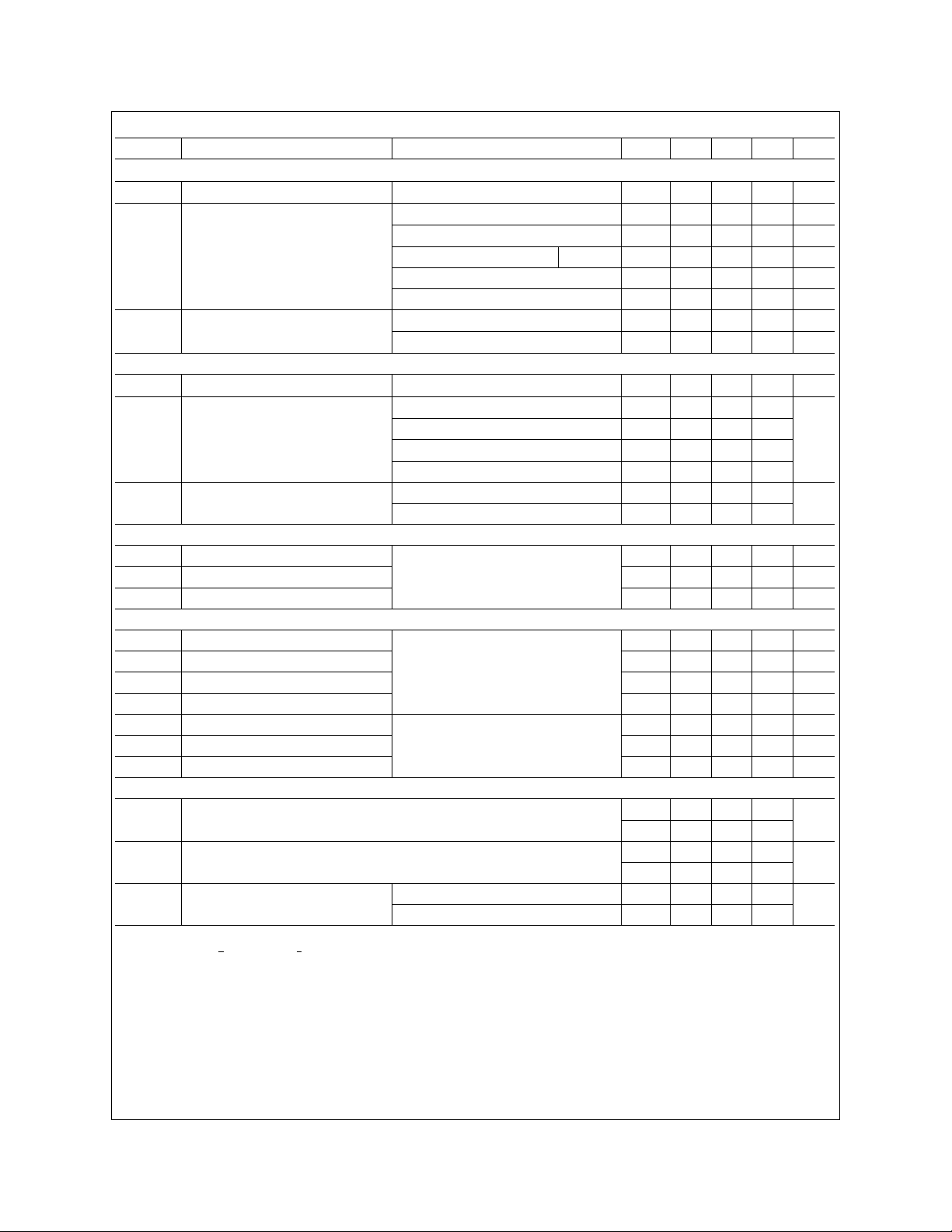

Typical Electrical Characteristics

0.6

0.5

0.4

0.3

0.2

0.1

D

I , DRAIN-SOURCE CURRENT (A)

0

0 1 2 3 4 5

V =10V

GS

5.0

4.0

3.5

V , DRAIN-SOURCE VOLTAGE (V)

DS

3.0

2.5

2.0

2.4

V =2.5V

2

1.6

DS(on)

R , NORMALIZED

1.2

DRAIN-SOURCE ON-RESISTANCE

0.8

0 0.1 0.2 0.3 0.4 0.5 0.6

GS

I , DRAIN CURRENT (A)

D

Figure 1. On-Region Characteristics. Figure 2. On-Resistance Variation with Gate

Voltage and Drain Current.

2.2

2

I = 220mA

D

V =10V

1.8

1.6

1.4

1.2

DS(ON)

R , NORMALIZED

0.8

DRAIN-SOURCE ON-RESISTANCE

0.6

0.4

GS

1

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

3

V = 10V

2.5

1.5

DS(on)

R , NORMALIZED

0.5

DRAIN-SOURCE ON-RESISTANCE

GS

T = 125°C

J

2

25°C

1

0

0 0.2 0.4 0.6 0.8 1

I , DRAIN CURRENT (A)

D

3.0

-55°C

3.5

4.0

5.0

10

Figure 3. On-Resistance Variation

with Temperature.

1.2

V = V

DS

I = 250µA

1.1

1

0.9

th

V , NORMALIZED

0.8

GATE-SOURCE THRESHOLD VOLTAGE

0.7

-50 -25 0 25 50 75 100 125 150 175

T , JUNCTION TEMPERATURE (°C)

J

D

Figure 5. Gate Threshold Variation with

Temperature.

Figure 4. On-Resistance Variation with Drain

Current and Temperature.

1.15

I = 250µA

GS

DSS

BV , NORMALIZED

D

1.1

1.05

1

0.95

DRAIN-SOURCE BREAKDOWN VOLTAGE

0.9

-50 -25 0 25 50 75 100 125 150 175

T , JUNCTION TEMPERATURE (°C)

J

Figure 6. Breakdown Voltage Variation with

Temperature.

BSS100 Rev. F1 / BSS123 Rev. F1

Page 4

Typical Electrical Characteristics (continued)

80

50

20

10

5

CAPACITANCE (pF)

f = 1 MHz

V = 0V

GS

1

0.1 0.2 0.5 1 2 5 10 50

V , DRAIN TO SOURCE VOLTAGE (V)

DS

C

C

iss

oss

C

rss

10

I =220mA

D

8

6

4

2

GS

V , GATE-SOURCE VOLTAGE (V)

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4

Q , GATE CHARGE (nC)

g

V = 5V

Figure 7. Capacitance Characteristics. Figure 8. Gate Charge Characteristics.

0.8

V = 5V

DS

0.6

0.4

0.2

T = -55°C

J

25°C

125°C

DS

20

FS

g , TRANSCONDUCTANCE (SIEMENS)

0

0 0.1 0.2 0.3 0.4 0.5 0.6

I , DRAIN CURRENT (A)

D

Figure 9. Transconductance Variation with Drain

Current and Temperature.

V

DD

V

IN

R

L

D

V

GS

R

GEN

G

DUT

S

Figure 10. Switching Test Circuit.

V

OUT

t t

on off

t

d(on)

t

r

90%

V

OUT

V

IN

10%

50%

10%

PULSE WIDTH

Figure 11. Switching Waveforms.

t

d(off)

50%

90%

90%

10%

t

f

INVERTED

BSS100 Rev. F1 / BSS123 Rev. F1

Page 5

t , TIME (sec)

TRANSIENT THERMAL RESISTANCE

2

t , TIME (sec)

TRANSIENT THERMAL RESISTANCE

1

0.5

RDS(ON) Limit

0.2

0.1

0.05

D

I , DRAIN CURRENT (A)

0.01

0.005

V = 20V

GS

SINGLE PULSE

T = 25°C

A

1 5 10 20 50 100 150

V , DRAIN-SOURCE VOLTAGE (V)

DS

DC

10s

10ms

100ms

1s

1ms

100us

2

1

0.5

RDS(ON) Limit

0.2

0.1

0.05

D

I , DRAIN CURRENT (A)

0.01

0.005

V = 20V

GS

SINGLE PULSE

T = 25°C

A

1 5 10 20 50 100 150

V , DRAIN-SOURCE VOLTAGE (V)

DS

DC

10s

10ms

100ms

1s

100us

1ms

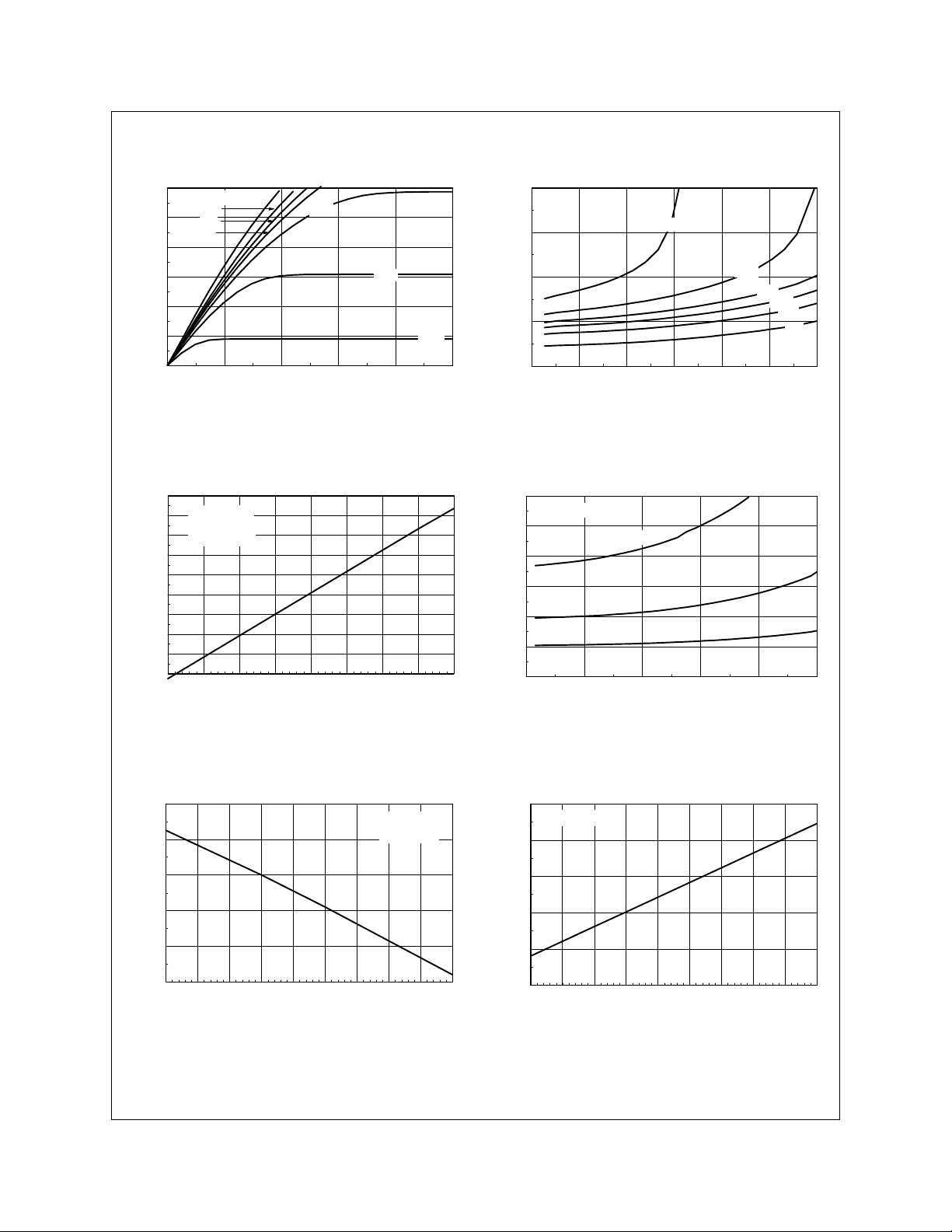

Figure 12. BSS100 Maximum Safe

Operating Area.

Figure 13. BSS123 Maximum Safe

Operating Area.

1

0.5

0.2

0.1

0.05

r(t), NORMALIZED EFFECTIVE

0.02

0.01

D = 0.5

R (t) = r(t) * R

θ

JA

R = 200 C/W

θ

JA

P(pk)

t

1

t

2

T - T = P * R (t)

J

A

Duty Cycle, D = t /t

0.05

0.02

0.01

0.2

0.1

Single Pulse

0.0001 0.001 0.01 0.1 1 10 100 300

1

Figure 14. BSS100 Transient Thermal Response Curve.

1

D = 0.5

0.5

0.2

0.2

0.1

0.1

0.05

0.05

0.02

0.01

r(t), NORMALIZED EFFECTIVE

0.01

Single Pulse

0.002

0.001

0.0001 0.001 0.01 0.1 1 10 100 300

1

R (t) = r(t) * R

θ

JA

R = 347 C/W

θ

JA

P(pk)

t

1

t

2

T - T = P * R (t)

J

A

Duty Cycle, D = t /t

o

θ

θ

JA

o

θ

JA

1 2

θ

JA

JA

1 2

Figure 15. BSS123 Transient Thermal Response Curve.

BSS100 Rev. F1 / BSS123 Rev. F1

Page 6

TO-92 Package Dimensions

TO-92; TO-18 Reverse Lead Form (J35Z Option)

(FS PKG Code 92, 94, 96)

1:1

Scale 1:1 on letter size paper

Dimensions shown below are in:

inches [millimeters]

Part Weight per unit (gram): 0.22

;

*

*

Note: All package 97 or 98 transistors are leadformed

to this configuration prior to bulk shipment. Order

L34Z option if in-line leads are preferred on package

97 or 98.

* Standard Option on 97 & 98 package code

January 2000, Rev. B

Page 7

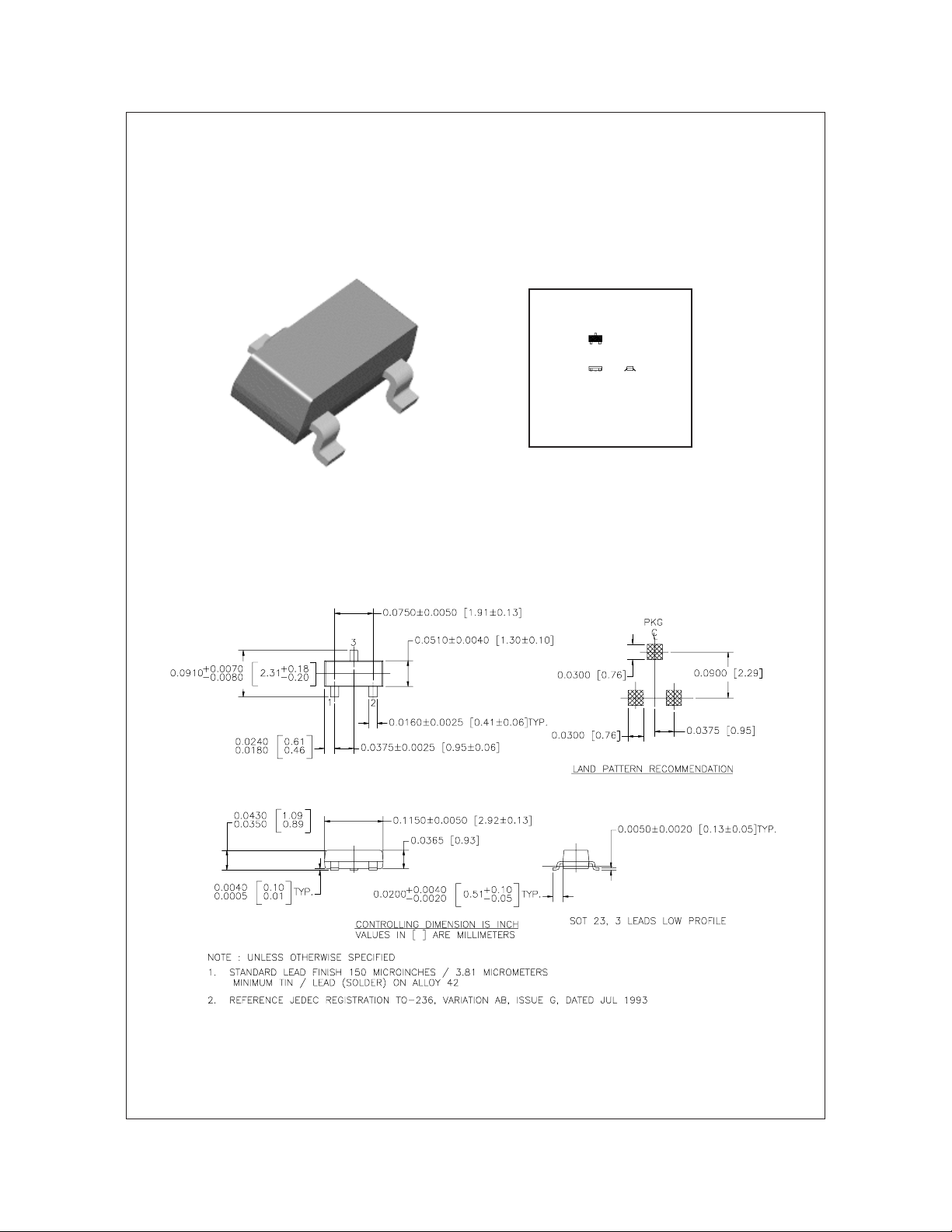

SOT-23 Tape and Reel Data and Package Dimensions

SOT-23 Packagin g

Configu ration: Figur e 1.0

SOT-23 Packaging Information

Packaging Option

Packaging type

Qty per Reel/Tube/Bag

Reel Size

Box Dimension (mm )

Max qty per B o x

Weight per unit (gm)

Weight per Reel (kg)

Note/Comments

Customized Label

Stan dard

(no flow code)

3,000 10,000

7" Dia

187x107x183 34 3x34 3x64

24,000 30,000

0.0082 0.0082

0.1175 0.4006

TNR

D87Z

TNR

13"

Antistatic Cover Tape

Human Readable

Label

Embossed

Carrier Tape

343mm x 342mm x 64mm

Intermediate box for L87Z Option

Packaging Description:

SOT-23

parts are shipped in tape. The carrier tape is

made from a dissipative (carbon filled) polycarbonat e

resin. The cover tape is a multilayer film (Heat Activated

Adhesive in nature) primaril y composed of polyester film,

adhesive layer, sealant, and anti-static sprayed agent.

These reeled parts i n standard option are shipped with

3,000 uni ts per 7" or 177cm diameter reel. The reels are

dark blue in color and is made of polystyrene plastic (antistatic coated). Other option comes in 10,000 units per 13"

or 330cm diameter reel. This and some other opt i ons are

described in the Packaging Information table.

These full reels are individually labeled and placed insi de

a standard intermediat e made of recyclable corrugated

brown paper with a Fairchil d logo printing. One pizza box

contains eight reels max imum. And these intermediate

boxes are placed inside a labeled shipping box which

comes in diff erent sizes dependin g on the number of parts

shipped.

3P 3P 3P 3P

SOT-23 Unit Orientation

Human Readable Label

Human Readable Label sample

SOT-23 Tape Leader and Trailer

Configuration: Figur e 2.0

Carrier Tape

Cover Tape

Trailer Tape

300mm minimum or

75 empty pockets

Components

Human readable

Label

187mm x 107mm x 183mm

Intermediate Box for Standard Option

Leader Tape

500mm minimum or

125 empty pockets

September 1999, Rev. C

Page 8

SOT-23 Tape and Reel Data and Package Dimensions, continued

SOT-23 Embossed Carrier Tape

Confi guration: Figure 3.0

T

B0

Wc

D0P0 P2

D1

E1

W

F

E2

Tc

K0

P1

A0

User Direction of Feed

Dimensions are in millimeter

Pkg type

SOT-23

(8mm)

Notes: A0, B0, and K0 dimensions are determined with respect to the EIA/Jedec RS-481

SOT-23 Reel Configuration: Figure 4.0

A0 B0 W D0 D1 E1 E2 F P1 P0 K0 T Wc Tc

3.15

2.77

8.0

1.55

1.125

1.75

6.25

+/-0.10

+/-0.10

+/-0.3

+/-0.05

+/-0.125

+/-0.10

3.50

min

+/-0.05

rotational and lateral movement requirements (see sketches A, B, and C).

20 deg maximum

B0

20 deg maximum component rotation

Sketch A (Side or Fro nt Sectional View)

Component Rotation

W1 Measured at Hub

A0

Sketch B (Top View)

Component Rotation

4.0

+/-0.1

Typical

component

cavity

center line

Typical

component

center line

Dim A

Max

4.0

+/-0.1

1.30

0.228

+/-0.013

5.2

+/-0.3

0.5mm

maximum

+/-0.10

0.5mm

maximum

Sketch C (Top View)

Component lateral movement

0.06

+/-0.02

Dim A

max

Tape Size

8mm 7" Dia

8mm 13" Dia

Reel

Option

Dim N

Diameter Option

7"

See detail AA

B Min

Dim C

13" Diameter Option

See detail AA

W2 max Measured at Hub

W3

Dim D

min

DETAIL AA

Dimensions are in inches and millimeters

Dim A Dim B Dim C Dim D Dim N Dim W1 Dim W2 Dim W3 (LSL-USL)

7.00

0.059

177.8

13.00

330

1.5

0.059

1.5

512 +0.020/-0.008

13 +0.5/-0.2

512 +0.020/-0.008

13 +0.5/-0.2

0.795

2.165550.331 +0.059/-0.000

20.2

0.795

4.00

20.2

100

8.4 +1.5/0

0.331 +0.059/-0.000

8.4 +1.5/0

0.567

14.4

0.567

14.4

0.311 – 0.429

7.9 – 10.9

0.311 – 0.429

7.9 – 10.9

September 1999, Rev. C

Page 9

SOT-23 Tape and Reel Data and Package Dimensions, continued

SOT-23 (FS PKG Code 49)

1:1

Scale 1:1 on letter size paper

Dimensions shown below are in:

inches [millimeters]

Part Weight per unit (gr am): 0.0082

September 1998, Rev. A1

Page 10

TRADEMARKS

The following are registered and unregistered trademarks Fairchild Semiconductor owns or is authorized to use and is

not intended to be an exhaustive list of all such trademarks.

ACEx™

CoolFET™

CROSSVOLT™

2

CMOS

E

TM

FACT™

FACT Quiet Series™

®

FAST

FASTr™

GTO™

HiSeC™

ISOPLANAR™

MICROWIRE™

POP™

PowerTrench

QFET™

QS™

Quiet Series™

SuperSOT™-3

SuperSOT™-6

SuperSOT™-8

SyncFET™

TinyLogic™

UHC™

VCX™

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER

NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD

DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICA TION OR USE OF ANY PRODUCT

OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT

RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROV AL OF FAIRCHILD SEMICONDUCTOR CORPORA TION.

As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, or (c) whose

failure to perform when properly used in accordance

with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the

user.

2. A critical component is any component of a life

support device or system whose failure to perform can

be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or

effectiveness.

PRODUCT STA TUS DEFINITIONS

Definition of Terms

Datasheet Identification Product Status Definition

Advance Information

Preliminary

No Identification Needed

Obsolete

Formative or

In Design

First Production

Full Production

Not In Production

This datasheet contains the design specifications for

product development. Specifications may change in

any manner without notice.

This datasheet contains preliminary data, and

supplementary data will be published at a later date.

Fairchild Semiconductor reserves the right to make

changes at any time without notice in order to improve

design.

This datasheet contains final specifications. Fairchild

Semiconductor reserves the right to make changes at

any time without notice in order to improve design.

This datasheet contains specifications on a product

that has been discontinued by Fairchild semiconductor.

The datasheet is printed for reference information only.

Rev. D

Loading...

Loading...