Page 1

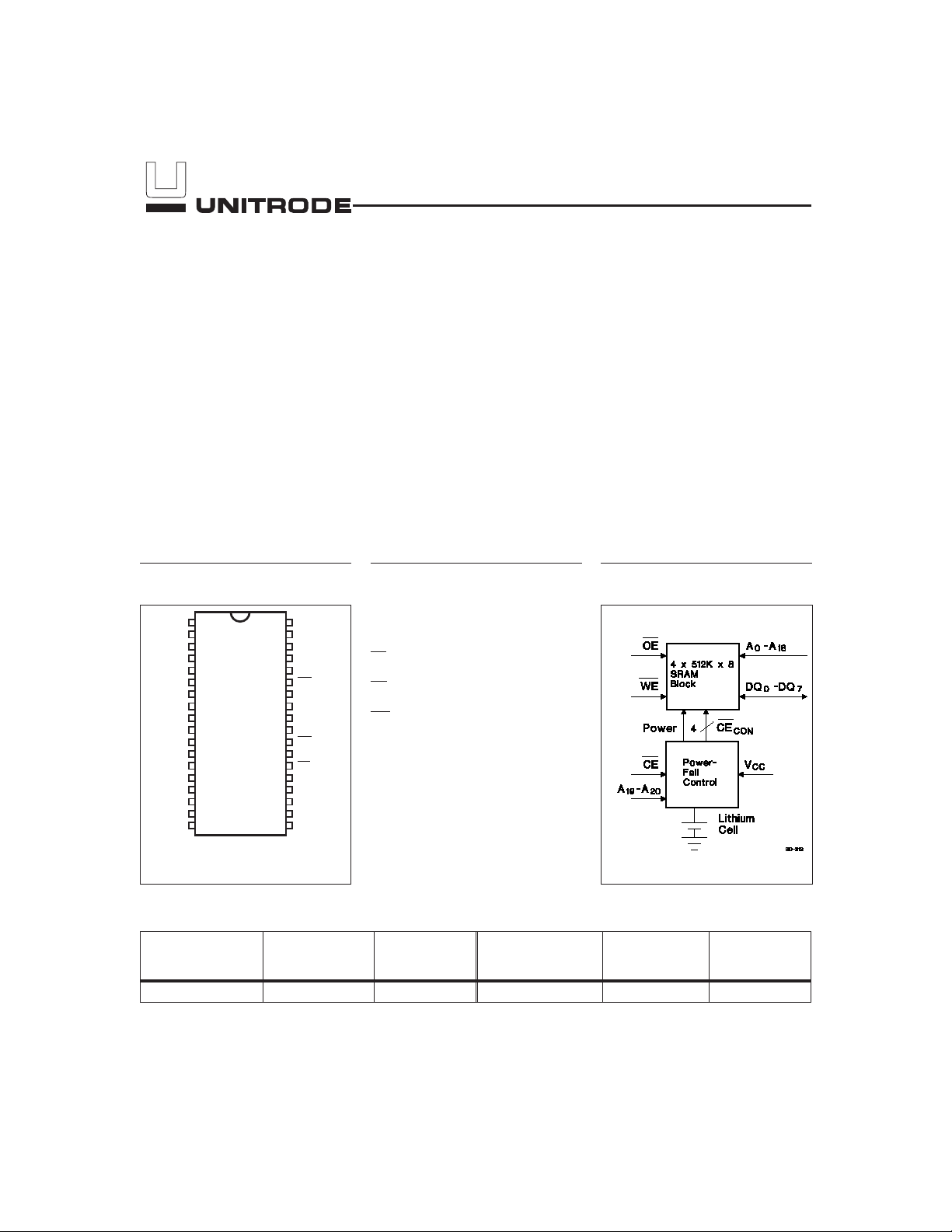

bq4017/bq4017Y

2048Kx8 Nonvolatile SRAM

Features

Data retention in the absence of

➤

power

Automatic write-protection dur

➤

ing power-up/power-down cycles

Conventional SRAM operation;

➤

unlimited write cycles

5-year minimum data retention

➤

in absence of power

Battery internally isolated until

➤

power is applied

Pin Connections

36

V

CC

A

35

19

NC

34

A

33

15

A

32

17

31

WE

A

30

13

A

29

8

A

28

9

A

27

11

26

OE

A

25

10

24

CE

DQ

23

22

DQ

DQ

21

20

DQ

19

DQ

DQ

DQ

DQ

V

NC

1

A

2

20

A

3

18

A

4

16

A

5

14

A

6

12

A

7

7

A

8

6

9

A

5

A

10

4

11

A

3

A

12

2

A

13

1

A

14

0

15

0

16

1

17

2

18

SS

General Description

The CMOS bq4017 is a nonvolatile

16,777,216-bit static RAM organized

as 2,097,152 words by 8 bits. The

integral control circuitry and lith

ium energy source provide reliable

nonvolatility coupled with the un

limited write cycles of standard

SRAM.

The control circuitry constantly

monitors the single 5V supply for an

out-of-tolerance condition. When V

falls out of tolerance, the SRAM is

At this time the integral energy

source is switched on to sustain the

memory until after V

returns valid.

CC

The bq4017 uses extremely low

standby current CMOS SRAMs, cou

pled with small lithium coin cells to

provide nonvolatility without long

write-cycle times and the write-cycle

limitations associated with EE

PROM.

The bq4017 has the same interface

as industry-standard SRAMs and

CC

requires no external circuitry.

-

-

unconditionally write-protected to

prevent an inadvertent write opera

-

tion.

Pin Names

A0–A

DQ

0

CE

OE

WE

V

CC

7

6

5

4

3

V

SS

NC No connect

Address inputs

20

–DQ7Data input/output

Chip enable input

Output enable input

Write enable input

Supply voltage input

Ground

Block Diagram

36-Pin DIP Module

PN401701.eps

Selection Guide

Part

Number

Maximum

Access

Time (ns)

Negative

Supply

Tolerance

Part

Number

Maximum

Access

Time (ns)

bq4017MC -70 70 -5% bq4017YMC -70 70 -10%

5/95

1

Negative

Supply

Tolerance

Page 2

bq4017/bq4017Y

Functional Description

When power is valid, the bq4017 operates as a standard

CMOS SRAM. During power-down and power-up cycles,

the bq4017 acts as a nonvolatile memory, automatically

protecting and preserving the memory contents.

Power-down/power-up control circuitry constantly moni

tors the V

V

. The bq4017 monitors for V

PFD

use in systems with 5% supply tolerance. The bq4017Y

monitors for V

with 10% supply tolerance.

When V

automatically write-protects the data. All outputs be

come high impedance, and all inputs are treated as

“don’t care.” If a valid access is in process at the time of

power-fail detection, the memory cycle continues to com

pletion. If the memory cycle fails to terminate within

time t

WPT

supply for a power-fail-detect threshold

CC

= 4.37V typical for use in systems

PFD

falls below the V

CC

= 4.62V typical for

PFD

threshold, the SRAM

PFD

, write-protection takes place.

As V

falls past V

CC

circuitry switches to the internal lithium backup supply,

which provides data retention until valid V

When V

returns to a level above the internal backup

CC

cell voltage, the supply is switched back to V

V

ramps above the V

CC

continues for a time t

processor stabilization. Normal memory operation may

resume after this time.

The internal coin cells used by the bq4017 have an ex

tremely long shelf life. The bq4017 provides data reten

tion for more than 5 years in the absence of system

power.

As shipped from Unitrode, the integral lithium cells are

electrically isolated from the memory. (Self-discharge in

this condition is approximately 0.5% per year.) Follow

ing the first application of V

and the lithium backup provides data retention on sub

sequent power-downs.

and approaches 3V, the control

PFD

is applied.

CC

threshold, write-protection

PFD

(120ms maximum) to allow for

CER

, this isolation is broken,

CC

CC

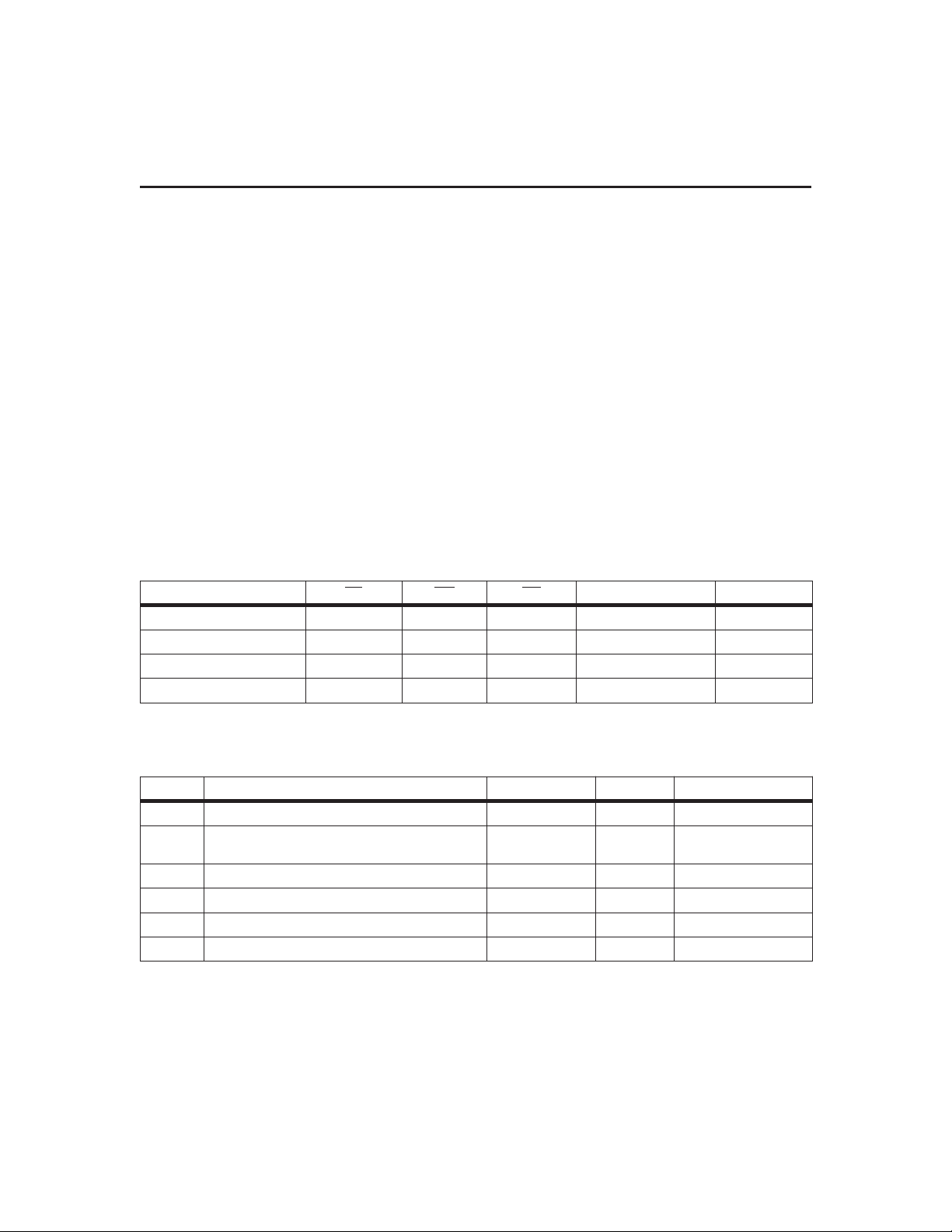

Truth Table

Mode CE WE OE I/O Operation Power

Not selected H X X High Z Standby

Output disable L H H High Z Active

Read L H L D

Write L L X D

OUT

IN

Active

Active

. After

-

-

-

-

Absolute Maximum Ratings

Symbol Parameter Value Unit Conditions

V

CC

V

T

T

OPR

T

STG

T

BIAS

T

SOLDER

Note: Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional operation

DC voltage applied on VCCrelative to V

SS

DC voltage applied on any pin excluding V

relative to V

SS

CC

-0.3 to 7.0 V

-0.3 to 7.0 V

V

+ 0.3

V

≤

T

CC

Operating temperature 0 to +70 °C

Storage temperature -40 to +70 °C

Temperature under bias -10 to +70 °C

Soldering temperature +260 °C For 10 seconds

should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Exposure to con

ditions beyond the operational limits for extended periods of time may affect device reliability.

2

-

Page 3

bq4017/bq4017Y

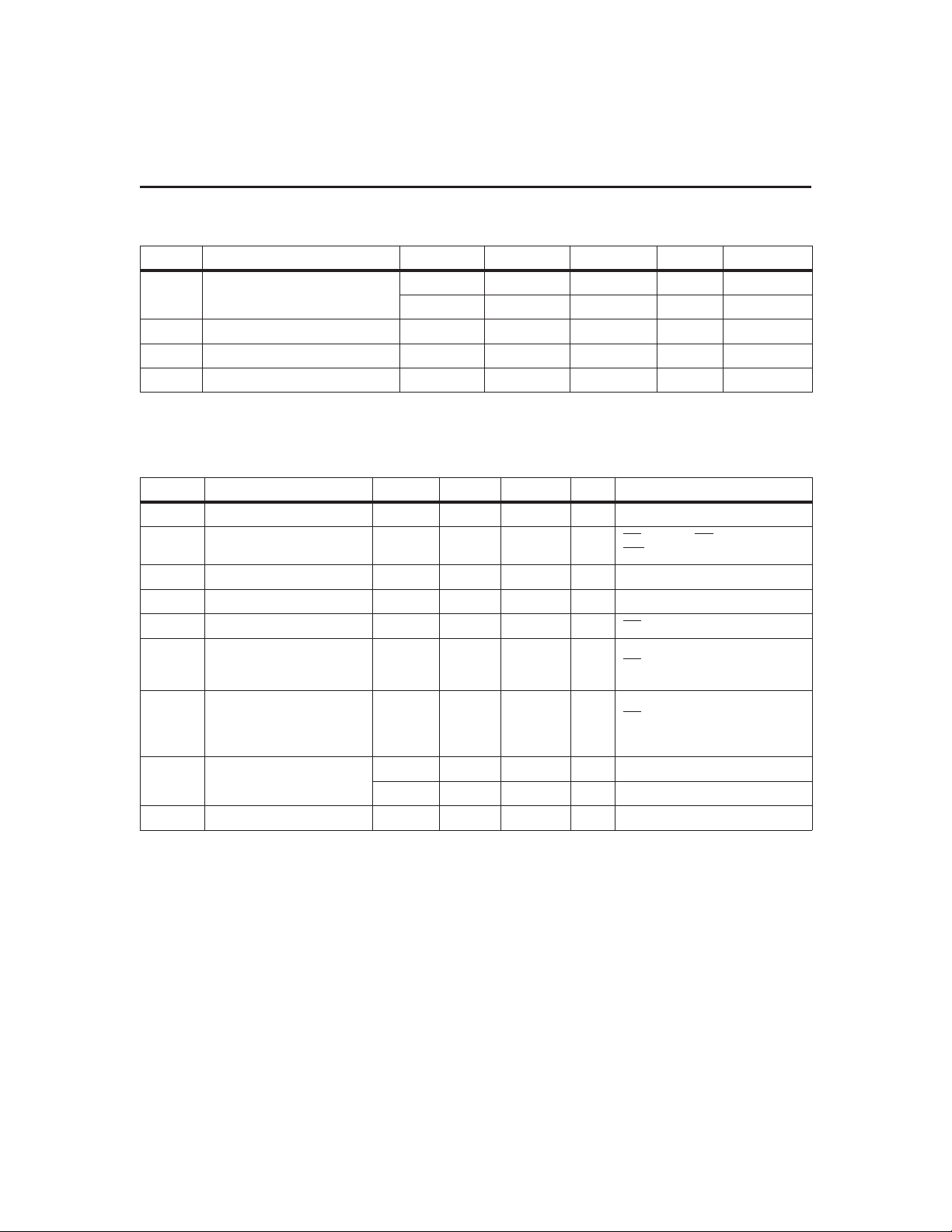

Recommended DC Operating Conditions (T

= 0 to 70°C)

A

Symbol Parameter Minimum Typical Maximum Unit Notes

V

CC

V

SS

V

IL

V

IH

Supply voltage

Supply voltage 0 0 0 V

Input low voltage -0.3 - 0.8 V

Input high voltage 2.2 - VCC+ 0.3 V

4.5 5.0 5.5 V bq4017Y

4.75 5.0 5.5 V bq4017

Note: Typical values indicate operation at TA= 25°C.

DC Electrical Characteristics (T

= 0 to 70°C, V

A

CCmin

V

CC

V

≤

≤

CCmax

)

Symbol Parameter Minimum Typical Maximum Unit Conditions/Notes

I

I

V

V

I

I

LI

LO

OH

OL

SB1

SB2

Input leakage current - -

Output leakage current - -

Output high voltage 2.4 - - V IOH= -1.0 mA

Output low voltage - - 0.4 V IOL= 2.1 mA

Standby supply current - 7 17 mA CE = V

Standby supply current - 2.5 5 mA

4

±

4

±

AVIN= VSSto V

µ

= VIHor OE = VIHor

CE

A

µ

WE

= V

IL

IH

0V≤V

IN

CE

V

≥

CC

or V

V

≥

IN

0.2V,

≤

- 0.2V,

CC

CC

- 0.2

Min. cycle, duty = 100%,

= VIL,I

I

CC

Operating supply current - 75 115 mA

CE

A19 < V

A20 < V

V

PFD

V

SO

Power-fail-detect voltage

Supply switch-over voltage - 3 - V

4.55 4.62 4.75 V bq4017

4.30 4.37 4.50 V bq4017Y

= 0mA,

I/O

or A19 > VIH,

IL

or A20 > V

IL

IH

Note: Typical values indicate operation at TA= 25°C, VCC= 5V.

3

Page 4

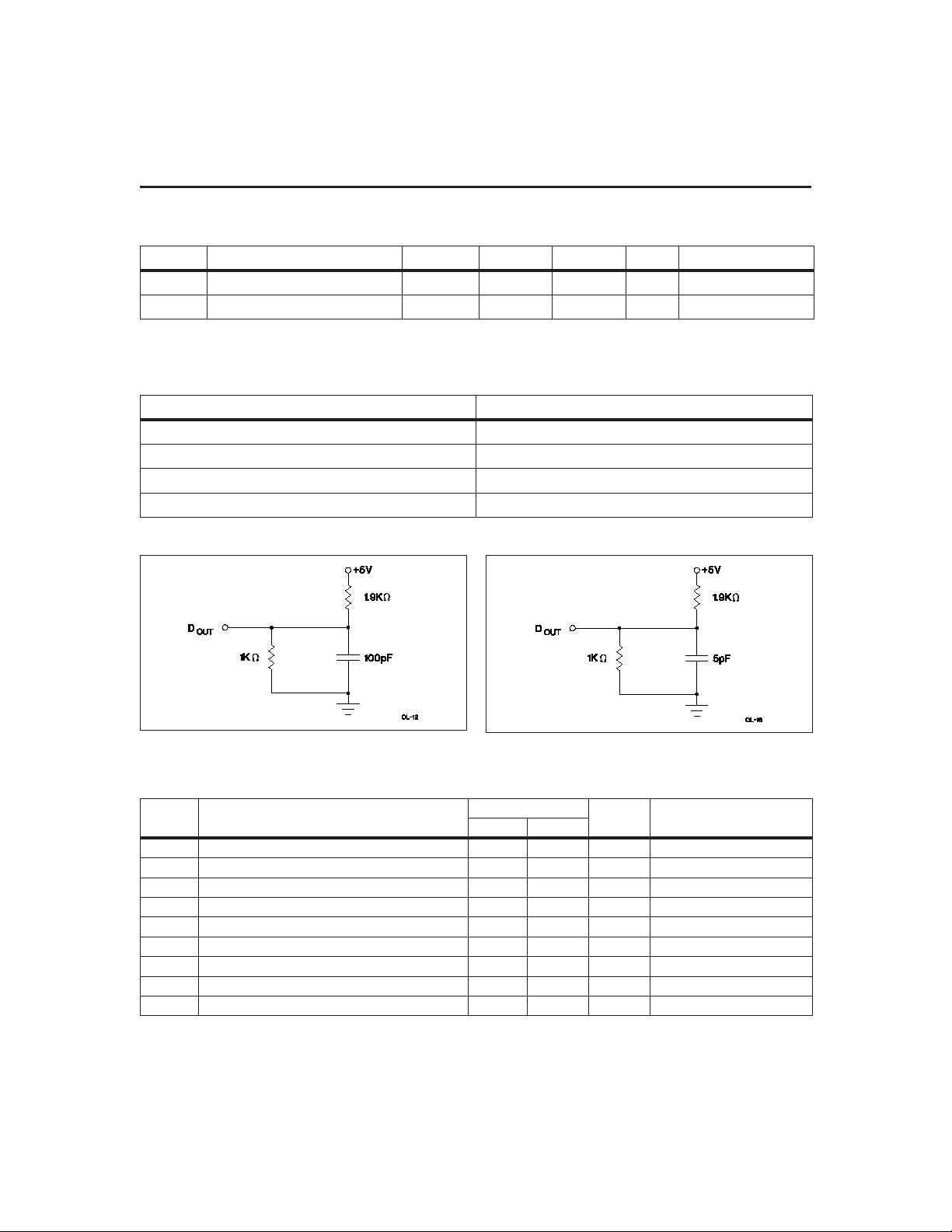

bq4017/bq4017Y

Capacitance (T

= 25°C, F = 1MHz, VCC= 5.0V)

A

Symbol Parameter Minimum Typical Maximum Unit Conditions

C

I/O

C

IN

Input/output capacitance - - 40 pF Output voltage = 0V

Input capacitance - - 40 pF Input voltage = 0V

Note: These parameters are sampled and not 100% tested.

AC Test Conditions

Parameter Test Conditions

Input pulse levels 0V to 3.0V

Input rise and fall times 5 ns

Input and output timing reference levels 1.5 V (unless otherwise specified)

Output load (including scope and jig) See Figures 1 and 2

Figure 1. Output Load A

Read Cycle

Symbol Parameter

t

RC

t

AA

t

ACE

t

OE

t

CLZ

t

OLZ

t

CHZ

t

OHZ

t

OH

(TA= 0 to 70°C, V

CCmin

Read cycle time 70 - ns

Address access time - 70 ns Output load A

Chip enable access time - 70 ns Output load A

Output enable to output valid - 35 ns Output load A

Chip enable to output in low Z 5 - ns Output load B

Output enable to output in low Z 5 - ns Output load B

Chip disable to output in high Z 0 25 ns Output load B

Output disable to output in high Z 0 25 ns Output load B

Output hold from address change 10 - ns Output load A

Figure 2. Output Load B

V

CC

V

≤

≤

CCmax

)

-70

Min. Max.

4

Unit Conditions

Page 5

bq4017/bq4017Y

Read Cycle No. 1 (Address Access)

Read Cycle No. 2 (CE Access)

Read Cycle No. 3 (OE Access)

1,3,4

1,5

1,2

Notes: 1. WE is held high for a read cycle.

2. Device is continuously selected: CE

3. Address is valid prior to or coincident with CE

4. OE

= VIL.

5. Device is continuously selected: CE

=OE= VIL.

transition low.

= VIL.

5

Page 6

bq4017/bq4017Y

Write Cycle (T

= 0 to 70°C, V

A

CCmin

V

CC

V

≤

≤

CCmax

)

-70

Symbol Parameter

t

t

t

t

t

t

t

t

t

t

t

t

WC

CW

AW

AS

WP

WR1

WR2

DW

DH1

DH2

WZ

OW

Write cycle time 70 - ns

Chip enable to end of write 65 - ns (1)

Address valid to end of write 65 - ns (1)

Address setup time 0 - ns

Write pulse width 55 - ns

Write recovery time

(write cycle 1)

Write recovery time

(write cycle 2)

Data valid to end of write 30 - ns

Data hold time

(write cycle 1)

Data hold time

(write cycle 2)

Write enabled to output in high Z 0 25 ns I/O pins are in output state. (5)

Output active from end of write 5 - ns I/O pins are in output state. (5)

Min. Max.

Units Conditions/Notes

5-ns

15 - ns

0-ns

10 - ns

Measured from address valid to be

ginning of write. (2)

Measured from beginning of write to

end of write. (1)

Measured from WE going high to

end of write cycle. (3)

Measured from CE going high to

end of write cycle. (3)

Measured to first low-to-high transition of either CE

Measured from WE going high to

end of write cycle. (4)

Measured from CE going high to

end of write cycle. (4)

Notes: 1. A write ends at the earlier transition of CE going high and WE going high.

2. A write occurs during the overlap of a low CE

of CE

going low and WE going low.

3. Either t

4. Either t

5. If CE

or t

or t

must be met.

WR2

must be met.

DH2

WR1

DH1

goes low simultaneously with WE going low or after WE going low, the outputs remain in

and a low WE. A write begins at the later transition

high-impedance state.

-

or WE.

6

Page 7

bq4017/bq4017Y

Write Cycle No. 1 (WE-Controlled)

Write Cycle No. 2 (CE-Controlled)

1,2,3

1,2,3,4,5

Notes: 1. CE or WE must be high during address transition.

2. Because I/O may be active (OE

outputs must not be applied.

3. If OE

4. Either t

5. Either t

is high, the I/O pins remain in a state of high impedance.

or t

or t

must be met.

WR2

must be met.

DH2

WR1

DH1

low) during this period, data input signals of opposite polarity to the

7

Page 8

bq4017/bq4017Y

Power-Down/Power-Up Cycle (T

= 0 to 70°C)

A

Symbol Parameter Minimum Typical Maximum Unit Conditions

t

PF

t

FS

t

PU

VCCslew, 4.75 to 4.25 V 300 - -

VCCslew, 4.25 to V

VCCslew, VSOto V

(max.)

SO

PFD

10 - -

0--

s

µ

s

µ

s

µ

Time during which SRAM

t

CER

Chip enable recovery time 40 80 120 ms

is write-protected after

V

passes V

CC

FPD

on

power-up.

t

t

DR

WPT

Data-retention time in

absence of V

CC

5 - - years

Write-protect time 40 100 150

s

µ

T

= 25°C. (2)

A

Delay after V

down past V

CC

PFD

slews

before

SRAM is write-protected.

Notes: 1. Typical values indicate operation at TA= 25°C, VCC= 5V.

2. Batteries are disconnected from circuit until after V

is applied for the first time. tDRis the

CC

accumulated time in absence of power beginning when power is first applied to the device.

Caution: Negative undershoots below the absolute maximum rating of -0.3V in battery-backup mode

may affect data integrity.

Power-Down/Power-Up Timing

8

Page 9

MC: 36-Pin C-Type Module

bq4017/bq4017Y

36-Pin MC

Dimension Minimum Maximum

All dimensions are in inches.

(C-Type Module)

A 0.365 0.375

A1 0.015 -

B 0.017 0.023

C 0.008 0.013

D 2.070 2.100

E 0.710 0.740

e 0.590 0.630

G 0.090 0.110

L 0.120 0.150

S 0.175 0.210

9

Page 10

bq4017/bq4017Y

Ordering Information

bq4017 MC -

Temperature:

blank = Commercial (0 to +70°C)

Speed Options:

70 = 70 ns

Package Option:

MC = C-type module

Supply Tolerance:

no mark = 5% negative supply tolerance

Y = 10% negative supply tolerance

Device:

bq4017 2048K x 8 NVSRAM

10

Page 11

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...