Datasheet BQ2057SN-C1TR, BQ2057SN-C1, BQ2057PN-C1, BQ2057CTS-C1TR, BQ2057CTS-C1 Datasheet (Texas Instruments)

...Page 1

1

Features

➤

Ideal for single- and dual-cell Li-Ion

packs with coke or graphite anodes

➤

Dropout voltage as low as 0.3V

➤

AutoComp™ dynamic compensa

-

tion of battery pack’s internal im

-

pedance

➤

Optional temperature-monitoring

before and during charge

➤

Integrated voltage and current

regulation with programmable

charge-current and high- or

low-side current sensing

➤ Integrated cell conditioning for

reviving deeply discharged cells

and minimizing heat dissipation

during initial stage of charge

➤ Better than ±1% voltage regula-

tion accuracy

➤ Charge status output for LED or

host processor interface

➤ Automatic battery-recharge feature

➤

Charge termination by minimum

current

➤

Low-power sleep mode

➤

Packaging: 8-pin SOIC, 8-pin

TSSOP

General Description

The BENCHMARQ bq2057 series

advanced Li-Ion linear charge-man

agement ICs are designed for

cost-sensitive and compact portable

electronics. They combine high-accu

racy current and voltage regulation,

battery conditioning, temperature

monitoring, charge termination,

charge-status indication, and

AutoComp charge-rate compensation in a single 8-pin IC.

The bq2057 continuously measures

battery temperature using an exter

nal thermistor. For safety reasons,

the bq2057 inhibits charge until the

battery temperature is within

user-defined thresholds. The bq2057

then charges the battery in three

phases: conditioning, constant current, and constant voltage. If the

battery voltage is below the

low-voltage threshold V

MIN

, the

bq2057 trickle-charges to condition

the battery. The conditioning charge

rate is set at 10% of the regulation

current. The conditioning current

also minimizes heat dissipation in

the external pass-element during

the initial stage of charge.

After conditioning, the bq2057 ap

-

plies a constant current to the bat

-

tery. An external sense-resistor sets

the magnitude of the current. The

sense-resistor can be on either the

low or the high side of the battery

without additional components. The

constant-current phase continues

until the battery reaches the

charge-regulation voltage.

The bq2057 then begins the con

stant-voltage phase. The accuracy of

the voltage regulation is better than

±1% over the operating-temperature

and supply-voltage ranges. For sin

gle and dual cells with either coke

or graphite anodes, the bq2057 is of

fered in four fixed-voltage versions:

4.1V, 4.2V, 8.2V, and 8.4V. Charge

stops when the current tapers to the

charge termination threshold,

V

TERM

. The bq2057 automatically

restarts the charge if the battery

voltage falls below the V

RCH

thresh-

old.

The designer also may use the

AutoComp feature to reduce charging time. This proprietary technique

allows safe and dynamic compensation for the internal impedance of

the battery pack during charge.

bq2057

Pin Connections

Advanced Li-Ion Linear Charge

Management IC

1

PN-205701.eps

8-Pin PDIP, Narrow SOIC, or TSSOP

2

3

4

8

7

6

5

SNS

BAT

V

CC

TS

COMP

CC

V

SS

STAT

Pin Names

SNS Current-sense input

BAT Battery-voltage input

V

CC

Supply voltage

TS Temperature sense

input

STAT Charge status output

V

SS

Ground input

CC Charge control output

COMP Charge-rate

compensation input

SLUS025A – JANUARY 2000 - REVISED MAY 2000

Page 2

Pin Descriptions

SNS Current-sense input

Battery current is sensed via the voltage de

-

veloped on this pin by an external sense re

-

sistor.

BAT Battery voltage input

Voltage sense-input tied directly to the posi

-

tive side of the battery.

V

CC

VCCsupply input

TS Temperature sense input

Input for an external battery-temperature

monitoring circuit. Connecting this input to

Vcc/2 disables this feature.

STAT Charge status output

Tri-state indication of charge-in-progress,

charge-complete, and temperature fault.

V

SS

Ground input

CC Charge-control output

Source-follower output that drives an exter

nal pass-transistor for current and voltage

regulation.

COMP Charge-rate compensation input

Sets the charge-rate compensation level. The

voltage-regulation output may be pro

grammed to vary as a function of the charge

current delivered to the battery.

2

bq2057

VCC

CC

CONTROL

BLOCK

V

REG

V

SS

V

CC

COMP

BAT

POWER

RESET

ON

SNS

2057FBD.eps

TS

V

TS1

, V

TS2

V

SNS

LED

STAT

STAT

K

COMP

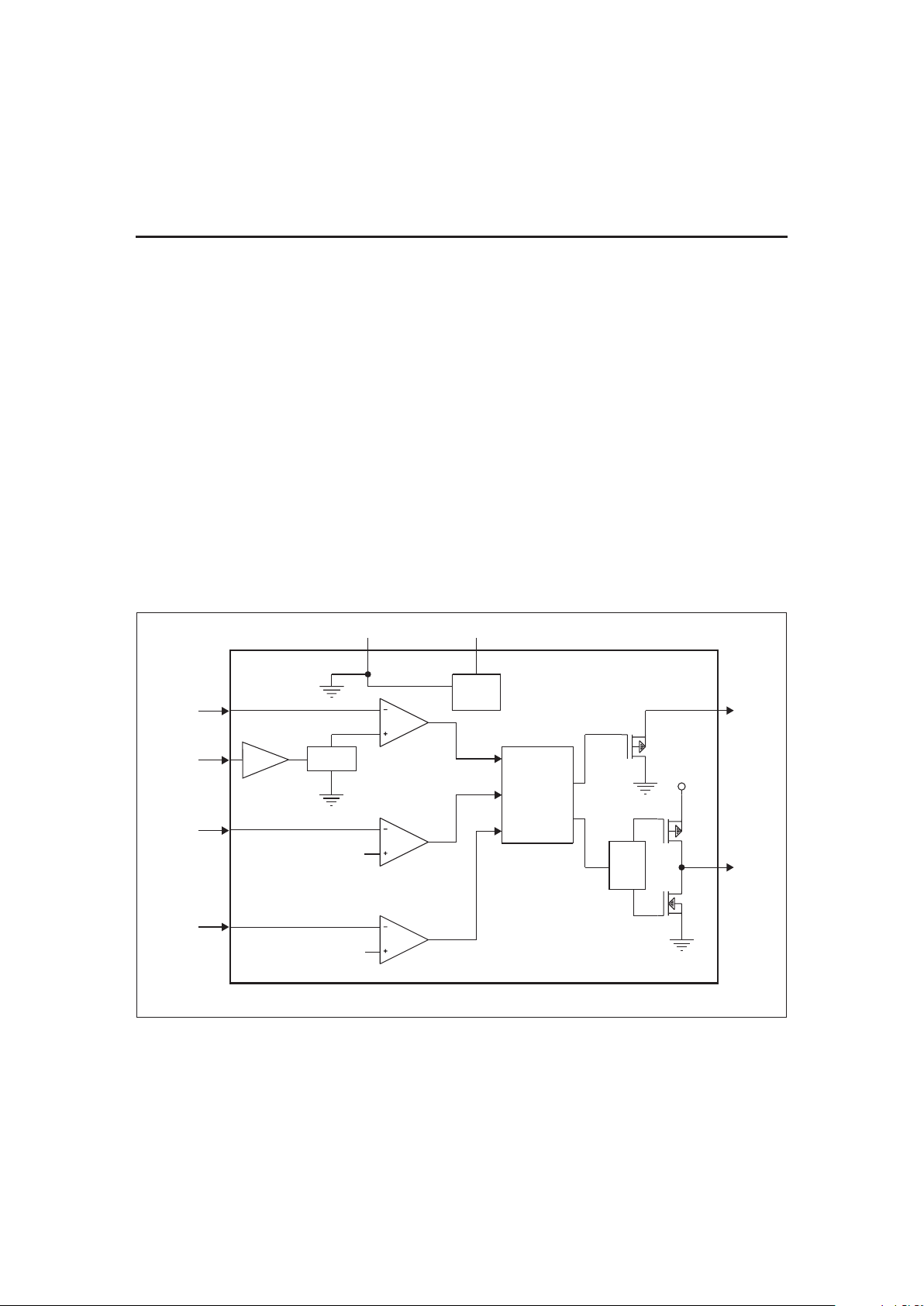

Figure 1. Functional Block Diagram

Page 3

Functional Description

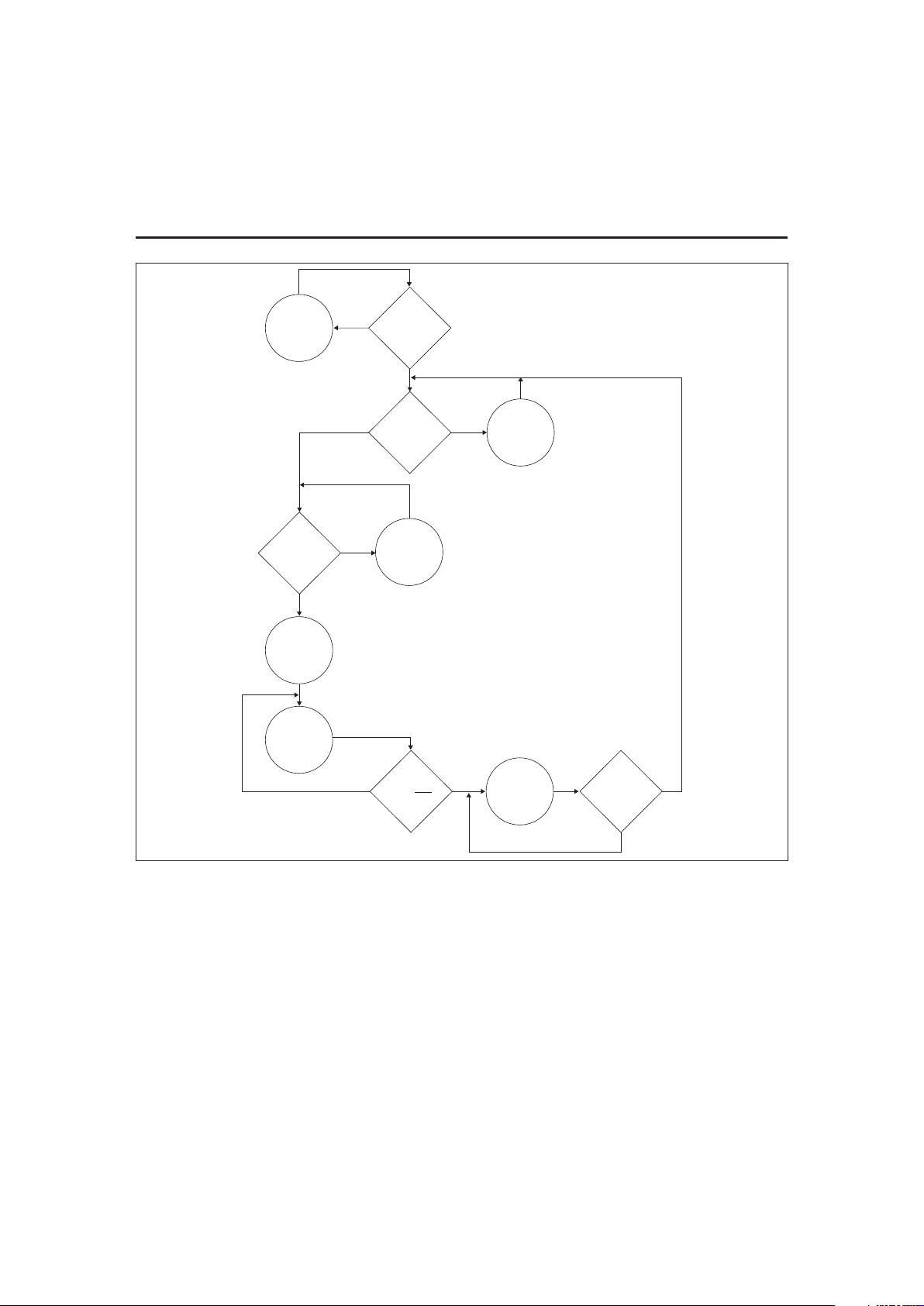

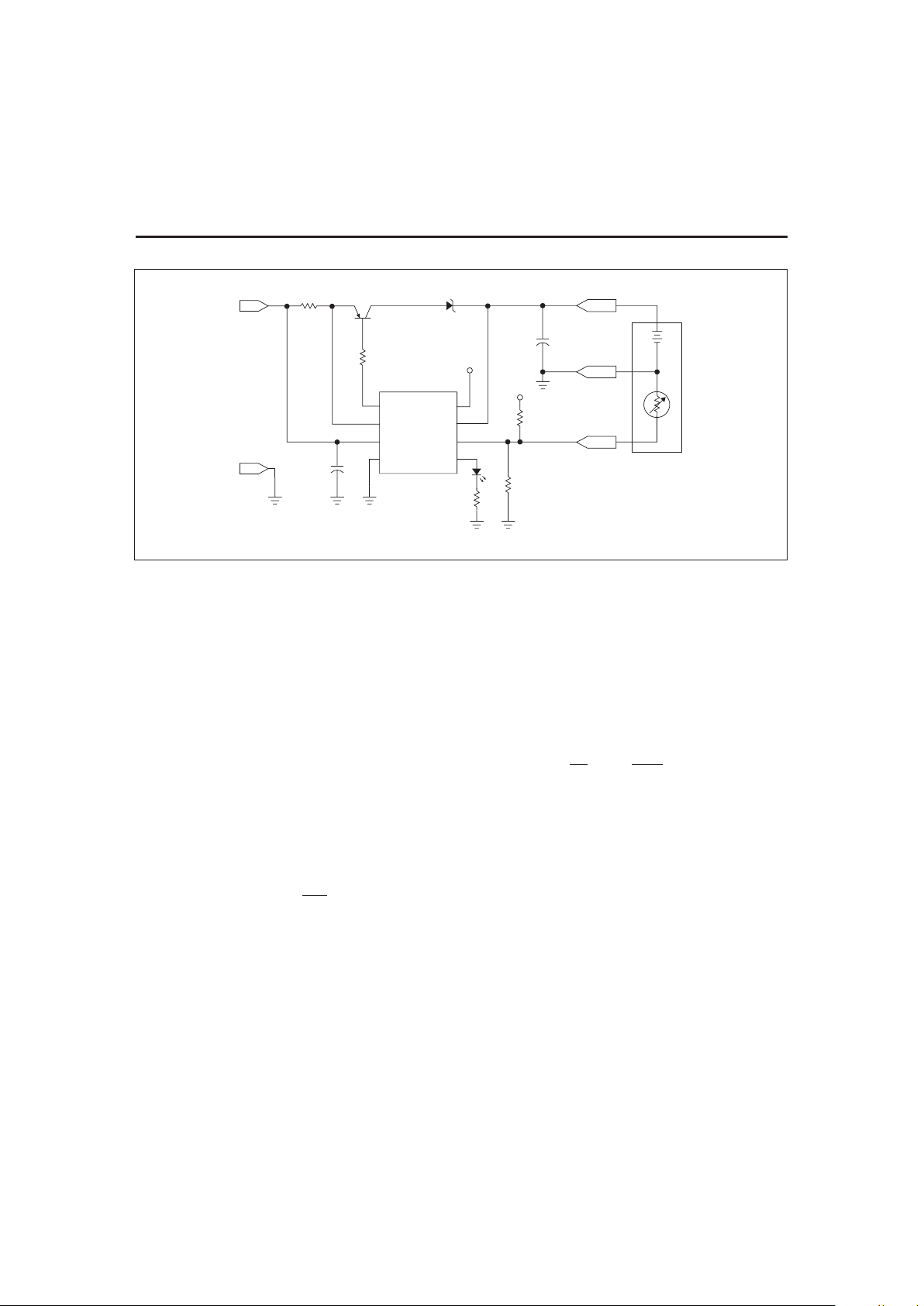

Figure 1 is a functional block diagram, Figure 2 an oper

-

ational flow chart, and Figure 3 a typical charger sche

-

matic for the bq2057.

Charge Qualification and Conditioning

When power is applied, the bq2057 starts a charge-cycle

if a battery is already present or when a battery is in

-

serted. Charge qualification is based on battery temper

-

ature and voltage. The bq2057 suspends charge if the

battery temperature is outside the V

TS1

to V

TS2

range

and suspends charge until the battery temperature is

within the allowed range. The bq2057 also checks the

battery voltage. If the battery voltage is below the

low-voltage threshold V

MIN

, the bq2057 uses

trickle-charge to condition the battery. The conditioning

charge rate I

COND

is set at 10% of the regulation cur

-

rent. The conditioning current also minimizes heat dis

-

3

bq2057

VCC > V

BAT

Temperature

Check

TS > V

TS1

TS < V

TS2

V

BAT

≤ V

MIN

I

BAT

≤ V

BAT

≤ V

RCH

Sleep Mode

LED = Hi-Z

NO

YES

YES

NO

NO

NO

2057OFC.eps

NO

YES

YES

YES

Current

Regulation

Phase

LED = High

Voltage

Regulation

Phase

LED = HIGH

Charge

Complete

LED = LOW

Temperature

Fault

LED = Hi-Z

Conditioning

Phase

LED = High

I

REG

10

Figure 2. bq2057 Operational Flow Chart

Page 4

sipation in the external pass-element during the initial

stage of charge. See Figure 4 for a typical charge-algorithm.

Current Regulation

The bq2057 regulates current while the battery-pack

voltage is less than the regulation voltage, V

REG

. The

bq2057 monitors charge current at the SNS input by the

voltage drop across a sense-resistor, R

SNS

, in series with

the battery pack. In high-side current sensing configura

-

tion (Figure 5), R

SNS

is placed between the Vcc and SNS

pins, and in low-side sensing (Figure 6) the R

SNS

is

placed between Vss (battery negative) and SNS (charger

ground) pins.

Charge-current feedback, applied through pin SNS, main

-

tains regulation around a threshold of V

SNS

. The follow

-

ing formula calculates the value of the sense resistor:

R

SNS

=

V

I

SNS

REG

where I

REG

is the desired charging current.

Voltage Monitoring and Regulation

Voltage regulation feedback is through pin BAT. This in

put is tied directly to the positive side of the battery

pack. The bq2057 monitors the battery-pack voltage be

tween the BAT and V

SS

pins. The bq2057 is offered in

four fixed-voltage versions for single- and dual-cells with

either coke or graphite anodes: 4.1V, 4.2V, 8.2V, and

8.4V.

Other regulation voltages can be achieved by adding a

voltage divider between the positive and negative terminals of the battery pack. The voltage divider presents a

scaled battery pack voltage to BAT input. (See Figures 7

and 8.) The resistor values R

B1

and RB2for the voltage

divider are calculated by the following equation:

R

R

N

V

V

B1

B2

CELL

REG

=∗

− 1

where

N = Number of cells in series

V

CELL

= Desired regulation voltage per cell

Charge Termination and Re-Charge

The bq2057 monitors the charging current during the

voltage-regulation phase. The bq2057 declares a “batterycomplete” condition and terminates charge when the

current tapers off to the charge termination threshold,

V

TERM

. A new charge cycle begins when the battery volt

-

age falls below the

VRCH threshold.

4

bq2057

2057ldc.eps

PACK+

Q1

FZT788B

D2

bq2057

CC

Battery

Pack

V

CC

V

CC

R

T1

R

T2

NTC

C1

0.1µF

C2

0.1µF

R2

2kΩ

R

SNS

0.2Ω

R1

1kΩ

D1

SNS

V

CC

V

SS

COMP

BAT

TS

STAT

DC+

DC-

TEMP

PACK-

78

2

4

5

1

3

6

Figure 3. Low-Dropout Single- or Dual-Cell Li-Ion Charger

*

* Optional.

Page 5

5

bq2057

BAT+

BAT-

DC+

DC-

R

SNS

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

2057HSCS.eps

Figure 5. High-Side Current Sensing

GR2057b.eps

V

BAT

I

BAT

V

PACK

V

REG

V

MIN

I

REG

Low-Current

Conditioning

Phase

Current

Regulation

Phase

Voltage Regulation Phase

(Shown with the optional AutoComp feature)

I

REG

10

I

REG

10

I

COND

=

I

FULL

=

Figure 4. bq2057 Typical Charge Algorithm

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

BAT+

BAT-

DC+

R

SNS

2057LSCS1.eps

DC-

Figure 6. Low-Side Current Sensing

Page 6

Temperature Monitoring

The bq2057 continuously monitors temperature by measuring the voltage between the TS and V

SS

pins. A negative- or a positive-temperature coefficient thermistor

(NTC, PTC) and an external voltage-divider typically develop this voltage. (See Figure 9.) The bq2057 compares

this voltage against its internal V

TS1

and V

TS2

thresholds

to determine if charging is allowed. (See Figure 10.) The

temperature sensing circuit is immune to any fluctuation

in the V

CC

, since both the external voltage divider and

the internal thresholds (V

TS1

and V

TS2

) are referenced to

V

CC

.

The resistor values of R

T1

and RT2are calculated by the

following equations:

For NTC thermistors

()

()

()

R=

5R R

3R-R

T1

TH TC

TC TH

∗∗

∗

()

()()

()

R=

5R R

2R 7R

T2

TH TC

TC TH

∗∗

∗−∗

6

bq2057

BAT+

BAT-

2057OVDHSC.eps

R

SNS

R

B1

R

B2

DC+

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

DC-

Figure 7. Optional Voltage Divider for

Non-Standard Regulation Voltage,

(High-Side Current Sensing)

BAT+

BAT-

2057OVDLSC.eps

R

SNS

R

B1

R

B2

DC+

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

DC-

Figure 8. Optional Voltage Divider for

Non-Standard Regulation Voltage,

(Low-Side Current Sensing)

BAT+

BAT-

Thermistor

DC+ DC+

R

SNS

RT2

RT1

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

High-Side Current Sensing Low-Side Current Sensing

2057TSC.eps

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

BAT+

BAT-

R

SNS

R

T2

R

T1

Thermistor

DC-

DC-

Figure 9. Temperature Sensing Circuits

Page 7

For PTC thermistors

()

()

R=

5R R

3R-R

T1

TH TC

TH TC

∗∗

∗

()

()()

()

R=

5R R

2R 7R

T2

TH TC

TH TC

∗∗

∗−∗

where R

TC

is the cold-temperature resistance and RTHis

the hot-temperature resistance of the thermistor, as

specified by the thermistor manufacturer.

R

T1

or RT2can be omitted if only one temperature set

-

ting (Hot or Cold) is required.

Applying a voltage between the V

TS1

and V

TS2

thresh

-

olds to pin TS disables the temperature-sensing feature.

Low-Power Mode

The bq2057 enters the sleep mode if the VCCfalls below

the voltage at the BAT input. This feature prevents

draining the battery pack during the absence of V

CC

.

Charge Status Display

The bq2057 reports the status of the charger on the

tri-state STAT pin. The three states include “charge in

progress, charge complete, and temperature fault.

Condition STAT Pin

Battery conditioning and charging High

Charge complete Low

Temperature fault or sleep mode High-Z

Automatic Charge-Rate

Compensation

To reduce charging time, the bq2057 uses the propri

-

etary AutoComp technique to compensate safely for in

-

ternal impedance of the battery pack.

Figure 11 outlines the major components of a single-cell

Li-Ion battery pack. The Li-Ion battery pack consists of

a cell, protection circuit, fuse, connector, current

sense-resistors, and some wiring. Each of these compo

nents contains some resistance. Total impedance of the

battery pack is the sum of the minimum resistances of

all battery-pack components. Using the minimum resis

tance values reduces the odds for overcompensating.

Overcompensating may activate the safety circuit of the

battery pack.

Compensation is through input pin COMP (Figure 12).

A portion of the current-sense voltage, presented

through this pin, is scaled by a factor of K

COMP

and

summed with the regulation threshold, V

REG

. This process increases the output voltage to compensate for the

battery pack’s internal impedance and for undesired

voltage drops in the circuit.

7

bq2057

V

CC

V

TS2

V

TS1

Temp Fault

2057TSIT.eps

Temp Fault

Normal Temp Range

V

SS

Figure 10. bq2057 TS Input Thresholds

BAT-

BAT+

Wire

Terminal

Terminal

Discharge

Charge

2057SCLIP.eps

Protection

Controller

R2

FUSE

Wire

Cell

WireWire

Figure 11. Typical Components of a

Single-Cell Li-Ion Pack

Page 8

AutoComp setup requires the following information:

n

Total impedance of battery pack (Z

PACK

)

n

Maximum charging current (I

REG

)

The voltage drop VZ across the internal impedance of

the battery pack can then be calculated by

V

Z

= Z

PACK

∗ I

REG

The required compensation is then calculated using the

following equations:

V=

V

K

COMP

Z

COMP

V

PACK

= V

REG

+ (K

COMP

∗ V

COMP

)

where V

COMP

is the voltage on COMP pin. This voltage

is referenced to Vcc in high-side current-sensing configuration and to Vss for low-side sensing. V

PACK

is the

voltage across the battery pack.

The values of R

COMP1

and R

COMP2

can be calculated us-

ing the following equation:

V

V

R

R+R

COMP

SNS

COMP2

COMP1 COMP2

=

8

bq2057

R

COMP1

R

SNS

R

COMP2

DC+

High-Side Current Sensing

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

BAT+

BAT+

BAT-

R

COMP1

STAT

5

V

SS

6

CC

7

COMP

8

SNS

1

BAT

2

V

CC

3

TS

4

bq2057

DC+

R

SNS

Low-Side Current Sensing

2057AC.eps

R

COMP2

DC-

DC-

Figure 12. AutoComp Circuits

Page 9

9

bq2057

DC Thresholds (T

A=TOPR

and VCC= 4.5–15V unless otherwise specified)

Symbol Parameter Rating Tolerance Unit Notes

V

REG

Voltage regulation reference

4.10

±1%

V For bq2057 only; See Note 1,2,3

4.20

±1%

V For bq2057C only; See Note 1,2,3

8.20

±1%

V For bq2057T only; See Note 1,2,3

8.40

±1%

V For bq2057W only; See Note 1,2,3

V

SNS

Current regulation reference

-110

±10%

mV

V

CC

= 5V, See Note 4

-115 ±10% mV V

CC

= 9V, See Note 4

-115 ±15% mV All other V

CC

, See Note 4

V

MIN

Conditioning voltage reference

3.0 ±2% V For bq2057 only

3.1 ±2% V For bq2057C only

6.0 ±2% V For bq2057T only

6.2 ±2% V For bq2057W only

K

COMP

AutoComp gain 2.2

±15%

V/V See Note 1

V

TS1

Lower temperature threshold

0.3 ∗ V

CC

±3% of V

CC

V

Voltage at pin TS, relative to V

SS

V

TS2

Upper temperature threshold

0.6 ∗ V

CC

±3% of V

CC

V

Voltage at pin TS, relative to V

SS

V

RCH

Recharge threshold

V

REG

- 0.1

±2% V

Voltage on BAT pin, bq2057 and

bq2057C only

V

RCH

Recharge threshold

V

REG

- 0.2

±2% V

Voltage on BAT pin, bq2057T

and bq2057W only

V

TERM

Charge termination reference -14 ±10mV mV See Note 4

Notes: 1. VCC= V

BAT

+ 0.3V to 15V.

2. For high-side current-sensing configuration.

3. For low-side current-sensing, the tolerance is ±1% for T

A = 25°C and ±1.2% for TA = TORR.

Absolute Maximum Ratings

Symbol Parameter Min. Max. Units Notes

V

CC

VCCrelative to V

SS

-0.3 +18 V

V

T

VCCrelative to V

SS

-0.3

V

CC

+ 0.3

V

DC voltage applied on any pin (ex

-

cluding V

CC

)

T

OPR

Operating ambient temperature -20 70

°C

T

STG

Storage temperature -40 125

°C

P

D

Power dissipation 300 mW

4. Voltage at pin SNS, relative to VCC for high-side sensing, and to VSS for low-side sensing,

0°C <= T

A <= 50°C

abcdefghijklmnopqrstuvwxyz1234567890-=`[]\;',./

ABCDEFGHIJKLMNOPQRSTUVWXYZ!@#%^&*()_+{}|:"<>?~

Page 10

10

bq2057

DC Electrical Characteristics (T

A

= T

OPR

, and VCC= 4.5 - 15V unless otherwise specified))

Symbol Parameter Min Typical Max Units Notes

V

CC

Supply voltage 4.5 - 15 V

I

CC

Operating current - 2 4 mA Excluding external loads

I

CCS

Sleep current

-36µAFor bq2057 and bq2057C, See note

--10µAFor bq2057T and bq2057W, See note

V

OL

Output-low voltage - 0.4 0.6 V IOL= 10mA; STAT pin

V

OH

Output-high voltage VCC- 0.5 - - V IOH= 5mA; STAT pin

I

IH

Input leakage current

--1

µA

BAT input, V

BAT

= V

REG

--5

µA

SNS, COMP, and TS inputs,

V

SNS

= V

COMP

= VTS= 5V

I

SNK

Sink current 5 - 40 mA CC pin, not to exceed PDspecification

V

OLCC

CC pin output-low

voltage

- - 1.5 V

At I

SNK

(minimum)

Note: V

BAT

≥ V

MIN,VBAT -VCC

≥ 0.8V, +20°C ≤ TA≤ 70°C.

8-Pin SOIC Narrow (SN)

8-Pin SN(0.150" SOIC

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.060 0.070 1.52 1.78

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.18 0.25

D 0.185 0.200 4.70 5.08

E 0.150 0.160 3.81 4.06

e 0.045 0.055 1.14 1.40

H 0.225 0.245 5.72 6.22

L 0.015 0.035 0.38 0.89

Page 11

11

bq2057

Notes:

1. Controlling dimension: millimeters. Inches shown for reference only.

2 'D' and 'E' do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15mm per side

3 Each lead centerline shall be located within ±0.10mm of its exact true position.

4. Leads shall be coplanar within 0.08mm at the seating plane.

5 Dimension 'B' does not include dambar protrusion. The dambar protrusion(s) shall not cause the lead width

to exceed 'B' maximum by more than 0.08mm.

6 Dimension applies to the flat section of the lead between 0.10mm and 0.25mm from the lead tip.

7 'A1' is defined as the distance from the seating plane to the lowest point of the package body (base plane).

Dimension

Inches Millimeters

Min. Max. Min. Max.

A - 0.043 - 1.10

A1 0.002 0.006 0.05 0.15

B 0.007 0.012 0.18 0.30

C 0.004 0.007 0.09 0.18

D 0.114 0.122 2.90 3.10

E 0.169 0.176 4.30 4.48

e 0.0256BSC 0.65BSC

H 0.246 0.256 6.25 6.50

TS: 8-Pin TSSOP

Ordering Information

bq2057

Package Option:

SN = 8-pin narrow SOIC

TS = 8-pin TSSOP

Device:

bq2057 Advanced Li-Ion Linear Charger for One Cell (4.1V)

bq2057C Advanced Li-Ion Linear Charger for One Cell (4.2V)

bq2057T Advanced Li-Ion Linear Charger for Two Cells (8.2V)

bq2057W Advanced Li-Ion Linear Charger for Two Cells (8.4V)

Page 12

12

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue any

product or service without notice, and advise customers to obtain the latest version of relevant information to verify,

before placing orders, that information being relied on is current and complete. All products are sold subject to the

terms and conditions of sale supplied at the time of order acknowledgement, including those pertaining to warranty,

patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in accor

dance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent TI deems

necessary to support this warranty. Specific testing of all parameters of each device is not necessarily performed, ex

cept those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH,

PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). TI

SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BE SUITABLE FOR

USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF TI

PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating safeguards

must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent that

any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellec

tual property right of TI covering or relating to any combination, machine, or process in which such semiconductor

products or services might be or are used. TI’s publication of information regarding any third party’s products or ser

vices does not constitute TI’s approval, warranty or endorsement thereof.

Copyright © 2000, Texas Instruments Incorporated

Loading...

Loading...