Page 1

1

Features

➤

Safe charge of Lithium Ion bat

-

tery packs

➤

Voltage-regulated currentlimited charging

➤

Fast charge terminated by se

lectable minimum current; safety

backup termination on maximum

time

➤

Charging continuously qualified

by temperature and voltage lim

its

➤

Pulse-width modulation control

ideal for high-efficiency switchmode power conversion

➤ Direct LED control outputs dis-

play charge status and fault conditions

General Description

The bq2054 Lithium Ion FastCharge IC is designed to optimize

charging of lithium ion (Li-Ion)

chemistry batteries. A flexible

pulse-width modulation regulator

allows the bq2054 to control voltage

and current during charging. The

regulator frequency is set by an ex

ternal capacitor for design flexibility.

The switch-mode design keeps

power dissipation to a minimum.

The bq2054 measures battery tem

perature using an external thermis

tor for charge qualification. Charging

begins when power is applied or on

battery insertion.

For safety, the bq2054 inhibits

charging until the battery voltage

and temperature are within con-

figured limits. If the battery voltage

is less than the low-voltage thresh

old, the bq2054 provides low-current

conditioning of the battery.

A constant current-charging phase re

plenishes up to 70% of the charge ca

pacity, and a voltage-regulated phase

returns the battery to full. The charge

cycle terminates when the charging

current falls below a user-selectable

current limit. For safety, charging ter

minates after maximum time and is

suspended if the temperature is out

side the preconfigured limits.

The bq2054 provides status indica

tions of all charger states and faults

for accurate determination of the

battery and charge system condi

tions.

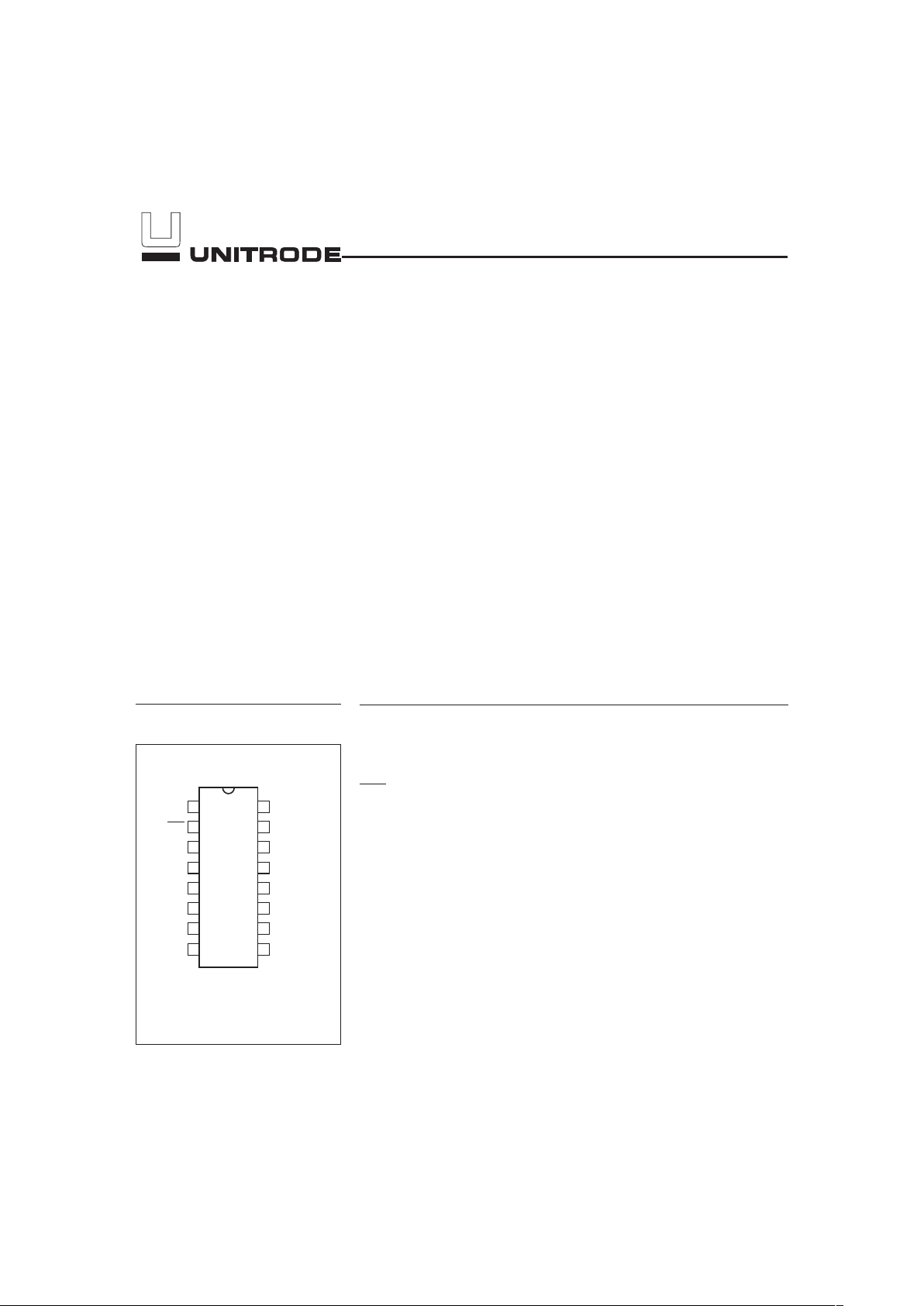

Lithium Ion Fast-Charge IC

bq2054

TM Time-out programming

input

ICTL

Inrush current control

output

BAT Battery voltage input

VCOMP Voltage loop comp input

ICOMP Current loop comp input

I

TERM

Minimum current

termination select input

SNS Sense resistor input

TS Temperature sense input

1

PN205401.eps

16-Pin Narrow

DIP or SOIC

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

LED2/DSEL

LED

1

MOD

V

CC

V

SS

LCOM

LED

3

TPWM

TM

ICTL

BAT

VCOMP

ICOMP

I

TERM

SNS

TS

TPWM Regulator timebase input

LED

3

Charge status output 3

LCOM Common LED output

V

SS

System ground

V

CC

5.0V±10% power

MOD Modulation control output

LED

1

Charge status output 1

LED

2

/ Charge status output 2/

DSEL Display select input

Pin Connections

Pin Names

6/99 H

Page 2

Pin Descriptions

TM Time-out programming input

This input sets the maximum charge time.

The resistor and capacitor values are deter

mined using Equation 5. Figure 7 shows the

resistor/capacitor connection.

ICTL

Inrush current control output

ICTL

is driven low during the fault or

charge-complete states of the chip. It is used

to disconnect the capacitor across the battery

pack terminals, preventing inrush currents

from tripping overcurrent protection fea

-

tures in the pack when a new battery is in

-

serted.

BAT Battery voltage input

BAT is the battery voltage sense input. This

potential is generally developed using a

high-impedance resistor divider network

connected between the positive and the

negative terminals of the battery. See Figure 4 and Equation 1.

VCOMP Voltage loop compensation input

This input uses an external R-C network for

voltage loop stability.

I

TERM

Minimum current termination select

This three-state input is used to set I

MIN

for

fast charge termination. See Table 2.

ICOMP Current loop compensation input

This input uses an external R-C network for

current loop stability.

SNS Charging current sense input

Battery current is sensed via the voltage de

-

veloped on this pin by an external sense re

-

sistor, R

SNS

, connected in series with the

negative terminal of the battery pack. See

Equation 6.

TS Temperature sense input

This input is used to monitor battery tempera

ture. An external resistor divider network sets

the lower and upper temperature thresholds.

See Figure 6 and Equations 3 and 4.

TPWM Regulation timebase input

This input uses an external timing capacitor

to ground to set the pulse-width modulation

(PWM) frequency. See Equation 7.

LCOM Common LED output

Common output for LED

1–3

. This output is

in a high-impedance state during initiali

zation to read programming input on

DSEL.

MOD Current-switching control output

MOD is a pulse-width modulated push/pull

output that is used to control the charging

current to the battery. MOD switches high

to enable current flow and low to inhibit current flow.

LED

1

–

LED

3

Charger display status 1–3 outputs

These charger status output drivers are for

the direct drive of the LED display. Display

modes are shown in Table 1. These outputs are

tri-stated during initialization so that DSEL

can be read.

DSEL Display select input

This three-level input controls the LED

1–3

charge display modes. See Table 1.

V

CC

VCCsupply

5.0V,±10% power

V

SS

Ground

2

bq2054

Page 3

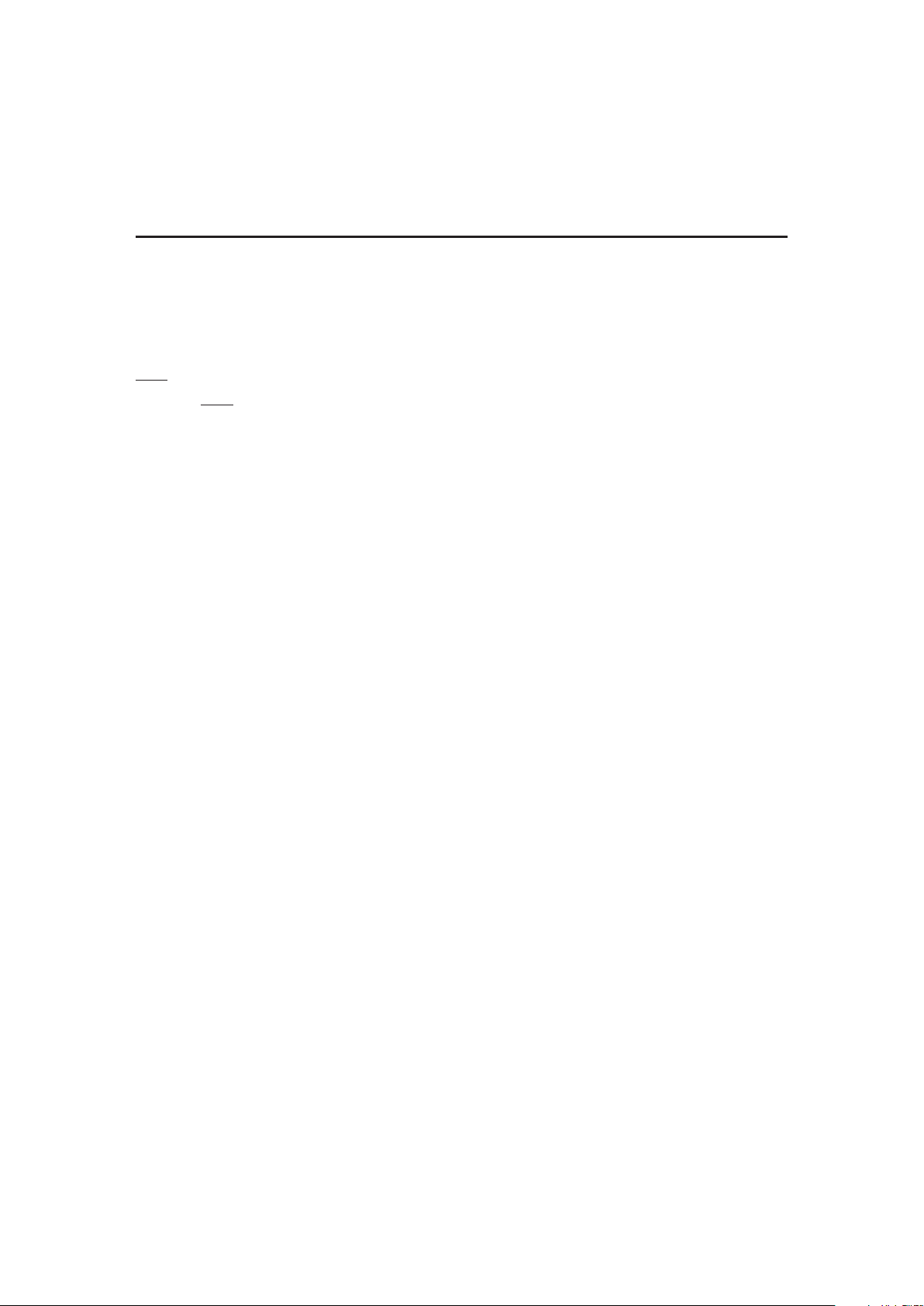

Charge Algorithm

The bq2054 uses a two-phase fast charge algorithm. In

phase 1, the bq2054 regulates constant current (I

SNS

=

I

MAX

) until V

CELL

(= V

BAT-VSNS

) rises to V

REG

. The

bq2054 then transitions to phase 2 and regulates con

-

stant voltage (V

CELL=VREG

) until the charging current

falls below the programmed I

MIN

threshold. The charg

-

ing current must remain below I

MIN

for 120±40ms bef

ore a valid fast charge termination is detected. Fast

charge then terminates, and the bq2054 enters the

Charge Complete state. See Figures 1 and 2.

Charge Qualification

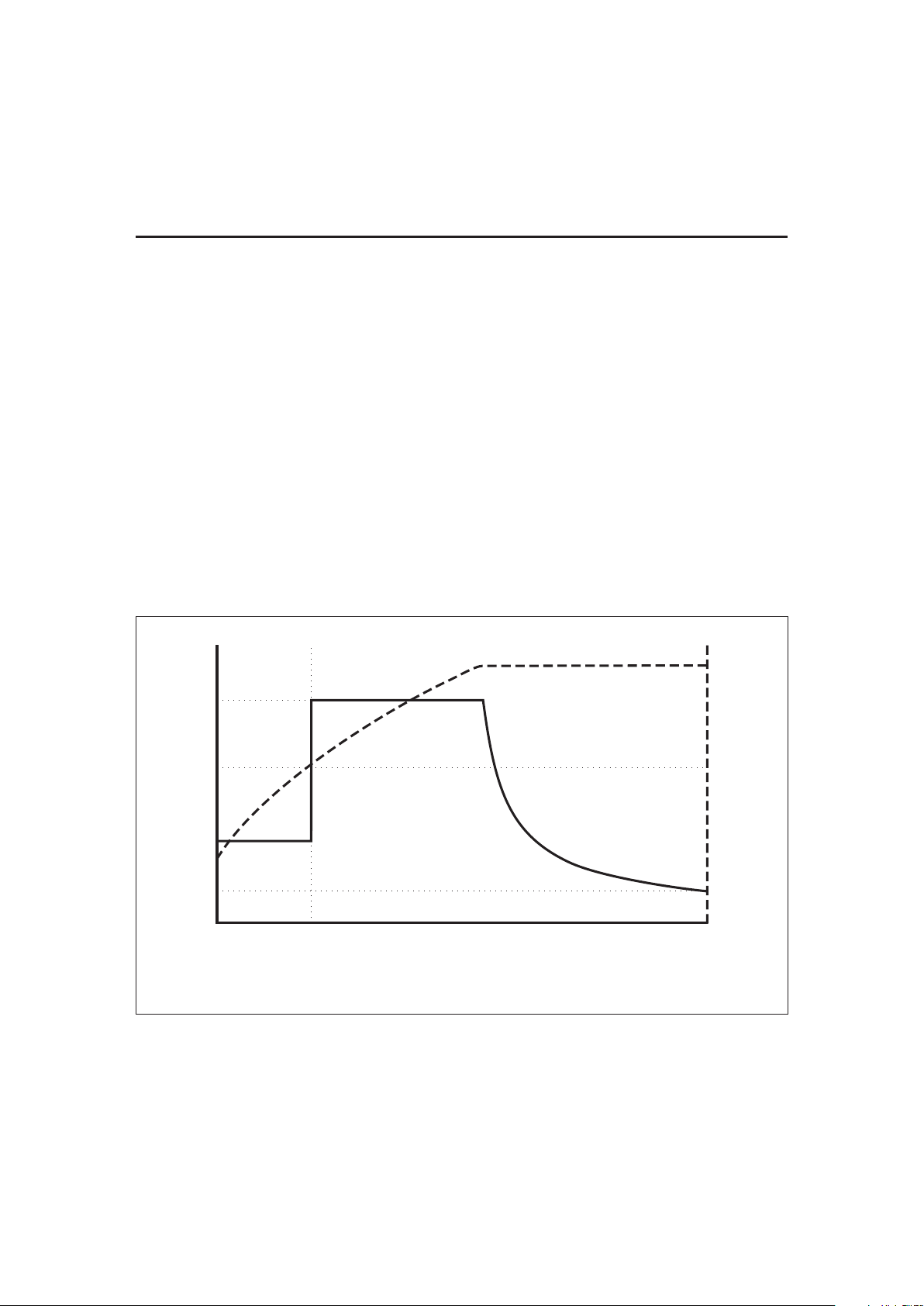

The bq2054 starts a charge cycle when power is applied

while a battery is present or when a battery is inserted.

Figure 2 shows the state diagram for pre-charge qualifi

cation and temperature monitoring. The bq2054 first

checks that the battery temperature is within the al

lowed, user-configurable range. If the temperature is out

of range, the bq2054 enters the Charge Pending state

and waits until the battery temperature is within the allowed range. Charge Pending is enunciated by LED

3

flashing.

Thermal monitoring continues throughout the charge

cycle, and the bq2054 enters the Charge Pending state

when the temperature out of range. (There is one excep

tion; if the bq2054 is in the Fault state—see below—the

out-of-range temperature is not recognized until the

bq2054 leaves the Fault state.) All timers are sus

pended (but not reset) while the bq2054 is in Charge

Pending. When the temperature comes back into range,

the bq2054 returns to the point in the charge cycle

where the out-of-range temperature was detected.

When the temperature is valid, the bq2054 then regu

lates current to I

COND

(=I

MAX

/5). After an initial holdoff

period t

HO

(which prevents the chip from reacting to

transient voltage spikes that may occur when charge

current is first applied), the chip begins monitoring

V

CELL

.IfV

CELL

does not rise to at least V

MIN

before the

expiration of time-out limit t

MTO

(e.g. the cell has failed

short), the bq2054 enters the Fault state. If V

MIN

is

achieved before expiration of the time limit, the chip be

-

gins fast charging.

Once in the Fault state, the bq2054 waits until V

CC

is

cycled or a new battery insertion is detected. It then

starts a new charge cycle and begins the qualification

process again.

3

bq2054

GR205401.eps

I

MAX

I

MIN

I

COND

V

MIN

V

REG

Current

Voltage

Qualification

Time

Phase 1 Phase 2

Fast Charge

Voltage

Current

Figure 1. bq2054 Charge Algorithm

Page 4

4

Chip On

VCC 4.5V

Temperature

Checks On

Battery

Status?

Temperature

in Range

Temperature Out

of Range or

Thermistor Absent

Qualification Test

Current

Regulation

@ I

COND

Phase 2

V = V

REG

Fault

LED3 =1

MOD = 0

Charge

Complete

Charge

Pending

LED3 flash

MOD = 0

Phase 1

I = I

MAX

Temperature Out

of Range or

Thermistor Absent

Temperature In

Range, Return

to Original State

V

BAT

< V

LCO

or

V

BAT

> V

HCO

t t > t

MTO

or

V

BAT

< V

LCO

or

V

BAT

> V

HCO

Fail: t = tQT or

V

BAT

< V

LCO

V

BAT

> V

HCO

Present

V

LCO

< V

BAT

< V

HCO

V

BAT

< V

MIN

PASS: V

BAT

V

MIN

V

BAT

< V

REG

V

BAT

V

REG

Fast

Charge

I

SNS

> I

MIN

I

SNS

I

MIN

or

t t

MTO

FG205401.eps

Absent

V

BAT

< V

LCO

or

V

BAT > VHCO

>

>

<

>

>

V

BAT

V

LCO

or

V

BAT

V

HCO

V

BAT

V

LCO

or

V

BAT

V

HCO

Figure 2. bq2054 State Diagram

bq2054

Page 5

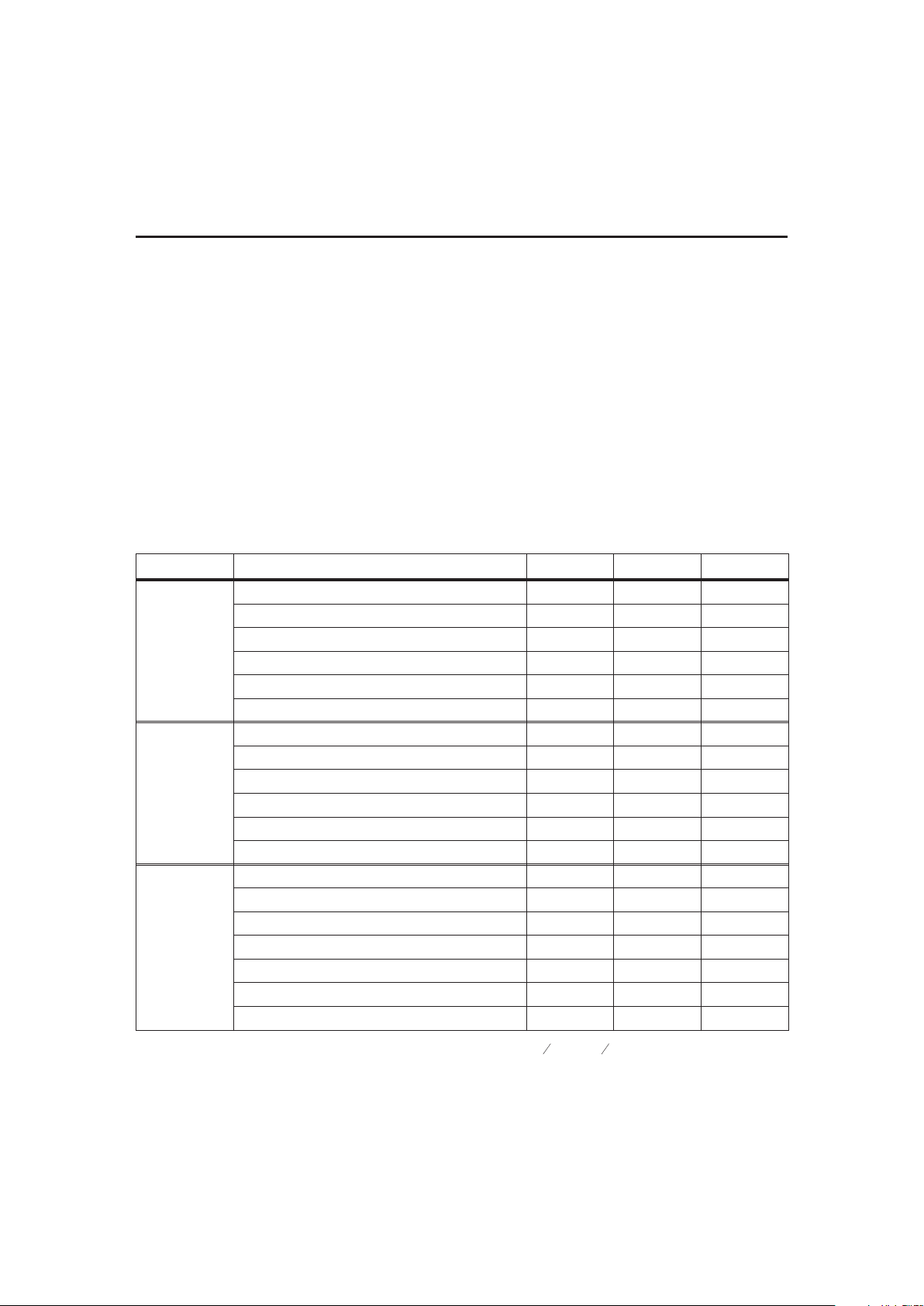

Charge Status Display

Charge status is enunciated by the LED driver outputs

LED

1

–LED3. Three display modes are available in the

bq2054; the user selects a display mode by configuring

pin DSEL. Table 1 shows the three display modes.

The bq2054 does not distinguish between an overvoltage fault and a “battery absent” condition. The

bq2054 enters the Fault state, enunciated by turning on

LED

3

, whenever the battery is absent. The bq2054,

therefore, gives an indication that the charger is on even

when no battery is in place to be charged.

Configuring the Display Mode and I

MIN

DSEL/LED

2

is a bi-directional pin with two functions; it

is an LED driver pin as an output and a programming

pin as an input. The selection of pull-up, pull-down, or

no pull resistor programs the display mode on DSEL per

Table 1. The bq2054 latches the programming data

sensed on the DSEL input when any one of the following

three events occurs:

1. V

CC

rises to a valid level.

2. The bq2054 leaves the Fault state.

3. The bq2054 detects battery insertion.

The LEDs go blank for approximately 750ms (typical)

while new programming data is latched.

5

bq2054

Mode Charge Action State LED

1

LED

2

LED

3

DSEL = 0

(Mode 1)

Battery absent or over-voltage fault Low Low High

Pre-charge qualification Flash Low Low

Fast charging High Low Low

Charge complete Low High Low

Charge pending (temperature out of range) X X Flash

Charging fault X X High

DSEL = 1

(Mode 2)

Battery absent or over-voltage fault Low Low High

Pre-charge qualification High High Low

Fast charge Low High Low

Charge complete High Low Low

Charge pending (temperature out of range) X X Flash

Charging fault X X High

DSEL = Float

(Mode 3)

Battery absent or over-voltage fault Low Low High

Pre-charge qualification Flash Flash Low

Fast charge: current regulation Low High Low

Fast charge: voltage regulation High High Low

Charge complete High Low Low

Charge pending (temperature out of range) X X Flash

Charging fault X X High

Note: 1 = VCC; 0 = VSS; X = LED state when fault occurred; Flash =

1

6

sec. low,

1

6

sec high.

Table 1. bq2054 Display Output Summary

Page 6

Fast charge terminates when the charging current drops

below a minimum current threshold programmed by the

value of I

TERM

(see Table 2) and remains below that

level for 120±40ms.

Figure 3 shows the bq2054 configured for display mode 2

and I

MIN=IMAX

/10.

Voltage and Current Monitoring

The bq2054 monitors battery pack voltage at the BAT

pin. The user must implement a voltage divider between the positive and negative terminals of the battery

pack to present a scaled battery pack voltage to the BAT

pin. The bq2054 also uses the voltage across a sense resistor (R

SNS

) between the negative terminal of the battery pack and ground to monitor the current into the

pack. See Figure 4 for the configuration of this network.

The resistor values are calculated from the following:

Equation 1

RB1

RB2

NV

V

REG

=−

*

.205

1

where:

n

N = Number of cells in series

n

V

REG

= Desired fast-charging voltage per cell

These parameters are typically specified by the battery

manufacturer. The total resistance presented across the

battery pack by RB1 + RB2 should be between 150k

Ω

and 1MΩ. The minimum value ensures that the divider

network does not drain the battery excessively when the

power source is disconnected. Exceeding the maximum

value increases the noise susceptibility of the BAT pin.

The current sense resistor, R

SNS

(see Figure 5), deter

-

mines the fast charge current. The value of R

SNS

is

given by the following:

Equation 2

I

V

R

MAX

SNS

=

0 250.

where:

n

I

MAX

= Desired maximum charge current

Hold-Off Period

Both V

HCO

and I

MIN

terminations are ignored during

the first 1.33±0.19 seconds of both the Charge Qualification and Fast Charge phases. This condition prevents

premature termination due to voltage spikes that may

occur when charge is first applied.

6

bq2054

Table 2. I

MIN

Termination Thresholds

I

TERM

I

MIN

0I

MAX

/10

1I

MAX

/20

Float I

MAX

/30

Page 7

7

FG205403.eps

BAT

SNS

bq2054

7

3

13

V

CC

12

BAT +

BAT -

V

SS

R

SNS

RB2

RB1

V

SS

V

CC

Figure 4. Configuring the Battery Divider

LED2/DSEL

FG205402.eps

LED1

V

CC

V

SS

LCOM

LED3

bq2054

11

10

12

13

15

16

6

V

SS

V

CC

10K

1K

1K

1K

Figure 3. Configured Display Mode/IMIN Threshold

bq2054

Page 8

Battery Insertion and Removal

V

CELL

is interpreted by the bq2054 to detect the pres

ence or absence of a battery. The bq2054 determines

that a battery is present when V

CELL

is between the

High-Voltage Cutoff (V

HCO=VREG

+ 0.25V) and

the Low-Voltage Cutoff (V

LCO

= 0.8V). When V

CELL

is

outside this range, the bq2054 determines that no bat

tery is present and transitions to the Fault state. Tran

sitions into and out of the range between V

LCO

and V

HCO

are treated as battery insertions and removals, respec

tively. The V

HCO

limit also implicitly serves as an over-

voltage charge termination.

Inrush Current Control

Whenever the bq2054 is in the fault or charge-complete

state, the ICTL

output is driven low. This output can be

used to disconnect the capacitor usually present in the

charger across the positive and negative battery termi

nals, preventing the cap from supplying large inrush

currents to a newly inserted battery. Such inrush cur

rents may trip the overcurrent protection circuitry usu

ally present in Li-Ion battery packs.

Temperature Monitoring

The bq2054 monitors temperature by examining the

voltage presented between the TS and SNS pins by a re

sistor network that includes a Negative Temperature

Coefficient (NTC) thermistor. Resistance variations

around that value are interpreted as being proportional

to the battery temperature (see Figure 6).

The temperature thresholds used by the bq2054 and

their corresponding TS pin voltage are:

n

TCO (Temperature Cutoff): Higher limit of the tem

-

perature range in which charging is allowed. V

TCO

=

0.4*V

CC

n

HTF (High-Temperature Fault): Threshold to which

temperature must drop after temperature cutoff is

exceeded before charging can begin again. V

HTF

=

0.44 * V

CC

n

LTF (Low-Temperature Fault): Lower limit of the

temperature range in which charging is allowed.

V

LTF

=0.6*V

CC

8

V

CC

V

LTF

= 0.6V

CC

V

HTF

= 0.44V

CC

V

TCO

= 0.4V

CC

HotterV

SS

TCO

HTF

LTF

Colder

V

o

lt

age

Temperature

Figure 6. Voltage Equivalent

of Temperature

SNS

bq2054

7

13

V

CC

12

BAT -

V

SS

R

SNS

RT2

RT1

V

SS

V

CC

TS

8

˚t

NTC

Thermistor

RT

Figure 5. Configuring

Temperature Sensing

bq2054

Page 9

A resistor-divider network can be implemented that

presents the defined voltage levels to the TS pin at the

desired temperatures (see Figure 6).

The equations for determining RT1 and RT2 are:

Equation 3

06

0 250

1

.*

(.)

*( )

(* )

V

V

RT1 RT2 R

RT2 R

CC

CC

LTF

LTF

=

−

+

+

Equation 4

044

1

1

.

*( )

(* )

=

+

+RT1 RT2 R

RT2 R

HTF

HTF

where:

n

R

LTF

= thermistor resistance at LTF

n

R

HTF

= thermistor resistance at HTF

TCO is determined by the values of RT1 and RT2. 1%

resistors are recommended.

Disabling Temperature Sensing

Temperature sensing can be disabled by placing 10k

Ω

resistors between TS and SNS and between SNS and

V

CC

.

Maximum Time-Out

MTO is programmed from 1 to 24 hours by an R-C net

-

work on the TM pin (see Figure 7) per the equation:

Equation 5

t

MTO

= 0.5*R*C

Where R is in kΩandCisinµF, t

MTO

is in hours. The

maximum value for C (0.1µF) is typically used.

The MTO timer is reset at the beginning of fast charge

and when fast charge transitions from the current regu

-

lated to the voltage regulated mode. If MTO expires dur

ing the current regulated phase, the bq2054 enters the

Fault state and terminates charge. If the MTO timer ex

pires during the voltage regulated phase, fast charging

terminates and the bq2054 enters the Charge Complete

state.

The MTO timer is suspended (but not reset) during the

out-of-range temperature (Charge Pending) state.

Charge Regulation

The bq2054 controls charging through pulse-width

modulation of the MOD output pin, supporting both

constant-current and constant-voltage regulation.

Charge current is monitored at the SNS pin, and charge

voltage is monitored at the BAT pin. These voltages are

compared to an internal reference, and the MOD output

modulated to maintain the desired value.

Voltage at the SNS pin is determined by the value of re

-

sistor R

SNS

, so nominal regulated current is set by:

Equation 6

I

MAX

= 0.250V/R

SNS

The switching frequency of the MOD output is deter

mined by an external capacitor (CPWM) between the

pin TPWM and ground, per the following:

Equation 7

F

PWM

= 0.1/C

PWM

Where C is inµF and F is in kHz. A typical switching

rate is 100kHz, implying C

PWM

= 0.001µF. MOD pulse

width is modulated between 0 and 90% of the switching

period.

To prevent oscillation in the voltage and current control

loops, frequency compensation networks (C or R-C) are typi

-

cally required on the V

COMP

and I

COMP

pins (respectively).

9

TM

FG205406.eps

V

CC

V

SS

bq2054

12

13

1

V

SS

V

CC

C

R

Figure 7. R-C Network for Setting MTO

bq2054

Page 10

10

Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Unit Notes

V

CC

VCCrelative to V

SS

-0.3 +7.0 V

V

T

DC voltage applied on any pin ex

-

cluding V

CC

relative to V

SS

-0.3 +7.0 V

T

OPR

Operating ambient temperature -20 +70 °C Commercial

T

STG

Storage temperature -55 +125 °C

T

SOLDER

Soldering temperature - +260 °C 10 sec. max.

Note: Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional opera

-

tion should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Expo

-

sure to conditions beyond the operational limits for extended periods of time may affect device reliability.

bq2054

Page 11

11

DC Thresholds (T

A

= T

OPR

; VCC= 5V±10%)

Symbol Parameter Rating Unit Tolerance Notes

V

REF

Internal reference voltage 2.05 V 1% TA= 25°C

Temperature coefficient -0.5 mV/°C 10%

V

LTF

TS maximum threshold 0.6*V

CC

V

±

0.03V Low-temperature fault

V

HTF

TS hysteresis threshold 0.44*V

CC

V

±

0.03V High-temperature fault

V

TCO

TS minimum threshold 0.4*V

CC

V

±

0.03V Temperature cutoff

V

HCO

High cutoff voltage 2.3V V 1%

V

MIN

Under-voltage threshold at BAT 0.2*V

CC

V

±

0.03V

V

LCO

Low cutoff voltage 0.8 V

±

0.03V

V

SNS

Current sense at SNS

0.250 V 10% I

MAX

0.050 V 10% I

COND

bq2054

Page 12

12

Recommended DC Operating Conditions (T

A

= T

OPR)

Symbol Parameter Minimum Typical Maximum Unit Notes

V

CC

Supply voltage 4.5 5.0 5.5 V

V

TEMP

Temperature sense voltage 0 - V

CC

VVTS- V

SNS

V

CELL

Per cell battery voltage input 0 - V

CC

VV

BAT

- V

SNS

I

CC

Supply current - 2 4 mA Outputs unloaded

I

IZ

DSEL tri-state open detection -2 - 2

µ

A Note 2

I

TERM

tri-state open detection -2 2

µ

A

V

IH

Logic input high VCC-0.3 - - V DSEL, I

TERM

V

IL

Logic input low - - VSS+0.3 V DSEL, I

TERM

V

OH

LED

1-3

, ICTL, output high VCC-0.8 - - V I

OH

≤

10mA

MOD output high V

CC

-0.8 - - V I

OH

≤

10mA

V

OL

LED

1-3

, ICTL, output low - - VSS+0.8V V I

OL

≤

10mA

MOD output low - - V

SS

+0.8V V I

OL

≤

10mA

LCOM output low - - V

SS+

0.5 V I

OL

≤

30mA

I

OH

LED

1-3

, ICTL, source -10 - - mA VOH=VCC-0.5V

MOD source -5.0 - - mA V

OH=VCC

-0.5V

I

OL

LED

1-3

, ICTL, sink 10 - - mA VOL= VSS+0.5V

MOD sink 5 - - mA V

OL

= VSS+0.8V

LCOM sink 30 - - mA V

OL

= VSS+0.5V

I

IL

DSEL logic input low source - - +30

µ

A V = VSSto VSS+ 0.3V, Note 2

I

TERM

logic input low source - - +70

µ

A V = VSSto VSS+ 0.3V

I

IH

DSEL logic input high source -30 - -

µ

A V = VCC- 0.3V to V

CC

I

TERM

logic input high source -70 - -

µ

A V = VCC- 0.3V to V

CC

Notes: 1. All voltages relative to VSSexcept where noted.

2. Conditions during initialization after V

CC

applied.

bq2054

Page 13

13

Impedance

Symbol Parameter Minimum Typical Maximum Unit Notes

R

BATZ

BAT pin input impedance 50 - - M

Ω

R

SNSZ

SNS pin input impedance 50 - - M

Ω

R

TSZ

TS pin input impedance 50 - - M

Ω

R

PROG1

Soft-programmed pull-up or pull-down

resistor value (for programming)

--10

k

Ω

DSEL

R

PROG2

Pull-up or pull-down resistor value - - 3 k

Ω

I

TERM

R

MTO

Charge timer resistor 20 - 480 k

Ω

Timing (T

A

= T

OPR;VCC

= 5V±10%)

Symbol Parameter Minimum Typical Maximum Unit Notes

t

MTO

Charge time-out range 1 - 24 hours See Figure 7

t

QT

Pre-charge qual test time-out period - t

MTO

--

t

HO

Termination hold-off period 1.14 - 1.52 sec.

t

IMIN

Min. current detect filter period 80 160 msec.

F

PWM

PWM regulator frequency range - 100 kHz

C

PWM

= 0.001µF

(equation 7)

Capacitance

Symbol Parameter Minimum Typical Maximum Unit

C

MTO

Charge timer capacitor - - 0.1

µ

F

C

PWM

PWM R-C capacitance - 0.001 -

µ

F

bq2054

Page 14

14

bq2054

16-Pin PN(0.300" DIP

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.160 0.180 4.06 4.57

A1 0.015 0.040 0.38 1.02

B 0.015 0.022 0.38 0.56

B1 0.055 0.065 1.40 1.65

C 0.008 0.013 0.20 0.33

D 0.740 0.770 18.80 19.56

E 0.300 0.325 7.62 8.26

E1 0.230 0.280 5.84 7.11

e 0.300 0.370 7.62 9.40

G 0.090 0.110 2.29 2.79

L 0.115 0.150 2.92 3.81

S 0.020 0.040 0.51 1.02

16-Pin DIP Narrow (PN)

16-Pin SOIC Narrow (SN)

A

A1

.004

C

B

e

D

E

H

L

16-Pin SN(0.150" SOIC

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.060 0.070 1.52 1.78

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.18 0.25

D 0.385 0.400 9.78 10.16

E 0.150 0.160 3.81 4.06

e 0.045 0.055 1.14 1.40

H 0.225 0.245 5.72 6.22

L 0.015 0.035 0.38 0.89

Page 15

15

bq2054

Data Sheet Revision History

Change No. Page No. Description Nature of Change

1 5, 7, 8, 10 Value Change Changed V

SNS

and I

MAX

2 5, 10 Value Change Changed V

REF

3 10 Coefficient Addition Temperature coefficient added

4 5 New state diagram Diagram inserted

4 1, 2, 8, 12 NC pin replaced with ICTL

4 3,5,13

Termination hold-off period added

I

MIN

detect filtering added

511

V

HCO

Rating changed to 2.3V

V

HCO

Tolerance changed to 1%

Changed values for V

HCO

613

t

QT

in Timing Specifications

t

QT

changed from (0.16 ∗ t

MTO

) to t

MTO

75I

TERM

in Table 2 Z changes to Float

7 8 Figure 6 RB1 and RB2 changed to RT1 and RT2

810T

OPR

Deleted industrial temperature range.

Notes: Change 3 = April 1996 C changes from Dec. 1995 B.

Change 4 = Sept. 1996 D changes from April 1996 C.

Change 5 = Nov. 1996 E changes from Sept. 1996 D.

Change 6 = Oct. 1997 F changes from Nov. 1996 E.

Change 7 = Oct. 1997 G changes from Oct. 1997 F.

Change 8 = June 1999 H changes from Oct. 1997 G.

Ordering Information

bq2054

Package Option:

PN = 16-pin plastic DIP

SN = 16-pin narrow SOIC

Device:

bq2054 Li-Ion Fast-Charge IC

Page 16

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...