Page 1

1/4

STRUCTURE Silicon Monolithic Integrated Circuit

PRODUCT SERIES 1ch. Reversible Motor Driver

TYPE BD6736FV

FEATURES ・Full-ON type 1ch. H-bridge Driver

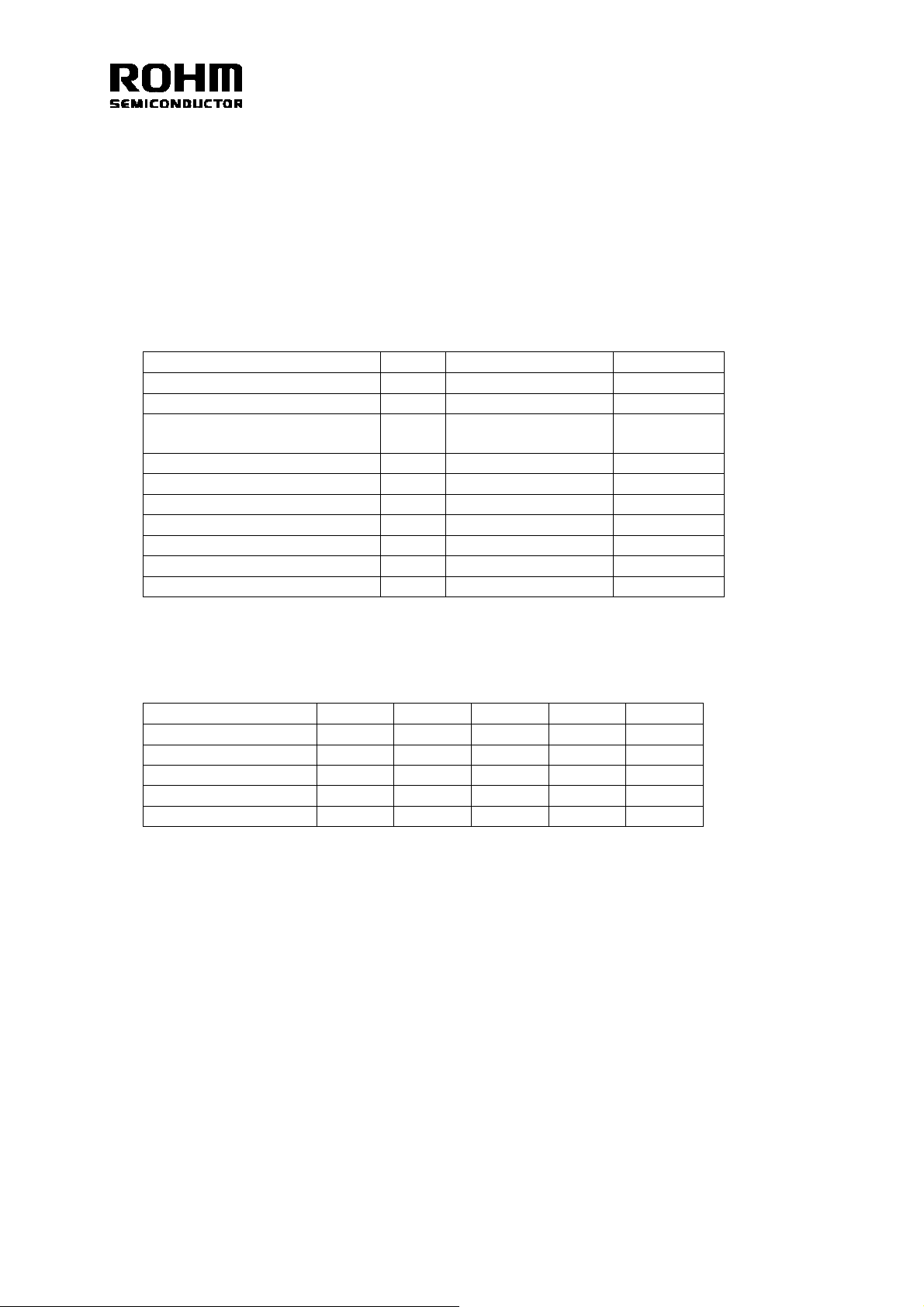

zAbsolute maximum ratings (Ta=25°C)

Parameter Symbol Limit Unit

Power supply voltage VCC -0.5 to +10.0 V

Motor power supply voltage VM -0.5 to +10.0 V

Charge pump step-up

power supply voltage

Control input voltage VIN -0.5 to VCC+0.5 V

Power dissipation Pd 930※1 mW

Operating temperature range Topr -30 to +75 °C

Junction temperature Tjmax 150 °C

Storage temperature range Tstg -55 to +150 °C

H-bridge output current DC Iout -1000 to +1000※2 mA

H-bridge output current (100msec) Iopeak -3200 to +3200※2 mA

※1

Reduced by 7.44mW/°C over 25°C, when mounted on a glass epoxy board (70mm × 70mm × 1.6mm)

※2

Must not exceed Pd, ASO, or Tjmax of 150°C.

VBST -0.5 to +15.0 V

zOperating Conditions (Ta= -30°C to +75°C)

Parameter Symbol Min. Typ. Max. Unit

Power supply voltage VCC 2.0 5.0 9.0 V

Motor power supply voltage VM 2.0 5.0 9.0 V

Control input voltage VIN 0 - VCC V

Logic input frequency FIN 0 - 100 kHz

Min. logic pulse width TIN 0.5 - - μs

The product described in this specification is a strategic product (and/or service) subject to COCOM regulations.

It should not be exported without authorization from the appropriate government authorities.

This product isn’t designed for protection against radioactive rays.

Status of this document: The Japanese version of this document is the formal specification. A customer may use this translation

version only for a reference to help reading the formal version. If there are any differences in translation version of this document,

formal version takes priority.

REV. C

Page 2

2/4

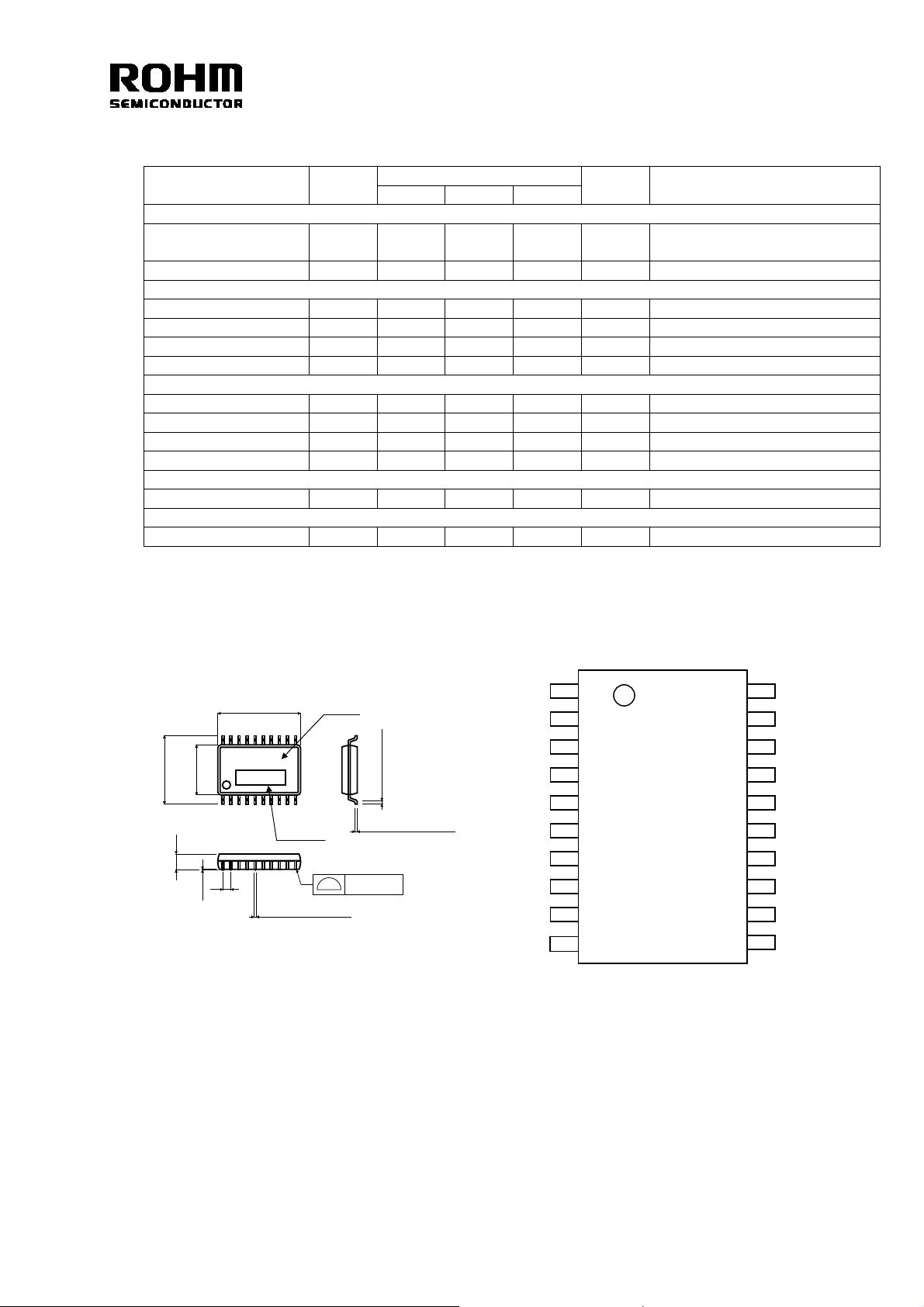

zBD6736FV Electrical Characteristics (Unless otherwise specified Ta=25°C, VCC=5.0V, VM=5.0V)

Parameter Symbol

Overall

Circuit current

during standby operation

Circuit current ICC 0.5 2.0 4.0 mA PS=H, FIN=100kHz

Power saving

High-level input voltage VPSH 2.0 - VCC V

Low-level input voltage VPSL -0.3 - 0.5 V

High-level input current IPSH 25 50 100 μA VPSH=5V

Low-level input current IPSL -1 0 1 μA VPSL=0V

Control input

High-level input voltage VINH 2.0 - VCC V

Low-level input voltage VINL -0.3 - 0.7 V

High-level input current IINH 25 50 100 μA VINH=5V

Low-level input current IINL -1 0 1 μA VINL=0V

UVLO

UVLO voltage VUVLO 1.5 - 1.9 V

Full-ON Drive block

Output ON-Resistance RON - 0.35 0.5 Ω Io=±500mA on high and low sides in total

ICCST - 0 1 μA PS=0V

Min. Typ. Max.

Limit

Unit Conditions

zPackage Outline zPin Arrangement (Top View)

1

6.4 ± 0.3

6.5 ± 0.2

20

4.4 ± 0.2

1

BD6736

11

10

Lot No.

Type name

0.3Min.

0.15 ± 0.1

1.15 ± 0.1

0.1

0.65

0.22 ± 0.1

0.1

VM

2

N.C.

3

OUTA

4

OUTA

MGND

5

MGND

6

OUTB

7

OUTB

8

VM

9

10

GND

Fig.1 SSOP-B20 Package (Unit: mm)

Fig.2 BD6736FV Pin Arrangement (Top View)

VCC

PS

INA

INB

PWM

CPL1

CPL2

CPH1

CPH2

BST

20

19

18

17

16

15

14

13

12

11

REV. C

Page 3

3/4

zBlock Diagram zPin No. and Pin Name

PS

19

Power Save

INA

INB

18

17

16

PWM

Logic

Power Save

1~100uF

Level Shift

&

Pre Driver

BST

VCC

20

BandGapTSD & UVLO

9

4

8

6

1~100uF

VM

OUTA

OUTB

MGND

H bridge

1

3

F

7

5

OSC Charge Pump Charge Pump

10

GND

14

15 13 11

CPL1 CPL2

CPH1

12

CPH2

BST

Fig.3 BD6736FV Block Diagram

No. Pin ame

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

VM

N.C.

OUTA

OUTA

MGND

MGND

OUTB

OUTB

VM

GND

BST

CPH2

CPH1

CPL2

CPL1

PWM

INB

INA

PS

VCC

I/O Truth Table

z

BD6736FV I/O Truth Table

INPUT OUTPUT

Input mode

EN/IN

IN/IN L

- L X X X Z Z

L: Low, H: High, X: Don’t care, Z: High Impedance

PS

H

PWM

EN

H

INA INB OUTA OUTB

L X L L

H L H L

H H L H

L L Z Z

H L H L

L H L H

H H L L

REV. C

Page 4

4/4

zOperation Notes

(1) Absolute maximum ratings

Use of the IC in excess of absolute maximum ratings such as the applied voltage or operating temperature range (Topr) may

result in IC damage. Assumptions should not be made regarding the state of the IC (short mode or open mode) when such

damage is suffered. The implementation of a physical safety measure such as a fuse should be considered when use of the IC in

a special mode where the absolute maximum ratings may be exceeded is anticipated.

(2) Power supply pins and lines

None of the VM line for the H-bridge is internally connected to the VCC power supply line, which is only for the control logic or

analog circuit. Therefore, the VM and VCC lines can be driven at different voltages. Although these lines can be connected to a

common power supply, do not open the power supply pin but connect it to the power supply externally.

Regenerated current may flow as a result of the motor's back electromotive force. Insert capacitors between the power supply

and ground pins to serve as a route for regenerated current. Determine the capacitance in full consideration of all the

characteristics of the electrolytic capacitor, because the electrolytic capacitor may loose some capacitance at low temperatures.

If the connected power supply does not have sufficient current absorption capacity, regenerative current will cause the voltage

on the power supply line to rise, which combined with the product and its peripheral circuitry may exceed the absolute maximum

ratings. It is recommended to implement a physical safety measure such as the insertion of a voltage clamp diode between the

power supply and ground pins.

For this IC with 2 power supplies and a part consists of the CMOS block, it is possible that rush current may flow instantaneously

due to the internal powering sequence and delays, and to the unstable internal logic, respectively. Therefore, give special

consideration to power coupling capacitance, width of power and ground wirings, and routing of wiring.

(3) Ground pins and lines

Ensure a minimum GND pin potential in all operating conditions. Make sure that no pins are at a voltage below the GND at any

time, regardless of whether it is a transient signal or not.

When using both small signal GND and large current MGND patterns, it is recommended to isolate the two ground patterns,

placing a single ground point at the application's reference point so that the pattern wiring resistance and voltage variations

caused by large currents do not cause variations in the small signal ground voltage. Be careful not to change the GND wiring

pattern of any external components, either.

The power supply and ground lines must be as short and thick as possible to reduce line impedance.

(4) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

(5) Actions in strong magnetic field

Use caution when using the IC in the presence of a strong magnetic field as doing so may cause the IC to malfunction.

(6) ASO

When using the IC, set the output transistor for the motor so that it does not exceed absolute maximum ratings or ASO.

(7) Thermal shutdown circuit

This IC incorporates a TSD (thermal shutdown) circuit. If the temperature of the chip reaches the following temperature,

the motor coil output will be opened. The TSD circuit is designed only to shut the IC off to prevent runaway thermal operation.

It is not designed to protect the IC or guarantee its operation. Do not continue to use the IC after operating this circuit or use

the IC in an environment where the operation of this circuit is assumed.

TSD ON temperature [°C] (Typ.) Hysteresis temperature [°C] (Typ.)

(8) Application example

The application circuit is recommended for use. Make sure to confirm the adequacy of the characteristics. When using the circuit

with changes to the external circuit constants, make sure to leave an adequate margin for external components including static

and transitional characteristics as well as dispersion of the IC.

160 20

REV. C

Page 5

Appendix

No copying or reproduction of this document, in part or in whole, is permitted without the consent of ROHM

CO.,LTD.

The content specified herein is subject to change for improvement without notice.

The content specified herein is for the purpose of introducing ROHM's products (hereinafter "Products"). If you

wish to use any such Product, please be sure to refer to the specifications, which can be obtained from ROHM

upon request.

Examples of application circuits, circuit constants and any other information contained herein illustrate the

standard usage and operations of the Products. The peripheral conditions must be taken into account

when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specified in this document. However, should

you incur any damage arising from any inaccuracy or misprint of such information, ROHM shall bear no re-

sponsibility for such damage.

The technical information specified herein is intended only to show the typical functions of and examples

of application circuits for the Products. ROHM does not grant you, explicitly or implicitly, any license to

use or exercise intellectual property or other rights held by ROHM and other parties. ROHM shall bear no re-

sponsibility whatsoever for any dispute arising from the use of such technical information.

The Products specified in this document are intended to be used with general-use electronic equipment

or devices (such as audio visual equipment, office-automation equipment, communication devices, elec-

tronic appliances and amusement devices).

The Products are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a Product may fail or

malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard against the

possibility of physical injury, fire or any other damage caused in the event of the failure of any Product, such as

derating, redundancy, fire control and fail-safe designs. ROHM shall bear no responsibility whatsoever for your

use of any Product outside of the prescribed scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or system

which requires an extremely high level of reliability the failure or malfunction of which may result in a direct

threat to human life or create a risk of human injury (such as a medical instrument, transportation equipment,

aerospace machinery, nuclear-reactor controller, fuel-controller or other safety device). ROHM shall bear

no responsibility in any way for use of any of the Products for the above special purposes. If a Product is intend-

ed to be used for any such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specified herein that may be controlled under

the Foreign Exchange and the Foreign Trade Law, you will be required to obtain a license or permit under the Law.

Notes

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact your nearest sales office.

ROHM Customer Support System

www.rohm.com

Copyright © 2009 ROHM CO.,LTD.

21 Saiin Mizosaki-cho, Ukyo-ku, Kyoto 615-8585, Japan

THE AMERICAS / EUROPE / ASIA / JAPAN

Contact us : webmaster@ rohm.co. jp

TEL : +81-75-311-2121

FAX : +81-75-315-0172

Appendix-Rev4.0

Loading...

Loading...