Page 1

1/5

BAT60J

May 2000 - Ed: 4A

SMALL SIGNAL SCHOTTKY DIODE

n VERY SMALL CONDUCTION LOSSES

n NEGLIGIBLE SWITCHING LOSSES

n LOW FORWARDVOLTAGE DROP

n EXTREMELY FAST SWITCHING

n SURFACE MOUNTED DEVICE

FEATURES AND BENEFITS

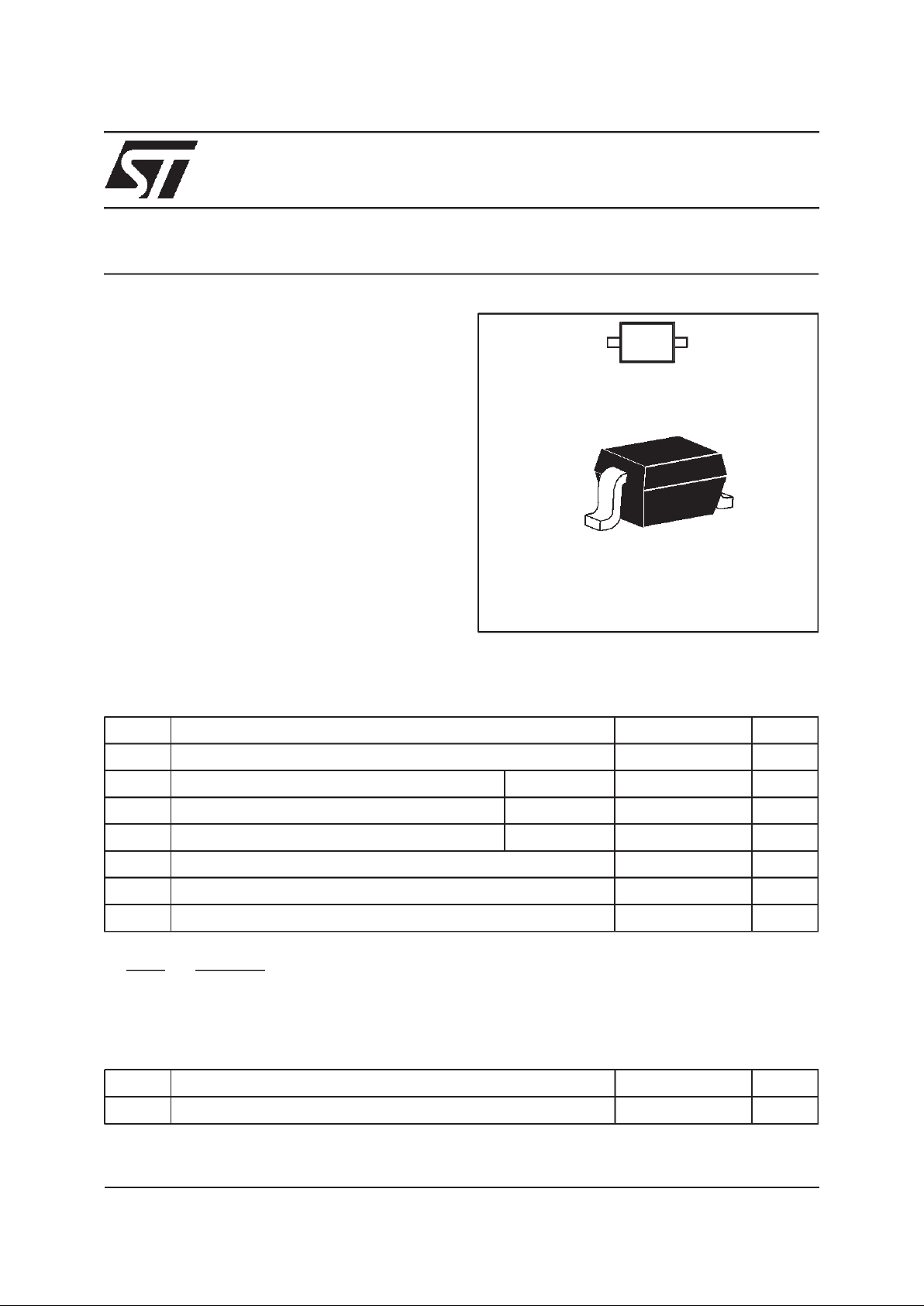

Schottky barrierdiode encapsulated in aSOD-323

small SMD package.

This device is intended for use in portable

equipments. It is suited for DC to DC converters,

step-up conversionand power management.

DESCRIPTION

SOD-323

Symbol Parameter Value Unit

V

RRM

Repetitive peak reverse voltage 10 V

I

F

Peak forward current δ = 0.11 3 A

I

FSM

Surge non repetitive forward current tp=10ms 5 A

P

tot

Power Dissipation Ta=25°C 310 mW

T

stg

Storage temperature range - 65 to +150 °C

Tj Maximum operatingjunction temperature * 150 °C

TL Maximum temperaturefor soldering during 10s 260 °C

ABSOLUTE RATINGS (limiting values)

Symbol Parameter Value Unit

R

th (j-a)

Junction to ambient (*) 400 °C/W

(*) Mounted onepoxy board with recommended padlayout.

THERMAL RESISTANCE

*:

dPtot

dTj Rth j a

<

−1()

thermal runaway condition for a diode on its own heatsink

A

K

60

Page 2

BAT60J

2/5

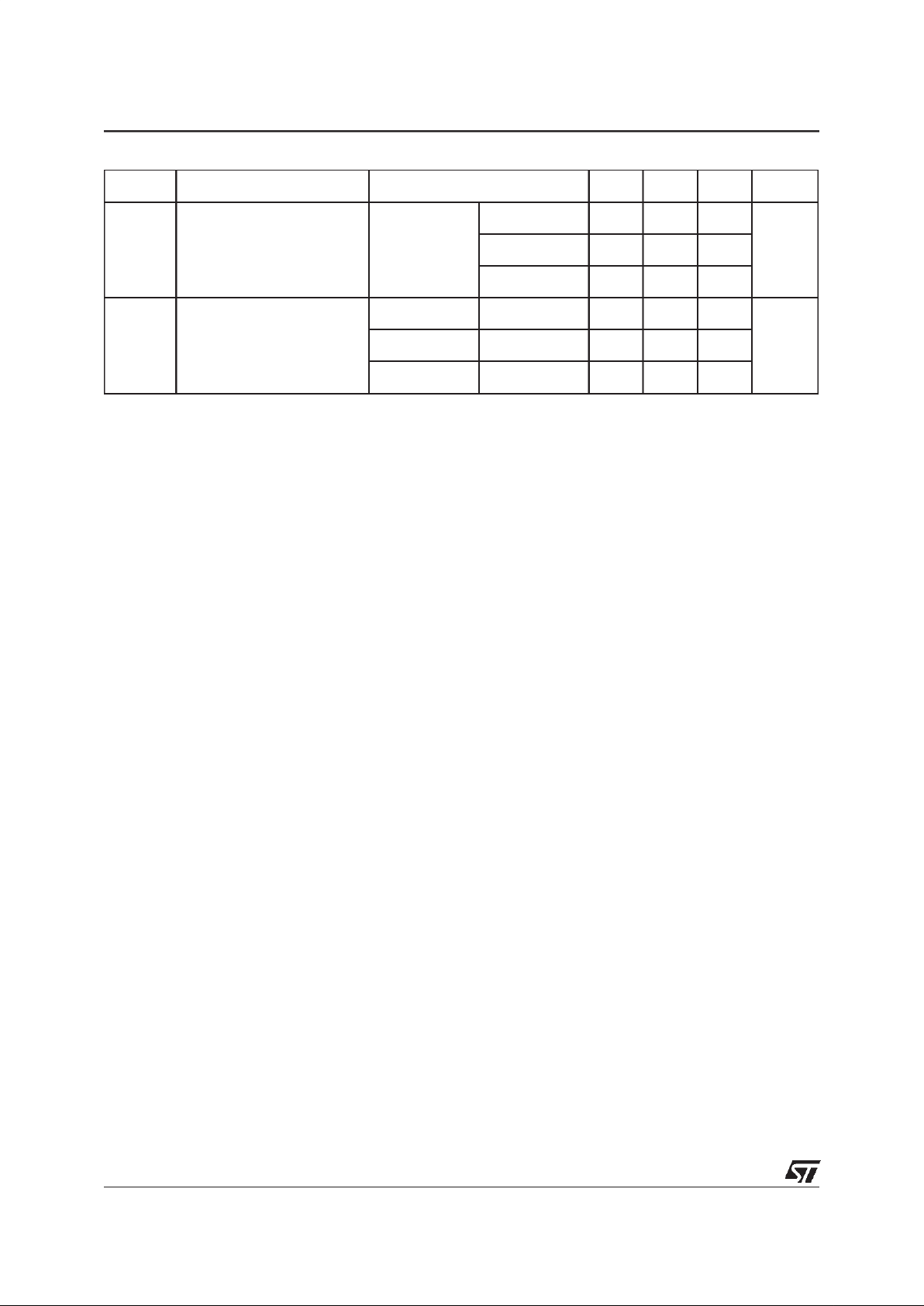

Symbol Tests Conditions Tests conditions Min. Typ. Max. Unit

VF* Forward voltage drop Tj = 25°CI

F

= 10 mA 0.28 0.32 V

IF= 100 mA 0.35 0.40

IF= 1 A 0.53 0.58

IR** Reverseleakage current Tj = 25°CV

R

=5V 1 3 µA

Tj = 25°CV

R

= 8 V 1.3 4

Tj = 80°CV

R

= 8 V 73 150

STATIC ELECTRICAL CHARACTERISTICS

Pulse test: * tp = 380µs, δ <2%

** tp = 5ms, δ <2%

To evaluate the conduction losses the following equation:

P = 0.38 x I

F(AV)

+ 0.17 I

F2(RMS)

Page 3

BAT60J

3/5

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

IF(av) (A)

PF(av)(W)

T

δ

=tp/T

tp

δ = 0.05

δ = 0.1

δ = 0.2

δ = 0.5

δ =1

Fig. 1: Average forward power dissipation versus

average forward current.

0 25 50 75 100 125 150

0.0

0.4

0.8

1.2

1.6

2.0

2.4

2.8

3.2

Tamb(°C)

IF(A)

T

δ

=tp/T

tp

Fig. 2-1: Peak forward current versus ambient

temperature (δ = 0.11).

0 25 50 75 100 125 150

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

Tamb(°C)

IF(av)(A)

T

δ

=tp/T

tp

Fig. 2-2: Average forward current versus ambient

temperature (δ = 0.5).

1E-3 1E-2 1E-1 1E+0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

t(s)

IM(A)

Ta=25°C

Ta=50°C

Ta=75°C

IM

t

δ=0.5

Fig. 3: Non repetitive surge peakforward current

versus overload duration (maximum values).

1E-4 1E-3 1E-2 1E-1 1E+0 1E+1 1E+2

1E-3

1E-2

1E-1

1E+0

t(s)

Zth(j-a)/Rth(j-a)

δ =0.5

δ =0.2

δ = 0.1

Single pulse

T

δ

=tp/T tp

Fig.4:Relative variation of thermal impedance junctionto ambient versuspulseduration (Epoxy printed

circuit boardFR4 with recommended padlayout).

012345678910

1E-4

1E-3

1E-2

1E-1

1E+0

1E+1

VR(V)

IR(mA)

Tj=80°C

Tj=25°C

Tj=150°C

Fig.5: Reverseleackage current versus reverse

voltageapplied (typical values).

Page 4

BAT60J

4/5

0 25 50 75 100 125 150

1E-1

1E+0

1E+1

1E+2

1E+3

1E+4

1E+5

Tj(°C)

IR[Tj] / IR[Tj=25°C]

VR=8V

Fig.6: Reverseleackage current versus junction

temperature(typical values).

110

10

100

VR(V)

C(pF)

F=1MHz

Tj=25°C

Fig.7:Junction capacitance versus reverse voltage

applied (typicalvalues).

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

1E-1

1E+0

1E+1

VFM(V)

IFM(A)

Tj=150°C

(Typicalvalues)

Tj=80°C

(Typicalvalues)

Tj=25°C

(Maximumvalues)

Fig.8-1:Forwardvoltagedropversusforwardcurrent(Highlevel).

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

VFM(V)

IFM(A)

Tj=150°C

(Typicalvalues)

Tj=25°C

(Maximumvalues)

Tj=80°C

(Typicalvalues)

Fig.8-2: Forwardvoltagedropversusforwardcurrent(Lowlevel).

0 102030405060708090100

100

150

200

250

300

350

400

450

500

550

600

S(Cu) (mm )

Rth(j-a) (°C/W)

IF=0.75A

Fig.9:Thermal resistance junction to ambient versuscopper surface (epoxyprinted circuitboard FR4,

copper thickness: 35µm).

Page 5

BAT60J

5/5

Information furnished isbelieved to beaccurate and reliable. However, STMicroelectronics assumes no responsibility for theconsequences of

use of such information nor forany infringementof patents or other rightsof third parties which may result from its use.No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

PACKAGE MECHANICAL DATA

SOD-323

H

b

D

E

A1

A

L

Q1

c

REF.

DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 1.17 0.046

A1 0 0.1 0 0.004

b 0.25 0.44 0.01 0.017

c 0.1 0.25 0.004 0.01

D 1.52 1.8 0.06 0.071

E 1.11 1.45 0.044 0.057

H 2.3 2.7 0.09 0.106

L 0.1 0.46 0.004 0.02

Q1 0.1 0.41 0.004 0.016

Type Marking Package Weight Base qty Delivery mode

BAT60J 60 SOD-323 0.005 g. 3000 Tape & reel

n Epoxy meets UL94V-0

MARKING

Loading...

Loading...