Page 1

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

DYNAMIC, PEAK-DETECTING, DIFFERENTIAL

HALL-EFFECT GEAR-TOOTH SENSORS

1

2

3

4

Pin 1 = Supply

Pin 2 = Output

Pin 3 = Capacitor

Pin 4 = Ground

PRELIMINARY INFORMATION

(subject to change without notice)

December 2, 1998

ABSOLUTE MAXIMUM RATINGS

over operating temperature range

Supply Voltage, VCC.........................16 V*

Reverse Supply Voltage, V

Output OFF Voltage, V

Reverse Output Voltage, V

Continuous Output Current, I

Minimum External Capacitance,

............................................. 0.1 µF

C

3

Package Power Dissipation,

.................................... See Graph

P

D

Operating Temperature Range,

........................... -40°C to +150°C*

T

A

Storage Temperature, TS............ +170°C

* Operation at increased supply voltages with

external circuitry is described in Applications

Information. Devices for operation at increased

temperatures are available on special order.

RCC

................. 18 V

OUT

OUT

OUT

Dwg. AH-006

....... -0.5 V

....... -0.5 V

... 25 mA

ATS610LSA

AND

ATS611LSB

The ATS610LSA and ATS611LSB gear-tooth sensors are optimized Hall IC plus magnet subassemblies that provide a user-friendly

solution for digital gear-tooth sensing applications. Each subassembly

combines in a compact high-temperature plastic package, a samarium-cobalt

magnet, a pole piece, and a differential Hall-effect IC that has been

optimized to the magnetic circuit. These sensors can be easily used in

conjunction with a wide variety of gear or target shapes and sizes.

The ATS610LSA is designed to provide increased immunity to

false switching in applications that require the sensing of large-tooth

gears (e.g., crank angle or cam angle). The ATS611LSB is optimized

to sense fine-pitch gears over large working air gaps (e.g., transmission or ABS). These sensor subassemblies are ideal for use in

gathering speed, position, and timing information using gear-tooth-based

configurations.

The gear-sensing technology used for these sensor plus magnet

subassemblies is Hall-effect based. The sensor incorporates a

dual-element Hall IC that switches in response to differential magnetic

signals created by the ferrous target. The circuitry contains a patented

track-and-hold peak-detecting circuit to eliminate magnet and system

offset effects. This circuit has the ability to detect relatively fast changes,

such as those caused by gear wobble and eccentricities, and provides

stable operation at extremely low rotation speeds.

continued next page…

FEATURES AND BENEFITS

■ Fully Optimized Differential Digital Gear-Tooth Sensor

■ Single-Chip Sensing IC for High Reliability

■ Extremely Low Timing Accuracy Drift with Temperature

■ Large Operating Air Gaps

■ Small Mechanical Size

■ Optimized Magnetic Circuit

■ Patented Peak-Detecting Filter:

<200 µs Power-On Time

<10 RPM Operation (single-tooth target)

Correct First-Edge Detection

Uses Small Value Ceramic Capacitors

■ Under-Voltage Lockout

■ Wide Operating Voltage Range

■ Defined Power-Up State

Always order by complete part number, e.g., ATS610LSA .

Data Sheet

27627.100

Page 2

ATS610LSA AND ATS611LSB

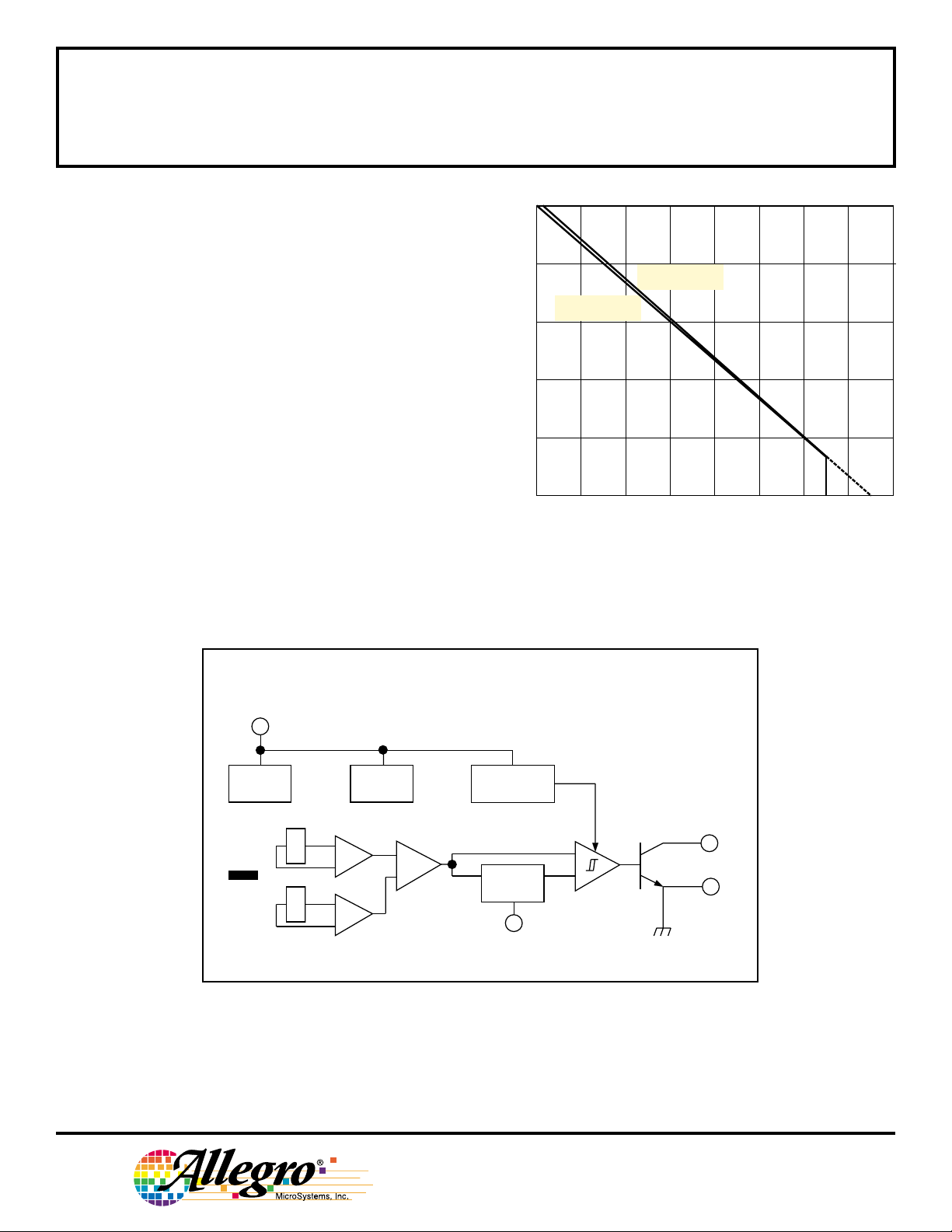

ALLOWABLE PACKAGE POWER DISSIPATION IN mW

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

Both sensors are packaged in miniature plastic

housings that have been optimized for size, ease of assembly,

and manufacturability. High operating temperature materials are used in all aspects of construction. Devices for

operation at increased temperatures are also available on

special order.

ATS610LSA: Large-tooth, gear-position sensing —

crank angle, cam angle.

ATS611LSB: Fine-pitch, large air gap, gear-speed

sensing — transmission, ABS.

1000

800

600

400

200

0

"SA" PACKAGE

θJA

= 147°C/W

R

"SB" PACKAGE

θJA

~ 150°C/W

R

60 100 140 18020

40 80 120

AMBIENT TEMPERATURE IN °C

160

Dwg. GH-065

1

REG

MAGNET

SUPPLY

X

X

FUNCTIONAL BLOCK DIAGRAM

POWER-ON

LOGIC

TRACK &

HOLD

3

CAPACITOR

E1

E2

UVLO

+

–

OUTPUT

2

+

–

4

GROUND

Dwg. FH-014

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

W

Copyright © 1997, Allegro MicroSystems, Inc.

Page 3

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

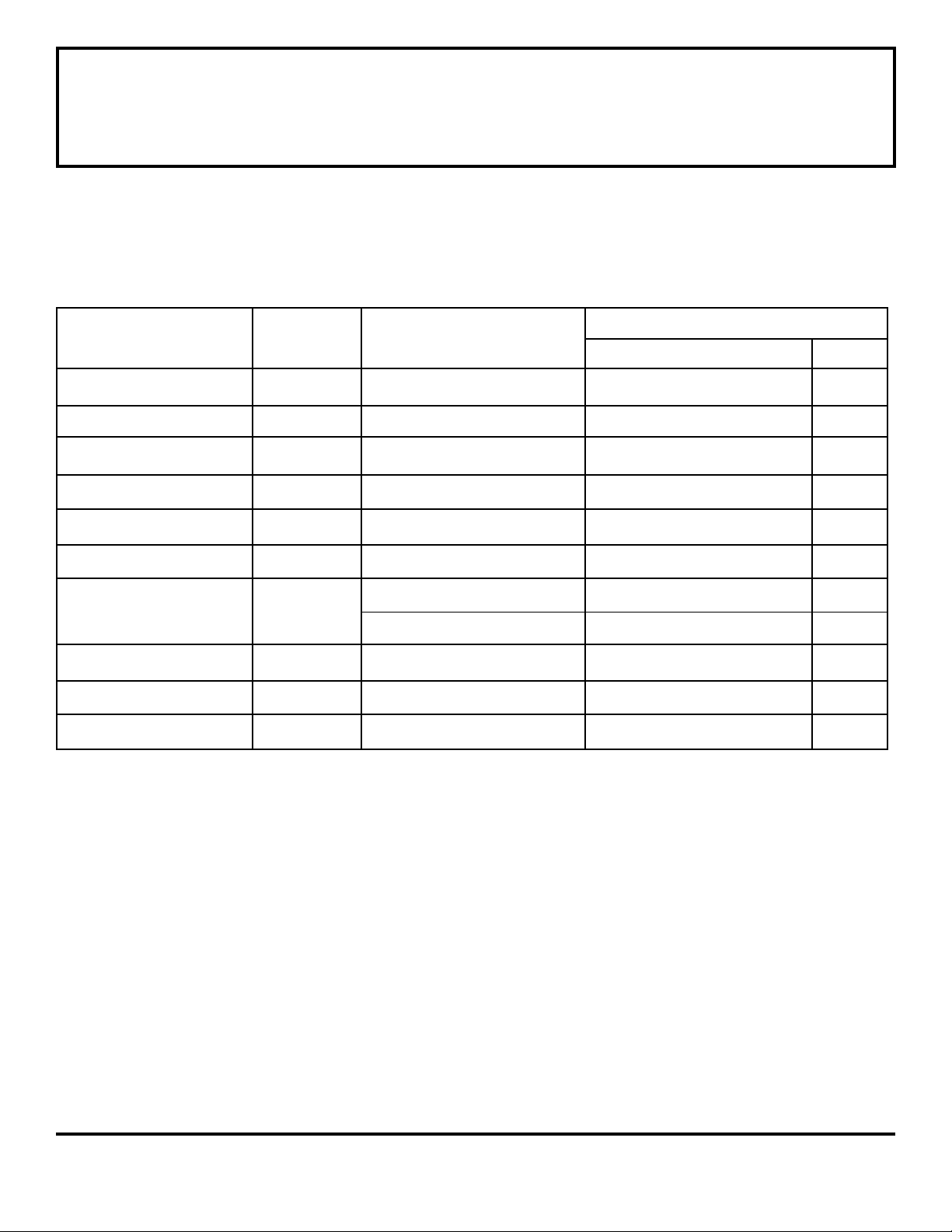

ELECTRICAL CHARACTERISTICS over operating voltage and temperature range,

C

= 0.1 µF to 0.47 µF.

3

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage V

CC

Power-On State POS V

Under-Voltage Lockout V

Under-Voltage Hysteresis V

Output Saturation Voltage V

Output Leakage Current I

Supply Current I

CC(UV)

CC(hys)

OUT(SAT)

OFF

CC

Operating, TJ < 165°CV

= 0 → 5 V HIGH HIGH HIGH –

CC

I

= 20 mA, VCC = 0 → 5 V 2.5 – 3.5 V

OUT

Lockout (V

I

= 20 mA – 90 400 mV

OUT

V

= 16 V – 0.2 15 µA

OUT

) – Shutdown – 0.1 – V

CC(UV)

Output OFF 5.5 7.7 11 mA

Output ON 8.5 10.5 13 mA

Power-On Delay t

Output Rise Time t

Output Fall Time t

NOTE: Typical data is at VCC = 5 V and TA = +25°C and is for design information only.

on

r

f

RL = 500 Ω, CL = 10 pF – 0.2 2.0 µs

RL = 500 Ω, CL = 10 pF – 0.2 2.0 µs

CC(UV)

– 16 V

––200 µs

Page 4

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

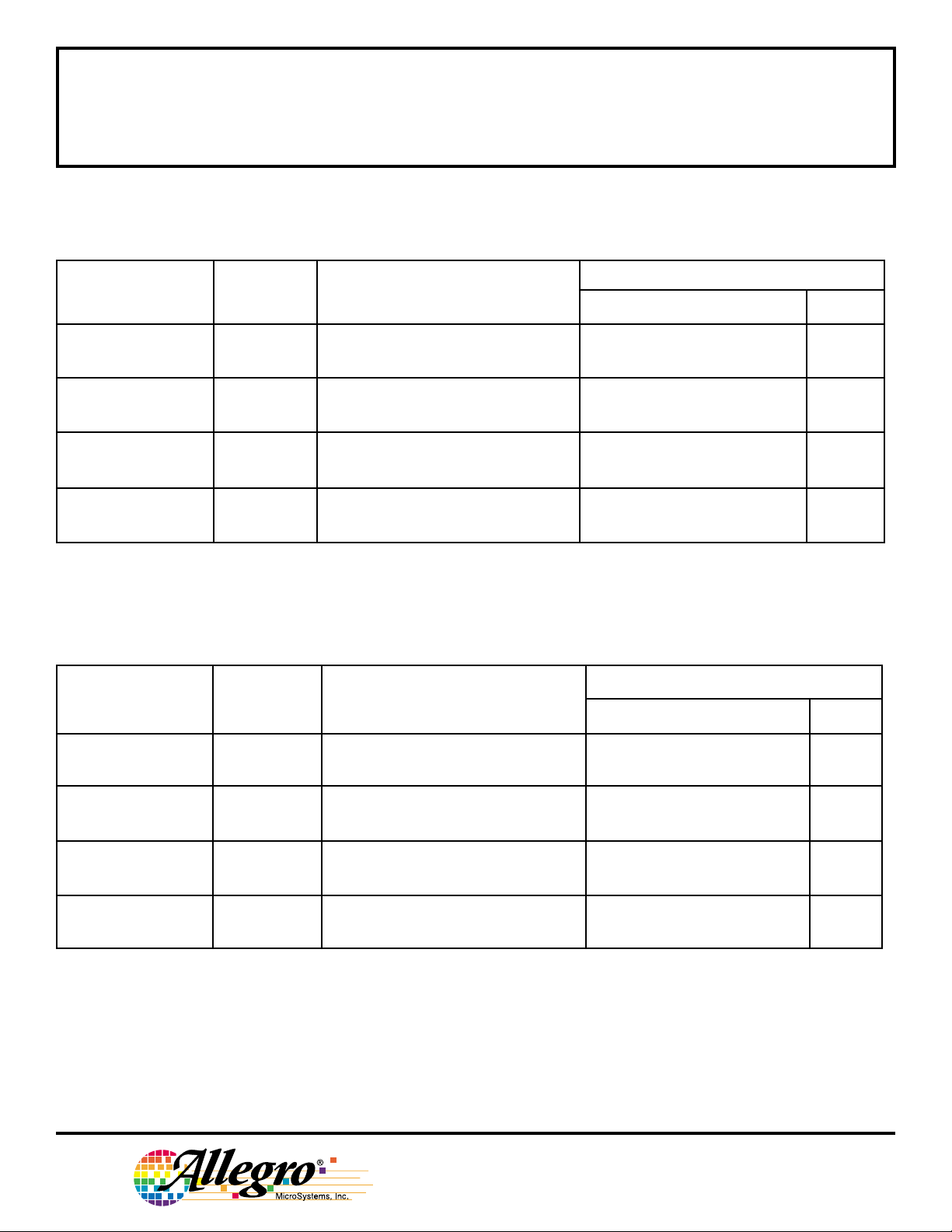

ATS610LSA OPERATION over operating voltage and temperature range with reference target

(unless otherwise specified).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Air Gap Range AG Operating, 0.4 – 2.25 mm

Target Speed > 20 RPM

Minimum Air Gap AG

Maximum Air Gap AG

Timing Accuracy t

min

max

θ

Operating, One-Tooth (180°) – 0.25 – mm

Target, Target Speed = 1000 RPM

Operating, One-Tooth (180°) – 2.75 – mm

Target, Target Speed = 1000 RPM

Target Speed = 1000 RPM, – ±0.5 ±1.0 °

0.4 mm ≤ AG ≤ 2 mm

ATS611LSB OPERATION over operating voltage and temperature range with reference target

(unless otherwise specified).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Air Gap Range AG Operating, 0.4 – 2.5 mm

Target Speed > 20 RPM

Minimum Air Gap AG

min

Operating, One-Tooth (180°) – 0.75 – mm

Target*, Target Speed = 1000 RPM

Maximum Air Gap AG

Timing Accuracy t

max

θ

Operating, One-Tooth (180°) – 3.25 – mm

Target*, Target Speed = 1000 RPM

Target Speed = 1000 RPM, – ±0.5 ±1.0 °

0.4 mm ≤ AG ≤ 2 mm

* The one-tooth (180°) target is not recommended for use with the ATS611LSB.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

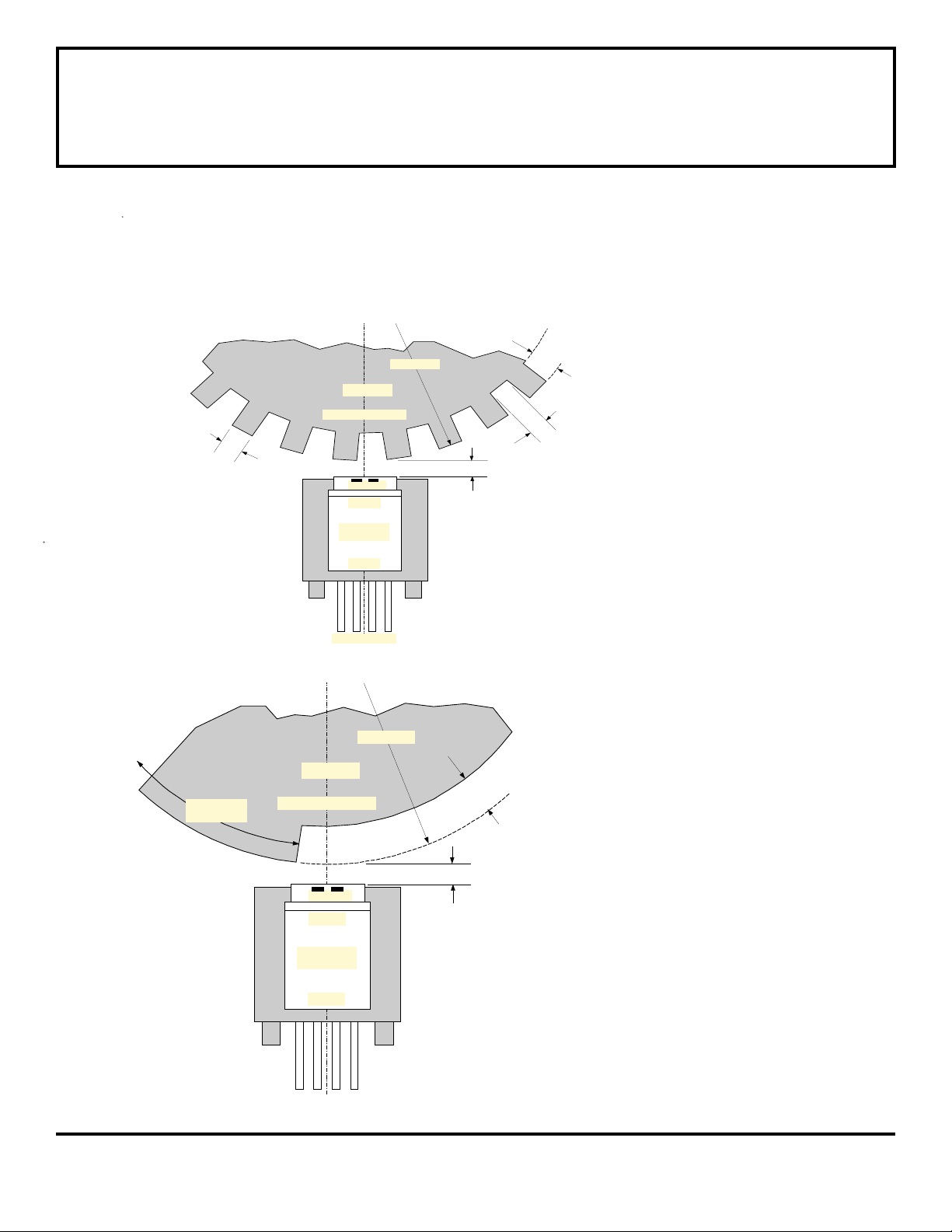

D = 115 mm

o

TARGET

F (THICKNESS) ≥ 3 mm

t

h = 5 mm

REFERENCE TARGET

3 mm

T = 3 mm

T = 180°

(ONE TOOTH)

E1 E2

SENSOR

POLE PIECE

SOUTH

PERMANENT

MAGNET

NORTH

1 2 3 4

TARGET

F (THICKNESS) ≥ 3 mm

E1 E2

SENSOR

POLE PIECE

SOUTH

D = 115 mm

o

AIR GAP

AIR GAP

t

h = 5 mm

Dwg. MH-016 mm

ONE-TOOTH (180

°) TARGET

PERMANENT

MAGNET

NORTH

1 2 3 4

Dwg. MH-016-1 mm

Page 6

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

TYPICAL ATS610LSA AND ATS611LSB ELECTRICAL CHARACTERISTICS

14

12

11

10

9.0

8.0

7.0

SUPPLY CURRENT IN mA

6.0

4.0

-40

0 40 80 120

AMBIENT TEMPERATURE IN °C

OUTPUT ON

V = 5 V

CC

OUTPUT OFF

160

200

Dwg. GH-014-1

13

12

11

10

9.0

8.0

7.0

SUPPLY CURRENT IN mA

6.0

5.0

OUTPUT ON

OUTPUT OFF

T = 25°C

A

2.0 6.0 10 14 18

SUPPLY VOLTAGE IN VOLTS

Dwg. GH-058

150

125

100

75

I = 20 mA

OUT

OUTPUT SATURATION VOLTAGE IN mV

50

-40

0 40 80 120

AMBIENT TEMPERATURE IN °C

175

150

125

100

75

50

25

OUTPUT SATURATION VOLTAGE IN mV

160

200

0

0

10 20 30

OUTPUT SINK CURRENT IN mA

Dwg. GH-013-1

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

T = 25°C

A

40

Dwg. GH-059

Page 7

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

TYPICAL ATS610LSA OPERATING CHARACTERISTICS

(with reference target)

3.0

TRAILING TARGET EDGE

2.5

2.0

1.5

1.0

0.5

RELATIVE ACCURACY IN DEGREES

0

-40°C

+25°C

+150°C

0.5 1.5 2.5 3.5

1.0 2.0 3.00

AIR GAP IN MILLIMETERS

Dwg. GH-008

3.0

LEADING TARGET EDGE

2.5

2.0

1.5

1.0

0.5

RELATIVE ACCURACY IN DEGREES

0

-40°C

+25°C

+150°C

0.5 1.5 2.5

1.0 2.0 3.00

AIR GAP IN MILLIMETERS

3.5

Dwg. GH-008-2

53.0

52.8

52.6

52.4

52.2

52.0

51.8

DUTY CYCLE IN PER CENT

51.6

51.4

-40°C

+25°C

+150°C

0.5 1.5 2.5 3.5

1.0 2.0 3.00

AIR GAP IN MILLIMETERS

Dwg. GH-008-1

continued next page…

Page 8

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

TYPICAL ATS610LSA OPERATING CHARACTERISTICS

(with reference target) — Continued

4.5

4.0

3.5

3.0

2.5

2.0

1.5

MAXIMUM AIR GAP IN MILLIMETERS

1.0

0

10 30 50 70

20 40 60

REFERENCE TARGET SPEED IN RPM

TYPICAL ATS611LSB OPERATING CHARACTERISTICS

-40°C

+25°C

+150°C

4.5

4.0

3.5

3.0

2.5

2.0

1.5

MAXIMUM AIR GAP IN MILLIMETERS

1.0

0

Dwg. GH-011-1

(with reference target)

-40°C

+25°C

+150°C

500 1500 2500 3500

1000 2000 3000

REFERENCE TARGET SPEED IN RPM

Dwg. GH-011

4.5

4.0

3.5

3.0

2.5

2.0

1.5

MAXIMUM AIR GAP IN MILLIMETERS

1.0

0

500 1500 2500 3500

1000 2000 3000

REFERENCE TARGET SPEED IN RPM

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

-40°C

+25°C

+150°C

Dwg. GH-011-2

Page 9

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

DEVICE DESCRIPTION

The ATS610LSA and ATS611LSB dynamic,

peak-detecting, differential Hall-effect gear-tooth sensors

are Hall IC plus magnet subassemblies that are fully

optimized to provide digital detection of gear-tooth edges

in a small package size. Both sensors are packaged in

identical miniature plastic housings that have been

optimized for size, ease of assembly, and manufacturability.

High operating temperature materials are used in all

aspects of construction.

The application of these sensors is uncomplicated.

After power is applied to the device, they are capable of

quickly providing digital information that is representative

of a rotating gear or specially designed target. No additional optimization or processing circuitry is required. This

ease of use should reduce design time and incremental

assembly costs for most applications.

Sensing Technology. Both gear-tooth sensor subassemblies contain a single-chip differential Hall-effect

sensor IC, a samarium-cobalt magnet, and a flat ferrous

pole piece. The Hall IC consists of two Hall elements

spaced 2.235 mm (0.088") apart, which sense the magnetic gradient created by the passing of a ferrous object (a

gear tooth). The two Hall voltages are compared and the

difference is then processed to provide a digital output

signal.

The processing circuit uses a patented peak-detection

technique to eliminate magnet and system offsets. This

technique allows coupling and filtering of offsets without

the power-up and settling time disadvantages of classical

high-pass filtering schemes. Here, the peak signal of

every tooth and valley is detected and is used to provide

an instant reference for the operate-point and releasepoint comparators. In this manner, the thresholds are

adapted and referenced to individual signal peaks and

valleys, thereby providing immunity to zero-line variation

due to installation inaccuracies (tilt, rotation, and

off-center placement), as well as for variations caused by

target and shaft eccentricities. The peak detection

concept also allows extremely low-speed operation when

used with small-value capacitors.

OPERATE

0

DIFFERENTIAL

MAGNETIC FLUX

V

BB

OUTPUT

V

OUT(SAT)

RELEASE

OPERATE

RELEASE

Dwg. WH-011

Power-On Operation. The device will power on in the

OFF state (output high) irrespective of the magnetic field

condition. The power-on time of the circuit is no greater

than 200 µs. The circuit is then ready to accurately detect

the first target edge that results in a HIGH-to-LOW transition.

Under-Voltage Lockout. When the supply voltage is

below the minimum operating voltage (V

CC(UV)

), the device

is OFF and stays OFF irrespective of the state of the

magnetic field. This prevents false signals, which may be

caused by under-voltage conditions (especially during turn

on), from appearing at the output.

Output. The device output is an open-collector stage

capable of sinking 25mA. An external pull-up (resistor) to

a supply voltage of not more than 18V must be supplied.

Superior Performance. The ATS610LSA and

ATS611LSB peak-detecting differential gear-tooth sensor

sub-assemblies have several advantages over conventional Hall-effect gear-tooth sensors.

continued next page…

Page 10

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

DEVICE DESCRIPTION — Continued

Differential vs. Single-Element Sensing. The differential Hall-element configuration is superior in most applications to the classical single-element gear-tooth sensor.

The single-element configuration commonly used

(Hall-effect sensor mounted on the face of a simple

permanent magnet) requires the detection of a small

signal (often <100G) that is superimposed on a large

back-biased field, often 1500G to 3500G. For most

gear/target configurations, the back-biased field values

change due to concentration effects, resulting in a varying

baseline with air gap, with valley widths, with eccentricities, and with vibration. The differential configuration

cancels the effects of the back-biased field and avoids

many of the issues presented by the single Hall element.

NOTE — 10 G = 1 mT, exactly.

Peak-Detecting vs. AC-Coupled Filters. High-pass

filtering (normal ac coupling) is a commonly used technique for eliminating circuit offsets. AC coupling has

errors at power up because the filter circuit needs to hold

the circuit zero value even though the circuit may power

up over a large signal. Such filter techniques can only

perform properly after the filter has been allowed to settle,

which is typically greater than one second. Also, highpass filter solutions cannot easily track rapidly changing

baselines such as those caused by eccentricities. Peak

detection switches on the change in slope of the signal

and is baseline independent at power up and during

running.

Track-and-Hold Peak Detecting vs. Zero-Crossing

Reference. The usual differential zero-crossing sensors

are susceptible to false switching due to off-center and

tilted installations, which result in a shift in baseline that

changes with air gap. The track-and-hold peak-detection

technique ignores baseline shifts versus air gaps and

provides increased immunity to false switching. In addition, using track-and-hold peak-detecting techniques,

increased air gap capabilities can be expected because a

peak detector utilizes the entire peak-to-peak signal range

as compared to zero-crossing detectors that switch on

fixed thresholds.

NOTE — “Baseline” refers to the zero-gauss differential where each Hall-effect element is subject to the

same magnetic field strength.

TARGET

-2000

-2500

-3000

-3500

-4000

-4500

SINGLE ELEMENT MAGNETIC FIELD IN GAUSS

-5000

0

10 20 30 60

ANGLE OF TARGET ROTATION IN DEGREES

AIR GAP = 0.5 mm

AIR GAP = 1.0 mm

AIR GAP = 1.5 mm

AIR GAP = 2.0 mm

AIR GAP = 2.5 mm

showing the impact of varying valley widths

T = 25°C

A

5040

Dwg. GH-061-1

1500

1000

500

0

-500

-1000

DIFFERENTIAL MAGNETIC FIELD IN GAUSS

-1500

0

AIR GAP = 0.5 mm

AIR GAP = 1.0 mm

AIR GAP = 2.5 mm

AIR GAP = 2.0 mm

AIR GAP = 1.5 mm

10 20 30 60

ANGLE OF TARGET ROTATION IN DEGREES

Differential flux maps vs. air gapsSingle-element flux maps

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

TARGET

T = 25°C

A

5040

Dwg. GH-061

Page 11

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

CRITERIA FOR DEVICE QUALIFICATION

All Allegro sensors are subjected to stringent qualification requirements prior to being released to production.

To become qualified, except for the destructive ESD tests, no failures are permitted.

Qualification Test Test Method and Test Conditions Test Length Samples Comments

Temperature Humidity JESD22-A101, 1000 hrs 48 Device biased for

Bias Life TA = 85°C, RH = 85% minimum power

Bias Life JESD22-A108, 1000 hrs 48

TA = 150°C, TJ = 165°C

(Surge Operating Life) JESD22-A108, 168 hrs 24

TA = 175°C, TJ = 190°C

Autoclave, Unbiased JESD22-A102, 96 hrs 48

TA = 121°C, 15 psig

High-Temperature JESD22-A103, 1000 hrs 48

(Bake) Storage Life TA = 170°C

Temperature Cycle JESD22-A104 1000 cycles 60

ESD, CDF-AEC-Q100-002 Pre/Post 3 per Test to failure

Human Body Model Reading test All leads > 3 kV

Page 12

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

APPLICATIONS INFORMATION

Gear Diameter and Pitch. Signal frequency is a direct

function of gear pitch and rotational speed (RPM). The

width of the magnetic signal in degrees and, hence, the

signal slope created by the tooth is directly proportional to

the circumference of the gear (πDo). Smaller diameters

limit the low-speed operation due to the slower rate of

change of the magnetic signal per degree of gear rotation

(here the limitation is the droop of the capacitor versus the

signal change). Larger diameters limit high-speed operation due to the higher rate of change of magnetic signal

per degree of rotation (here the limitation is the maximum

charge rate of the capacitor versus the rate of signal

change). These devices are optimized for a 50mm gear

diameter (signal not limited by tooth width), 0.33 µF

capacitor, and speeds of 10 RPM to 8000 RPM. For very

large diameter gears (diameter >200 mm), the devices

must be configured with a lower value capacitor, but not

less than 0.1 µF. This allows for a range of 5:1 in gear

diameters.

NOTE — In application, the terms “gear” and “target” are

often interchanged. However, “gear” is preferred when

motion is transferred.

Air Gap and Tooth Geometry. Operating specifications

are impacted by tooth width (T), valley width (pc - T) and

depth (ht), gear material, and gear face thickness (F). The

target can be a gear or a specially cut shaft-mounted tone

wheel made of stamped ferrous metal. In general, the

following gear or target guidelines must be followed to

achieve greater than 2mm air gap from the face of unit:

Tooth width, T.............................. >2 mm

Valley width, pc - T...................... >2 mm

(Whole) depth, ht......................... >3 mm

Gear material............................... low-carbon steel

Gear face width (thickness), F .... >3 mm

Deviation from these guidelines will result in a reduction of air gap and a deterioration in timing accuracy. For

applications that require the sensing of large-tooth targets,

the optimal sensor choice is the ATS610LSA. Here, the

higher switching thresholds provide increased immunity to

false switching caused by magnetic overshoot and other

non-uniformities in the gear or target. For applications

that require the sensing of a target with a repetitive target

structure (valley width less than 5mm), the optimal sensor

choice is the ATS611LSB. Here, the lower switching

thresholds make the device more sensitive to magnetic

field changes and will provide larger operating air gaps.

Operation with Fine-Pitch Gears. For targets with a

circular pitch of less than 4mm, a performance improvement can be observed by rotating the front face of the

sensor subassembly. This sensor rotation decreases the

effective sensor-to-sensor spacing and increases the

capability of detecting fine tooth or valley configurations,

provided that the Hall elements are not rotated beyond the

width of the target.

2.235

TARGET FACE WIDTH, F

>2.235 SIN

α

α

α

2.235 COS

A

A

Dwg. MH-018-1 mm

Signal Timing Accuracy. The magnetic field profile

width is defined by the sensor element spacing and

narrows in degrees as the target diameter increases. This

results in improved timing accuracy performance for larger

gear diameters (for the same number of gear teeth). The

slope of this magnetic profile also changes with air gap,

resulting in timing accuracy shift with air gap (refer to

typical operating characteristic curves). Valley-to-tooth

transitions will generally provide better accuracy than

tooth-to-valley transitions for large-tooth or large-valley

configurations. For highest accuracy, targets greater than

100mm in diameter should be used.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

continued next page…

Page 13

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

APPLICATIONS INFORMATION — Continued

Signal Duty Cycle. For repetitive target structures,

precise duty cycle is maintained over the operating air gap

and temperature range due to an extremely good symmetry in the magnetic switch points of the device. For

nonrepetitive target structures, there will be a small but

measureable change in pulse width versus air gap.

Output Polarity. The output of the device will switch from

HIGH to LOW as the leading edge of the target passes

the subassembly in the direction indicated below (pin 4 to

pin 1), which means that the output will be LOW when the

unit is facing a tooth. If rotation is in the opposite direction

(pin 1 to pin 4), the output of the device will switch from

LOW to HIGH as the leading edge of the target passes

the subassembly, which means that the output will be

HIGH when the unit is facing a tooth.

1

2

3

4

4

3

2

1

Dwg. AH-007

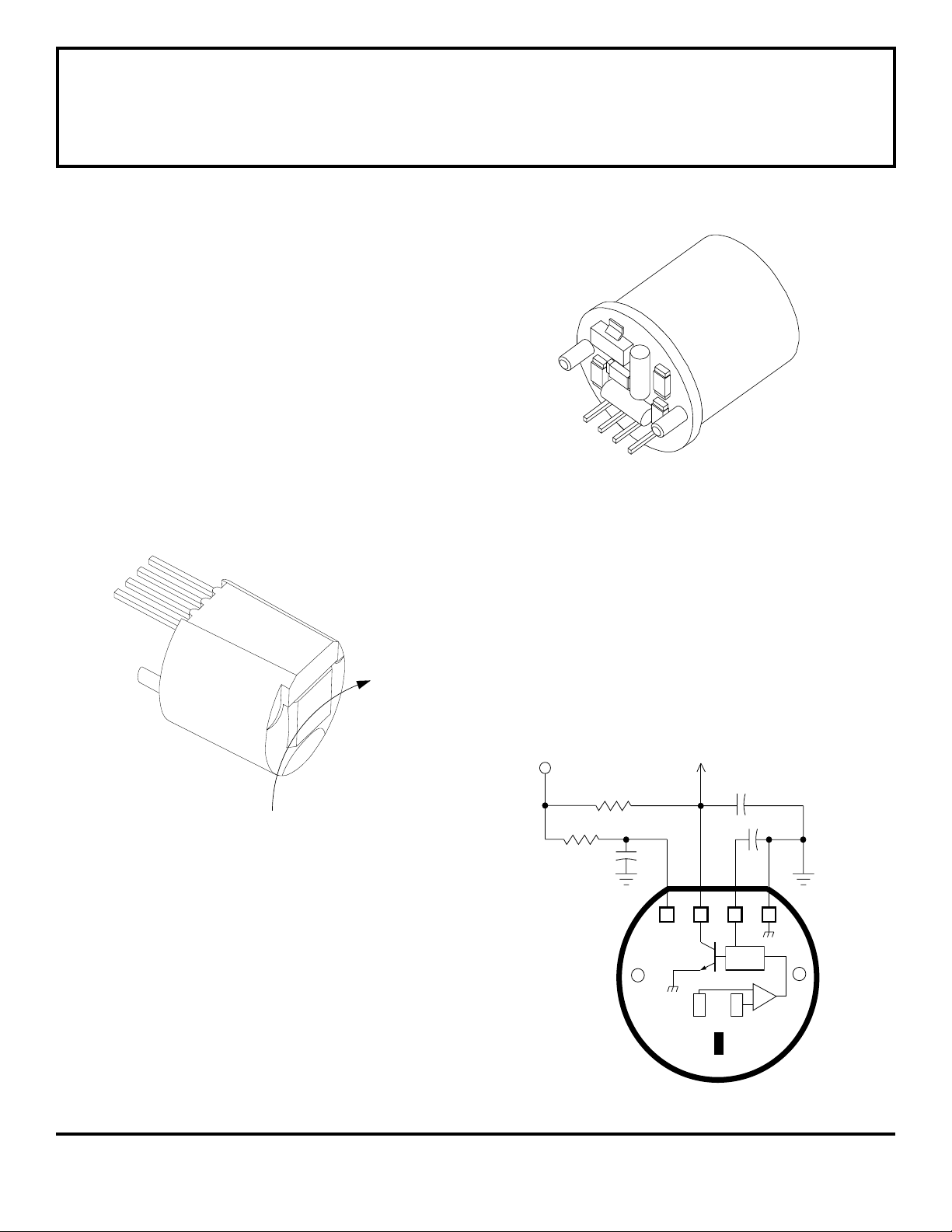

Operation From a Regulated Power Supply. These

devices require minimal protection circuitry during operation from a low-voltage regulated line. The on-chip

voltage regulator provides immunity to power supply

variations between 3.5V and 16V. However, even while

operating from a regulated line, some supply and output

filtering is required to provide immunity to coupled and

injected noise on the supply line. A basic RC low-pass

circuit (R1C1) on the supply line and an optional output

capacitor (C2) is recommended for operation in noisy

environments. Because the device has an open-collector

output, an output pull-up resistor (RL) must be included

either at the sensor output (pin 2) or by the signal processor input.

Dwg. AH-006-1

Power Supply Protection. The sensor contains an onchip voltage regulator and can operate over a wide supply

voltage range. For devices that need to operate from an

unregulated power supply, transient and double-battery

protection should be added externally. For applications

using a regulated supply, external EMI/RFI protection is

often required. Insufficient protection can result in unexplained pulses on the output line, providing inaccurate

sensing information to the user.

The filter capacitor and EMI protection circuitry can

easily be added to a PC board for use with these devices.

Provisions have been made for simple mounting of a

board on the back of the unit.

SUPPLY

20 Ω

OUTPUT

C

R

L

C

R

1

0.033 µF

1

12

Vcc

X

2

100 pF

0.22 µF

C

3

4

3

+

-

X

continued next page…

Dwg. EH-008-1A

Page 14

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

APPLICATIONS INFORMATION — Continued

Operation From an Unregulated Power Supply. In

automotive applications, where the device receives its

power from an unregulated supply such as the battery, full

protection is generally required so that the device can

withstand the many supply-side transients. Specifications

for such transients vary between car manufacturers, and

protection-circuit design should be optimized for each

application. In the circuit below, a simple

Zener-controlled regulator is constructed using discrete

components. The RC low-pass filter on the supply line

(R1C1) and a low-value supply bypass capacitor (CS) can

be included, if necessary, so as to minimize susceptibility

to EMI/RFI. The npn transistor should be chosen with

sufficiently high forward breakdown voltage so as to

withstand supply-side transients. The series diode should

be chosen with sufficiently high reverse breakdown

capabilities so as to withstand the most negative transient. The current-limiting resistor (RZ) and the Zener

diode should be sized for power dissipation requirements.

SUPPLY

R

L

OUTPUT

C

2

100 pF

Capacitor Requirements. The choice of the capacitor at

pin 3 (C3) defines the minimum operating speed of the

target. This capacitor (0.1 µF minimum) is required to

stabilize the internal amplifiers as well as to eliminate the

signal offsets. Typically, a 0.33 µF low-leakage ceramic

capacitor is recommended. Values greater than 0.47 µF

should not be used as this may cause high-speed performance degradation.

Capacitor leakage current at pin 3 will cause degradation in the low-speed performance of the device. Excess

capacitor leakage can result in the sensor changing output

state without movement of the gear tooth being sensed.

In addition to the capacitor leakage, it is extremely important to minimize the leakage at the PC board and between

the pins of the sensor. Up to 50nA of external leakage

can be tolerated at the capacitor pin node to ground.

Choice of low-leakage-current potting compounds and the

use of clean PC board techniques are extremely important.

0.033 µF

C

2.5 kΩ

R

S

20 Ω

R

1

Z

6.8 V

C

1

0.033 µF

12

Vcc

0.22 µF

3

C

3

4

Additional applications Information on gear-tooth and

other Hall-effect sensors is provided in the Allegro Electronic Data Book AMS-702 or Application Note 27701.

+

-

X

X

Dwg. EH-008A

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 15

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

MECHANICAL INFORMATION

Component Material Function Units

Sensor Face Thermoset epoxy Maximum temperature 170°C*

Plastic Housing Thermoplastic PBT, 264 psi deflection temp. (DTUL) 204°C

30% glass filled 66 psi deflection temp. (DTUL) 216°C

Approximate melting temperature 225°C

Leads Copper ––

Lead Pull –– 8 N

Lead Finish 90/10 tin/lead solder plate –†

Flame Class Rating –– UL94V-0

*Temperature excursions to 225 °C for 2 minutes or less are permitted.

†All industry-accepted soldering techniques are permitted for these subassemblies provided the indicated

maximum temperature for each component (e.g., sensor face, plastic housing) is not exceeded. Reasonable

dwell times, which do not cause melting of the plastic housing, should be used.

Sensor Location (in millimeters)

(sensor location relative to package center is the design

objective)

2.235

1.1

0.1

Lead Cross-Section (in millimeters)

0.41

0.38

A

Dwg. MH-018 mm

0.0076

MIN. PLATING

THICKNESS

Dwg. MH-019 mm

continued next page…

Page 16

ATS610LSA AND ATS611LSB

DYNAMIC, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT

GEAR-TOOTH SENSORS

ATS610LSA DIMENSIONS IN MILLIMETERS

3.0

NOM

0.38

0.38

1.27

TYP

1 2 3 4

8.3

8.0

SEE NOTE

1.27

TYP

1 2 3 4

0.41

0.9

7.25

5.00

DIA

2.0

9.0

3.9

ATS611LSB DIMENSIONS IN MILLIMETERS

0.41

8.8

7.0

7.0

A

9.0

Dwg. MH-017A mm

3.0

NOM

0.9

DIA

3.9

A

2.0

Tolerances unless otherwise specified:1 place ±0.1 mm, 2 places ±0.05 mm.

NOTE — Nominal dimension and tolerances dependent on package material. Contact factory.

Allegro MicroSystems, Inc. reserves the right to make, from time

to time, such departures from the detail specifications as may be

required to permit improvements in the design of its products.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights of

third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

8.968.09

Dwg. MH-017-1B mm

Loading...

Loading...