Page 1

NAND Flash Support in AT91SAM9

Microcontrollers

1. Scope

The purpose of this application note is to introduce the NAND Flash technology and to

describe how to interface NAND Flash memory to Atmel

based Microcontrollers that do not feature a NAND Flash Controller. The NAND Flash

logic is driven by the Static Memory Controller on the NCS3 address space.

Sample code is provided the associated zip file, Basic NAND Source Code.zip; the

source code is based on the product libV3.

2. NAND Flash Overview

2.1 General Overview

NAND Flash provides a cost effective alternative to hard drives, especially for portable

and handheld systems. The performance, pricing, and memory size options make it

optimal for storage applications

(pictures, audio files, etc.).

®

AT91SAM9 ARM® Thumb®-

AT91 ARM

Thumb

Microcontrollers

Application

Note

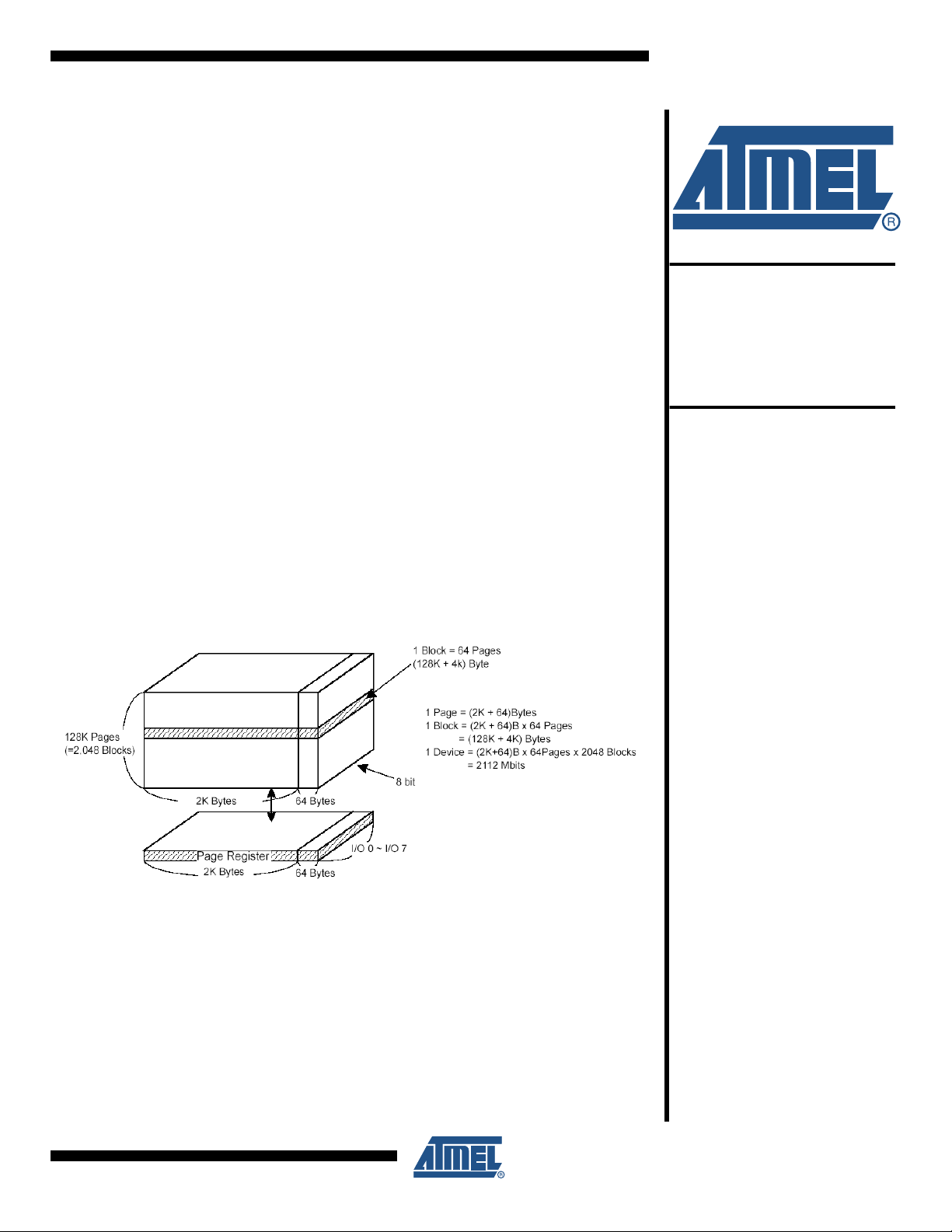

The NAND Flash used to illustrate this interface is the K9F2G08U0M, manufactured

by Samsung

Figure 2-1. K9F2G08U0M Organization

®

Electronics. Figure 2-1 shows the memory organization of this device.

6255B–ATARM–26-Jun-09

Page 2

2.2 NAND Flash vs. NOR Flash

The most important item for memories is the cost per bit which depends on memory cell area per

bit. The cell area of NAND Flash is smaller than that of NOR Flash, making the NAND Flash

more cost effective than NOR Flash.

The first significant difference between NAND and NOR Flash is the hardware interface.

2.2.1 Hardware Interface

NOR Flash has a fully memory-mapped random access interface similar to a RAM, with dedicated address lines and data lines making it “bootable”.

NAND Flash uses a multiplexed I/O interface and additional control signals. It is controlled by

sending commands and addresses through an 8-bit or 16-bit bus to an internal command and

address register.

NOR Flash random-access interface typically composed of 41 pins:

– CE# - chip enable

– WE# - write enable

– OE# - output enable

– D[15:0] - data bus

– A[20:0] - address bus

– WP# - write protect

NAND Flash I/O device-type interface composed of up to 24 pins:

2.2.2 Array Architecture

NOR Flash is divided into blocks which typically contain many 16-bit wide words. Random

access to stored data words is achieved by placing the selected word address on the address

bus and then reading that data off the data bus. Erase operations are managed at the block level

and words can be programmed after a block has been erased.

NAND Flash is also divided into blocks which contain many pages instead of words (2K +64

bytes). Read and program operations take place on a per-page basis whereas erase operations

takes place on a block basis.

To read or write from NAND Flash, a command sequence is issued to select a block and a page.

After this selection, the entire page can be read or written.

– CE# - chip enable

– WE# - write enable

– RE# - read enable

– CLE - command latch enable

– ALE - address latch enable

– I/O[7:0] or I/O[15:0] - data bus

– WP# - write protect

– R/B# - ready / busy

– RE - Read enable

2

Application Note

6255B–ATARM–26-Jun-09

Page 3

2.2.3 Performances

Application Note

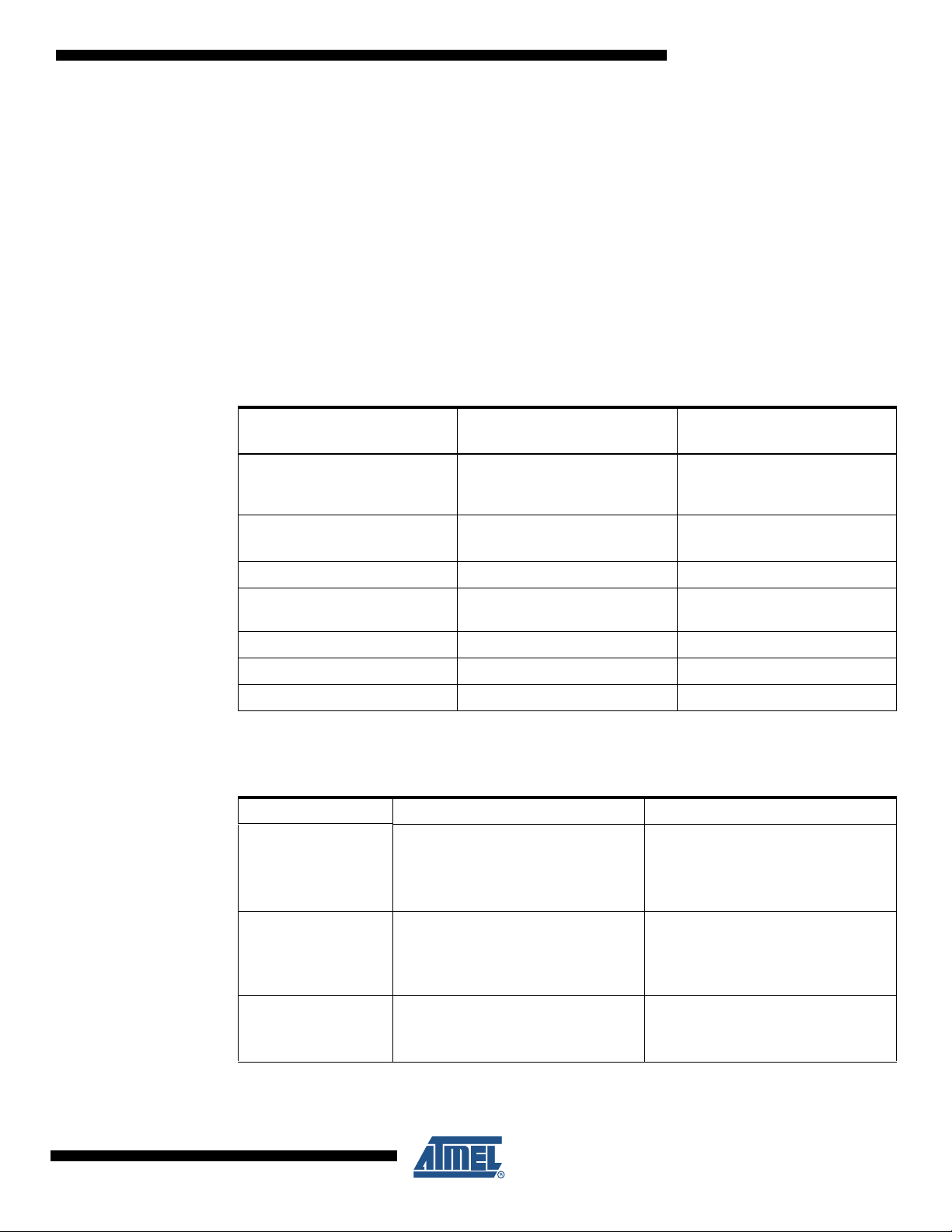

NAND Flash typically contains blocks that contain errors and cannot be used. A check must be

done by software to list and maintain a table of bad blocks. Data integrity is achieved by using

hardware or software techniques, such as ECC, that check and correct bad data.

Further differences between NOR and NAND Flash can be found in read/write performances.

Table 2-1 shows random access time for NOR Flash specified at 0.09 µs, whereas NAND ran-

dom access is significantly slower — 25 µs — for the first byte. Once the initial access has been

made, however, the remaining 2,111 bytes are shifted out of NAND at only 30 ns per byte. This

results in a bandwidth of more than 23 Mb/s for 8-bit I/Os or 37 Mb/s for 16-bit I/Os.

The real benefits for NAND Flash can be found in the faster program and erase times, since

NAND provides over five megabytes per second of sustained write performance. The block

erase times are an impressive 2 ms for NAND versus 200 ms for NOR.

Table 2-1. Differences in Performance

2.2.4 Conclusion

NAND Flash

Characteristics

Random access read

Sustained read speed

(sector basis)

Random write speed 300 µs/2,112 bytes 20 µs / bytes

Sustained write speed (sector

basis)

Erase block size 128 Kbytes 64 Kbytes

Erase cycles 100,000 to 1,000,000 10,000 to 100,000

Erase time per block 2 ms 200 ms

K9F2G08U0M

25 µs (first byte)

30 ns each for remaining 2111

bytes

37 Mbytes/s 11 Mbytes/s

5 Mbytes/s 0.05 Mbytes/s

NOR Flash

AT49BV16x4-90

0.09 µs

Table 2-2 summarizes NAND/NOR advantages and disadvantages.

Table 2-2. NAND/NOR Comparison

NAND NOR

Fast writes

Advantages

Fast erases

Lower bit cost

Higher density

Random access

Byte writes possible

6255B–ATARM–26-Jun-09

Slow random access

Disadvantages

Applications

Byte writes difficult

Bad blocks management and ECC

required

File (disk) applications

Voice, data, video recorder

Any large sequential data

Slow writes

Slow erase

Execute directly from non volatile

memory

Clearly, NAND Flash has several significant positive attributes. The one negative attribute is that

it is not well-suited for direct random access.

3

Page 4

NAND is available in large capacities and is the lowest cost Flash memory available today.

NAND is used in virtually all removable cards for cost/density reasons: USB Cards, Memory

Stick, MMC Multimedia Card, SD Secure Digital, CF Compact Flash.

3. Bad Block Management and Error Corrected Code (ECC)

3.1 Definition of “Bad Block”

By default, NAND devices contain invalid blocks which have one or more invalid bits.

Furthermore, since the first memory block (physical block address 00h) in NAND devices is

guaranteed to be free of defects (up to 1,000 PROGRAM/ERASE cycles), the first 8 Kb of Flash

memory can safely be used for system bootstrapping functions.

3.2 Software Considerations

To avoid writing to and reading from bad memory blocks, system software must create a map of

invalid memory blocks. If the application code executes from RAM rather than Flash memory,

system software bad-block mapping is only necessary at boot time and during Flash storage

updates.

All device locations are erased (FFh for X8, FFFFh for X16) except locations where the invalid

block information is written prior to shipping. The invalid block status is defined by the 1st byte

(X8 device) or 1st word (X16 device) in the spare area.

The 1st or 2nd page of every invalid block has non-FFh(X8) or non-FFFFh(X16) data at the column address of 2048 (X8 device) or 1024 (X16 device). Since the invalid block information is

also erasable in most cases, it is impossible to recover the information once it has been erased.

Therefore, the system must be able to recognize the invalid block(s) based on the original invalid

block information and create the invalid block table via the flow chart in Figure 3-1.

Figure 3-1. Bad Block Recognition Flow Chart

4

Application Note

6255B–ATARM–26-Jun-09

Page 5

Important Note: Any intentional erasure of the original invalid block information is prohibited.

3.3 ECC

NAND devices are subject to data failures that occur during device operation. To ensure data

read/write integrity, system error-checking and correction (ECC) algorithms must be implemented. Depending on the AT91 product, the ECC algorithm must be calculated by software or

can be generated by the embedded hardware ECC controller. The ECC controller is capable of

single bit error correction and 2-bit random detection. When NAND has more than 2 bits of

errors, the data cannot be corrected. This controller allows ECC management without CPU intervention and thus improves the total bandwidth of the system.

4. NAND Flash Signals

4.1 Bus Operation

The bus on NAND Flash devices is internally multiplexed. Data I/O, addresses, and commands

all share the same pins. I/O pins. I/O[15:8] are used only for data in the x16 configuration.

Addresses and commands are always supplied on I/O[7:0].

The command sequence normally consists of a command latch cycle, an ADDRESS LATCH

cycle, and a DATA cycle — either READ or WRITE.

Application Note

4.2 Control Signals

The signals CE#, WE#, RE#, CLE and ALE control Flash device READ and WRITE operations.

CE# is used to enable the device. When CE# is low and the device is not in the busy state, the

Flash memory accepts command, data, and address information.

When the device is not performing an operation, the CE# pin is typically driven HIGH and the

device enters standby mode. The memory enters standby if CE# goes HIGH while data is being

transferred and the device is not busy.

A subset of NAND Flash supports the CE# “Don’t Care” operation allowing the NAND Flash to

reside on the same asynchronous memory bus as other Flash or SRAM devices. Other devices

on the memory bus can then be accessed while the NAND Flash is busy with internal operations. This capability is important for designs that require multiple memory devices on the same

bus.

4.3 Commands (ALE = 0, CLE = 1)

All the NAND operations (except READ STATUS and RESET commands) consist of a command write cycle followed by address write cycle. The READ STATUS command does not have

an address write cycle. The command is transferred into the NAND command register followed

by the start address, for the read or program operation, latched into the address register.

Commands are written to the command register on the rising edge of WE# when:

• CE# and ALE are low

• CLE is high

Commands are input on I/O[7:0] only. For devices with a x16 interface, I/O[15:8] must be written

with zeros when issuing a command.

6255B–ATARM–26-Jun-09

5

Page 6

4.4 Address (ALE = 1, CLE = 0)

Addresses are written to the address register on the rising edge of WE# when:

• CE# and CLE are low

• ALE is high

Addresses are input on I/O[7:0] only. For devices with a x16 interface, I/O[15:8] must be written

with zeros when issuing an address. Generally all five ADDRESS cycles are written to the

device.

4.5 Data (ALE = 0, CLE = 0)

Data is written to the data register on the rising edge of WE# when CE#, CLE, and ALE are low.

Data is input on I/O[7:0] for x8 devices, and I/O[15:0] on x16 devices.

4.6 Ready / Busy

The R/B# output provides a hardware method of indicating the completion of a PROGRAM/ERASE/READ operation. The signal is typically high, and transitions to low after the

appropriate command is written to the device. A dedicated PIO should be assigned to this signal

with a pull-up resistor for proper operation. Alternatively, the READ STATUS command can be

used by the software.

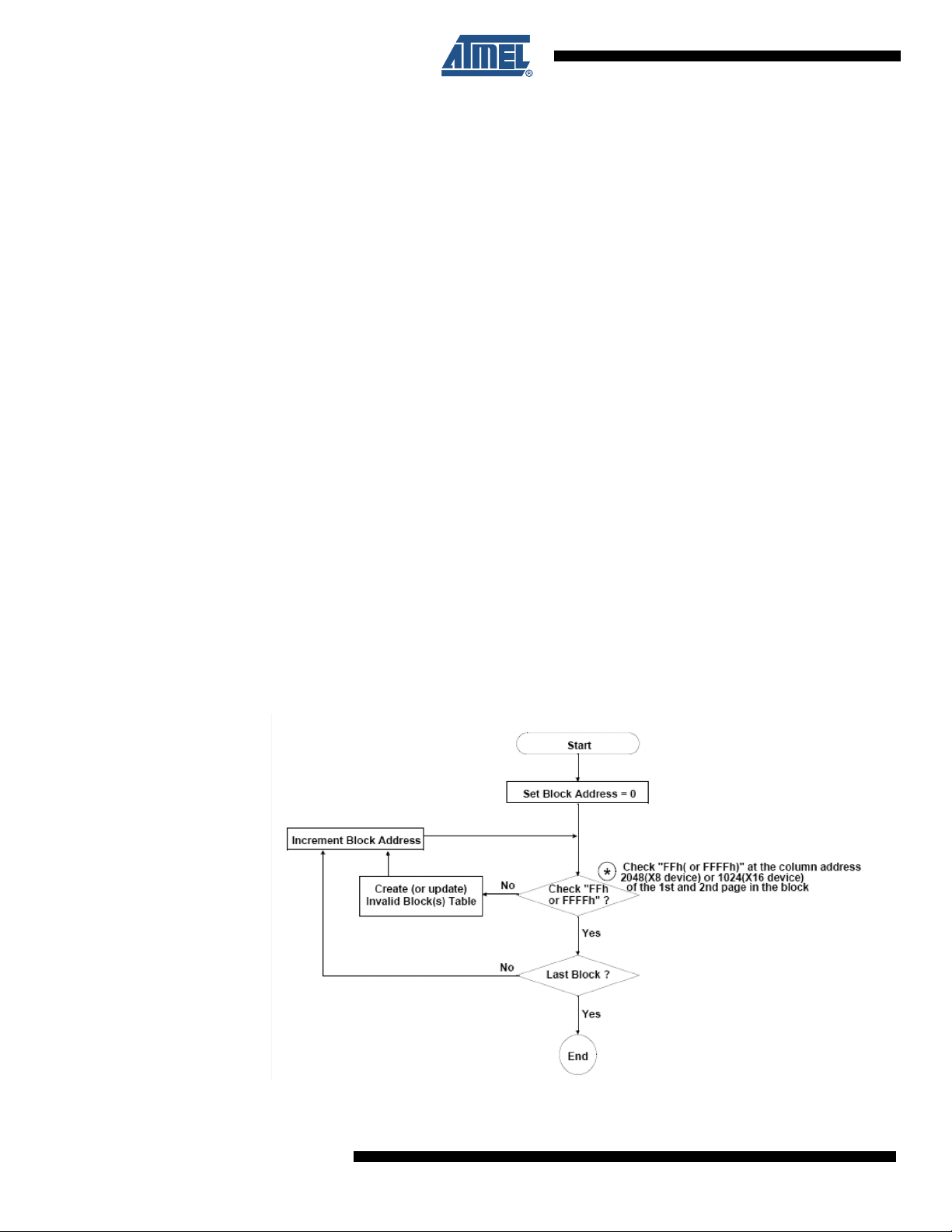

4.7 Example

The following waveforms shows the successive accesses: COMMAND Latch, ADDRESS Latch

and DATA Output with a “CE don’t Care” NAND. Notice that no command can be sent to the

NAND Flash during tR, because it is busy.

Figure 4-1. Page READ Operation

6

Application Note

6255B–ATARM–26-Jun-09

Page 7

5. AT91 EBI NandFlash Logic

The NAND Flash logic is driven by the Static Memory Controller (SMC) on the NCS3 address

space. Programming the CS3A field in the EBI_CSA Register in the Bus Matrix User Interface to

the appropriate value enables the NAND Flash logic. For details on this register, refer to the Bus

Matrix User Interface section in the product datasheet. Access to an external NAND Flash

device is then made by accessing the address space reserved to NCS3 (i.e., between

0x40000000 and 0x4FFF FFFF).

The NAND Flash Logic drives the read and write command signals of the SMC on the NANDOE

and NANDWE signals when the NCS3 signal is active.(refer to the Static Memory Controller

section in the product datasheet).

The address latch enable and command latch enable signals on the NAND Flash device are

driven by address bits A22 and A21 of the EBI address bus.The command, address or data

words on the data bus of the NAND Flash device are distinguished by using their address within

the NCS3 address space. The chip enable (CE) signal of the device and the ready/busy (R/B)

signals are connected to PIO lines.

Two NAND Flash types exists, those who are “CE don’t care” and those who are not.

For “CE don’t care” NAND, the chip enable state is don’t care during the busy period preceding

the data read cycle. Thus allowing this flash to be connected to active memory buses such as

the AT91 memory bus.

Application Note

For standard NAND, the CE signal remains asserted even when NCS3 is not selected, preventing the device from returning to standby mode. In this case, a PIO line should be dedicated to

drive the Chip Enable signal.

Unlike the AT91SAM9261, where A21 and A22 are not specifically dedicated to NAND flash

ALE and CLE signals, on the AT91SAM9260 A21/ALE and A22/CLE are the signals mandatory

to drive the NAND flash and ECC controller. Another combination of addresses prevent using

the ECC controller with the NAND Flash.

Table 5-1. EBI Signals Example for AT91SAM9261

Name Function Type Active Level

NANDCS NAND Flash Chip Select Line Output Low

NANDOE NAND Flash Output Enable Output Low

NANDWE NAND Flash Write Enable Output Low

CLE(A21) (3) Command Latch Enable Output High

ALE(A22) (4) Address Latch Enable Output High

PIOx/CE Chip Enable (1)(2) Output Low

PIOy/RDY/BSY Ready/Busy (1) Input Low

Notes: 1. Any free PIO can be used for this purpose

2. For standard NAND

3. For AT91SAM9261 the address bit A21 is arbitrarily dedicated to CLE

4. For AT91SAM9261 the address bit A22 is arbitrarily dedicated to ALE

6255B–ATARM–26-Jun-09

7

Page 8

D[7:0]

ALE

NCS7/NANDWE

NCS6/NANDOE

NOE

NWE

A[22:21]

CLE

AD[7:0]

PIO

R/B

EBI

CE

"CE don't Care"

NAND Flash

NCS3/NANDCS

D[7:0]

ALE

NCS7/NANDWE

NCS6/NANDOE

NOE

NWE

A[22:21]

CLE

AD[7:0]

PIO

R/B

EBI

CE

NAND Flash

PIO

NCS3/NANDCS

Not Connected

Table 5-2. EBI Signals Example for AT91SAM9260

Name Function Type Active Level

NANDCS NAND Flash Chip Select Line Output Low

NANDOE NAND Flash Output Enable Output Low

NANDWE NAND Flash Write Enable Output Low

A22/CLE Command Latch Enable Output High

A21/ALE Address Latch Enable Output High

PIOx/CE Chip Enable (1)(2) Output Low

PIOy/RDY/BSY Ready/Busy (1) Input Low

Notes: 1. Any free PIO can be used for this purpose

2. For standard NAND

Table 5-3. ALE/CLE Management

ALE CLE

AT91SAM9261 Memory

Address Offset

AT91SAM9260 Memory

Address Offset NAND Register Selected

0 0 0x000000 0x000000 DATA register

0 1 0x200000 0x400000 COMMAND register

1 0 0x400000 0x200000 ADDRESS register

1 1 0x600000 0x600000 Undefined (Don’t use)

Figure 5-1. “CE don’t care” and Standard NAND Flash Application Example

8

Application Note

6255B–ATARM–26-Jun-09

Page 9

Application Note

6. AT91 System Initialization for a K9F2G08U0M Device

6.1 Clocks

The system is running at full speed, this means 198 MHz for the processor and 99 MHz for the

Bus. The EBI NCS3 is to be assigned for NAND Flash usage.

Table 6-1. System Configuration

Description Settings Register/field Value

System

PLL frequency 198 MHz PMC_PLLAR 0x20603F09

Processor / Bus Clock 198 / 99 MHz PMC_MCKR 0x00000102

EBI Chip Select Assignment NAND EBI_CSA

EBI_CS3A 0x8

6.2 PIOs

6.2.1 Standard NAND

Two PIO lines are needed for CE and RDY/BSY. NANDOE (PC0) and NANDWE (PC1) are to

be configured for NAND Flash usage.

Table 6-2. Peripheral Configuration for Standard NAND on AT91SAM9261

Description Settings AT91 libV3 Function

NANDOE and NANDWE are

respectively PC0 and PC1 Output

PC14 is CE (1) Output

PC15 is RDY/BSY (1) Input

Enable PIO clock (1)

Note: 1. Any free PIO can be used for this purpose

AT91F_PIO_CfgPeriph(AT91C_BASE_PIOC, (AT91C_PC0_SMOE

| AT91C_PC1_SMWE), 0);

AT91F_PIO_CfgOutput(AT91C_BASE_PIOC, AT91C_PIO_PC14);

AT91F_PIO_CfgInput(AT91C_BASE_PIOC, AT91C_PIO_PC15);

AT91F_PIOC_CfgPMC ();

6.2.2 “CE don’t care” NAND

One PIO line only is needed, for RDY/BSY. NCS3 has the NANDCS function. On the

AT91SAM9260 the NCS3 is multiplexed with a PIO line allowing standard NAND Flash and “CE

don’t care” device support without any hardware modification.

Table 6-3. Peripheral Configuration for “CE don’t Care” NAND on AT91SAM9260

Description Settings AT91 libV3 function

NCS3 is CE

PC13 is RDY/BSY (1) Input

Enable PIO clock (1)

Output

AT91F_PIO_CfgPeriph(AT91C_BASE_PIOC,

AT91C_PC14_NCS3_NANDCS,0);

AT91F_PIO_CfgInput(AT91C_BASE_PIOC, AT91C_PIO_PC13);

AT91F_PIOC_CfgPMC ();

Note: 1. Any free PIO can be used for this purpose

6255B–ATARM–26-Jun-09

9

Page 10

6.3 SMC Timings

ALE/CLE

NCS

NWE_SETUP NWE_PULSE NWE_HOLD

NWE

NCS_WR_SETUP

NCS_WR_PULSE

NCS_WR_HOLD

NWE_CYCLE

D[31:0]

NCS

NRD_SETUP NRD_PULSE NRD_HOLD

NRD

D[31:0]

NCS_RD_SETUP

NCS_RD_PULSE

NCS_RD_HOLD

NRD_CYCLE

The K9F2G08U0M is a 256 MB device connected with an 8-bit data bus width.

An accurate one-to-one comparison is necessary between NandFlash and SMC waveforms for

a complete SMC configuration. Figure 6-1 and Figure 6-2 show two cases that highlight all the

required timings.

Figure 6-1. COMMAND LATCH and ADDRESS LATCH Cycle

Figure 6-2. SERIAL ACCESS Cycle after READ

These timings are summarized in Table 6-4.

10

Application Note

6255B–ATARM–26-Jun-09

Page 11

Table 6-4. NAND Flash Timings vs. SMC Configuration

Application Note

Timing Name

tCLS 25 NWE Setup + NWE Pulse N/A - CE is a PIO line 3

tALS 25 NWE Setup + NWE Pulse N/A - CE is a PIO line 3

tCS 35 NWE Setup + NWE Pulse N/A - CE is a PIO line 4

Setup

Hold

Pulse

tDS 20 NWE Setup + NWE Pulse NWE Setup + NWE Pulse 2

tCEA 45 Not programmable Not programmable

tREA 30 Not programmable Not programmable

tRR 20 managed by software managed by software

tCLH 10 NWE Hold NWE Hold 1

tALH 10 NWE Hold NWE Hold 1

tCH 10 NWE Hold N/A - CE is a PIO line 1

tDH 10 Data Float Time Data Float Time 1

tOH 15 Data Float Time Data Float Time 2

tREH 15 NRD Cycle - NRD Pulse NRD Cycle - NRD Pulse 2

tWP 25 NWE pulse length NWE pulse length 3

tRP 25 NRD pulse length NRD pulse length 3

tWC 45 NWE cycle NWE cycle 5

tRC 50 NRD cycle NRD cycle 5

Value (ns)

Min / Max

SMC Description for “CE don’t Care”

NAND

SMC Description for Standard

NAND

Val ue @

100 MHz

(cycles)

6255B–ATARM–26-Jun-09

As CLE and ALE are address lines (A21, A22), an additional setup timing is required to respect

tAR (10 ns) and tCLR (10 ns) on STATUS or RANDOM DATA READ Cycle.

11

Page 12

To fit these requirements the values to program in SMC are:

• NRD_SETUP = NWE_SETUP = 1

• NRD_CYCLE = NWE_CYCLE = 5

• NRD_PULSE = NWE_PULSE = 3

• Data Float Time = 2

Therefore all the timings are realized:

• NWE_HOLD = NRD_CYCLE - NRD_PULSE - NRD_SETUP = 1

• NRD_CYCLE - NRD_PULSE = 2

• NWE_SETUP + NWE_PULSE = 4

Table 6-5 gives SMC register configurations, other fields keep the reset values.

Table 6-5. SMC NCS3 Configuration

Description Settings Register/field Value

NWE and NRD Setup 1 cycle SMC_SETUP[3] 0x01010101

NRD and NWE Pulse length 3 cycles SMC_PULSE[3] 0x03030303

NRD and NWE Cycle length 5 cycles SMC_CYCLE[3] 0x05050505

Chip Select Control SMC_CTRL[3] 0x00020003

Read Mode NRD READ_MODE 0x1

Write Mode NWE WRITE_MODE 0x2

NWAIT action disable EXNW_MODE 0

Databus Width 8 (bits) DBW 0

Data Float Time 2 (cycles) TDF_CYCLES 2

12

Application Note

6255B–ATARM–26-Jun-09

Page 13

7. NAND Flash Connection Example on AT91SAM9260

D6

D0

D3

D4

D2

D1

D5

D7

NANDOE

NANDWE

(ANY PIO)

(ANY PIO)

ALE

CLE

D[0..7]

3V3

3V3

2 Gb

TSOP48 PACKAGE

U1 K9F2G08U0MU1 K9F2G08U0M

WE

18

N.C

6

VCC

37

CE

9

RE

8

N.C

20

WP

19

N.C

5

N.C

1

N.C

2

N.C

3

N.C

4

N.C

21

N.C

22

N.C

23

N.C

24

R/B

7

N.C

26

N.C

27

N.C

28

I/O0

29

N.C

34

N.C

35

VSS

36

PRE

38

N.C

39

VCC

12

VSS

13

ALE

17

N.C

11

N.C

10

N.C

14

N.C

15

CLE

16

N.C

25

N.C

33

I/O1

30

I/O3

32

I/O2

31

N.C

47

N.C

46

N.C

45

I/O7

44

I/O6

43

I/O5

42

I/O4

41

N.C

40

N.C

48

R2 10KR2 10K

C2

100NF

C2

100NF

R1

10KR110K

C1

100NF

C1

100NF

7.1 8-bit NAND Flash

7.1.1 Hardware Configuration

Application Note

7.1.2 Software Configuration

6255B–ATARM–26-Jun-09

The following configuration must be carried out:

• Assign the EBI CS3 to the NAND Flash by setting the bit EBI_CS3A in the EBI Chip Select

Assignment Register located in the bus matrix memory space

• Reserve A21/A22 for CLE/ALE functions. Address and Command Latches are controlled

respectively by setting to 1 the address bit A21 and A22 during accesses.

• Configure a PIO line as an input and enable the clock of this PIO to manage the Ready/Busy

signal.

• Configure Static Memory Controller CS3 Setup, Pulse, Cycle and Mode depending on NAND

Flash timings, the data bus width and the system bus frequency.

13

Page 14

7.2 16-bit NAND Flash

D6

D0

D3

D4

D2

D1

D5

D7

D14

D8

D11

D12

D10

D9

D13

D15

NANDOE

NANDWE

(ANY PIO)

ALE

CLE

D[0..15]

(ANY PIO)

3V3

3V3

2 Gb

TSOP48 PACKAGE

R1

10KR110K

R2 10KR2 10K

C2

100NF

C2

100NF

C1

100NF

C1

100NF

U1 MT29F2G16AABWP-ETU1 MT29F2G16AABWP-ET

WE

18

N.C

6

VCC

37

CE

9

RE

8

N.C

20

WP

19

N.C

5

N.C

1

N.C

2

N.C

3

N.C

4

N.C

21

N.C

22

N.C

23

N.C

24

R/B

7

I/O0

26

I/O8

27

I/O1

28

I/O9

29

N.C

34

N.C

35

N.C

36

PRE

38

N.C

39

VCC

12

VSS

13

ALE

17

N.C

11

N.C

10

N.C

14

N.C

15

CLE

16

VSS

25

I/O11

33

I/O2

30

I/O3

32

I/O10

31

I/O15

47

I/O7

46

I/O14

45

I/O6

44

I/O13

43

I/O5

42

I/O12

41

I/O4

40

VSS

48

7.2.1 Hardware Configuration

7.2.2 Software Configuration

The software configuration is the same as for 8-bit NAND Flash except the data bus width programmed in the mode register of the Static Memory Controller.

8. NAND Flash Access on AT91SAM9260

8.1 Boot on NAND Flash

8.1.1 NAND Flash Initialization

14

Application Note

Each AT91SAM9 product embeds a Boot Program that integrates different programs permitting

download and/or upload into the different memories of the product.

For the NAND Flash, an initialization phase is done and the NAND Flash Boot program is then

executed.

Refer to the section “AT91SAM Boot Program” of the product datasheet for more details.

The following actions compose the initialization phase of the “CE don’t Care” NAND.

• NAND Flash logic is enabled on NCS3 through EBI_CSA.

• NAND Flash timings are programmed with SMC_SETUP3, PULSE3, CYCLE3 and MODE3

SMC registers.

• PC13 PIO line is dedicated to handle NAND R/B#.

6255B–ATARM–26-Jun-09

Page 15

• Another PIO line must be declared to handle CE# on standard devices (not “CE don’t Care”).

• PC14 PIO line is configured for an NCS3_NANDCS usage.

• The corresponding PIO Clock is started.

• A NAND Flash identification is done on NCS3 memory space.

• A NAND structure is created and filled-in with Flash ID relevant data.

• Data bus width is modified depending on the NAND Flash type.

Once completed, the system is ready to access the NAND Flash with best performances.

A software package that performs this configuration is provided with this Application Note.

8.1.2 NAND Flash Boot

First, it looks for a boot.bin file in the root directory or in the FIRMWARE directory of a FAT12/16

formatted NAND Flash. If such a file is found, code is downloaded into the internal SRAM. This

is followed by a remap and a jump to the first address of the SRAM.

If the NAND Flash is not formatted, the NAND Flash Boot program looks for a sequence of eight

valid ARM exception vectors. If such a sequence is found, code is downloaded into the internal

SRAM. This is followed by a remap and a jump to the first address of the SRAM.

8.1.3 NAND Flash Waveforms

Application Note

Figure 8-1. CE During Two Page Read on Standard NAND

6255B–ATARM–26-Jun-09

15

Page 16

Figure 8-2. CE During Two Page Read on “CE don’t care” NAND

8.1.4 NAND Flash and SAM-BA

SAM-BA allows the user to read, write, erase and verify NAND Flash devices through RS232 or

USB interfaces. This feature is not supported on all the AT91SAM9 Microcontrollers (Refer to

SAM Boot Assistant (SAM-BA) User Guide for a more detailed description, lit° 6132.

8.1.4.1 Management of “Bad Blocks”

As a NAND Flash Memory may contain invalid blocks, an Invalid Block Management algorithm is

implemented. If an invalid block is detected, it is skipped and data are written in the next block.

The SAM-BA application marks a NAND Flash block as invalid by setting the “BadBlock Info”

byte in the 8-byte Invalid Block Information structure to a value different from 0xFF. This is performed for the first two pages of each bad block.

The same principle has to be implemented in a user application in order to read data from a

NAND Flash memory written by the SAM-BA application.

8.1.4.2 File Operations

The memory download area provides a simple way to upload and download data.

Files can be sent and received and the target’s memory content can be compared with a file on

the PC.

This area also gives access to some specific scripts such as “Enable NAND” that performs the

initialization phase necessary before any file operations, and “Erase NAND” that performs a full

erase of the device.

®

16

Application Note

6255B–ATARM–26-Jun-09

Page 17

Revision History

Doc. Rev Date Comments

6255A 09-Oct-06 First issue

6255B 16-Jun-09

page 1: AT91SAM -> AT91SAM9

Table 6-5 on page 12: NAND Flash support App Note: SMC Timings are not correct

Application Note

Change

Request Ref.

3906

5582

6255B–ATARM–26-Jun-09

17

Page 18

Headquarters International

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Atmel Asia

Unit 1-5 & 16, 19/F

BEA Tower, Millennium City 5

418 Kwun Tong Road

Kwun Tong, Kowloon

Hong Kong

Tel: (852) 2245-6100

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

www.atmel.com/AT91SAM

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054 Saint-Quentin-enYvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

AT91SAM Support

Atmel techincal support

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contacts

www.atmel.com/contacts/

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2009 Atmel Corporation. All rights reserved. Atmel®, Atmel logo and combinations thereof, and others are registered trademarks or trademarks of Atmel Corporation or its subsidiaries. ARM® and Thumb® are registered trademarks of ARM Ltd. Other terms and product names may

be trademarks of others.

6255B–ATARM–26-Jun-09

Loading...

Loading...