Page 1

Features

•

Fulfills IEC 1036, Class 1 Accuracy Requirements

•

Fulfills IEC 687, Class 0.5 and Class 0.2 Accuracy, with External Temperature

Compensated Voltage Reference

•

Simultaneous Active, Reactive and Apparent Power and Energy Measurement

•

Power Factor, Frequency, Voltage and Current Measurement

•

Single and Poly Phase Operation

•

Three Basic Operating Modes: Stand-Alone Mode, Microprocessor Mode and MultiChannel Mode

•

Flexible Interfacing, 8-bit Microprocessor Interface, 8-bit Status Output and Eight

Impulse Outputs

•

Calibration of Gain and Phase Error

•

Compensation of the Non-Linearity of Low Power Measurement

•

Adjustable Starting Current and Meter Constant

•

Measurement Bandwidth of 1000 Hz

•

Tamper Proof Design

•

Single +5V Supply

Description

A two chip solution, consisting of AT73C500 and AT73C501 (or AT73C502), offers all

main features required for the measurement and calculation of various power and

energy quantiti es in static Watt-h our meters. The dev ices operate acco rding to

IEC1036, class 1, specification. IEC 687, class 0.5 and 0.2 requirements are fulfilled

when used with external temperature compensated voltage reference.

The AT73C501 contains six, high-performance, Sigma-Delta analog-to-digital converters (ADC). The AT73C500 is based on an efficient digital signal processor (DSP) core

and it supports interfacing both with the AT73C501 and with an external microprocessor. The AT73C500 DSP can also be used with the differential input ADC, AT73C502.

With this chipset, only a minimum of discrete components is required to develop products ranging from si mple domestic Wa tt-hour meters to sop histicated indus trial

meters. The chipset can be used in single-pha se as well as in poly- phase systems .

The DSP core of th e AT73C500 is easy to co nfigure . By changi ng the mode of the

AT73C500, the device can be operate d in a stand-al one enviro nment or be used wit h

a separate contr ol proc essor . It i s als o pos sible to co nfigure the c ircui t to p erform the

functions of three independent single phase Wh meters.

The chips support calibration of gain and phase error. All calibrations are done in the

digital domain and no trimming components are needed. The calibration coefficients

are either stored in an EEPROM memory or supplied by an external microprocessor.

(continued)

Chip Set

Solution for

Watt-Hour

Meters

AT73C500 with

AT73C501 or

AT73C502

Rev. 1035A–08/98

1

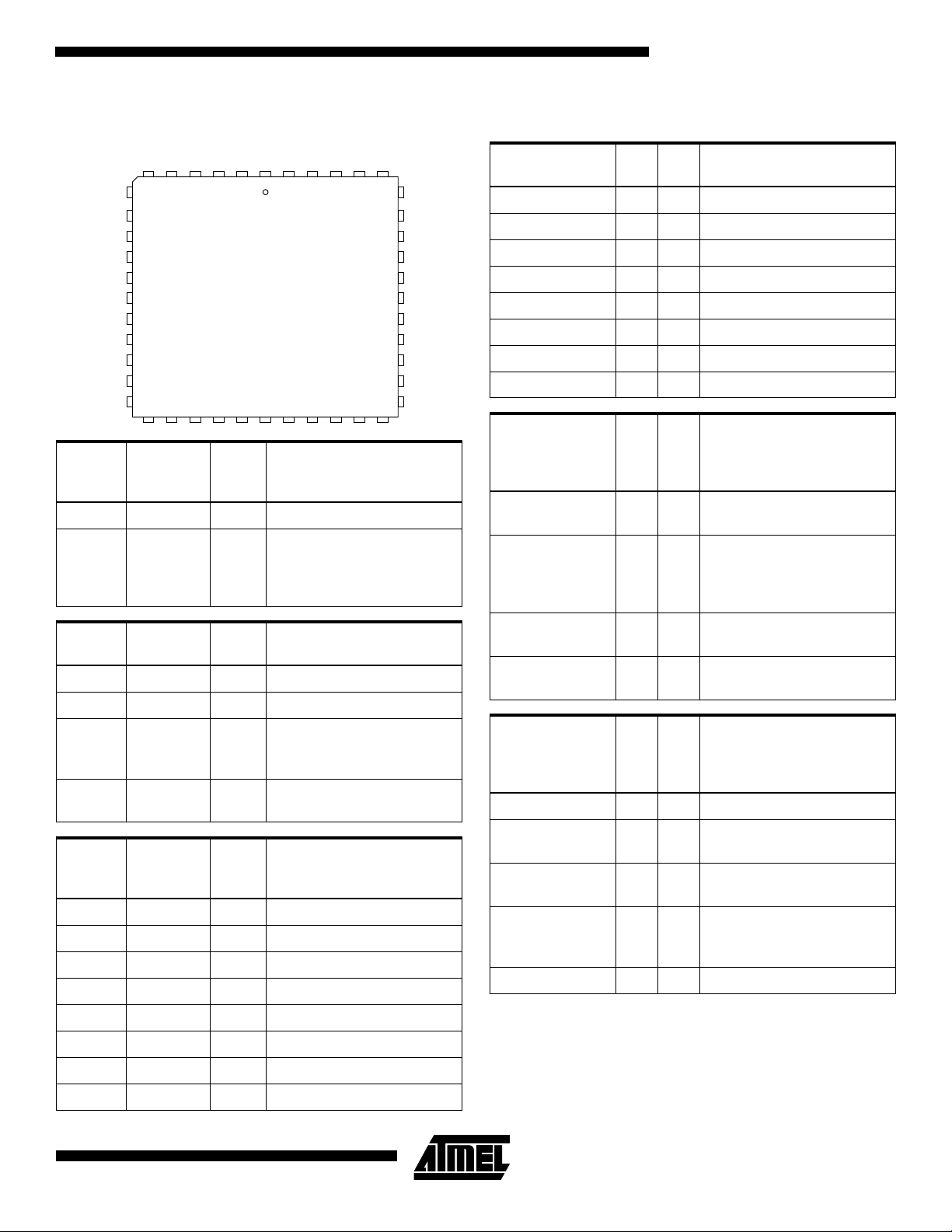

Page 2

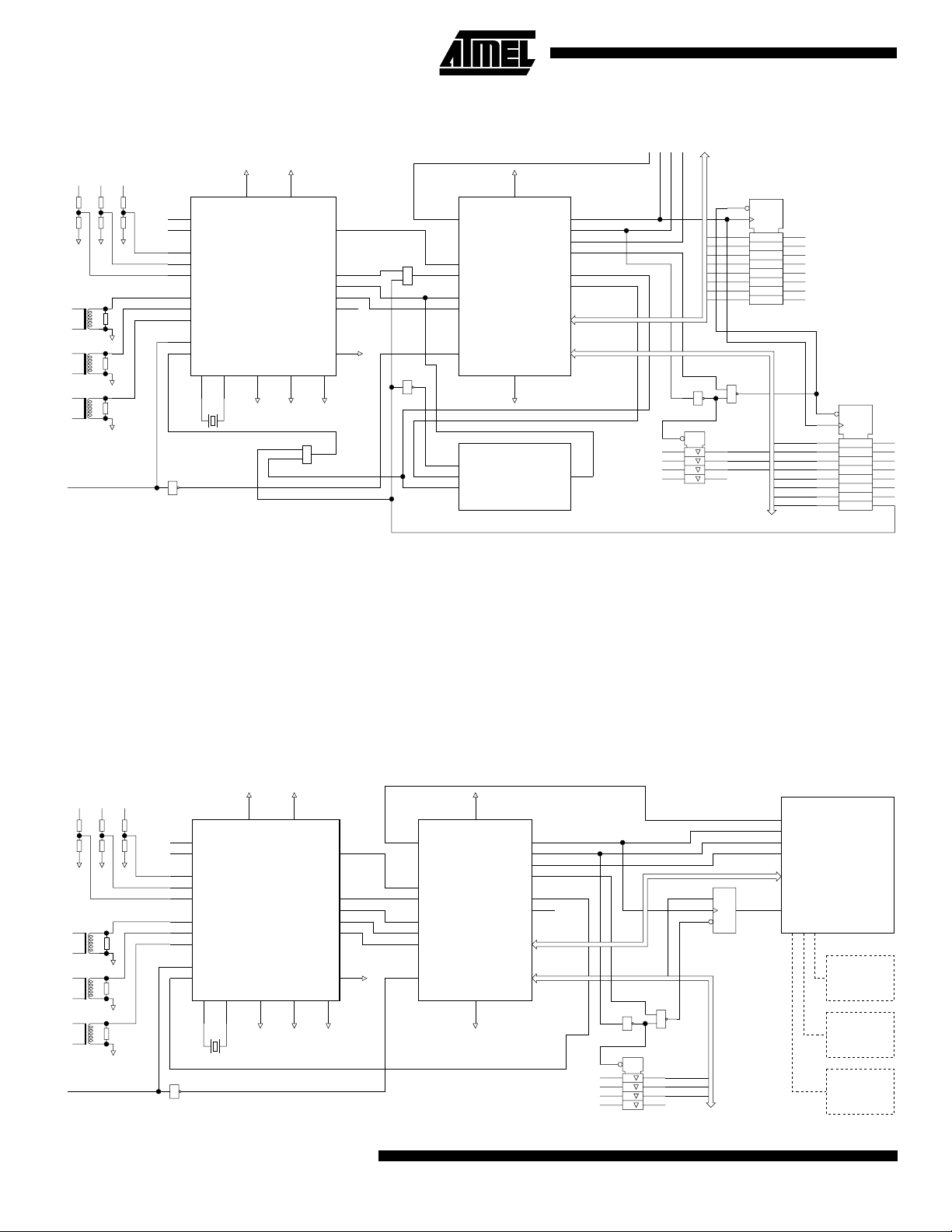

Figure 1.

Block diagram of the AT73C500 chipset in stand-alone configuration

EXTERNAL CONNECTOR

L1 L2 L3

L1

VREF

BGD

RESET

VI1

VI2

VI3

CI1

CI2

CI3

CS

VDA

VDDA

VCC

AT73501

SIX SINGLE-ENDED,

INDEPENDENT

SIGMA-DELTA

CONVERTERS

PFAIL

ACK

DATA

CLKR

CLK

AGND

BRDY

IRQ0

IRQ1

&

SIN

SCLK

XRES

L2

XI XO MODE

VSA

VSSA

GND

1

L3

RESET

&

1

CS

SK

The AT73C500 is progra mmed to m easure act ive, rea ctive

and apparent phase powers. Phase factors, phase voltages, phase currents and line frequenc y are also measured, simultaneously. Based on the individu al phase

powers, total active power is determined.

The power value s are calc ulated ove r one-li ne freque ncy

cycle. The negative and positive results are accumulated in

different registers, which allows for separate billing of

imported and e xported act ive energ y. Also, the reactive

results are sorted depending on whether capacitive or

inductive load is applied.

VCC

STROBE

RD/WR

DEDICATED DSP

DI

AT73500

FOR ENERGY

METERING

GND

AT93C46

EEPROM

128*8 bit

ADDR1

ADDR0

SOUT1

SOUT0

DATA BUS

STATUS BUS

DO

MODE2

MODE1

MODE0

1

1

1

1

1

-VArh

+VArh

-Wh

+Wh

+Wh

-Wh

+VArh

-VArh

&

Eight pulse outputs are provided. Each billing quantity

(+Wh, -Wh, +VArh, -Varh) is supplied with its own meter

constant output, as well as a display counter output. In

multi-channel mode, AT73C500 per forms the fu nctions of

three independent s ingle phase Wh me ters and three

impulse outputs are available, one for each meter element.

All measurement inform ation is av ailab le on an 8-bit microprocessor bus. The results are o utput in six packages, 16

bytes each. Mode and s tatus information of the meter is

also transferred with each data block.

TAMP

STUP

L3

L2

L1

FAIL

DATRDY

INI

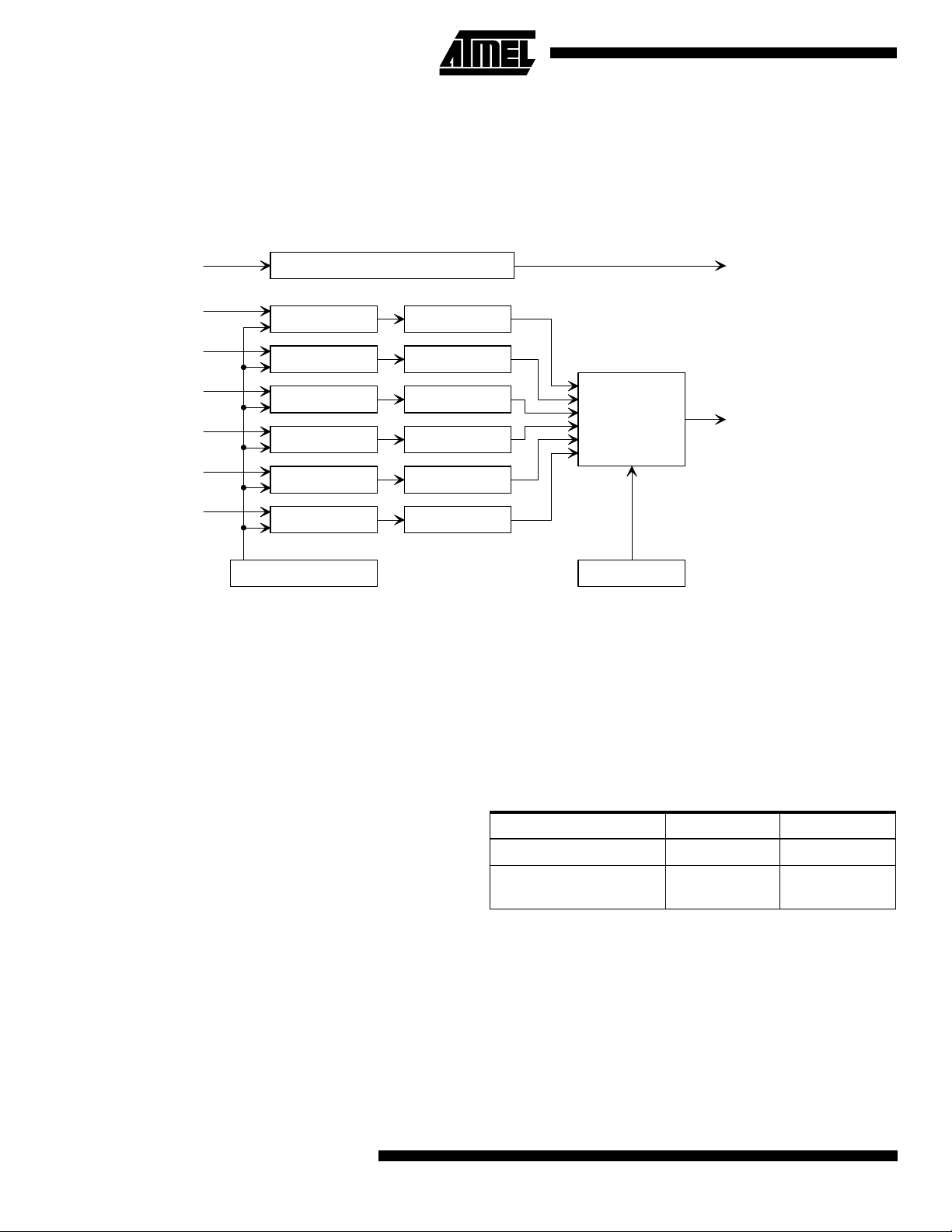

Figure 2.

L1 L2 L3

L1

L2

L3

RESET

2

Block diagram of the AT73C500 chipset in microprocessor configuration

VDA

VREF

BGD

RESET

1

VI1

VI2

VI3

CI1

CI2

CI3

CS

VDDA

AT73501

SIX SINGLE-ENDED,

INDEPENDENT

SIGMA-DELTA

CONVERTERS

XI XO MODE

VCC

VSA

VSSA

GND

PFAIL

ACK

DATA

CLKR

CLK

AGND

BRDY

IRQ0

IRQ1

SIN

SCLK

XRES

VCC

AT73500

DEDICATED DSP

FOR ENERGY

METERING

GND

STROBE

RD/WR

ADDR1

ADDR0

SOUT1

SOUT0

DATA BUS

STATUS BUS

MODE2

MODE1

MODE0

AT73C500

AT90Sxx

D

DATRDY

B9

&

1

1

1

1

1

B14

B13

B12

MICROCONTROLLER

MODEM

LCD

EEPROM

Page 3

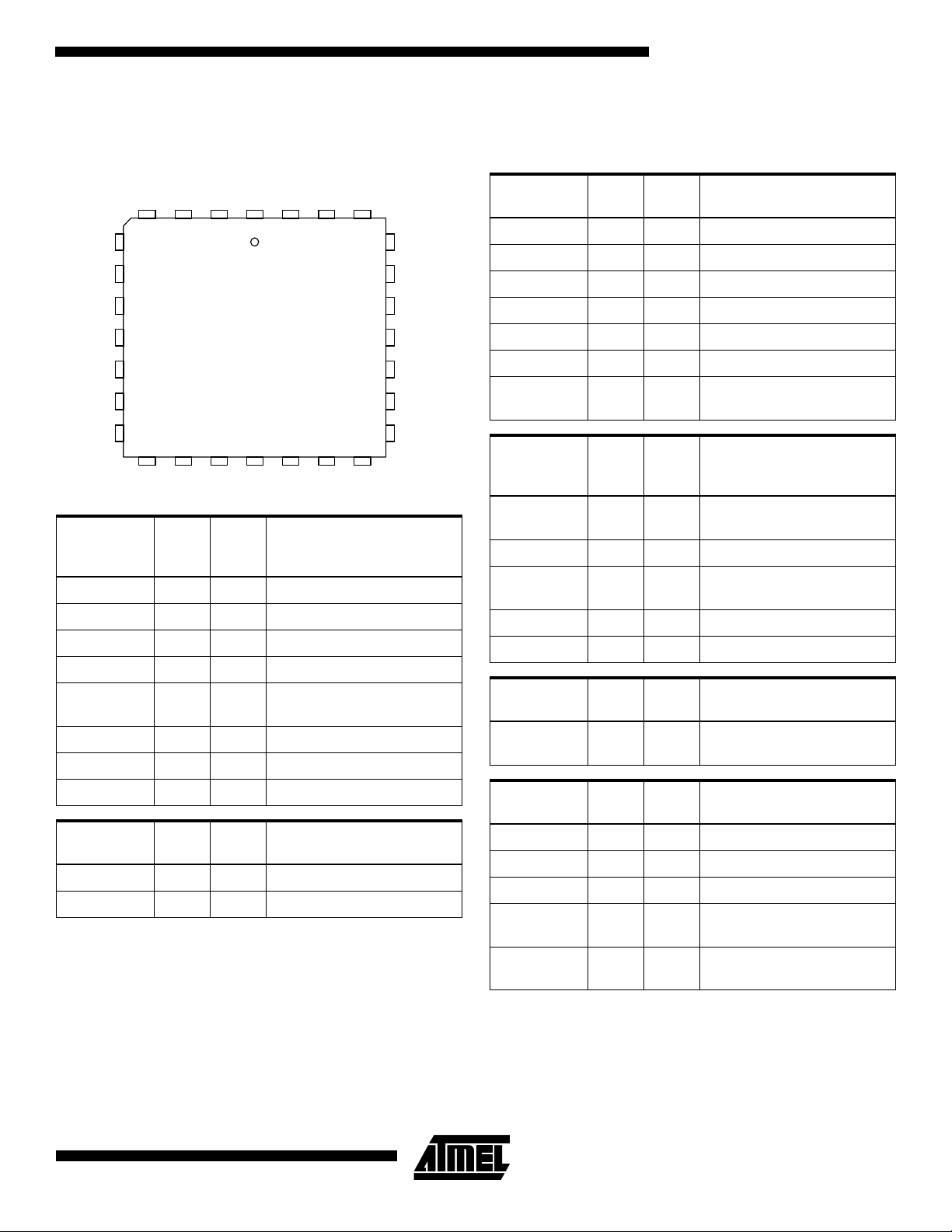

Pin Description

AT73C501 Single-ended ADC

AT73C500

Figure 3.

PFAIL

AGND

VREF

PLCC-28 package pin layout

34

5

BGD

6

CS

7

VCC

8

9

10

VCIN

11

VSSA VDDA AIN2 AIN4 AIN6 AIN1 AIN3

DATAFSRACKCLKRCLKXIXO

26272812

25

24

23

22

21

20

19

18171615141312

Power

Supply

Pins Pin I/O Description

VDDA 13 PWR Analog Supply, Positive, +5V

VSSA 12 PWR Analog Supply, Negative, 0V

VDA 21 PWR Analog Supply, Positive, +5V

VSA 20 PWR Analog Supply, Negative, 0V

AGND 9 PWR

Analog Ground Reference

Output

VREF 11 PWR Reference Voltage Output

VCC 7 PWR Digital Supply, Positive, +5V

VGND 23 PWR Digital Supply, Negative, 0V

Crystal Osc

Signals Pin I/O Description

XI 3 I Crystal Oscillator Input

XO 4 O Crystal Oscillator Output

RESET

MODE

GND

PD

VDA

VSA

AIN5

Analog

Signals Pin I/O Description

AIN1 17 I Input to Converter #1

AIN2 14 I Input to Converter #2

AIN3 18 I Input to Converter #3

AIN4 15 I Input to Converter #4

AIN5 19 I Input to Converter #5

AIN6 16 I Input to Converter #6

VCIN 10 I

Input to Voltage Monitoring

Block

Digital

Control

Signals Pin I/O Description

BGD 5 I

By-pass Control

for Reference Voltage

CS 6 I Chip Select Input

PD 22 I

Power Down Cont r o l

for A/D Modulators

MODE 24 I Mode Selection Control

RESET 25 I Reset Input, Active High

Status

Flags Pin I/O Description

PFAIL 8 O

Output of V olta ge Monitoring

Block

Output Bus

Signals Pin I/O Description

CLK 2 O Master Clock Output

CLKR 1 O Serial Bus Clock Output

DATA 26 O Serial Data Output

FSR 27 O

Output Sample Frame

Signal

ACK 28 O

Data Ready Acknowledge

Output

3

Page 4

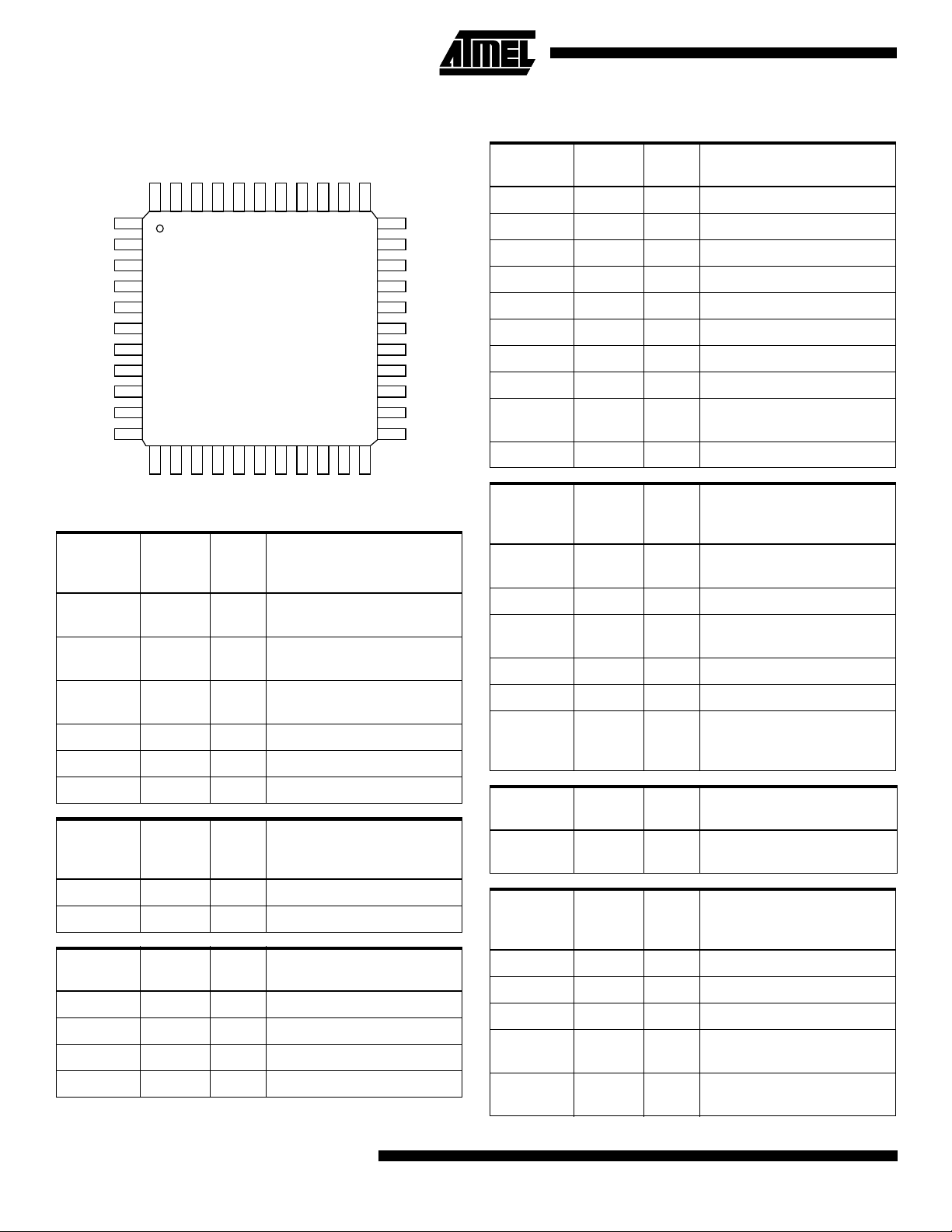

AT73C502 Differential-Ended ADC

T

A

A

Figure 4.

IADJUS

QFP-44 package pin layout

XI

BGD MODE

CS

VCC

VCC

PFAIL

AGND

VCIN

VREF

VS

VS

4344 42 41 40 39 38 37 36 35 34

133

3

4

5

6

7

8

9

10

11

1312 14 15 16 17 18 19 20 21 22

CLKRCLK

N/CN/CN/C

FSR

DATAACK

RESETXO

322

31

30

29

28

27

26

25

24

23

IINP2IINP1VINP3VINP2VINP1VDA

IINN1VINN3VINN2VINN1VDA

Power

Supply

Pins Pin I/O Description

VDA

VSA

AGND 6 PWR

12, 13,

29, 30

10, 11,

27, 28

PWR

PWR

Analog Supply, Positive, +5V

Analog Supply, Negative, 0V

Analog Ground Reference

Output

VREF 8 PWR Reference Voltage Output

VCC 3, 4 PWR Digital Supply, Positive, +5V

GND

PD

VDA

VDA

VSA

VSA

SINGLE

IINN3

IINP3

IINN2

Analog

Signals Pin I/O Description

VINP3 18 I Input to Converter #3 (+)

VINN3 19 I Input to Converter #3 (-)

IINP1 20 I Input to Converter #4 (+)

IINN1 21 I Input to Converter #4 (-)

IINP2 22 I Input to Converter #5 (+)

IINN2 23 I Input to Converter #5 (-)

IINP3 24 I Input to Converter #6 (+)

IINN3 25 I Input to Converter #6 (-)

VCIN 7 I

Input to Voltage Monitoring

Block

IADJUST 9 I Must be left floating

Digital

Control

Signals Pin I/O Description

BGD 1 I

By-pass Control for

Reference Voltage

CS 2 I Chip Select Input

PD 31 I

Power Down Control for A/D

Modulators

MODE 33 I Mode Selection Control

RESET 35 I Reset Input, Active High

Single / Differential selector.

SINGLE 26 I

· Low: Differential

· High or n/c: Single-ended

GND 32 PWR Digital Supply, Negative, 0V

Crystal

Osc

Signals Pin I/O Description

XI 43 I C rystal O scillator Input

XO 44 O Crystal Oscillator Output

Analog

Signals Pin I/O Description

VINP1 14 I Input to Converter #1 (+)

VINN1 15 I Input to Converter #1 (-)

VINP2 16 I Input to Converter #2 (+)

VINN2 17 I Input to Converter #2 (-)

4

AT73C500

Status

Flags Pin I/O Description

PFAIL 5 O

Output of Voltage Monitoring

Block

Output

Bus

Signals Pin I/O Description

CLK 41 O Master Clock Output

CLKR 3 9 O Serial Bus Clock Output

DATA 35 O Serial Data Output

FSR 36 O

ACK 37 O

Output Sample Frame

Signal

Data Ready Acknowledge

Output

Page 5

AT73C500 DSP

AT73C500

Figure 5.

PLCC-44 package pin layout

GND

SOUT15SOUT0

6

GND ADDR0

7 39

B0

8

B1

9

B2

10

GND

11

GND

12

B12

13

B13

14

B14

15

GND

16

B15

17

18

B3

IRQ0 /

GND2GND1CLK44STROBE43VCC42ADDR241ADDR1

PFAIL

4

3

B419GND20B521B622B723N/C24B825B926GND27B10

40

38

37

36

35

34

33

32

31

30

29

28

Power

Supply

Pins Pin I/O Description

VCC 35, 42 PWR Digital Supply, Positive, +5V

1, 2, 6, 7,

GND

11, 12,16,

20, 27, 30,

PWR Digital Supply, Negative, 0V

34

Digital

Inputs Pin I/O Description

CLK 44 I C lock Input

XRES 38 I Reset Input, active low

Interrupt Input, usually

IRQ0 3 I

connected to PFAIL output

of AT73C 501

IRQ1 31 I

Interrupt Input, connected to

ACK Output of AT73C501

Status/

Mode

Bus Pin I/O Description

B15 17 I/O Status/Mode Bus, Bit7

B14 15 I/O Status/Mode Bus, Bit6

B13 14 I/O Status/Mode Bus, Bit5

B12 13 I/O Status/Mode Bus, Bit4

B11 29 I/O Status/Mode Bus, Bit3

XRES

BRDY

RD/WR

VCC

GND

SIN

SCLK

IRQ1 / ACK

GND

B11

Microprocessor

Bus Pin I/O Description

B7 23 I/O

B6 22 I/O

B5 21 I/O

B4 19 I/O

B3 18 I/O

B2 10 I/O

B1 9 I/O

B0 8 I/O

P Bus, Bit7

µ

P Bus, Bit6

µ

P Bus, Bit5

µ

P Bus, Bit4

µ

P Bus, Bit3

µ

P Bus, Bit2

µ

P Bus, Bit1

µ

P Bus, Bit0

µ

AT73C501 /

AT73C502 and

EEPROM

Interface Pin I/O Description

SOUT0 4 O

Serial Output, used as a

clock for EEPROM

Serial Output, used as Chip

SOUT1 5 O

Select (CS) for AT73C501

and as Data Input (DI) for

EEPROM

SIN 33 I

SCLK 32 I

Serial Data Input, data from

AT73C501 or from EEPROM

Serial Clock Input, bit clock

from AT73C501

Control Signals

of µµµµP Bus and

Status/Mode

Bus Pin I/O Description

STROBE 43 O Strobe Output

BRDY 37 I

ADDR1 40 O

Microprocessor ready for

I/O, Active Low

Address Output 1, used for

P bus

µ

Address Output 0, used for

ADDR0 39 O

Status/ Mode bus and for

Impulse Outputs

RD/WR 36 O Read/Write Signal

B10 28 I/O Status/Mode Bus, Bit2

B9 26 I/O Status/Mode Bus, Bit1

B8 25 I/O Status/Mode Bus, Bit0

5

Page 6

AT73C501 and AT73C502

The AT73C501 consis ts of s ix, 16-b it anal og-to-d igital c onverters. The converters are equipped with single-ended

inputs. For di fferential ended applic ations, the AT73C50 2

chip is used.

The converters contain a reference vo ltage gen erator , voltage monitoring bl ock and se rial output i nterfac e. Both converters are based on high-performance, oversampling

Sigma-Delta modulators and digital decimation filters.

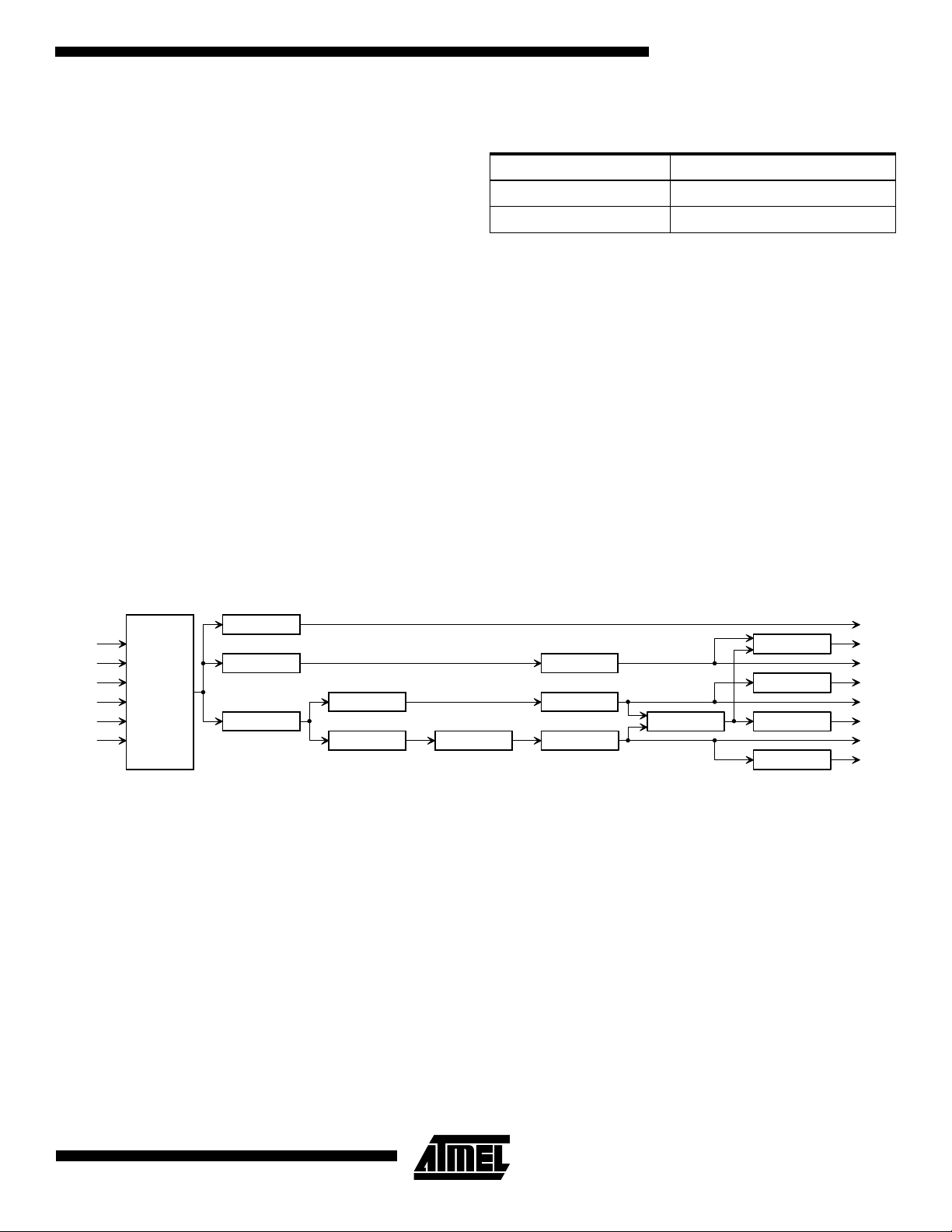

Figure 6.

Block diagram of the single-ended ADC chip, AT73C501

VOLTAGE

MONITORING

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

VOLTAGE

REFERENCE

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

In a 50 Hz meter, the nominal decimated sampling rate of

3200 Hz is used. This corresponds to 64 sa mpl es per eac h

line frequency cycle. 60 H z meters operate with 3840 Hz

sample rate. The master clock frequency of the ADC is

1024 times higher than the above frequencies, i.e. 3.2768

MHz in 50 Hz meters and 3.9321 6 MHz in 60 Hz system s.

The default meter constant of AT73C500 energy counters

is based on the above sample rates.

Other sample frequenci es can be used, bu t the energy

results have to be scaled accordingly. If higher sampling

rate is selected, the meter constant will also be increased

by the same ratio.

The three current inputs of AT73C501 are fed from secondary outputs of current transformers, from Hall sensors or

other similar sensors. In differential-ended applications,

such as with current shunt resistors, the AT73C502 ADC

can be used. On a ny of these converter s, the voltage

inputs must be equipped with simple external voltage dividers.

The input voltage range of each converter is 2V

PP

. The

characteristics of a Watt-hour meter operating, according to

IEC1036 specification, are based on a certain basic current, I

. As a default, the basic current of AT73C500

B

chipset is to 6.25% of the current input full scale value. This

means that if a meter is designed for I

= 5A

B

RMS

, the full

scale range of the current channels will be:

SERIAL OUTPUT

LOGIC

TIMING AND

CONTROL

100

-----------

IFS = 5 A

× 80 A

RMS

6.25

=

RMS

The following current transformer and voltage divider configuration is recommended for a 230V, 3-phase system,

with 5A basic current:

Voltage Inputs Current Inputs

Converter full-scal e input 2.0V

Corresponding full-scale

line voltage / current

270V

PP

RMS

2.0V

80A

PP

RMS

With the above settings, the nominal pulse rate of the

meter constant outp uts is 1250 impulses/kWh (1 250

impulses/kVArh) and the rate of four display outputs 100

impulses/kWh (100 imp/kVArh).

When used in a 5A transformer operated meter, the maximum current range ca n b e s c al ed down to 8A f or exam pl e.

In this case, the me ter constant wi ll be ten times hi gher

than in an 80A meter, i.e. 12500 impulses/kWh. Similarly,

the starting current level will be tra nsferred 2mA from

20mA.

6

AT73C500

Page 7

AT73C500

If the nominal voltage is chosen to be 120V, the vo ltage

divider can either ha ve the same config uration as in the

230V meter, or it can be modified to produce 2.0V

pp

with

140V phase voltage. In the latter case, the default meter

constant will be roughly twice the constant of 230V meter,

i.e. 2411 impulses/ kWh. The mete r constan t can be s cale d

to an even number value by means of calibration.

As described above, th e config uration of voltag e divider s

and current trans form ers aff ects to a lmost all param eters

being metered, like energy counters and impuls e outputs.

A calibration coefficient is provided for the adjustment of

the display pulse rates. With this coefficient, the effect of

various voltage divider and current transformer configurations can be compensated. Care should be tak en that the

dynamic range of the A/D conve rters is a lways effectiv ely

utilized. The use o f calibrat ion coeff icients i s described in

the next section.

Current and voltage samples of AT73C501/AT73C502 are

multiplexed and transferred to AT73C500 through a serial

interface. The ti ming of the interf ace is presented in the

next section.

AT73C501/AT73C502 c ontai n an internal band gap v oltag e

reference. When used in cl ass 0.5 and 0.2 meter s, smaller

temperature drift is required. This can be achieved by

bypassing the internal reference and using temperature

compensated external reference instead. The reference is

selected with the BGD input.

BGD Reference

) Internal

0 (V

SS

1 (VDD) External

There is an integrated voltage mo ni tor ing blo ck on the converter chip. The PFAIL output is forced high if the level of

voltage supplied to V

input drops below 4.2V. There is a

CIN

hysteresis in the monitoring function and PFAIL returns low

if voltage at V

is raised back above 4.3V.

CIN

PFAIL output of AT73C501/AT73C502 can be connected

to an interrupt input o f AT73C500. A T73C500 det ects the

rising edge of PFAIL. To as sure reliable power -down procedure after voltage break, the V

supply of AT73C500

CC

must be equipped with a 470 µF or larger capacitor.

AT73C500

AT73C500 performs p ower and energy calculations. It a lso

controls the interfacing to the AT73C501 (or AT73C502)

and to an external microprocessor. The block diagram of

the DSP is presented below.

Figure 7.

u1(n)

u2(n)

u3(n)

i1(n)

i2(n)

i3(n)

Block diagram of DSP software

FREQUENCY

MEASUREMENT

VOLTAGE

MEASUREMENT

DC OFFSET

SUPPRESSION

PHASE

CALIBRATION

ACTIVE POWER

MEASUREMENT

HILBERT

TRANSFORM

REACTIVE POWER

MEASUREMENT

Serial Bus Interface

The timing of the serial bus interface connec ting the ADC

and DSP devices is presented in Figure 5. The same bus is

used to read the calibration data from an exter nal

EEPROM. This operation is described in section “Loading

of Calibration Coefficients” on page 19.

f

I

U

W

P

PF

Q

Wq

GAIN

CALIBRATION

GAIN AND OFFSET

CALIBRATION

GAIN AND OFFSET

CALIBRATION

APPARENT POWER

EVALUATION

CURRENT

DERIVATION

ACTIVE ENERGY

CALCULATION

POWER FACTOR

DERIVATION

REACTIVE ENERGY

CALCULATION

When the three current and three voltage samples are

ready, AT73C50 1/AT73C502 raises the ACK output.

AT73C500 detects the ri sing edge of ACK, and, after a f ew

clock cycles, it i s ready to read the sample s through the

serial bus. Th e transfer is initiated by CS/SOUT1 signal

and the data bits are strobed in at the falling edge of

CLKR/SCLK clock. Six 16-bit samples is transferred in the

following sequence: I1, U1, I2, U2, I3 and U3.

7

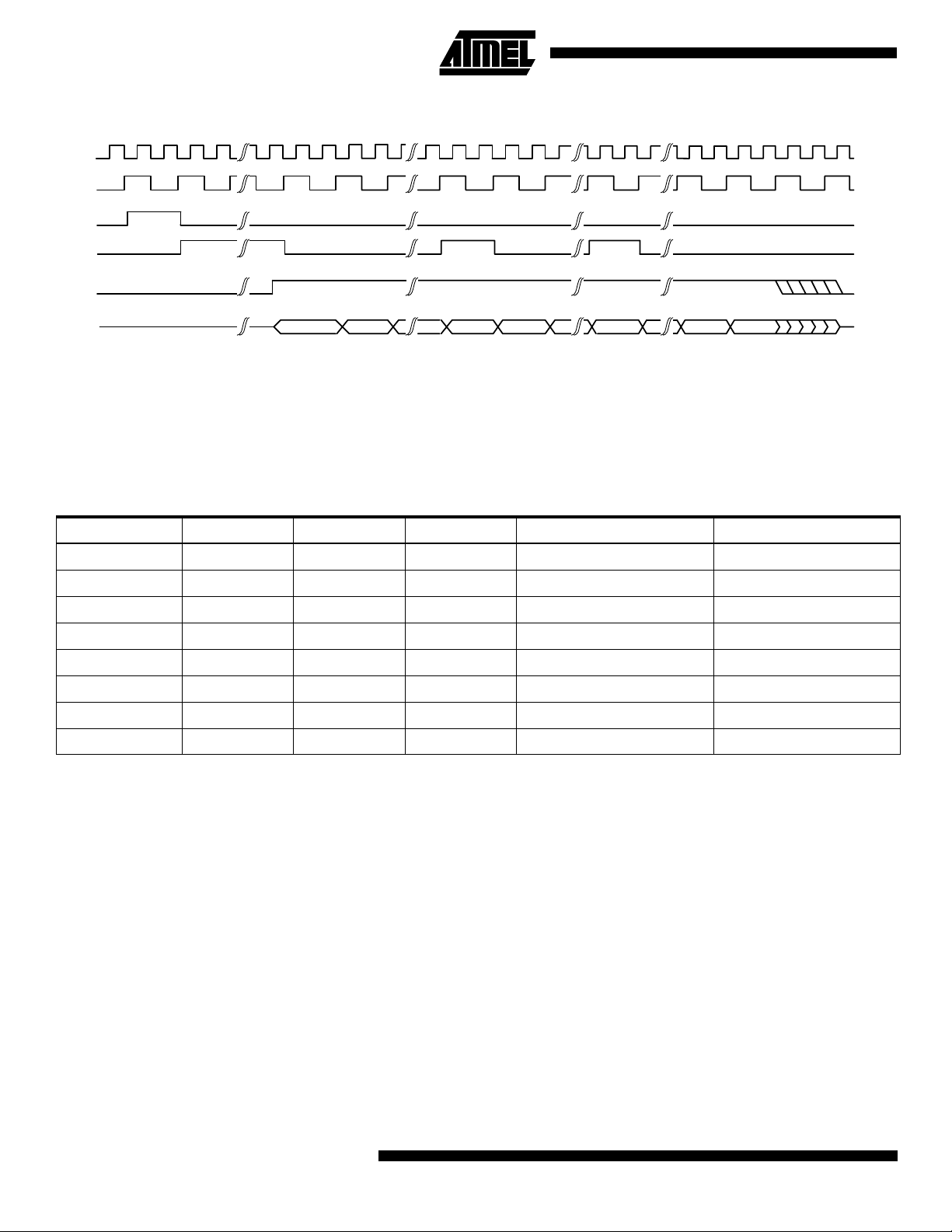

Page 8

Figure 8.

CLK

CLKR

ACK

FSR

CS

DATA

Serial bus timing

CH1, B15

MSB

6 * 16 BITS

CH1, B14 CH1, B0

LSB

CH2, B15

MSB

CH2, B0

LSB

CH6, B1 CH6, B0

Operating Modes of AT73C500

The AT73C500 chips et has six operating modes. The

mode is selected by three mode control inputs which

AT73C500 reads through a bus during the initialization procedure after a reset state. The operation of

AT73C501/AT73C502 is independent of the mode

selected.

Mode Number Mode Bit 2 Mode Bit 1 Mode Bit 0 Operating Mode Calibration Data Storage

0 000 Not in use

In operating mode 7, the default display pul se rate is 10

impulses per kWh, instead of 100 impulses per kWh, as in

other modes.

1 0 0 1 Normal operation EEPROM

2 0 1 0 Multi-channel operation EEPROM

3 0 1 1 Normal operation Micro-processor

4 1 0 0 Multi-channel operation Micro-processor

5 101 Test mode None

6 110 Not in use

7 1 1 1 Normal operation EEPROM

Normal Measurement Mode

AT73C500 devices support both stand-alone and microprocessor configurati on. The cal ibrat ion coe fficient s ca n either

be supplied by a processor or stored in an 128 x 8-bit

EEPROM. The ROM is interfaced with AT73C500 via three

pin serial bus. AT73C500 and the processor communicate

through an 8-bit bus.

The only operational difference be tween stand- alone and

µP mode is the way of readi ng c al ib ra tio n c oeffi c ien ts. This

allows various combinations of these two configurations to

be utilized. For example, th e calibratio n data can be store d

in an EEPROM even though the processor reads and displays the measurement results supplied by AT73C500

device.

In most cases, the use of external EEPROM gives flexibility

to the meter testing and calibra tion, and also makes the

processor inte rface easier to implement. Th erefore, th is

configuration is recommended even in meters equipped

with a separate microprocessor.

The same sequence of basic ca lculations is performed

both in poly-phase and single-phase meters. This

sequence consists of DC offset suppression, phase, gain

and offset cal ibr atio n, ca lcul atio ns of m easu remen t qu ant ities and data transfer to µP bus and pulse outputs.

AT73C500 constantly m oni tor s v ar ious ta mpe ri ng an d faul t

situations, which are indicated by status bits.

After a reset state, AT73C500 goes through an initialization

sequence. The device reads the operating mode and

fetches the calibration coefficients an d adjustment factors

for output pulse rate and starting current level, either from a

non-volatile memory or from a microprocessor. After that

the normal measurement starts. The reset state is normally

activated by power-up reset following the recovery from a

voltage interruption.

8

AT73C500

Page 9

AT73C500

Measurements and Calculations

The first operation performed by AT73C500 is digital highpass filtering. The purpose of the filtering is to remove the

DC offset of both current and voltage samples.

From offset free samples, active power i s calculated

phase-by-phase with simple multiplication and additio n

operations.

First, the current samples are multiplied by voltage samples. The multiplic ation resu lts are s ummed ov er one lin e

period and finally the sum value is divided by 64. This discrete time operation gives the average power of one

50/60Hz period and the result corresponds to the following

continuous time formula:

N

T

1

---

P

ANUNsin n wt

=

×

∑

n0

∫

T

0

=

N

1

=

-- -

A

∑

n0

=

nAnUnIn

2

A

×{}

N

I

sin n wt

×××××[]

N

cos

∅

()×××××

n

dt

∅+×N{}

where

T = 1/50 Hz or 1/60 Hz,

n = 1, 2, 3,..., 20 (basic 50/60 Hz frequency and the

harmonics),

= frequency response of calculations.

A

n

The total power is calculated by summing the power of

each line phase. Reactive power calculation is based on a

similar procedure. Before multipl ying the current an d voltage samples AT73C500 performs a frequency independent

-90 degree phase shift of the voltage signal. This is realized

with a digital Hilbert transformation filter. The bandwidth of

reactive power measuremen t is limited to 360 Hz.

Based on the active and reactive results apparent power

and power factors are d etermined. RMS phase voltages

are calculated by squaring and summing the voltage samples and fina lly tak ing a s quare r oot of the re sults. Curr ent

is determined by divi ding apparent po wer result by cor responding phase voltage.

Frequency measurement is based on a comparison of the

line frequency and AT73C500 sampling clock frequency.

The measurement range is from 20 Hz to 350 Hz.

All measurements and calculations, except frequency measurement, are made ov er 1 0 l ine cy cle per io ds . The resu lts

are updated and transferred to processor bus once in 200

ms.

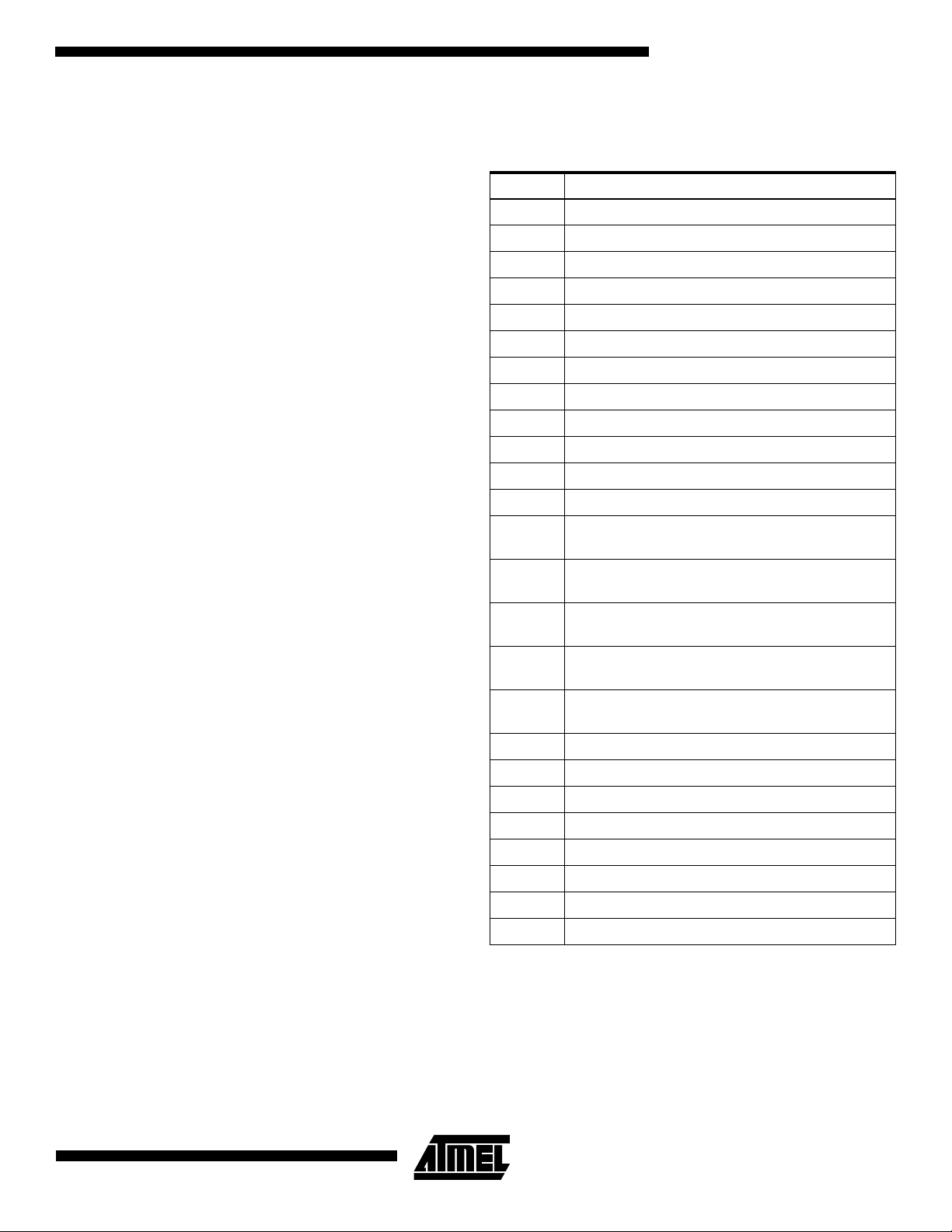

Measurement Registers

For the measurement parameters 25 registers are allocated:

Register Meaning

REG0 Phase 1, active power, P1(10T), 32-bit register;

REG1 Phase 2, active power, P2(10T), 32-bit register;

REG2 Phase 3, active power, P3(10T), 32-bit register;

REG3 Phase 1, reactive power, Q1(10T), 32-bit register;

REG4 Phase 2, reactive power, Q2(10T), 32-bit register;

REG5 Phase 3, reactive power, Q3(10T), 32-bit register;

REG6 Phase 1, apparent power, S1(10T), 16-bit register;

REG7 Phase 2, apparent power, S2(10T), 16-bit register;

REG8 Phase 3, apparent power, S3(10T), 16-bit register;

REG9 Phase 1, power factor, PF1, 16-bit register;

REG10 Phase 2, power factor, PF2, 16-bit register;

REG11 Phase 3, power factor, PF3, 16-bit register;

REG12

REG13

REG14

REG15

REG16

REG17 Frequency, f, 16-bit register;

REG18 Reserved for further use, 16-bit register;

REG19 Phase 1, voltage U1, 16-bit register;

REG20 Phase 2, voltage U2, 16-bit register;

REG21 Phase 3, voltage U3, 16-bit register;

REG22 Phase 1, current I1, 16-bit register;

REG23 Phase 2, current I2, 16-bit register;

REG24 Phase 3, current I3, 16-bit register.

Active e xported energy since the lates t reset, +Wp ,

32-bit counter;

Active imported energ y s ince the l atest re set, -Wp,

32-bit counter;

Reactive energy, inductive load, Wqind, 32-bit

counter;

Reactive energy, capacitive load, Wqcap, 32-bit

counter;

Number of 10T periods elapsed since the latest

reset, 32-bit counter;

The size of the registers is either 16-bit or 32-bit. IEC specifications apply to the calculations of active and reactive

power and energy (REG 0-5 and REG 12-15). Other results

are intended mainly for demand recording and for va rious

diagnostic and display functions. The accuracy of those are

limited due to the finite resolution.

9

Page 10

In multi-channel mode the active exported energy of each

three meters (phases) is stored in registers 12-14. REG15

is not in use.

The maximum value of different power registers differs,

depending on the calculation formulas used. The scaling of

registers is described below.

If a full scale sine signal is applied to voltage and current

inputs and the voltage and current channels are exactly in

the same phase, a value of 258F C2F7H will be produced

in the 32-bit P1, P2 a nd P 3 regi ster s. The LS bi t wi ll cor respond to about 34 microwatts in nominal input conditions of

270V maximum phase voltage and 80A maximum current.

If the load is fully reactive ( ± 90° phase difference) and full

scale signals are applied, the Q1, Q2 and Q3 register content will be 2231 594DH positive or negative, and the LSB

will represent about 38 µVAr. The maximum valu e of the

16-bit S registers is 258 EH and this value is obtained if a

full scale amplitude is produced to the current and voltage

inputs. LS bit of the S registers correspond to about 2.25VA

power.

The following formula is used to calculate the power factor:

abs P()

PF sign Q()

The PF register contents 7FFFH represents power factor

value one and the contents 0000H value zero. Negative PF

values are stored corres pondi ngly a s nega tive b inary nu mbers. It should b e note d that the s ign of pow er fact or r esult

indicates whether the loading is inductive (+) or capacitive

(-).

The contents of frequ enc y regi st er (R EG1 7) ac tua lly repr esents a 16-bit figure which corresponds to the duration of

50 line frequency cycles. The measurement is made by

comparing the line frequency with one of the sampling

clocks of AT73C500 and therefore the result depends on

the crystal frequency used. With default 3.2768 MHz crystal, the resolution of time value is 1.25 ms . To get the frequency, the following calculation has to be made:

40000

-------------------

f

REG17

If the master clock frequency (MCLK) of AT73C500 is not

nominal, the following formula gives frequency results:

40000

-------------------

f

REG17

× Hz=

----------------- -

×=

abs S()

Hz=

MCLK

----------------------------- -

3.2768MHz

In the default condition, value 7FFFH of register 17 corresponds to 1.22 Hz frequency, value 0320H represents

50Hz and 0001H 40 kHz. Ho wever, in practice, th e bandwidth of frequency measurement is limited to 20 Hz to 350

Hz.

The frequency measurement is locked with one of the

phase voltages. If th is volt age disappe ars, AT73C5 00 tries

to track one of the other phases. The frequency measurement works down to about 10% level of the full scale voltage range. The harmonics content of phase voltage should

be below 10%. If i t is highe r, errone ous freque ncy re sults

may be obtained.

The voltage registers (REG19- REG21) are scaled so that

full scale sinusoidal input signal at AT73C501/AT73C502

voltage channels will produce 7A8 BH value into vo ltage

registers. This means that the resolution of the registers is

about 8.6 mV. Accordingly, full scale current will produce

7DA4H to current registers (REG22-REG24) providing a

resolution of about 2.5 mA. In practice, the voltage can be

measured down to about 25V level and current do wn to

about 100mA.

If either voltage or current, or both, contain a considerable

amount of harmonics pr oducing a squ are wave type waveform, it is recommended to scale the input range so that the

maximum peak-to-peak v al ue i s at l eas t 1 0% be low the ful l

scale range of inputs. This is to avoid overflow in the calculations performed by AT73C500.

Energy Counters

Four 32-bit counters (REG12-REG15 ) measure energy

consumption. In nominal situations, the counters are

always increm ented wh en 0.4W h (0.4V Arh) en ergy is co nsumed. The counters can store minimum of 1100 days consumption, provided that AT73C501/AT73C502 and

AT73C500 are used with default settings.

Impulse outputs are generated from these counters. The

meter constant rate represents 2 LSBs of a counter which

equals 0.8 Wh (0.8 VArh) and produces 1250

impulses/kWh. (1250 impulses/kVArh). In modes 1 to 4, the

display pulses are generated from 25 LSBs of a counter.

This corresponds to an impulse rate of 100 impulses/kWh

(100 impulses/kVArh). It is possible to adjust this rate with

MCC calibration c oefficient. In mode 7, 2 50 LSBs of th e

energy register is needed to gene rate one impu lse (10

impulses/kWh) .

The default values above are based on 80A

current, 270V

rate.

The crystal frequen cy wi ll aff ect the values of energy regi sters (REG12-REG15) and time register (REG 16). It will

also change the pulse rates of the impulse outputs.

full scale voltage and 3.2768 MHz clock

RMS

full scale

RMS

10

AT73C500

Page 11

AT73C500

It is recommended that 50 Hz m eters are oper ated from

3.2768MHz crystal. In 60 Hz s yste m, a 3.93 216 MHz c lock

is normally used. Because the clock frequency generates a

time referenc e for energy c alculations, the content o f

energy registers an d also the pulse rate of impu lse outpu ts

will change when crys tal is changed. For ex ample, the

nominal meter constant and display pulse rate of 60 Hz

meter (3.93216 MHz clock) is:

60Hz

MC

------------- -

==

× 1500

50Hz

1250

imp

----------- -

kWh

imp

----------- -

kWh

and

60Hz

------------- -

DP

==

50Hz

Register Conditions Full Scale Output (hex) Resolution (hex)

REG0 - REG2 U = 270V, I = 80A, PF = 1 258F C2F7 34.276 µW

REG3 - REG5 U = 270V, I = 80A, PF = 0 2231 594D 37.653 µVAr

REG6 - REG8 U = 270V, I = 80A 258E 2.2467 VA

REG9 - REG11

imp

----------- -

100×

kWh

120

imp

----------- -

kWh

PF = 1

PF = -1

The LSB of energy registers correspond to 0.33Wh instead

of 0.4Wh, as follows:

3.2768MHz

E

LSB

--------------------------------- -

3.93216MHz

0.4Wh× 0.333333…Wh==

The pulse rate can be scaled to 100 imp/ kWh by programming value 5 to MCC coefficient, as below:

1

---------

IMP (25 MCC)

+

===

imp

×

E

LSB

30

1

---------

0.3333…Wh×10

imp

Wh

-------- -

imp

which equals 100 impulses per kilowatt hour.

The following table sum marizes the contents of al l mea-

surement registers.

7FFF

8001

0.0000305

-0.0000305

REG12 - REG15 W = 1.718GWh FFFF FFFF 0.4Wh

REG16

REG17 50*T = 40.959s 7FFF 1.25 ms

REG19 - 21 U = 270V 7A8B 8.6 mV

REG22 - 24 I = 80A 7DA4 2.5 mA

T = 238609.3h FFFF FFFF 0.2s

∆

11

Page 12

Output Operations

The data output by AT73 C500 can be divided in to three

categories: data to external proc essor, sta tus informat ion

and impulse outputs. AT73C500 reads mode informa tion,

and in mode 3 and 4, also calibration data via external bus.

For the I/O operation, two 8-bit buses are allocated.

The same eight data lines are reserved both for the

impulse outputs and for the pr ocessor in terface. The se paration is done with two address pins. When c omm uni ca tin g

with the microproce ssor, address 1 (pin ADDR1) is activated (high). Impulses are output combined with a high

level of address 0 (ADDR0). For sta tus information sep arate 8-bit bus is reserved. The table below describes the

use of the two buses of AT73C500.

PACKAGE 0

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchronization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG0 LS byte Active power, phase 1

6 REG0 (LS+1) byte Active power, phase 1

7 REG0 (LS+2) byte Active power, phase 1

8 REG0 MS byte Active power, phase 1

Data bits Bus Address Mode Usage

B0 - B7 Data Bus ADDR0 Output

B8 - B15 Status Bus ADDR0 Output

B0 - B7 Data Bus ADDR1

B12 - B14 Status Bus ADDRx Input

Input/

Output

Impulse

Outputs

Status

Information

Processor

Interface

Mode

Inputs

For status and impulse outputs, external latches are

needed to store the information while buses are used for

other tasks. In most case s, the data bus of AT73C500 an d

processor I/O bus c an be connecte d directly with each

other. The data transfer is controlled by handshake signals,

ADDR1, RD/WR, STROBE and BRDY. One of the status

outputs DATRDY (B9, ADDR0) can be used as an interrupt

signal. Interrupt can be also generated from the handshake

lines.

In most meters, only some of the I/O operations of

AT73C500 are needed. If a meter con tains a sepa rate processor, status outputs of AT73C500 are typically not used

since the processor will anyway track the status information

supplied by AT73C50 0. Often only one or two o f the

impulse output s are wi red to t he test LED or electrom echanical coun ter.

Data Transfer to External Microprocessor

The calculation results of AT73C500 are transferred to processor via 8-bit parallel bus. During normal oper ation, the

information transfer is divided into six packages which are

written in 200ms intervals after the calculations over ten

line frequency cycles have been completed. There is a time

interval of one line cycle between each individual data

package. The first four bytes of a package contain synchronization, mode and status inf ormation, and the rest 12

bytes are reserved for the actual measurement results. The

contents of the six data packages are as follows:

9 REG1 LS byte Active power, phase 2

10 REG1 (LS+1) byte Active power, phase 2

11 REG1 (LS+2) byte Active power, phase 2

12 REG1 MS byte Active power, phase 2

13 REG2 LS byte Active power, phase 3

14 REG2 (LS+1) byte Active power, phase 3

15 REG2 (LS+2) byte Active power, phase 3

16 REG2 MS byte Active power, phase 3

PACKAGE 1

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchronization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG3 LS byte Reactive power, phase 1

6 REG3 (LS+1) byte Reactive power, phase 1

7 REG3 (LS+2) byte Reactive power, phase 1

8 REG3 MS byte Reactive power, phase 1

9 REG4 LS byte Reactive power, phase 2

10 REG4 (LS+1) byte Reactive power, phase 2

11 REG4 (LS+2) byte Reactive power, phase 2

12 REG4 MS byte Reactive power, phase 2

13 REG5 LS byte Reactive power, phase 3

14 REG5 (LS+1) byte Reactive power, phase 3

15 REG5 (LS+2) byte Reactive power, phase 3

16 REG5 MS byte Reactive power, phase 3

12

AT73C500

Page 13

AT73C500

PACKAGE 2

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchronization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG6 LS byte Apparent power, phase 1

6 REG6 MS byte Apparent power, phase 1

7 REG7 LS byte Apparent power, phase 2

8 REG7 MS byte Apparent power, phase 2

9 REG8 LS byte Apparent power, phase 3

10 REG8 MS byte Apparent power, phase 3

11 REG9 LS byte Power factor, phase 1

12 REG9 MS byte Power factor, phase 1

13 REG10 LS byte Power factor, phase 2

14 REG10 MS byte Power factor, phase 2

15 REG11 LS byte Power factor, phase 3

16 REG11 MS byte Power factor, phase 3

PACKAGE 3

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchron ization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG12 LS byte Active exported energy

6 REG12 (LS+1) byte Active exported energy

7 REG12 (LS+2) byte Active exported energy

8 REG12 MS byte Active exported energy

9 REG13 LS byte Active imported energy

10 REG13 (LS+1) byte Active imported energy

11 REG13 (LS+2) byte Active imported energy

12 REG13 MS byte Active imported energy

13 REG14 LS byte

14 REG14 (LS+1) byte

15 REG14 (LS+2) byte

16 REG14 MS byte

Reactive energy, inductive

load

Reactive energy, inductive

load

Reactive energy, inductive

load

Reactive energy, inductive

load

13

Page 14

PACKAGE 4

PACKAGE 5

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchronization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG15 LS byte

6 REG15 (LS+1) byte

7 REG15 (LS+2) byte

8 REG15 MS byte

9 REG16 LS byte Counter

10 REG16 (LS+1) byte Counter

11 REG16 (LS+2) byte Counter

12 REG16 MS byte Counter

13 REG17 LS byte Frequency

14 REG17 MS byte Frequency

15 REG18 LS byte Reserved

Reactive energy,

capacitive load

Reactive energy,

capacitive load

Reactive energy,

capacitive load

Reactive energy,

capacitive load

Byte Data Order Meaning

1 Sync LS Single byte Synchronization

2 Sync MS Single byte Synchronization

3 Mode Single byte Mode information

4 Status Single byte Status information

5 REG19 LS byte Voltage, phase 1

6 REG19 MS byte Voltage, phase 1

7 REG20 LS byte Voltage, phase 2

8 REG20 MS byte Voltage, phase 2

9 REG21 LS byte Voltage, phase 3

10 REG21 MS byte Voltage, phase 3

11 REG22 LS byte Current, phase 1

12 REG22 MS byte Current, phase 1

13 REG23 LS byte Current, phase 2

14 REG23 MS byte Current, phase 2

15 REG24 LS byte Current, phase 3

16 REG24 MS byte Current, phase 3

16 REG18 MS byte Reserved

14

AT73C500

Page 15

The six data packages arrive as follows:

AT73C500

Figure 9.

Data transfer to processor in six packages

20 ms

200ms = 655360 clocks @ 3.2768 MHz

Pack0Pack1Pack2Pack

3

DATRDY

LINE PERIOD

1234567891012345

In normal mode, the Sync LS byte indicates the number of

data package which wi ll follo w (va lue 0... 5). There are als o

two special situations indicated by this byte. Value six of

Sync LS byte means that the processor is expected to supply calibration data to AT73C500. Value seven is written by

AT73C500 in case power interruption is detected and billing information needs to be transferred to microprocessor.

In this case the proc ess or k now s th at bo th packages 3 and

4 will follow one after each other as shown in Figure 10.

Content of Sync LS byte i s des cr i bed in t he fo ll owi ng ta ble.

Bits 3-7 of the Sync LS byte are not used.

Sync LS byte

Data

B7 - B3 B2 B1 B0

X X X X X 0 0 0 0

X X X X X 0 0 1 1

X X X X X 0 1 0 2

X X X X X 0 1 1 3

X X X X X 1 0 0 4

X X X X X 1 0 1 5

X X X X X 1 1 0 (none)

package Mode

Normal operation,

Data output

Normal operation,

Data output

Normal operation,

Data output

Normal operation,

Data output

Normal operation,

Data output

Normal operation,

Data output

DSP waiting for

calibration data

Pack4Pack5Pack0Pack1Pack2Pack

3

The Sync MS byte contains a unique 8-bit data, 80H. It can

be used as a synchronization byte by the external controller.

The mode byte contains the following information:

Figure 10.

Mode byte

Meaning of bits in mode byte

B0B1B2B3B4B5B6B7

Not used State of MODE

input pins of the

DSP

The contents of the status byte equals the content of the

external Status bus as described in the section “Status

Information” on page 17.

In the beginning of I/O operation, AT73C500 writes a high

pulse to B9 pin of the Status bus (ADDR0). This pin can be

externally latched to lengthen the pulse over the whole output operation. It can be used to generate a da ta ready

(DATRDY) interrupt to processor.

Figure 11 shows the timing of one data package. In nominal conditions, it takes 200 clock cycles to transfer all 16

bytes. A high pulse (DATRDY) is written to bit B9

(SMBUS1) of Status bus 11 c locks befor e the fir st byte is

available and low pulse 12 c locks after the last by te has

been sent.

X X X X X 1 1 1 3 and 4

PFAIL active,

billing information

to be transferred

15

Page 16

Figure 11.

LATCHED

DATRDY

CLK

STROBE

Contents of a data package

200 clock cycles

45 clock cycles 143 clock cycles

Sync LS Sync MS Mode Status Data 1 Data 2 Data 11

Synchronisation data Status data

AT73C500 offers some time for the processor to analyze

the synchronization, status and mode information before

starting to supply the measurement results. The 12 measurement bytes are written on every 11th clock period.

Four handshake signals are provided, ADDR1, RD/WR,

STROBE and BRDY, for interfacing with the microprocessor. ADDR1 is always taken high when AT73C500 is either

Figure 12.

STROBE

Handshake signals of the DSP

CLK

SDLY

DATA

FROM DSP

DDLY

BRDY

SH

Measurement data, 12 bytes

Data 12

writing to µP bus or reading the bus contents. When used

with slow peripheral, the BRDY input of AT73C500 can be

used to hold the device in write mode until the processor

has finished reading the bus. However, the total length of

one data package should always be less than 300 clock

cycles of AT73C500. Longer I/O periods may result erroneous measurement results.

BRS

ASU

ADDR1

RWSU

RD/WR

RWH

Following the falling edge of BRDY, the data ca n be

strobed into th e µP by the rising edge of the STROBE signal. If the microprocessor is able to read data continuously,

BRDY can be kept constantly low. Also BRDY should be

low whenever DATR DY is inactive al lowing AT73C50 0

freely use its buses.

16

AT73C500

To avoid conflicts, the processor shou ld always keep its

bus in tri-state mod e, unless it is used to write cali bration

coefficients to AT73C500.

Page 17

AT73C500

Status Information

AT73C500 provides the following status information

through the Status bus of AT73C500 (B8 - B15, ADDR0).

Status

Bus Bit

B15 TAMP

B14 STUP

B13 L3

B12 L2

B11 L1

B10 FAIL High: Operating error detected

B9 DATRDY High: Data available on the µP bus

B8 INI

Status

Flag M ea ning

High: Potential event of

tampering detected

High: Current of all phases

below starting level

High: Phase 1 voltage above

10% of full-scale

High: Phase 2 voltage above

10% of full-scale

High: Phase 3 voltage above

10% of full-scale

Low: AT73C500 in initial ization phase,

EEPROM interf ace in us e, AT73C501

(or AT73C502) interface disabled

High level of Lx fl ags indicates that a phase voltage is

above 10% level of the full scale voltage. If a voltage drop

is detected, the correspondi ng status bit is writte n low.

AT73C500 is continuou sly monitoring the vo ltage of each

phase.

FAIL flag signifies that som ething abnormal has been

detected. The following situations may cause a high level of

FAIL: read operation of c alibration coe fficients is not su ccessful, the serial bus of A T73C501 or AT73C5 02 is not

working properly, the measurement results can't be transferred to microprocessor, AT73C500 has detected an internal failure.

If any of the calibration coefficients and co rresponding

back-up values do n ot match, AT73C500 performs two

extra read operati ons to eliminat e the poss ibil ity of a transfer error. If the error still exists after the third trial, incorrect

coefficients are replaced by the default values. FAIL flag is

activated indi cating that a potentia l error has been

detected. FAIL is also taken high in case it is not possible

to read calibration coe fficients from the µP or EEPROM, or

if the processor supplies too few coefficients. In both cases,

the read operation will finish in a time-out situation.

The voltage monitoring block of AT73C501/AT73C502 is

used to detect voltage interruptions before the supply voltage of AT73C500 drops. High level of PFAIL output at the

ADC indicates a voltage break situation. The measurement

results supplied by AT73C501/AT73C502 may be erroneous, and AT73C500 and microprocessor has to be prepared for supply volta ge interr uption. A hig h level of PF AIL

causes an immediate write of data packages 3 and 4

(accumulated energy information) to processor bus. The

timing of this operation is presented in Figure 13. There are

16 clocks between the two 12 byte data packages but the

header bytes are no t repeated in the b eginni ng of pa ckag e

4.

Figure 13.

LATCHED

DATDRY

CLK

STROBE

Transfer of billing information to processor following a PFAIL interrupt

337 clock cycles

45 clock cycles 280 clock cycles

Sync LS Sync MS Mode Status Data 1 Data 2 Data 12

Synchronisation data Status data

In case of an imminent voltage break, the microprocessor

stores the energy v alues into a non- volatile memory. Th e

devices can operate for a short per iod of time powered by

an electr olytic capacitor or by battery back-up.

AT73C500 dev ices ar e taken to a soft re set st ate and normal operation will be recovered after the supply voltage is

high again. About one line cycle is needed to start normal

measurements. During this initialization phase no calculations are performed.

Measurement data, 12 bytes + 12 bytes

Data 1

Data 12Data 2

STUP output (active high) indicates that the current of each

of the three phases is below the specified starting level and

no energy is accumulated. This status flag is very useful

during the calibration of a meter sinc e immediate feedba ck

about staring current level is provided.

TAMP flag informs about potential tampering. It is activated

if one or more phase currents are zero or negative. Therefore it very effectively indicates current transformer reversal

or short-circuit.

17

Page 18

Impulse Outputs

AT73C500 provides eigh t impul se ou tputs, four mete r constant outputs and four pulse outputs to dri ve electromechanical display counters which can register exported and

imported active energy and capacitive and inductive reactive energy. These outputs use the same output lines as

used for the processor interface. Impulses are combined

with address 0 (ADDR0). The table below shows the

impulse outputs avail able in mo des 1 and 3 . M ode 7 offers

the same outputs, but the rate of the display pulses is

10imp/kWh (kVArh).

Impulse Outputs in Operating Modes 1 and 3

Output Bit Impulse Output Type Impulse Rate

B7 - VArh Meter Constant 1250imp/kVArh

B6 + VArh Meter Constant 1250imp/kVArh

B5 - Wh Meter Constant 1250imp/kWh

B4 + Wh Meter Constant 1250imp/kWh

B3 + Wh Display 100imp/kWh

B2 - Wh Display 100imp/kWh

B1 + VArh Display 100imp/kVArh

B0 - VArh Display 100imp/kVArh

An external regis ter is needed to latch and buffer the

pulses. The regist er c an furth er d rive b oth el ectrom echan ical display counters and LEDs. In modes 1 to 4, the nominal pulse rate of display outputs is 100imp/kWh or

100imp/kVArh (U

MAX

= 270V, I

= 80A) and meter con-

MAX

stant outputs 1250imp/kWh (1250imp/kVArh). The length

of each display pulse is 117ms when operated from 3.2678

MHz crystal. Meter constant pulse stays high for 20 ms.

If the devices are used in a 5A meter, current input s can be

scaled to 8A full scale level. In this case, the nominal

impulse rates are ten times higher than the above values.

Multi-channel Mode

Modes 2 and 4 are reser v ed fo r mul ti- chan nel op er ati on. I n

these modes, the chip s oper ate like thr ee ind ependen t single phase meter s and st ore the calc ulatio n res ults in separate registers ph ase-by -phase (m eter-by- meter ). The b asic

sequence of operation is otherwise similar to the normal

mode.

Impulse Outputs

In multichannel operation, three impulse outputs are available for display counters. The absolute energy value is

measured and the rever sal of cur rent flow doe sn’t affe ct to

pulse rates. Meter cons tant pulse rate correspon ds to total

active energy of the three single phase channels summed

together as shown in the table below.

Output Bit Impulse Output Type Impulse Rate

B7 Not Used Not Used B6 Not Used Not Used B5 Not Used Not Used -

Meter Constant

B4

B3

B2

B1

B0 Not Used Not Used -

±

±

±

±

Wh

Wh

Wh

Wh

Sum of all 3

channels

Display,

Channel 1

Display,

Channel 3

Display,

Channel 2

1250imp/kWh

100imp/kWh

100imp/kWh

100imp/kVArh

Test Mode

This mode can be used for ini tial cali brati on purpo se s or i n

a special meter for additional processing of sample data. In

this mode, AT73C501/AT73C502 sample s the six inputs

normally and transfers the samples to AT73C500, which

performs DC suppression and further writes the samples to

8-bit processor bus together with header bytes in the following sequence.

Byte Contents

1 Sync LS byte

2 Sync MS byte

3 Mode Byte

4 Status Byte

5 I1, LS byte and MS byte

6 U1, LS byte and MS byte

7 I2, LS byte and MS byte

8 U2, LS byte and MS byte

9 I3, LS byte and MS byte

10 U3, LS byte and MS byte

Several input combinations can be measured to check the

gain and phase error in different conditions. An interfacing

computer can be progr ammed to ca lculate t he cali bratio n

coefficients based on the samples supplied by AT73C500.

At the end of the calibra tion, the coeffi cients have to be

stored in a non-volatile memory of the meter as described

in “Loading of Calibration Coefficients” on page 19.

18

AT73C500

Page 19

Calibration

The calibration coefficien ts always hav e to be loaded in to

AT73C500 registers after reset state. The co efficients are

either read from an external EEPROM or supplied by a

microprocessor via the 8-bit bus.

Loading of Calibration Coefficients

In modes 3 and 4, a microprocessor takes care that the

coefficients are kep t in a non-vol atile memor y during voltage break. After the voltag e break, the DSP first write s the

AT73C500

four header bytes, Sy nc LS, Sync MS, mo de and status

information on the µP bus and then starts waiting for the

calibration data. The processor reads the status and mode

and after that writes the coeffi cients on the bus. T he contents of AT73C500 header bytes is described in “Data

Transfer to External Micropr ocessor ” on page 12 and “Status Information” on page 17.

Figure 14.

Timing of calibration coefficient read operation

CLK

DATRDY

STROBE

SYNC LS SYNC MS MODE STATUS COEFFICIENT 0

HEADER DATA SUPPLIED BY FT500D 44 COEFFEICIENTS READ

Before using the µP bus, AT73C500 writes a short pulse

(DATRDY) to B9 bit of the Status bus combined with hi gh

level of address 0 (ADDR0 output). This bit can be taken

directly or through an e xternal latch to the inte rrupt in put of

the processor. After writing the status and mode bytes,

AT73C500 goes to a read mo de and star ts waiti ng for calibration coeffici ents from the µP. Processor su pplies the

coefficients as 8-bit bytes one after another. The timing of

this sequence is presented in Figure 14.

FT500 READY TO

READ CALIBRATION DATA

. . .

COEFFICIENT 1

COEFFICIENT 42

COEFFICIENT 43

Nine gain calibratio n, si x offs et ca librati on and three phas e

calibration coeffici ents are r ead into the AT73C50 0 memory. At the sa me ti me, a s c ali ng f actor for the di sp la y pu ls e

rate and an adjustment value for starting current is stored.

To minimize the risk of erroneous calibr ation values, a

back-up value of each coeff ici ent i s als o tran sfer red b y th e

microprocessor or from the ROM. The back-up value has to

be written as 2’s complement binary number of the actual

calibration figure.

19

Page 20

The calibration data is transferred in the following sequence:

Byte Calibration Coefficient Byte Calibration Coefficient

0 PC1 1 PC1 back-up

2 PC2 3 PC2 back-up

4 PC3 5 PC3 back-up

6 MCC 7 MCC back-up

8 Not used 9 Not used

10 AGC1 11 AGC1 back-up

12 AGC2 13 AGC2 back-up

14 AGC3 15 AGC3 back-up

16 RGC1 17 RGC1 back-up

18 RGC2 19 RGC2 back-up

20 RGC3 21 RGC3 back-up

22 UGC1 23 UGC1 back-up

24 UGC2 25 UGC2 back-up

26 UGC3 27 UGC3 back-up

28 STUPC 29 STUPC back-up

30 AOF1 31 AOF1 back-up

32 AOF2 33 AOF2 back-up

34 AOF3 35 AOF3 back-up

36 ROF1 37 ROF1 ba ck-up

38 ROF2 39 ROF2 ba ck-up

40 ROF3 41 ROF3 back-up

42 OFFMOD 43 OFFMOD back-up

The meaning of the calibration coefficient mnemonics are as follows:

Mnemonic Meaning

PC

N

MCC Display pulse adjustment factor for active and reactive energy

AGC

N

RGC

N

UGC

N

STUPC Starting current adjustment factor

AOF

N

ROF

N

OFFMOD Controls the use of offset factors

Phase calibration factor, phase N

Gain calibration factor for active power and energy calculation, phase N

Gain calibration factor for reactive power and energy calculation, phase N

Gain calibration factor for phase voltage, phase N

Offset calibration factor for active power and energy calculation, phase N

Offset calibration factor for reactive power and energy calculation, phase N

20

AT73C500

Page 21

AT73C500

AT73C500 provides four handshaking signals, ADDR1,

RD/WR, STROBE and BRDY, for interfacing with the

microprocessor. Microprocessor can use the BRDY input of

AT73C500 to extend the read a nd wr ite cycles . AT73 C500

stays in the read or w rite mo de as long as BRDY is high.

BRDY is sampled at the rising edg e of AT73 C500 master

clock. As soon as BRDY goes low, the read/write cy cle of

AT73C500 will end a t the first rising edge of CLK clock.

During read operation data is latched into AT73C500 register on the rising edge of the STROB E signal following the

low level of BRDY. A more detailed description about the

handshake signals is presented in sec tion “Data Tra nsfer

to External Microprocessor” on page 12.

Fifteen idle cycles are inserted by AT73C500 be tween the

read operation of each calibration byte. This allows the processor to prepare the next coefficient for transfer or to raise

the BRDY signal in case it is not ready to write the following

byte. If the data is avail able, BRDY ca n be kept consta ntly

low. Microprocess or ha s to always sup ply all 44 c alib ratio n

bytes even though some of those may be zero and don't

affect to measurement results.

If AT73C500 detects an error when comparing the calibration data and corresponding back-up values, it writes the

DATRDY bit high and after that the header bytes on processor bus indicating that it is still in initialization routine

and wishes to get the calibration data to be transported

once again. If the error still exists after the third trial,

AT73C500 notifies the situation by a FAIL status bit and

starts normal operation, discarding potentially incorrect calibration coefficients.

If AT73C500 is programmed to mode 1 or 2, the coefficients are stored in an EEPROM of type AT93C46. The

ROM has to support commun ication throu gh a three pin

serial I/O port. Th e serial ROM i nterface uses th e same

port, which also connects AT73C500 to

AT73C501/AT73C502 sample output. During the initialization phase, the ADC interfa ce has to be dis abled. This ca n

be done by B8 bit of AT73C500 Status bus (ADDR0). The

output has to be latc hed by an ex te rnal flip-flop to keep th e

state over the whole initialization period. The same output

can be used as Chip Select input for the EEPRO M.

AT73C500 reads, checks and stores automatically all 44

calibration coe fficients. After that, B8 b it of Statu s byte is

written low and normal measurement can start. If the

EEPROM contains erroneo us data a nd on e or more c oefficients don’t match with their back-up values, the same procedure is followed as in the processor mode.

Gain Calibration

Gain calibration is used to compensate the accumulated

magnitude error of voltage dividers, current transformers

and A/D converters. There is a separate 8-bit gain calibration coefficient for each phase, and for active and reactive

energy measure men t. A si mi la r f ormul a i s als o u se d to ca l-

ibrate the phase voltage values, only the calibration range

is different, 20% for power and 8% for voltage. These calibrations will automatically cor rect the gain error of other

measurement parameters.

The following calculations are done to get the calibrated

results. For active power:

AGC

×=

P

P

N

10.2

N

where PN is the active power of phase N and AGC

----------------

×+

128

N

is the

N

gain calibration facto r of that phase. The valid r ange for

is -128 to +127. Similarly, for reactive power:

AGC

N

RGC

Q

N

×=

Q

10.2

N

×+

where QN is the reactive power of phase N and RGC

the gain calibration coefficient for that phase. RGC

---------------- -

128

N

is

N

valid

N

range is -128 to +127.

Gain calibration performed on voltage measurements are:

UGC

U

N

×=

U

10.08

N

×+

where UN is the line voltage of phase N and UGC

---------------- -

128

N

is the

N

corresponding gain calibration coefficient, ranging from

-128 to +127.

Apparent power an d current are automatically g ain

adjusted to match the calibrated se ttings of activ e power,

reactive power and voltage.

Offset Calibration

The low current response of current sensors is often more

or less non-linear. The error caused by this non-linearity

can be compensat ed by a small of fset factor whic h is

added in power results. Offs et cali bration i s done for act ive

and reactive power, separ ately for each p hase. The following formulas are used:

AOF

N

P

N

--------------- -

P

N

128

0.004157 sign×× (P

×+≡

)P

N

FS

and

ROF

N

Q

N

where P

and QN are the active and reactive power for

N

phase N, AOF

tion coefficients and P

--------------- -

Q

N

128

and ROFN are the respective offset calibra-

N

0.00457 sign(Q

and QFS are the corresponding full

FS

×× )Q

×+=

N

FS

21

Page 22

scale values of the powers. Th e nominal full-sc ale values

are:

current. The chip set has a preprogrammed starting current

level of

P

Q

270V 80A× 21.6kW==

FS

270V 80A× 21.6VA r==

FS

The valid range for the offset cali bration facto rs is -128 to

+127.

The scale of offset calibration for active and reactive power

is different, 89W versus 98VAr in nominal conditions of

270V maximum phase voltage and 80A maximum phase

current. Typically, a small of fset factor of a few watts is

enough to compensa te the non- line ar ity of cu r ren t se ns ing .

It should be noted that offset calibration will also affect the

starting current level of a meter. If the full scale current or

voltage is changed to a non-default value, the range for offset calibration will be scaled accordingly.

The same offset value is used independent of phase angle.

However, as default (OFFMOD=0), the sign of power is

taken into accoun t in the c al c ula tio ns so tha t pos i tiv e of fset

factor will always increase the absolute power value and

negative coefficient will decrease absolute results. This

guarantees that curr ent sens or no n-l ineari ty is corr ect ed i n

the same way even though the current flow is reversed.

It is possible to ch ange this defaul t conditi on by programming value one to OFFMOD coeffic ient. In this case, of fset

coefficient will be always added to power result without

checking the sign of the power. Pos itive coefficient will

increase the abs olute value of positive po wer results an d

decrease the absolute value of negative result.

Phase Calibration

The phase difference betwee n vol tag e and curr ent chan nel

is compensated with three 8-bi t phase calibrati on figures.

The displacement is usua lly due to the phase shi ft in current transformers. Ba sed on the calibr ation values, the

DSP interpolates new current samples with sample instants

coinciding with the corresponding voltage samples. The following formula is used to determine the phase offset to be

used in the interpolation. One 8-bit phase calibration value

is stored for each of the three phases.

PC

N

----------- -

PO

N

128

5.625 °×=

SU

------------ -

4000

I

×=

FS

where I

I

is the full scale current of th e meter, i.e. 80A in

FS

1

nominal conditions. The defau lt startup current corresponds to 0.4% of the 5A I

, assuming that the full-scale

b

range is 80A. When the phase current is below the star ting

level, the calculated cycle power results are replaced by

zeros and no energy is accumulated.

It is possible to adjust the start-up level in the range of 0.2

to 10 compared with the nominal value. This is performed

with a special calibration factor. The following form ula is

used to determine the current:

SU

------------ -

4000

I

I

(1 0.2 STUPC)×+××=

FS

1

where STUPC is the start ing current c alibratio n factor,

allowed to vary in rang e -4 to +45, onl y. Care should b e

taken that the STUPC is correctly programme d and is not

beyond -4 to 45 range. Also, it s hould be noted that low

starting thresholds may force the device to a level where

accuracy is restricted due to a finite resolution of converters

and mathematics.

Adjustment of Display Pulse Rate

An 8-bit byte is pr ovid ed for a djust ment of the impuls e ra te

of display pulses. This coefficient will only affect the display

pulse rate of active and reactive energy but not to the meter

constant rate. The content of all measurement registers will

remain unchanged.

The impulse rate can be scaled in the range of 1 to 10 compared to the nominal value. In default conditions (U

270V, I

= 80A) the L SB of ener gy regi sters REG12-1 5

max

max

=

(See “Status Information” on page 17.) corresponds to

0.4Wh. This means that accumulated 25 LSBs of energy

will generate one pulse to the displa y pulse output (25 x

0.4Wh/impulse = 10 Wh/impulse = 100 impulses/kWh).

By using MCC calibration coeff icient, the nomina l figure 25

can be changed in the range of 25 to 250. The following

formulas are used to calculate the impulse rate.

where PO

is the sample phase offset of channel N, mea-

N

sured as phase(U) - phase (I). The allowed range for phase

calibration factor, PC

, is -128 to +127.

N

Starting Current Adjustment

The meter IC is designed to fulfill IEC 1036, class 1 specification. This specification is based on a certain basic current, I

22

. As a default, AT73C5 00 operates with 5A basic

b

AT73C500

IMP (25 MC C) E

×+=

LSB

and

------------------------------------------------- -=

PR

(25 MCC) E

1000

×+

LSB

where ELSB is the energy value of one LSB in the energy

register, 0.4Wh in default con ditions. W hen the mete r is

Page 23

AT73C500

3

operated in non-standard conditions, the energy LSB may

be recalculated as:

×

3.2768MHz

E

LSB

----------------------------- -

f

where f is the clock frequency used, and U

U

FSIFS

------------------------------ -

270V 80A×

0.4Wh××=

and IFS are

FS

the full-scale values of voltage and current.

In case the meter is used with a non-default voltage divider

or current sensor, MC C factor is a conve nient way to readjust the impulse rate.

Example

The meter is to be configured for u se in 120V networks,

with a maximum li ne voltage o f 140V. The display pu lse

rate is required to remain at 100imp/kWh. To start off, the

front end of the meter must be configured for the new line

voltage. The voltage dividers must be configured to produce an input signal of 0.707V at the input of the ADC at

maximum line voltage. At nominal meter settings, the voltage divider rati o is 270V:0.7 07V, in this case it must b e

140V:0.707V.

Note that adjusting the line voltage of the meter wil l render

the formatting of most calculation registers to alternative

settings. For example, the meter constant pulse rate will

change as follows:

MC

270V 80A×

------------------------------ -

U

×

FSIFS

f

----------------------------- -

3.2768MHz

××=

1250

imp

----------- -

kWh

In our case of a meter for 120V ne twork s, the new meter

constant pulse rate would be:

270V

MC

------------- -

==

× 2410.714…

140V

1250

imp

----------- -

kWh

imp

----------- -

kWh

To make the meter consta nt pu ls e rate to a n ev en n umb er ,

say 2500, we may choose to either re-scale the line voltage

or scale the maximum li ne current. 25 00 impuls es per kilowatt hour is gained by e ith er se tti ng th e ma xi mu m li ne vo ltage to:

example, the line voltage is chosen to be rescaled to 135V,

this is realized with a resistor divider of half the nominal,

and finetuning using the voltage gain coefficients. Also, all

values resulting from voltage calculation, such as the data

transferred via energy regist ers, s houl d be norma lize d with

respect to the new voltage setting.

Going back to the calibration of the display pulse rate, the

new LSB value of energy registers is:

140V

E

LSB

------------- -

270V

0.4Wh× 0.20741…Wh==

To maintain the display pulse rate at 100, the MCC calibration coefficient must be programmed as:

CC

1000

== =

----------------------------- -25–

PR E

×

LSB

-------------------------------------------- ---------------25–

100

imp

----------- -

kWh

1000

0.20741Wh

×

23.216…2

≈

The energy value of ea ch display coun ter impu lse i s ther eafter:

IMP (25 23)

---------

imp

140V

------------- -

270V

0.4Wh 10.0

Wh

---------

≈××+=

imp

1

In mode 7, the default display pulse rate is 10

impulses/kWh(kVArh) instead of 100 impulses/kWh. This is

convenient for meters where only one decimal digit wants

to be shown. This default rate can also calibrated and the

calibration formulas are:

IMP (250 MCC) E

×+=

LSB

and

FS

-------------------------

imp

----------- -

2500

kWh

× 135V==

U

270V

1250

imp

----------- -

kWh

or by retaining the line voltage at 140V and scaling the

maximum line current to:

FS

140V 2500

×

imp

----------- -

kWh

270V 80A×

--------------------------------------------- -

I

× 77.143…A==

1250

imp

----------- -

kWh

Regardless of which parameter (or both) is chosen, the

scaling process is a simple matter of gain ca libratio n. If, for

PR

-----------------------------------------------------=

(250 MCC) E

1000

×+

LSB

Master Clock

The master clock of AT73C500 is generated by a crystal

oscillator with crystal connected between pins XI and XO of

AT73C501/AT73C502. M aster clo ck can also be f ed to the

XI input from a separate clock source. The system clock

rate of AT73C500 is the same as the clock of

AT73C501/AT73C502 and is fed to the CLK input of the

device from the CLK output of AT73C501/AT73C502.

23

Page 24

Electrical Characteristics

Absolute Maximum Ratings

Parameter Min Typ Max Unit

Supply Voltage V

V

, V

DA

DDA

Input Voltage, Digital

Input Voltage, Analog

Input Voltage, CI and

VI inputs

Ambient Operating

Temp.

Storage Temperature -65 +150 C

CC

,

4.75 5.25 V

-0.3

-0.3

1.25 3.75 V

-25 +70 C

V

DD

+0.3

V

DA

+0.3

Calibration Characteristics

Parameter Min Typ Max Units

Gain Calibration

Calibration Range

Calibration

Resolution

Phase Calibration

Calibration Range

Calibration

Resolution

Offset Calibration,

Active Power

Calibration Range 89.8 W

Calibration

Resolution

Range,% of Full

Scale Phas e Power

Offset Calibration,

Reactive Power

±

±

20 %

0.16 %

5.625 degree

0.044 degree

0.7015 W

0.4157 %

Measurement Accuracy

The accuracy measurements are based on the usage of

the AT73C500 DSP with the single-ended ADC,

AT73C501. Using the differential-ended ADC, AT73C502,

improves some of the results.

V

V

Input Conditions

When specifying measurement accuracy, it is assumed

that 80A

voltage to current converters. The basic current, I

posed to be 5A

The nominal phase voltage, U

and 2VPP full scale input is produced by 270V

phase current will produce 2VPP full scale input

RMS

RMS

B

.

RMS

.

, is specified to be 230V

N

, is sup-

RMS