Datasheet AT27BV512-90TI, AT27BV512-90TC, AT27BV512-90RI, AT27BV512-90RC, AT27BV512-90JI Datasheet (ATMEL)

...Page 1

AT27BV512

Features

0602A

Fast Read Access Ti me - 90 ns

•

Dual Voltage Range Operation

•

Unregulated Battery Power Sup ply Range, 2.7V to 3.6V

or Standard 5V ± 10% Supply Range

Pin Compatible with JEDEC Standard AT27C512

•

Low Power CMOS Operation

•

20 µA max. (less than 1µA typical) Standby for VCC = 3.6V

29 mW max. Active at 5 MHz for VCC = 3.6V

JEDEC Standard Surface Mount Packa ge s

•

32-Lead PLCC

28-Lead 330-mil SOIC

28-Lead TSOP

High Reliabili ty C MOS Te ch nology

•

2,000V ESD Protection

200 mA Latchup Imm un ity

RapidProgramming Algorithm - 100 µs/byte (typical)

•

CMOS and TTL Compatible Inputs and Outputs

•

JEDEC Standard for LVTTL and LVBO

Integrated Produc t Ide nti fication Code

•

Commercial and Industrial Temperature Ranges

•

Description

The AT27BV512 is a high performance, low power, low voltage 524,288 bit one-time

programmable read only memory (OTP EPROM) organized as 64K by 8 bits. It requires only one supply in the range of 2.7V to 3.6V in normal read mode operation,

making it ideal for fast, portable systems using either regulated or unregulated battery

power.

Atmel’s innovative design techniques provide fast speeds that rival 5V parts while

keeping the low power consumption of a 3V supply. At V

accessed in less than 90 ns. With a typical power consumption of only 18 mW at 5

MHz and V

standard 5V EPROM.

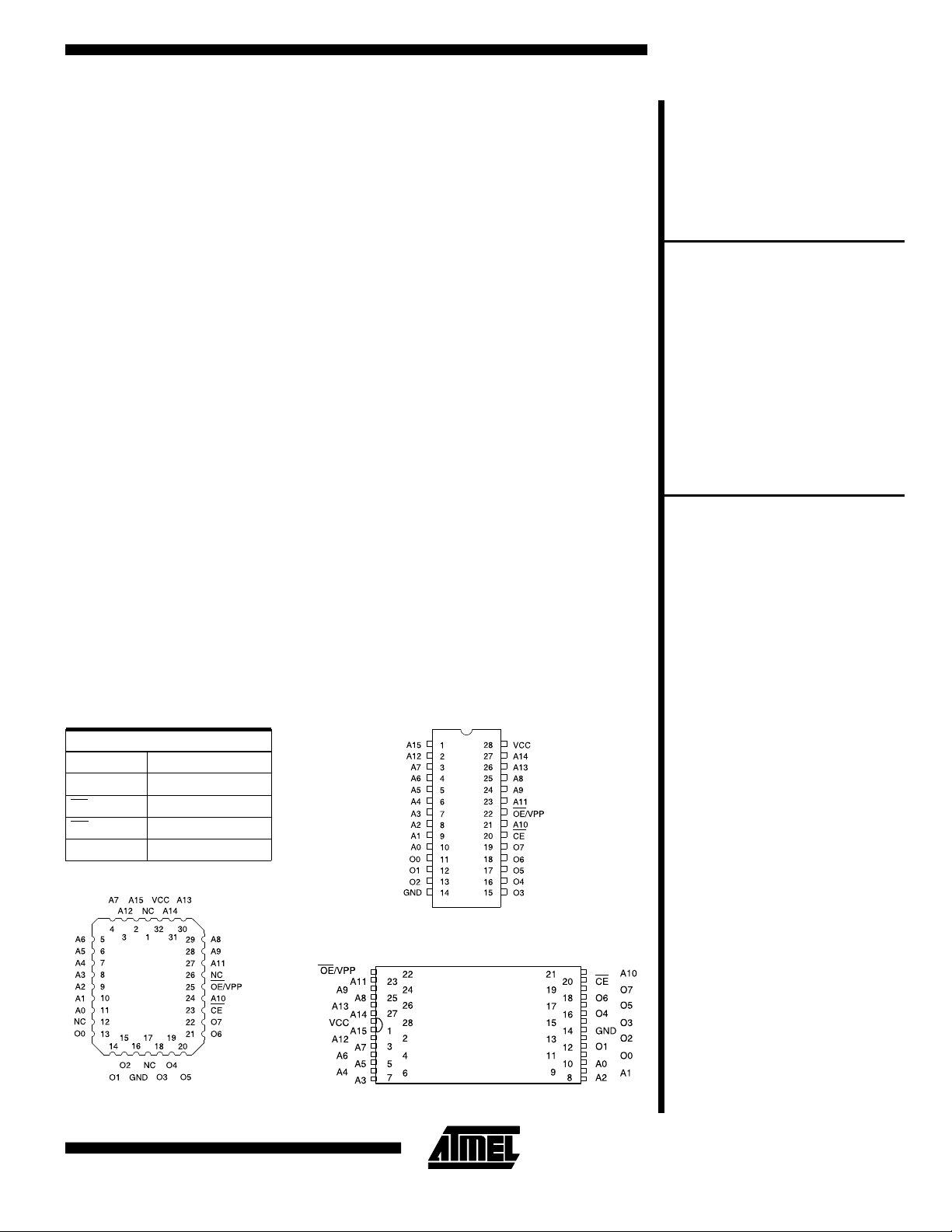

Pin Configurations

= 3V, the AT27BV512 consumes less than one fifth the power of a

CC

SOIC Top View

= 2.7V, any byte can be

CC

(continued)

AT27BV512

512K (64K x 8)

Unregulated

Battery-Voltage

High Speed

OTP

CMOS EPROM

Pin Name Function

A0 - A15 Addresses

O0 - O7 Outputs

CE Chip Enable

OE/V

NC No Connect

Note: PLCC Package Pins 1 and

17 are DON’T CONNECT.

PP

PLCC Top View

Output Enable

TSOP Top View

Type 1

3-13

Page 2

Description (Continued)

Standby mode supply current is typically less than 1 µA at

3V. The AT27BV512 simplifies s ystem design and

stretches battery lifetime even further by eliminating the

need for power supply regulation.

The AT27BV512 is available in industry standard JEDECapproved one-time programmable (OTP) plastic PLCC,

SOIC, and TSOP packages. All devices feature two-line

control (

bus contention.

The AT27BV512 operating with V

level outputs that are compatible with standard TTL logic

devices operating at V

is compatible with JEDEC approved low voltage battery

operation (LVBO) interface specifications. The device is

also capable of standard 5-volt operation making it ideally

suited for dual supply range systems or card products that

are pluggable in both 3-volt and 5-volt hosts.

Atmel’s AT27BV512 has additional features to ensure

high quality and efficient production use. The Rapid

gramming Algorithm reduces the time required to program

the part and guarantees reliable programming. Programming time i s typically only 100 µs/byte. The Integrated

Product Identification Code electronically identifies the device and manufacturer. This feature is used by industry

standard programming equipment to select the proper

programming algorithms and voltages. The AT27BV512

programs exactly the same way as a standard 5V

AT27C512R and uses the same programming equipment.

CE, OE) to give designers the flexibility to prevent

at 3.0V produces TTL

CC

= 5.0V. At VCC = 2.7V, the part

CC

Pro-

System Considerations

Switching between active and standby conditions via the

Chip Enable pin may produce transient voltage excursions. Unless accommodated by the system design, these

transients may exceed data sheet limits, resulting in device non-conformance. At a minimum, a 0.1 µF high frequency, low inherent inductance, ceramic capacitor

should be utilized for each device. This capacitor should

be connected between the V

the device, as close to the device as possible. Additionally,

to stabilize the supply voltage level on printed circuit

boards with large EPROM arrays, a 4.7 µF bulk electrolytic

capacitor should be utilized, again connected between the

and Ground terminals. This capacitor should be posi-

V

CC

tioned as close as possible to the point where the power

supply is connected to the array.

and Ground terminals of

CC

3-14 AT27BV512

Page 3

AT27BV512

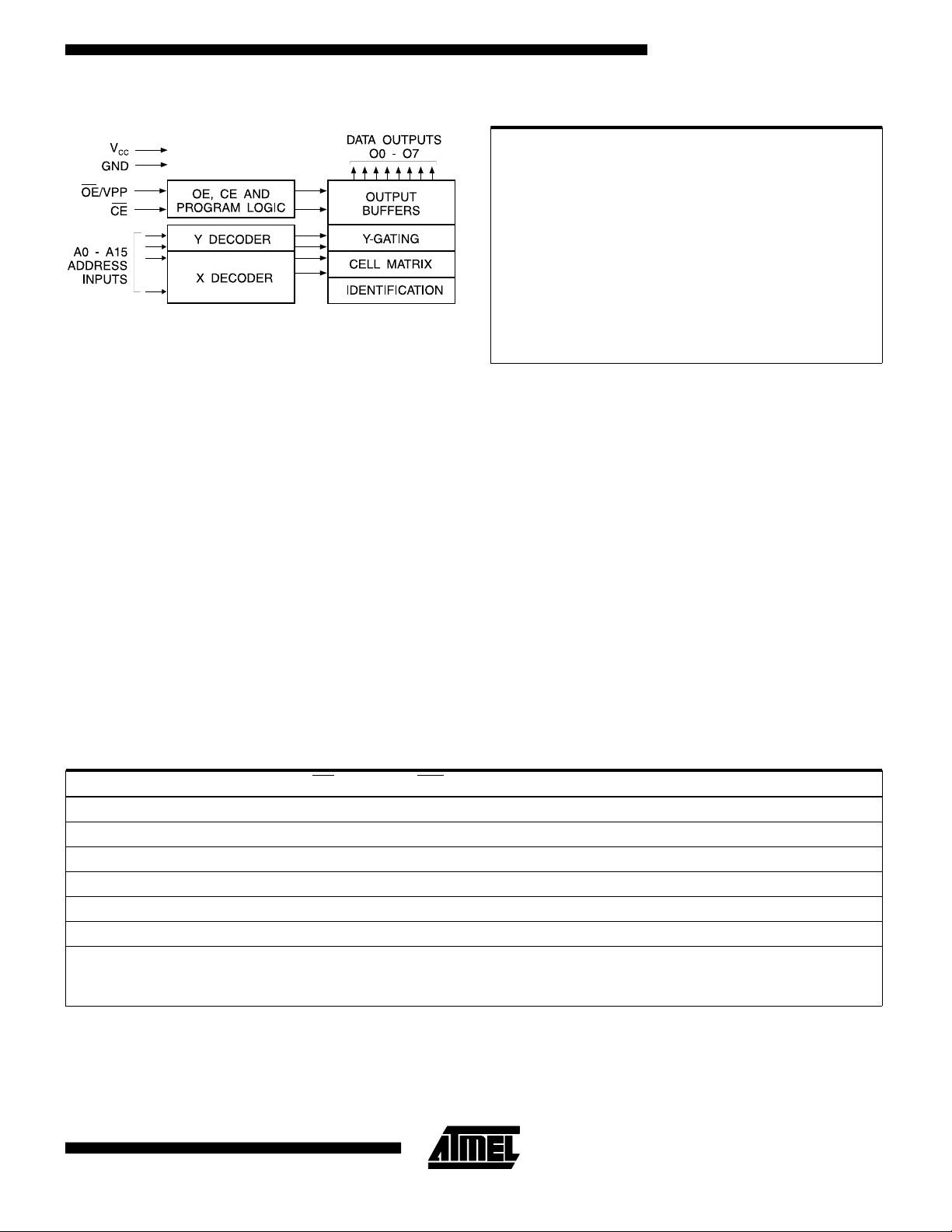

Block Diagram

Absolute Maximum Ra ti ngs *

Temperature Under Bias .................. -40°C to +85°C

Storage Temperature...................... -65°C to +125°C

Voltage on Any Pin with

Respect to Ground.........................-2.0V to +7.0V

Voltage on A9 with

Respect to Ground ......................-2.0V to +14.0V

VPP Supply Voltage with

Respect to Ground.......................-2.0V to +14.0V

*NOTICE: Stresses beyond those listed unde r “Absolu te Maxi-

mum Ratings” may cause permanent da ma ge to th e de vice .

This is a stress rating only and functional operation of the

device at these or any other conditions beyond those indicated in the operational sections of this specification is not

implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

Note: 1. Minimum voltage is -0.6V dc which may undershoot

to -2.0V for pulses of less than 20 ns. Maximum output pin voltage is V

ceeded if certain precautions are observed (consult

application notes) and which may overshoot to

+7.0V for pulses of less than 20 ns.

+ 0.75V dc which may be ex-

CC

(1)

(1)

(1)

Operating Modes

Mode \ Pin

(2)

Read

Output Disable

Standby

Rapid Program

PGM Verify

PGM Inhibit

Product Identification

Notes: 1. X can be VIL or VIH.

2. Read, output disable, and standby modes require,

3. Refer to Programming Characteristics.

(2)

(2)

(3)

(3)

(3)

(3, 5)

2.7V ≤ V

Programming mode s require VCC = 6.5V.

≤ 3.6V, or 4.5V ≤ VCC ≤ 5.5V.

CC

CE OE/V

V

IL

V

IL

V

IH

V

IL

V

IL

V

IH

V

IL

V

V

XXV

V

PP

V

V

PP

V

PP

IL

IH

IL

IL

4. V

H

5. Two identifier by tes may be select e d . Al l A i inputs are held

low (V

gled low (V

and high (V

Ai V

Ai VCC

(1)

X

Ai VCC

Ai VCC

XV

A9 = VH

(4)

A0 = VIH or VIL

A1 - A15 = V

= 12.0 ± 0.5V.

), except A9 which is set to VH and A0 which is tog-

IL

IL

) to select the Manuf ac tu rer’s Identification byte

IL

) to select the Dev ice Code byte.

IH

CC

VCC

CC

CC

VCC

(2)

(2)

(2)

(3)

(3)

(3)

(3)

Outputs

D

OUT

High Z

High Z

D

IN

D

OUT

High Z

Identification

Code

3-15

Page 4

DC and AC Operating Conditions f or Read Operation

AT27BV512

-90 -12 -15

Operating Temperature

(Case)

V

Power Supply

CC

Com. 0°C - 70°C 0°C - 70°C 0°C - 70°C

Ind. -40°C - 85°C -40°C - 85°C -40°C - 85°C

2.7V to 3.6V 2.7V to 3.6V 2.7V to 3.6V

5V ± 10% 5V ± 10% 5V ± 10%

DC and Operating Characte ristics for Read Opera tion

Symbol Parameter Condition Min Max Units

VCC = 2.7V to 3.6V

I

LI

I

LO

I

PP1

I

SB

I

CC

V

IL

V

IH

V

OL

V

OH

VCC = 4.5V to 5.5V

I

LI

I

LO

I

PP1

I

SB

I

CC

V

IL

V

IH

V

OL

V

OH

Notes: 1. VCC must be applied simulta ne ou sl y wit h or be fo re

Input Load Current VIN = 0V to V

Output Leakage Current V

(2)

(1)

VPP

Read/Standby Current VPP = V

(1)

VCC

Standby Current

VCC Active Current

Input Low Voltage

Input High Voltage

Output Low Voltage

Output High Voltage

Input Load Current VIN = 0V to V

Output Leakage Current V

(2)

(1)

VPP

Read/Standby Current VPP = V

(1)

VCC

Standby Current

VCC Active Current f = 5 MHz, I

= 0V to V

OUT

I

(CMOS), CE = VCC ± 0.3V

SB1

(TTL), CE = 2.0 to VCC + 0.5V

I

SB2

f = 5 MHz, I

V

= 3.0 to 3.6V -0.6 0.8 V

CC

V

= 2.7 to 3.6V -0.6 0.2 x V

CC

V

= 3.0 to 3.6V 2.0 VCC + 0.5 V

CC

V

= 2.7 to 3.6V 0.7 x VCCVCC + 0.5 V

CC

I

= 2.0 mA 0.4 V

OL

I

= 100 µA 0.2 V

OL

I

= 20 µA 0.1 V

OL

I

= -2.0 mA 2.4 V

OH

I

= -100 µAV

OH

I

= -20 µAV

OH

= 0V to V

OUT

I

(CMOS), CE = VCC ± 0.3V 100 µA

SB1

I

(TTL), CE = 2.0 to VCC + 0.5V 1 mA

SB2

CC

CC

CC

CC

= 0 mA, CE = VIL, VCC = 3.6V

OUT

CC

CC

= 0 mA, CE = V

OUT

IL

- 0.2 V

CC

- 0.1 V

CC

Input Low Voltage -0.6 0.8 V

Input High Voltage 2.0 VCC + 0.5 V

Output Low Voltage IOL = 2.1 mA 0.4 V

Output High Voltage IOH = -400 µA 2.4 V

2. VPP may be connected directly to VCC, except during proOE/VPP, and removed simultane ou sl y wit h or af ter

OE/VPP.

gramming. The suppl y current would then be the sum of I

and IPP.

±1 µA

±5 µA

10 µA

20 µA

100 µA

8mA

CC

±1 µA

±5 µA

10 µA

20 mA

V

CC

3-16 AT27BV512

Page 5

AT27BV512

AC Characteristics for Read Operation (V

Symbol Parameter Condition

(3)

t

ACC

(2)

t

CE

(2, 3)

t

OE

(4, 5)

t

DF

t

OH

Notes: 2, 3, 4, 5. - see AC Waveforms for Read Operation.

Address to Output Delay CE = OE/VPP = V

CE to Output Delay OE/VPP = V

OE/VPP to Output Delay CE = V

IL

OE/VPP or CE High to Output Float,

whichever occurred first

Output Hold from Address, CE or

OE/VPP, whichever occurred first

(1)

AC Waveforms for Rea d Ope ration

= 2.7V to 3.6V and 4.5V to 5.5V)

CC

AT27BV512

-90 -12 -15

Min Max Min Max Min Max

IL

IL

90 120 150 ns

90 120 150 ns

50 50 60 ns

40 40 50 ns

0 0 0ns

Units

Notes: 1. Timing measurement refe ren ce s are 0.8 V a nd 2.0 V.

Input AC drive le ve ls are 0.45V and 2.4 V, un less

otherwise spec ified.

OE/VPP may be delayed up to t

2.

falling edge of

OE/VPP may be delayed up to t

3.

address is valid without impact on t

CE without impact on tCE.

- tOE after the

CE

- tOE after the

ACC

.

ACC

4. This parameter is only sampled and is not 100 % te st ed .

5. Output float is defined as the point when data is no longer

driven.

6. When reading the 27BV5 12 , a 0.1 µF capacitor is required

across V

and grond to supress spurious voltage transients.

CC

3-17

Page 6

Input Test Waveform and Meas urement Level

tR, tF < 20 ns (10% to 90%)

Output Test Load

Note: CL = 100 pF

including jig capacitance.

Pin Capacitance (f = 1 MHz, T = 25°C)

(1)

Typ Max Units Conditions

C

IN

C

OUT

Note: 1. Typic al val ue s fo r nomin al sup pl y voltage. This paramete r is on ly sampl ed and is not 10 0% tes ted.

46pFV

812pFV

= 0V

IN

OUT

= 0V

3-18 AT27BV512

Page 7

AT27BV512

Programming Wavef or ms

(1)

Notes: 1. The Input Timing Re fe rence is 0.8V for VIL and

2.0V for V

and t

2. t

OE

be accommodated by the programmer.

.

IH

are characteristics of the device but must

DFP

3. When programming th e 27 BV51 2, a 0.1 µF capacitor is required across V

transients.

and ground to supress spurious voltage

PP

DC Programming Characteristics

TA = 25 ± 5°C, VCC = 6.5 ± 0.25V, OE/VPP = 13.0 ± 0.25V

Symbol Parameter

I

LI

V

IL

V

IH

V

OL

V

OH

I

CC2

I

PP2

V

ID

Input Load Current VIN = VIL, V

Input Low Level -0.6 0.8 V

Input High Level 2.0 V

Output Low Voltage I

Output High Volta ge I

VCC Supply Current (Program and Verify) 25 m A

OE/VPP Current CE = V

A9 Product Identi fication Voltage 11.5 12.5 V

Test

Conditions

IH

= 2.1 mA 0.4 V

OL

= -400 µA2.4 V

OH

IL

Min

Limits

Max

Units

±10 µA

+ 0.5 V

CC

25 mA

3-19

Page 8

AC Programming Characteristics

TA = 25 ± 5°C, VCC = 6.5 ± 0.25V, OE/VPP = 13.0 ± 0.25V

Symbol Param ete r

Address Setup Time 2 µs

t

AS

OE/VPP Setup Time 2 µs

t

OES

OE/VPP Hold Time 2 µs

t

OEH

Data Setup Time 2 µs

t

DS

Address Hold Time 0 µs

t

AH

Data Hold Time 2 µs

t

DH

CE High to Out-

t

DFP

put Float Delay

VCC Setup Time 2 µs

t

VCS

CE Program Pulse Width

t

PW

Data Valid from CE

t

DV

OE/VPP Recovery Time 2 µs

t

VR

OE/VPP Pulse Rise

t

PRT

Time During Programming

*AC Conditions of Test:

Input Rise and Fa ll Times (10% to 90).............. 20 ns

Input Pulse Levels................................0.45V to 2.4V

Input Timing Reference Level................0.8V to 2.0V

Output Timing Reference Level.............0.8V to 2.0V

Notes: 1. VCC must be applied simultaneou sl y or before

OE/VPP and removed simultaneously or after

OE/VPP.

2. This parameter i s on ly sampl ed and is no t 100%

tested. Output Float is defined as the point where

data is no longer driven — see timing diagram.

3. Program Pulse width tolerance is 100 µsec ± 5%.

Test

Conditions*

(2)

(3)

(2)

(1)

Limits

Min Max

0130ns

95 105 µs

50 ns

Units

1 µs

Rapid Programming Algor ithm

A 100 µs CE pulse width is used to program. The address

is set to the first location. V

OE/VPP is raised to 13.0V . Each address is first programmed with one 100 µs

Then a verification / reprogramming loop is executed for

each address. In the event a byte fails to pass verification,

up to 10 successive 100 µs pulses are applied with a verification after each pulse. If the byte fails to verify after 10

pulses have been applied, the part is considered failed.

After the byte ve rifies properly, the next address is selected until all have been checked.

ered to V

and VCC to 5.0V. All bytes are read again and

IL

compared with the original data to determine if the device

passes or fails.

is raised to 6.5V and

CC

CE pulse without verification.

OE/VPP is then low-

Atmel’s 27BV512 Integrated

(1)

Product Identification Code

Pins

Codes

Manufacturer0000111101E

Device Type 1000011010D

Note: 1. The AT27BV512 has the same Product Identification

A0 O7 O6 O5 O4 O3 O2 O1 O0

Code as the AT27C512R. Both are programming

compatible.

3-20 AT27BV512

Hex

Data

Page 9

AT27BV512

Ordering Informati o n

t

ACC

(ns)

90 8 0.02 AT27BV512-90JC 32J Commercial

120 8 0.02 AT27BV512-12JC 32J Commercial

150 8 0.02 AT27BV512-15JC 32J Commercial

I

(mA)

CC

Active Standby

8 0.02 AT27BV512-90JI 32J Industrial

8 0.02 AT27BV512-12JI 32J Industrial

8 0.02 AT27BV512-15JI 32J Industrial

Ordering Code Package Operation Range

AT27BV512-90RC 28R (0°C to 70°C)

AT27BV512-90TC 28T

AT27BV512-90RI 28R (-40°C to 85°C)

AT27BV512-90TI 28T

AT27BV512-12RC 28R (0°C to 70°C)

AT27BV512-12TC 28T

AT27BV512-12RI 28R (-40°C to 85°C)

AT27BV512-12TI 28T

AT27BV512-15RC 28R (0°C to 70°C)

AT27BV512-15TC 28T

AT27BV512-15RI 28R (-40°C to 85°C)

AT27BV512-15TI 28T

Package Type

32J 32 Lead, Plastic J-Leaded Chip Carrier (PLCC)

28R 28 Lead, 0.3 30 " Wide , Pla st ic Gull Wing S mall Outl in e (SOIC)

28T 28 Lead, Thin Small Outline Package (TSOP)

3-21

Loading...

Loading...