Page 1

Programmable Multi-Phase Synchronous

Buck Converter with PMBus

Preliminary Technical Data

ASP0800

ERY FEATURES

Selectable 1-, 2-, 3-, 4-, 5-, 6, 7 or 8- phase operation at up to

1 MHz per phase

PMBus Interface - enables digital programmability of set

points and readback of monitored values

Logic-level PWM outputs for interface to external high

power drivers

Fast-Enhanced PWM flex mode for excellent load transient

performance

Active current balancing between all output phases

Built-in power-good/crowbar blanking supports on-the-fly

VID code changes

Digitally programmable 0.375 V to 1.6 V output supports

both VR11 and VR11.1 specifications

Programmable Offset up to ±200mV

Programmable short-circuit protection with programmable

latch-off delay

Supports PSI# – Power saving mode during light loads

Over – Clocking Control

APPLICATIONS

CPU Power controllers for Servers, Workstations and high

end Desktops.

Next generation Intel® VRM modules

POL Applications such as Memory

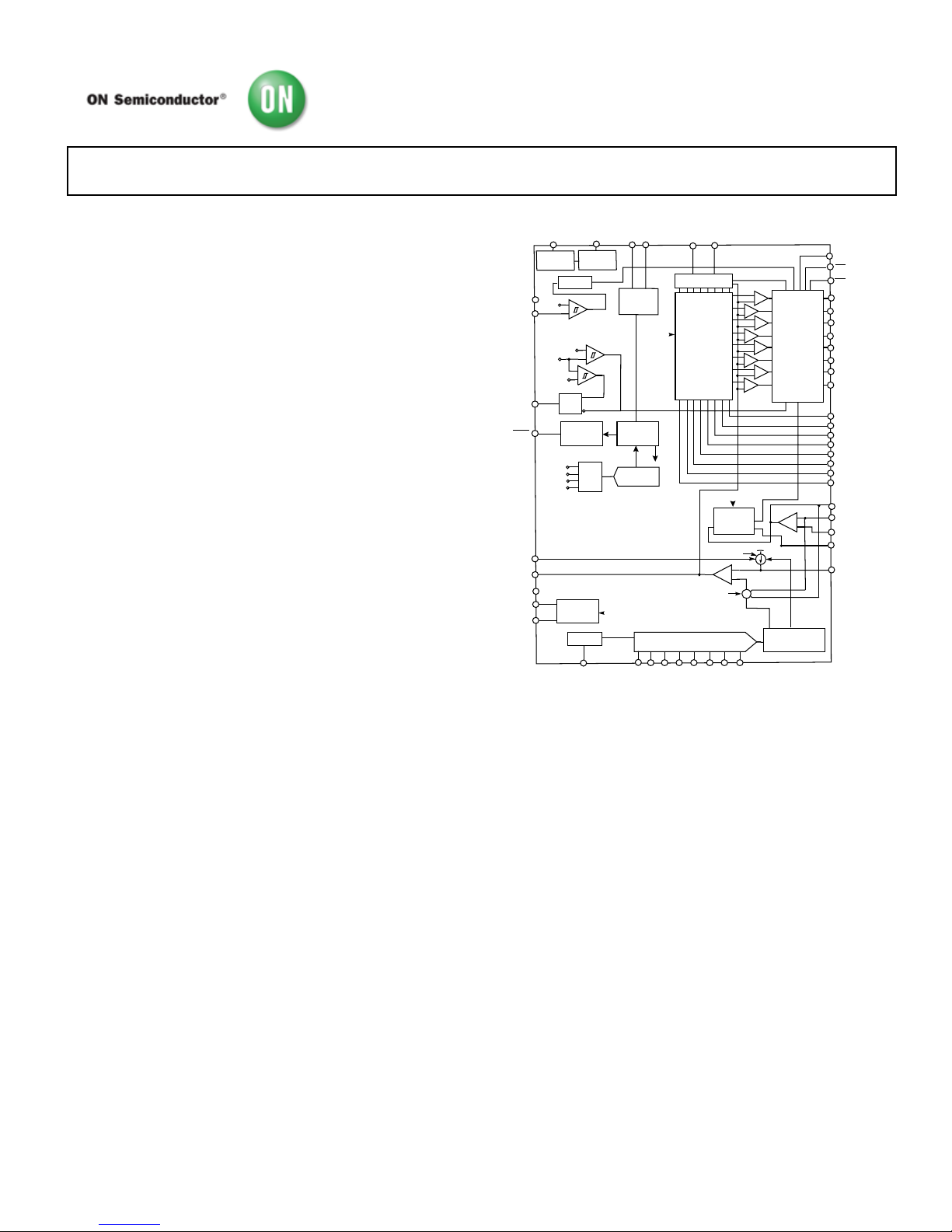

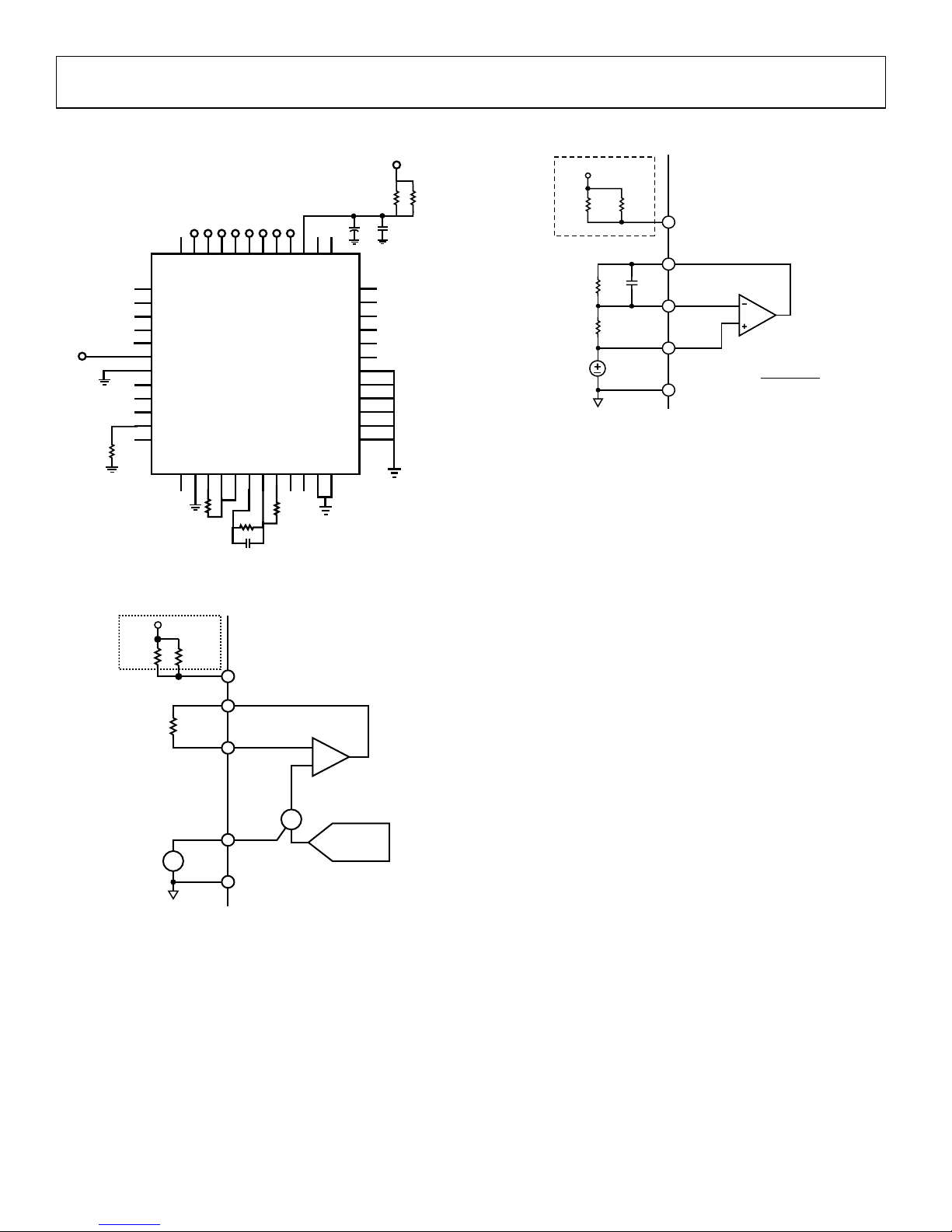

FUNCTIONAL BLOCK DIAGRAM

VCC

PRECISION

REFERENCE

DEL AY

–

+

GND

ASP0800

EN/VTT

13

PWRGD

6

RAMPADJ

18

RT

17

28

SW3

PWM2

37

CSREF

7

CSCOMP

PWM3

36

PWM4

35

CSSUM

22

FB

19

PWM1

VID2VID1 VID3 VID4 VID5 VID7VID6

2

COMP

FBRTN

VID DAC

CURRENT

MEASUREMENT

AND LIMIT

CROWBAR

CURRENT

LIMIT

+

–

40444546

47

OD1

SW2

29

SW4

27

12

16

+

–

OSCILLATOR

–

+

SW1

30

38

4143 42

11

IREF

VID0

10

IMON

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

ADC

PSI#

39

14

48

SMBUS

SCL

SD

A

5

4

BOOT VOLTAGE&

SOFT START CONTROL

ILIMITFS

20

1

VCC3

CONTROL

–

+

850mV

–

+

CONTROL

+

–

CSREF

UVLO

SHUTDOWN

SHUNT

REGULATOR

3.3V

REGULATOR

CLOCK

CONTROL

OC1

OC2

CONTROL

9

8

15

21

ODN

DIG ITAL

REGISTERS

24

SW7

SW6

25

SW8

23

SW5

26

+

–

CMP

PWM6

33

PWM7

32

PWM8

31

+

–

CMP

+

–

CMP

+

–

CMP

+

–

CMP

+

–

CMP

+

–

CMP

+

–

CMP

PWM5

34

CURRENT

BALANCING

CIRCUIT

1- 8 PHASE

DRIVER LOGIC

EN

SET

RESET

RESET

RESET

RESET

RESET

RESET

RESET

RESET

EN

FB

FBRTN

IMON

MUX

ALERT

3

COMPARATORS

Figure 1. Functional Block Diagram

GENERAL DESCRIPTION

The ASP08001 is an integrated power control IC with a PMBus

interface. The ASP0800 is a highly efficient, multiphase,

synchronous buck switching regulator controller, which aids

design of High Efficiency and High Density solutions.

The PMBus interface enables digital programming of key

system parameters to optimize system performance and provide

feedback to the system. The ASP0800 is compatible for use with

coupled inductors,

The ASP0800 is optimized for converting a 12 V main supply

into the core supply voltage required by high performance Intel

processors. It uses an internal 8-bit DAC to read the voltage

identification (VID) code directly from the processor, which is

used to set the output voltage between 0.375 V and 1.6 V.

This device uses a multimode PWM architecture to drive the

logic-level outputs at a programmable switching frequency that

can be optimized for VR size and efficiency. The ASP0800 can

be programmed for 1-, 2-, 3-, 4-, 5-, 6, 7 or 8- phase operation,

allowing for the construction of up to 8 complementary buck

switching stages. The ASP0800 support PSI#, which is a power

phases at light loads.

The ASP0800 includes a PMBus interface, which can be used to

program system set points such as voltage offset, load line,

phase balance and output voltage. Key system performance data

such as CPU current, CPU voltage, and power and fault

conditions can also be read back over the PMBus from the

ASP0800.

The ASP0800 OC Feature allows programming different offset

voltages depending on the load current being supplied. 3 OC

Thresholds and 4 OC Offsets value registers are supported.

The ASP0800 has a built in shunt regulator that allows the part

to be powered from the +12V system supply through a series

resistor. The ASP0800 is specified over the extended

commercial temperature range of 0°C to +85°C and is available

in a 48 Lead LFCSP package.

1

Protected by U.S. Patent Number 6,683,441; other patents pending.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

©2008 SCILLC. All rights reserved. Publication Order Number:

March 2008 - Rev. P1 ASP0800/S

Page 2

ASP0800 Preliminary Technical Data

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Specifications..................................................................................... 3

Test Circuits....................................................................................... 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution.................................................................................. 7

Pin Configuration and Function Descriptions............................. 8

Typical Performance Characteristics ........................................... 10

Theory of Operation ...................................................................... 11

Start-Up Sequence...................................................................... 11

Phase Detection Sequence......................................................... 11

Master Clock Frequency............................................................ 12

Output Voltage Differential Sensing ........................................ 12

Output Current Sensing ............................................................ 12

Output current monitor ............................................................ 12

Dynamic VID ............................................................................. 13

INTERNAL Delay Timer .......................................................... 14

Soft Start ...................................................................................... 14

Current-Limit, Short-Circuit, and Latch-Off Protection...... 16

Power-Good Monitoring........................................................... 17

POWER STATE INDICATOR ................................................. 17

Output Crowbar......................................................................... 18

Output Enable and UVLO........................................................ 18

OVERCLOCKING (OC) LIMITS AND OFFSETS .............. 18

PMBUS Interface........................................................................ 18

Write Operations........................................................................ 21

Read Operations......................................................................... 22

PMBus Timeout.......................................................................... 23

Outline Dimensions....................................................................... 38

03/08—Rev P1: Conversion to ON Semiconductor

REVISION HISTORY

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 2 of 36 | www.onsemi.com

Page 3

Preliminary Technical Data ASP0800

SPECIFICATIONS

VCC = 5 V, FBRTN = GND, TA = 0°C to 85°C, unless otherwise noted.1

Table 1

Parameter Symbol Conditions Min Typ Max Unit

REFERENCE CURRENT

Reference Bias Voltage V

IREF

1.75 1.8 1.85 V

Reference Bias Current I

IREF

R

IREF

= 121 kΩ 15 uA

ERROR AMPLIFIER

Output Voltage Range2 V

COMP

0 4.4 V

Accuracy VFB

Relative to nominal DAC output,

referenced to FBRTN (see Figure 3)

−10 +10 mV

V

FB(BOOT)

In startup 1.09 1.1 1.11 V

Load Line Positioning Accuracy −77 −80 −83 mV

Load Line Range −350 0 mV

Load Line Attenuation 0 100 %

Differential Nonlinearity −1 +1 LSB

Input Bias Current IFB I

FB = IIREF

13.5 15 16.5 µA

Offset Accuracy VR Offset Register = TBD, VID = 1.0V −200 mV

VR Offset Register = TBD , VID = 1.0V 200 mV

FBRTN Current I

FBRTN

70 200 µA

Output Current I

COMP

FB forced to V

OUT

– 3% 500 µA

Gain Bandwidth Product GBW

(ERR)

COMP = FB 20 MHz

Slew Rate COMP = FB 25 V/µs

BOOT Voltage Hold Time t

BOOT

Internal Timer 2 ms

VID INPUTS

Input Low Voltage V

IL(VID)

VID(X) 0.3 V

Input High Voltage V

IH(VID)

VID(X) 0.8 V

Input Current I

IN(VID)

−5 µA

VID Transition Delay Time2 VID code change to FB change 400 ns

No CPU Detection Turn-Off

Delay Time

2

VID code change to PWM going low 5 µs

OSCILLATOR

Frequency Range2 f

OSC

0.25 9 MHz

Frequency Variation f

PHASE

T

A

= 25°C, RT = 500 kΩ, 4-phase 170 195 225 kHz

T

A

= 25°C, RT = 250 kΩ, 4-phase 375 kHz

T

A

= 25°C, RT = 121 kΩ, 4-phase 750 kHz

Output Voltage VRT R

T

= 500 kΩ to GND 1.9 2.0 2.1 V

RAMPADJ Output Voltage V

RAMPADJ

RAMPADJ − FB, VFB = 1V, −50 +50 mV

RAMPADJ Input Current Range I

RAMPADJ

5 125 µA

CURRENT SENSE AMPLIFIER

Offset Voltage V

OS(CSA)

CSSUM − CSREF (see Figure 3) −1.0 +1.0 mV

Input Bias Current, CSREF I

BIAS(CSREF)

CSREF = 1V −20 +20 µA

Input Bias Current, CSSUM I

BIAS(CSSUM)

CSREF = 1V −10 +10 nA

Gain Bandwidth Product GBW

(CSA)

CSSUM = CSCOMP 10 MHz

Slew Rate C

CSCOMP

= 10 pF 10 V/µs

Input Common-Mode Range CSSUM and CSREF 0 3.0 V

Output Voltage Range 0.05 3.0 V

Output Current I

CSCOMP

500 µA

Current Limit Latch off Delay Time Internal Timer 8 ms

1

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

2

Guaranteed by design or bench characterization, not tested in production.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 3 of 36 | www.onsemi.com

Page 4

ASP0800 Preliminary Technical Data

Parameter Symbol Conditions Min Typ Max Unit

PSI#

Input Low Voltage 0.3 V

Input High Voltage 0.8 V

Input Current −5 µA

Assertion Timing Fsw = 300kHz 3.3 µs

Deassertion Timing Fsw = 300kHz 825 ns

IMON OUTPUT

Clamp Voltage 1.0 1.15 V

Accuracy

10 × (CSREF − CSCOMP)/RILIM

−3 3 %

Output Current

800 µA

Offset

−3 3 mV

CURRENT LIMIT COMPARITOR

ILIM Bias Current I

LIM

CSREF − CSCOMP)/RILIM , (CSREF −

CSCOMP)=150 mV, RI

LIMC=7.5 kΩ

20 µA

Current Limit Threshold Current ICL

4/3 × IIREF

20 µA

CURRENT BALANCE AMPLIFIER

Common-Mode Range V

SW(X)CM

−600 +200 mV

Input Resistance R

SW(X)

SW(X) = 0 V 14 19 25 kΩ

Input Current I

SW(X)

SW(X) = 0 V 7 12 20 µA

Input Current Matching

'I

SW(X)

SW(X) = 0 V −6 +6 %

Phase Balance Adjustment Range Low Phase Bal Registers = 00000 -25 %

Phase Balance Adjustment Range

High

Phase Bal Registers = 11111 +25 %

DELAY TIMER

Internal Timer Delay Time Register = 011 2 ms

Timer Range Low Delay Time Register = 000 0.5 ms

Timer Range High Delay Time Register = 111 4 ms

SOFT START

Internal Timer Soft Start Slope Register = 010 0.5 V/ms

Timer Range Low Soft Start Slope Register = 000 0.1 V/ms

Timer Range High Soft Start Slope Register = 111 1.5 V/ms

ENABLE INPUT

Input Low Voltage V

IL(EN)

0.3 V

Input High Voltage V

IH(EN)

0.8 V

Input Current I

IN(EN)

−1 µA

Delay Time t

DELAY(EN)

EN > 0.8V , Internal Delay 2 ms

ODN / OD1 OUTPUTS

Output Low Voltage V

OL(

ODN/1

, )

I

OD(SINK)

= −400 PA

160 500 mV

Output High Voltage V

OH(

ODN/1

)

I

OD(SOURCE)

= 400 PA

4 5 V

ODN / OD1 Pull-Down Resistor

60 kΩ

OVER-CLOCKING OUTPUTS (OC1, OC2)

Output Low Voltage VOL I

OC(SINK)

= -1 mA 160 500 mV

POWER GOOD COMPARATOR

Undervoltage Threshold V

PWRGD(UV)

Relative to nominal DAC output −600 −500 −400 mV

Undervoltage Adjustment Range Low PWRGD_LO Register = 000 −500 mV

Undervoltage Adjustment Range

High

PWRGD_LO Register = 111 −150 mV

Overvoltage Threshold V

PWRGD(OV)

Relative to DAC output, PWRGD_Hi = 00 200 300 400 mV

Overvoltage Adjustment Range Low PWRGD_Hi Register = 11 150 mV

Overvoltage Adjustment Range High PWRGD_Hi Register = 00 300 mV

Output Low Voltage V

OL(PWRGD)

I

PWRGD(SINK)

= −4 mA 150 300 mV

Power Good Delay Time

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 4 of 36 | www.onsemi.com

Page 5

Preliminary Technical Data ASP0800

Rev. Pr H| Page 5 of 38

Parameter Symbol Conditions Min Typ Max Unit

During Soft Start2 Internal Timer 2 ms

VID Code Changing 100 250 µs

VID Code Static 200 ns

Crowbar Trip Point V

CROWBAR

Relative to DAC output, PWRGD_Hi = 00 200 300 400 mV

Overvoltage Adjustment Range Low PWRGD_Hi Register = 11 150 mV

Overvoltage Adjustment Range High PWRGD_Hi Register = 00 300 mV

Crowbar Reset Point Relative to FBRTN 250 300 350 mV

Crowbar Delay Time t

CROWBAR

Overvoltage to PWM going low

VID Code Changing 100 250 µs

VID Code Static 400 ns

PWM OUTPUTS

Output Low Voltage V

OL(PWM)

I

PWM(SINK)

= −400 µA 160 500 mV

Output High Voltage V

OH(PWM)

I

PWM(SOURCE)

= 400 µA 4 5 V

PMBus Interface

Logic High Input Voltage V

IH(SDA, SCL)

2.1 V

Logic Input Low Voltage V

IL(SDA, SCL)

0.8 V

Hysteresis 500 mV

SDA Output Low Voltage VOL I

SDA

= −6mA 0.4 V

Input Current I

IH

; IIL −1 1 µA

Input Capacitance C

SCL, SDA

5 pF

Clock Frequency f

SCL

400 kHz

SCL Falling Edge to SDA Valid Time 1 µs

ALERT

FAU LT

OUTPUTS

Output Low Voltage VOL I

OUT

= -6mA 0.4 V

Output High Leakage Current IOH V

OH

= 5V 1 uA

ANALOG/DIGITAL CONVERTER

Total Unadjusted Error (TUE) ±2 %

Differential Non linearity (DNL) TBD Bits 1 LSB

Conversion Time Averaging Enabled (32 averages) 80 ms

SUPPLY V

SYSTEM

= 12 V, R

SHUNT

= 340 Ω

VCC2 VCC 4.70 5 5.45 V

DC Supply Current I

VCC

V

SYSTEM

= 13.2 V, R

SHUNT

= 340 Ω 21 26 mA

UVLO Turn-On Current 6.5 11 mA

UVLO Threshold Voltage V

UVLO

VCC rising 9 V

UVLO Turn-Off Voltage VCC falling 4.1 V

VCC3 Output Voltage VCC3 I

VCC3

= 1mA 3.0 3.3 3.6 V

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 5 of 36 | www.onsemi.com

Page 6

ASP0800 Preliminary Technical Data

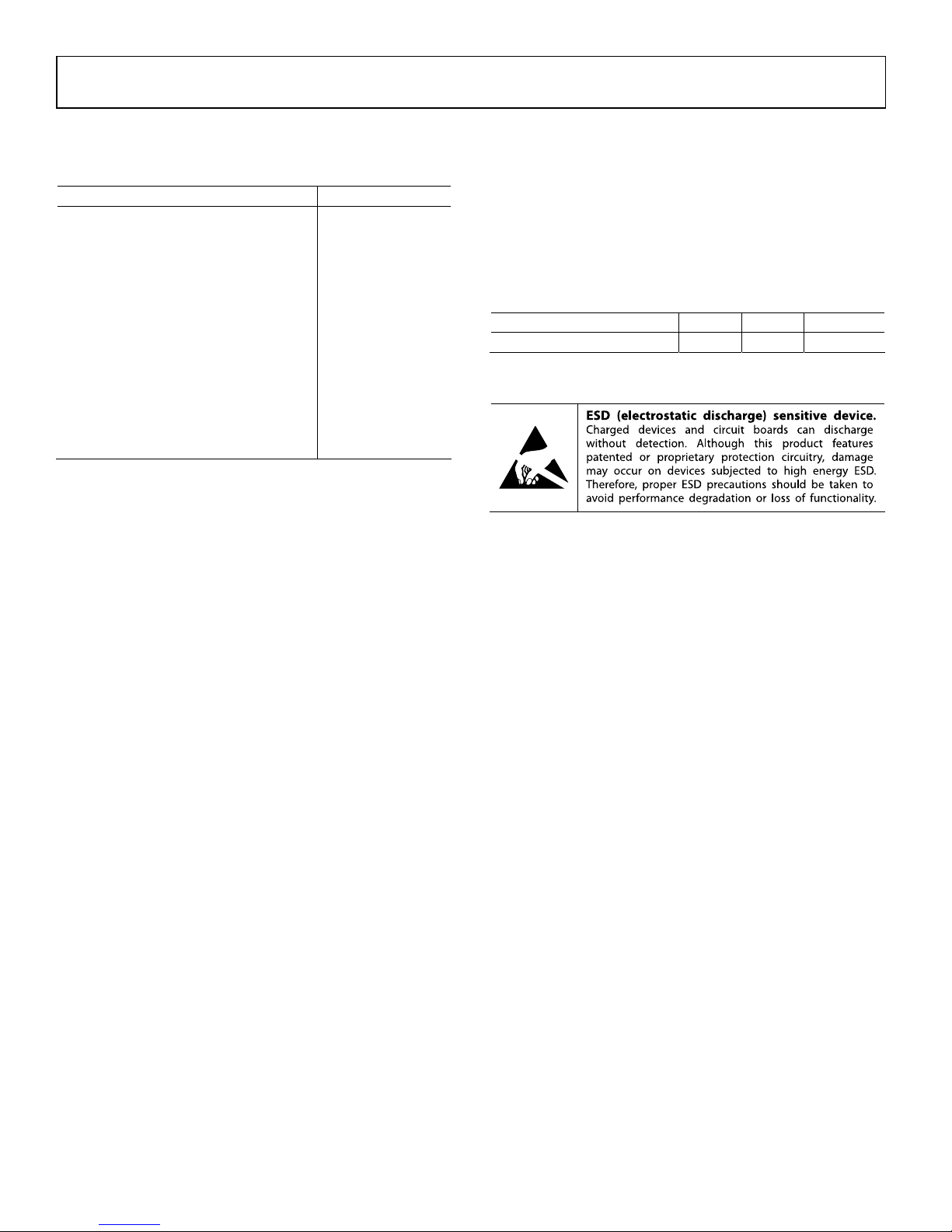

TEST CIRCUITS

VCC3

PWRGD

ALERT

SDA

SCL

EN

GND

OC1

OC2

IMON

IREF

RT

RAMPADJ

FBRTN

COMPFBCSREF

CSSUM

CSCOMP

ILIMITFS

ODN

OD1

SW8

SW7

PWM3

PWM4

PWM5

PWM6

PWM7

PWM8

SW1

SW2

SW3

SW4

SW5

SW6

PSI

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VID7

VCC

PWM1

PWM2

ASP0800

8 BIT

VID CODE

100nF

+12V

680

:

680

:

1

µF

+

121k:

10k:

20k:

100nF

1k:

+1.25V

Figure 2. Closed-Loop Output Voltage Accuracy

+

–

39

VCC

CSREF

GND

7

FB

15

COMP

16

10k

A

SP0800

+

–

+

'VFB = FB'V=80mV - F B'V=0mV

VID

DAC

1.0V

+

–

+12V

680:

680:

17

Figure 3 . Current Sense Amplifier V

OS

CSSUM

19

CSCOMP

18

39

VCC

CSREF

17

GND

7

39k

680 680

100nF

1k

1V

ASP0800

VOS =

CSCOMP – 1V

40

12V

Figure 4 . Positioning Voltage

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 6 of 36 | www.onsemi.com

Page 7

Preliminary Technical Data ASP0800

Rev. Pr H| Page 7 of 38

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VCC −0.3 V to +6 V

FBRTN −0.3 V to +0.3 V

PWM2 to PWM8, RAMPADJ −0.3 V to VCC + 0.3 V

SW1 to SW8 −5 V to +25 V

<200 ns −10 V to +25 V

All Other Inputs and Outputs −0.3 V to VCC + 0.3 V

Storage Temperature Range −65°C to +150°C

Operating Ambient Temperature Range 0°C to 85°C

Operating Junction Temperature 125°C

Lead Temperature

Soldering (10 sec)

300°C

Infrared (15 sec) 260°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θJA θ

JC

Unit

Thermal Impedance (θJA) 27°C/W

ESD CAUTION

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 7 of 36 | www.onsemi.com

Page 8

ASP0800 Preliminary Technical Data

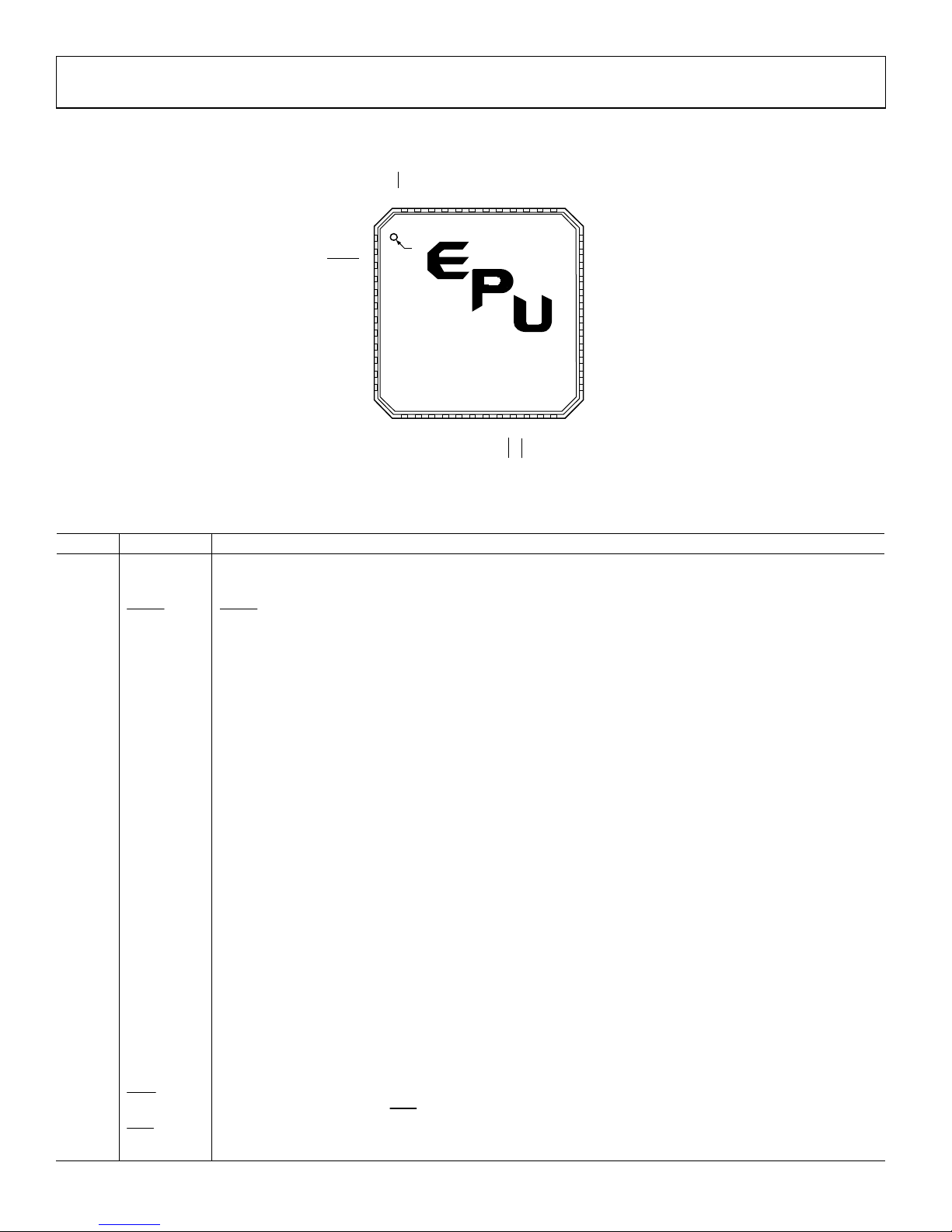

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

13141516171819

2021222324

FBRTN

COMP

FB

CSREF

CSSUM

CSCOMP

ILIMFS

ODN

OD1

SW8

SW7

RAMPADJ

4847464544434241403938

37

PSI

VID0

VID1

VID2

VID3

VID4

VID5

VID6

PWM1

PWM2

1

2

3

4

5

6

7

8

9

10

11

12

VCC3

PWRGD

ALERT

SDA

SCL

EN

GND

OC1

OC2

IMON

IREF

RT

PWM4

PWM5

PWM6

PWM7

PWM8

SW1

SW2

SW3

SW4

SW5

SW6

35

PWM336

34

33

32

31

30

29

28

27

26

25

ASP0800

JCPZ

XXXXX

XXXXXXX

(Not to Scale)

PIN 1

INDICATOR

VCC

VID7

Figure 5. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 VCC3 3.3V Power Supply Output. A capacitor from this pin to ground provided decoupling for the interval 3.3V LDO.

2 PWRGD

Power-Good Output: Open-drain output that signals when the output voltage is outside of the proper operating

range.

3

ALERT

ALERT

Output : Open drain output that asserts low when the VR exceeds a programmable limit. Can be

configured for Comparator Mode or Interrupt Mode.

4 SDA

Digital Input / Output. PMBus serial data bidirectional pin. Requires PMBus pull up.

5 SCL

Digital Input. PMBus serial bus clock open drain input. Requires PMBus pull up.

6 EN Power Supply Enable Input. Pulling this pin to GND disables the PWM outputs and pulls the PWRGD output low.

7 GND Ground. All internal biasing and the logic output signals of the device are referenced to this ground

8 OC1 Over Clocking Bit 1 Output. The pin is connected to the clock control chip to set the over-clocking state.

9 OC2 Over Clocking Bit 2 Output. The pin is connected to the clock control chip to set the over-clocking state.

10 IMON

Total Current Output Pin.

11

IREF Current Reference Input. An external resistor from this pin to ground sets the reference current for I

FB

, and I

ILIMFS

.

12 RT

Frequency Setting Resistor Input. An external resistor connected between this pin and GND sets the oscillator

frequency of the device.

13 RAMPADJ PWM Ramp Current Input. An external resistor from the converter input voltage to this pin sets the internal PWM ramp.

14 FBRTN Feedback Return. VID DAC and error amplifier reference for remote sensing of the output voltage.

15 COMP Error Amplifier Output and Compensation Point.

16 FB

Feedback Input. Error amplifier input for remote sensing of the output voltage. An external resistor between this

pin and the output voltage sets the no load offset point.

17 CSREF

Current Sense Reference Voltage Input. The voltage on this pin is used as the reference for the current sense

amplifier and the power-good and crowbar functions. This pin should be connected to the common point of the

output inductors.

18 CSSUM

Current Sense Summing Node. External resistors from each switch node to this pin sum the average inductor

currents together to measure the total output current.

19 CSCOMP

Current Sense Compensation Point. A resistor and capacitor from this pin to CSSUM determines the gain of the

current sense amplifier and the positioning loop response time.

20 ILIMFS

Current Sense and Limit Scaling Pin. An external resistor from this pin to CSCOMP sets the internal current

sensing signal for current-limit and IMON. This value can be over-written using the PMBus interface.

21

ODN

Output Disable Logic Output for PSI# operation. This pin is actively pulled low when PSI# is low, otherwise it

functions in the same way as

OD1

.

22

OD1

Output Disable Logic Output. This pin is actively pulled low when the EN input is low or when VCC is below its

UVLO threshold to signal to the Driver IC that the driver high-side and low-side outputs should go low.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 8 of 36 | www.onsemi.com

Page 9

Preliminary Technical Data ASP0800

Rev. Pr H| Page 9 of 38

Pin No. Mnemonic Description

23 to

30

SW8 to SW1 Current Balance Inputs. Inputs for measuring the current level in each phase. The SW pins of unused phases

should be left open.

31 to

38

PWM8 to

PWM1

Logic-Level PWM Outputs. Each output is connected to the input of an external MOSFET driver such as the

ADP3121. Connecting the PWM8, PWM7, PWM6, PWM5, PWM4, PWM3 and PWM2 outputs to VCC causes that

phase to turn off, allowing the ASP0800 to operate as a 1, 2-, 3-, 4-, 5-, 6, 7 or 8-phase controller.

39 VCC

Supply Voltage for the Device. A 340 Ω resistor should be placed between the 12 V system supply and the VCC

pin. The internal shunt regulator maintains VCC = 5 V.

40 to

47

VID7 to VID0

Voltage Identification DAC Inputs. These eight pins are pulled down to GND, providing a logic zero if left open. When

in normal operation mode, the DAC output programs the FB regulation voltage from 0.375 V to 1.6

48

PSI

Power State Indicator. Pulling this pin low places the controller in lower power state operation.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 9 of 36 | www.onsemi.com

Page 10

ASP0800 Preliminary Technical Data

TYPICAL PERFORMANCE CHARACTERISTICS

TBD

Rev. P1 | Page 10 of 36 | www.onsemi.com

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Page 11

Preliminary Technical Data ASP0800

Rev. Pr H| Page 11 of 38

THEORY OF OPERATION

The ASP0800 combines a multi-mode, fixed frequency PWM

control with multi-phase logic outputs for use in multi-phase

synchronous buck CPU core supply power converters. The

internal VID DAC is designed to interface with the Intel 8-bit

VR 11 and VR 11.1 compatible CPUs .

In addition, the ASP0800 incorporates a serial interface to allow

the programming of key system performance specifications and

read back CPU data such as voltage, current and power.

Multiphase operation is important for producing the high

currents and low voltages demanded by today’s

microprocessors. Handling the high currents in a single-phase

converter would place high thermal demands on the

components in the system such as the inductors and MOSFETs.

The multimode control of the ASP0800 ensures a stable, high

performance topology for:

x Balancing currents and thermals between phases for

both static and dynamic operation.

x High speed response at the lowest possible switching

frequency and output decoupling

x FEPWM improves load step response.

x Minimizing thermal switching losses by utilizing

lower frequency operation

x High current output due to 8 phase operation

x Tight load line regulation and accuracy

x Reduced output ripple due to multiphase cancellation

x PC board layout noise immunity

x Ease of use and design due to independent component

selection

x Flexibility in operation for tailoring design to low cost

or high performance

START-UP SEQUENCE

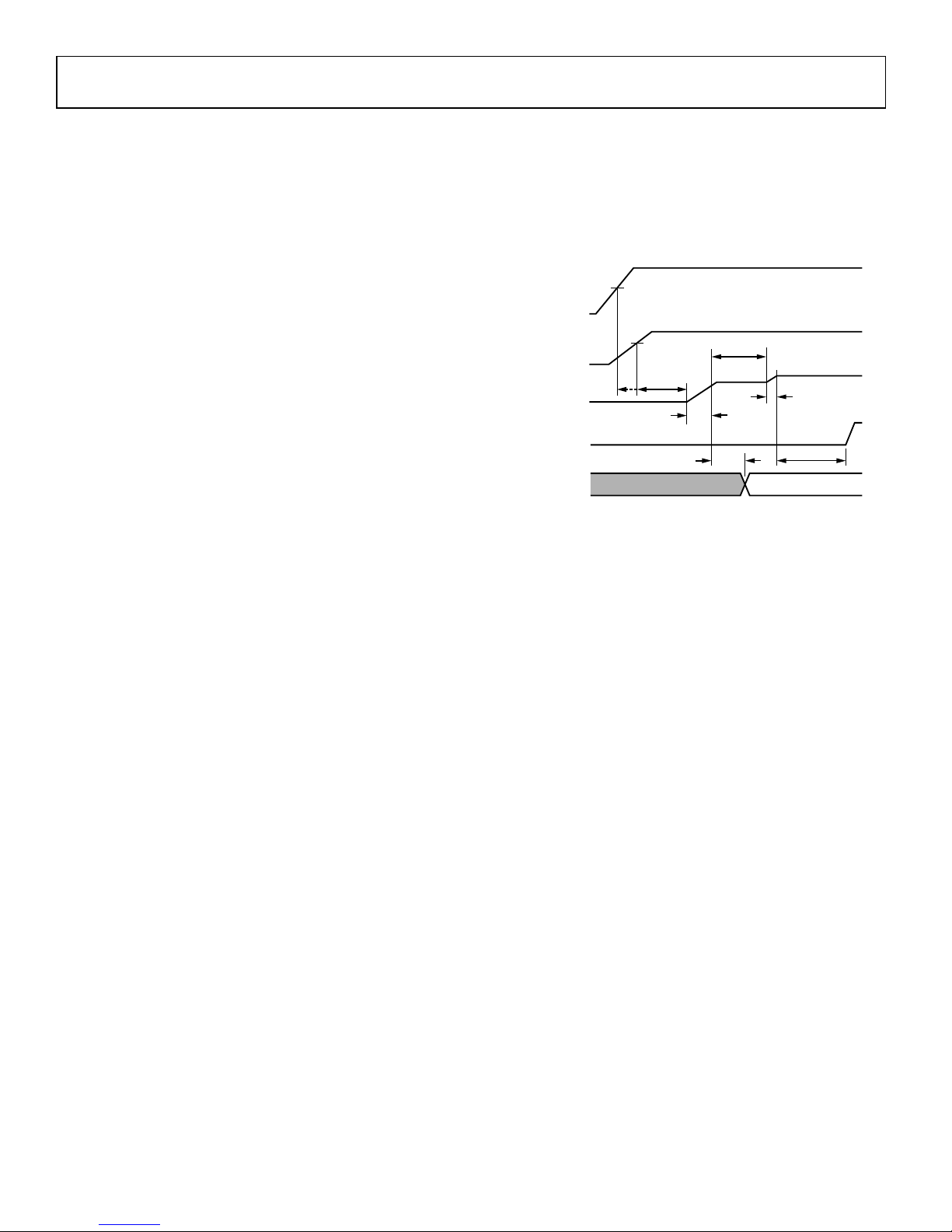

The ASP0800 follows the VR11 start-up sequence shown in

Figure 7. After both the EN and UVLO conditions are met, a

programmable internal timer goes through one cycle TD1. This

delay cycle is programmed using Delay Command, default

delay = 2ms). The first eight clock cycles of TD2 are blanked

from the PWM outputs and used for phase detection as

explained in the following section. Then the programmable

internal soft-start ramp is enabled (TD2) and the output comes

up to the boot voltage of 1.1V. The boot hold time is also set by

the Delay Command. This second delay cycle is called TD3.

During TD3 the processor VID pins settle to the required VID

code. When TD3 is over, the ASP0800 reads the VID inputs

and soft starts either up or down to the final VID voltage

(TD4). After TD4 has been completed and the PWRGD

masking time (equal to VID on the fly masking) is finished, a

third cycle of the internal timer sets the PWRGD blanking

(TD5).

The internal delay and soft start times are programmable using

the serial interface and the Delay Command and Soft Start

Command.

TD1

TD3

TD2

TD5

50µs

TD4

5V

SUPPLY

VTT I/O

(ADP3298 EN)

VCC_CORE

VR READY

(ADP3298 PWRG D)

CPU

VID I NPUTS

VID INVALID VID VALID

V

BOOT

(1.1V)

UVLO

THRESHOL D

0.85V

V

VID

Figure 7. System Start-Up Sequence for VR11

PHASE DETECTION SEQUENCE

During startup, the number of operational phases and their

phase relationship is determined by the internal circuitry that

monitors the PWM outputs. Normally, the ASP0800 operates as

a 8-phase PWM controller.

To operate as a 7-phase controller connect PWM8 to VCC.

To operate as a 6-phase controller connect PWM7 and PWM8

to VCC.

To operate as a 5-phase controller connect PWM6, PWM7 and

PWM8 to VCC.

To operate as a 4-phaase controller connect PWM5, PWM6,

PWM7 and PWM8 to VCC.

To operate as a 3-phase controller connect PWM4, PWM5,

PWM6, PWM7 and PWM8 to VCC.

To operate as a 2-phase controller connect PWM3, PWM4,

PWM5, PWM6, PWM7 and PWM8 to VCC.

To operate as a 1-phase controller connect PWM2, PWM3,

PWM4, PWM5, PWM6, PWM7 and PWM8 to VCC.

Prior to soft start, while EN is low, the PWM8, PWM7, PWM6,

PWM5, PWM4, PWM3 and PWM2 pins sink approximately

100 µA each. An internal comparator checks each pin’s voltage

vs. a threshold of 3 V. If the pin is tied to VCC, it is above the

threshold. Otherwise, an internal current sink pulls the pin to

GND, which is below the threshold. PWM1 is low during the

phase detection interval that occurs during the first eight clock

cycles of TD2. After this time, if the remaining PWM outputs

are not pulled to VCC, the 100 µA current sink is removed, and

they function as normal PWM outputs. If they are pulled to

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 11 of 36 | www.onsemi.com

Page 12

ASP0800 Preliminary Technical Data

VCC, the 100 µA current source is removed, and the outputs

are put into a high impedance state.

The PWM outputs are logic-level devices intended for driving

fast response external gate drivers such as the ADP3121 and

ADP3122. Because each phase is monitored independently,

operation approaching 100% duty cycle is possible. In addition,

more than one output can be on at the same time to allow

overlapping phases.

MASTER CLOCK FREQUENCY

The clock frequency of the ASP0800 is set with an external

resistor connected from the RT pin to ground. The frequency

follows the graph in Figure 6. To determine the frequency per

phase, the clock is divided by the number of phases in use. If all

phases are in use, divide by 6. If 4 phases are in use divide by 4.

OUTPUT VOLTAGE DIFFERENTIAL SENSING

The ASP0800 combines differential sensing with a high

accuracy VID DAC and reference, and a low offset error amplifier. This maintains a worst-case specification of ±10 mV

differential sensing error over its full operating output voltage

and temperature range. The output voltage is sensed between

the FB pin and FBRTN pin. FB is connected through a resistor,

R

B,

to the regulation point, usually the remote sense pin of the

microprocessor. FBRTN is connected directly to the remote

sense ground point. The internal VID DAC and precision

reference are referenced to FBRTN, which has a minimal

current of 70 µA to allow accurate remote sensing. The internal

error amplifier compares the output of the DAC to the FB pin to

regulate the output voltage.

OUTPUT CURRENT SENSING

The ASP0800 provides a dedicated current-sense amplifier

(CSA) to monitor the total output current for proper voltage

positioning vs. load current, for the IMON output and for

current-limit detection. Sensing the load current at the output

gives the total real time current being delivered to the load,

which is an inherently more accurate method than peak current

detection or sampling the current across a sense element such

as the low-side MOSFET. This amplifier can be configured

several ways, depending on the objectives of the system, as

follows:

x Output inductor DCR sensing without a thermistor for

lowest cost.

x Output inductor DCR sensing with a thermistor for

improved accuracy with tracking of inductor temperature.

x Sense resistors for highest accuracy measurements.

The positive input of the CSA is connected to the

CSREF pin, which is connected to the average output

voltage. The inputs to the amplifier are summed together

through resistors from the sensing element, such as the

switch node side of the output inductors, to the inverting

input CSSUM. The feedback resistor between CSCOMP and

CSSUM sets the gain of the amplifier and a filter capacitor is

placed in parallel with this resistor. The gain of the amplifier

is programmable by adjusting the feedback resistor.

This difference signal is used internally to offset the

VID DAC for voltage positioning. This different signal can

be adjusted between 50%-150% of the external value using

the PMBus Loadline Calibration (0xDE) and Loadline Set

(0xDF) commands.

The difference between CSREF and CSCOMP is then used

as a differential input for the current-limit comparator.

To provide the best accuracy for sensing current, the CSA is

designed to have a low offset input voltage. Also, the sensing

gain is determined by external resistors to make it extremely

accurate.

The CPU current can also be monitored over the PMBus.

The current limit and the load line can be programmed over

PMBus.

OUTPUT CURRENT MONITOR

IMON is an analog output from the ASP0800 representing the

total current being delivered to the load. It outputs an accurate

current that is directly proportional to the current set by the

ILIMFS resistor. The current is then run through a parallel RC

connected from the IMON pin to the FBRTN pin to generate an

accurately scaled and filtered voltage as per the VR11.1

specification. The size of the resistor is used to set the IMON

scaling.

If the IMON and the OCP need to be changed based on the

TDC of the CPU, then the ILIMFS resistor is the only

component that needs to be changed. If the IMON scaling is the

only change needed then changing the IMON resistor

accomplishes this.

The IMON pin also includes an active clamp to limit the IMON

voltage to 1.15V MAX while maintaining 900mV MIN full scale

accurate reporting.

ACTIVE IMPEDANCE CONTROL MODE

For controlling the dynamic output voltage droop as a

function of output current, the CSA gain and load line

programming can be scaled to be equal to the droop

impedance of the regulator times the output current. This

droop voltage is then used to set the input control voltage to

the system. The droop voltage is subtracted from the DAC

reference input voltage directly to tell the error amplifier

where the output voltage should be. This allows enhanced

feed-forward response.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 12 of 36 | www.onsemi.com

Page 13

Preliminary Technical Data ASP0800

Rev. Pr H| Page 13 of 38

CURRENT CONTROL MODE AND THERMAL

BALANCE

The ASP0800 has individual inputs (SW1 to SW8) for each

phase that are used for monitoring the current of each

phase. This information is combined with an internal ramp

to create a current balancing feedback system that has been

optimized for initial current balance accuracy and dynamic

thermal balancing during operation. This current balance

information is independent of the average output current

information used for positioning as described in the Output

Current Sensing section.

The magnitude of the internal ramp can be set to optimize

the transient response of the system. It also monitors the

supply voltage for feed-forward control for changes in the

supply. A resistor connected from the power input voltage

to the RAMPADJ pin determines the slope of the internal

PWM ramp.

The balance between the phases can be programmed using

the PMBus Phase Bal SW(x) commands (TBD to TBD).

This allows each phase to be adjusted if there is a difference

in temperature due to layout and airflow considerations.

The phase balance can be adjusted from a default gain of 5

(Bits 4:0 = 10000). The minimum gain programmable is 3.75

(Bits 4:0 = 00000) and the max gain is 6.25 (Bits 4:0 =

11111).

VOLTAGE CONTROL MODE

A high gain, high bandwidth, voltage mode error amplifier

is used for the voltage mode control loop. The control input

voltage to the positive input is set via the VID logic

according to the voltages listed in

Ta bl e 5. The VID code is

set using the VID Input pins or it can be programmed over

the PMBus using the VOUT_Command. By default, the

ASP0800 outputs a voltage corresponding to the VID

Inputs. To output a voltage following the VOUT_Command

the user first needs to program the required VID Code.

Then the VID_EN Bits need to be enabled. The following is

the sequence

1. Program the required VID Code to the

VOUT_Command code (0x21)

2. Set the VID_EN bit (Bit 3) in the VR Config 1A (0xD2)

and on the VR Config 1B (0xD3).

This voltage is also offset by the droop voltage for active

positioning of the output voltage as a function of current,

commonly known as active voltage positioning. The output

of the amplifier is the COMP pin, which sets the

termination voltage for the internal PWM ramps.

The negative input (FB) is tied to the output sense location

with Resistor R

B

and is used for sensing and controlling the

output voltage at this point. A current source (equal to

IREF) from the FB pin flowing through R

B

is used for setting

the no load offset voltage from the VID voltage. The no load

voltage is negative with respect to the VID DAC for Intel

CPU’s. The main loop compensation is incorporated into

the feedback network between FB and COMP.

An offset voltage can be added to the control voltage over

the serial interface. This is done using Bits <5:0> of the

VOUT_TRIM (0xDB) and VOUT_CAL (0xDC)

Commands. The max offset that can be applied is +/200mV (even if the sum of the offsets > 200mV). The LSB

size id 6.25mV. A positive offset is applied when Bit 4 = 0. A

negative offset is applied when Bit 4 = 1.

Table 5. Offset Codes

VOUT_TRI

M CODE

TRIM

OFFSET

V O LTA G

E

VOUT_CA

L CODE

CAL

OFFSET

V O LTA G

E

TOTAL

OFFSET

V O LTA G

E

TBD TBD TBD TBD TBD

TBD TBD TBD TBD TBD

TBD TBD TBD TBD TBD

DYNAMIC VID

The ASP0800 has the ability to dynamically change the VID

inputs while the controller is running. This allows the output

voltage to change while the supply is running and supplying

current to the load. This is commonly referred to as Dynamic

VID (DVID). A DVID can occur under either light or heavy

load conditions. The processor signals the controller by

changing the VID inputs (or by programming a new

VOUT_Command) in a single or multiple steps from the start

code to the finish code. This change can be positive or negative.

When a VID bit changes state, the ASP0800 detects the change

and ignores the DAC inputs for a minimum of 200 ns. This time

prevents a false code due to logic skew while the VID inputs are

changing. Additionally, the first VID change initiates the

PWRGD and CROWBAR blanking functions for a minimum of

100 µs to prevent a false PWRGD or CROWBAR event. Each

VID change resets the internal timer.

If a VID off code is detected the ASP0800 will wait for 5usec to

ensure that the code is correct before initiating a shutdown of

the controller.

Rev. P1 | Page 13 of 36 | www.onsemi.com

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Page 14

ASP0800 Preliminary Technical Data

The ASP0800 also uses the TON_Transition (0xD6) to limit the

DVID slew rates. These can be encountered when the system

does a large single VID step for power state changes, thus the

DVID slew rate needs to be limited to prevent large inrush

currents.

The transition slew rate is programmed using Bits <2:0> of

the Ton_Transition (0xD6) command code.

Ta bl e 6

provides the transition rate values.

Table 6. Transition Rate Codes

Code Transition Rate (V/msec)

000 1

001 3

010 5 = default

011 7

100 9

101 11

110 13

111 15

ENHANCED TRANSIENTS MODE

The ASP0800 incorporates enhanced transient response for

both load step up and load release. For load step up it senses

the output of the error amp to determine if a load step up

has occurred and then sequences on the appropriate

number of phases to ramp up the output current.

CURRENT REFERENCE

The IREF pin is used to set an internal current reference.

This reference current sets I

FB

. A resistor to ground

programs the current based on the 1.8 V output.

Typically, R

IREF

is set to 121 k to program IREF = 15 µA.

The following currents are then equal to

I

FB

= IREF = 15 µA

INTERNAL DELAY TIMER

The delay times for the start up timing sequence are set by an

internal timer. The default time is 2msec which can be changed

through the PMBus interface. This timer is used for multiple

delay timings (TD1, TD3, and TD5) during the start-up

sequence. Also, it is used for timing the current limit latch off

as explained in the CURRENT LIMIT section. The current

limit timer is set to 4 times the delay timer.

The delay timer is programmed using Bits <2:0> of the Ton

Delay command (0xD4). The delay can be programmed

between 0.5msec and 4msec.

Ta bl e 7 provides the

programmable delay values

Table 7. Delay Codes

Code Delay (msec)

000 0.5

001 1

010 1.5

011 2 = default

100 2.5

101 3

110 3.5

111 4

SOFT START

The Soft Start slope for the output voltage is set by an internal

timer. The default value is 0.5V/msec., which can be

programmed through the PMBus interface. After TD1 and the

phase detection cycle have been completed, the SS time (TD2 in

Figure 7) starts. The SS circuit uses the internal VID DAC to

increase the output voltage in 6.25mV steps up to the 1.1 V boot

voltage.

Once the SS circuit has reached the boot voltage, the boot

voltage delay time (TD3) is started. The end of the boot voltage

delay time signals the beginning of the second soft start time

(TD4). The SS voltage changes from the boot voltage to the

programmed VID DAC voltage (either higher or lower) using

6.25mV steps.

The soft start slew rate is programmed using Bits <2:0> of

the Ton_Rise (0xD5) command code.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 14 of 36 | www.onsemi.com

Page 15

Preliminary Technical Data ASP0800

Table 8. Soft Start Codes provides the soft start values. Figure

8 shows typical start-up waveforms for the ASP0800.

Preliminary Technical Data ASP0800

ASP0800 Preliminary Technical Data

Table 8. Soft Start Codes

Code Soft Start (V/msec)

000 0.3

001 0.3

010 0.5 = default

011 0.7

100 0.9

101 1.1

110 1.3

111 1.5

Figure 8 shows typical start up waveforms for the ASP0800.

Figure 8. Typical Start up waveforms

Channel 1: CSREF

Channel 2: EN

Channel 3: PWM1

CURRENT-LIMIT, SHORT-CIRCUIT, AND LATCHOFF PROTECTION

The ASP0800 compares a programmable current limit set point

to the voltage from the output of the current sense amplifier.

The level of current limit is set with the resistor from the

ILIMFS pin to CSCOMP, and can be adjusted using the PMBus

interface.

The current limit threshold can be modified from the

resistor programmed value by using the PMBus interface

using Bits <4:0> of the Current Limit Threshold command

(0xE2). The limit is programmable between 50% of the

external limit and 146.7% of the external limit. The

resolution is 3.3%.

Ta bl e 9 gives some examples codes

Ta bl e 9 gives some examples codes

Preliminary Technical Data ASP0800

Table 9. Current Limit

Code Current Limit (% of external

limit)

0 0000 50%

0 0001 53.3%

1 0000 100% = default

1 0001 103.3%

1 1110 143.3%

1 1111 146.7%

The current limit threshold can be modified from the resistor

programmed value by using the serial interface.

If the limit is reached and TD5 has completed, an internal latchoff delay time will start, and the controller will shut down if the

fault is not removed. This delay is four times longer than the

delay time during the start-up sequence. The current limit

delay time only starts after the TD5 has completed. If there is a

current limit during start-up, the ASP0800 will go through TD1

to TD5, and then start the latch-off time. Because the controller

continues to cycle the phases during the latch-off delay time, if

the short is removed before the timer is complete, the controller

can return to normal operation.

The latch-off function can be reset by either removing and

reapplying the supply voltage to the ASP0800, or by toggling the

EN pin low for a short time.

The OCP latch-off function can be disabled by using the

PMBus interface. Setting the CLIM_EN bit (bit 1) of the VR

Config 1A (0xD2) and VR Config 1B (0xD3) registers to 0

disables the current limit latch off function. The ASP0800 can

continue to operate in current limit indefinitely.

During start-up when the output voltage is below 200 mV, a

secondary current limit is active. This is necessary because the

voltage swing of CSCOMP cannot go below ground. This

secondary current limit limits controls the internal COMP

voltage to the PWM comparators to 1.5 V. This limits the

voltage drop across the low-side MOSFETs through the current

balance circuitry. Typical over-current latch-off waveforms are

shown in Figure 9.

Figure 9. Overcurrent Latch-off Waveforms

Channel 1: CSREF,

Channel 2: COMP, Channel 3: PWM1

An inherent per phase current limit protects individual phases

if one or more phases stops functioning because of a faulty

component. This limit is based on the maximum normal mode

COMP voltage.

POWER-GOOD MONITORING

The power good comparator monitors the output voltage via

the CSREF pin. The PWRGD pin is an open-drain output

whose high level (when connected to a pull-up resistor)

indicates that the output voltage is within the nominal limits

specified in the specifications above based on the VID voltage

setting. PWRGD goes low if the output voltage is outside of this

specified range, if the VID DAC inputs are in no CPU mode, or

whenever the EN pin is pulled low. PWRGD is blanked during a

DVID event for a period of 100 µs to prevent false signals

during the time the output is changing.

The PWRGD circuitry also incorporates an initial turn-on

delay time (TD5). Prior to the SS voltage reaching the

programmed VID DAC voltage and the PWRGD masking time

finishing, the PWRGD pin is held low. Once the SS circuit

reaches the programmed DAC voltage, the internal timer

operates.

The value for the PWRGD high limit and low limit can be

programmed using the serial interface.

POWER STATE INDICATOR

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 15 of 36 | www.onsemi.com

Page 16

Figure 9. Overcurrent Latch-off Waveforms

Channel 1: CSREF,

Channel 2: COMP, Channel 3: PWM1

An inherent per phase current limit protects individual phases

if one or more phases stops functioning because of a faulty

component. This limit is based on the maximum normal mode

COMP voltage.

POWER-GOOD MONITORING

The power good comparator monitors the output voltage via

the CSREF pin. The PWRGD pin is an open-drain output

whose high level (when connected to a pull-up resistor)

indicates that the output voltage is within the nominal limits

specified in the specifications above based on the VID voltage

setting. PWRGD goes low if the output voltage is outside of this

specified range, if the VID DAC inputs are in no CPU mode, or

whenever the EN pin is pulled low. PWRGD is blanked during a

DVID event for a period of 100 µs to prevent false signals

during the time the output is changing.

The PWRGD circuitry also incorporates an initial turn-on

delay time (TD5). Prior to the SS voltage reaching the

programmed VID DAC voltage and the PWRGD masking time

finishing, the PWRGD pin is held low. Once the SS circuit

reaches the programmed DAC voltage, the internal timer

operates.

The value for the PWRGD high limit and low limit can be

programmed using the serial interface.

POWER STATE INDICATOR

The PSI# pin is an input used to determine the operating state

of the load. If this input is pulled low, the load is in a low power

state and the controller asserts the

ODN

pin low, which can be

used to disable phases and maintain better efficiency at lighter

loads.

The sequencing into and out of low power operation is

maintained to minimize output deviations as well as providing

full power load transients immediately after exiting a low power

ASP0800 Preliminary Technical Data

ASP0800 Preliminary Technical Data

OUTPUT CROWBAR

As part of the protection for the load and output components of

the supply, the PWM outputs are driven low (turning on the

low-side MOSFETs) when the output voltage exceeds the upper

crowbar threshold. This crowbar action stops once the output

voltage falls below the release threshold of approximately

300 mV.

The value for the crowbar limit follows the programmable

PWRGD high limit.

Turning on the low-side MOSFETs pulls down the output as the

reverse current builds up in the inductors. If the output

overvoltage is due to a short in the high-side MOSFET, this

action current-limits the input supply or blows its fuse,

protecting the microprocessor from being destroyed.

OUTPUT ENABLE AND UVLO

For the ASP0800 to begin switching, the input supply current to

the controller must be higher than the UVLO threshold and the

EN pin must be higher than its 0.8 V threshold. This initiates a

system start-up sequence. If either UVLO or EN is less than

their respective thresholds, the ASP0800 is disabled. This holds

the PWM outputs at ground and forces PWRGD,

ODN

and

OD1

signals low.

In the application circuit (see Figure TBD), the

OD1

pin should

be connected to the

OD

inputs of the external drivers for the

phases that are always on. The

ODN

pin should be connected to

the

OD

inputs of the external drivers on the phases that are shut

down during low power operation. Grounding the driver

OD

inputs disables the drivers such that both DRVH and DRVL are

grounded. This feature is important in preventing the discharge

of the output capacitors when the controller is shut off. If the

driver outputs are not disabled, a negative voltage can be

generated during output due to the high current discharge of

the output capacitors through the inductors.

OVERCLOCKING (OC) LIMITS AND OFFSETS

The ASP0800 includes an overclocking function. The total

output current is monitored by the ASP0800 using the I

MON

output.

Read_IOUT Command gives the total current in Amps

The IOUT value is compared with the Over Clocking or OC

Thresholds. There are three OC thresholds

Command TBD = OC Threshold 1; Default = TBD

Command TBD = OC Threshold 2; Default = TBD

Command TBD = OC Threshold 3; Default = TBD

I

OUT

is first compared with OC3, If I

OUT

is greater than OC3

then the system is in OC State TBD and Offset TBD is applied.

If I

OUT

is less than OC3 but greater than OC2 then the system is

in OC State TBD

.

If I

OUT

is less than OC2 but greater than OC1

then the system is in OC State TBD. If I

OUT

is less than OC1

then the system is in OC State TBD. Each offset state has a

corresponding Offset voltage. The offset voltage for each state is

programmable in TBD mV steps up to a max value of ±200

mV.

Register TBD VR Offset 1 = Offset voltage for State 1, default

value = 0x00

Register TBD VR Offset 2 = Offset voltage for State 2, default

value = 0x00

Register TBD VR Offset 3 = Offset voltage for State 3, default

value = 0x00

Register TBD VR Offset 4 = Offset voltage for State 4, default

value = 0x00

PMBUS INTERFACE

Control of the ASP0800 is carried out using the PMBus

Interface. The physical protocol for PMBus closely matches that

of SMBus.

The ASP0800 is connected to this bus as a slave device, under

the control of a master controller.

To setup the PMBus Address the ASP0800 sources a 10uA

current from the ADD pin through an external resistor. The

voltage is then measured by the ADC and user to set the PMBus

address. The table below gives the thresholds for each possible

PMBus address and also a suitable resistor value.

Table 10: Setting up the PMBus Address

Address

(8 Bits)

High

Threshold

Low

Threshold

Suggested Resistor

Va lu e

0xC0

0.1

0xC2

0.25 0.15

0xC4

0.5 0.3

0xC6

0.75 0.55

0xC8

1.0 0.8

0xCA

1.4 1.1

0xCC

1.9 1.5

0xCE

2.0

Data is sent over the serial bus in sequences of nine clock pulses:

eight bits of data followed by an acknowledge bit from the slave

device. Transitions on the data line must occur during the low

period of the clock signal and remain stable during the high

period, because a low-to-high transition when the clock is high

might be interpreted as a stop signal. The number of data bytes

that can be transmitted over the serial bus in a single read or

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 16 of 36 | www.onsemi.com

Page 17

corresponding Offset voltage. The offset voltage for each state is

programmable in TBD mV steps up to a max value of ±200

mV.

Register TBD VR Offset 1 = Offset voltage for State 1, default

value = 0x00

Register TBD VR Offset 2 = Offset voltage for State 2, default

value = 0x00

Register TBD VR Offset 3 = Offset voltage for State 3, default

value = 0x00

Register TBD VR Offset 4 = Offset voltage for State 4, default

value = 0x00

PMBUS INTERFACE

Control of the ASP0800 is carried out using the PMBus

Interface. The physical protocol for PMBus closely matches that

of SMBus.

The ASP0800 is connected to this bus as a slave device, under

the control of a master controller.

To setup the PMBus Address the ASP0800 sources a 10uA

current from the ADD pin through an external resistor. The

voltage is then measured by the ADC and user to set the PMBus

address. The table below gives the thresholds for each possible

PMBus address and also a suitable resistor value.

Table 10: Setting up the PMBus Address

Address

(8 Bits)

High

Threshold

Low

Threshold

Suggested Resistor

Va lu e

0xC0

0.1

0xC2

0.25 0.15

0xC4

0.5 0.3

0xC6

0.75 0.55

0xC8

1.0 0.8

0xCA

1.4 1.1

0xCC

1.9 1.5

0xCE

2.0

Data is sent over the serial bus in sequences of nine clock pulses:

eight bits of data followed by an acknowledge bit from the slave

device. Transitions on the data line must occur during the low

period of the clock signal and remain stable during the high

period, because a low-to-high transition when the clock is high

might be interpreted as a stop signal. The number of data bytes

that can be transmitted over the serial bus in a single read or

Preliminary Technical Data ASP0800

Preliminary Technical Data ASP0800

write operation is limited only by what the master and slave

devices can handle.

1. When all data bytes have been read or written, stop

conditions are established. In write mode, the master pulls the

data line high during the tenth clock pulse to assert a stop

condition. In read mode, the master device overrides the

acknowledge bit by pulling the data line high during the low

period before the ninth clock pulse; this is known as No

Acknowledge. The master takes the data line low during the low

period before the tenth clock pulse, and then high during the

tenth clock pulse to assert a stop condition.

Any number of bytes of data can be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation because the type of operation is determined

at the beginning and cannot subsequently be changed without

starting a new operation.

In the ASP0800, write operations contain one, two or three

bytes, and read operations contain one or two bytes. The

command code or register address determines the number of

bytes to be read or written, See the register map for more

information.

To write data to one of the device data registers or read data

from it, the address pointer register must be set so that the

correct data register is addressed (i.e. command code), and then

data can be written to that register or read from it. The first byte

of a read or write operation always contains an address that is

stored in the address pointer register. If data is to be written to

the device, the write operation contains a second data byte that

is written to the register selected by the address pointer register.

This write byte operation is shown in Figure 11. The device

address is sent over the bus, and then R/

W

is set to 0. This is

followed by two data bytes. The first data byte is the address of

the internal data register to be written to, which is stored in the

address pointer register. The second data byte is the data to be

written to the internal data register.

2. The read byte operation is shown in Figure 12. First

the command code needs to be written to the ASP0800 so that

the required data is sent back. This is done by performing a

write to the ASP0800 as before, but only the data byte

containing the register address is sent, because no data is

written to the register. A repeated start is then issued and a read

operation is then performed consisting of the serial bus address;

R/

W

bit set to 1, followed by the data byte read from the data

register.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 17 of 36 | www.onsemi.com

Page 18

ASP0800 Preliminary Technical Data

R/W

1

SCL

SDA

10

0

0

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADP3298

STOP BY

MASTER

STA RT BY

MASTER

FRAME 1

SERIAL BUS ADDRESS

BYTE

FRAME 2

COMMAND CODE

1

1

ACK. BY

ADP3298

9

9

Figure 10. Send Byte

R/W

1

SCL

SDA

1

0

0

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADP3298

START BY

MASTER

FRAME 1

SERIAL BUS ADDRESS

BYTE

FRAME 2

COMMAND CODE

1

1

ACK. BY

ADP3298

9

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADP3298

STOP BY

MASTER

FRAME 3

DA TA

BYTE

1

9

SCL (CONTINUED)

SDA (CONTINUED)

0

9

Figure 11. Write Byte

R/W

1

SCL

SDA

1

0

0

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

NO ACK. BY

MASTER

REPEATED START

BY MASTER

FRAME 1

SERIAL BUS ADDRESS

BYTE

FRAME 2

1

1

ACK. BY

ADP3298

9

0

9

DA TA BY TE

FROM ADP3298

R/W

1

SCL

SDA

10

0

0

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

ACK. BY

ADP3298

START BY

MASTER

FRAME 1

SERIAL BUS ADDRESS

BYTE

FRAME 2

COMMAND CO DE

1

1

ACK. BY

ADP3298

9

9

STOP B

Y

MASTER

Figure 12. Read Byte

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 18 of 36 | www.onsemi.com

Page 19

Preliminary Technical Data ASP0800

3. It is not possible to read or write a data byte from a

data register without first writing to the address pointer register,

even if the address pointer register is already at the correct

value.

4. In addition to supporting the send byte, the ASP0800

also supports the read byte, write byte, read word and write

word protocols. (See System Management Bus Specifications Rev.

2.0 and the PMBus Specification Rev 1.1 Part I and Part II for

more information.)

WRITE OPERATIONS

The PMBus specification defines several protocols for different types of read and write operations. The ones used in the

ASP0800 are discussed in this section. The following

abbreviations are used in the diagrams:

S—START

P—STOP

R—READ

W—WRITE

A—ACKNOWLEDGE

A

—NO ACKNOWLEDGE

The ASP0800 uses the following PMBus write protocols.

Send Byte

In this operation, the master device sends a single command

byte to a slave device as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by

the write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

5. The slave asserts ACK on SDA.

6. The master asserts a stop condition on SDA and the

transaction ends.

For the ASP0800, the send byte protocol is used to clear Faults.

This operation is shown in Figure 13.

SLAVE

ADDRESS

COMMAND

CODE

AAWSP

2 46531

Figure 13.. Send Byte Command

If the master is required to read data from the register immediately after setting up the address, it can assert a repeat start

condition immediately after the final ACK and carry out a

single byte read without asserting an intermediate stop

condition.

Write Byte

In this operation, the master device sends a command byte and

one data byte to the slave device as follows:

5. The master device asserts a start condition on SDA.

6. The master sends the 7-bit slave address followed by the

write bit (low).

7. The addressed slave device asserts ACK on SDA.

8. The master sends a command code.

9. The slave asserts ACK on SDA.

10. The master sends a data byte.

11. The slave asserts ACK on SDA.

12. The master asserts a stop condition on SDA and the

transaction ends.

The byte write operation is shown in Figure 14.

SL AVE

ADDRESS

COMMAND

CODE

DA TAAAWS AP

2 46531 78

Figure 14. Single Byte Write to a Register

Write Word

In this operation, the master device sends a command byte and

two data bytes to the slave device as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by

the write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

5. The slave asserts ACK on SDA.

6. The master sends the first data byte.

7. The slave asserts ACK on SDA.

8. The master sends the second data byte.

9. The slave asserts ACK on SDA.

10. The master asserts a stop condition on SDA and the

transaction ends.

The word write operation is shown in Figure 15.

SL AVE

ADDRESS

COMMAND

CODE

DA TA

(LSB)

AAWS AP

2 46531 78

DA TA

(MSB)

A

109

Figure 15. Single Word Write to a Register

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 19 of 36 | www.onsemi.com

Page 20

ASP0800 Preliminary Technical Data

Block Write

In this operation, the master device sends a command byte and

a byte count followed by the stated number of data bytes to the

slave device as follows:

1. The master device asserts a START condition on SDA.

2. The master sends the 7-bit slave address followed by

the write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code

5. The slave asserts ACK on SDA

6. The master sends the byte count N

7. The slave asserts ACK on SDA

8. The master sends the first data byte

9. The slave asserts ACK on SDA

10. The master sends the second data byte.

11. The slave asserts ACK on SDA

12. The master sends the remainder of the data byes

13. The slave asserts an ACK on SDA after each data byte.

14. After the last data byte the master asserts a STOP

condition on SDA

13.

SLAVE

ADDRESS

COMMAND

CODE

D ATA

BYTE 1

AAWS

2 46531 78

9

BYTE COUNT

= N

AA

...

10

DA TA

BYTE 2

A

...

DA TA

BYTE N

PA

11 12 13 14

Figure 16. Block Write to a Register

READ OPERATIONS

The ASP0800 uses the following PMBus read protocols.

Read Byte

In this operation, the master device receives a single byte from

a slave device as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by the

write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

5. The slave asserted ACK on SDA.

6. The master sends a repeated start condition on SDA

7. The master sends the 7 bit slave address followed by the

read bit (high)

8. The slave asserts ACK on SDA

9. The slave sends the Data Byte

10. The master asserts NO ACK on SDA.

11. The master asserts a stop condition on SDA and the

transaction ends.

SL AVE

ADDRESS

COMMAND

CODE

D ATAAAWS AP

2 46531 78

S

SLAVE

ADDRESS

AR

109

11

Figure 17. Single Byte Read from a Register

Read Word

In this operation, the master device receives two data bytes

from a slave device as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by

the write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

5. The slave asserted ACK on SDA.

6. The master sends a repeated start condition on SDA

7. The master sends the 7 bit slave address followed by

the read bit (high)

8. The slave asserts ACK on SDA

9. The slave sends the first Data Byte (low Data Byte)

10. The master asserts ACK on SDA.

11. The slave sends the second Data Byte (high Data Byte)

12. The masters asserts a No ACK on SDA

13. The master asserts a stop condition on SDA and the

transaction ends.

SL AVE

ADDRESS

COMMAND

CODE

DA TA

(LSB)

AAWSA

2 46531 78

S

SLAVE

ADDRESS

AR

109

DA TA

(MSB)

AP

1211

13

Figure 18. Word Read from a Command Code

Block Read

In this operation, the master device sends a command byte, the

slave sends a byte count followed by the stated number of data

bytes to the master device as follows:

1. The master device asserts a START condition on SDA.

2. The master sends the 7-bit slave address followed by

the write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a REPEATED START condition on

SDA

5. The master sends the 7-bit slave address followed by

the read bit (high).

6. The slave asserts ACK on SDA

7. The slave sends the byte count N

8. The master asserts ACK on SDA

9. The slave sends the first data byte

10. The master asserts ACK on SDA

11. The slave sends the remainder of the data byes, the

master asserts an ACK on SDA after each data byte.

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 20 of 36 | www.onsemi.com

Page 21

Preliminary Technical Data ASP0800

12. After the last data byte the master asserts a No ACK

on SDA.

13. The master asserts a STOP condition on SDA

14.

SL AVE

ADDRESS

BYTE COUNT

= N

AWS

2 465317

S

SLAVE

ADDRESS

AR

8 1211

DA TA

BYTE N

AP

13

A

DA TA

BYTE 1

A

...

109

Figure 19. Block Write to a Command Coder

PMBus TIMEOUT

The ASP0800 includes an PMBus timeout feature. If there is

no PMBus activity for 35 ms, the ASP0800 assumes that the

bus is locked and releases the bus. This prevents the device

from locking or holding the PMBus expecting data. Some

PMBus controllers cannot handle the PMBus timeout feature,

so it can be disabled.

Configuration Register 1 (0xTBD)

Bit 3 SMB_TO_EN = 1; PMBus timeout enabled.

Bit 3 TODIS = 0; PMBus timeout disabled (default).

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 21 of 36 | www.onsemi.com

Page 22

ASP0800 Preliminary Technical Data

Table 11. VR11 and VR10.x VID Codes for the ASP0800

VR11 DAC CODES: VIDSEL = HIGH

OUTPUT VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0

OFF 0 0 0 0 0 0 0 0

OFF 0 0 0 0 0 0

0 1

1.60000 0 0 0 0 0 0 1 0

1.59375 0 0 0 0 0 0 1 1

1.58750 0 0 0 0 0 1 0 0

1.58125 0 0 0 0 0 1 0 1

1.57500 0 0 0 0 0 1 1 0

1.56875 0 0 0 0 0 1 1 1

1.56250 0 0 0 0 1 0 0 0

1.55625 0 0 0 0 1 0 0 1

1.55000 0 0 0 0 1 0 1 0

1.54375 0 0 0 0 1 0 1 1

1.53750 0 0 0 0 1 1 0 0

1.53125 0 0 0 0 1 1 0 1

1.52500 0 0 0 0 1 1 1 0

1.51875 0 0 0 0 1 1 1 1

1.51250 0 0 0 1 0 0 0 0

1.50625 0 0 0 1 0 0 0 1

1.50000 0 0 0 1 0 0 1 0

1.49375 0 0 0 1 0 0 1 1

1.48750 0 0 0 1 0 1 0 0

1.48125 0 0 0 1 0 1 0 1

1.47500 0 0 0 1 0 1 1 0

1.46875 0 0 0 1 0 1 1 1

1.46250 0 0 0 1 1 0 0 0

1.45625 0 0 0 1 1 0 0 1

1.45000 0 0 0 1 1 0 1 0

1.44375 0 0 0 1 1 0 1 1

1.43750 0 0 0 1 1 1 0 0

1.43125 0 0 0 1 1 1 0 1

1.42500 0 0 0 1 1 1 1 0

1.41875 0 0 0 1 1 1 1 1

1.41250 0 0 1 0 0 0 0 0

1.40625 0 0 1 0 0 0 0 1

1.40000 0 0 1 0 0 0 1 0

1.39375 0 0 1 0 0 0 1 1

1.38750 0 0 1 0 0 1 0 0

1.38125 0 0 1 0 0 1 0 1

1.37500 0 0 1 0 0 1 1 0

1.36875 0 0 1 0 0 1 1 1

1.36250 0 0 1 0 1 0 0 0

1.35625 0 0 1 0 1 0 0 1

1.35000 0 0 1 0 1 0 1 0

1.34375 0 0 1 0 1 0 1 1

1.33750 0 0 1 0 1 1 0 0

1.33125 0 0 1 0 1 1 0 1

1.32500 0 0 1 0 1 1 1 0

1.31875 0 0 1 0 1 1 1 1

1.31250 0 0 1 1 0 0 0 0

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 22 of 36 | www.onsemi.com

Page 23

Preliminary Technical Data ASP0800

VR11 DAC CODES: VIDSEL = HIGH

OUTPUT VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0

1.30625 0 0 1 1 0 0 0 1

1.30000 0 0 1 1 0 0 1 0

1.29375 0 0 1 1 0 0 1 1

1.28750 0 0 1 1 0 1 0 0

1.28125 0 0 1 1 0 1 0 1

1.27500 0 0 1 1 0 1 1 0

1.26875 0 0 1 1 0 1 1 1

1.26250 0 0 1 1 1 0 0 0

1.25625 0 0 1 1 1 0 0 1

1.25000 0 0 1 1 1 0 1 0

1.24375 0 0 1 1 1 0 1 1

1.23750 0 0 1 1 1 1 0 0

1.23125 0 0 1 1 1 1 0 1

1.22500 0 0 1 1 1 1 1 0

1.21875 0 0 1 1 1 1 1 1

1.21250 0 1 0 0 0 0 0 0

1.20625 0 1 0 0 0 0 0 1

1.20000 0 1 0 0 0 0 1 0

1.19375 0 1 0 0 0 0 1 1

1.18750 0 1 0 0 0 1 0 0

1.18125 0 1 0 0 0 1 0 1

1.17500 0 1 0 0 0 1 1 0

1.16875 0 1 0 0 0 1 1 1

1.16250 0 1 0 0 1 0 0 0

1.15625 0 1 0 0 1 0 0 1

1.15000 0 1 0 0 1 0 1 0

1.14375 0 1 0 0 1 0 1 1

1.13750 0 1 0 0 1 1 0 0

1.13125 0 1 0 0 1 1 0 1

1.12500 0 1 0 0 1 1 1 0

1.11875 0 1 0 0 1 1 1 1

1.11250 0 1 0 1 0 0 0 0

1.10625 0 1 0 1 0 0 0 1

1.10000 0 1 0 1 0 0 1 0

1.09375 0 1 0 1 0 0 1 1

OFF N/A

OFF N/A

OFF N/A

OFF N/A

1.08750 0 1 0 1 0 1 0 0

1.08125 0 1 0 1 0 1 0 1

1.07500 0 1 0 1 0 1 1 0

1.06875 0 1 0 1 0 1 1 1

1.06250 0 1 0 1 1 0 0 0

1.05625 0 1 0 1 1 0 0 1

1.05000 0 1 0 1 1 0 1 0

1.04375 0 1 0 1 1 0 1 1

1.03750 0 1 0 1 1 1 0 0

1.03125 0 1 0 1 1 1 0 1

1.02500 0 1 0 1 1 1 1 0

Downloaded from DatasheetLib.com - datasheet search engine Downloaded from DatasheetLib.com - datasheet search engine

Rev. P1 | Page 23 of 36 | www.onsemi.com

Page 24

ASP0800 Preliminary Technical Data

VR11 DAC CODES: VIDSEL = HIGH

OUTPUT VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0

1.01875 0 1 0 1 1 1 1 1

1.01250 0 1 1 0 0 0 0 0

1.00625 0 1 1 0 0 0 0 1

1.00000 0 1 1 0 0 0 1 0

0.99375 0 1 1 0 0 0 1 1

0.98750 0 1 1 0 0 1 0 0