Page 1

RJ(ARJ2)

SMD RELAYS

WITH 8GHz CAPABILITIES

RJ-RELAYS

FEATURES

14.0

.551

14.0

.551

9.00

.354

8.20

.323

9.00

.354

8.20

.323

• Excellent high frequency characteristics (50Ω, at 5GHz)

V.S.W.R.: Max. 1.25

Insertion loss: Max. 0.5dB

Isolation: Min. 35dB

• Surface mount terminal

Surface mount terminals are now standard so there is much less work in designing PC boards.

• Small size

Size: 14.00 (L)×9.00 (W)×8.20 (H) mm

.551 (L)×.354 (W)×.323 (H) inch

SPECIFICATIONS

Contact

Arrangement 2 Form C

Contact material Gold alloy

Initial contact resistance Max. 150m

Contact rating

Rating

High frequency

characteristics

(Initial)

(~5GHz,

Impedance

Ω

)

50

Expected life

(min. operations)

Contact carrying power

Max. switching voltage 30 V DC

Max. switching current 0.3 A DC

V.S.W.R. Max. 1.25

Insertion loss

(without D.U.T. board’s loss)

Between

Isolation

Input power

Mechanical (at 180 cpm) 10

Electrical

(at

20cpm)

open contacts

Between

contact sets

1W, at 5GHz,

&

V.S.W.R.

10mA 10V DC

(resistive load)

Coil (at 20°C, 68°F)

Nominal operating power

Single side stable 200 mW

2 coil latching 150 mW

1W (at 5 GHz, Impedance

Ω

, V .S .W .R. &1.25)

50

10mA 10V DC (resistive load)

1W (at 5 GHz, Impedance

50 Ω, V .S .W .R. &1.25)

Max. 0.5dB

Min. 35dB

Min. 30dB

1W (at 5GHz, impedance 50Ω,

1.25

V.S.W.R.

&

10

10

1.25, at 20°C)

7

5

6

(Between open contacts)

Min. 30dB

(Between contact sets)

Characteristics

Initial insulation resistance*

Ω

Initial breakdown

2

voltage*

Operate time [Set time]*3 (at 20°C) Max. 5ms

Release time (without diode)[Reset time]*3

(at 20°C)

Temperature rise (at 20°C)*

Shock resistance

Vibration resistance

Conditions for operation,

transport and storage*

(Not freezing and condensing at low temperature)

Unit weight Approx. 3 g .11 oz

Remarks

* Specifications will vary with foreign standards certification ratings.

*1Measurement at same location as "Initial breakdown voltage" section.

*2Detection current: 10mA

3

Nominal operating voltage applied to the coil, excluding contact bounce time.

*

*4By resistive method, nominal voltage applied to the coil, 5GHz, V.S.W.R. & 1.25

5

Half-wave pulse of sine wave: 6ms, detection time: 10µs.

*

*6Pulse of sine wave: 11ms.

7

Detection time: 10µs

*

*8Refer to 6. Conditions for operation, transport and storage mentioned in NOTES

TYPICAL

APPLICATIONS

Measurement equipment market

Attenuator circuits, spectrum analyzer,

oscilloscope, mobile equipment, tester

Mobile telecommunication market

IMT2000, microwave communication

Medical instruments market

1

Between open contacts

Between contact sets 500 Vrms

Between contact and coil

4

Functional*

Destructive*

Functional*

Destructive

Ambient temp.

8

Humidity 5 to 85% R.H.

5

6

7

Min. 500 MΩ (at 500 V DC)

Min. 500 m/s

Min. 1,000 m/s

10 to 55 Hz at double

amplitude of 3 mm

10 to 55 Hz at double

amplitude of 5 mm

–30°C to 70°C

–22°F to 158°F

500 Vrms

500 Vrms

Max. 5ms

Max. 50°C

2

2

ORDERING INFORMATION

2Ex. ARJ

Contact arrangement

2: 2 Form C 0: Single side stable

2: 2 coil latching

Note: Tape and reel packing symbol “-Z” is not marked on the relay. “X” type tape and reel packing (picked from 1/2/3-pin side) is

also available. Suffix “X” instead of “Z”.

Nil: Standard PC board terminal

A: Surface-mount terminal

2

Terminal shapeOperating function Packing style

Coil voltage (DC)

03 : 3V

4H: 4.5V

12 : 12V

24 : 24V

Nil: Carton packing

X: Tape end reel packing

(picked from 1/2/3-pin side)

Z: Tape and reel packing (picked

from 6/7/8-pin side)

Page 2

TYPES AND COIL DATA (at 20°C 68°F)

1. Standard PC board terminal

• Packing of standard PC board terminal: 50 pcs. in an inner package (carton); 500 pcs. in an outer package

Operating

function

Single side

stable

Coil Rating,

V DC

Part No.

Standard PC

board terminal

3 ARJ2003 2.25 0.3 66.6 45 200 3.3

4.5 ARJ204H 3.375 0.45 44.4 101.2 200 4.95

12 ARJ2012 9 1.2 16.6 720 200 13.2

24 ARJ2024 18 2.4 8.3 2,880 200 26.4

Pick-up voltage,

V DC (max.)

(initial)

Drop-out voltage,

V DC (min.)

(initial)

Nominal operating

current, mA

(±10%)

Coil resistance,

Ω (±

10%)

Nominal

operating

power, mW

RJ(ARJ2)

Max. allowable

voltage, V DC

Operating

function

Coil Rating,

V DC

Part No.

Standard PC

board terminal

Set voltage,

V DC (max.)

(initial)

Reset voltage,

V DC (min.)

(initial)

Nominal operating

current, mA

(±10%)

Coil resistance,

Ω (±

10%)

Nominal

operating

power, mW

3 ARJ2203 2.25 2.25 50 60 150 3.3

2 coil

latching

4.5 ARJ224H 3.375 3.375 33.3 135 150 4.95

12 ARJ2212 9 9 12.5 960 150 13.2

24 ARJ2224 18 18 6.3 3,840 150 26.4

2. Surface-mount terminal

• Packing of surface-mount terminal: 50 pcs. in an inner package (carton); 500 pcs. in an outer package

• Packing of surface-mount terminal: 500 pcs. in an inner package (tape and reel); 500 pcs. in an outer package

Operating

function

Single side

stable

Operating

function

2 coil

latching

Coil Rating,

V DC

Carton

packing

Part No.

T ape and reel

packing

3 ARJ20A03 ARJ20A03Z 2.25 0.3 66.6 45 200 3.3

4.5 ARJ20A4H ARJ20A4HZ 3.375 0.45 44.4 101.2 200 4.95

12 ARJ20A12 ARJ20A12Z 9 1.2 16.6 720 200 13.2

24 ARJ20A24 ARJ20A24Z 18 2.4 8.3 2,880 200 26.4

Coil Rating,

V DC

Carton

packing

Part No.

T ape and reel

packing

3 ARJ22A03 ARJ22A03Z 2.25 2.25 50 60 150 3.3

4.5 ARJ22A4H ARJ22A4HZ 3.375 3.375 33.3 135 150 4.95

12 ARJ22A12 ARJ22A12Z 9 9 12.5 960 150 13.2

24 ARJ22A24 ARJ22A24Z 18 18 6.3 3,840 150 26.4

Pick-up

voltage, V DC

(max.) (initial)

Set voltage,

V DC (max.)

(initial)

Drop-out

voltage, V DC

(min.) (initial)

Reset voltage,

V DC (min.)

(initial)

Nominal operating

current, mA

(±10%)

Nominal operating

current, mA

(±10%)

Coil

resistance,

Ω (±

10%)

Coil

resistance,

Ω (±

10%)

Nominal

operating

power, mW

Nominal

operating

power, mW

Max. allowable

voltage, V DC

Max. allowable

voltage, V DC

Max. allowable

voltage, V DC

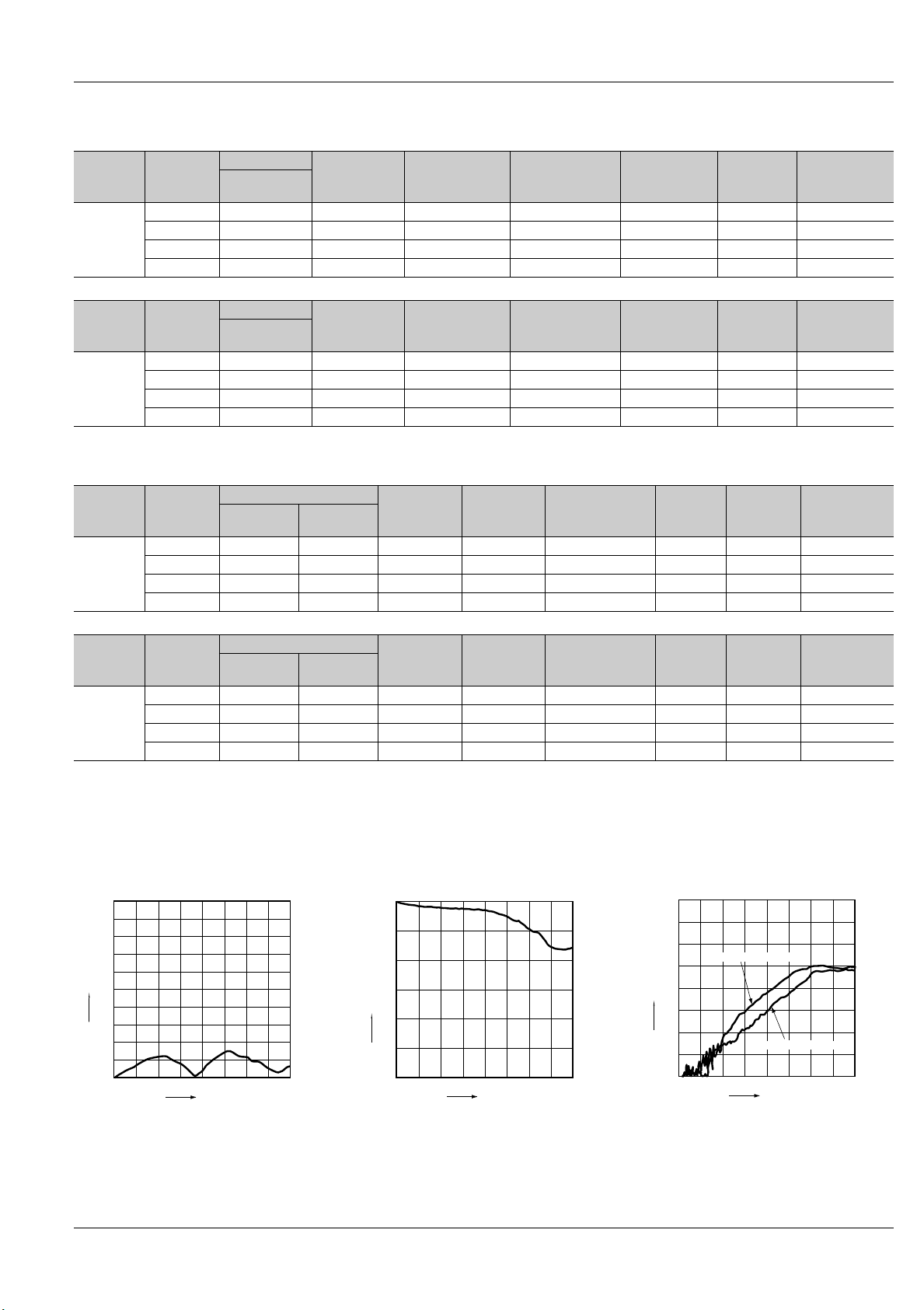

REFERENCE DATA

1. High frequency characteristics

Sample: ARJ20A12

Measuring method: Measured with MEW PC board by HP network analyzer (HP8510C).

• V.S.W.R. characteristics • Insertion loss characteristics

(without D.U.T. board’s loss)

2.0

1.9

1.8

1.7

1.6

V.S.W.R.

1.5

1.4

1.3

1.2

1.1

1.0

45MHz 5GHz 8GHz

Frequency

0

0.5

1.0

1.5

Insertion loss, dB

2.0

2.5

3.0

Frequency

8GHz5GHz45MHz

• Isolation characteristics

0

10

20

Between contact sets

30

40

Isolation, dB

50

60

70

80

45MHz 8GHz5GHz

Between open contact

Frequency

3

Page 3

RJ(ARJ2)

NONC

Com

Com

59

2

87106

3

4

1

+

–

Direction

indication

DIMENSIONS

1. Standard PC board terminal

10.4

.409

3.50

.138

0.50

.020

6.36

.250

0.20

.008

10.6

.417

12.2

.480

14.0

.551

8.89

.350

12.70

.500

11.40

.449

Expansion of A

0 to 0.2

0 to .008

(Typical: 0.1)

(Typical: .004)

24 ribs should be soldered with PC board ground.

9.00

0.40

.016

.354

A

7.62

0.20

.008

0.15

.006

.300

0.50

.020

1All bottom surface of the base should be

touched closely or soldered with PC board

ground.

3Better HF characteristics

may be obtained when this

8.20

portion is soldered with

.323

PC board ground.

0.50

.020

3.81

.150

General tolerance: ±0.3 ±.012

Schematic (Bottom view)

Single side stable

(Deenergized condition)

2 coil latching

Com

1103

2

7

8

Com

–

4

5

6

–

+

9

+

(Reset condition)

mm inch

NONC

2. Surface mount terminal

10.4

.409

6.36

.250

0.50

.020

0.40

.016

0.50

.020

10.6

.417

8.89

.350

12.2

.480

14.0

.551

15.0

.591

11.40

.449

Expansion of A

0 to 0.2

3.81

.150

24 ribs should be soldered with PC board ground.

9.00

.354

A

0.20

.008

10.0

.394

0.50

.020

1All bottom surface of the base should be

touched closely or soldered with PC board

ground.

0 to .008

(Typical: 0.1)

(Typical: .004)

3Better HF characteristics

may be obtained when this

8.20

portion is soldered with

.323

PC board ground.

General tolerance: ±0.3 ±.012

Schematic (Top view)

Single side stable

Direction

indication

(Deenergized condition)

87106

1

+

Com

2

Com

3

–

2 coil latching

Com

7

8

2

1103

Com

–

6

5

NONC

4

–

+

59

NONC

4

9

+

(Reset condition)

4

Page 4

B

1.0mm .039inch

A: Surface of PC board where relay is mounted.

B: Above the PC board surface.

A

NOTES

1. Coil operating power

Pure DC current should be applied to the

coil. The wav e form should be rectangular.

If it includes ripple, the ripple factor should

be less than 5%.

However, check it with the actual circuit

since the characteristics may be slightly

different. The nominal operating voltage

should be applied to the coil for more than

20 ms to set/reset the latching type relay.

2. Coil connection

When connecting coils, refer to the wiring

diagram to prevent mis-operation or malfunction.

3. External magnetic field

Since RJ relays are highly sensitive polarized relays, their characteristics will be affected by a strong e xternal magnetic field.

Avoid using the rela y under that condition.

4. Cleaning

For automatic cleaning, the boiling method is recommended. Avoid ultrasonic

cleaning which subjects the relays to high

frequency vibrations, which may cause

the contacts to stick.

It is recommended that alcoholic solvents

be used.

5. Tape and reel packing

1) T ape dimensions

1.50

.059

16.00

+0.1

0

+.004

.630

0

dia.

dia.

1.20

.441

3 to 5°

2) Dimensions of plastic reel

2.0±0.5

.079±.020

4.00 .157

2.0

(Accumulation 10 pitch:

.079

40±0.1 1.575±.004)

6.20

.244

11.40

.449

9.40

.370

1.33

.052

2.57

.101

21±0.8 dia.

.827±.031 dia.

.512±.008 dia.

1.75

.069

11.50

.453

(10.75)

(.423)

13±0.2 dia.

24.4

.961

0.40±0.05

.016±.002

24.00

.945

+2

0

+.079

0

16.00

.630

8.80

.346

8.50

.337

7.40

.291

1.50

3 to 5°

.059

14.40

.570

100±1 dia.

3.937±.039 dia.

370±2 dia.

14.567±.079 dia.

2.0±0.2

.079±.008

6. Conditions for operation, transport

and storage conditions

1) Ambient temperature, humidity, and atmospheric pressure during usage, transport, and storage of the relay:

(1) T emper ature:

–30 to +70°C –22 to +158°F

(However, tolerance range is –30 to

+60°C –22 to +140°F if package is carried

as is.)

(2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the temperature. Use within the range indicated

in the graph below.

(3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for usage, transport, and storage:

Humidity, %R.H.

85

Tolerance range

(Avoid freezing

when used at

temperatures

lower than

0°C 32°F)

–30

–22

(Avoid

condensation

when used at

temperatures

higher than

0°C 32°F)

5

0

32

Temperature, °C °F

70

158

2) Condensation

Condensation forms when there is a sudden change in temperature under high

temperature and high humidity conditions.

Condensation will cause deterioration of

the relay insulation.

3) Freezing

Condensation or other moisture may

freeze on the relay when the temperature

is lower than 0°C 32°F. This causes prob-

lems such as sticking of movab le parts or

operational time lags.

4) Low temperature, low humidity en vironments

The plastic becomes brittle if the relay is

exposed to a low temperature, lo w humidity environment for long periods of time.

5) Storage procedures for surface-mount

terminal types

Since the relay is very sensitive to humidity, it is packed in humidity-free, hermetically sealed packaging. When storing the

relay, be careful of the following points:

(1) Be sure to use the relay immediately

after removing it from its sealed package.

(2) When storing the relay f or long periods

of time after removing it from its sealed

package, we recommend using a humidity-free bag with silica gel to prevent subjecting the relay to humidity.

Furthermore, if the relay is solder mounted when it has been subjected to excessive humidity , cr acks and leaks can occur .

Be sure to mount the relay under the required mounting conditions.

RJ(ARJ2)

7. Soldering

1) Surface-mount terminal

In case of automatic soldering, the following conditions should be observed

(1) Position of measuring temperature

(2) IR (infrared reflow) soldering method

A: B:

T5

T4

T3

T2

T1

t1 t3 t4 t5t2

1=150°C 302°F

T

2=160°C 320°F

T

3=183°C 361°F

T

4=245°C 473°F

T

5=270°C 518°F

T

Temperature rise of relay itself may vary

according to the mounting level or the

heating method of reflow equipment.

Therefore, please set the temperature of

soldering portion of relay terminal and the

top surface of the relay case not to e xceed

the above mentioned soldering condition.

It is recommended to check the temperature rise of each portion under actual

mounting condition before use.

2) Standard PC board terminal

Please meet the following conditions if

this relay is to be automatically soldered.

(1) Preheating: Max. 100°C 212°F (termi-

nal solder surface) for max. 60 seconds

(2) Soldering: Max. 250°C 482°F for max.

5 seconds

The effect on the relay depends on the actual substrate used. Please v erify the substrate to be used.

3) Hand soldering

Please meet the following conditions if

this relay is to be soldered by hand.

(1) Wattage: 30 to 60 W

(2) Tip temperature/time: 280 to 300°C

536 to 572°F for max. 5 seconds

The effect on the relay depends on the actual substrate used. Please v erify the substrate to be used.

4) Avoid high frequency cleaning since

this may adversely affect relay characteristics. Use alcohol-based cleaning solutions when cleaning relays.

t2 - t1 = 80 to 120 s

5 - t3 = 30 to 40 s

t

4 = 170 to 190 s

t

5

Page 5

RJ(ARJ2)

Measuring method (Impedance 50Ω)

1 2

B

Network

analyzer

HP 8510C HP 8515A

RF

OUT

B

S parameter

A

R

RF

IN

test set

A

R

Connector

No. Product name Contents

1 HP 85131-60013

2 HP 83059

(Step 1) Calibrate the test system with HP

calibration kit [HP85052B]

(Step 2) After calibration, connect the

D.U.T. board and measure. Connect 50 Ω terminals on connectors other than those for

measurement.

Notes)

1. All bottom surface of the base should be

touched closely or soldered with PC board

ground.

2. 4 ribs should be soldered with PC board

ground.

Measuring board

1) Dimensions

<Surface mount terminal>

6-1.76

6-.069

0.80

.031

7.07

.278

2.81

.111

0.40

.016

1.00

.039

20.00

.787

PORT2

PORT1

3.5 mm testport,

Extension cable

3.5 mm coaxial

adaptor

17.00

.669

0.40

.016

0.40

.016

0.40

.016

8.89

.350

12.04

.474

8.35

.329

30.00

1.181

1

7.22

.284

Through hole

86-0.40 dia.

86-.016 dia.

45°

<Standard PC board terminal>

4-1.60 dia.

4-.063 dia.

78-0.40 dia.

78-.016 dia.

2

7.62

.300

20.00

.787

3.81

.150

6-0.70 dia.

6-.028 dia.

6.62

.261

0.90

.035

0.50

.020

6-1.86

6-.073

8.35

.329

12.70

.500

17.00

.669

8.89

.350

11.70

.461

30.00

1.181

0.50

.020

0.40

.016

0.40

.016

<Calibration board>

14.5

.571

10.0

.394

0.40 or 0.50

.016 or .020

1.76 or 1.86

.069 or .073

2) Material: Glass PTFE double-sided

through hole PC board R-4737 (Matsushita Electric Works)

3) Board thickness: t = 0.8 mm

4) Copper plating: 18µm

• Connector (SMA type receptacle)

Product name: R125 510 (RADIALL)

Insertion loss compensation

The insertion loss of relay itself is given by

subtracting the insertion loss of shortcircuit the Com and the NC (or NO). (signal path and two connectors)

9. Others

1) The switching lifetime is defined under

the standard test condition specified in the

JIS* C 5442-1996 standard (temperature

15 to 35°C 59 to 95°F, humidity 25 to

75%). Chec k this with the real device as it

is affected by coil driving circuit, load type,

activation frequency, activation phase,

ambient conditions and other factors.

Also, be especially careful of loads such

as those listed below.

• When used for AC load-operating and

the operating phase is synchronous.

Rocking and fusing can easily occur due

to contact shifting.

4-0.60 dia.

4-.024 dia.

6-1.70 dia.

6-.067 dia.

1.00

.039

45°

6.72

.265

• High-frequency load-operating

When high-frequency opening and closing of the relay is performed with a load

that causes arcs at the contacts, nitrogen

and oxygen in the air is fused by the arc

energy and HNO

3

is formed. This can cor-

rode metal materials.

Three countermeasures for these are listed

here.

(1) Incorporate an arc-extinguishing circuit.

(2) Lower the operating frequency

(3) Lower the ambient humidity

2) Use the relay within specifications such

as coil rating, contact rating and on/off

service life. If used beyond limits, the rela y

may overheat, generate smoke or catch

fire.

3) Be careful not to drop the relay. If accidentally dropped, carefully check its appearance and characteristics before use.

4) Be careful to wire the relay correctly.

Otherwise, malfunction, overheat, fire or

other trouble may occur.

5) If a relay stays on in a circuit for many

months or years at a time without being

activated, circuit design should be reviewed so that the relay can remain nonexcited. A coil that receives current all the

time heats, which degrades insulation

earlier than expected. A latching type relay is recommended for such circuits.

6) The latching type rela y is shipped in the

reset position. But jolts during transport or

impacts during installation can change

the reset position. It is, therefore, advisable to build a circuit in which the relay

can be initialized (set and reset) just after

turning on the power.

7) If silicone materials (e.g., silicone rubbers, silicone oils, silicone coating agents,

silicone sealers) are used in the vicinity of

the relay , the gas emitted from the silicone

may adhere to the contacts of the relay

during opening and closing and lead to

improper contact. If this is the case , use a

material other than silicone.

8) We recommend latching type when using in applications which involve lengthy

duty cycles.

* Japanese Industrial Standards

12/2/2002 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

16

Go To Online Catalog

Loading...

Loading...