Page 1

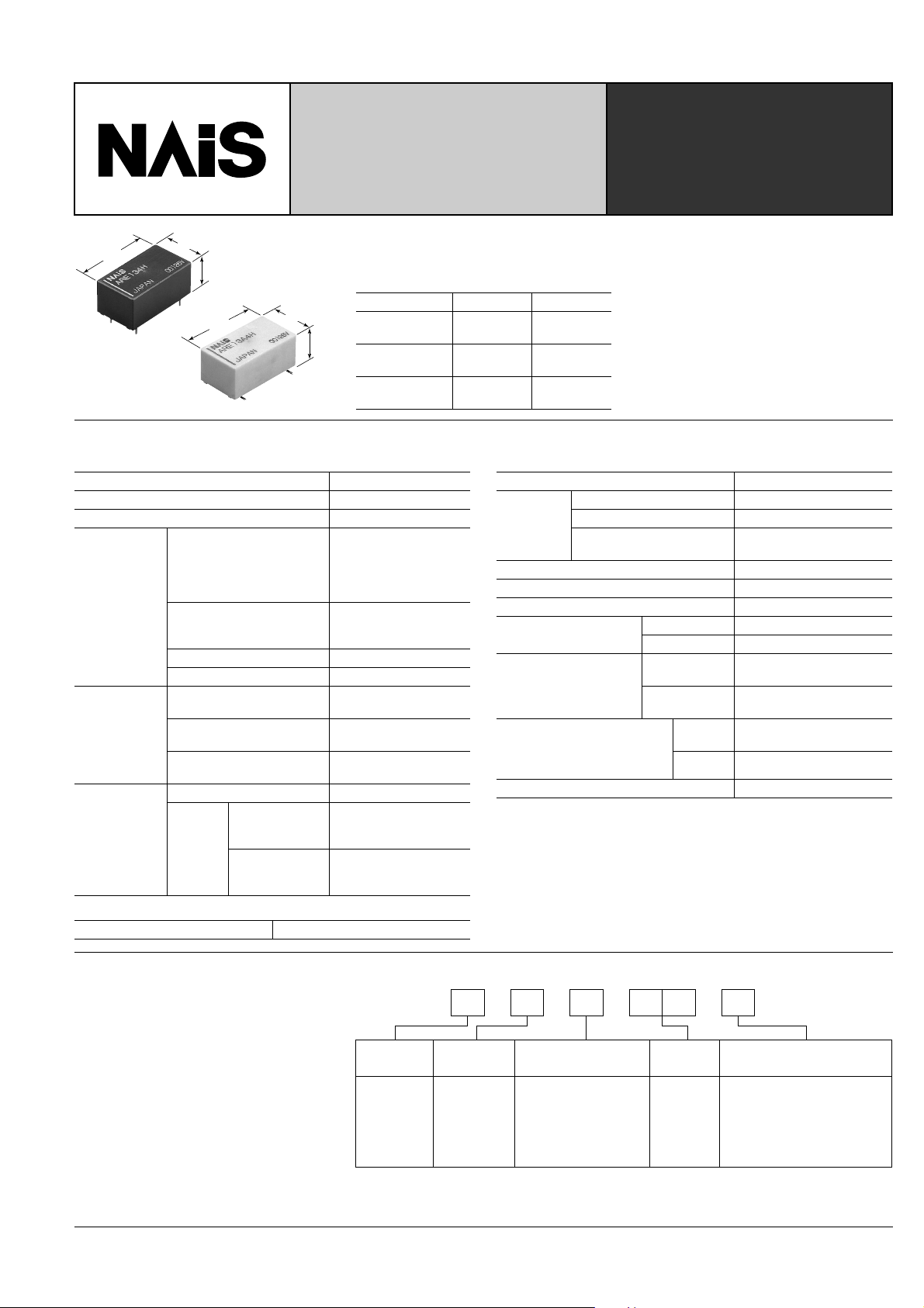

2.6 GHz 75Ω RELAYS FOR

BROADCASTING INDUSTRY

RE-RELAYS

20.2

.795

11.2

.441

8.9

.350

20.2

.795

11.2

.441

FEATURES

• Excellent high frequency characteristics (Impedance 75Ω)

Frequency 900MHz 2.6GHz

V.S.W.R.

9.6

.378

(Max.)

Insertion loss

(dB, Max.)

Isolation

mm inch

(dB, Min.)

SPECIFICATIONS

Contact

Arrangement 1 Form C

Contact material Gold

Initial contact resistance Max. 100m

Contact rating

75 Ω, V .S.W .R. Max.1.5)

Rating

Contact carrying power

Max. switching voltage 30 V DC

Max. switching current 0.5 A DC

(at 2.6 GHz, Impedance

Max. 1.2 (to 900MHz)

Max. 1.5 (to 2.6GHz)

Max. 0.2 (to 900MHz)

Max. 0.5 (to 2.6GHz)

Min. 60dB (to 900MHz)

Min. 30dB (to 2.6GHz)

High frequency

characteristics

(Impedance

75Ω)

V.S.W.R.

Insertion loss

Isolation

Mechanical (at 180 cpm) 10

1W, 2.6GHz,

Expected life

(min. operations)

Electrical

Impedance 75Ω,

V.S.W.R. & 1.5

10mA 24V DC

(resistive load)

(at 20cpm)

Coil (at 20°C, 68°F)

Nominal operating power 200 mW

1W

10mA 24V DC

(resistive load)

10W (at 2.6GHz,

Impedance 75 Ω,

V.S.W.R. Max.1.5)

3×10

3×10

• Surface-mount terminal type also

available

1.2 1.5

0.2 0.5

60 30

Characteristics

Initial insulation resistance*

Ω

Initial

breakdown

voltage*

Between open contacts 500 Vrms

Between contact and coil 1,000 Vrms

2

Between contact and

ground terminal

1

Operate time*3 (at 20°C) Max. 10ms

Release time (without diode)*3 (at 20°C) Max. 5ms

Temperature rise (at 20°C)*

Shock resistance

4

Functional*

Destructive*

Functional*

Vibration resistance

Destructive

Conditions for operation,

transport and storage*8

(Not freezing and condensing

at low temperature)

6

Unit weight Approx. 5 g .18 oz

Ambient

temp.

Humidity 5 to 85% R.H.

Remarks

5

5

* Specifications will vary with foreign standards certification ratings.

1

Measurement at same location as "Initial breakdown voltage" section.

*

*2Detection current: 10mA

*3Nominal operating voltage applied to the coil, excluding contact bounce time.

4

By resistive method, nominal voltage applied to the coil: Contact carrying power:

*

10W, at 2.6GHz, Impedance 75Ω, V .S.W.R. & 1.5

5

Half-wave pulse of sine wave: 11ms, detection time: 10µs.

*

*6Half-wave pulse of sine wave: 6ms

7

Detection time: 10µs

*

*8Refer to 5. Conditions for operation, transport and storage mentioned in NOTES

Min. 100 MΩ (at 500 V DC)

500 Vrms

Max. 60°C

5

7

Min. 500 m/s2{50 G}

6

Min. 1,000 m/s2{100 G}

10 to 55 Hz at double

amplitude of 3 mm

10 to 55 Hz at double

amplitude of 5 mm

–40°C to 60°C

–40°F to 140°F

TYPICAL APPLICATIONS

Broadcasting market

• Set Top Box (CS/BS tuner, CATV tuner)

• Multi-function TV

• Measuring instruments for broadcasting

ORDERING INFORMATION

Ex.

ARE 1 3

Contact

arrangement

1: 1 Form C 3: Single side

Note: Tape and reel packing symbol “-Z” is not marked on the relay.

“X type tape and reel packing (picked from 8/9/10/11/12/13/14-pin side) is also availabe.

Suffix “X” instead of “Z”.

Operating

function

stable type

Terminal shape

Nil:A:Standard PC board

terminal

Surface-mount

terminal

Coil voltage

(DC)

03: 3 V

4H: 4.5 V

06: 6 V

09: 9 V

12: 12 V

24: 24 V

Packing style

Nil:Z:Carton (PC board terminal)

Tube (Surface-mount

terminal)

Tape and reel packing

(picked from 1/7 pin side)

77

Page 2

RE

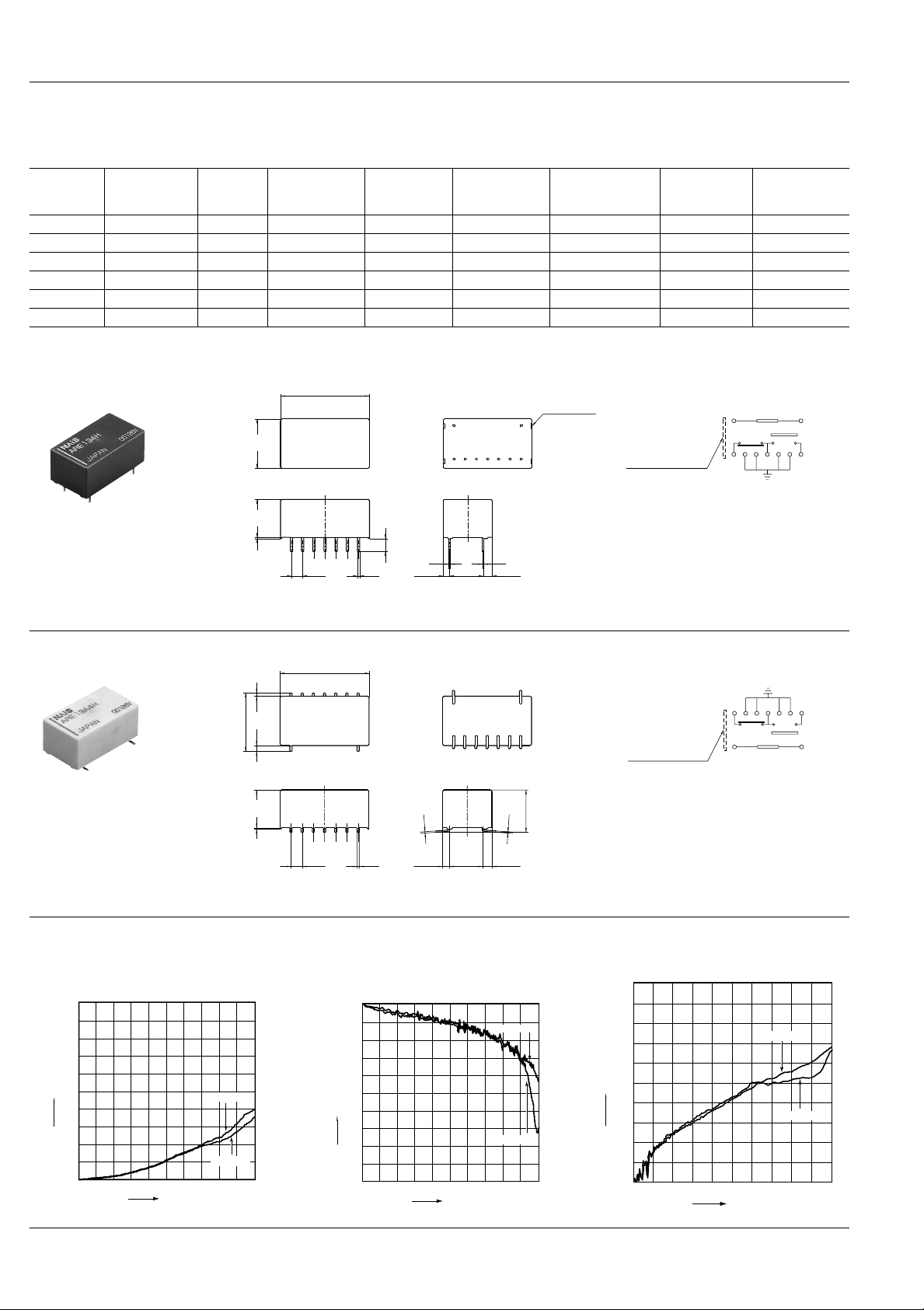

TYPES AND COIL DATA (at 20°C 68°F)

• Packing of standard PC board terminal: 50 pcs. in an inner package (carton); 500 pcs. in an outer package

• Packing of surface-mount terminal: 25 pcs. in an inner package (tube); 200 pcs. in an outer package

400 pcs. in an inner package (tape and reel); 800 pcs. in an outer package

Standard

PC board

terminal

Surface-mount

terminal

ARE1303 ARE13A03 3 2.25 0.3 45 66.7 200 3.3

ARE134H ARE13A4H 4.5 3.375 0.45 101 44.4 200 4.95

ARE1306 ARE13A06 6 4.5 0.6 180 33.3 200 6.6

ARE1309 ARE13A09 9 6.75 0.9 405 22.2 200 9.9

ARE1312 ARE13A12 12 9 1.2 720 16.7 200 13.2

ARE1324 ARE13A24 24 18 2.4 2,880 8.3 200 26.4

Nominal

voltage,

V DC

Pick-up voltage,

V DC (max.)

(initial)

Drop-out

voltage, V DC

(min.)(initial)

Coil resistance,

Ω (±

10%)

Nominal

operating current,

mA (±10%)

Nominal oper-

ating power,

mW

Max. allowable

voltage, V DC

DIMENSIONS

1. Standard PC board terminal

2. Surface mount terminal

13.2

.520

±0.5

±.020

11.2

.441

8.6

.339

0.3

.012

(0.7)

(.028)

11.2

.441

(1.3)

(.511)

8.6

.339

2.54

.100

20.2

.795

20.2

.795

0.5

.020

3.0

.118

0.3

.012

(1.49)

7.62

(.059)

.300

General tolerance: ±0.3 ±.012

0.3

.012

0.3

.012

(2.09)

(.082)

0.3

.012

9.6

.378

Stand off

Schematic (Bottom view)

Direction indication

(Deenergized condition)

NC

Schematic (Top view)

Direction indication

(Deenergized condition)

mm inch

71

COM NO

17

891011121314

NOCOMNC

811 10 9121314

REFERENCE DATA

1. High frequency characteristics

(Standard PC board terminal)

• V .S.W.R. characteristics

2.0

1.9

1.8

1.7

1.6

1.5

78

V.S.W.R.

1.4

1.3

1.2

1.1

1

900MHz

Frequency

COM-NO

COM-NC

0.3

.012

3GHz

2.54

.100

0.5

.020

(1.49)

(.059)

7.62

.300

(2.09)

(.082)

General tolerance: ±0.3 ±.012

• Insertion loss characteristics • Isolation characteristics

0

0

0.1

0.2

0.3

0.4

0.5

Insertion loss, dB

0.6

0.7

0.8

0.9

1.0

900MHz

COM-NC

COM-NO

3GHz

Frequency

10

20

30

40

50

Isolation, dB

60

70

80

90

100

900MHz

COM-NC

COM-NO

3GHz

Frequency

Page 3

NOTES

(Avoid

condensation

when used at

temperatures

higher than

0°C32°F)

Temperature, °C °F

Humidity, %R.H.

85

5

0

+32

+60

+140

–40

–40

Tolerance range

(Avoid freezing

when used at

temperatures

lower than

0°C32°F)

1. Coil operating power

Pure DC current should be applied to the

coil. The wav e form should be rectangular.

If it includes ripple, the ripple factor should

be less than 5%.

However, check it with the actual circuit

since the characteristics may be slightly

different.

2. Cleaning

For automatic cleaning, the boiling method is recommended. Avoid ultrasonic

cleaning which subjects the relays to high

frequency vibrations, which may cause

the contacts to stick.

It is recommended that alcoholic solvents

be used.

3. Soldering

1) The soldering shall be performed under

following condition.

Max. 260°C 500°F 10s

Max. 350°C 662°F 3s

The affect of the PCB on the relay will differ depending on the type of PCB used.

Please verify the type of PCB to be used.

Soldering time: within 5s

2) In case of automatic soldering, the following conditions should be observed

(Surface-mount terminal)

(1) Position of measuring temperature

1.0mm .039inch

A: Surface of PC board where relay is mounted.

B: Above the PC board surface.

B

A

(2) IR (infrared reflow) soldering method

A: B:

T5

T4

T3

T2

T1

t1 t3 t4 t5t2

1=150°C 302°F

T

2=160°C 320°F

T

3=183°C 361°F

T

4=245°C 473°F

T

5=270°C 518°F

T

t2 - t1 = 80 to 120 s

5 - t3 = 30 to 40 s

t

4 = 170 to 190 s

t

Temperature rise of relay itself may vary

according to the mounting level or the

heating method of reflow equipment.

Therefore, please set the temperature of

soldering portion of relay terminal and the

top surface of the relay case not to e xceed

the above mentioned soldering condition.

It is recommended to check the temperature rise of each portion under actual

mounting condition before use.

4. Packing style

1) T ape dimensions

+0.1

+.004

−0 dia..059

−0

Relay polarity bar

1.7

.067

R0.75

.030

1.5 .059

1.5

RE Relay

Tape coming out direction

.157

20.0

.787

4

2.0

.079

1.75

±0.15

±.006

20.75

.817

13.85

.545

.069

20.2

.795

40.4

1.591

44

1.732

.016

±0.3

0.4

±.012

+0.2

10.6

−0.3

+.008

.417

−.012

2) Dimensions of plastic reel

±0.8

21

dia.

±.031

.827

dia.

380

14.961

±0.2

±.008

.079

±0.1

80

±.004

3.150

±0.2

13

dia.

±.008

.512

±0.5

2.0

±.020

dia.

44.4

1.748

Max. 50.5

1.988

+0.2

−0

+.008

−0

5. Conditions for operation, transport

and storage

1) Ambient temperature, humidity, and atmospheric pressure during usage, transport, and storage of the relay:

(1) T emper ature:

–40 to +60°C –40 to +140°F

(2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the temperature. Use within the range indicated

in the graph below.

(3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for usage, transport, and storage:

2) Condensation

Condensation forms when there is a sudden change in temperature under high

temperature and high humidity conditions.

Condensation will cause deterioration of

the relay insulation.

3) Freezing

Condensation or other moisture may

freeze on the relay when the temperature

is lower than 0°C 32°F. This causes problems such as sticking of movab le parts or

operational time lags.

4) Low temperature, low humidity en vironments

The plastic becomes brittle if the relay is

exposed to a low temperature, lo w humidity environment for long periods of time.

RE

For Cautions for Use, see Relay Technical Information (Page 48 to 76).

3/7/2002 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

79

Loading...

Loading...