Page 1

APW7138

High-Performance Notebook PWM Controller

Features

• Adjustable Output Voltage from +0.6V to +3.3V

- 0.6V Reference Voltage

- ±1% Accuracy Over Temperature

• Operates from an Input Battery Voltage Range of

+3V to +25V

• Wide Output Load Range from 0A to 25A

• Power-On-Reset Monitoring on VCC Pin

• Excellent Line and Load Transient Response

• PFM Mode for Increased Light Load Efficiency

• Programmable PWM Frequency from 200kHz to

600kHz

• Integrated MOSFET Drivers and Bootstrap Diode

• Internal Integrated Soft-Start and Soft-Stop

• Selectable Forced PWM or Automatic PFM/PWM

Mode (only for QFN4x4-16A and TQFN3x3-16

Packages)

• Power Good Monitoring

• Fault Identification by PGOOD Pull-Down

Resistance

• 70% Under-Voltage Protection (UVP)

• 124% Over-Voltage Protection (OVP)

• Adjustable Over-Current Protection (OCP)

- Sensing Low-Side MOSFET’s Current

• Over-Temperature Protection (OTP)

• SSOP-16, Compact 4mmx4mm QFN-16 (QFN4x4-

16A), and TQFN3x3-16 Packages

• Lead Free and Green Devices Available

(RoHS Compliant)

General Description

The APW7138 is a single-phase, constant-on-time, and

synchronous PWM controller which drives N-channel

MOSFETs. The APW7138 steps down high voltage of a

battery to generate low-voltage chipset or RAM supplies

in notebook computers.

The APW7138 provides excellent transient response and

accurate DC voltage output in either PFM or PWM Mode.

In Pulse Frequency Modulation (PFM) Mode, the APW7138

provides very high efficiency over light load with loadingmodulated switching frequencies. When the inductor

current is continuous, the operation automatically enters

PWM mode with relatively constant switching frequency.

For QFN4x4-16A and TQFN3x3-16 packages, the ForcedPWM Mode works nearly at constant frequency for lownoise requirements.

The APW7138 is equipped with accurate over-current,

output under-voltage, and over-voltage protections perfect for NB application. A Power-On-Reset function monitors the voltage on VCC pin to prevent errorneous operation during power-on. The APW7138 has a digital softstart and soft-stop. The internal integrated soft-start ramps

up the output voltage with controlled slew rate to reduce

the start-up current. The digital soft-stop function actively

discharges the output capacitors with controlled reverse

inductor current.

The APW7138 is available in SSOP-16, QFN4x4-16A, and

TQFN3x3-16 packages.

Applications

• PCI Express Graphical Processing Unit

• Notebook Adapter

• Auxiliary Power Rail

• VRM

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

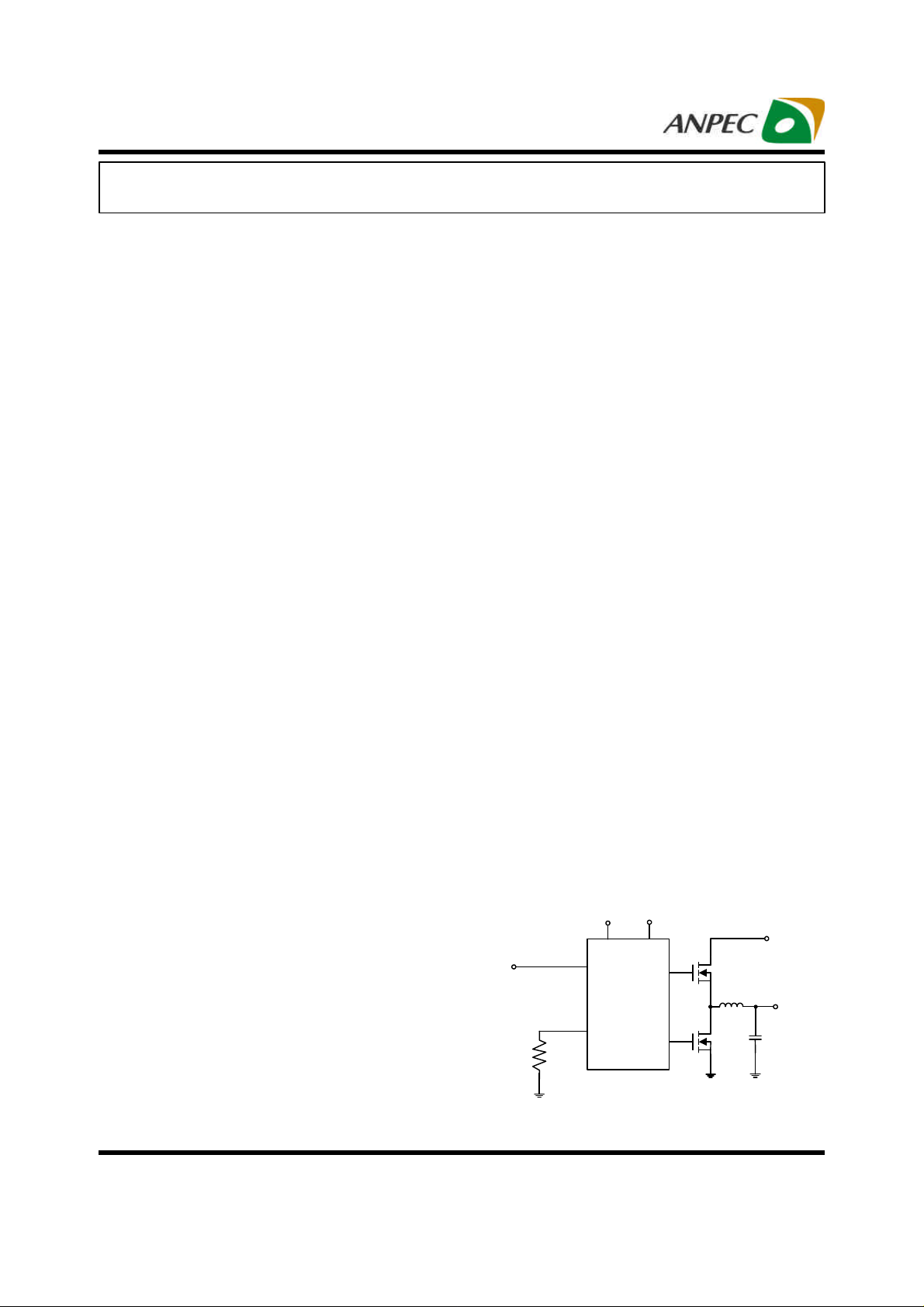

Simpilfied Application Circuit

V

+3V~25V

L

IN

V

OUT

FCCM

(Only QFN)

R

FSET

VCC=5V

APW7138

EN

Q1

Q2

www.anpec.com.tw1

Page 2

APW7138

Ordering and Marking Information

APW7138

Assembly Material

Handling Code

Temperature Range

Package Code

APW7138 N :

APW7138 QA :

APW7138 QB :

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

APW7138

XXXX

APW7138

XXXX

APW

7138

XXXX

Package Code

N : SSOP-16 QA: QFN4x4-16A QB: TQFN3x3-16

Operating Ambient Temperature Range

I : -40 to 85 oC

Handling Code

TR : Tape & Reel

Assembly Material

G : Halogen and Lead Free Device

XXXXX - Date Code

XXXXX - Date Code

XXXXX - Date Code

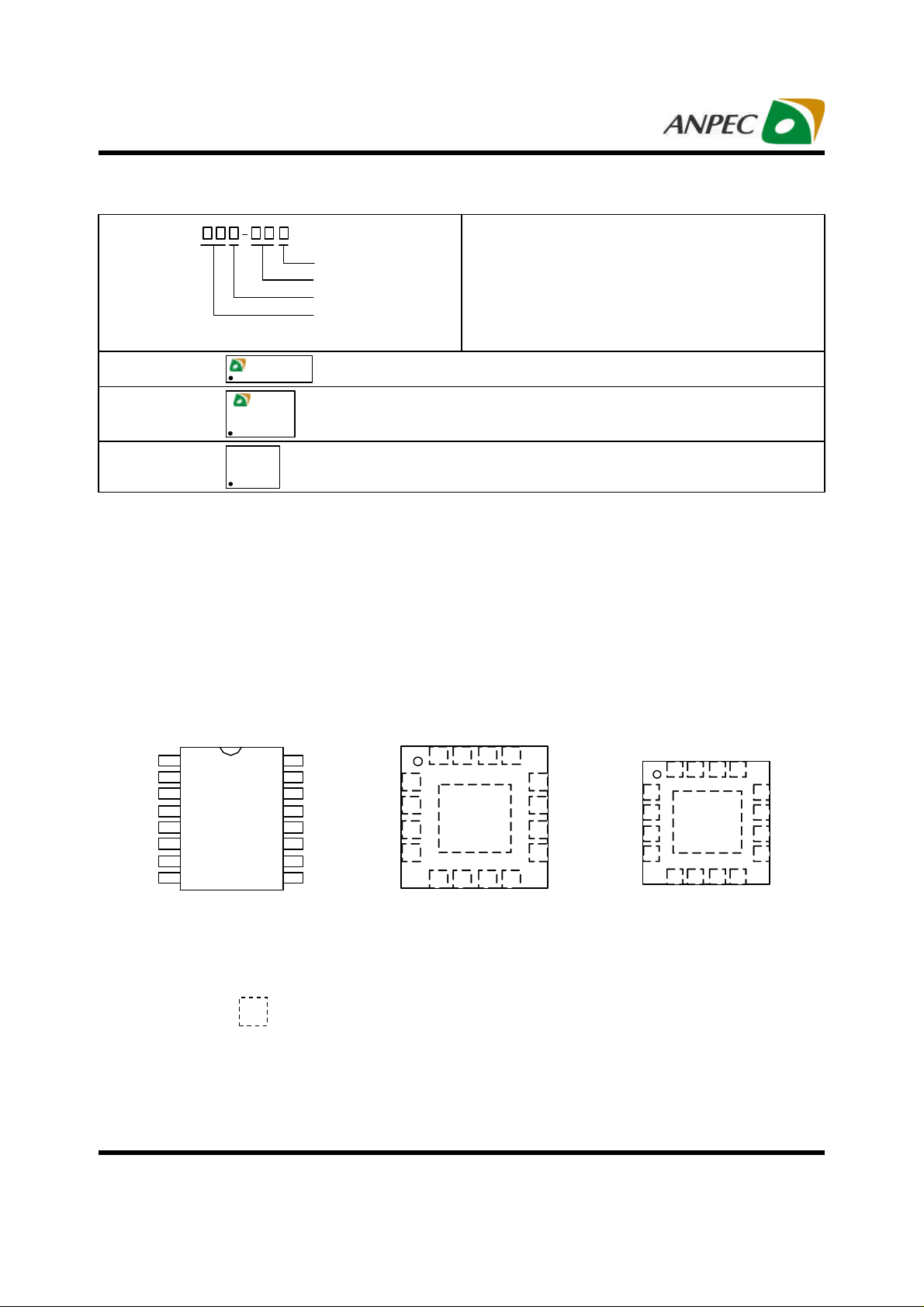

Pin Configuration

VIN

VCC

EN

NC

FB

GND

1

2

3

4

5

6

7

8

SSOP-16

(TOP VIEW)

16

UG

BOOT

15

PVCC

14

13

LG

12

PGND

ISEN

11

VO

10

9

FSET

= Thermal Pad (connected to GND plane for better heat dissipation)

PHASE

PGOOD

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

VIN

VCC

FCCM

EN

1

2

3

4

PHASE

PGOOD

NC

UG

1516 14 13

Metal

GND Pad

(Bottem)

65 7 8

FB

FSET

QFN4x4-16A

(TOP VIEW)

BOOT

12

PVCC

11

LG

10

PGND

ISEN

9

VO

VIN

VCC

FCCM

EN

1

2

3

4

PHASE

UG

PGOOD

1516 14 13

Metal

GND Pad

(Bottem)

65 7 8

FB

NC

FSET

TQFN3x3-16

(TOP VIEW)

www.anpec.com.tw2

BOOT

12

PVCC

11

LG

PGND

10

ISEN

9

VO

Page 3

APW7138

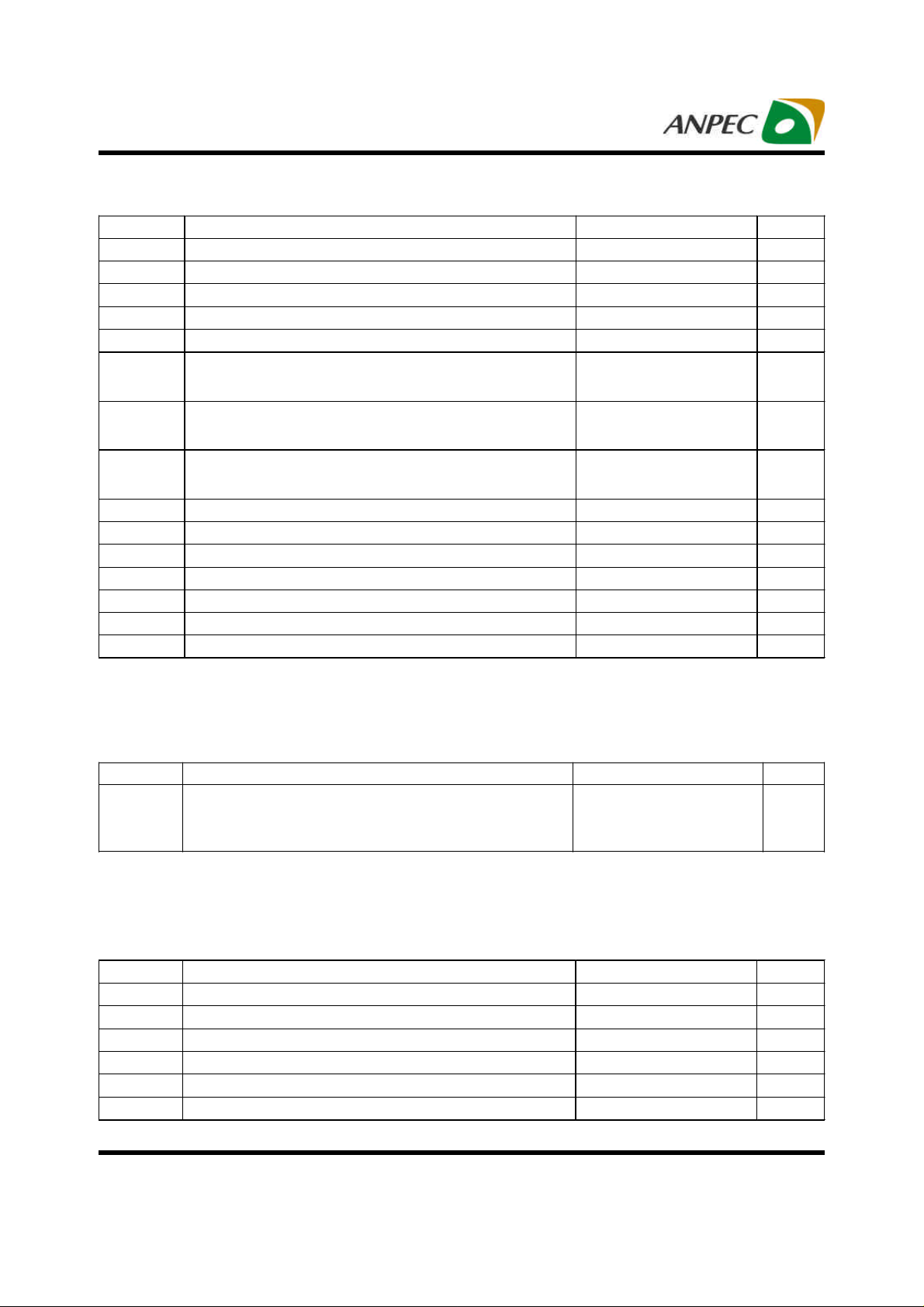

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VCC VCC Supply Voltage (VCC to GND) -0.3 ~ 7 V

V

PVCC Supply Voltage (PVCC to GND) -0.3 ~ 7 V

PVCC

VIN Input Power Voltage (VIN to GND) -0.3 ~28 V

V

BOOT Supply Voltage (BOOT to PHASE) -0.3 ~ 7 V

BOOT

V

V

V

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

BOOT Supply Voltage (BOOT to GND) -0.3 ~ 35 V

BOOT-GND

UG Voltage (UG to PHASE)

UG-PHASE

<400ns pulse width

>400ns pulse width

LG Voltage (LG to PGND)

LG-PGND

<400ns pulse width

>400ns pulse width

PHASE Voltage (PHASE to GND)

V

PHASE

<400ns pulse width

>400ns pulse width

V

PGND to GND Voltage -0.3 ~ 0.3 V

PGND

V

ISEN Supply Voltage (ISEN to GND) -0.3 ~ 28 V

ISEN

V

PGOOD Supply Voltage (PGOOD to GND) -0.3 ~ 7 V

PGOOD

V

All Other Pins (VO, FB, EN, FCCM and FSET to GND) -0.3 ~ VCC+0.3 V

I/O

-5 ~ V

-0.3 ~ V

BOOT

BOOT

+0.3

+0.3

-5 ~ VCC+0.3

-0.3 ~ VCC+0.3

-5 ~ 35

-2 ~ 28

TJ Maximum Junction Temperature 150

T

Storage Temperature Range -65 ~ 150

STG

T

Maximum Lead Soldering Temperature, 10 Seconds 260

SDR

V

V

V

°C

°C

°C

Thermal Characteristics (Note 2)

Symbol

Thermal Resistance -Junction to Ambient

θJA

Note 2: θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

of package is soldered directly on the PCB.

Parameter Typical Value Unit

SSOP-16

QFN4x4-16A

TQFN3x3-16

105

40

55

°C/W

Recommended Operating Conditions

Symbol Parameter Range Unit

VCC,V

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

V

VIN

I

OUT

OUT

TA

TJ

VCC, PVCC Supply Voltage 4.5 ~ 5.5 V

PVCC

Converter Output Voltage 0.6 ~ 3.3 V

Converter Input Voltage 3 ~ 25 V

Converter Output Current 0 ~ 25 A

Ambient Temperature -40 ~ 85

Junction Temperature -40 ~ 125

www.anpec.com.tw3

o

C

o

C

Page 4

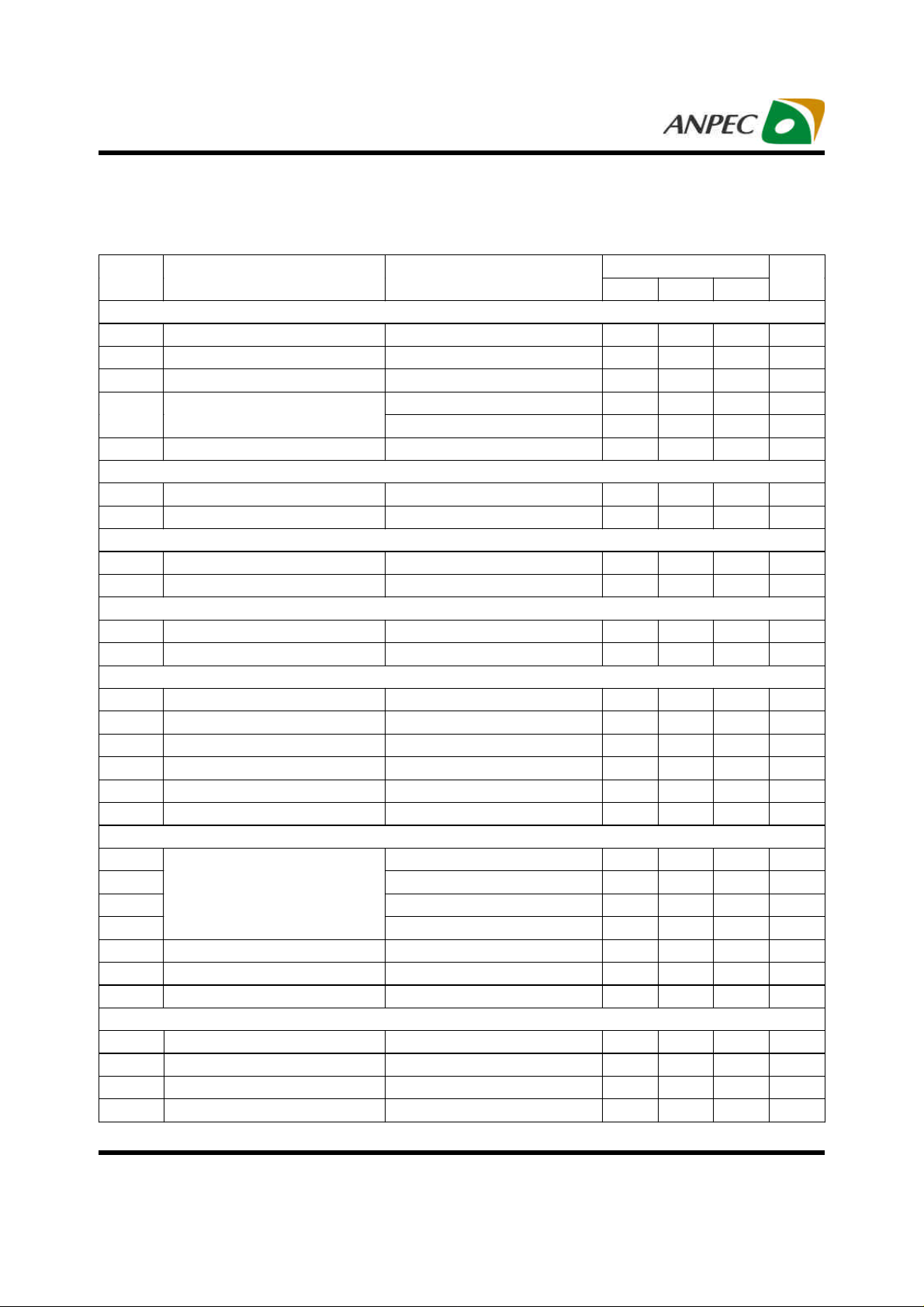

APW7138

Electrical Characteristics

Refer to the typical application circuits. These specifications apply over VCC=5V, VIN=7~25V and TA= -40 ~ 85 °C, unless

otherwise specified. Typical values are at TA=25°C.

Symbol

Parameter Test Conditions

SUPPLY CURRENT

I

VCC Input Bias Current VEN=5V, VFB=0.65V, VIN=7V to 25V - 1.7 2.5 mA

VCC

VCC Shutdown Current VEN=GND, VCC=5V - 0.1 1.0

PVCC Shutdown Current VEN=GND, V

I

VIN Input Bias Current

VIN

VEN=5V, VIN=7V - 6.5 10

VEN=5V, VIN=25V - 25 35

=5V - 0.1 1.0

PVCC

VIN Shutdown Current VEN=GND, VIN=25V - 0.1 1.0

POWER-ON-RESET (POR)

V

VCC_THR

Rising VCC POR Threshold Voltage 4.1 4.2 4.3 V

VCC POR Hysteresis - 0.2 - V

VOLTAGE REGULATION

V

Reference Voltage - 0.6 - V

REF

Regulation Accuracy Over Temperature -1 - +1 %

SWITCHING FREQUENCY

FSW Frequency Range DC Output Current 200 - 600 kHz

Frequency-Set-Accuracy

R

FSET

=44.5kΩ

PWM CONVERTERS

UG Minimum-Off Time Over temperature and VCC - 550 - ns

VO Pin Input Impedance V

= 3.3V - 134 -

OUT

IFB FB Input Bias Current VFB=0.6V -0.5 - +0.5

TSS Soft-Start Time VEN High to V

Regulation

OUT

(Note3)

- 1.5 - ms

Zero-Crossing Voltage Threshold -5 0 +5 mV

On-Time Ratio of PFM to PWM - 1.5 - -

POWER GOOD

R

I

PG_SS

R

I

PG_UV

R

PG_OV

R

PG_OC

I

PGOOD

PGOOD Pull-Down Impedance

I

PGOOD Leakage Current V

=5mA Sink (Soft-Start) 75 95 125

PGOOD

=5mA Sink (Under-Voltage) 75 95 125

PGOOD

=5mA Sink (Over-Voltage) 50 63 85

PGOOD

I

=5mA Sink (Over-Current) 25 32 45

PGOOD

=5V - 0.1 1.0

PGOOD

PGOOD Maximum Sink Current - 5.0 - mA

PGOOD Soft-Start Delay VEN High to V

High 2.20 2.75 3.30 ms

PGOOD

MOSFET GATE DRIVERS

UG Pull-Up Resistance V

UG Source Current V

UG Sink Resistance V

UG Sink Current V

=5V, IUG=0.1A - 1 2

BOOT

=5V, VUG-V

BOOT

=5V, IUG=0.1A - 1 2

BOOT

=5V, VUG-V

BOOT

=2.5V - 2 - A

PHASE

=2.5V - 2 - A

PHASE

APW7138

Min. Typ. Max.

Unit

µA

µA

µA

µA

µA

270 300 330 kHz

kΩ

µA

Ω

Ω

Ω

Ω

µA

Ω

Ω

Copyright ANPEC Electronics Corp.

www.anpec.com.tw4

Rev. A.5 - Jul., 2010

Page 5

APW7138

Electrical Characteristics (Cont.)

Refer to the typical application circuits. These specifications apply over VCC=5V, VIN=7~25V and TA= -40 ~ 85 °C, unless

otherwise specified. Typical values are at TA=25°C.

Symbol

Parameter Test Conditions

APW7138

Min. Typ. Max.

MOSFET GATE DRIVERS (CONT.)

LG Pull-Up Resistance V

LG Source Current V

LG Sink Resistance V

LG Sink Current V

=5V, ILG=0.1A - 1 2

PVCC

=5V, VLG-V

PVCC

=5V, ILG=0.1A - 0.6 1.2

PVCC

=5V, VLG-V

PVCC

=2.5V - 2 - A

PGND

=2.5V - 3 - A

PGND

TD Dead Time - 20 - ns

BOOTSTRAP DIODE

VF Forward Voltage V

PVCC-VBOOT-GND

=5V, IF=2mA - 0.8 - V

IR Reverse Leakage VR=25V - 0.2 -

CONTROL INPUTS

V

FCCMTHR

V

FCCMTHF

V

V

FCCM High Threshold 2.0 - - V

FCCM Low Threshold

EN High Threshold 2.0 - - V

ENR

EN Low Threshold - - 0.8 V

ENF

Only for QFN4x4-16A and

TQFN3x3-16 packages

- - 0.8 V

EN Leakage VEN=5V - 0.1 1.0

PROTECTION

IOC ISEN OCP Threshold I

ISC ISEN Short-Circuit Threshold I

Sourcing 20 26 30

SEN

Sourcing - 50 -

SEN

VUV UVP Threshold 65 70 75 %

UVP Debounce Interval - 2 -

V

OVP Rising Threshold 119 124 129 %

OVR

V

OVP Falling Threshold 99 104 109 %

OVF

OVP Debounce Interval - 2 -

T

OTP Rising Threshold

OTR

OTP Hysteresis

Note 3: Guaranteed by design.

(Note 3)

- 150 -

(Note 3)

- 25 -

Unit

Ω

Ω

µA

µA

µA

µA

µs

µs

o

C

o

C

Copyright ANPEC Electronics Corp.

www.anpec.com.tw5

Rev. A.5 - Jul., 2010

Page 6

APW7138

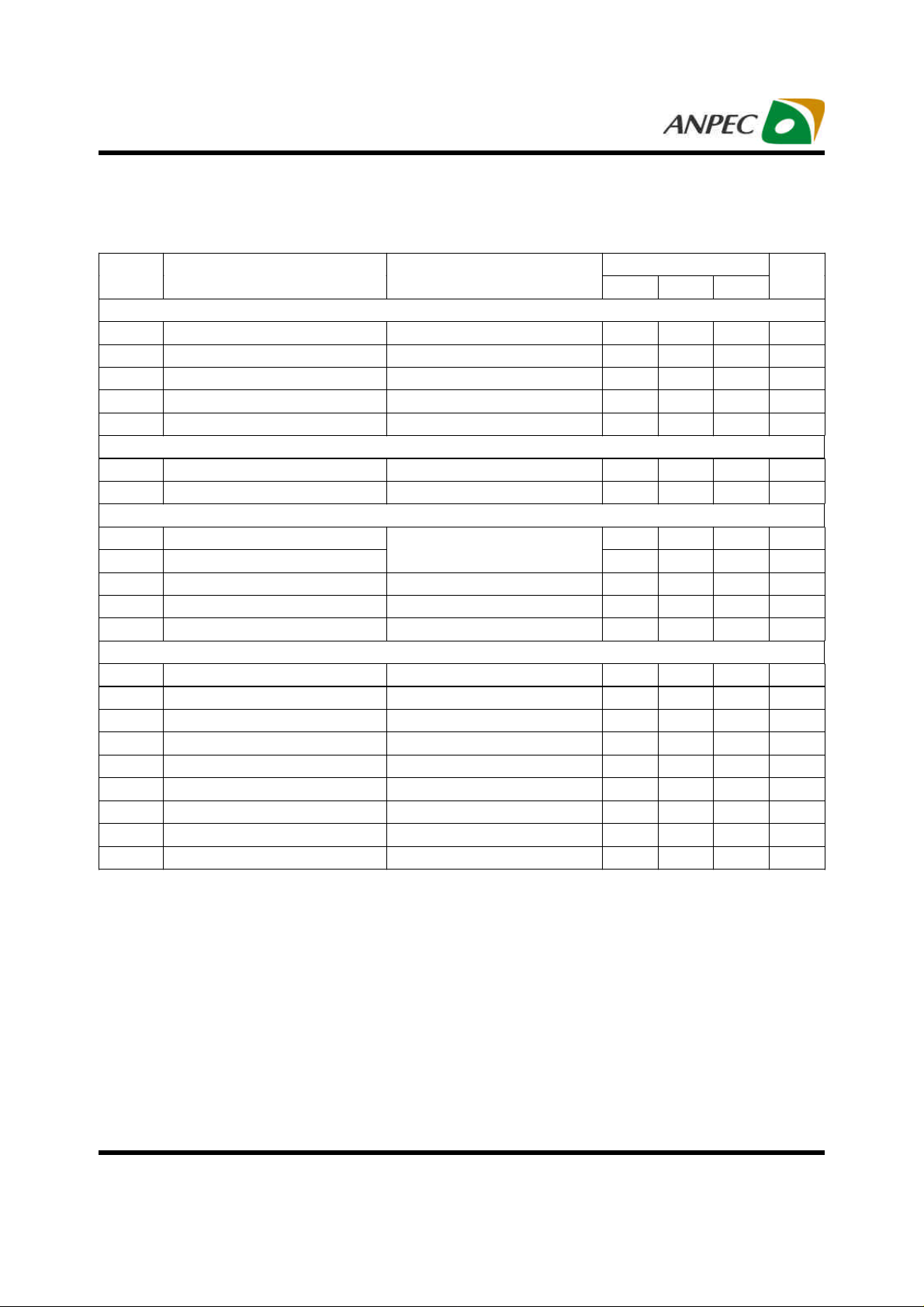

Typical Operating Characteristics

Output Voltage vs. Output Current

1.215

V

=1.2V

1.21

(V)

1.205

OUT

1.2

1.195

Output Voltage, V

1.190

1.185

OUT

V

=19V

IN1

V

=15V

IN1

V

=10V

IN1

0 1 2 3 4 5 6 7 8 9 10

Output Current, I

OUT

Reference Voltage Accuracy Over

Temperature

0.604

0.602

(V)

REF

0.6

0.598

(A)

Switching Frequency (300kHz)

345

335

325

(kHz)

SW

315

305

295

285

275

265

Switching Frequency, F

255

-40

Over Temperature

In PWM Mode

DC Output Current

-20 0 20 40

Junction Temperature, TJ (oC)

Switching Frequency vs. V

330

In PWM Mode

(kHz)

SW

320

310

300

290

DC Output Current

60 80 100 120 140

IN

0.596

Reference Voltage, V

0.594

-40 -20 0

20 40 60 80

Junction Temperature, TJ (oC)

Switching Frequency vs.

Ouput Current

350

300

(kHz)

250

SW

200

150

100

Switching Frequency, F

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

V

=1.2V, I

OUT

50

0

0 1 2 3 4 5 6 7 8 9 10

Output Current, I

OUT

rising

OUT

(A)

100

120 140

280

Switching Frequency, F

270

5 7 9 11 13 15 17 19 21 23 25

Input Voltage, VIN (V)

www.anpec.com.tw6

Page 7

APW7138

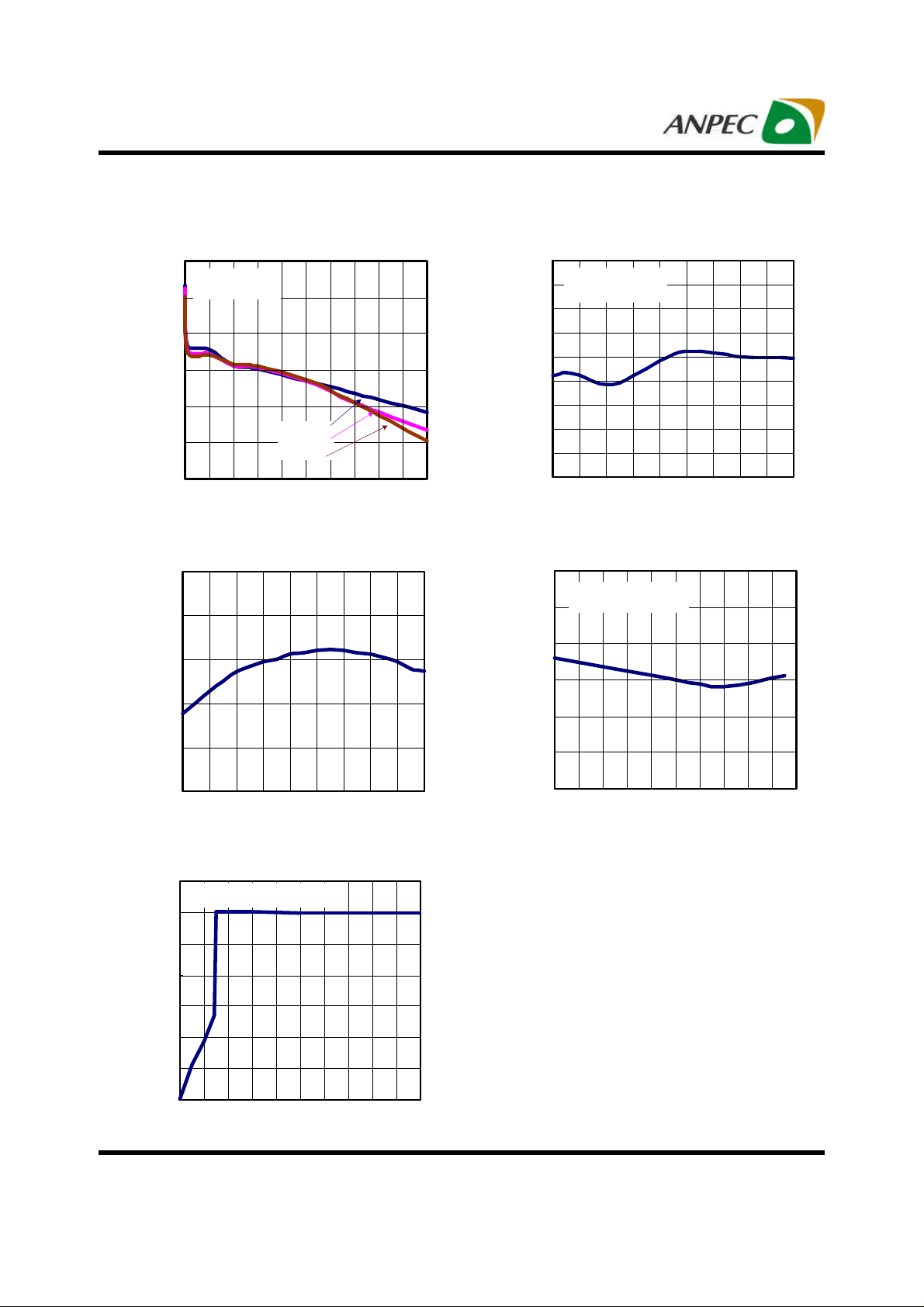

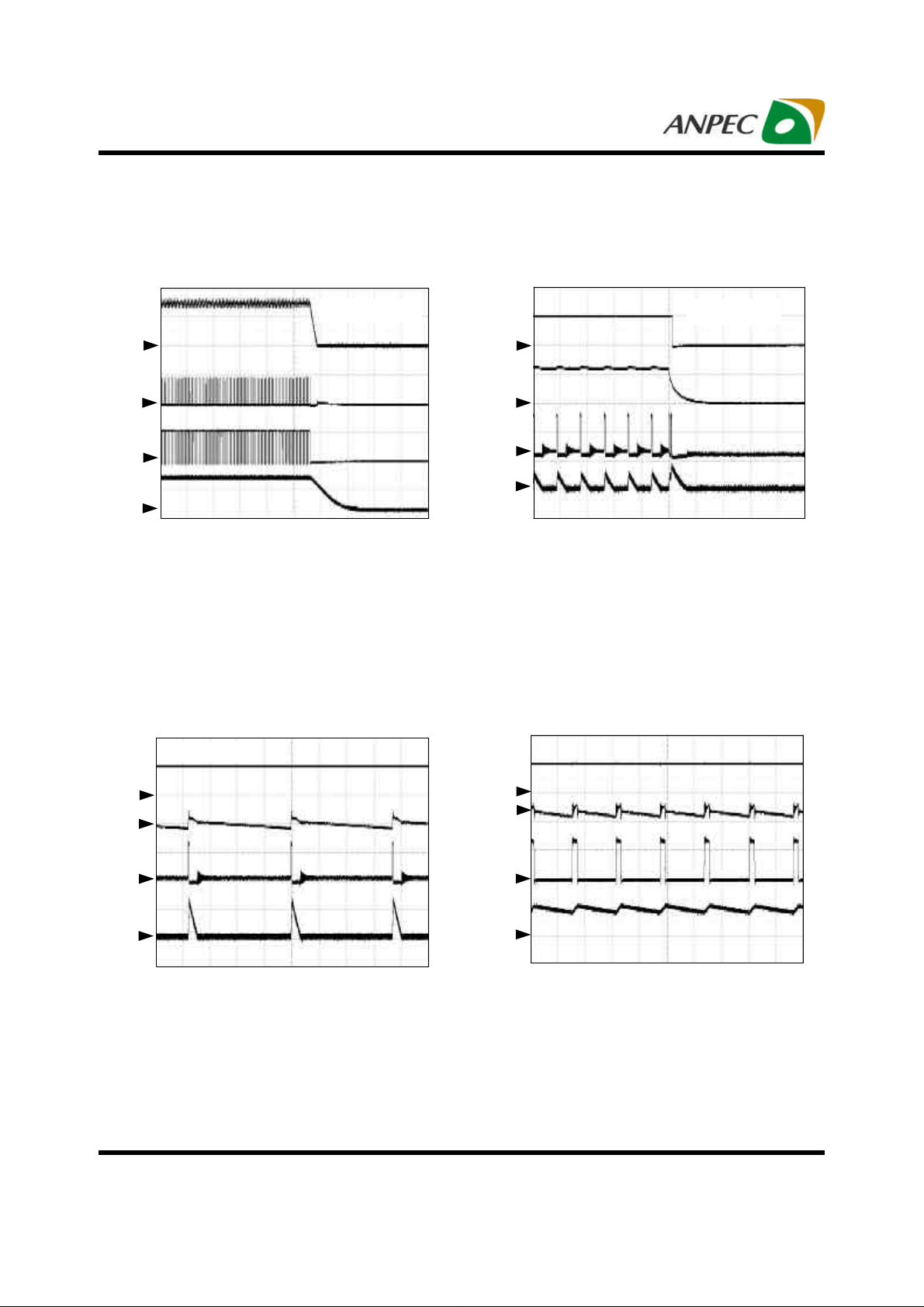

Operating Waveforms

Enable at Zero Initial Voltage of V

I

=5A

OUT

1

2

3

4

CH1: VEN (5V/div)

CH2: V

CH3: V

CH4: V

Time: 2ms/div

OUT

PGOOD

PHASE

(1V/div)

(5V/div)

(10V/div)

Shutdown at I

OUT

=5A

OUT

Enable Before End of Soft-Stop

No Load

1

2

3

4

CH1: VEN (5V/div)

CH2: V

CH3: V

CH4: V

Time: 2ms/div

OUT

PGOOD

PHASE

(1V/div)

(5V/div)

(10V/div)

Shutdown with Soft-Stop at No Load

1

2

3

4

CH1: VEN (5V/div)

CH2: V

CH3: V

CH4: V

Time: 5ms/div

OUT

PGOOD

PHASE

(1V/div)

(5V/div)

(10V/div)

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

1

2

3

4

CH1: VEN (5V/div)

CH2: V

CH3: V

CH4: V

Time: 5ms/div

OUT

PGOOD

PHASE

(1V/div)

(5V/div)

(10V/div)

www.anpec.com.tw7

Page 8

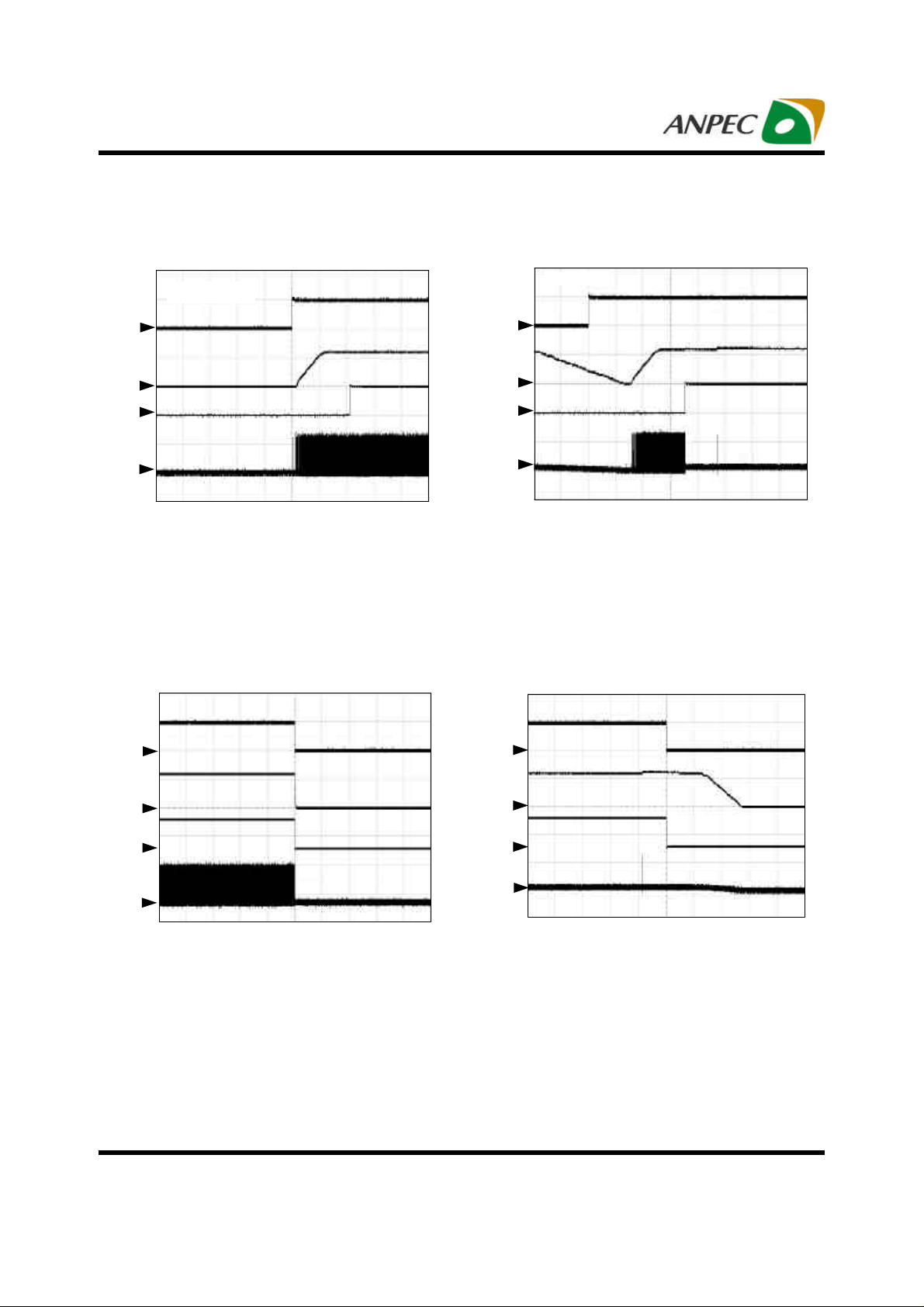

APW7138

Operating Waveforms (Cont.)

Under-Voltage Protection

Short Circuit Test

1

2

3

4

CH1: IL (5A/div)

CH2: V

CH3: VLG (5V/div)

CH4: V

Time: 10µs/div

(20V/div)

UG

(1V/div)

OUT

Mode Transient From PWM to PFM

Mode Transient From PFM to PWM

I

=0.1A to 5A

OUT

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (5A/div)

(5V/div)

PGOOD

(10V/div)

PHASE

(AC, 100mV/div)

OUT

Time: 10µs/div

Load Transient

0A->5A->0A

I

=5A to 0.1A

OUT

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (5A/div)

(5V/div)

PGOOD

(10V/div)

PHASE

(AC, 100mV/div)

OUT

Time: 10µs/div

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

I

OUT1

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (5A/div)

Time: 50µs/div

rise/fall time=1us

(5V/div)

PGOOD

(10V/div)

PHASE

(AC, 100mV/div)

OUT

www.anpec.com.tw8

Page 9

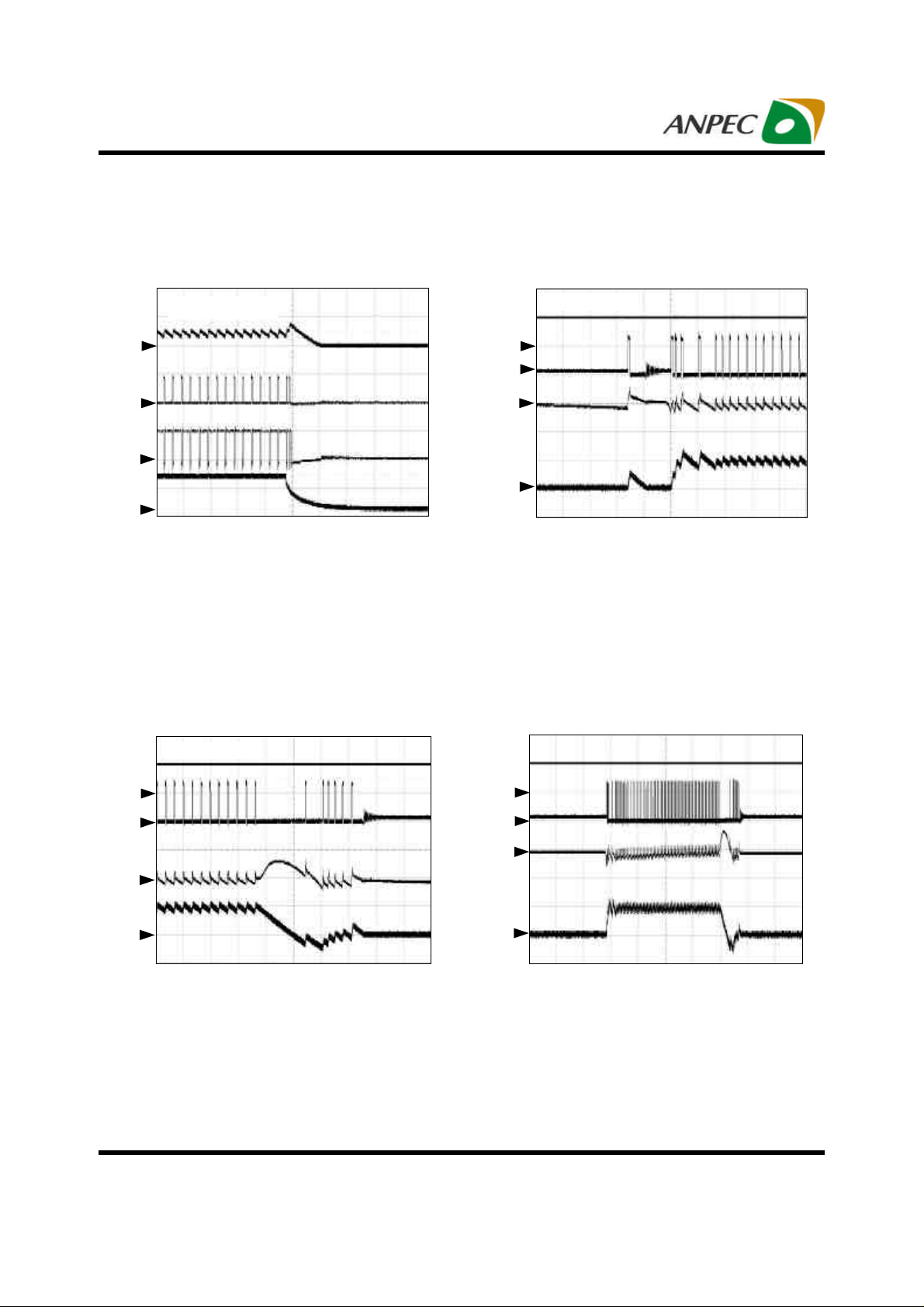

APW7138

Operating Waveforms (Cont.)

Over-Current Protection

1

2

3

4

CH1: IL (5A/div)

CH2: VUG (20V/div)

CH3: VLG (5V/div)

CH4: V

Time: 50µs/div

OUT

(1V/div)

Operating at Light Load of 100mA

I

rises slowly

OUT

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (5A/div)

Time: 20µs/div

Short Circuit Test

In PFM Mode

(5V/div)

PGOOD

(1V/div)

OUT

(10V/div)

PHASE

Operating at Heavy Load of 5A

In PFM Mode

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (2A/div)

(5V/div)

PGOOD

(AC, 100mV/div)

OUT1

(10V/div)

PHASE

Time: 20us/div

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

1

2

3

4

CH1: V

CH2: V

CH3: V

CH4: IL (5A/div)

Time: 2µs/div

(5V/div)

PGOOD

(AC, 100mV/div)

OUT1

(10V/div)

PHASE

www.anpec.com.tw9

Page 10

APW7138

side MOSFET Source, output filter inductor and the

nnect +5V from the VCC pin to

the GND pin. Decoupling at least 1µF of a MLCC capacitor from the VCC pin

, and force PWM is disabled

Output voltage feedback pin. This pin is connected to the resistive divider that

signal to

rect measurement of the converter output voltage. The

+5V from the PVCC pin to the PGND pin. Decoupling at least 1µF of a MLCC

shift circuit. Connect

Pin Description

PIN

NO.

SSOP-16 QFN4x4-16A TQFN3x3-16

1 15 15 PHASE

2 16 16 PGOOD

3 1 1 VIN

4 2 2 VCC

- 3 3 FCCM

5 4 4 EN

6 5 5 NC No Connection.

NAME

Junction point of the highlow-side MOSFET Drain. Connect this pin to the Source of the high-side

MOSFET. PHASE serves as the lower supply rail for the UG high-side gate

driver.

The PGOOD pin is an open-drain output that indicates when the converter is

able to supply regulated voltage. Connect the PGOOD pin to +5V through a

pull-up resistor. The PGOOD pin has three distinct pull-down impedances

that correspond to an OVP (63Ω), OCP (32Ω), UVP (95Ω), and soft-start

(95Ω).

Battery voltage input pin. Connect this pin to the drain of the high-side

MOSFET.

Supply voltage input pin for control circuitry. Co

to the GND pin.

Selection pin for PWM controller to operate in either forced PWM or

automatic PWM/PFM mode. Force PWM mode is enable when FCCM pin is

pulled above the rising threshold voltage V

when the FCCM pin is pulled below the falling threshold voltage V

Enable pin of the PWM controller. The PWM is enabled when EN=1. When

the EN=0, the PWM is shutdown and only low leakage current is taken from

VCC and VIN.

FUNCTION

FCCMTHR

FCCMTHF

.

7 6 6 FB

8 Thermal Pad Thermal Pad GND Signal ground for the IC.

9 7 7 FSET

10 8 8 VO

11 9 9 ISEN

12 10 10 PGND

13 11 11 LG

14 12 12 PVCC

15 13 13 BOOT

16 14 14 UG

set the desired output voltage. The UVP and OVP circuits detect this

report output voltage status.

This pin is allowed to adjust the switching frequency. Connect a resistor R

from the FSET pin to the GND pin.

The VO pin makes a di

VO pin should be connected to the top feedback resistor at the converter

output.

Current sense pin. This pin is used to monitor the voltage drop across the

Drain and Source of the low-side MOSFET for over-current protection. For

precise current detection this input can be connected to the optional current

sense resistor placed in series with the Source of the low-side MOSFET.

Power ground of the LG low-side MOSFET driver. Connect the pin to the

Source of the low-side MOSFET.

Output of the low-side MOSFET driver. Connect this pin to Gate of the

low-side MOSFET. Swings from PGND to VCC.

Supply voltage input pin for the LG low-side MOSFET gate driver. Connect

capacitor from the PVCC pin to the PGND pin.

Supply Input for the UG Gate Driver and an internal levelto an external capacitor and diode to create a boosted voltage suitable to

drive a logic-level N-channel MOSFET.

Output of the high-side MOSFET driver. Connect this pin to Gate of the

high-side MOSFET.

FSET

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw10

Page 11

APW7138

Block Diagram

GND

FB

VCC

EN

124% V

70% V

V

CC

V

REF

POR

VIN

REF

OV

UV

REF

Comparator

Digital

Soft-Start/Soft-Stop

Error

VO

PGOOD

60Ω 90Ω 30Ω

TON

Generator

Thermal

Shutdown

PWM

Frequency

Control

OC

LG

ISEN

I

SEN

V

CC

BOOT

UG

15k

PHASE

PVCC

PWM Signal Controller

LG

PGND

FSET

Typical Application Circuit

APW7138

PGOOD

R

PGOOD

1K

C

+5V

PVCC

1µF

R

VCC

2.2

C

VCC

1µF

Enable

Shutdown

PVCC

VCC

GND

EN1

VIN

UG

BOOT

PHASE

ISEN

LG

PGND

VO

FB

FSET

R

SEN

5.1K

C

BOOT

0.1µF

R

44.5K, 1%

FSET

Q1

APM4810

L

3.3µH

Q2

APM4810

OUT

C

IN

10µF

V

IN

3V~25V

C

OUT

150µFx2

R

GND

10K, 1%

V

OUT

1.2V

R

TOP

10K, 1%

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw11

Page 12

APW7138

Function Description

Constant-On-Time PWM Controller with Input FeedForward

The constant-on-time control architecture is a pseudofixed frequency with input voltage feed-forward. This architecture relies on the output filter capacitor’s effective

series resistance (ESR) to act as a current-sense resistor,

so the output ripple voltage provides the PWM ramp signal.

In PFM operation, the high-side switch on-time controlled

by the on-time generator is determined solely by a oneshot whose pulse width is inversely proportional to input

voltage and directly proportional to output voltage. In PWM

operation, the high-side switch on-time is determined by

a switching frequency control circuit in the on-time generator block. The switching frequency control circuit

senses the switching frequency of the high-side switch

and keeps regulating it at a constant frequency in PWM

mode. This design improves the frequency variation to is

more outstanding than a conventional constant-on-time

controller which has large switching frequency variation

over input voltage, output current, and temperature. Both

in PFM and PWM, the on-time generator, which senses

input voltage on VIN pin, provides very fast on-time response to input line transients.

Another one-shot sets a minimum off-time (typical:

550ns). The on-time one-shot is triggered if the error comparator is high, the low-side switch current is below the

over-current threshold, and the minimum off-time oneshot has timed out.

Pulse-Frequency Modulation (PFM) Mode

In PFM mode, an automatic switchover to pulse-frequency

modulation (PFM) tak es place at light loads. This

switchover is affected by a comparator that truncates the

low-s ide switch on-time at the inductor current zero

crossing. This mechanism causes the threshold between

PFM and PWM operations to coincide with the boundary

between continuous and discontinuous inductor-current

operation (also known as the critical conduction point).

The on-time of PFM mode is designed as 1.5 time of the

nominal on-time of PWM mode. The on-time of PFM is

given by:

OUT

V

T ×=−

PFMON

5.1

IN

SW

V

F

Where FSW is the nominal switching frequency of the converter in PWM mode.

This design provides a hysteresis of converter output

current to prevent wrong or repeatedly PFM/PWM handoff

with constant output current. The load current at handoff

from PFM to PWM mode is given by:

OUTIN

I

LOAD(PFM to PWM)

1

2

=

VV

−

×=

L

OUTIN

VV

−

L2

T

×

ON-PFM

OUT

V

5.1

××

IN

SW

V

F

The load current at handoff from PWM to PFM mode is

given by:

OUTIN

I

LOAD(PWM to PFM)

Therefore, the I

1

2

=

LOAD(PFM to PWM)

VV

−

×=

VV

−

L2

×

L

OUTIN

T

1

SW

F

is 1.5 time of the I

ON-PWM

OUT

V

××

IN

V

LOAD(PWM to PFM)

Forced-PWM Mode (Only for QFN4x4-16A and TQFN3x316 Packages)

The Forced-PWM mode disables the zero-crossing comparator which truncates the low-side switch on-time at

the inductor current zero cross ing. This causes the lowside gate-drive waveform to become the complement of

the high-s ide gate-drive waveform. This in turn causes

the inductor current to rev erse at light loads while UG

maintains a duty factor of V

. The benefit of Forced-

OUT/VIN

PWM mode is to k eep the switching frequency fairly

constant. The Forced-PWM mode is the most useful for

reducing audio frequency noise, improving load-transient

response, and providing s ink-current capability for dynamic output voltage adjustment.

Power-On-Reset

A Power-On-Reset (POR) function is designed to prevent

wrong logic controls when the VCC v oltage is low. The

POR function continually monitors the bias supply voltage on the VCC pin if at least one of the enable pins is set

high. When the rising VCC voltage reaches the rising POR

voltage threshold (4.2V typical), the POR signal goes high

and the chip initiates soft-start operations. When this voltage drop lower than 4V (typical), the POR disables the

chip.

.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw12

Page 13

APW7138

Function Description (Cont.)

Enable Control

When the EN pin is high (EN=1), the PWM is enabled and

the soft-start is initiated. When EN is low (EN=0), the chip

is in the shutdown mode and only low leakage current is

taken from VCC and VIN. In shutdown mode, LG will be

pulled high.

Soft-Start and Soft-Stop

The APW7138 integrates digital soft-start/soft-stop circuits to ramp up/down the output voltage of the converter

to the programmed regulation setpoint at a predictable

slew rate. The slew rate of output voltage is internally

controlled to limit the inrush current through the output

capacitors during soft-start process. The figure 1 shows

soft-start sequence. When the EN pin is pulled above the

rising EN threshold voltage, the device initiates a softstart process to ramp up the output voltage. The soft-start

interval is 1.5ms (ty pical) and independent of the UG

switching frequency.

2.75ms

V

and V

CC

1.5ms

EN

PVCC

V

OUT

In the event of under-voltage or EN shutdown, the chip

enables the soft-stop function. At light load, the soft-stop

gradually ramps down the output voltage, following the

internal falling soft-stop voltage, by controlling the lowside MOSFET working as a sinking linear regulator. At

heavy load, the soft-stop will not regulate the output voltage if the output voltage is below the falling soft-stop

regulation voltage level. The soft-stop process, which

takes about 3 times of the time from VEN high to V

PGOOD

high, is completed when the internal counter finishes

counting. At this moment, the LG goes high level with

latch. Cycling the EN signal or VCC power-on-reset signal can reset the latch.

Under-Voltage Protection (UVP)

In the process of operation, if a short-circuit occurs, the

output voltage will drop quickly. The under-voltage continually monitors the VFB voltage after soft-start process is

completed. If a load step is strong enough to pull the

output voltage lower than the under-voltage threshold,

PGOOD pin will pull down to 95Ω immediately and start a

soft-stop process to shut down the output. The undervoltage threshold is 70% of the normal output voltage.

The under-voltage comparator has a built-in 2µs noise

filter to prevent the chip from wrong UVP shutdown caused

by noise. Toggling EN pin to low, or recycling VCC, will

clear the latch and bring the chip back to operation.

V

PGOOD

Figure 1. Soft-Start Sequence

During soft-start stage before the PGOOD pin is ready,

the under-voltage protection is prohibited. The over-voltage and over-current protection functions are enabled. If

the output capacitor has residue voltage before start-up,

both low-side and high-side MOSFETs are in off-state

until the internal digital soft start voltage equal the V

voltage, which ensures the output voltage starts from its

existing voltage level.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

Over-Voltage Protection (OVP)

The over-voltage function monitors the output voltage by

FB pin. When the V

voltage increase over 124% of the

FB

reference voltage due to the high-side MOSFET failure or

for other reasons, the over-voltage protection comparator is designed with a 2µs noise filter will force the lowside MOSFET gate driver to be high. This action actively

pulls down the output voltage. When the OVP occurs, the

PGOOD pin will pull down to 63Ω and latch-off the

converter. This OVP scheme only clamps the voltage overshoot and doesn’t invert the output voltage when otherwise activated with a continuously high output from lowside MOSFET driver. It’s a common problem for OVP

FB

schemes with a latch. The OVP fault will remain latched

until cycling the EN signal or VCC power-on-reset signal.

www.anpec.com.tw13

Page 14

APW7138

Function Description (Cont.)

Power Good Indicator

The APW7138 features an open-drain PGOOD output pin

to indicate one of the IC’s working statuses including

soft-start, under-voltage fault, over-current fault, and overvoltage faule. The unique fault-identification capability can

drastically reduce trouble-shooting time and effort.

The pull-down resistance of the PGOOD pin corresponds

to the fault status of the controller. During soft-start or if

an under voltage fault occurs, the PGOOD pull-down resistance is 95Ω, or 32Ω for an over current fault, or 63Ω

for an over voltage fault. The pull-low resistance is undefined if VCC is below the rising/falling POR threshold.

Over-Temperature Protection (OTP)

When the junction temperature increases above the rising threshold temperature TOTR, the IC will enter the

over-temperature protection (OTP) state that suspends

the PWM, which forces the LG and UG gate drivers to

output low voltages. The status of the PGOOD pin does

not change, nor does the converter latch-off. The thermal

sensor allows the converters to start a start-up process

and regulate the output voltage again after the junction

temperature cools by 25oC. The OTP is designed with a

25oC hysteresis to lower the average TJ during continuous thermal overload conditions, which increases lifetime of the APW7138.

Over-Current Protection (OCP) and Short-Circuit Protection (SCP)

The over-current protection (OCP) is designed to resist

the slow slew rate load current; on the other hand, the

short-circuit protection (SCP) is used to take care of rapid

shorted output. The setpoint for OCP and SCP is programmed with resistor R

that is connected across the

SEN

ISEN pin and drain of the low-side MOSFET. The SCP

setpoint is internally set to twice the OCP setpoint.

The inductor current develops a negative voltage across

the R

of the low-side MOSFET that is sampled and

DS(ON)

held shortly before LG gate-driver output goes low. The

OCP fault occurs if I

rises above the OCP threshold

SEN

current IOC (typical :26µA) while attempting to null the nega-

tive voltage across the PHASE and GND pins. When the

I

exceeds IOC, the OCP counter starts to work.

SEN

Meanwhile, pulses on all the PWM (I

20µs, the OCP will be triggered. When I

> IOC) remains for

SEN

falls below I

SEN

on a PWM puls es before 20µs has elapsed, the counter

will be reset. The SCP fault will occur within 10 µs when

I

exceeds twice IOC. The relationship between the

SEN

sampled current and MOSFET current is given by:

L)ON(DSSENSEN IRRI ×=×

Which means the current sensing pin will source current

to make the voltage drop on the MOSFET and is equal to

the voltage generated on the sensing resistor along the

ISEN pin current flowing path.

In the formula, the value of R

SEN

R×=

IR

OC

I

is then written as:

SEN

)OC(OUT)ON(DS

where:

- R

is the resistor used to program the over-current

SEN

setpoint.

- I

- IOC is the I

is the desired overcurrent setpoint, the setting

OUT(OC)

value is close to the continuous DC load current I

threshold current sourced from the ISEN

SEN

OUT

.

pin that will activate the OCP circuit. The typical value is

26µA.

When the OCP or SCP fault is detected, the PGOOD pin

will pull down to 32Ω and latch off the converter. The fault

will remain latched until the EN pin has been pulled below the falling EN threshold voltage or if VCC has decayed

below the falling POR threshold voltage.

I

PEAK

I

OUT

I

VALLEY

INDUCTOR CURRENT

0

Time

Figure 2. Over-Current Algorithm

Programming the PWM Switching Frequency

The APW7138 does not use a clock signal to produce

PWM. The resistor R

that is connected from the FSET

FSET

pin to the GND pin programs the PWM switching frequency

OC

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw14

Page 15

APW7138

Function Description (Cont.)

Programming the PWM Switching Frequency (Cont.)

FSW. The approximate PWM switching frequency is written as:

SW

F×=

Where:

- FSW is the PWM switching frequency

- R

FSET

- K = 75 x 10

1

FSET

RK

is the FSW programming resistor

-12

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw15

Page 16

APW7138

TOP

GND

Application Information

Output Voltage Setting

The output voltage is adjustable from 0.6V to 3.3V

with a resistor-divider connected with FB, GND, and

converter’s output. Using 1% or better resistors for the

resistor-divider is recommended. The output voltage is

determined by:

V0.61

=×+

OUT

Where 0.6 is the reference voltage, R

connected from converter’s output to FB, and R

resistor connected from FB to GND. Suggested R

R

R

is the resistor

TOP

is the

GND

is

GND

in the range from 1K to 20kΩ. To prevent stray pickup,

locate resistors R

TOP

and R

close to APW7138.

GND

Output Inductor Selection

The duty cycle (D) of a buck converter is the function of

the input voltage and output voltage. Once an output voltage is fixed, it can be written as:

V

OUT

D =

V

IN

The inductor value (L) determines the inductor ripple

current, I

, and affects the load transient reponse.

RIPPLE

Higher inductor value reduces the inductor’s ripple current and induces lower output ripple voltage. The ripple

current and ripple voltage can be approximated by:

OUT

OUTIN

V- V

RIPPLE

I ×

=

SW

V

IN

V

LF

×

Where FSW is the switching frequency of the regulator.

Although the inductor value and frequency are increased

and the ripple current and voltage are reduced, there is a

tradeoff exists between the inductor’s ripple current and

the regulator load transient response time.

A smaller inductor will give the regulator a faster load

transient response at the expense of higher ripple current.

Increasing the switching frequency (FSW) also reduces

the ripple current and voltage, but it will increase the

switching loss of the MOSFETs and the power dissipation of the converter. The maximum ripple current occurs

at the maximum input voltage. A good starting point is to

choose the ripple current to be approximately 30% of the

maximum output current. Once the inductance value has

been chosen, selecting an inductor that is capable of carrying the required peak current without going into

saturation. In some types of inductors, espec ially core

that is made of ferrite, the ripple current will increase

abruptly when it saturates. This results in a larger output

ripple voltage.

Output Capacitor Selection

Output voltage ripple and the transient voltage deviation

are factors that have to be taken into consideration when

selecting an output capacitor. Higher capacitor value and

lower ESR reduce the output ripple and the load transient drop. Therefore, selecting high performance low

ESR capacitors is recommended for switching regulator

applications. In addition to high frequency noise related

to MOSFET turn-on and turn-off, the output voltage ripple

includes the capacitance voltage drop ∆V

voltage drop ∆V

caused by the AC peak-to-peak

ESR

and ESR

COUT

inductor’s current. These two voltages can be represented

by:

RIPPLE

I

OUTC

V

=∆

RIPPLEESR

SWOUT

F8C

ESR

RIV

×=∆

These two components constitute a large portion of the

total output voltage ripple. In some applications, multiple

capacitors have to be parallelled to achieve the desired

ESR value. If the output of the converter has to support

another load with high pulsating current, more capacitors are needed in order to reduce the equivalent ESR

and suppress the voltage ripple to a tolerable level. A

small decoupling capacitor in parallel for bypassing

the noise is also recommended, and the voltage rating

of the output capacitors are also must be considered.

To support a load transient that is faster than the

switching frequency, more capacitors are needed for

reducing the voltage excursion during load step change.

Another aspect of the capacitor selection is that the

total AC current going through the capacitors has to be

less than the rated RMS current specified on the capacitors in order to prevent the capacitor from overheating.

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw16

Page 17

APW7138

Application Information (Cont.)

Input Capacitor Selection

The input capacitor is chosen based on the voltage rating

and the RMS current rating. For reliable operation, selecting the capacitor voltage rating to be at least 1.3 times

higher than the maximum input voltage. The maximum

RMS c urrent rating requirement is approximately I

where I

is the load current.

OUT

OUT

/2,

During power up, the input capacitors have to handle great

amount of surge current. For low-duty notebook

appliactions, ceramic capacitor is recommended. The capacitors must be connected between the drain of highside MOSFET and the source of low-side MOSFET with

very low-impeadance PCB layout.

MOSFET Selection

The applic ation for a notebook battery with a maximum

voltage of 24V, at least a minimum 30V MOSFETs should

be used. The design has to trade off the gate charge with

the R

of the MOSFET:

DS(ON)

• For the low-side MOSFET, before it is turned on, the

body diode has been conducting. The low-side MOSFET

driver will not charge the miller capacitor of this MOSFET.

• In the turning off process of the low-side MOSFET, the

load current will shift to the body diode first. The high dv/

dt of the phase node voltage will charge the miller capacitor through the low-side MOSFET driver sinking current

path. This results in much less switching loss of the lowside MOSFETs. The duty cycle is often very small in high

battery voltage applications, and the low-side MOSFET

will conduct most of the switching cycle; therefore, when

using smaller R

verter can reduce power loss. The gate charge for this

MOSFET is usually of secondary consideration. The highside MOSFET does not have this zero voltage switching

condition; in addition, becaus e it conducts for less time

compared to the low-side MOSFET, the switching loss

tends to be dominant. Priority should be given to the

MOSFETs with les s gate charge, so that both the gate

driver loss, and switching loss, will be minimized.

The selection of the N-channel power MOSFETs are determined by the R

(C

) and maximum output current requirement. The

RSS

losses in the MOSFETs have two components: conduc-

of the low-side MOSFET, the con-

DS(ON)

, reversing transfer capacitance

DS(ON)

tion loss and transition loss. For the high-side and lowside MOSFETs, the losses are approximately given by

the following equations:

P

= I

high-side

P

low-side

= I

OUT

OUT

2(1+ TC)(R

2(1+ TC)(R

DS(ON)

DS(ON)

)D + (0.5)( I

)(1-D)

)(VIN)( tSW)F

OUT

SW

Where

I

is the load current

OUT

TC is the temperature dependency of R

DS(ON)

FSW is the switching frequency

tSW is the switching interval

D is the duty cycle

Note that both MOSFETs have conduction losses while

the high-side MOSFET includes an additional transition

loss. The switching interval, tSW, is the function of the reverse transfer capacitance C

factor in the temperature dependency of the R

can be extracted from the “R

. The (1+TC) term is a

RSS

vs. Temperature” curve

DS(ON)

DS(ON)

and

of the power MOSFET.

Layout Consideration

In any high switching frequency converter, a correct layout is important to ensure proper operation of the

regulator. With power devices switching at higher

frequency, the resulting current transient will cause voltage spike across the interconnecting impedance and

parasitic circuit elements. As an example, consider the

turn-off transition of the PWM MOSFET. Before turn-off

condition, the MOSFET is carrying the full load current.

During turn-off, current stops flowing in the MOSFET and

is freewheeling by the low side MOSFET and parasitic

diode. Any parasitic inductance of the circuit generates a

large voltage spike during the switching interval. In

general, using short and wide printed circuit traces should

minimize interconnecting impedances and the magnitude of voltage spike. Besides, signal and power grounds

are to be kept separate and finally combined using ground

plane construction or single point grounding. The best

tie-point between the signal ground and the power ground

is at the negative side of the output capacitor on each

channel, where there is less noise. Noisy traces beneath

the IC are not recommended. Below is a checklist for

your layout:

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw17

Page 18

APW7138

Application Information (Cont.)

Layout Consideration (Cont.)

• Keep the switching nodes (UG, LG, BOOT, PHASE,

and ISEN) away from sensitive small s ignal nodes since

these nodes are fast moving signals.Therefore, keep

traces to these nodes as short as poss ible and there

should be no other weak signal traces in parallel with

theses traces on any layer.

• The s ignals going through theses traces have both

high dv/dt and high di/dt with high peak charging and discharging current. The traces from the gate drivers to the

MOSFETs (UG, LG) should be short and wide.

• Place the source of the high-side MOSFET and the

drain of the low-side MOSFET as close as possible. Minimizing the impedance with wide layout plane between

the two pads reduces the voltage bounc e of the node. In

addition, the large layout plane between the drain of the

MOSFETs (VIN and PHASE nodes) can get better heat

sinking.

• For accurate current sensing, the ISEN trace should be

a separate trace and independently go to the drain terminal of the low s ide MOSFET. The PGND is the current

sensing circuit reference ground and also the power

ground of the LG low-side MOSFET. On the hand, the

PGND trace should be a separate trace and independently go to the source of the low-side MOSFET. Besides,

the current sense resistor should be close to ISEN pin to

avoid parasitic capacitor effect and noise coupling.

• Decoupling capacitors, the resistor-divider, and boot

capacitor should be close to their pins. (For example, place

the decoupling ceramic capacitor close to the drain of the

high-side MOSFET as close as possible).

• The input bulk capacitors should be close to the drain

of the high-side MOSFET, and the output bulk capacitors

should be close to the loads. The input capacitor’s ground

should be close to the grounds of the output capacitors

and low-side MOSFET.

• Locate the resistor-divider close to the FB pin to mini-

mize the high impedance trace. In addition, FB pin traces

can’t be close to the switching signal traces (UG, LG,

BOOT, PHASE, and ISEN).

0.5mm*

0.65mm 0.3mm

0.5mm*

0.24mm

0.5mm

16 15 14 13

5.59mm

1 2 3 4

0.635mm

2.3mm

0.508mm

QFN4x4-16A

0.508mm

TQFN3x3-16

12 11

SSOP-16

4mm

2.3mm

3mm

1.66mm

1.66mm

5

0.254mm

10 9

7 8

6

0.342mm

* Just Recommend

0.162mm

* Just Recommend

1.625mm

4mm

3mm

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

Figure 3. Rec ommended Minimum Footprint

www.anpec.com.tw18

Page 19

APW7138

Pack age Information

SSOP-16

D

SEE VIEW A

E1

E

h X 45

L

INCHES

0.025 BSC

o

c

θ

0.069

0.197

0.244

0.157

o

8

be

A2

A

A1

VIEW A

1.75

0.25

5.00

6.20

4.00

8

o

SSOP-16

MIN. MAX.

0.004 0.010

0.049

0.008 0.012

0.006 0.010

0.189

0.228

0.150

0.016 0.050

0.010 0.020

0

S

Y

M

B

O

L

A

A2

b

c

D

E

E1

e

L

h

θ

Note: 1. Follow JEDEC MO-137 AB.

2. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion or gate burrs shall not exceed 6 mil per side.

3. Dimension "E" does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

MILLIMETERS

MIN. MAX.

0.10A1

1.24

0.20 0.30

0.15 0.25

4.80

5.80

3.80

0.635 BSC

0.40 1.27

0.25 0.50

o

0

0.25

GAUGE PLANE

SEATING PLANE

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw19

Page 20

APW7138

Pack age Information

QFN4x4-16A

D

Pin 1

D2

Pin 1 Corner

A

E

b

A1

A3

E2KL

S

Y

M

B

O

L

A

A1

A3

b

D

D2

E

E2

e

L

K

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

MIN. MAX.

0.80

0.00

0.25 0.35

3.90 4.10

2.10 2.50

3.90 4.10

2.10

0.30 0.50

0.20

e

QFN4x4-16A

MILLIMETERS

1.00

0.05

0.20 REF

2.50

0.65 BSC 0.026 BSC

INCHES

MIN. MAX.

0.031

0.000

0.008 REF

0.010 0.014

0.154 0.161

0.083 0.098

0.154 0.161

0.083

0.012 0.020

0.008

0.039

0.002

0.098

www.anpec.com.tw20

Page 21

APW7138

Pack age Information

TQFN3x3-16

D

A

A

A1

A3

b

D

D2

E

E2

e

L

K

E

Pin 1

D2

Pin 1

Corner

e

S

Y

M

B

O

L

MILLIMETERS

MIN. MAX.

0.70

0.00

0.20 REF

0.18 0.30

2.90 3.10

1.50 1.80

2.90 3.10

1.50

0.50 BSC 0.020 BSC

0.30 0.50

0.20

TQFN3x3-16

0.80

0.05

1.80

E2

k

INCHES

MIN. MAX.

0.028

0.000

0.008 REF

0.007 0.012

0.114 0.122

0.059 0.071

0.114 0.122

0.059

0.012 0.020

0.008

b

A1

A3

0.031

0.002

0.071

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

Note : Follow JEDEC MO-220 WEED-4.

www.anpec.com.tw21

Page 22

APW7138

0.00

0.00

Carrier Tape & R eel Dimensions

OD0

B0

P0

P2

P1

A

E1

F

W

Application

SSOP-16

Application

QFN4x4-16A

Application

TQFN3x3-16

K0

SECTION A-A

B

A

H

A0

SECTION B-B

OD1

B

T

A

d

T1

A H T1 C d D W E1 F

330.0±2.00 50 MIN.

12.4+2.00

-

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.50±0.10

P0 P1 P2 D0 D1 T A0 B0 K0

4.00±0.10 8.00±0.10 2.00±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

6.40±0.20 5.20±0.20 2.10±0.20

A H T1 C d D W E1 F

330.0±2.00 50 MIN.

12.4+2.00

-

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.5±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 8.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

4.30±0.20 4.30±0.20 1.30±0.20

A H T1 C d D W E1 F

330±2.00 50 MIN.

12.4+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.5±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 8.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

3.30±0.20 3.30±0.20 1.30±0.20

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

(mm)

www.anpec.com.tw22

Page 23

APW7138

Devices Per Unit

Package Type Unit Quantity

SSOP-16

QFN4x4-16A

TQFN3x3-16

Taping Direction Information

SSOP-16

Tape & Reel 2500

Tape & Reel 3000

Tape & Reel 3000

USER DIRECTION OF FEED

QFN4x4-16A

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

USER DIRECTION OF FEED

www.anpec.com.tw23

Page 24

APW7138

Taping Direction Information (Cont.)

TQFN3x3-16

USER DIRECTION OF FEED

Classification Profile

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw24

Page 25

APW7138

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

Temperature min (T

Temperature max (T

Time (T

smin

to T

smax

smin

smax

) (ts)

)

)

Average ramp-up rate

(T

to TP)

smax

Liquidous temperature (TL)

Time at liquidous (tL)

Peak package body Temperature

(Tp)*

Time (tP)** within 5°C of the specified

classification temperature (Tc)

Average ramp-down rate (Tp to T

smax

Time 25°C to peak temperature

See Classification Temp in table 1 See Classification Temp in table 2

)

100 °C

150 °C

60-120 seconds

150 °C

200 °C

60-120 seconds

3 °C/second max. 3°C/second max.

183 °C

60-150 seconds

217 °C

60-150 seconds

20** seconds 30** seconds

6 °C/second max. 6 °C/second max.

6 minutes max. 8 minutes max.

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Table 1. SnPb Eutectic Process – Classification Temperatures (Tc)

Package

Thickness

<2.5 mm

Volume mm

3

Volume mm

<350

235 °C 220 °C

≥350

3

≥2.5 mm 220 °C 220 °C

Table 2. Pb-free Process – Classification Temperatures (Tc)

Package

Thickness

<1.6 mm

1.6 mm – 2.5 mm

Volume mm3

<350

Volume mm3

350-2000

Volume mm3

260 °C 260 °C 260 °C

260 °C 250 °C 245 °C

>2000

≥2.5 mm 250 °C 245 °C 245 °C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102

HOLT JESD-22, A108

PCT JESD-22, A102

TCT JESD-22, A104

HBM MIL-STD-883-3015.7

MM JESD-22, A1 15

Latch-Up JESD 78

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

5 Sec, 245°C

1000 Hrs, Bias @ Tj=125°C

168 Hrs, 100%RH, 2atm, 121°C

500 Cycles, -65°C~150°C

VHBM≧2KV

VMM≧200V

10ms, 1tr≧100mA

www.anpec.com.tw25

Page 26

APW7138

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics Corp.

Rev. A.5 - Jul., 2010

www.anpec.com.tw26

Page 27

Loading...

Loading...