Page 1

Copyright ANPEC Electronics Corp.

Rev.a.2 - Sep., 2001

APW7026

www.anpec.com.tw1

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Advanced PWM and Dual Linear Power Control

Applications

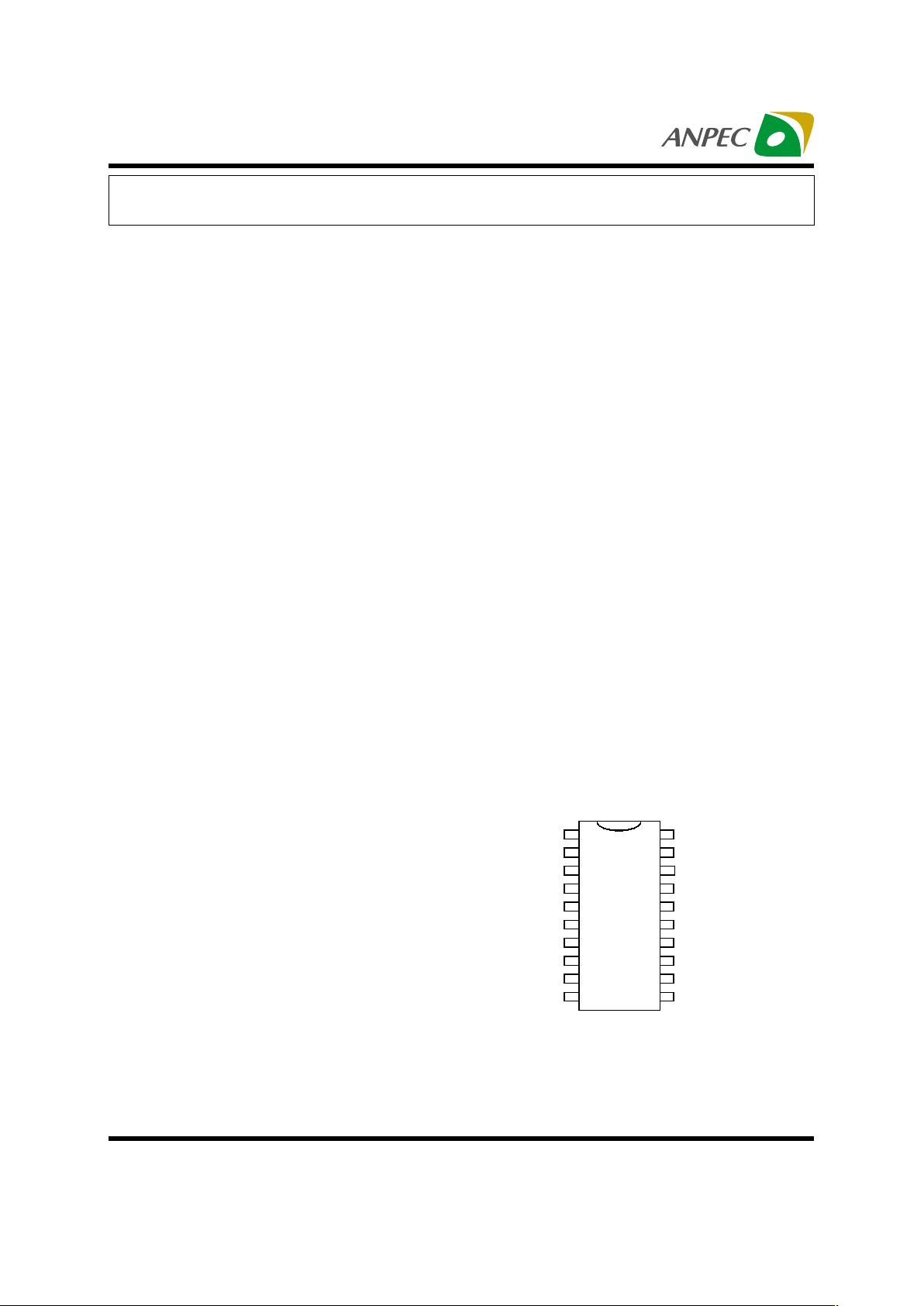

Pin Description

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

UGATE1

VCC

UGATE2

PHA SE2

PG OOD

OCSET 2

FB2

V5

SS

FAULT/RT

PHA SE1

LGATE1

PG ND

OCSET 1

VSE N1

FB1

FB3

GAT E

GND

V3.3

•

VGA Card Power Regulation

Features

••

••

•

3 Regulated Voltage are provided

••

••

• SYNC Switching Power for VTT(1.25V)

••

••

• ASYNC Switching Power for NVVDD(2.05V)

••

••

• Linear Regulator for FBVDDQ(2.5V)

••

••

•

Simple Single-Loop Control Design

••

••

• Voltage-Mode PWM Control

••

••

•

Excellent Output Voltage Regulation

••

••

• VTT Output: ±1% Over Temperature

••

••

• NVVDD Output: ±2% Over Temperature

••

••

• FBVDDQ Output:±2.5% Over Temperature

••

••

• Fast Transient Response

••

••

• On-Chip Feedback Compensation

••

••

• Full 0% to 100% Duty Ratio

••

••

• Power-Good Output Voltage Monitor

••

••

• Over-Voltage and Over-Current Fault Monitors

••

••

• Small Converter Size

••

••

• Constant Frequency Operation(200kHz)

••

••

• Programmable Oscillator from 50kHz to

800KHz

••

••

• Reduce External Component Count

General Description

The APW7026 Provides the power control and

protection for three output voltages in VGA Card

applications. It integrates two PWM controllers, one

linear controller as well as the monitoring and

protection functions into a single package. One PWM

controller (PWM1) regulates the termination voltage

VTT(1.25V) with a synchronous-rectified buck

converter. The second PWM controller (PWM2)

supplies the Core power NVVDD ( 2.05V ) with a

standard buck converter . The linear controller

regulates 2.5V power for FBVDDQ.

The APW7026 can monitor all the output voltages

(VTT ,NVVDD,FBVDDQ) and a single power good

signal is issued when the VTT is within ± 10% of

the reference voltage (VREF1) and the other levels

are above its lower power good threshold voltage.

Additional built-in overvoltage protection (OVP) will

be started when the VTT output is above 118% of

the VREF1.The OVP function will shutdown the upper

MOSFET and turn on the lower MOSFET

until the over-voltage is disappeared. The PWM

controllers over-current function monitors the output current by sensing the voltage drop across the

upper MOSFET rDS(ON), eliminating the need for a

current sensing resistor.

Page 2

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw2

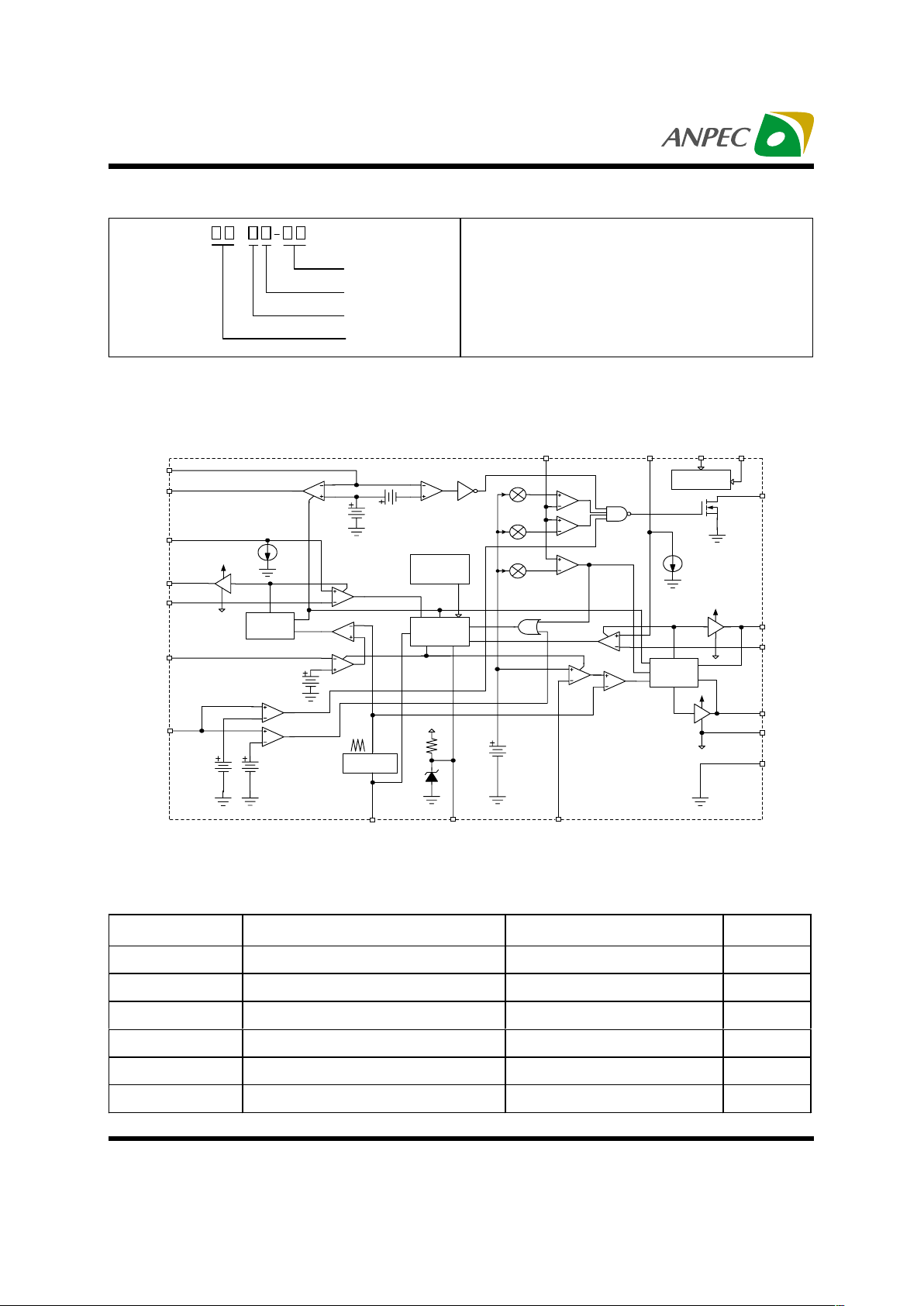

Block Diagram

Absolute Maximum Ratings

Ordering information

Symbol Parameter Rating Unit

VCC Supply Voltage 15 V

VI , V

O

Input , Output or I/O Voltage GND -0.3 V to VCC +0.3 V

T

A

Operating Ambient Temperature Range 0 to 70

o

C

T

J

Junction Temperature Range 0 to 125

o

C

T

STG

Storage Temperature Range -65 to +150

o

C

T

S

Soldering Temperature 300 ,10 seconds

o

C

APW7026

Voltage Code

12 : 1.2 5V

Package Code

K : SOP - 2 0

Te m p. R a ng e

C : 0 to 70

°

C

Handling Code

TU : Tu be TR : Tape & Ree l

Handling Code

Te m p. R a ng e

Package Code

Voltage Code

GATE

CONTROL

SOFT-START

AND FAULT

LOGIC

THERMAL

PROTECTION

GATE

CONTROL

POWER-ON

RESET

FB3

GATE

OCSET2

UGATE2

PHASE2

FB2

V3.3

GND

PGND

LGATE1

PHASE1

UGATE1

PGOOD

V5VCCOCSET1VSEN1

FB1SSFAULT/RT

0.3V

V

4-.!

1.26V

200uA

VCC

DRIVE2 OC2

INHIBIT

PWM2

V

4-.

2.0V

ERROR

AMP2

2.5V 4.1V

5V

OSCILLATOR

23K

4.6V

V

4-.

ERROR

AMP1

0V

FAULT

OC1

PWM1

VCC

LOW ER

DRIVE

VCC

DRIVE1

INHIBIT

118%

90%

110%

200uA

LUV

Page 3

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw3

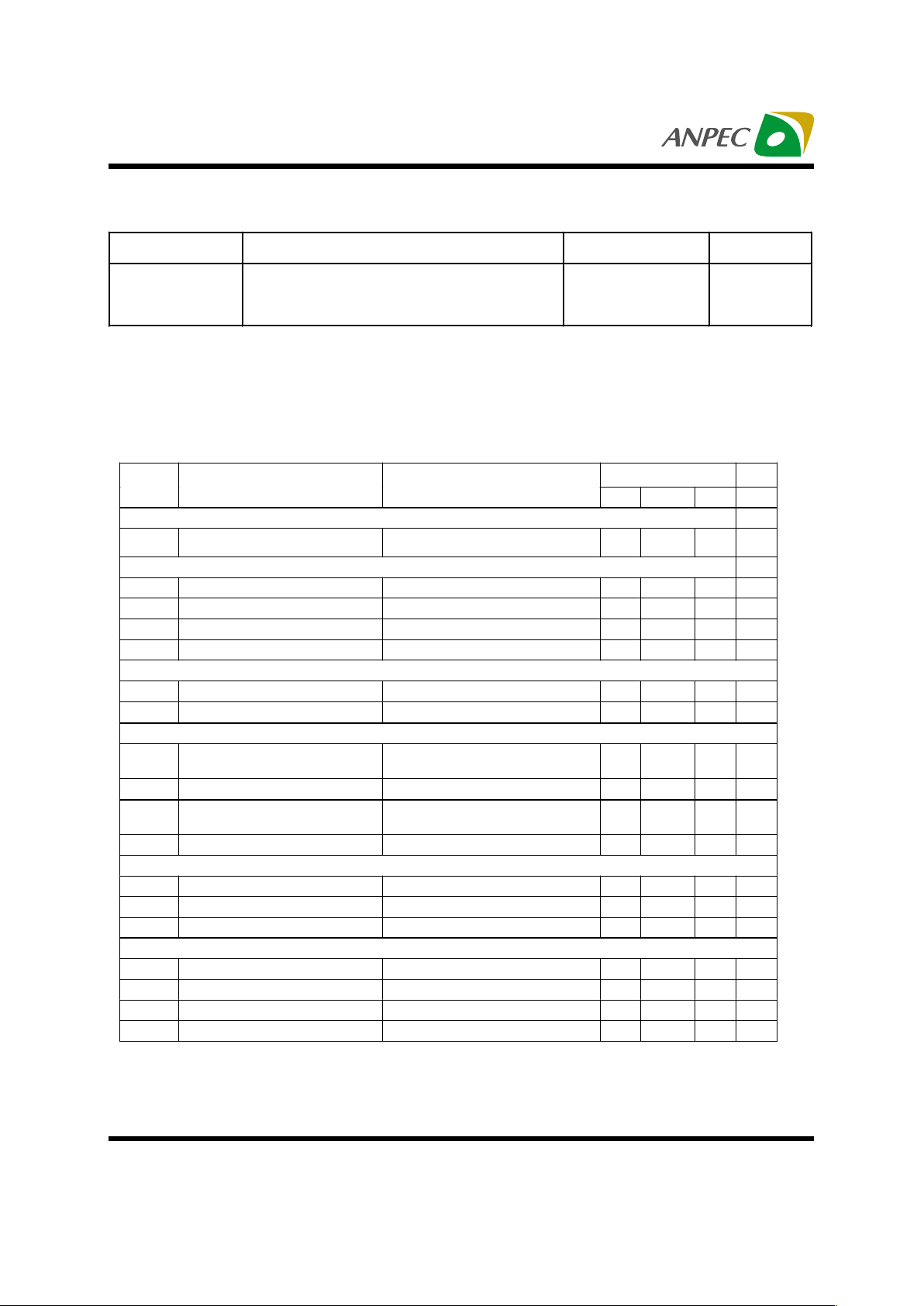

Electrical Characteristics

Thermal Characteristics

Symbol Parameter Value Unit

R

JA

Thermal Resistance in Free Air

SOIC

SOIC (with 3in

2

of Copper)

75

65

o

C

1. Recommended operating conditions, Unless otherwise noted.

2. Refer to Block and Simplified Power System Diagrams , and Typical Application Schematic.

APW7026 Unit

Symbol Parameter Test Conditions

Min Typ Max

SUPPLY CURRENT

I

CC

Nominal Supply Current

UGATE1, LGATE1, UGATE2, and

GATE Open

6mA

POWER-ON RESET

Rising VCC Threshold 9.5 10.4 V

Falling VCC Threshold 8.2 9.0 V

Rising V5 Threshold 4.4 4.7 V

Falling V5 Threshold 3.7 4.0 V

OSCILLATOR

F

OSC

Free Running Frequency RT = Open 185 200 215 kHz

∆

V

OSC

Ramp Amplitude RT = Open 1.9 V

PWM CONTROLLER REFERENCE VOLTAGE

V

REF1

SYNC PWM Controller Reference

Volta ge

1.25 V

V

REF1

Accuracy -1 +1 %

V

REF2

ASYNC PWM Controller Reference

Volta ge

2.0 V

V

REF2

Accuracy -2 +2 %

LINEAR CONTROLLER

V

REF3

Reference Voltage GATE=FB3 1.26 V

V

REF3

Accuracy -2.5 +2.5 %

GATE Drive Current V

GATE

=4V 20 50 mA

PWM CONTROLLERS GATE DRIVERS

I

UGATE

UGATE1,2 Source VCC = 12V, V

UGATE1

(or V

UGATE2

) = 6V 1.0 A

R

UGATE

UGATE1,2 Sink VCC = 12V, V

UGATE1

(or V

UGATE2

) = 1V 2.2 3.5

Ω

I

LGATE

LGATE1 Source VCC = 12V, V

LGATE1

= 1V 1.0

A

R

LGATE

LGATE1 Sink VCC = 12V, V

LGATE1

= 1V 1.6 3.0

Ω

Page 4

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw4

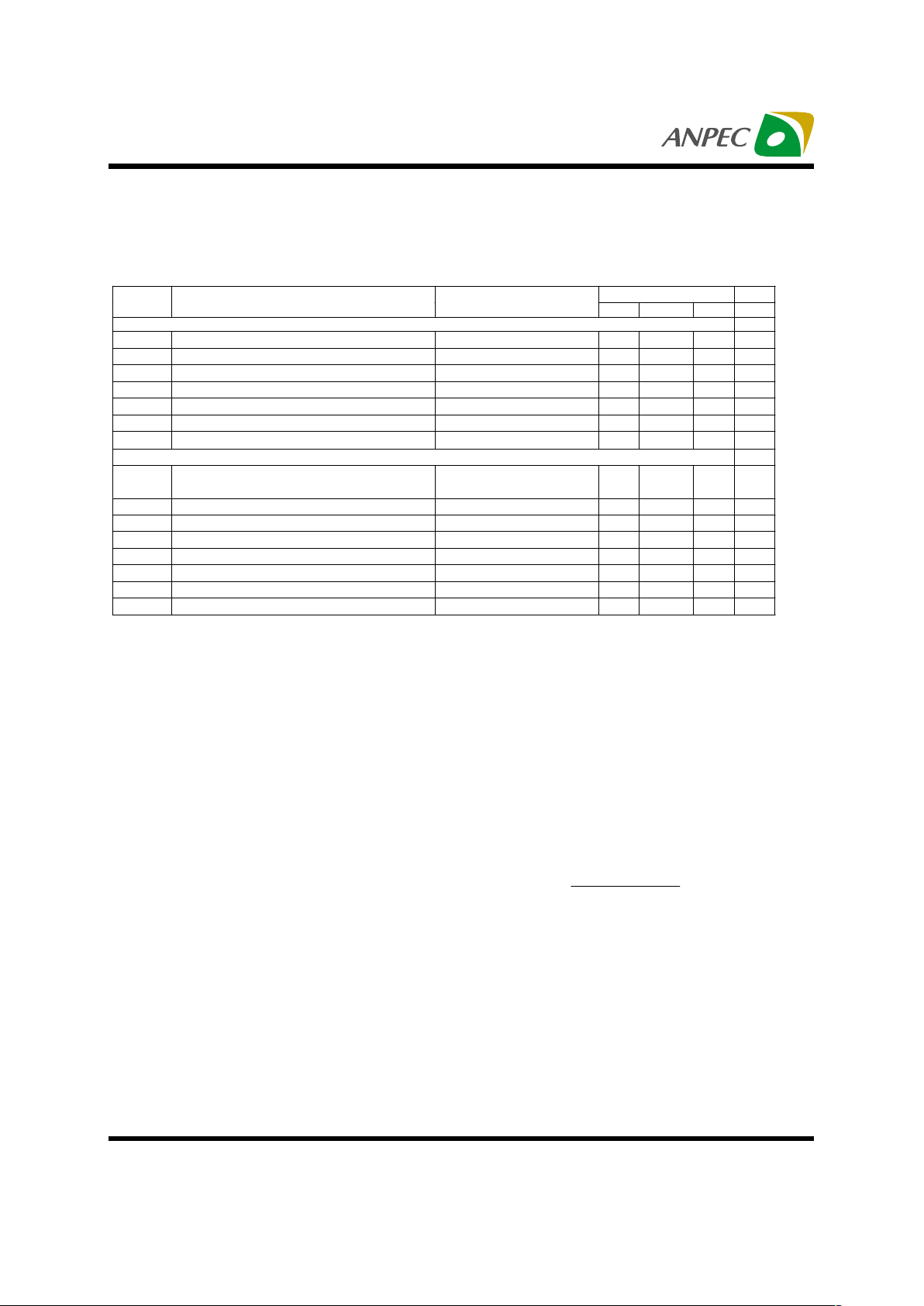

Electrical Characteristics Cont.

Functional Pin Description

1. Recommended operating conditions, Unless otherwise noted.

2. Refer to Block and Simplified Power System Diagrams , and Typical Application Schematic.

AP W 7026 Unit

Sym bol Param eter Test Conditions

Min Typ Max

PROTECTION

V S E N 1 O .V. tr ip p o int (V S E N 1/V

REF1

)

VSEN 1 Rising

118 %

VSEN1 O.V. Hysteresis 2%

V 3 .3 O .V. trip p o in t V 3 .3 R is in g 4 .1 V

V 3 .3 O .V. H y s te re s is 0.1 V

l

OVP

FAULT Souring Current V

FAU LT/RT

= 2.0V 25 m A

O C S E T 1 ,2 C urre n t S o urc e Vo cse t = 4.5V 170 200 230 uA

R

SS

Pull up resistor to 5V 23

K

Ω

POWER GOOD

VSEN1 Upper Threshold

(V S E N 1/V

REF1

)

VSEN1 Rising 110 %

VSEN 1 Lower Threshold VSEN 1 Rising 94 %

VSEN 1 PG D Hysteresis Upper/Lower Threshold 2 %

V 3 .3 L ow er T h re s h o ld V 3 .3 R is in g 2.5 V

V 3 .3 P G D H ys te re s is 0.1 V

FB3 Lower Threshold V

FB3

R is in g 1 .0 V

FB3 PG D Hysteresis 0.1 V

V

PGOOD

PGOOD Voltage Low l

PGOOD

= -4 m A 0 .8 V

UGATE1 (Pin 1)

Connect UGATE1 pin to the SYNC PWM Converters

upper MOSFET gate .This pin provides the gate drive

for the upper MOSFET.

VCC (Pin 2)

Provide a + 12V bias supply for the IC to this pin . This

pin also provides the gate bias charge for all the

MOSFETs controlled by the IC. The voltage at this pin is

monitored for Power-On Reset (POR) purpose.

UGATE2 (Pin 3)

Connect UGATE2 pin to the ASYNC PWM converters

MOSFET gate . This pin provides the gate drive for the

MOSFET.

PHASE2 (Pin 4)

Connect the PHASE2 pin to the ASYNC PWM

converters MOSFET source. This pin is used to monitor

the voltage drop across the MOSFET for over-current

protection.

PGOOD (Pin 5)

PGOOD is an open drain output used to indicate the

status of the output voltages. This pin is pulled low when

the SYNC PWM regulator output is not within ± 10%

of the reference voltage (V

REF1

) or when V3.3 or V

FB3

is

below its lower power good threshold.

OCSET2 (Pin 6)

Connect a resistor (R

OCSET

) from this pin to the drain of

the ASYNC PWM converters MOSFET . R

OCSET

, an

internal 200

µA current source (I

OCSET

) , and the

MOSFETs on-resistance (r

DS(ON)

) set the converters

over-current (OC) trip point according to the following

equation:

I

PEAK

=

An over-current trip cycles the soft-start function.

FB2 (Pin 7)

Connect this pin to the output of the ASYNC PWM

converter . The voltage at this pin is regulated to the

reference voltage V

REF2

. A resistor driver is connected

from this pin to V

OUT2(ROUT2

) and to GND(R

GND2

) that sets

the output voltage as the following equation :

1

OCSET

N 4

OCS ET

H

DS(ON)

Page 5

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw5

Functional Pin Description Cont.

V

OUT2

=

The value of the resistor connected from V

OUT2

to FB2 must

be less than 150Ω .

V5 (Pin 8)

The +5V input voltage at this pin is monitored for power-on

reset (POR) purpose.

SS (Pin 9)

This pin provides the soft-start for the all PWM converters

and linear regulator . An internal resistor charges an

external capacitor that is connected from 5V supply to

this pin which ramps up the all outputs , preventing the

outputs from overshooting as well as limiting the input

current . The second function of the soft-start cap is to

provides long off time for the synchronous MOSFET during

current limiting .

FAULT / RT (Pin 10)

This pin provides oscillator switching frequency

adjustment . By placing a resistor ( R

T

) from this pin to

GND , the nominal 200kHz switching frequency is

increased .Conversely, connecting a pull-up resistor ( R

T

)

from this pin to VCC reduces the switching frequency.

Nominally , the voltage at this pin is 1.26V. In the event of

an over-voltage or over-current condition , this pin is

internally pulled to VCC.

V3.3 (Pin 11)

This pin is connected to the +3.3V or the output of the

ASYNC PWM converter for power good and

over-voltage detection. When the output voltage of the

ASYNC PWM converter is not in the range from 3V to

4V, connect this pin to +3.3V voltage.

GND (Pin 12)

Signal ground for the IC. All voltage levels are measured

with respect to this pin.

GATE (Pin 13)

Connect this pin to the gate of an external MOSFET.

This pin provides the drive for the linear regulators

R

OUT2

R

GND2

( 1+ ) x V

REF2

pass MOSFET.

FB3 (Pin 14)

Connect this pin to the output of the linear regulator . A

resistor driver is connected from this pin to V

OUT3

and

GND that sets the output voltage as same as V

OUT2

. This

pin is monitored for power good function.

FB1 (Pin 15)

This pin provides the feedback for the SYNC PWM

converter. Typically this pin can be connected directly to

the output of the converter . However , a resistor

divider is recommended to be connected from this pin to

V

OUT1

and GND to adjust the output voltage as same as

V

OUT2

. The value of the resistor connected from V

OUT1

to

FB1 must be less than 200Ω.

VSEN1 (Pin 16)

This pin is connected to the SYNC PWM converters

output voltage . The PGOOD and OVP comparator

cicuits use this signal to report output voltage status

and over-voltage protection.

OCSET1 (Pin 17)

Connect a resistor (R

OCSET

) from this pin to the drain of

the SYNC PWM converters upper MOSFET . The

over-current (OC) trip point for the SYNC PWM

converter is set by the R

OCSET

as same as the OCSET2.

An over-current trip cycles the soft-start function.

PGND (Pin 18)

This is the power ground connection . Tie the SYNC

PWM converters lower MOSFET source to this pin.

LGATE1 (Pin 19)

Connect LGATE1 to the SYNC PWM converters lower

MOSFET gate . This pin provides the gate drive for the

lower MOSFET.

PHASE1 (Pin 20)

Connect the PHASE1 pin to the SYNC PWM

Converters upper MOSFET source. This pin is used

to monitor the voltage drop across the upper MOSFET

for over-current protection.

Page 6

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw6

Typical Performance Curves

# # # !# "# ## $# %#

Switching Frequency ( kHz )

-1.0%

-0.8%

-0.6%

-0.4%

-0.2%

0.0%

0.2%

0.4%

0.6%

0.8%

1.0%

0255075100125

Reference Voltage Deviation(V

4-.

)

Junction Tempe rature (oC)

-1.0%

-0.8%

-0.6%

-0.4%

-0.2%

0.0%

0.2%

0.4%

0.6%

0.8%

1.0%

0255075100125

Reference Voltage Deviation(V

4-.

)

Junction Temperature (oC)

-1.0%

-0.8%

-0.6%

-0.4%

-0.2%

0.0%

0.2%

0.4%

0.6%

0.8%

1.0%

0255075100125

Note : The Referance Voltage(V

REF

) Deviation is

Junction Tempe rature (oC)

V

REF(TJ

) - V

REF

(25oC)

V

REF

(25oC)

x 100%

RT ( k

Ω

ΩΩ

Ω

)

RT pull up

to +12V

RT pull down to G ND

Reference Voltage Deviation(V

4-.

)

HJ

TJ is Junction Temperature.

Page 7

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw7

Typical Application Circuit

UGATE1

PGOOD

PHASE2

UGATE2

VCC

SS

FB2

OCSET2

V5 FB3

VSEN1

FB1

GATE

LGATE1

PGND

OCSET1

PHASE1

1

7

6

5

4

3

2

13

14

15

16

17

18

19

20

12

11

+5V

NVVDD

2.05V/4A

VTT

1.25V/3.5A

AGP

3.3V

+12V

AGP

3.3V

FBVDDQ

2.5V/1.5A

C807

330uF

C808

330uF

R812

1.5k

C809

220pF

R813

5.1R

Q802

APM9410

D800

FM5820

C811

330uF

R814

100RF

C810

330uF

R810

97.6RF

C817

330uF

Q800

APM3055

C802

330uF

R820

5.1R

Q803B

APM7313

C815

330uF

C816

330uF

C814

10uF

C813

330uF

L802

2uH

L803

7.8uH

Q803A

APM7313

C812

220pF

R817

1.2K

R819

5.1R

C801

1uF

RX1

10R

L801

7.8uH

L800

2uH

APW7026-12

R811

100RF

10

9

8

5V

C805

1uF

R816

4.02KF

FAULT/RT

GND

V3.3

R821

0R

R824

NC

Simplified Power System Diagram

V

OUT1

Q1

Q2

Q3

Q4

V

OUT3

+3.3V

ASYNC

PWM

C o ntro ller

Linear

C o ntro ller

SYNC

PWM

C o ntro ller

+3.3v

V

OUT2

+5V

Page 8

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw8

SO 300mil ( Reference JEDEC Registration MS-013)

Millimeters Variations- D Inches Variations- D

Dim

Min. Max. Variations Min. Max.

Dim

Min. Max. Variations Min. Max.

A2.35

2.65

SO-16

10.10 10.50

A 0.093 0.1043 SO-16 0.398 0.413

A1

0.10 0.30

SO-18

11. 35 11 .76

A1 0.004 0.0120 SO-18 0.447 0.463

B

0.33 0.51

SO-20

12.60 13

B 0.013 0.020 SO-20 0.496 0.512

D See variations SO-24

15.20 15.60

D See variations SO-24 0.599 0.614

E

7.40 7.60

SO-28

17.70 18.11

E 0.2914 0.2992 SO-28 0.697 0.713

e 1.27BSC SO-14

8.80 9.20

e 0.050BSC SO-14 0.347 0.362

H

10 10.65

H 0.394 0.419

L

0.40 1.27

L 0.016 0.050

N See variations N See variations

φ

1 0

°

8

°φ

10°8

°

N

12

3

EH

D

L

GAUGE

PLANE

1

e

B

A1

A

Page 9

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw9

Classification Reflow Profiles

Package Reflow Conditions

Refolw Condition (IR/ Convection or VPR Reflow)

Physical Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb)

Lead Solderability Meets EIA Specification RSI86-91, ANSI/J-STD-002 Category 3.

Packaging 1000 devices per reel

Convection or IR/ Convection VPR

Average ramp-up rate(183°C to Peak) 3°C/second max. 10 °C /second max.

Preheat temperature 125 ± 25°C)

120 seconds max.

Temperature maintained above 183°C

60 ~ 150 seconds

Time within 5°C of actual peak

temperature

10 ~ 20 seconds 60 seconds

Peak temperature range

220 +5/-0°C or 235 +5/-0°C 215~ 219°C or 235 +5/-0°C

Ramp-down rate

6 °C /second max. 10 °C /second max.

Time 25°C to peak temperature

6 minutes max.

pkg. thickness ≥≥≥≥ 2.5mm

and all bags

pkg. thickness < 2.5mm and

pkg. volume ≥≥≥≥ 350 mm³

pkg. thickness < 2.5mm and pkg.

volume < 350mm³

Convection 220 +5/-0 °C Convection 235 +5/-0 °C

VPR 215-219 °C VPR 235 +5/-0 °C

IR/Convection 220 +5/-0 °C IR/Convection 235 +5/-0 °C

Reference JEDEC Standard J-STD-020A APRIL 1999

Pre-heat temperature

183 C

Peak temperature

Time

°

temperature

Page 10

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw10

Tape & Reel Dimensions

Reliability test program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

245°C , 5 SEC

HOLT MIL-STD-883D-1005.7

1000 Hrs Bias @ 125 °C

PCT JESD-22-B, A102

168 Hrs, 100 % RH , 121°C

TST MIL-STD-883D-1011.9

-65°C ~ 150°C, 200 Cycles

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms , Itr > 100mA

t

Ao

E

W

Po P

Ko

Bo

D1

D

F

P1

A

J

B

T2

T1

C

Application

A B C J T1 T2 W P E

SOP-20 330±1 62 ± 1.5

12.75

±

0.15

2 + 0.6 24.4 +0.2

2± 0.2

24 + 0.3

- 0.1

12± 0.1 1.75± 0.1

Application

F D D1 Po P1 Ao Bo Ko t

SOP-20

11.5 ± 0.1

1.5+0.1 1.5+0.25

4.0 ± 0.1 2.0 ± 0.1 8.2 ± 0.1 13± 0.1 2.5± 0.1 0.35±0.013

(mm)

Page 11

Copyright ANPEC Electronics Corp.

Rev. A.2 - Sep., 2001

APW7026

www.anpec.com.tw11

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 886-2-89191369

Cover Tape Dimensions

Carrier Width

24

Cover Tape Width

21.3

(mm)

Loading...

Loading...