Page 1

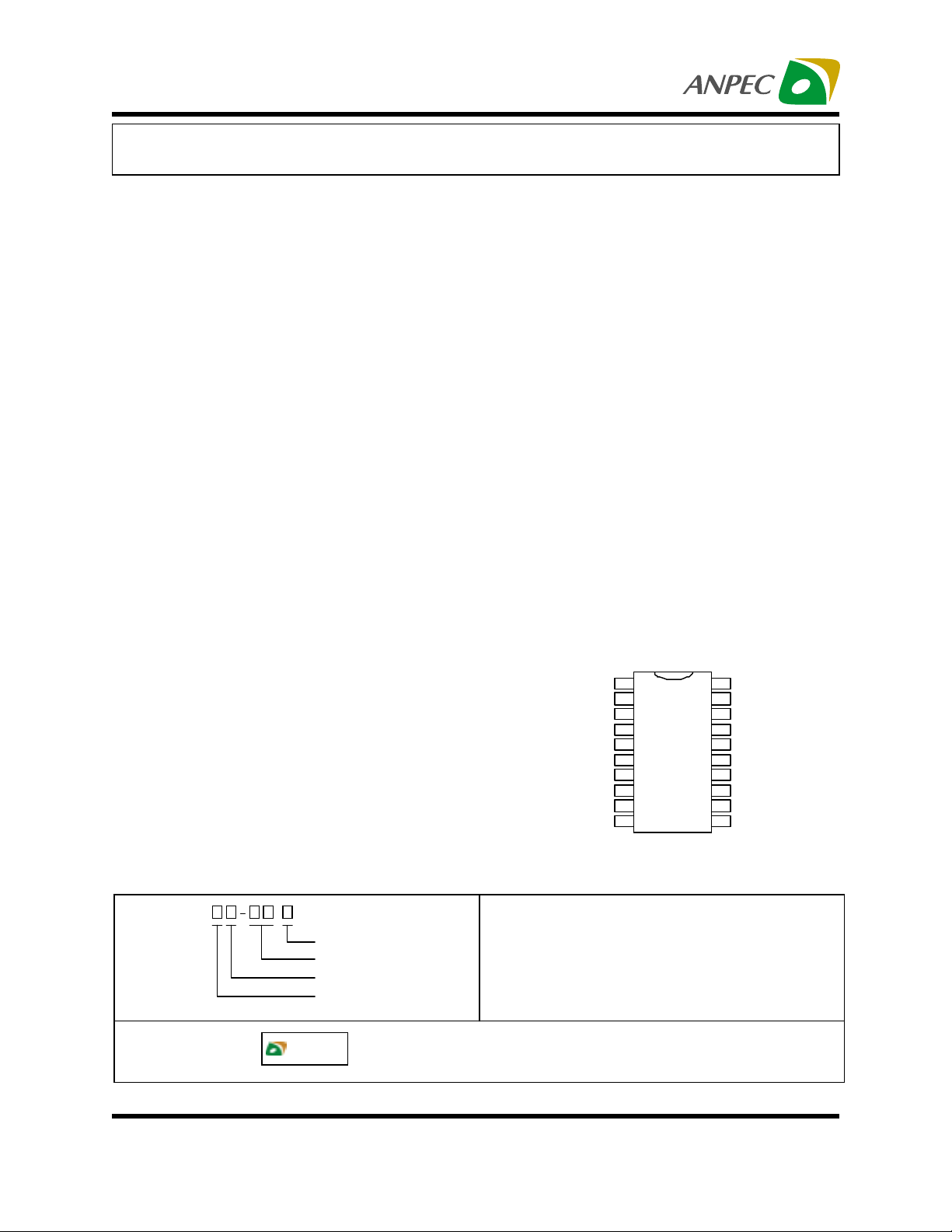

APW1175

Dual Synchronous DC/DC Controllers with Current Sharing Control

Features

• Two Operation Modes

- Independent Operation

- Two-Phase Operation with Current Sharing

• Driving N-Channel MOSFETs

•

300kHz Constant Frequency Operation

• Built-in Feedback Compensation

- Voltage-Mode PWM Control

- Fast Transient Response

• ±1% VREF Accuracy Over Temperature

•

Adjustable Output Voltage by an External Resistor

Divider

• Phase-Shifted Switchers to Minimize Ripple

• Current Limit with 50% Fold-Back

•

Soft-Start and Enable Function

••

• Power-ON Reset (POR) Monitor

••

••

• Power Good Monitor for Outputs

••

General Description

The APW1175 is a two-phase, synchronous, and voltage

mode PWM controller to provide dual channel or single

outputs in two distinct operation modes. In independent

mode, the two PWM converters supply two independently

regulated voltages by converting a common or two differ-

ent power inputs. In two-phase mode, the two PWM con-

verters supply one regulated voltage with programmable

current sharing control by converting a common or two

different power inputs. The two-phase mode can supply

the larger power than that provided each single channel.

APW1175 features an internal 300KHz oscillator, VCC

Power-On-Reset (POR), an external adjustable soft-start

and the programmable output current limit with 50% fold-

o

back. The two PWM controllers are 180

out of phase to

minimize the input ripple (common power input) and the

output ripple (two-phase mode).

Pin Description

Applications

••

• Graphics Cards

••

••

• DDR Memory

••

••

• SSTL-2 Termination

••

••

• Power Supply Requiring Two Outputs

••

VREF

+IN 2

-IN 2

VCC

CL2-

CL2+

BST2

DH2

DL2

PGND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

GND

PWR G D

-IN 1

SS/ENA

CL1-

CL1+

BST1

DH1

DL1

BSTC

Ordering and Marking Information

)29 %#

Lead Free Code

Handling Code

Temp. Range

Package Code

APW 1175 K :

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

APW 1175

XXXXX

Package Code

K : SOP -20

Temp. Range

C : 0 to 70°C

Handling Code

TU : Tube TR : Tap e & Reel

Lead Free Code

L : Lead Free Device Blank : Orginal Device

XXXXX - Date Code

www.anpec.com.tw1

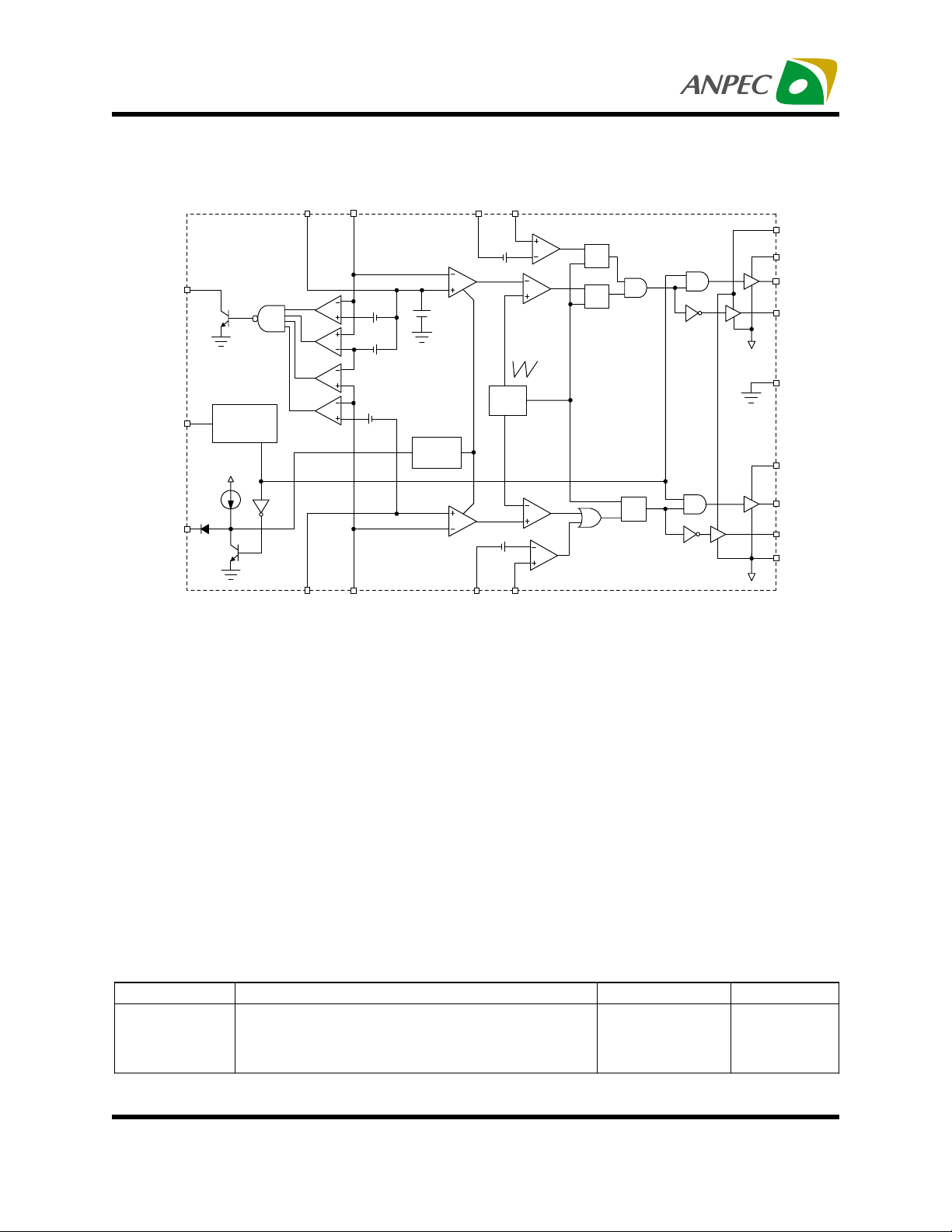

Page 2

APW1175

Block Diagram

VR EF -IN1 CL1- CL1+

PWRGD

VCC

SS/ENA

25uA

POWER-ON

RESET(POR)

4V

+IN2

-IN2

0.125V

0.125V

0.125V

Master Error

Am plifier

V REF

1.25V

soft-start

control

Slave Error

Am plifier

V CL1

OSC

V

CL2

CL2- CL2+

300KHZ

R

Q

S

R

Q

S

S

Q

R

Absolute Maximum Ratings Operating Conditions

BSTC

BST1

DH1

DL1

GND

BST2

DH2

DL2

PGND

••

• VCC to GND . . . . . . . . . . . . . -0.3V ~ 15V

••

••

• PGND to GND . . . . . . . . . . . . ±1V

••

••

• BST to GND . . . . . . . . . . . . . -0.3V ~ 22V

••

••

• Junction Temperature . . . . . . . 150

••

••

• Storage Temperature . . . . . . . -65

••

••

• Soldering Temperature . . . 300

••

••

• Minimum ESD Rating . . . . . . . ±3kV

••

o

C

o

C ~ 150oC

o

C , 10 Seconds

Thermal Characteristics

Symbol

R

JA

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

Thermal Resistance in Free Air

Parameter Rating Unit

SOIC

SOIC(with 3in

••

• VCC . . . . . . . . . . . . . . . . . . . . 4.2V ~ 15V

••

••

• BST. . . . . . . . . . . . . . . . . . . . . 5V ~ 17V

••

www.anpec.com.tw2

o

C to 85oC

o

C to 125oC

C/W

°

••

• Ambient Temperature Range . . . 0

••

••

• Junction Temperature Range. . . . 0

••

75

of Copper)

65

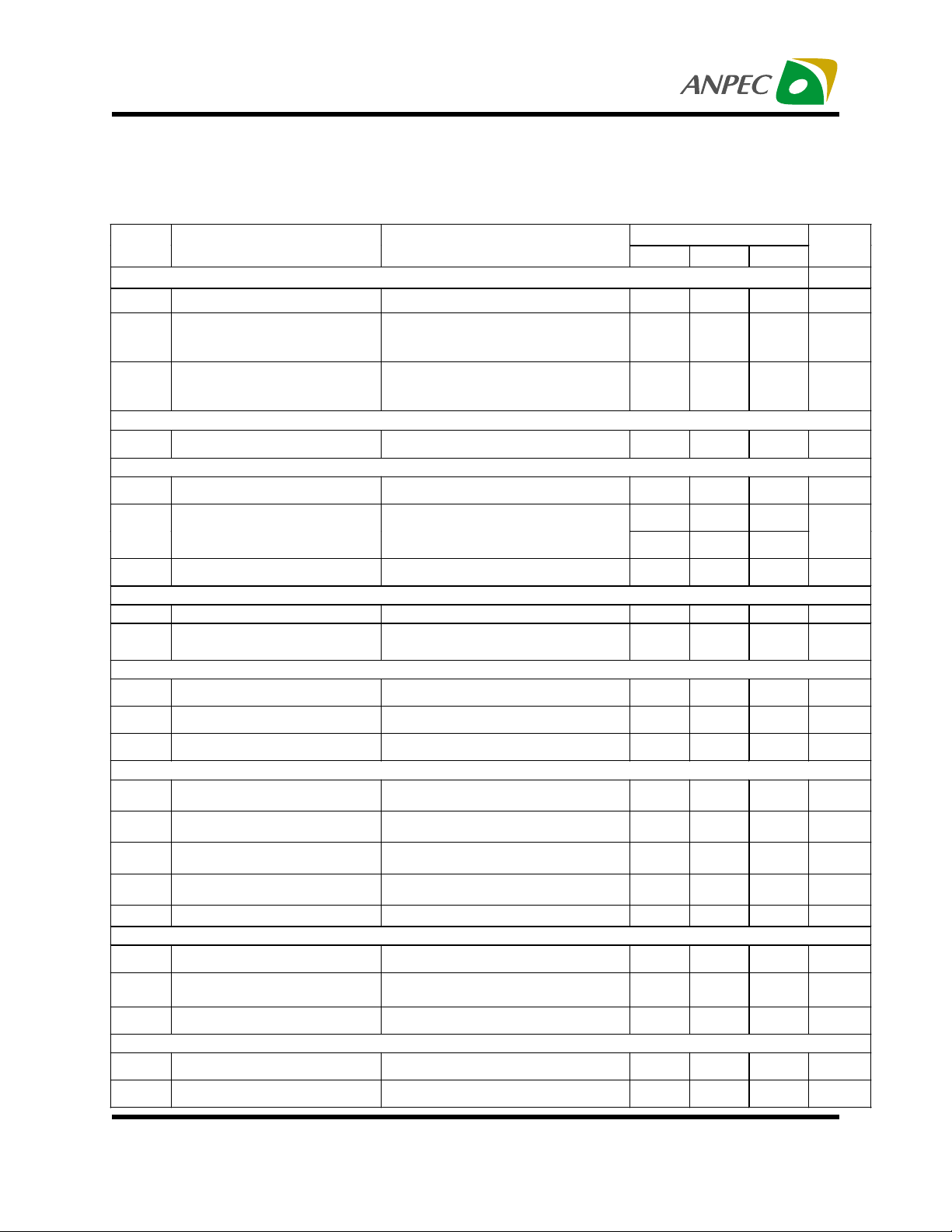

Page 3

APW1175

Electrical Characteristics

Unless otherwise specified, these specifications apply over VCC=4.75~5.25V, GND=PGND=0V, and T)=0~85°C.

Typical values refer to T

Symbol Parameter Test Conditions

SUPPLY CURRENT

ICC V

BSTC

I

BST1,2

I

CC

Supply Current

BSTC Supply Current

BST1,2 Supply Current

POWER-ON RESET

CC

POR Threshold Voltage VCC Rising 3.6 4.2 V

V

OSCILLATOR

OSC

F

O s c illator F requency

Maxim um Duty C ycle

Ramp Amplitude

∆V

OSC

ERROR AMPLIFIER

AOL Error Amplifier Voltage Gain 35 dB

REFERENCE VOLTAGE

V

Reference Voltage Measure Pin 1 1.238 1.250 1.262 V

REF

REF

Load Regulation I

V

REF

Line Regulation VCC = 5~15V

V

PWM CONTROLLERS GATE DRIVERS

DH Source

DH Sink

DL Source

DL Sink

Dead Time 50 200 nS

CURRENT LIMIT PROTECTION

VCL

Current Limit Voltage 60 70 80 mV

SOFT-START

ISS

Soft-S tart C urrent V

Soft-Start Transition Synchronous PW M 3.3 V

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

)=25°C.

CC

V

=5~15V, F

BSTC=5V, DL1,2=Open,

OSC

=300kHz

F

BST1,2=10V, DH1,2=Open,

OSC

=300kHz

F

Input Bias Current

(-IN1, +IN2, -IN 2)

Input Voltage = 1.25V

REF

= 1m A

BSTH-DH=5V

BSTH-DH=2.5V

DH-PGND=3.5V

DH-PGND=1.75V

BSTL-DL=5V

BSTL-DL=2.5V

DL-PGND=3.5V

DL-PGND=1.75V

OUT

=0V (refer to application

Fold Back Current

V

circuit)

Fold Back Voltage Knee I=I

SS

=1V 25

APW1175

Min Typ Max

OSC

=300kHz

9 mA

2.8

1.6

270 300 330 KHz

DH1

DH2

80 90

100

1.1 V

0.5 1

3.5

1

0.5

1

0.5

1

0.5

1

0.5

50% I

LIM

(refer to application circuit) 1.25 V

www.anpec.com.tw3

0.5 %

OUT

V

Unit

mA

mA

%

µA

mV

A

A

A

A

LIM

µA

Page 4

APW1175

Electrical Characteristics Cont.

Symbol Parameter Test Conditions

POWER GOOD

Upper -IN1 Threshold

APW1175

Min Typ Max

110%

Unit

V

REF

Lower IN1 Threshold

Upper IN2 Threshold

Lower IN2 Threshold

PWRGD Voltage Low I

=-5mA 0.8 V

PWRGD

Functional Pin Description

VREF (Pin 1)

Internal 1.25V reference voltage . This pin is internally

connected to the positive input of the master channel

error amplifier.

+IN2 (Pin 2)

Positive input of the slave channel error amplifier. Con-

nect this pin to 1.25V reference (Pin 1) for the two

independent channel configuration.

-IN2, -IN1 (Pin 3, 18)

Negative inputs of the slave and master error amplifier.

VCC (Pin 4)

Connect this pin to 5V~15 V power to provides the

bias for the control circuitry. Need a 1uF multi-layer

ceramic decoupling capacitor to GND (Pin 20). The

voltage at this pin is also monitored for Power-On

Reset (POR) purpose.

CL2-, CL2+, CL1+, CL1- (Pin 5,6,15,16)

Current sense input pins. Connect the positive and

negative inputs to output current sense resistor for

each channel. A current limit comparator for each

channel to limit the output current while the difference

voltage between the positive and negaive inputs is

greater than the 75mV reference.

A RC filter is required for noise rejection.

BST2,BST1 (Pin 7,14)

Power inputs to the high-side MOSFET drivers. A boot-

strap circuit may be used to pump a boot voltage .

90%

V

+IN2

+0.1V

REF

90%

DH2, DH1 (Pin 8,13)

High-side MOSFET drivers to provide strong drive current

to drive each high-side MOSFET. A small series resistor

to the gate of the MOSFET maybe required for each pin.

DL2, DL1 (Pin 9,12)

Low-side MOSFET drivers to provide strong drive current

to drive each low-side MOSFET. A small series resistor

to the gate of the MOSFET maybe required for each pin.

PGND (Pin 10)

Power ground connection. The pin provide the path for

return of gate drive currents.

BSTC (Pin 11)

This pin provide supply voltage to the low-side MOSFET

drivers.

SS/ENA (Pin 17)

Connect a capacitor from this pin to ground.This

capacitor, along with an internal 25uA current source,

sets the soft-start interval, preventing the outputs from

overshoot as well as limiting the input current. Pull this

pin to below 1.4V to shutdown the outputs

PWRGD (Pin 19)

Power good signal output pin. This pin is an open collec-

tor output, which is pulled low if the output voltage is out-

side the power good window.

GND (Pin 20)

Signal ground for the control circuitry. All voltage levels

are measured with respect to this pin.

V

REF

V

V

REF

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

www.anpec.com.tw4

Page 5

APW1175

Typical Application

1. Independent Operation

16V

16V

16V

+12V

100uF

C1

100uF

C2

100uF

C3

APM4416

Q1

1uF

C5

+5V

150uF

C18

6V

150uF

C19

6V

150uF

C20

6V

R13

2.2

1N4148

D2

APM4416

Q3

R14

2.2

R15

2.2

1uF

C21

1nF

1uF

C22

C23

VREF

+IN2

-IN2

VCC

CL2CL2+

BST2

DH2

DL2

PGND

10nF

C11

GND

PWR GD

-IN1

SS/ENA

CL1CL1+

BST1

DH1

DL1

BSTC

PWR OK

10nF

C6

+5V

R2

2.2

0.22uF

C4

2.2

R1

2.2

1N4148

D1

R3

2.2

R4

APM4416

Q4

4.7uH

L2

150uF

6V

150uF

6V

150uF

6V

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

100

6m

10nF

R11

R12

C15

C16

C17

C8

10nF

C9

124

0.22uF

C7

R7

6V

6V

6V

0.22uF

C10

124

R8

220

R9

R10

100

1.8V / 6A

100

R5

6m

R6

150uF

C12

150uF

C13

150uF

C14

2.5V / 6A

APM4416

7.5uH

Q2

L1

www.anpec.com.tw5

Page 6

APW1175

Typical Application

2. Two-Phase Operation with Current Sharing Control

+5V

150uF

C12

6V

150uF

C13

6V

150uF

C14

6V

R12

2.2

1N4148

D2

APM4416

Q3

R13

2.2

R14

2.2

C18

1uF

C15

1uF

C16

1nF

10nF

C17

22k

VREF

+IN2

-IN2

VCC

CL2CL2+

BST2

DH2

DL2

PGND

R11

GND

PWRGD

-IN1

SS/ENA

CL1CL1+

BST1

DH1

DL1

BSTC

PWRO K

10nF

+5V

R2

2.2

0.22uF

C4

2.2

C6

R1

2.2

1N4148

D1

R3

2.2

R4

+12V

100uF

16V

C1

100uF

16V

C2

100uF

16V

C3

APM4416

Q1

1uF

C5

APM4416

Q4

4.7uH

L2

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

100

100

R9

10nF

C8

124

R8

R10

6m

0.22uF

C7

150

R7

150uF

6V

150uF

6V

150uF

6V

R5

6m

R6

C9

C10

C11

APM4416

Q2

7.5uH

L1

2.7V / 12A

www.anpec.com.tw6

Page 7

APW1175

Packaging Information

SO 300mil ( Reference JEDEC Registration MS-013)

D

N

EH

12

3

GAUGE

PLANE

A

e

Millimeters Variations- D Inches Variations- D

Dim

A1

φ

Min. Max. Variations Min. Max.

A2.35

0.10 0.30

0.33 0.51

B

D See variations SO-24

7.40 7.60

E

e 1.27BSC SO-14

H

L

N See variations N See variations

1 0

10 10.65

0.40 1.27

°

2.65

8

B

SO-16

SO-18

SO-20

SO-28

°φ

A1

10.10 10.50

11. 35 11. 76

12.60 13

15.20 15.60

17.70 18.11

8.80 9.20

Dim

A1 0.004 0.0120 SO-18 0.447 0.463

Min. Max. Variations Min. Max.

A 0.093 0.1043 SO-16 0.398 0.413

B 0.013 0.020 SO-20 0.496 0.512

D See variations SO-24 0.599 0.614

E 0.2914 0.2992 SO-28 0.697 0.713

e 0.050BSC SO-14 0.347 0.362

H 0.394 0.419

L 0.016 0.050

10°8

L

°

1

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

www.anpec.com.tw7

Page 8

APW1175

Physical Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb)

Lead Solderability Meets EIA Specification RSI86-91, ANSI/J-STD-002 Category 3.

Reflow Condition (IR/Convection or VPR Reflow)

Reference JEDEC Standard J-STD-020A APRIL 1999

Peak temperature

temperature

Pre-heat temperature

°

183 C

Time

Classification Reflow Prof iles

Convection or IR/

Convection

Average ramp-up rate(183°C to Peak) 3°C/second max. 10 °C /second max.

Preheat temperature 125 ± 25°C)

Temperature maintained above 183°C

Time within 5°C of actual peak temperature

Peak temperature range

Ramp-down rate

Time 25°C to peak temperature

120 seconds max

60 150 seconds

10 20 seconds 60 seconds

220 +5/-0°C or 235 +5/-0°C 215-219°C or 235 +5/-0°C

6 °C /second max. 10 °C /second max.

6 minutes max.

VPR

Package Reflow Conditions

pkg. thickness

and all bgas

Convection 220 +5/-0 °C Convection 235 +5/-0 °C

VPR 215-219 °C VPR 235 +5/-0 °C

IR/Convection 220 +5/-0 °C IR/Convection 235 +5/-0 °C

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

2.5mm

≥≥≥≥

pkg. thickness < 2.5mm and

pkg. volume

350 mm³

≥≥≥≥

pkg. thickness < 2.5mm and pkg.

volume < 350mm³

www.anpec.com.tw8

Page 9

APW1175

Re lia bility test program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms , IJH > 100mA

245°C , 5 SEC

1000 Hrs Bias @ 125 °C

168 Hrs, 100 % RH , 121°C

-65°C ~ 150°C, 200 Cycles

Carrier Tape

W

t

E

F

A

Po

P

P1

Ao

J

C

D

Bo

Ko

D1

T2

B

Application

A B C J T1 T2 W P E

330±1 62 ±1.5

SOP- 20

F D D1 Po P1 Ao Bo Ko t

11.5 ± 0.1 1.5 +0.1 1.5+ 0.25 4.0 ± 0.1 2.0 ± 0.1 8.2 ± 0.1 13± 0.1 2.5± 0.1

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

12.75 +

0.15

T1

2 + 0.6 24.4 + 0.2 2 ± 0.2

24 + 0.3

-0.1

12 + 0.1 1.75± 0.1

.35±0.01

3

www.anpec.com.tw9

Page 10

APW1175

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

SOP- 20

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 886-2-89191369

24 21.3 1000

Copyright ANPEC Electronics Corp.

Rev. A.3 - July., 2003

www.anpec.com.tw10

Loading...

Loading...