Page 1

APL5331

3A Bus Termination Regulator

Features General Description (Cont.)

••

• Provide Bi-direction Current

••

- Sourcing or Sinking Current up to 3A

••

• 1.25V/0.9V Output for DDR I/II Applications

••

••

• Fast Transient Response

••

••

• High Output Accuracy

••

- ±20mV over Load, VOUT Offset and

Temperature

••

• Adjustable Output Voltage by External Resistors

••

••

• Current-Limit Protection

••

••

• On-Chip Thermal Shutdown

••

••

• Shutdown for Standby or Suspend Mode

••

••

• Simple SOP-8, SOP-8-P with thermal pad,

••

TO-252- 5 and TO-263-5 Packages

Applications

• DDR I/II SDRAM Termination

• SSTL-2/3 Termination Voltage

On-chip thermal shutdown provides protection against

any combination of overload that would create excessive junction temperature. The output voltage of

APL5331 track the voltage at VREF pin. A resistor

divider connected to VIN, GND and VREF pins is

used to provide a half voltage of VIN to VREF pin. In

addition, an external ceramic capacitor and an opendrain transistor connected to VREF pin provides softstart and shutdown control respectively. Pulling and

holding the VREF to GND shuts off the output. The

output of APL5331 will be high impedance after being shut down by VREF or thermal shutdown function.

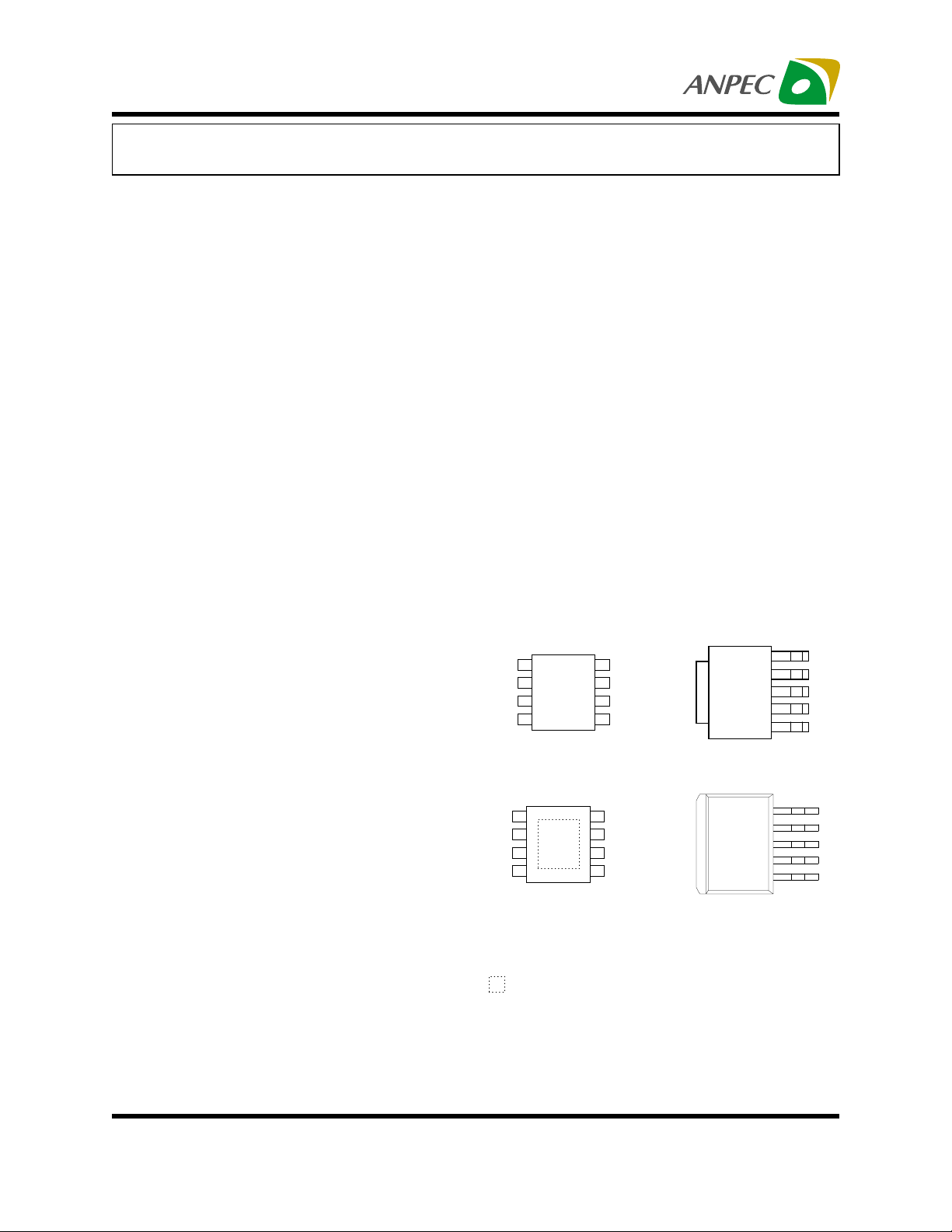

Pin Configuration

12345

VOUT

VREF

VCNTL

GND

VIN

VIN

1

GND

2

VREF

3

VOUT VCNTL

45

VCNTL

8

VCNTL

7

VCNTL

6

TAB is VCNTL

• Applications Requiring the Regulator with

Bi-direction 3A Current Capability

General Description

SOP-8 (Top View)

VIN

1

GND

2

VREF

3

VOUT

45

TO-252-5 (Top View)

NC

8

NC

7

6

VCNTL

NC

TAB is VCNTL

5

4

3

2

1

The APL5331 linear regulator is designed to provide

a regulated voltage with bi-directional output current

SOP-8-P (Top View)

TO-263-5 (Top View)

for DDR-SDRAM termination. The APL5331 integrates

two power transistors to source or sink current up to

3A. It also incorporate current-limit, thermal shutdown and shutdown control functions into a single

NC = No internal connection

= Thermal Pad

(connected to GND plane for better heat

dissipation)

chip. Current-limit circuit limits the short-circuit

current.

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw1

VOUT

VREF

VCNTL

GND

VIN

Page 2

APL5331

Ordering and Marking Information

APL5331

APL5331K C-TR :

APL5331 KAC -TR :

APL5331 U5C -TR :

APL5331 G5C -TR :

Lead Free Code

Handling Code

Tem p. Range

Package Cod e

APL5331

XXXXX

APL5331

XXXXX

Package Cod e

K : SO P-8 KA : SOP-8-P

U5 : TO-252-5 G5 : T O-263-5

Tem p. Range

C : 0 to 7 0

Handling Code

TR : Tape & Re el

Lead Free Code

L : Lead Free Device Blank : Orginal Device

XXXXX - Date Code

XXXXX - Date Code

o

C

Pin Description

PIN NAME I/O DESCRIPTION

Main power input pin. Connect this pin to a voltage source and an input

VIN I

capacitor. The APL5331 sources current to VOUT pin by controlling the upper

NPN pass transistor, providing a current path from VIN pin.

Power and signal ground. Connect this pin to s ystem ground plane with shortest

GND O

traces. The APL5331 sink s current from VOUT pin by controlling the lower NPN

pass transistor, pro viding a current path to GND pin. This pin is also the ground

path fo r inte rn a l co n tr o l c ircu itr y.

Power input pin for internal control circuitry. Connect this pin to a voltage source,

VCNTL I

providing a bias for the internal control circuitry. A bypass capacitor is usually

connected near this pin.

Reference voltage input and active-low shutdown control pin. Apply a voltage to

this pin as a reference voltage for the APL5331. Connect this pin to a resistor

VREF I

divider, between VIN and GND, and a capacitor for soft-start and filtering noise

purposes. Applying and holding this pin low b y an o pen-drain transistor to shut

down th e o u tp u t.

Output pin of the regulator. Connect this pin to load. Output capacitors

VOUT O

connected this pin improves stability and transient response. The output voltage

tracks the reference voltage and is capable of sourcing or sinking current up to

3A.

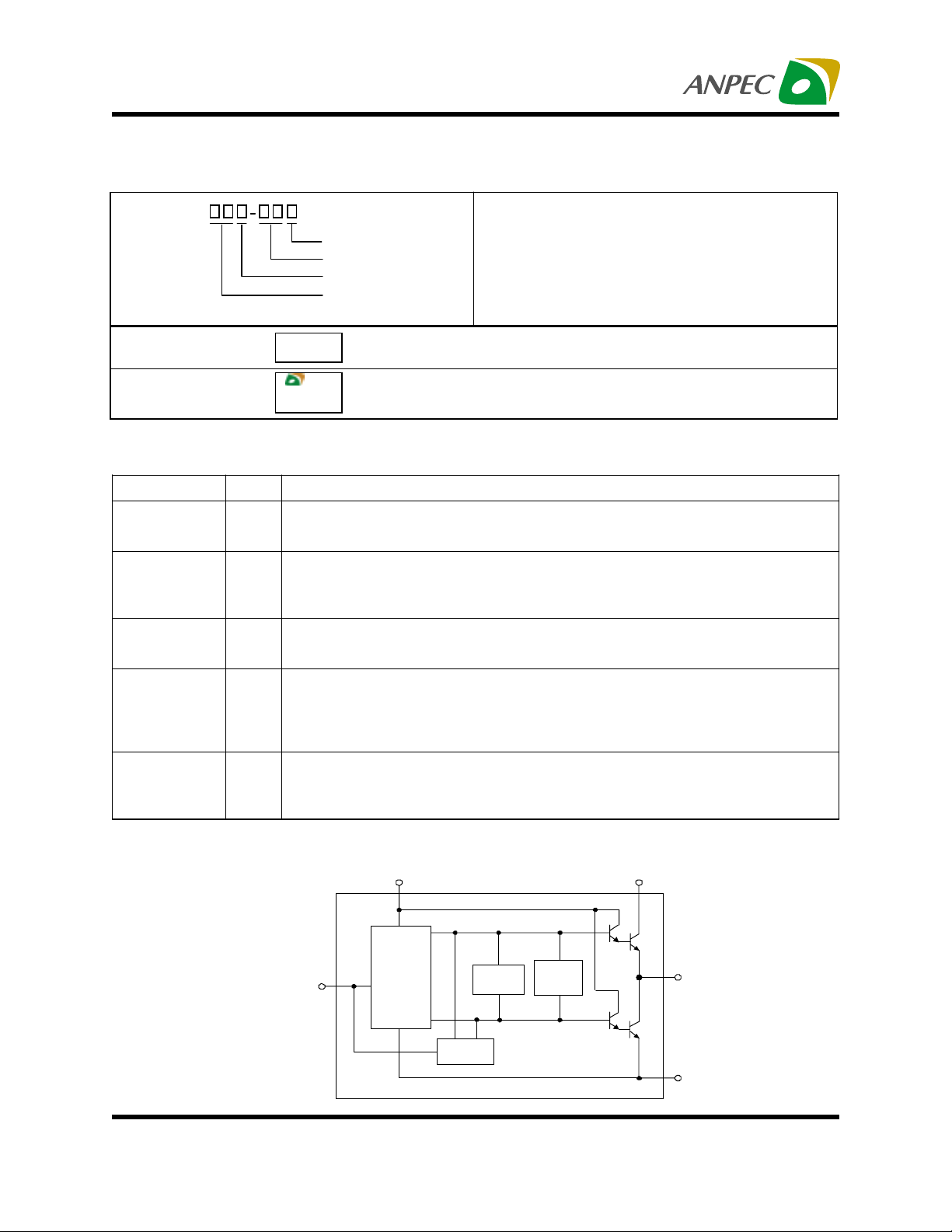

Block Diagram

VCNTL

VIN

VREF

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

Voltage

Regulation

Shutdown

Therm al

Limit

Current

Limit

VOUT

GND

www.anpec.com.tw2

Page 3

APL5331

Absolute Maximum Ratings

Symbol Parameter Rating Unit

CNTL

V

IN

V

D

P

J

T

STG

T

SDR

T

ESD

V

Thermal Characteristics

VCNTL Supply Voltage, VCNTL to GND -0.2 ~ 7 V

VIN Supply Voltage, VIN to GN D -0.2 ~ 3.9 V

Power Dissipation Internally Limited W

Junction Temperature 150

Storage Temperature -65 ~ 150

Soldering Temperature, 10 Seconds 300

Minimum ESD R ating (Human Body Mode)

±3

o

C

o

C

o

C

kV

Symbol

θ

JA

Thermal Resistance in Free Air

Parameter Rating Unit

SOP-8

SOP-8-P

TO-252-5

TO-263-5

160

80

80

50

°C/W

Recommended Operating Conditions

Symbol Parameter Range Unit

CNTL

V

IN

V

REF

V

OUT

I

J

T

Note1 : The symbol “+” means the VOUT sources current to load; the symbol “-“ means the VOUT sinks

current to GND.

Note2 : The max. IOUT varies with the TJ. Please refer to the typical characteristics.

VCNTL Supply Voltage 3.1 ~ 6V V

VIN Supply Voltage 1.6 ~ 3.5 V

VREF Input Voltage 0.8 ~ 1.75 V

VOUT Output Current (Note1, 2) -3 ~ +3 A

Junction Temperature 0 ~ 125

o

C

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw3

Page 4

APL5331

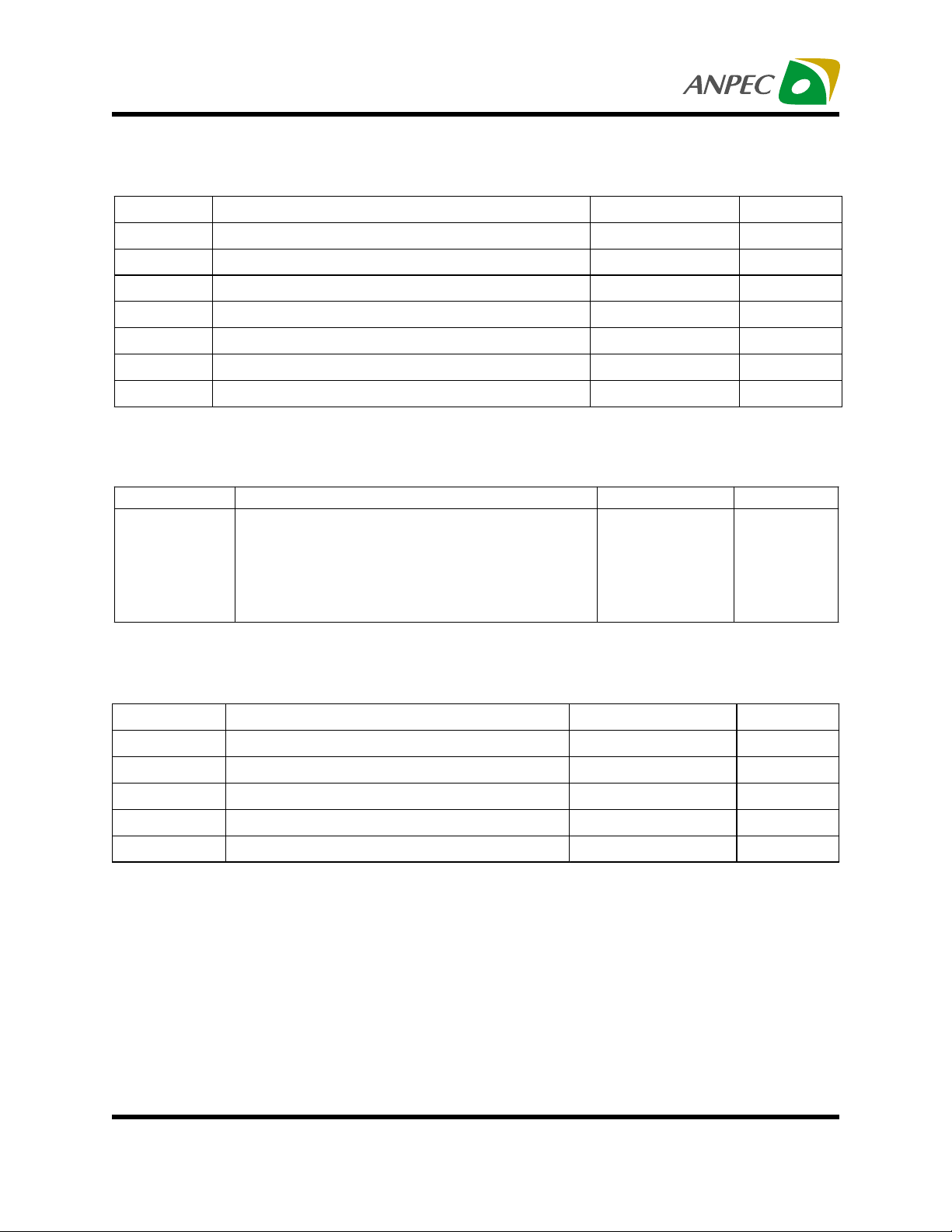

Electrical Characteristics

Refer to the typical application circuit. These specifications apply over, VCNTL=3.3V, VIN=2.5V/1.8V,

VREF=0.5VIN and TJ= 0 to 125°C, unless otherwise specified. Typical values refer to TJ =25°C.

Symbol

Parameter Test Conditions

Output Voltage

VOUT O utput Voltage I

OUT

V

System Accuracy

VOUT O ffset Voltage

OS

V

OUT–VREF

(V

Load Regulation

)

Protection

LIM

Current Limit

I

Thermal Shutdown

SD

T

Tem perature

Therm al Shutdown Hysteres is

Input Current

CNTL

VCNT L Supply Current

I

VREF Bias Current

VREF

I

(The current flows out of VREF)

Shutdown Control

Shutdown Threshold Voltage

APL5331

Min Typ Max

OUT

=0A

Over temperature, VOUT offset, and

load regulation

OUT

I

=+10mA -14

OUT

I

=-10mA

OUT

I

=+10mA to +3A -6

OUT

= -10 mA to -3 A

I

Sourcing Current TJ=25°C

IN

(V

=2.5V) TJ=125°C

Sinking Current TJ=25°C

IN

(V

=2.5V) TJ=125°C

Sourcing Current TJ=25°C

IN

(V

=1.8V) TJ=125°C

J

Sinking Current T

IN

(V

=1.8V) TJ=125°C

Rising T

OUT

I

OUT

I

CNTL

V

REF

V

REF

V

REF

V

J

=0A 2

=±3A (Norm al Operation),

=5V

=GND (S hutdown)

=1.25V/0.9V (Normal Operation)

=GND (Shutdown)

=25°C

-20 20 mV

+3.3 +3.6

-3.3 -3.6

+2.9 +3.2

-2.9 -3.2

0.2

REF

V

-9

2

-3

7

+3.1

-3.1

+2.6

-2.6

150

40

4.5

50 110

2.6

150

20

0.35

Unit

V

mV

8

mV

12

A

o

C

o

C

6

mA

500 nA

40

µA

0.65 V

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw4

Page 5

APL5331

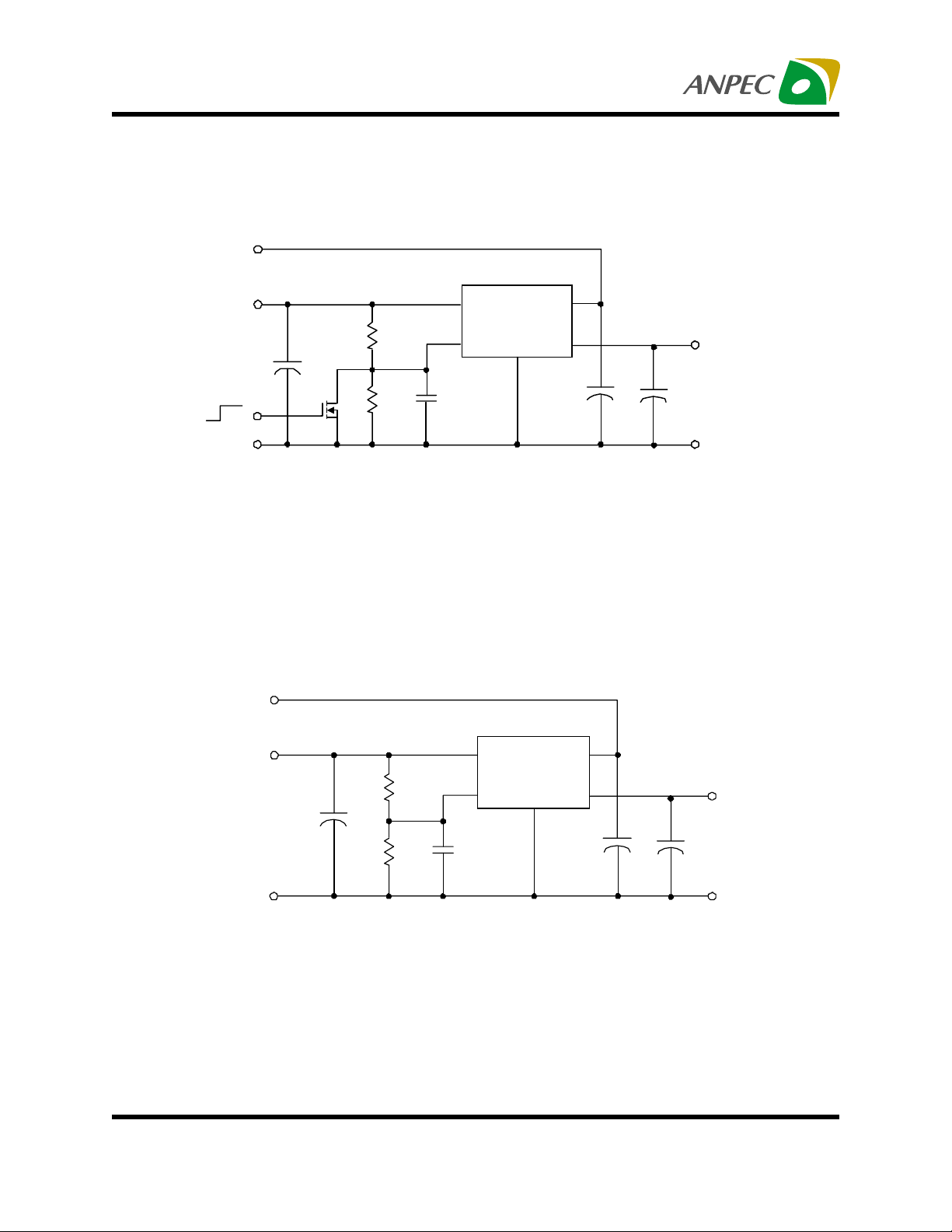

Typical Application Circuit

1. VOUT=1.25V/0.9V Application

V

CNTL

+3.3V

V

IN

+2.5V/1.8 V

R

1

1k

R

2

1k

Q

1

470uF

Shutdown

C

IN

V

REF

C

0.1uF

SS

VIN

VREF

GND

VCNTL

VOU T

C

47uF

CNTL

C

OUT

470uF

V

OUT

+1.25V/0.9V

-3~+3A

GND

COUT : 470µF, ESR=25mΩ

R1, R2 : 1kΩ, 1%

Q1 : APM2300 AC

Note : Since R1 and R2 are very small, the voltage offset

caused by the bias current of VREF can be ignore.

2. VOUT=1.4V Application

CNTL

V

+5V

IN

V

+2.8V

IN

C

470µF

R

1k

R

1k

GND

VIN

1

2

VREF

REF

V

SS

C

0.1µF

GND

VCNTL

VOU T

C

47µF

CNTL

OUT

C

470µF

OUT

V

+1.4V/

-3~+3A

GND

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

GND

www.anpec.com.tw5

Page 6

APL5331

Typical Characteristics

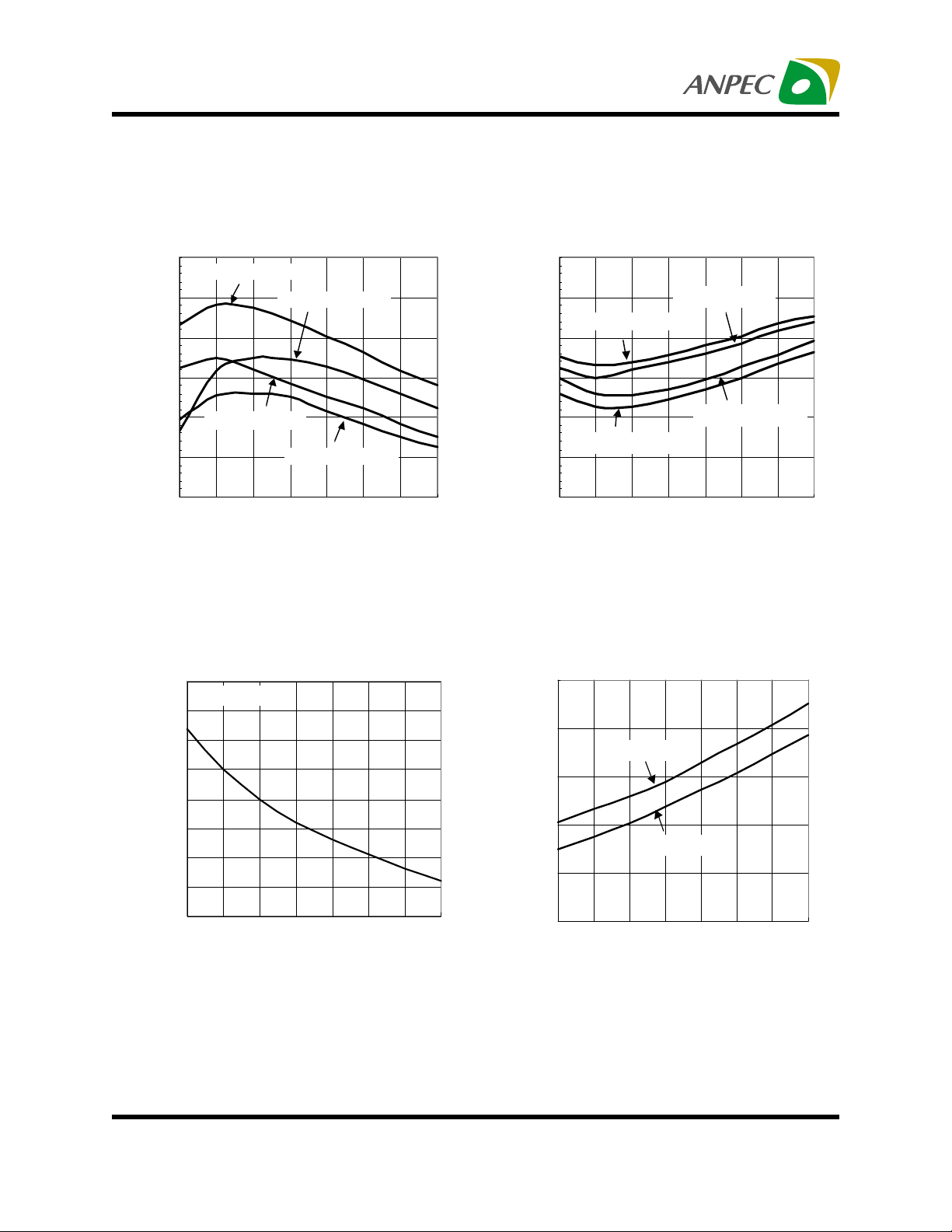

Sourcing Current-Limit

vs Junction T emperature

5.0

4.5

4.0

3.5

3.0

2.5

Current-Limit, ILIM (A)

2.0

VCNTL=5V,VIN=2.5V

VCNTL=3.3V,VIN=2.5V

VCNTL=5V,VIN=1.8V

VCNTL=3.3V,VIN=1.8V

-50 -25 0 25 50 75 100 125

Junction Temperature (°C)

VREF Bias Current

vs Junction T emperature

0.40

V

=1.25V/0.9V

REF

0.35

0.30

0.25

0.20

0.15

0.10

0.05

VREF Bias Current, IVREF (µA)

0.00

-50 -25 0 25 50 75 100 125

Sinking Current-Limit

vs Junction T emperature

-2.0

-2.5

VCNTL=3.3V,VIN=1.8V

-3.0

-3.5

-4.0

Current-Limit, ILIM (A)

-4.5

-5.0

VCNTL=5V,VIN=2.5V

-50 -25 0 25 50 75 100 125

VCNTL=5V,VIN=1.8V

VCNTL=3.3V,VIN=2.5V

Junction Temperature (°C)

VREF Shutdown Threshold

vs Junction T emperature

0.6

0.5

V

=5V

CNTL

0.4

0.3

V

=3.3V

CNTL

0.2

VREF Shutdown Threshold (V)

0.1

-50 -25 0 25 50 75 100 125

Junction Temperature (°C)

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

Junction Temperature (°C)

www.anpec.com.tw6

Page 7

APL5331

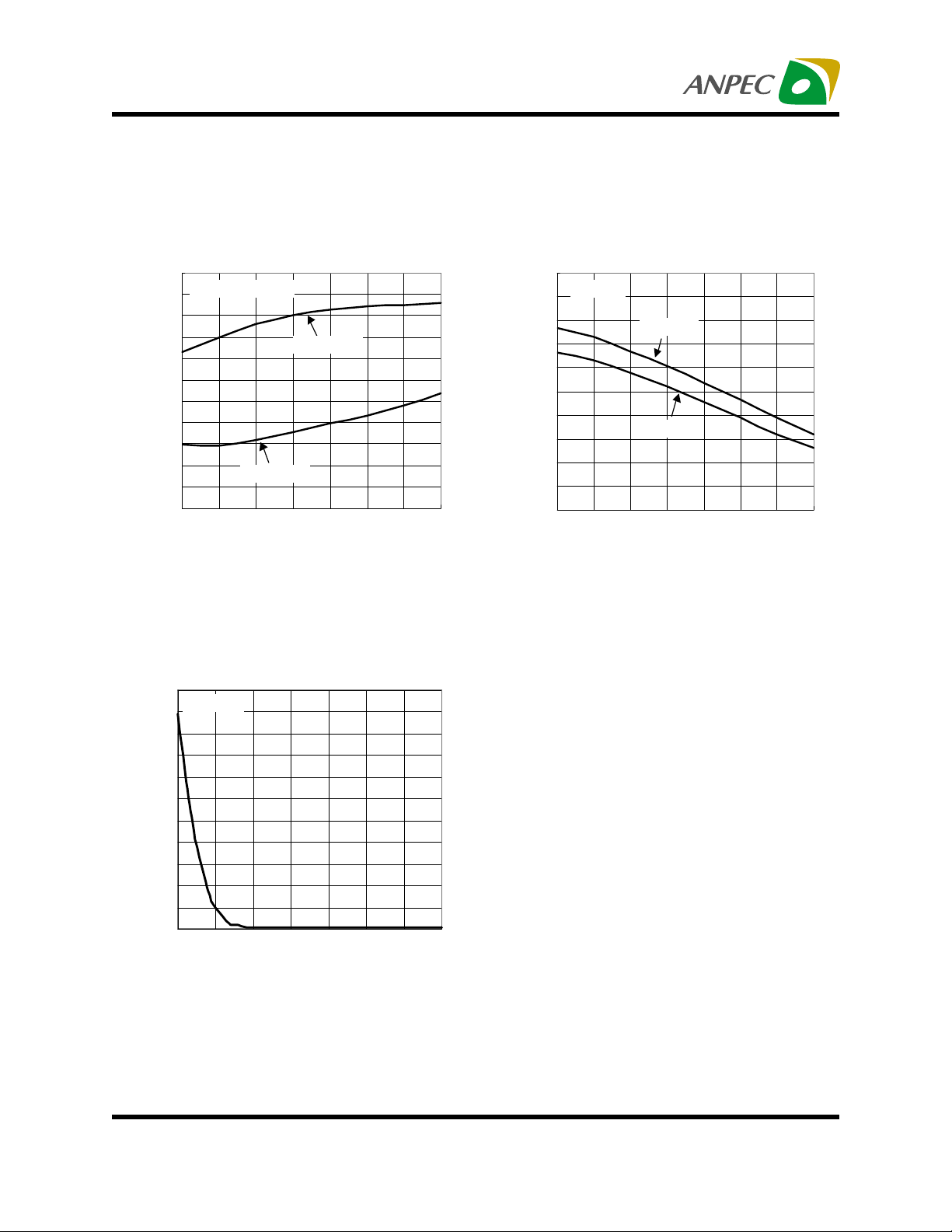

Typical Characteristics (Cont.)

VOUT Offset V oltage

vs Junction T emperature

6

V

=1.25V/0.9V

REF

4

2

0

-2

-4

-6

-8

-10

-12

-14

VOUT Offset V oltage, VOS (mV)

-16

-50 -25 0 25 50 75 100 125

I

OUT

=+10mA

I

OUT

=-10mA

Junction Temperature (°C)

VREF Bias Current

vs VREF Supply Voltage

22

TJ=25°C

20

18

16

14

12

10

8

6

4

VREF Bias Current, IVREF (µA)

2

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

Quiescent VCNTL Current

vs Junction T emperature

7.0

I

=0A

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

Quiescent VCNTL Current (mA)

2.0

OUT

V

=5V

CNTL

V

=3.3V

CNTL

-50-250 255075100125

Junction Temperature (°C)

VREF Supply Votage, VREF (V)

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw7

Page 8

APL5331

Operating Waveforms

1. Load Transient Response : IOUT = +10mA -> +3A -> +10mA

- VIN = 2.5V, VCNTL = 3.3V

- VREF is 1.250V supplied by a regulator

- COUT = 470µF/10V, ESR = 30mΩ

- IOUT slew rate = ±3A/µS

OUT = +10mA -> +3A

I

IOUT = +10mA -> +3A -> +10mA

Load Regulation = -2.8mV

OUT = +3A -> +10mA

I

V

OUT

I

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 1µS/Div

OUT

+10mA

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 20µS/Div

+3A

2. Load Transient Response : IOUT = -10mA -> -3A -> -10mA

- VIN = 2.5V, VCNTL = 3.3V

- VREF is 1.250V supplied by a regulator

- COUT = 470µF/10V, ESR = 30mΩ

- IOUT slew rate = ±3A/µS

IOUT = -10mA -> -3A

V

OUT

IOUT = -10mA -> -3A -> -10mA

Load Regulation = +6.2mV

V

OUT

I

OUT

V

OUT

I

OUT

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 1µS/Div

IOUT = -3A -> -10mA

V

OUT

V

OUT

I

OUT

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 1µS/Div

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

-10mA

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 20µS/Div

-3A

I

OUT

I

OUT

Ch1 : VOUT, 20mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 1A/Div

Time : 1µS/Div

www.anpec.com.tw8

Page 9

APL5331

Operating Waveforms (Cont.)

3. Load Transient Response : IOUT = +3A -> -3A -> +3A

- VIN = 2.5V, VCNTL = 3.3V

- VREF is 1.250V supplied by a regulator

- COUT = 470µF/10V, ESR = 30mΩ

- IOUT slew rate = ±3A/µS

I

OUT = +3A -> -3A

V

OUT

IOUT = +3A -> -3A -> +3A

OUT = -3A -> +3A

I

V

OUT

V

OUT

Ch1 : VOUT, 50mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 2A/Div

Time : 1µS/Div

4. Short-Circuit Test

- V

IN = 2.5V, VCNTL = 3.3V

VOUT is Shorted to GND

I

OUT

-3A

Ch1 : VOUT, 50mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 2A/Div

Time : 20µS/Div

I

OUT

+3A

I

OUT

Ch1 : VOUT, 50mV/Div, DC,

Offset = 1.250V

Ax1 : IOUT, 2A/Div

Time : 1µS/Div

VOUT is Shorted to VIN (2.5V)

I

OUT

I

OUT

V

OUT

Ch1 : VOUT, 500mV/Div, DC,

Ax1 : IOUT, 2A/Div

Time : 5mS/Div

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

V

OUT

V

OUT

I

OUT

Ch1 : VOUT, 500mV/Div, DC,

Ax1 : IOUT, 2A/Div

Time : 5mS/Div

www.anpec.com.tw9

Page 10

APL5331

Application Information

General

The APL5331 is a linear regulator and is capable of

sourcing or sinking current up to 3A. The APL5331

has fast transient response, accurate output voltage

(small voltage offset, load regulation), active-low shutdown control and fault protections (current-limit, thermal shutdown). The APL5331 is available in several

packages to meet different of power dissipation in

requirement various applications.

Output V oltage Regulation

The output voltage at VOUT pin tracks the reference

voltage applied at VREF pin. Two internal NPN pass

transistors controlled by separate high bandwidth error amplifiers regulate the output voltage by sourcing

current from VIN pin or sinking current to GND pin.

The base currents of the pass transistors are provided by VCNTL pin. An internal kelvin sensing

scheme use at the VOUT pin for perfect load regulation at various load current. To prevent the two pass

transistors from shoot-through, a small voltage offset

is created between the positive inputs of the two error

amplifiers. This results in higher output voltage while

the regulator sinks light or heavy load current. Since

the APL5331 exhibits very fast load transient

response, lesser amount of capacitors can be use.

In addition, capacitors with high ESR can also be

use.

Current Limit

The APL5331 monitors sourcing and sinking current,

and limits the maximum output current to prevent damages during overload or short-circuit, To increase

the input voltage of VIN or VCNTL will get higher

current-limit points.

Shutdown and Soft-Start

The VREF pin is a dual-function input pin, acting as

reference input and shutdown control input. Applying and holding a voltage below 0.35V(typ.) to VREF

pin shuts down the output of the regulator. An NPN

transistor or N-channel MOSFET is used to pull down

the VREF while applying a “high” signal to turn on the

transistor. When shutdown function is active, the

two pass transistors are turned off and the impedance of the VOUT is about 10MΩ (typ.), sourcing or

sinking no current. When release the VREF pin, the

current through the resistor divider charges the softstart capacitor to initiate a soft-start cycle. The output

voltage tracks the rising VREF. The soft start process

limits the input surge current.

Thermal Shutdown

An thermal shutdown circuit limits the junction temperature of the APL5331. When the junction temperature exceeds TJ= +150oC, a thermal sensor turns

off both pass transistors, allowing the device to cool

down. The regulator starts to regulate again after the

junction temperature reduces by 40oC, resulting in a

pulsed output during continuous thermal overload

conditions. The thermal limit designed with a 40oC

hysteresis lowers the average TJ during continuous

thermal overload conditions, extend life time of

APL5331.

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw10

Page 11

APL5331

Application Information

Power Inputs

Input power sequence are not required for VIN and

VCNTL. However, do not apply a voltage to VOUT

when there is not voltage VCNTL. This is due to the

internal parasitic diodes between VOUT to VIN and

VOUT to VCNTL which will be forward bias. The

APL5331 can source few current or sinks current up

to 3A for load when the input Voltage at VIN is not

present.

Reference V oltage

A reference voltage is applied at the VREF pin by a

resistor divider between VIN and GND pins. Normally

the bias current of the VREF pin flows out of the IC

and is about 150nA(typ.), creating voltage offset at

the resistor divider and affecting the output voltage

accuracy. The recommended resistor is <5kΩ to

maintain the accuracy of the output voltage. An external bypass capacitor is also connected to VREF.

The capacitor and the resistor divider form a lowpass filter to reduce the inherent reference noise from

VIN. A ceramic capacitor can be use and is selected

to be greater than 0.1µF. Connected the capacitor

as close to VREF as possible for optimal effect. More

capacitance and large resistor divider will increase

the soft-start interval. Do not place any additional loading on this reference input pin.

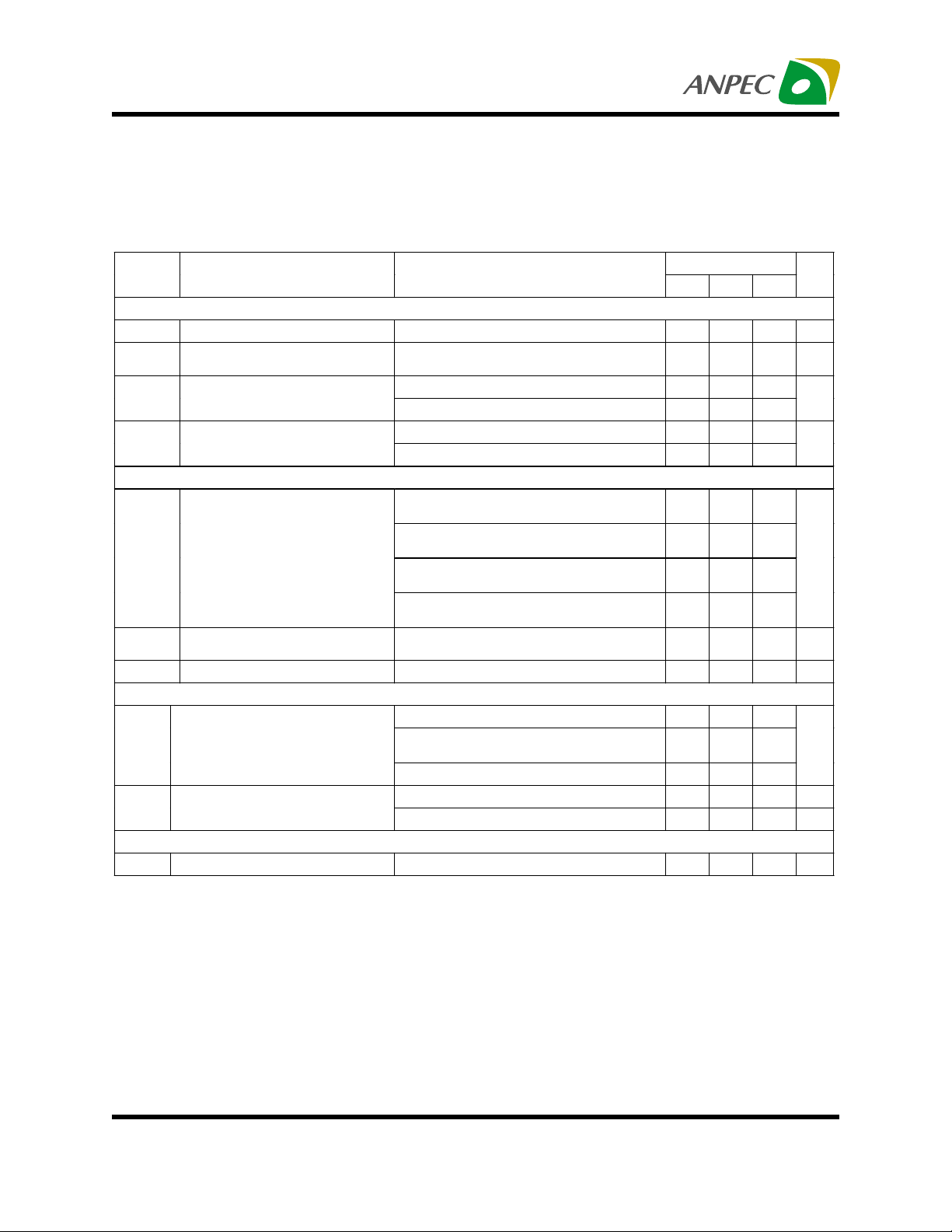

Output Capacitor

The APL5331 requires a proper output capacitor to

maintain stability over full temperature and current

ranges, and improve transient response. The output

capacitor selection is dependent upon the ESR

(equivalent series resistance) and capacitance of the

output capacitor over full temperature range. The following chart shows the stable region of the output

capacitor for APL5331. The stable region is above

the curve, indicating minimum required ESR and

capacitance to maintain stability. However, the out

put capacitor should have an ESR less than 1Ω.

25

25

ESR (m

ESR (m

20

20

Stable Region

15

15

Ω

Ω

10

10

)

)

5

5

0

0

10 100 1000

10 100 1000

Stable Region

Capacitance(µF)

Capacitance(µF)

Ultra-low-ESR capacitors, such as ceramic chip

capacitors, may promote under-damped transient

response, but proper ceramic chip capacitors placed

near loads can be used as decoupling capacitors. A

low-ESR solid tantalum and aluminum electrolytic capacitor (ESR<1Ω) works extremely well and provides

good transient response and stability over temperature.

The output capacitors are also used to reduce the

slew rate of load current and help the APL5331 to

minimize variations of the output voltage, improving

transient response. For this purpose, the low-ESR

capacitors are recommended and depend on the stepping and slew rate of load current.

Input Capacitor

The input capacitors of VCNTL and VIN pins are not

required for stability but for supplying surge currents

during large load transients, This will prevent the input rail from drooping and improve the performance

of the APL5331. Because of parasitic inductors from

voltage sources or other bulk capacitors to the VCNTL

and VIN pins will limit the slew rate of the surge currents during large load transients, resulting in voltage

drop at VIN and VCNTL pins.

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw11

Page 12

APL5331

A capacitor of 1µF (ceramic chip capacitor) or greater

(aluminum electrolytic capacitor) is recommended to

connect near VCNTL pin. For VIN pin, an aluminum

electrolytic capacitor (>50µF) is recommended. It is

not necessary to use low-ESR capacitors.

Layout and Thermal Consideration

The input capacitors for VIN and VCNTL pins are

normally placed near each pin for good

performances. Ceramic decoupling capacitors at

output must be placed as close to the load to reduce

the parasitic inductors of traces. It is also recommended that the APL5331 and output capacitors are

placed near the load for good load regulation and

load transient response. The negative pins of the input and output capacitors and the GND pin of the

APL5331 should connect to analog ground plane of

the load.

See figure 1. The SOP-8-P utilizes a bottom thermal

pad to minimize the thermal resistance of the package,

making the package suitable for high current

applications. The thermal pad is soldered to the top

ground pad and is connected to the internal or bottom ground plane by several vias. The printed circuit

board (PCB) forms a heat sink and dissipates most

of the heat into ambient air. The vias are recommended to have proper size to retain solder, helping

heat conduction.

Thermal resistance consists of two main elements,

? JC (junction-to-case thermal resistance) and ? CA

(case-to-ambient thermal resistance). ? JC is specified from the IC junction to the bottom of the thermal

pad directly below the die. ?CA is the resistance from

the bottom of thermal pad to the ambient air and it

includes ? CS (case-to-sink thermal resistance) and

?SA (sink-to-ambient thermal resistance). The speci-

fied path for heat flow is the lowest resistance path

and it dissipates majority of the heat to the ambient

air. Typically , ?CA is the dominant thermal resistance.

Therefore, enlarging the internal or bottom ground

plane reduces the resistance ?CA . The relationship

between power dissipation and temperatures is the

following equation :

PD = (TJ - TA) / ?JA

where,

PD : Power dissipation

TJ : Junction Temperature

TA : Ambient Temperature

? JA : Junction-to-Ambient Thermal Resis tance

102 mil

118 mil

Ambient

Air

SOP-8-P

Die

Vias

Thermal

pad

Internal

ground

plane

Top

ground

pad

Printed

circuit

board

Figure 1 Package Top and side view

Figure 2 shows a board layout using the SOP-8-P

package. The demo board is made of FR-4 material

and is a two-layer PCB. The size and thickness are

65mm* 65mm and 1.6mm. An area of 140mil*105mil

on the top layer is use as a thermal pad for the

APL5331 and this is connected to the bottom layer

by vias. The bottom layer using 2 oz. copper acts as

the ground plane for the system. The PCB and all

components on the board form a heat sink. The ?JA

of the APL5331(SOP-8-P) mounted on this demo

board is about 37oC/W in free air. Assuming the

TA=25oC and the maximum TJ=150oC (typical thermal

limit temperature), the maximum power dissipation is

calculated as :

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw12

Page 13

APL5331

PD (max) = (150 - 25) / 37

= 3.38W

If the TJ is designed to be below 125oC, the calculated power dissipation should be less than :

PD = (125 - 25) / 37

= 2.70W

APL5331

Figure 2(c) Bottom layer

Figure 2(a) TopOver layer

APL5331

Figure 2(b) Top layer

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw13

Page 14

APL5331

Packaging Information

SOP-8 pin ( Reference JEDEC Registration MS-012)

HE

0.015X45

e1 e2

D

A1

A

1

L

0.004max.

Dim

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

H 5.80 6.20 0.228 0.244

L 0.40 1.27 0.016 0.050

e1 0.33 0.51 0.013 0. 020

e2 1.27BSC 0.50BSC

18

φ

Millimeters Inches

Min. Max. Min. Max.

°

8

°

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw14

Page 15

APL5331

Packaging Information

SOP-8-P pin ( Reference JEDEC Registration MS-012)

E1

HE

0.015X45

D1

e1 e2

D

A1

A

1

L

0.004max.

Dim

A 1.3 5 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.0 10

D 4.80 5.00 0.189 0.197

D1

E 3.8 0 4.00 0.150 0.157

E1 2.60REF 0.102REF

H 5.80 6.20 0.228 0.244

L 0.40 1.27 0.016 0.050

e1 0.33 0.5 1 0.013 0.020

e2 1.27BSC 0.50BSC

φ 18° 8°

Millimeters Inches

Min. Max. Min. Max.

3.00REF

0.11 8REF

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw15

Page 16

APL5331

Packaging Information

TO-252-5

A

B

CD

M

PS

K

H

J

L

E1

D1

Dim

Min. Max. Min. Max.

A 6.40 6.80 0.25 0.26

B 5.20 5.50 0.20 0.21

C 6.80 7.20 0.26 0.27

D 2.20 2.80 0.08 0.11

D1 5.2REF 0.205REF

E1 5.3REF 0.209REF

P 1.27REF 0.05REF

S 0.50 0.80 0.02 0.03

H 2.20 2.40 0.08 0.09

J 0.45 0.55 0.01 0.02

K 0.45 0.60 0.018 0.024

L 0.90 1.50 0.03 0.06

M 5.40 5.80 0.21 0.22

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

Millimeters Inches

www.anpec.com.tw16

Page 17

APL5331

Packaging Information

TO-263-5

D

BE

L

b

L1

e

e1

L2

A

c1

v

A1

c

Dim

A

b

b1

c

c1

D

E

L

L1

Min. Max. Min. Max.

4.06 4.83

0.50 0.99

1.52 1.83

0.457 0.736

1.14 1.40

8.25 9.66

9.65 10. 29

14.60 15.88

2.28 2.80

L2

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

Millimeter s Inches

0.160 0.190

0.020 0.039

0.060 0.072

0.018 0.029

0.045 0.055

0.325 0.380

0.380 0.405

0.575 0.625

0.090 0.110

1.40

0.055

www.anpec.com.tw17

Page 18

APL5331

Physical Specifications

Terminal Material Solder-Plated Copper (So lder Material : 90/10 or 63/37 SnPb)

Lead Solderab ility Meets EIA Specification RSI86-91, A NSI/J-STD-002 Category 3.

Reflow Condition (IR/Convection or VPR Reflow)

Reference JEDEC Standard J-STD-020A APRIL 1999

Peak temperature

temperature

Pre-heat temperature

°

183 C

Time

Classification Reflow Prof iles

Convection or IR/

Convection

Average ramp-up rate(183°C to Peak) 3°C/second max. 10 °C /second max .

Preheat temperature 125 ± 25°C)

Temperature maintained above 183°C

Time within 5°C of actual peak temperature

Peak temperature range

Ramp-down rate

Time 25°C to peak temperature

120 seconds max

60 – 150 seconds

10 –20 seconds 60 seconds

220 +5/-0°C or 235 +5/-0°C 215-219°C or 235 +5/-0°C

6 °C /second max . 10 °C /second max .

6 minutes max.

VPR

Package Reflow Conditions

pkg. thickness

and all bgas

Convection 220 +5/-0 °C Convection 235 +5/-0 °C

VPR 215-219 °C VPR 235 +5/-0 °C

IR/Convection 220 +5/-0 °C IR/Convection 235 +5/-0 °C

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

2.5mm

≥≥≥≥

pkg. thickness < 2.5mm and

pkg. volume

350 mm³

≥≥≥≥

pkg. thickness < 2.5mm and pkg.

volume < 350mm³

www.anpec.com.tw18

Page 19

APL5331

R e lia bility te s t pro g r a m

SOLDERA BILITY MIL-STD-883D-2003

HO LT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

245°C , 5 SEC

1000 Hrs Bias @ 125 °C

168 Hrs, 100 % RH , 121°C

-65°C ~ 150°C, 200 Cycles

ESD MIL-STD-883D -3015.7 VHBM > 2KV, VMM > 200V

La tc h -Up J E SD 7 8 10 ms , Itr > 100mA

Carrier Tape

t

Test item Method D escription

E

F

W

Po

P

P1

Ao

D

Bo

Ko

D1

T2

A

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

J

C

B

T1

www.anpec.com.tw19

Page 20

APL5331

Application

SOP- 8

SOP-8-P

Application

TO-252

Application

TO-263

A B C J T1 T2 W P E

330 ± 1 62 +1.5

F D D1 Po P1 Ao Bo Ko t

5.5± 1 1.55 +0.1 1.55+ 0.25 4.0 ± 0.1 2.0 ± 0.1 6.4 ± 0.1 5.2± 0. 1 2.1± 0.1 0.3±0.013

A B C J T1 T2 W P E

330 ±3100 ± 213 ± 0. 5 2 ± 0.5

F D D1 Po P1 Ao Bo Ko t

7.5 ± 0.1 1.5 +0.1 1.5± 0.25 4.0 ± 0.1 2.0 ± 0.1 6.8 ± 0.1 10.4± 0.1 2.5± 0.1 0.3±0.05

A B C J T1 T2 W P E

380±380 ± 213 ± 0. 5 2 ± 0.5 24 ± 42± 0.3

F D D1 Po P1 Ao Bo Ko t

11.5 ± 0.1 1.5 +0.1 1.5± 0.25 4.0 ± 0.1 2.0 ± 0.1 10.8 ± 0.1 16.1± 0.1 5.2± 0.1 0.35±0.013

12.75+

0.15

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

SOP- 8 / SOP -8-P

TO- 252

TO- 263

12 9.3 2500

16 13.3 2500

24 21.3 1000

2 ± 0.5 12.4 ± 0.2 2 ± 0.2 12± 0. 3 8± 0.1 1.75±0.1

16.4 + 0.3

-0.2

2.5± 0.5

16+ 0.3

- 0.1

24 + 0.3

- 0.1

8 ± 0.1 1.75± 0.1

16 ± 0.1 1.75± 0.1

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, T aiwan, R.O.C.

T el : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, T aipei Hsien, Taiwan, R. O. C.

T el : 886-2-89191368

Fax : 886-2-89191369

Copyright ANPEC Electronics Corp.

Rev. A.8 - Oct., 2003

www.anpec.com.tw20

Page 21

Loading...

Loading...