Page 1

APL1117

1A Low Dropout Fast Response Positive Adjustable Regulator and Fixed

1.8V, 2.5V, 2.85V and 3.3V

Features

••

•

Guaranteed Output Voltage Accuracy within 2%

••

••

•

Fast Transient Response

••

••

•

Guaranteed Dropout Voltage at Multiple

••

Currents

••

•

Load Regulation : 0.1% Typ.

••

••

•

Line Regulation : 0.03% Typ.

••

••

• Low Dropout Voltage : 1.1V Typ. at I

••

••

• Current Limit : 1A Typ. at T

••

••

• On-Chip Thermal Limiting : 150°C Typ.

••

••

• Adjustable Output : 1.25~10.7V

••

••

• Standard 3-pin TO-220, TO-252, TO-263 and

••

SOT-223 Power Packages

=25°C

J

OUT

=1A

Applications

General Description

The APL1117 is a low dropout three-terminal adjustable regulators with 1A output current capability. In

order to obtain lower dropout voltage and faster transient response, which is critical for low voltage applications , the APL1117 has been optimized. The

device is available in an adjustable version and fixed

output voltages of 1.8V, 2.5V, 2.85V and 3.3V. The

output available voltage range of an adjustable version is from 1.25~10.7V with an input supply below

12V. Dropout voltage is guaranteed at a maximum of

1.3V at 1A. Current limit is trimmed to ensure specified output current and controlled short-circuit current.

On-chip thermal limiting provides protection against

any combination of overload that would create excessive junction temperatures. The APL1117 is available

in the industry standard 3-pin TO-220, TO-252, TO263, and the low profile surface mount SOT-223

power packages which can be used in applications

where space is limited.

Pin Description

••

• Active SCSI Terminators

••

••

• Low Voltage Logic Supplies

••

••

• Battery-Powered Circuitry

••

••

• Post Regulator for Switching Power Supply

••

TAB is V

TAB IS V

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

1

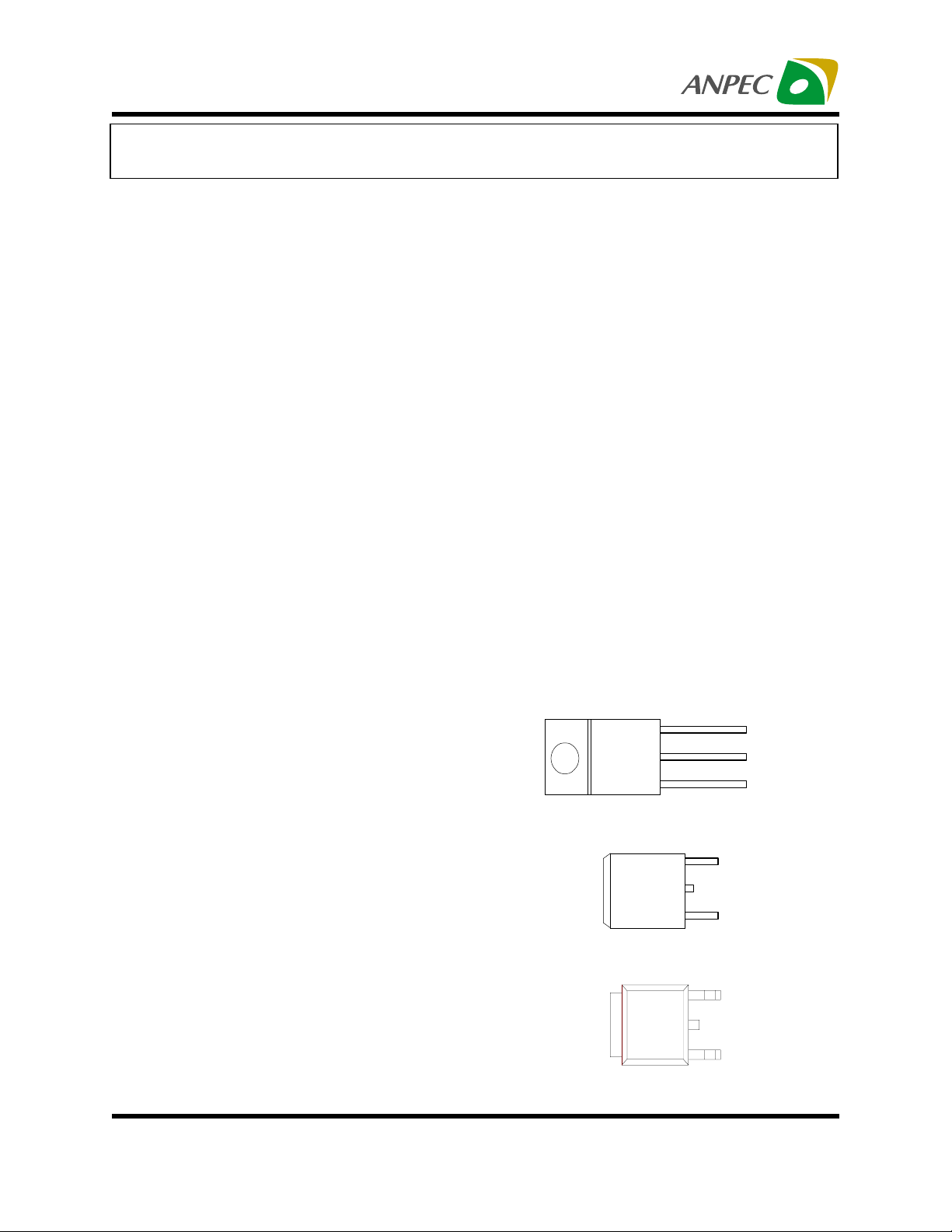

Front View for TO-220

3

2

1

Front View for TO-263

3

OUT

Front View for TO-252

OUT

2

1

3

2

1

V

IN

V

OUT

ADJ/GND

V

IN

V

OUT

ADJ/GND

V

IN

V

OUT

ADJ/GND

www.anpec.com.tw

Page 2

APL1117

Pin Description (Cont.)

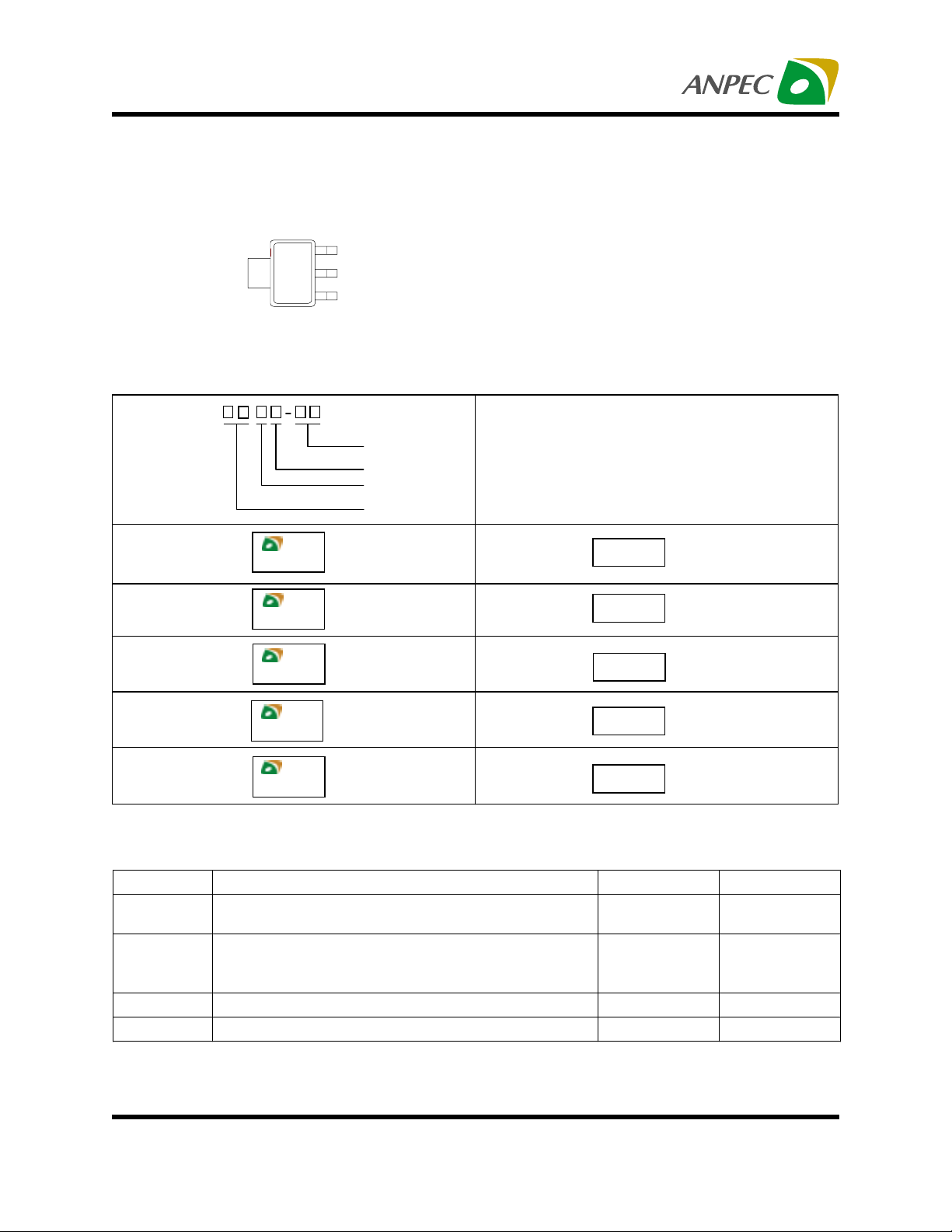

Front View for SOT-223

3

IN

T A B IS V

Ordering and Marking Information

OUT

OUT

2

1

ADJ/GN D

APL1117-

Handling Code

Tem p. Range

Package Code

Voltage Code

APL1117 F /G/U :

APL1117-18F/G/U :

APL1117-25F/G/U :

APL1117-28F/G/U :

APL1117

XXXXX

APL1117

XXXXX

25

APL1117

XXXXX

28

APL1117

XXXXX

33

APL1117

XXXXX

18

XXXXX

XXXXX

XXXXX

- D a te C od e

- D a te C od e

- D a te C od eXXXXX

- Date CodeXXXXX

- D a te C od e

Absolute Maximum Ratings

Package Code

F : T O -22 0 G : T O-26 3 U : T O -2 52 V : S OT-2 2 3

Tem p. Range

C : 0 to 70 C

Handling Code

TU : T u be TR : T ap e & R ee l

Voltage Code

18 : 1.8 V 25 : 2 .5V 28 : 2.8 5V 33 : 3.3 V

Blank : Adjustable Version

APL1117 V :

APL1117-28V :

°

APL1117

XXXXX

APL1117

XXXXX18

APL1117

XXXXX25

APL1117

XXXXX28

APL1117

XXXXX33

XXXXX - Date Code

XXXXX - Date CodeAPL1117-18V :

XXXXX - Date CodeAPL1117-25V :

XXXXX - Date Code

XXXXX - Date CodeAPL1117-33V :APL1117 -33F/G/U :

Symbol Parameter Rating

V

I

Input Voltage APL1117, APL1117-33

APL1117-18, APL1117-25, APL1117-28

T

J

Operating Junction Temperature Range

Control Section

Power Transistor

T

STG

T

L

Storage Temperature Range -65 to +150

Lead Temperature (Soldering, 10 second) 260

(Note)

15

9

0 to 125

0 to 150

Note : The values here show the absolute maximum rating, and for normal usage please refer the test condition in Electrical

Characteristics Table.

Copyright ANPEC Electronics Corp.

2

www.anpec.com.tw

Rev. B.8 - Jun., 2003

Unit

V

C

°

C

°

C

°

Page 3

APL1117

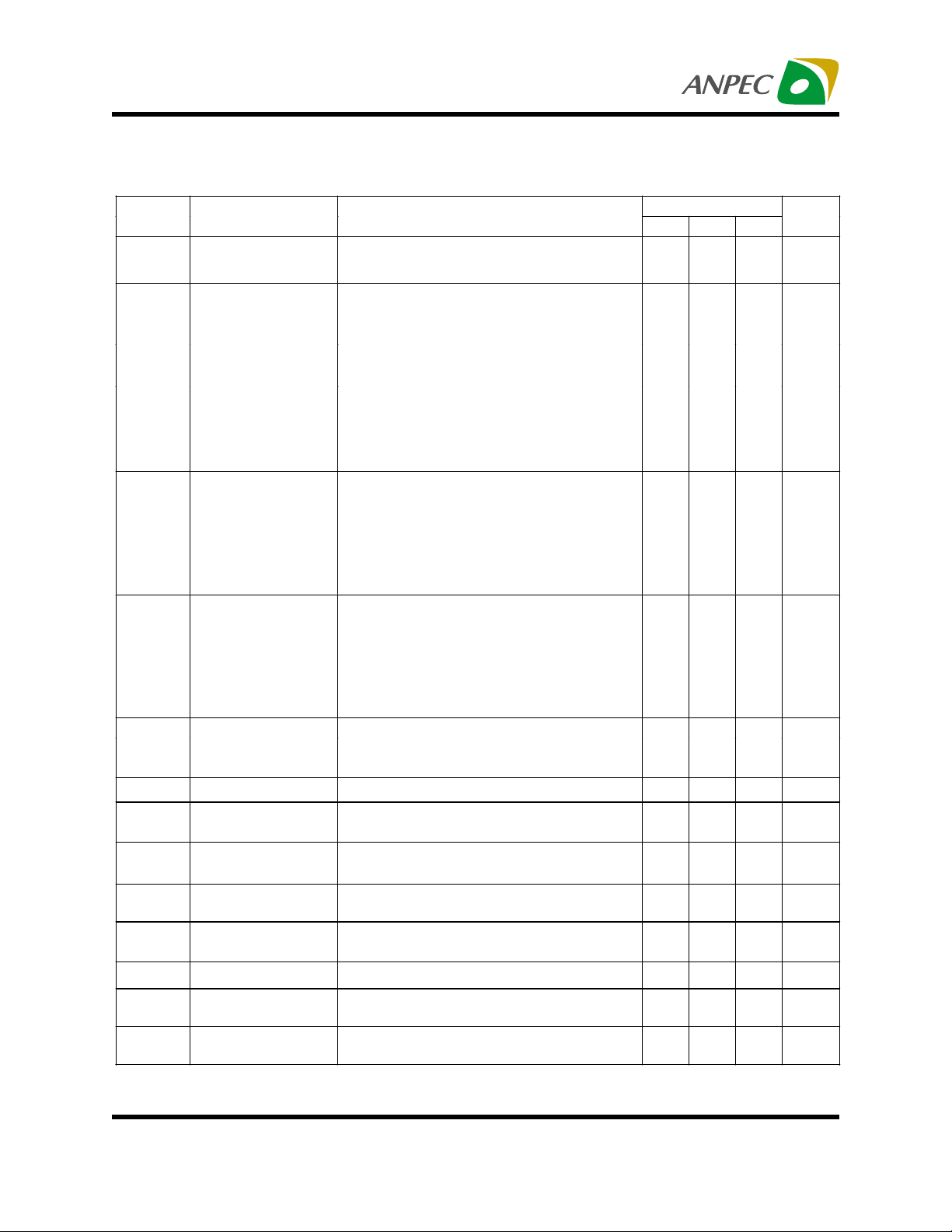

Electrical Characteristics (Cont.)

V

V

Reference Voltage

REF

Output Voltage

OUT

APL1117-18

APL1117-25

APL1117-28

APL1117-33

REG

Line Regulation

LINE

APL1117

APL1117-18

APL1117-25

APL1117-28

APL1117-33

REG

Load Regulation

LOAD

APL1117

APL1117-18

APL1117-25

APL1117-28

APL1117-33

Dropout Voltage

D

I

LIMIT

I

Current Limit

Adjust Pin Current

ADJ

APL1117

Adjust Pin Current

I

∆

ADJ

Change APL1117

I

Minimum Load

O

Current APL1117

PSRR Ripple R eje ctio n f

T

T

Thermal Regulation

R

Temperature

S

Stability

L

S

Long -Term

Stability

10mA≤ I

T

=0~125°C

J

T

=0~125°C,

J

0≤ I

OUT

=0~125°C,

T

J

0≤ I

OUT

=0~125°C,

T

J

0≤ I

OUT

=0~125°C,

T

J

0≤ I

OUT

I

10mA, 1.5V≤(V

=

OUT

I

0A, 3.5V≤V

=

OUT

I

0A, 4V≤V

=

OUT

I

0A, 4.25V≤V

=

OUT

I

0A, 4.75V≤V

=

OUT

(V

IN -VOUT

VIN=3.5V, 0≤ I

V

=4V, 0≤ I

IN

VIN=4.25V, 0≤ I

VIN=4.75V, 0≤ I

I

=100mA

OUT

=500mA

I

OUT

I

=1A

OUT

(V

IN -VOUT

(V

IN -VOUT

10mA≤ I

1.4V≤(V

(V

IN -VOUT

=120Hz, V

RIPPLE

(V

IN -VOUT

T

=25°C, 30ms Pulse

J

=125°C,1000Hrs.

T

J

1A, 1.4V≤(V

≤

OUT

1.5A, 3.5V≤V

≤

1A, 4V≤V

≤

1A, 4.25V≤V

≤

1A, 4.75V≤V

≤

IN

≤

IN

=3V, 0≤ I

)

OUT

≤

OUT

OUT

OUT

(Note2)

(Note2)

(Note2)

)=5V, TJ=25°C

=3V, I

)

OUT

1A,

≤

OUT

≤10.75V

)

IN -VOUT

)=10.75V

=3V

)

APL1117Symbol Parameter Test Conditions

Min. Typ. Max.

≤10.75V,

)

≤

IN

IN -VOUT

9V

≤

5.5V

5.15V

≤

IN

7.75V

≤

IN

OUT

1A

≤

(Note1)

1A

1A

≤

1A

≤

IN

9V,

≤

IN

IN

(Note1)

(Note1)

≤

(Note1)

≤

9V,

≤

1A

(Note1)

(Note1)

IN -VOUT

9V,

12V,

)≤10.75V

(Note1)

(Note1)

(Note1)

1.225 1.250 1.275

1.764 1.800 1.836

2.450 2.500 2.550

2.790 2.850 2.910

3.235 3.300 3.365

(Note1)

0.03

1

1

1

1

0.1

1

1

1

1

11.1V

1.05

1.1

1000 mA

=10mA 60 120

0.2 5

(Note3)

RIPPLE

=1V

P-P,

1.7 mA

60 75 dB

0.01 0.02 %/ W

0.5 %

0.3 %

0.2

6

6

6

6

0.4

10

10

10

10

1.2

1.3

Unit

V

V

%

mV

%

mV

V

A

µ

A

µ

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

3

www.anpec.com.tw

Page 4

APL1117

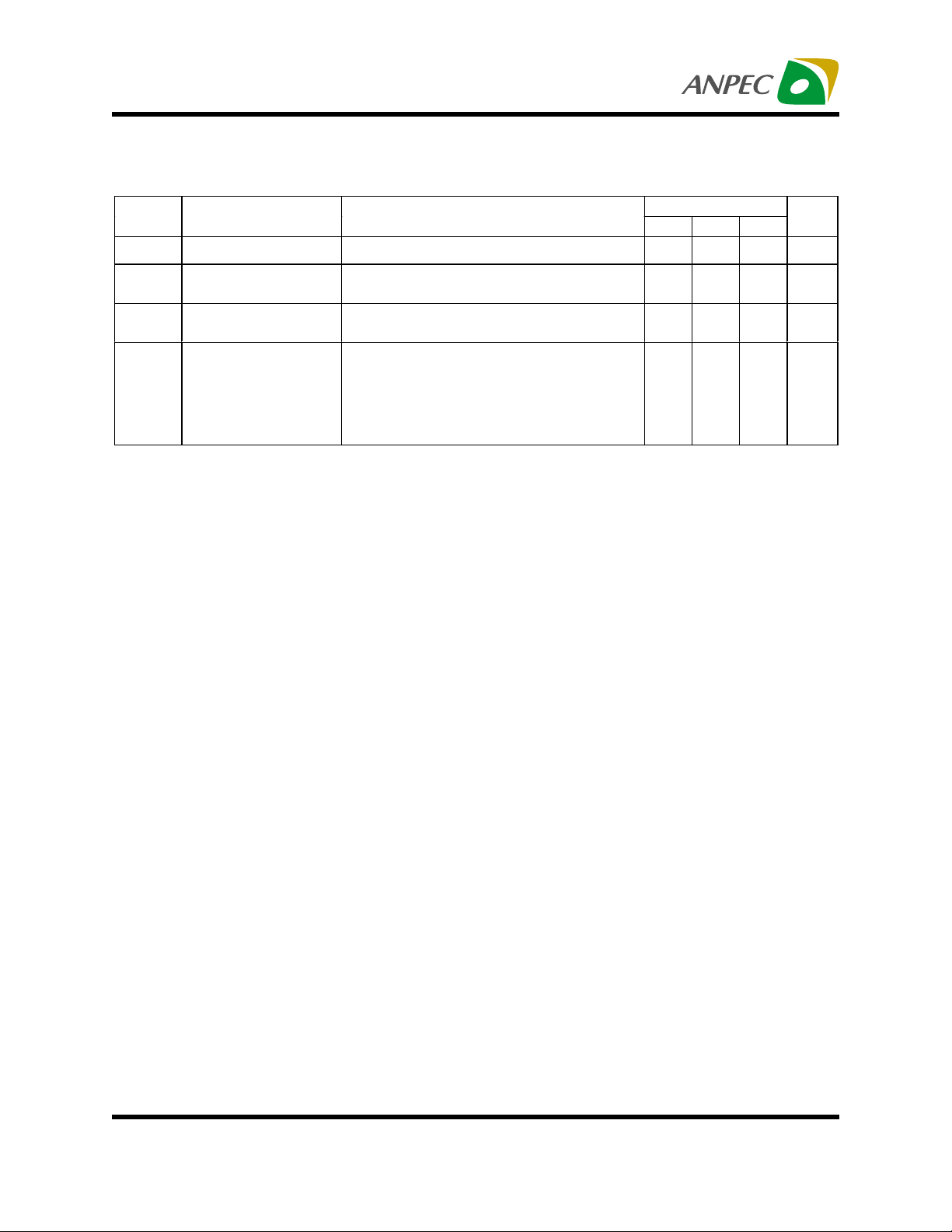

Electrical Characteristics (Cont.)

Symbol Parameter Test Conditions

V

RMS Output Noise

N

Thermal Resistance Junction to C ase, at Tab

θ

th

T

=25°C,10Hz≤F≤10kHz, (% of V

J

Junction to Ambient

OT

Over Temperature

OUT

)

APL1117

Min. Typ. Max.

0.003 %

15

50

150

Unit

C/ W

°

°

C

Point

I

Quiescent Current

Q

APL1117-18

APL1117-25

APL1117-28

APL1117-33

Note 1 : See thermal regulation specifications for changes in output voltage due to heating effects. Load line regulations are mea sured at a constant junction temperature by low duty cycle pulse testing.

Note 2 : Dropout voltage is specified over the full output current range of the device. Dropout voltage is defined as the minimum input/output

differential measured at the specified output current. Test points and limits are also shown on the Dropout Voltage curve.

Note 3 : Minimum load current is defined as the minimum output current required to maintain regulation.

V

9V

≤

IN

9V

V

≤

IN

V

9V

≤

IN

V

12V

≤

IN

5.5

5.5

5.5

5.5

10

10

10

10

mA

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

4

www.anpec.com.tw

Page 5

APL1117

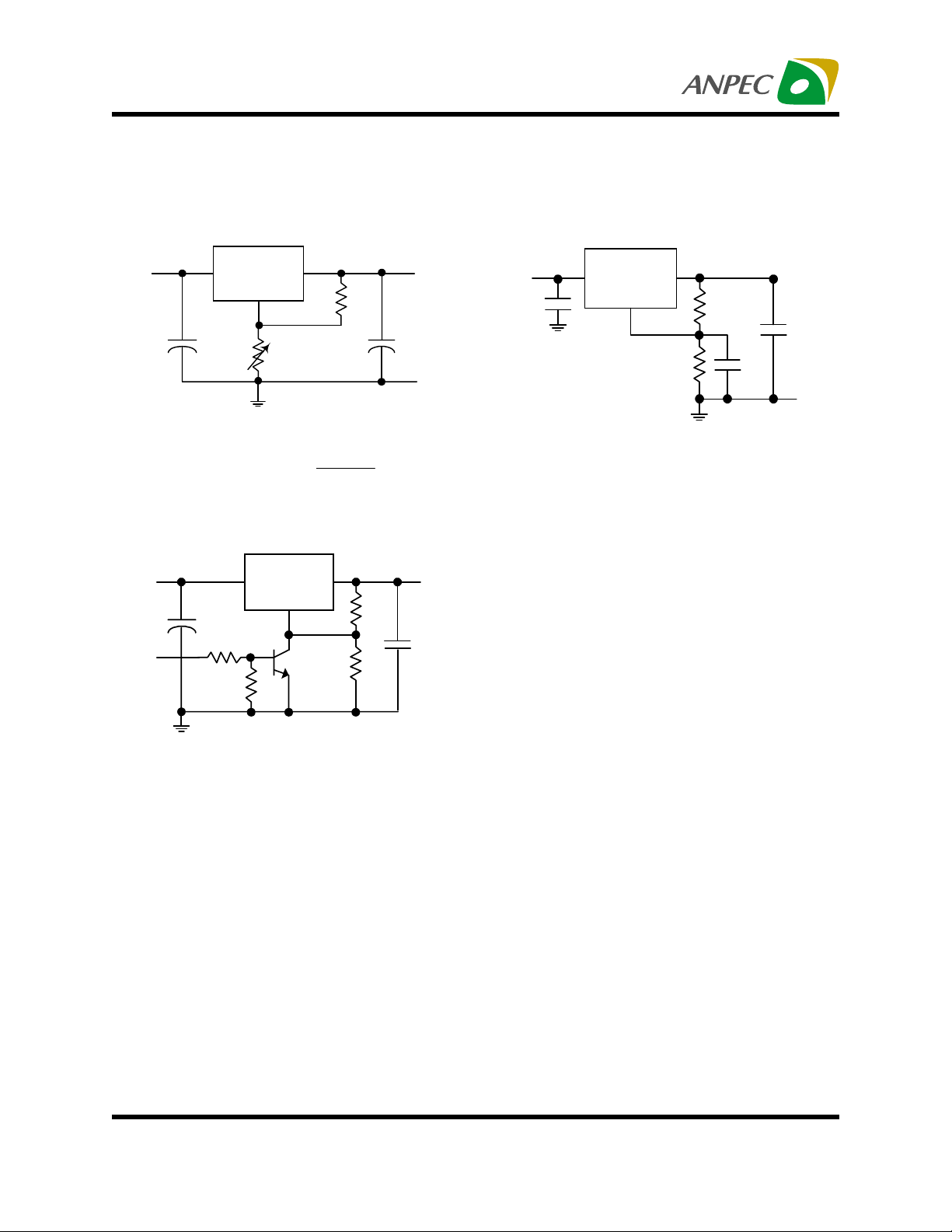

Application Circuits

1.25V to 10.7V Adjustable Regulator Impro ving Ripple Rejection

V

IN

+

* Needed if device is far from filter capacitors

APL1117

F

10µ

C

1*

OUT

V

= 1.250V X

ADJ

OUTIN

R1

121

R2

1k

R1 + R2

5V Regulator with Shutdown

APL1117

V

IN

TTL

+

10µ

F

1k

OUTIN

ADJ

1k

V

OUT1

Ω

F

100µ

+

C

2

V

10µ

ADJ

OUTIN

R1

121

Ω

IN

+

F

1%

R2

365

Ω

C1

+

10µ

F

V

OUT

150µF

1%

APL1117

* C1 improves ripple rejection.

X

should be approximately

C

equal to R1 at ripple frequency

R1

5V

121

Ω

1%

365

+

Ω

100µ

F

1%

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

5

www.anpec.com.tw

Page 6

APL1117

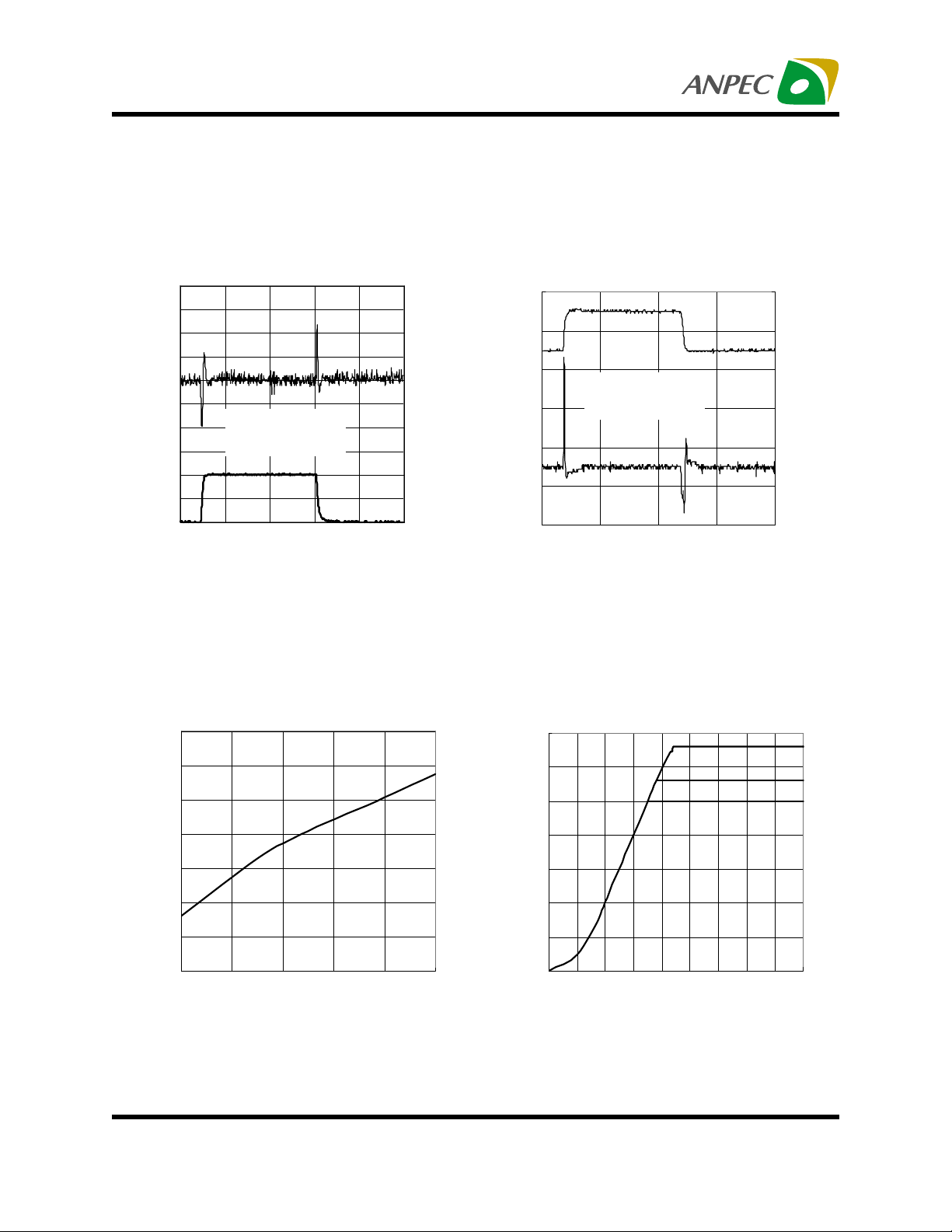

Typical Characteristics

Load Transietn Response

5

4.5

4

3.5

3

2.5

2

1.5

Output Current (A)

1

CIN=10µF

C

OUT=10µF T antalum

VIN=5V

0.5

0

-100 100 300 500 700 900

Time (µS)

Dropout Voltage vs. Output Current

1.25

APL1117-33

0.02

0.01

0

-0.01

-0.02

-0.03

APL1117-33

Line Transient Response

6

5

4

3

2

CIN=10µF

COUT=10µF T antalum

IOUT=0.1A

APL1117-33

Input Voltage (V)

1

0

-20 30 80 130 180

Time (µS)

Output Voltage vs. Input V oltage

3.5

0.15

0.1

0.05

0

-0.05

1.2

1.15

1.1

1.05

1

Dropout V oltage (V)

0.95

0.9

0 0.2 0.4 0.6 0.8 1

Output Current (A)

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

6

3

2.5

2

1.5

1

Output Voltage (V)

0.5

0

0123456789

Input V oltage (V)

www.anpec.com.tw

Page 7

APL1117

Typical Characteristics Cont.

Input Current vs. Input Voltage

6

5

4

3

2

Input Current (mA)

1

0

024681012

Input V oltage (V)

Output Voltage vs. Temperature

2.6

2.5

2.4

2.3

2.2

2.1

2

1.9

Output Voltage (V)

1.8

1.7

1.6

-50 -25 0 25 50 75 100 125

Current Limit vs. Input Voltage

2.4

2.2

2

1.8

1.6

1.4

Current Limit (A)

1.2

1

5 7 9 11 13

APL1117-33APL1117-33

Input V oltage (V)

Output Voltage vs. Temperature

3.4

3.3

3.2

3.1

3

2.9

Output Voltage (V)

2.8

2.7

-50-250255075100125

T emperature (°C)

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

Temperature (°C)

7

www.anpec.com.tw

Page 8

APL1117

Typical Characteristics Cont.

Adjustable Pin Current vs. T emperature

70

68

66

64

62

60

58

56

54

52

Adjustable Pin Current (µA)

50

-50 -25 0 25 50 75 100 125

Temperature (°C)

Current Limit vs. Temperature

1.9

1.8

1.7

1.6

1.5

1.4

1.3

Current Limit (A)

1.2

1.1

1

-50 0 50 100 150

VIN-VOUT=5V

APL1117-Adj

APL1117-33

Input Current vs. Tmeperature

8

7

6

5

4

APL1117-33

Input Current (mA)

3

2

-50 -25 0 25 50 75 100 125

Temperature (°C)

PSRR vs. Frequency

+0

Cadj=22µF

-10

IOUT=0.1A

Vripple=1Vp-p

-20

-30

-40

-50

-60

PSRR (dB)

-70

-80

-90

-100

10

20

VIN-VOUT>=Vdropout

VIN-VOUT>=3V

50 100 200 500 1k 2k 5k

10k 20k

50k

APL1117-33

200k

T emperature (°C)

Copyright ANPEC Electronics Corp.

$

Rev. B.8 - Jun., 2003

Frequency (Hz)

8

www.anpec.com.tw

Page 9

APL1117

Application Information

Output Voltage

The APL1117 develops a 1.25V reference voltage

between the output and the adjust terminal. By placing a resistor between these two terminals, a constant Current is caused to flow through R1 and down

through R2 to set the overall output voltage. Normally

this current is chosen to be the specified minimum

load current of 10mA. For fixed voltage devices R1

and R2 are included in the device.

OUT

APL1117

I

ADJ

60µA

= V

OUTIN

ADJ

REF

(1+ )+ I

R2

R1

ADJ

V

R2

REF

R1

R2

V

OUT

V

IN

V

Figure 1. Basic Adjustable Regulator

Rp

V

IN

APL1117

OUTIN

ADJ

PAR A SIT IC

LINE RESISTANCE

R1

CONNECT

R1 TO CASE

R2

CONNECT

R2 TO LOAD

R

Figure 2. Connections for Best Load Regulation

Input Capacitor

An input capacitor of 10µF or greater is

recommended. Tantalum, or aluminum electrolytic

capacitors can be used for bypassing. Larger Values will improve ripple rejection by bypassing the in-

L

Load Regulation

When the adjustable regulator is used. Load regulation will be limited by the resistance of the wire connecting the regulator to the load. The data sheet specification for load regulation is measured at the output

pin of the device. Best load regulation is obtained

when the top of the resistor divider (R1) is tied directly to the output pin of the device, not to the load.

For fixed voltage devices the top of R1 is internally

connected to the output, and the ground pin can be

connected to low side of the load. If R1 were connected to the load, RP is multiplied by the divider

ratio, the effective resistance between the regulator

and the load would be:

Rp X (1+ ), Rp = Parasitic L ine Resistance

R2

R1

put to the regulator.

Output Capacitor

The APL1117 requires an output capacitor to maintain stability and improve transient response. Proper

capacitor selection is important to ensure proper

operation. The APL1117 output capacitor selection

is dependent upon the ESR (equivalent series

resistance) of the output capacitor to maintain stability.

When the output capacitor is 10uF or greater, the

output capacitor should have an ESR less than 1Ω.

This will improve transient response as well as promote stability. A low-ESR solid tantalum capacitor

works extremely well and provides good transient response and stability over temperature.

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

9

www.anpec.com.tw

Page 10

APL1117

Application Information (Cont.)

Output Capacitor (Cont.)

Aluminum electrolytics can also be used, as long as

the ESR of the capacitor is <1Ω. The value of the

output capacitor can be increased without limit. Higher

capacitance values help to improve transient response

and ripple rejection and reduce output noise.

Ripple Rejection

The curves for Ripple Rejection were generated using an adjustable device with the adjust pin bypassed.

With a 22µF bypassing capacitor 75dB ripple rejection is obtainable at any output level. The impedance

of the adjust pin capacitor, at the ripple frequency,

should be < R1. R1 is normally in the range of 100Ω-

200Ω. The size of the required adjust pin capacitor

is a function of the input ripple frequency. At 120Hz,

with R1=100Ω, the adjust pin capacitor should be

13µF. For fixed voltage devices, and adjustable de-

Figure 3&4 shows for the TO-252 and SOT-223 the

measured values of θ(J-A) for different copper area

sizes using a 2 layers, 1.6mm, and 6Sq. cm FR-4

PCB with 2oz. copper and a ground plane layer on

the backside area used for heatsinking. It can be

used as a rough guideline in estimating thermal

resistance.

50

TA=25°C

45

40

35

Thermal Resistance

30

(Juntion to Ambient) (°C/W)

25

02468101214

Top Copper Area (cm2)

vices without an adjust pin capacitor, the output ripple

will increase as the ratio of the output voltage to the

reference voltage (VOUT /VREF ).

Thermal Considerations

APL1117 has thermal protection which limits junction

temperature to 150°C. However, device functionality

is only guaranteed to a maximum junction temperature of +125°C.

Both the TO-220, TO-252, TO-263 and SOT-223

packages use a copper plane on the PCB and the

PCB itself as a heatsink. To optimize the heat sinking

ability of the plane and PCB, solder the tab of the

package to the plane.

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

Figure 3.

θ(J-A) vs. copper area for the SOT-252 package

10

www.anpec.com.tw

Page 11

APL1117

Application Information (Cont.)

Thermal Considerations (Cont.)

60

TA=25°C

55

50

45

40

Thermal Resistance

35

(Juntion to Ambient) (°C/W)

30

0 2 4 6 8 10 12 14

Top Copper Area (cm2)

Figure 4.

θ(J-A) vs. copper area for the SOT-223 package

The thermal resistance for each application will be

affected by thermal interactions with other components on the board. Some experimentation will be

necessary to determine the actual value.

The power dissipation of APL1 117 is equal to :

PD = (VIN - VOUT) x IOUT

Maximum junction temperature is equal to :

TJUNCTION = TAMBIENT + (PD x θJA)

Note: TJUNCTION must not exceed 125°C

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

11

www.anpec.com.tw

Page 12

APL1117

Package Information

TO-220 ( Reference JEDEC Registration TO-220)

D

Q

R

E

L1

b

e

b1

e1

H1

A

F

L

c

J1

Millimeters Inches

Dim

Min. Max. Min. Max.

A 3.56 4.8 3 0.1 4 0 0.19 0

b1 1.14 1.78 0.04 5 0.070

b 0.51 1.14 0.0 2 0 0.04 5

c 0.31 1 .14 0 .012 0.045

D 14.23 16.51 0.560 0.650

e 2.29 2.79 0.0 9 0 0 .110

e1 4.83 5.33 0.19 0 0.210

E 9.65 10.67 0.380 0.420

F 0.51 1.40 0.02 0 0.05 5

H1 5.84 6.86 0.230 0.270

J1 2.03 2.92 0.080 0.115

L 12.7 14.73 0.500 0.580

L1 3.65 6.35 0.14 3 0.250

R 3.53 4 .09 0.1 3 9 0.16 1

Q 2.54 3.43 0.1 0 0 0.13 5

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

12

www.anpec.com.tw

Page 13

APL1117

Package Informaion

TO-252( Reference JEDEC Registration TO-252)

E

b2

L2

L1

A

C1

D

H

L

Dim

b

e1

D1

E1

Millimeters Inches

Min. Max. Min. Max.

C

A1

A 2.18 2.39 0.086 0.094

A1 0.89 1.27 0.035 0.050

b 0.508 0.89 0. 020 0.035

b2 5.2 07 5.461 0.205 0. 215

C 0.46 0.58 0.018 0.023

C1 0.46 0.58 0.018 0.023

D 5.334 6.2 2 0.210 0.2 45

D1 5.2 REF 0.205 REF

E 6.35 6.73 0.250 0.265

E1 5.3 REF 0.2 09 REF

e1 3.96 5.18 0.156 0.204

H 9.398 10.41 0.370 0.410

L 0.51 0.020

L1 0.64 1.02 0.025 0.040

L2 0.89 2.032 0.035 0. 080

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

13

www.anpec.com.tw

Page 14

APL1117

Package Information

TO-263 ( Reference JEDEC Registration TO-263)

E

e

e1

A

c

c2

b2

b

L2

D

L

L3

Φ 1

L4

R

L1

DE T A IL "A "R O T E D

E1

TERMINAL 4

D1

Millim e t er s Inch e s

Dim

Min. Max. Min. Max.

A 4.06 4.83 0.160 0.190

b

0.51 1.016

0.02 0.040

b2 1.14 1.651 0.045 0.065

c 0.38 TYP. 0.015 TYP.

c2

1.14 1.40

0.045 0.055

D 8.64 9.65 0.340 0.380

e 9.65 10.54 0.380 0.415

e1

2.54 TYP

0.100 TYP

L 14.60 15.88 0.575 0.625

L1 2.24 2.84 0.090 0.110

L2

1.02 2.92

0.040 0.112

L3 1.20 1.78 0.050 0.070

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

14

www.anpec.com.tw

Page 15

APL1117

Package Information

SOT-223( Reference JEDEC Registration SOT-223)

D

B1

H E

K

e

e1

B

A

A1

b

a

c

L

Millimeters InchesDim

Min. Max. Min. Max.

A 1.50 1.80 0.06 0.07

A1 0.02 0.08

B 0.60 0.80 0.02 0.03

B1 2.90 3.10 0.11 0.12

c 0.28 0.32 0.01 0.01

D 6.30 6.70 0.25 0.26

E 3.30 3.70 0.13 0.15

e 2.3 BSC 0.09 BSC

e1 4.6 BSC 0.18 BSC

H 6.70 7.30 0.26 0.29

L 0.91 1.10 0.04 0.04

K 1.50 2.00 0.06 0.08

α

β

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

0

°

13

°

10

°

15

0

°

13

10

°

°

www.anpec.com.tw

Page 16

APL1117

Physical Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb

Lead Solderability Meets EIA Specification RSI86-91, ANSI/J-STD-002 Category 3.

Packaging 2500 devices per reel

Reflow Condition (IR/Convection or VPR Reflow)

Reference JEDEC Standard J-STD-020A APRIL 1999

Peak temperature

temperature

Pre-heat temperature

°

183 C

Time

Classification Reflow Profiles

Convection or IR/

Convection

Average ramp-up rate(183°C to Peak) 3°C/second max. 10°C /second max.

Preheat temperature 125± 25°C)

°

Temperature maintained above 183

Time within 5°C of actual peak temperature

Peak temperature range

Ramp-down rate

Time 25°C to peak temperature

C

120 seconds max.

60 ~ 150 seconds

10 ~ 20 seconds

°

220 +5/-0

°

C /second max. 10°C /second max.

6

6 minutes max.

C or 235 +5/-0°C 215~ 219°C or 235 +5/-0°C

60 seconds

VPR

Package Reflow Conditions

pkg. thickness

and all bags

Convection 220 +5/-0°C

VPR 215-219°C

IR/Convection 220 +5/-0

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

2.5mm

≥≥≥≥

°

C IR/Convection 235 +5/-0

pkg. thickness < 2.5mm and

pkg. volume

≥≥≥≥

350 mm

16

pkg. thickness < 2.5mm and pkg.

volume <

°

Convection 235 +5/-0

VPR 235 +5/-0

°

C

C

°

C

www.anpec.com.tw

Page 17

APL1117

Re lia bility test p r o gram

Test item Method Description

SOLDERABILITY M IL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms , Itr > 100mA

245°C , 5 SEC

1000 Hrs Bias @ 125 °C

168 Hrs, 100 % RH , 121°C

-65°C ~ 150°C, 200 Cycles

Carrier Tape & Reel Dimension

P

P1

Ao

J

C

W

E

Po

F

A

D

D1

t

Bo

Ko

T2

B

T1

Applica tio n

TO-252

Applica tio n

TO-263

Applica tio n

SOT-223

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

A B C J T1 T2 W P E

330 ±3100 ± 213 ± 0. 5 2 ± 0.5

F D D1 Po P1 Ao Bo Ko t

7.5 ± 0 .1 1 .5 + 0 .1 1.5± 0.25 4.0 ± 0.1 2.0 ± 0 .1 6 .8 ± 0.1 10.4± 0 .1 2 .5± 0.1 0.3±0.05

A B C J T1 T2 W P E

380±380 ± 213 ± 0. 5 2 ± 0.5 24 ± 42± 0.3

F D D1 Po P1 Ao Bo Ko t

11 .5 ± 0 .1 1 .5 + 0 .1 1.5± 0.25 4.0 ± 0.1 2.0 ± 0.1 10.8 ± 0.1 16.1± 0 .1 5 .2± 0.1

A B C J T1 T2 W P E

330±162±1.5

F D D1 Po P1 Ao Bo Ko t

5.5 ± 0.05 1.5+ 0.1 1.5+ 0.1 4.0 ± 0 .1 2.0 ± 0.05 6.9 ± 0 .1 7 .5± 0 .1 2 .1± 0.1 0.3±0.05

12.75

0.15

16.4 + 0.3

-0.2

±

2 ± 0.6 12.4 +0.2 2± 0.2 12 ± 0.3 8 ± 0 .1 1 .7 5± 0.1

17

2.5± 0.5

16+ 0.3

- 0.1

24 + 0.3

- 0.1

8 ± 0.1

16 ± 0.1 1.75± 0.1

www.anpec.com.tw

1.75± 0.1

0.35±0.01

3

Page 18

APL1117

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

TO- 252

TO- 263

SOT- 223

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 886-2-89191369

16 13.3 2500

24 21.3 1000

12 9.3 2500

Copyright ANPEC Electronics Corp.

Rev. B.8 - Jun., 2003

18

www.anpec.com.tw

Loading...

Loading...