Page 1

AN3060

Application note

Applications guide for serial real-time clocks (RTCs)

By Doug Sams

Introduction

ST’s family of serial real-time clocks (RTCs) has been very popular with users. Over the

years, many topics associated with these devices have been addressed by the applications

groups supporting them. This document is a compilation of some of the most common

issues addessed ranging from layout considerations for crystals to proper software access

upon power-up. Readers will find this helpful in understanding some of the subtleties of

RTCs and what it takes to keep them running reliably.

July 2012 Doc ID 16253 Rev 2 1/23

www.st.com

Page 2

Contents AN3060

Contents

1 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 What are some basic layout considerations for the RTC crystal? . . . . . . . 5

2 Oscillator circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Besides the crystal, what other components do I need to add to make my

RTC oscillator work correctly? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Undershoot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Can undershoot affect operation of my real-time clock? How? What can be

done to guard against it? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Switchover voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Does the switchover voltage depend on the battery level? Or is it always a

fixed value? What is the maximum battery voltage for an RTC? . . . . . . . . 9

5 Oscillator fail detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 What is the OF bit? How does it work? . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Battery low detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1 How does the battery low bit work? Can it detect a missing battery? . . . 13

7 Halt (HT) bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1 What does the halt bit (HT) do? How do I use it? . . . . . . . . . . . . . . . . . . 15

8 RTC initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 What is the best sequence for accessing the RTC at first power-up? On

subsequent power-ups? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/23 Doc ID 16253 Rev 2

Page 3

AN3060 List of tables

List of tables

Table 1. Summary of deselect and switchover thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. M41T81S register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 3. M41ST85W register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Doc ID 16253 Rev 2 3/23

Page 4

List of figures AN3060

List of figures

Figure 1. Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Built-in load capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Typical parasitic diode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Undershoot protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Typical switchover circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Switchover circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Oscillator fail detect circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Battery monitor function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. Clock and non-clock registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. M41T83/M41T82 power-up defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. First power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Power-up from backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4/23 Doc ID 16253 Rev 2

Page 5

AN3060 Layout considerations

1 Layout considerations

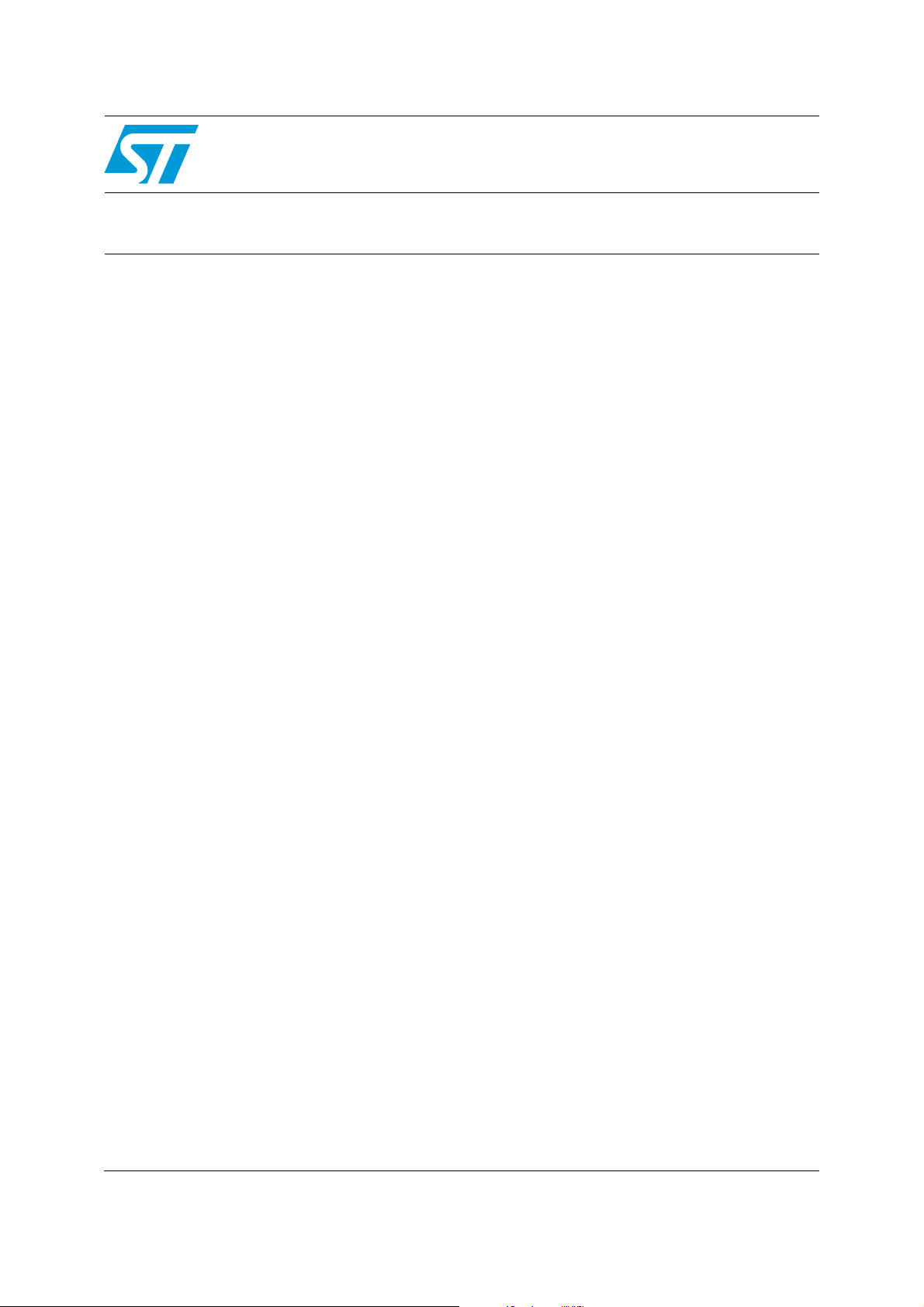

1.1 What are some basic layout considerations for the RTC crystal?

Layout considerations are straightforward for the 32 KHz crystals used with ST's M41 series

real-time clocks.

Figure 1. Layout considerations

MOUNT CRYSTAL AS CLOSE

TO RTC AS POSSIBLE

CRYSTAL

NO OTHER COMPONENTS

REQUIRED IN OSCILLATOR

CIRCUIT

IF POSSIBLE, ADD LOCAL GROUND PLANE,

ON SEPARATE LAYER, ISOLATED FROM PCB

GROUND PLANE, AND CONNECTED TO

RTC GND PIN

ADD GUARD RING AROUND

CRYSTAL CONNECTIONS,

CONNECT TO GND PIN

KEEP TRACES SHORT

XI

RTC

XO

GND

AM04719v1

The primary consideration is lead length. The crystal should be mounted as near as

possible to the RTC to keep the traces short. A guard ring around these connections,

connected to ground, is very important to avoid picking up unwanted noise, which might

affect timekeeping.

Users should avoid running signals directly underneath this area unless a ground plane

resides between the signals and the crystal connections.

When possible, users can add an island ground plane under the area of the ring and crystal

body. This plane is on a separate layer from the ring, and isolated from the PCB ground

plane. It connects to ground at the GND pin of the RTC.

No other components are shown in the layout because the crystal is all that is required for

the RTC oscillator to work. No external load capacitors or bias resistors should be added.

Doc ID 16253 Rev 2 5/23

Page 6

Oscillator circuit AN3060

2 Oscillator circuit

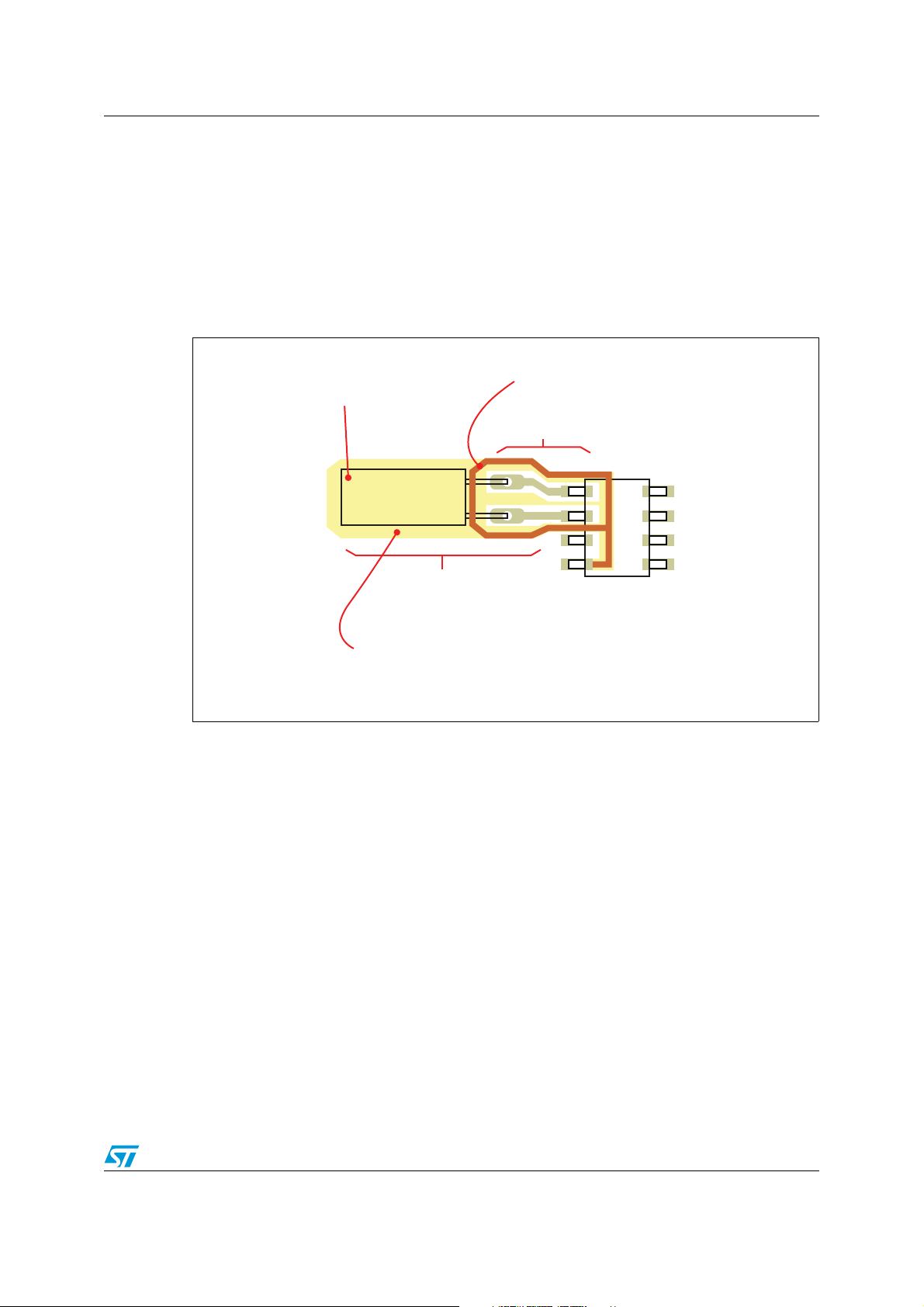

2.1 Besides the crystal, what other components do I need to add to make my RTC oscillator work correctly?

None. Nothing else is required. ST's real-time clocks have built-in load capacitors.

External load capacitors are not needed, nor are external resistors. All that is needed is the

crystal. It must be a 32,768 Hz watch crystal and be rated for the load capacitance built into

the RTC.

Figure 2. Built-in load capacitors

EXTERNAL LOAD CAPACITORS

NOT NEEDED

EXTERNAL RESISTOR

NOT NEEDED

No other components are required to make the oscillator run. Adding any external

components will only serve to reduce the accuracy and reliability of the oscillator. Extra load

capacitors will tend to slow the clock. At low temperatures, such capacitance, or any

external resistance, may keep the oscillator from starting.

CRYSTAL

C

X1

R

X

XI XO

INTERNAL RTC

CIRCUITRY

C

L1

CHOOSE CRYSTAL TO MATCH RTC’S RATED

LOAD CAPACITANCE - eg, 6pF OR 12.5pF

C

L2

THEY ARE BUILT INTO RTC

C

X2

AM04720v1

Matching load capacitance

Each RTC comes with built-in load capacitors. These are usually specified as 12.5 pF, or in

the case of the M41T6x family, 6 pF. The crystal selected for use with the RTC should have

this same rating. Mismatched crystals will tend to run slightly off frequency. For example, a

crystal rated for 12.5 pF expects to see that load. If it is used with an RTC rated for 6 pF, the

crystal will only see 6 pF instead of the specified 12.5 pF and will thus run fast.

6/23 Doc ID 16253 Rev 2

Page 7

AN3060 Oscillator circuit

Effective load capacitance value versus internal capacitance value

Occasionally, the reader will see a reference to the individual load capacitors. There are two

used inside the RTC - one on each leg of the crystal. The actual value of each is twice the

rated or effective load value - that is, twice the load value specified in the data sheet. This is

because the internal load capacitors add in series. In Figure 2, the effective load

capacitance is:

CC

•

L

L

2

LL

1

CwithseriesinCC

1

==

L

2

CC

+

L

L

2

1

Thus, when C

the data sheet - is half of C

and CL2 are equal, the effective load capacitance, CL - the value listed in

L1

and CL2. An ST RTC rated for 12.5 pF will have two 25 pF

L1

capacitors built into its oscillator circuit. The reader is encouraged to be aware of this.

Furthermore, the reader should keep in mind that the crystal specifications should match

the rated value - in this case 12.5 pF - and not the individual values.

Doc ID 16253 Rev 2 7/23

Page 8

Undershoot AN3060

3 Undershoot

3.1 Can undershoot affect operation of my real-time clock? How? What can be done to guard against it?

Inherent in all field effect devices - all CMOS devices - are parasitic diodes resulting from the

intersection of P and N type regions in the device. Every PN junction forms a diode which

will conduct under any condition which biases the P region above the N region.

In Figure 3, if V

drawing current through the device. Significant undershoot on V

drops sufficiently below ground, the parasitic diode will be turned on thus

CC

can result in enough

CC

current flow to cause some disturbance in the real-time clock registers and hence can

adversely affect timekeeping. Therefore, undershoot should be avoided.

Figure 3. Typical parasitic diode

V

CC

D

N+

G

N

S

N+

Most ST real-time clocks specify a minimum V

undershoot to 0.3 V below ground.

Some supplies ramp very quickly when power cycling with the result that ringing can occur

which produces an undershoot condition that can cause problems for real-time clocks.

In the rare situations where this occurs, the best protection is a back biased Schottky diode

on the V

pin as shown in Figure 4. This addition has been shown to be a very reliable fix

CC

for undershoot problems.

P

of –0.3 V thereby limiting negative

CC

AM04721v1

Figure 4. Undershoot protection

V

CC

1N5817 (through hole)

BAT54J (surface mount)

8/23 Doc ID 16253 Rev 2

V

XI

XO

SDA

SCL

V

RTC

CC

SS

AM04722v1

Page 9

AN3060 Switchover voltage

4 Switchover voltage

4.1 Does the switchover voltage depend on the battery level? Or is it always a fixed value? What is the maximum battery voltage for an RTC?

Figure 5. Typical switchover circuits

V

CC

V

V

BAT

V

SO

With fixed reference

Power fail deselect voltage, V

CC-INT

PFD

V

When VCC falls to the power-fail deselect level, V

BAT

PFD

V

CC

V

CC-INT

V

SO

With battery reference

AM04723v1

, the part deselects thereby cutting off

communications to the host; it is write protected.

For ST's serial real-time clocks, V

voltage, V

Switchover voltage, V

. Thus, the deselect and switchover operations are tightly coupled.

SO

SO

is either equal to - or a function of - the switchover

PFD

Switchover connects the backup supply - usually a battery, but sometimes a capacitor or

super-cap - to the internal V

in the absence of system power. V

V

.

BAT

of the device thereby maintaining the timekeeping operation

CC

is the value of VCC at which the part switches over to

SO

Fixed reference

Most ST serial real-time clocks use a fixed, precision reference for the switchover threshold.

Regardless of the level of V

V

levels.

CC

the part will always deselect and switchover at the same

BAT,

Battery reference

Some older RTCs use the battery as a reference. One diode drop is applied, internal to the

RTC, to the battery pin, and that level determines the switchover threshold. Typically, the

diode drop is 0.5 V, but it can vary from 0.3 to 0.8 V. For brand new lithium coin cell

batteries, the voltage output may be as high as 3.5 V. (Once under load for a while, this will

drop to approximately 3.0 V and remain there for the useful life of the battery.) At low

temperatures, the diode drop will tend toward the minimum value, 0.3 V. This means that,

with new batteries and low temperatures, the switchover threshold may be as high as

3.5 - 0.3 = 3.2 V. The implication is that parts employing battery references may be

problematic in 3.3 V applications, and will be unsuitable for 3.0 V applications. In those

cases, users should choose parts with fixed references. For example, the M41T81S with

Doc ID 16253 Rev 2 9/23

Page 10

Switchover voltage AN3060

fixed reference is well-suited for 3.3 V and 3.0 V applications, and is a drop-in replacement

for the older M41T81 (non-S).

Table 1. Summary of deselect and switchover thresholds

Root part

number

M41T00 V

V

PFD

– 0.5 V

BAT

M41T00AUD 2.8

M41T00S 2.6 V

M41T11 V

– 0.5 V

BAT

M41T56 1.25 x V

M41T81 V

– 0.5 V

BAT

M41T81S 2.6 V

M41T82 V

M41T83 V

RST

RST

Switchover and deselect parameters

V

SO

– 0.5 V

BAT

(1)

(1)

BAT

2.0 < V

V

BACK

V

V

V

V

BACK

BAT

BAT

BAT

BAT

< V

PFD

> V

PFD

< V

PFD

> V

PFD

– 0.5 V

BAT

V

BAT

– 0.5 V

BAT

< V

PFD

> V

PFD

(1)

V

RST

(1)

V

RST

: V

: V

: V

: V

: V

: V

PFD

BAT

PFD

BAT

PFD

BACK

M41ST85W 2.6 V 2.5 V V

M41ST87W

M41T93 V

2.62 V, THS = 0

2.88 V, THS = 1

(1)

RST

2.5 V V

(1)

V

RST

M41T94 2.6 V 2.5 V V

1. The reset voltage, V

, can be specified as 2.32, 2.63 or 2.93 V.

RST

V

BAT-MAX

CC

V

CC

V

CC

CC

3.5 V

CC

V

CC

V

CC(max)

V

CC(max)

CC(max)

CC(max)

V

CC(max)

CC(max)

Complex switchover thresholds

Some devices employ more sophisticated switchover circuits which select the lesser of V

and V

as possible before switching over to the backup supply thus extending the backup life

slightly.

Figure 6. Switchover circuit

10/23 Doc ID 16253 Rev 2

as the switchover threshold. This ensures that the part remains on VCC for as long

BAT

V

BAT

PFD

V

CC

V

CC-INT

V

SO

AM04724v1

Page 11

AN3060 Switchover voltage

Maximum battery levels

The maximum value for V

varies within ST's family of serial RTCs. It is a function of the

BAT

process used to fabricate the silicon and considerations made during the design process.

For most parts, the maximum value is V

For parts with V

as the limit, if V

CC

exceeds VCC, parasitic diodes, inherent in CMOS

BAT

CC(max)

(usually 5.5 V).

technology, can be turned on thereby causing problems within the devices. Obviously, it is

okay for V

mode, V

To be clear, when V

and not V

regardless of the operating level of V

to be above VCC during backup (when VCC is 0). But when operated in active

BAT

should not exceed VCC for these parts.

BAT

CC-MAX

is the listed limit for V

CC

. Conversely, when the limit is V

.

CC

, the limit is the actual working level of VCC

BAT

CC(max)

, the V

limit is V

BAT

CC(max)

Doc ID 16253 Rev 2 11/23

Page 12

Oscillator fail detect AN3060

5 Oscillator fail detect

5.1 What is the OF bit? How does it work?

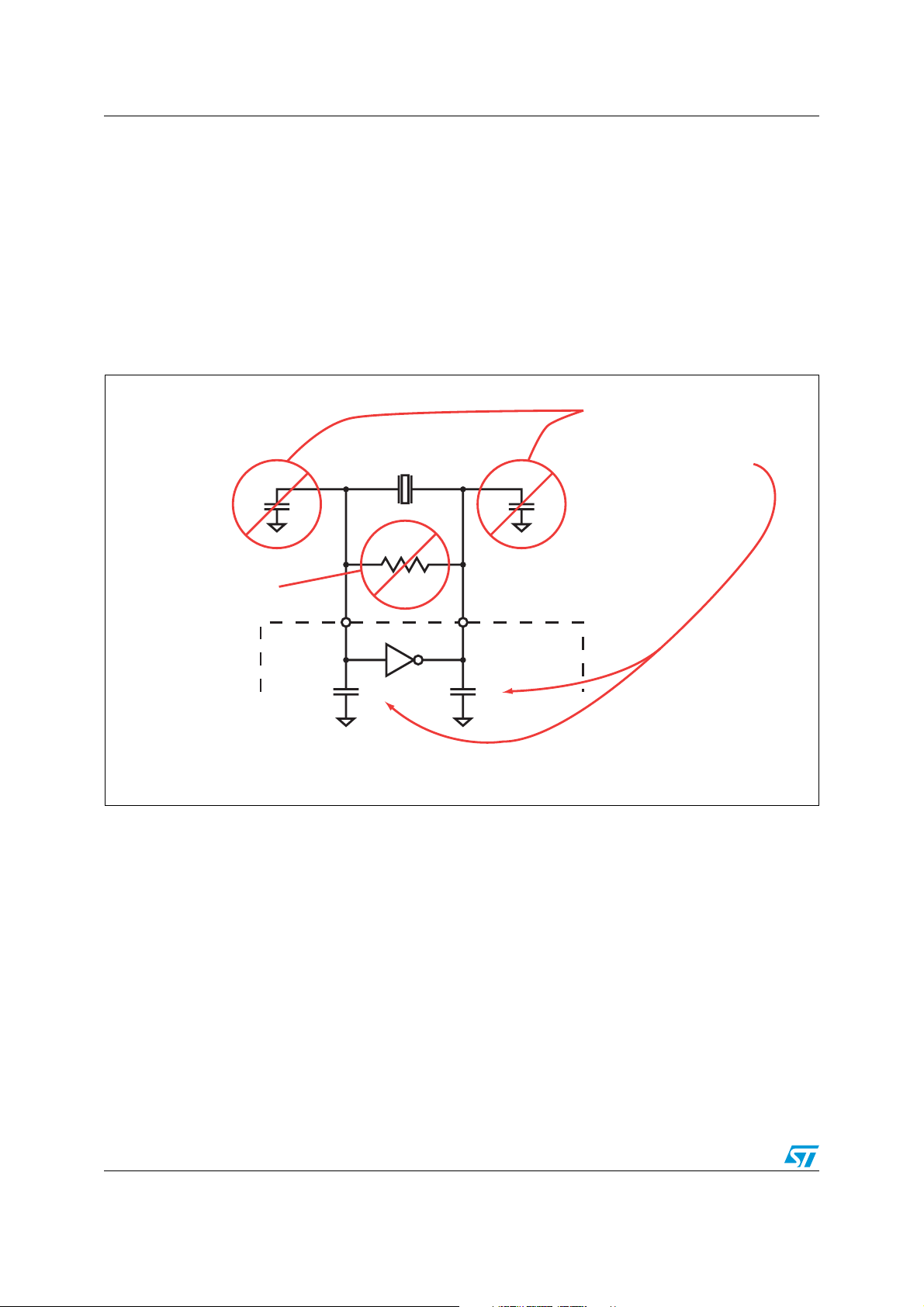

OF is the oscillator fail bit, and is set whenever the real-time clock detects approximately 4 to

6 consecutive missing pulses in the 4 KHz tap of the divider chain.

Figure 7. Oscillator fail detect circuit

CRYSTAL

OSCILLATOR FAIL DETECT CIRCUIT

V

CC

SET

Q

OF

AM04725v1

OSC TFF

(÷ 2)

TIME CONSTANT

SET TO 4-6 PULSES

TFF

(÷ 2)

TFF

(÷ 2)

4KHz

An RC circuit is used as an integrator. The 4 KHz pulses keep it discharged, and it slowly

charges between pulses. If sufficient pulses are missing, it charges high enough to trip the

comparator and set the OF bit. In the figure above, at low operating voltages, the time

constant will be shorter since the threshold voltage will be lower. Thus, fewer missing

pulses may be required to trigger the OF bit.

The basic mission of the OF function is to indicate when the oscillator has slowed or

stopped as might occur in capacitor backed applications or when the backup battery is

failing. When the backup voltage falls low enough, the part may stop keeping time, but the

registers will not necessarily become reset; the voltage may not drop low enough to

completely reset the part. Subsequently, after power-up, the oscillator will begin running

and, by merely reading the registers, it will not be clear that the timekeeping function had

become halted. The OF bit overcomes this. It provides a way for the system software to

monitor the timekeeping function and know when to advise the end user that the time may

need to be adjusted.

At first power-up, or anytime the oscillator has been turned off via the stop bit, the RC circuit

will be charged, and the OF bit will be set. The user should allow the oscillator to run for four

seconds prior to clearing the OF bit. This is done not only to discharge the RC circuit but to

ensure the oscillator has stabilized.

12/23 Doc ID 16253 Rev 2

Page 13

AN3060 Battery low detect

6 Battery low detect

6.1 How does the battery low bit work? Can it detect a missing battery?

Table 2. M41T81S register map

Addr

D7 D6 D5 D4 D3 D2 D1 D0

Function/range

BCD format

00h 0.1 seconds 0.01 seconds Seconds 00-99

01h ST 10 seconds Seconds Seconds 00-59

02h 0 10 minutes Minutes Minutes 00-59

03h CEB CB 10 Hours Hours (24-hour format) Century/hours 0-1/00-23

04h 0 0 0 0 0 Day of week Day 01-7

05h 0 0 10 date Date: day of month Date 01-31

06h 0 0 0 10M Month Month 01-12

07h 10 years Year Year 00-99

08h OUT FT S Calibration Calibration

09h OFIE BMB4 BMB3 BMB2 BMB1 BMB0 RB1 RB0 Watchdog

0Ah AFE SQWE ABE Al 10M Alarm month Al month 01-12

0Bh RPT4 RPT5 AI 10 date Alarm date Al date 01-31

0Ch RPT3 HT AI 10 hour Alarm hour Al hour 00-23

0Dh RPT2 Alarm 10 minutes Alarm minutes Al min 00-59

0Eh RPT1 Alarm 10 seconds Alarm seconds Al sec 00-59

0Fh WDF AF 0

BL 0 OF 0 0 Flags

10h 0 0 0 0 0 0 0 0 Reserved

11h 0 0 0 0 0 0 0 0 Reserved

12h 0 0 0 0 0 0 0 0 Reserved

13hRS3RS2RS1RS0 0 0 0 0 SQW

Many ST serial real-time clocks include a battery monitor function which sets the BL bit

when the battery is low. The basic functionality is to periodically compare the battery to the

internal 2.5 V reference and set the BL bit whenever the battery voltage is less than 2.5 V.

Figure 8. Battery monitor function

AT ROLLOVER &

AT POWER-UP

V

BAT

AT ROLLOVER

2.5V

AT ROLLOVER &

AT POWER-UP

Doc ID 16253 Rev 2 13/23

DBL

Q

AM04726v1

Page 14

Battery low detect AN3060

Periodic checking

The battery is checked every time the RTC powers up from backup mode, and every time

the clock rolls over at midnight (when not in backup mode). During the rollover check, the

battery is loaded to ensure a valid reading.

Power-up check

When an RTC has been in backup mode, its battery has already been loaded and thus a

load is not needed for the battery check. Batteries have a slow enough recovery time that

their outputs will not change quickly so it is not necessary to load them during the power-up

check. Nevertheless, a few devices - the M41T82, M41T83, M41ST87W and M41T93 include loading during the power-up check.

Detecting no battery - open circuit

Some applications call for being able to determine that no battery is installed. Ideally, a no

battery condition should read as low battery, but when the battery input, V

floated - the comparator output will be indeterminate. In order to reliably detect a no battery

condition, a load needs to be applied to the battery node prior to checking it. A resistor

applied across the battery terminals (or between B+ and ground in the case of devices with

no B– pin) is sufficient load for this purpose. This is impractical in the field, but can be useful

in the lab during development.

, is left open -

BAT

Using rollover to load the battery

Since the RTC applies a load to the battery during the midnight rollover check, it is possible

for applications to invoke the load by changing the time to near midnight, letting the clock

rollover, then setting the time back to its previous setting plus some delta to account for the

time spent waiting for rollover. This can be helpful during factory test to check that a battery

has been installed.

For example, if it's 17:53:27, the user would store that value, set the clock to 23:59:59, wait

two seconds, read the BL bit, then set the time back to 17:53:29 (17:53:27 + 2 seconds). In

this manner, the battery will be loaded during the check and thus a no battery condition will

be reliably read as battery low.

As stated above, some RTCs do load the clock during power-up, and thus a missing battery

can be detected by simply power-cycling the device.

14/23 Doc ID 16253 Rev 2

Page 15

AN3060 Halt (HT) bit

7 Halt (HT) bit

7.1 What does the halt bit (HT) do? How do I use it?

Table 3. M41ST85W register map

Address

00h 0.1 seconds 0.01 seconds Seconds 00-99

01h ST 10 seconds Seconds Seconds 00-59

02h 0 10 minutes Minutes Minutes 00-59

03h CEB CB 10 hours Hours (24 hour format) Century/hours 0-1/00-23

04h TR 0 0 0 0 Day of week Day 01-7

05h 0 0 10 date Date: day of month Date 01-31

06h 0 0 0 10M Month Month 01-12

07h 10 years Year Year 00-99

08h OUT FT S Calibration Control

09h WDS BMB4 BMB3 BMB2 BMB1 BMB0 RB1 RB0 Watchdog

0Ah AFE SQWE ABE Al 10M Alarm month Al month 01-12

0Bh RPT4 RPT5 AI 10 date Alarm date Al date 01-31

0Ch RPT3

0Dh RPT2 Alarm 10 minutes Alarm minutes Al min 00-59

0Eh RPT1 Alarm 10 seconds Alarm seconds Al sec 00-59

0Fh WDF AF 0 BL 0 0 0 0 Flags

10h00000000Reserved

11h00000000Reserved

12h00000000Reserved

13h RS3 RS2 RS1 RS0 0 0 0 0 SQW

D7 D6 D5 D4 D3 D2 D1 D0

HT AI 10 hour Alarm hour Al hour 00-23

Data

Function/range

BCD format

Many of ST's serial real-time clocks include a halt bit (HT) in the registers. This bit is used to

halt updates to the user clock registers. When HT is set, the internal counters continue

timekeeping, but the buffer/transfer registers accessed by the user are frozen.

Doc ID 16253 Rev 2 15/23

Page 16

Halt (HT) bit AN3060

Figure 9. Clock and non-clock registers

32KHz

OSC

DIVIDE BY

32768

1 Hz

SPI / I2C

SERIAL BUS

SERIAL

TRANSFER

REGISTER

READ / WRITE

BUFFER

TRANSFER

REGISTERS

SECONDS

MINUTES

HOURS

DAY-OF-WEEK

DATE

MONTHS

YEARS

CENTURIES

COUNTER

COUNTER

COUNTER

COUNTER

COUNTER

COUNTER

COUNTER

CLOCK COUNTERS

ARE BUFFERED VIA

BUFFER/TRANSFER

REGISTERS

NON-CLOCK REGISTERS

ARE DIRECTLY ACCESSED

Coherency

The clock counters are buffered to ensure coherency. At the start of a read of the clock

registers, the device will copy the counters to the buffer/transfer registers, then make no

further updates to these registers for the duration of the read cycle. (The HT bit is not set at

this time, but the updates are halted.) By copying all the counters simultaneously, the values

in the registers will all be from the same instant in time and thus will be coherent.

Example of incoherency

Without having the intervening buffer/transfer registers, if the user began directly reading the

counters at 23:59:59, a read of the seconds register would return 59 seconds. After the

address pointer incremented, the next read would return 59 minutes. The next read should

return 23 hours, but if the clock happened to increment between the reads, the user would

see 00 hours. When the time was re-assembled, it would appear as 00:59:59, and thus be

off by one hour. It would be incoherent.

WRITE FLAG

HALT BIT

NON-CLOCK

REGISTERS

SQUAREWAVE

CALIBRATION

WATCHDOG

COUNTER

WRITES TO ANY

CLOCK REGISTER CAUSE

WRITE FLAG TO BE SET.

AT END OF WRITE CYCLE,

IF WRITE FLAG IS SET,

BUFFER/TRANSFER

REGISTERS COPIED TO

COUNTERS

AM04727v1

By using the buffer/transfer registers to hold a copy of the time, the user is able to read the

entire set of registers without any values changing during the read.

Similarly, when the application needs to change the time in the counters, it is necessary that

all the counters be loaded simultaneously. Thus, the user writes sequentially to the various

buffer/transfer registers, then they are copied to the counters in a single transfer thereby

coherently loading the counters.

16/23 Doc ID 16253 Rev 2

Page 17

AN3060 Halt (HT) bit

Write flag

The copying to the counters is caused by an internal write flag which gets set anytime a

write occurs in one of the buffer transfer registers, but not to any of the other (non-clock)

registers. For example, writing the watchdog or calibration register will not set the write flag,

but writing the seconds or day-of-week will set the flag.

At the end of the write cycle, when a STOP condition occurs on the I

sees the write flag set, it copies all the buffer transfer registers to the clock counters. Even if

only one or two of the buffer/transfer registers is over-written by the application, all the

registers will be copied to the counters.

2

C bus, if the device

Auto-setting of the HT bit

Whenever the device is powered down, the time and date are copied to the buffer/transfer

registers and the HT bit is set automatically. At power-up, the user can read the device (with

the HT bit still set) and retrieve the time of power-down from the registers. This allows the

application to determine how long the power outage lasted which is needed in some

situations. As long as the HT bit remains set, reads will return the time of power-down

(assuming no writes have occurred to alter the contents of the buffer/transfer registers).

In order to read the present time, the user must first clear (write a 0 to) the HT bit.

Subsequent reads will return the current time. Subtracting the time of power-down from the

present time establishes the length of the power outage.

Writing with the HT bit set

Following a power failure, the buffer/transfer registers contain the time of power-down.

Should the user write to any of the clock registers (addresses 0x00 to 0x07 in the table

above), the write flag will be set. Thus, at the end of the write cycle, the counters will be

updated from the registers.

If the HT bit is still set, the buffer/transfer registers contain the time of power-down modified

by the written value. Thus, at the end of the write sequence, the modified time of powerdown will be written back into the counters thus causing an apparent loss of time.

Example: Let the time/date of power down be, Mon, 9-Mar-08, 7:23:44pm. At power-up,

prior to clearing the HT bit, the user writes the ST bit in the seconds register thus setting the

write flag, but writes no other bits. At the end of the write cycle, the present time will revert

to the time of power-down thus resulting in an apparent loss of time.

Conversely, if the HT bit had been cleared prior to the write, the buffer/transfer registers

would have been updated to the present time. As before, a write of the ST bit would have

set the write flag, but the resultant update of the counters would have placed the current

time back in them. They would have been written over with the same values already present

in the counters. No loss of time would occur.

For more information, refer to application note AN1572.

Doc ID 16253 Rev 2 17/23

Page 18

RTC initialization AN3060

8 RTC initialization

8.1 What is the best sequence for accessing the RTC at first power-up? On subsequent power-ups?

This will vary from device to device, and hence a comprehensive answer is beyond the

scope of this document. Instead, we offer an example for the M41T83/M41T82.

Initializing and accessing the M41T83/M41T82

At first power-up, the part is in a benign state - the alarms and interrupts are disabled as are

the watchdog and timer. The OUT bit is high, and the frequency test bit, FT, is disabled.

Both the digital and analog calibration functions are set to the neutral points and the OTP bit

is set to 0 thus selecting the user analog calibration register over the factory value. (OTP

applies only to the M41T83 in the embedded crystal [MY] package.)

The squarewave output is enabled and 32.768 kHz is selected. (This allows devices using

this as a reference to have it at first power-up without need of user intervention.)

Figure 10. M41T83/M41T82 power-up defaults

ST HT CB1:CB0 OUT FT

1st power-up 0 1 00 1 0 0000000 0 1 0 0 00000 0 0 0 11

Power-up from

backup

1st power-up

Power-up from

backup

UC 1 UC UC 0 0000000 UC UC UC UC UC 0 UC UC UC

Digital Cal

DCS, DC4:DC0

000000 00000000

UC UC

Analog Cal

ACS, AC5:AC0

Watchdog

BM4:BM0,

RB1:RB0

OSC Fail Alarm 1 Timer

OFIE OF

Squarewave output Alarm 2

SQWE RS3:RS0 OTP AL2E

1 1000 0 0 0 00000

UC UC UC UC UC UC

IRQ1/FT/OUT pin

A1IE

ABE RPT15:11 TE

A2IE

RPT25:21

TI/TP

TIE

TD1:TD0

The clock registers - hours, minutes, seconds, year, month, date - are unknown. Only the

century bits, CB1:CB0, are defined (00).

The stop bit, ST, powers up cleared thus enabling the 32 KHz oscillator. But, since the

oscillator has not been running (prior to this first power-up) the oscillator fail detect bit, OF,

will be set.

Lastly, as is the case at all power-ups, the HT bit is set.

AM04728v1

18/23 Doc ID 16253 Rev 2

Page 19

AN3060 RTC initialization

First power-up

Since most of the peripheral and alarm functions are not enabled at power-up, there is little

urgency to initialize the part. The only item which might require immediate attention is the

squarewave function which powers-up running. Some applications may prefer to disable

this, or change its frequency.

The next thing the user should do is to write the HT bit to 0, then set the time and date. (For

other RTCs, at this point in the flow, if the ST bit is 1, it should be cleared to 0.)

If the application will be calibrated, this should be the next step.

Then the OF bit should be cleared (written to 0). Since power-up - since oscillator startup four seconds must have elapsed before this step is done. If calibration was performed, then

the time required to do that can be subtracted from the four seconds, and if calibration took

longer than that, then no additional waiting is required. The software should verify that the

OF bit remained cleared before progressing to the next step.

The next few items are optional. If the watchdog will be used, it can be started now,

assuming the software will soon get to the operational code which updates the watchdog.

Otherwise, the software should wait until the top of its main routine to start the watchdog.

If the timer or alarms will be used, the user might set them here, or again wait until the top of

the main routine. That will prevent any of these functions from timing out (interrupting) while

the processor is still running its initialization routine.

Doc ID 16253 Rev 2 19/23

Page 20

RTC initialization AN3060

Figure 11. First power-up

st

1

power-up

Optional: Change Squarewave

frequency or disable it.

Clear HT bit

Write hours, minutes, seconds,

day-of-week, date, month, year

and century bits.

Optional: Set OTP to 1 to select

factory analog calibration

(M41T83-MY only).

Optional: Initialize analog or

digital calibration.

Wait 4 seconds, then clear OF bit.

Verify OF bit is clear.

Optional: Initialize watchdog.

Optional: Initialize timer.

Optional: Initialize alarm 1.

Optional: Initialize alarm 2.

END

AM04729v1

20/23 Doc ID 16253 Rev 2

Page 21

AN3060 RTC initialization

Power-up from backup

Coming out of backup, the first thing to do is read the time. Prior to clearing the HT bit, the

RTC's buffer/transfer registers will contain the time of power down. If the duration of power

outage is needed by the application, the time of power down will be required. Otherwise,

this step can be skipped.

The next step is to clear the HT bit by writing it to 0. It is very important that the HT bit be

cleared prior to writing any of the timekeeping registers (addresses 0x00 to 0x07). Failure to

do so can resulting in corrupting the RTC counters.

If, at this point in the application flow, the present time is required, the time would be read.

With the HT bit clear, the present time will be returned by a read.

Upon servicing any interrupts from the RTC - e.g., alarm or OF - the flags register must be

cleared. Most of the flag bits clear upon reading, but the OF bit must be written to 0. Also,

the user should bear in mind that clearing the alarm flags (AF1, AF2) and oscillator fail flag

(OF) will clear the associated interrupt.

Figure 12. Power-up from backup

Power-up from backup

Optional: Read time/date

(time of power-down).

Clear HT bit

Optional: Read time/date

(present time).

off_duration = present_time –

time_of-power-down

Clear any flags (read flags register)

Optional: Re-initialize watchdog.

Optional: Re-enable / Re-initialize

timer.

END

AM04730v1

Watchdog and timer

Lastly, power cycling always leaves the watchdog and timer disabled. If either is being used

by the application, they will need to be re-initialized.

Doc ID 16253 Rev 2 21/23

Page 22

Revision history AN3060

9 Revision history

Table 4. Document revision history

Date Revision Changes

04-Nov-2009 1 Initial release.

17-Jul-2012 2 Textual updates concerning device availability.

22/23 Doc ID 16253 Rev 2

Page 23

AN3060

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 16253 Rev 2 23/23

Loading...

Loading...