Page 1

AN2598

Application note

Smartcard interface with the

STM32F10x microcontrollers

Introduction

This document describes a firmware and hardware Smartcard interface solution based on

the STM32F10x USART peripheral. The main purpose of this firmware and hardware

package is to provide resources that facilitate the development of an application using the

USART peripheral in Smartcard mode.

The firmware interface consists of library source files developed so as to support the

ISO 7816-3/4 specification. An application example based on STMicroelectronics

STM3210B-EVAL, STM3210E-EVAL and STM3210C-EVAL evaluation boards is also

provided.

This document and its associated firmware are available for download from the

STMicroelectronics website: www.st.com.

Glossary

Low-density devices are STM32F101xx, STM32F102xx and STM32F103xx

microcontrollers where the Flash memory density ranges between 16 and 32 Kbytes.

Medium-density devices are STM32F101xx and STM32F103xx microcontrollers where

the Flash memory density ranges between 32 and 128 Kbytes. Medium-density devices are

implemented in the STMicroelectronics STM32F103xx evaluation board.

High-density devices are STM32F101xx and STM32F103xx microcontrollers where the

Flash memory density ranges between 256 and 512 Kbytes. High-density devices are

implemented in the STMicroelectronics STM3210E-EVAL evaluation board.

Connectivity line devices are STM32F105xx and STM32F107xx microcontrollers.

July 2009 Doc ID 13750 Rev 3 1/40

www.st.com

Page 2

Contents AN2598

Contents

1 Smartcard interface description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 External interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Smartcard clock generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Smartcard reader hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 ISO 7816: protocol overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 ISO 7816-2 – pin location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 ISO 7816-3 – Electronic signal and transmission protocol . . . . . . . . . 12

4.1 Card power-up and reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Answer to reset (ATR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 ISO 7816-4 – Smartcard commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 T0 protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Application-level protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 The ISO 7816-4 APDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.2 File system API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.3 ISO 7816-4 functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.4 Security API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Smartcard interface library: description . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 File organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Smartcard interface library functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2.1 SC_Handler function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2.2 SC_PowerCmd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.3 SC_Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.4 SC_ParityErrorHandler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.5 SC_PTSConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/40 Doc ID 13750 Rev 3

Page 3

AN2598 Contents

6.3 How to send APDU commands to the Smartcard . . . . . . . . . . . . . . . . . . 30

6.3.1 SC_GET_A2R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.2 SELECT_FILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.3 SC_GET_RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.4 SC_READ_BINARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.5 SC_CREATE_FILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.6 SC_UPDATE_BINARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.7 SC_VERIFY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Parity error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.1 Data sent from card to reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2 Data sent from reader to card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 Smartcard interface example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1.1 Smartcard startup: answer to reset (A2R) . . . . . . . . . . . . . . . . . . . . . . . 35

7.1.2 Reading a file at a specified path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.3 Enabling/disabling the PIN1 (CHV1) code . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.4 Verifying the PIN1 (CHV1) code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Doc ID 13750 Rev 3 3/40

Page 4

List of tables AN2598

List of tables

Table 1. Smartcard pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. STM32F10xxx and Smartcard connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Answer-to-reset structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. CLA instruction set definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6. ISO 7816-4 INS codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 7. File library description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 8. Smartcard library functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 9. SC_Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 10. SCState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 11. SC_PowerCmd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 12. SC_Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 13. SC_ParityErrorHandler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 14. SC_PTSConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 15. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4/40 Doc ID 13750 Rev 3

Page 5

AN2598 List of figures

List of figures

Figure 1. ISO 7816-3 asynchronous protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Smartcard interface hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3. Contact definitions for Smartcards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

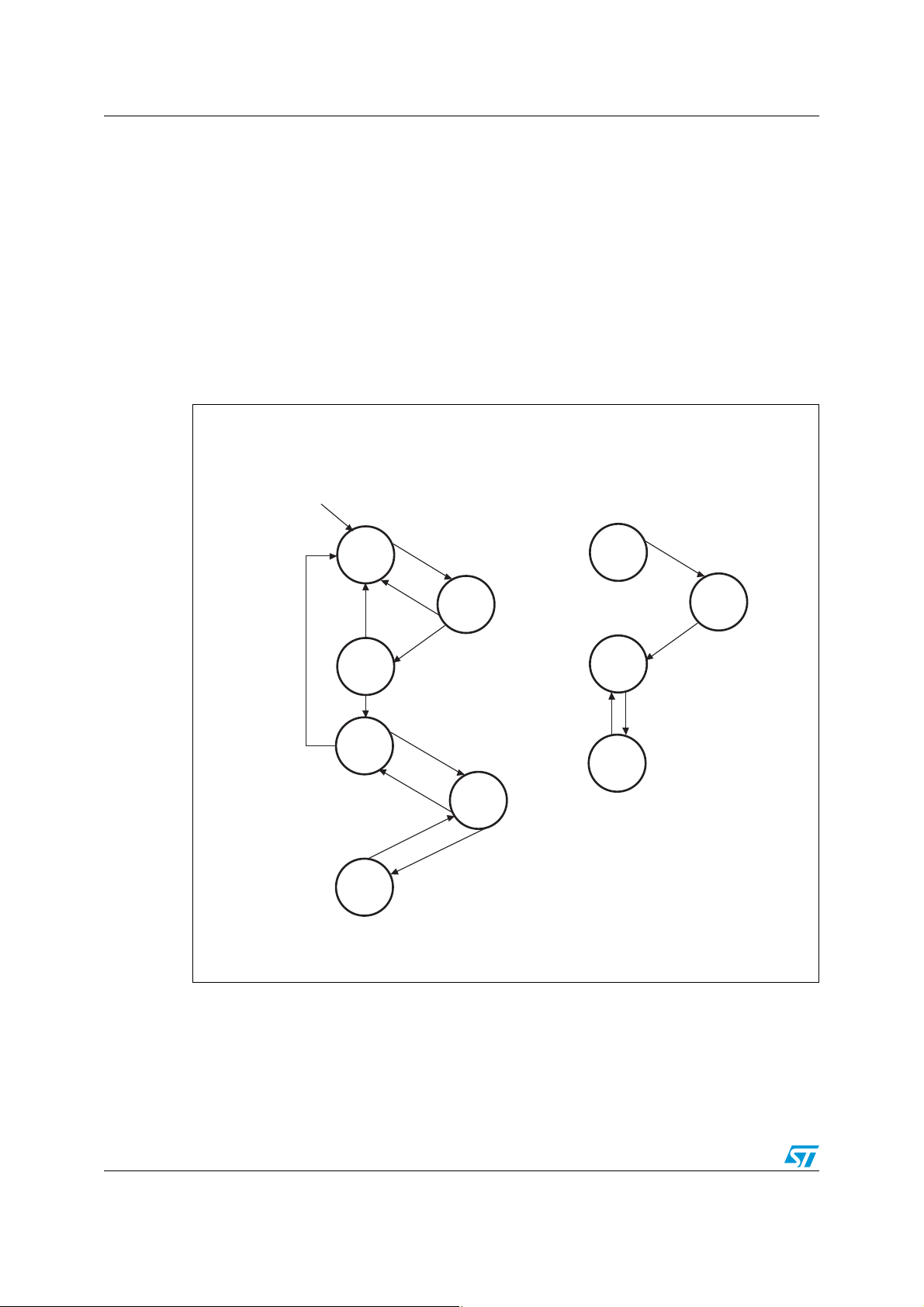

Figure 4. Reader and card FSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Answer to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Application communication architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. Command APDU structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 8. Response APDU structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Smartcard file system architecture

Figure 10. State machine for smartcard operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 11. Smartcard example: file system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Doc ID 13750 Rev 3 5/40

Page 6

Smartcard interface description AN2598

1 Smartcard interface description

1.1 Introduction

The Smartcard interface is developed using the USART Smartcard mode. For the

description of the USART registers, please refer to the STM32F10x reference manual. The

USART Smartcard mode supports asynchronous protocol Smartcards as defined in the

ISO 7816-3 standard.

With the Smartcard mode enabled, the USART must be configured as:

● eight data bits plus parity

● 0.5 or 1.5 stop bits

A 5-bit prescaler and the Smartcard clock generator provide the clock to the Smartcard.

GPIO pins in conjunction with software are used to provide the rest of the functions required

to interface to the Smartcard.

The inverse signalling convention as defined in ISO 7816-3, inverted data and MSB first, is

not handled in the software.

1.2 External interface

Table 1. Smartcard pins

STM32F10x pin Smartcard pin Function

USART CK CLK Smartcard clock

USART_TX IO IO serial data: open drain

Any GPIO RST Reset to card

Any GPIO V

Any GPIO V

The Smartcard_RST (Smartcard reset), Smartcard_3/5V (3 V or 5 V), Smartcard_CMDVCC

(command for V

GPIO bits of the I/O ports under software control. Programming the GPIO bits of the port for

alternate function open-drain mode connects the USART_TX data signal to the

Smartcard_IO pin with the correct driver type and the clock generator to the

Smartcard_CLK pin configured in alternate function output push-pull.

1.3 Protocol

The ISO 7816-3 standard defines the bit times for the asynchronous protocol in terms of

time units called ETUs (elementary time units), that are related to the clock frequency input

to the card. The length of an ETU is a bit time. The USART transmitter output and receiver

input are internally connected through the Rx_SW line. For the transmission of data from the

STM32F10x to the Smartcard, the USART must be set up in Smartcard mode.

CC

PP

), and Smartcard_OFF signals (signal for card detection) are provided by

CC

Supply voltage

Programming voltage

6/40 Doc ID 13750 Rev 3

Page 7

AN2598 Smartcard interface description

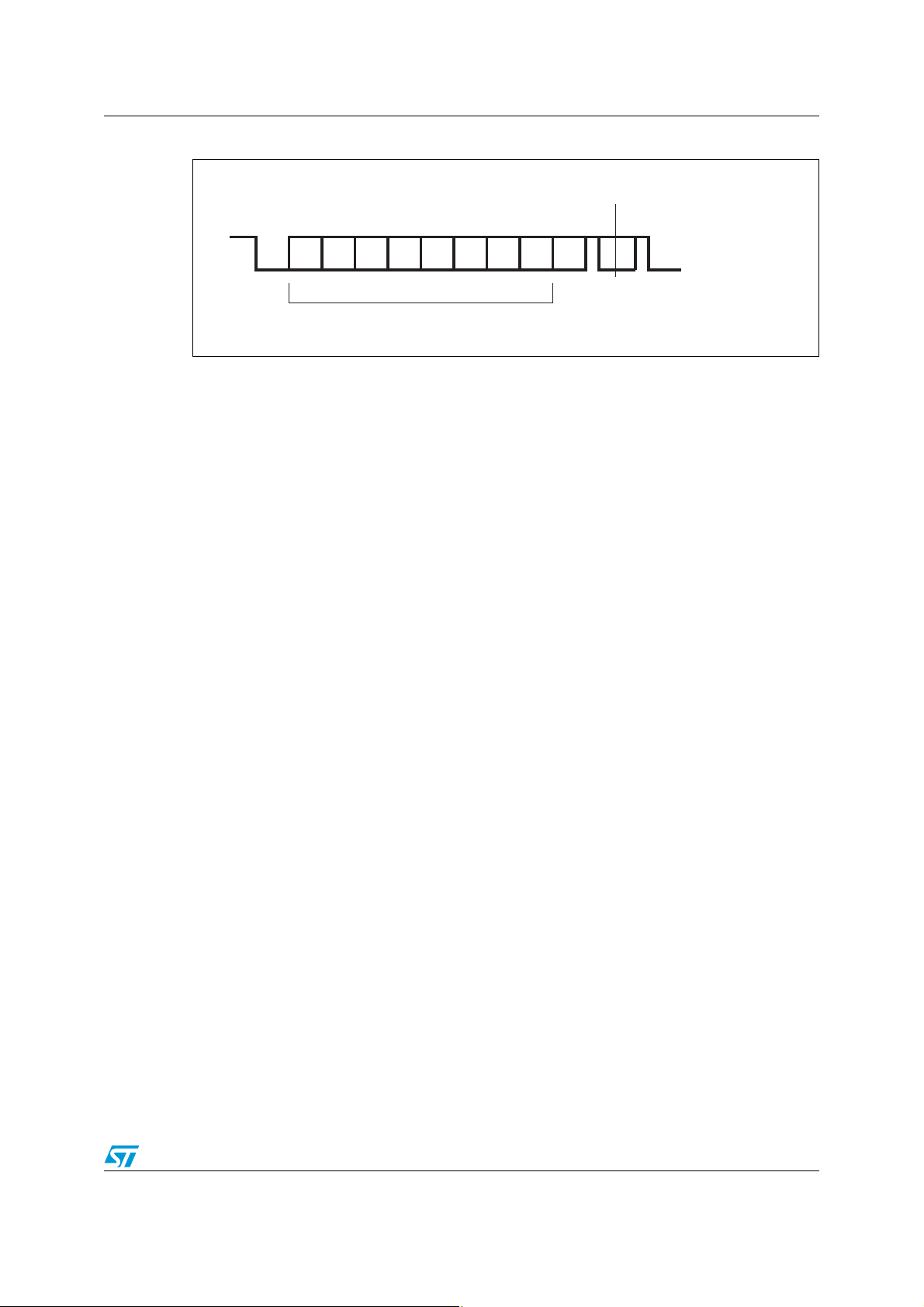

Sabcde fghP

Start

bit

8 data bits

Parity

bit

ETU

Line pulled low by receiver during

stop in case of parity error

ai14612

Figure 1. ISO 7816-3 asynchronous protocol

1.4 Smartcard clock generator

The Smartcard clock generator provides a clock signal to the connected Smartcard. The

Smartcard uses this clock to derive the baud rate clock for the serial I/O between the

Smartcard and another USART. The clock is also used for the CPU in the card, if present.

Operation of the Smartcard interface requires that the clock rate to the card is adjusted while

the CPU in the card is running code so that the baud rate can be changed or the

performance of the card can be increased. The protocols that govern the negotiation of

these clock rates and the altering of the clock rate are detailed in the ISO 7816-3 standard.

The clock is used as the CPU clock for the Smartcard, therefore updates to the

microcontroller clock rate must be synchronized to the Smartcard clock, that is the clock

high or low pulse widths must not be shorter than either the old or new programmed value.

Doc ID 13750 Rev 3 7/40

Page 8

Smartcard reader hardware connection AN2598

2 Smartcard reader hardware connection

To interface to the Smartcard, the ST8024 device was used. The ST8024 is a complete lowcost, analog interface for asynchronous 3 V and 5 V Smartcards. It is placed between the

Smartcard and the STM32F10x with few external components to perform all supply

protection and control functions.

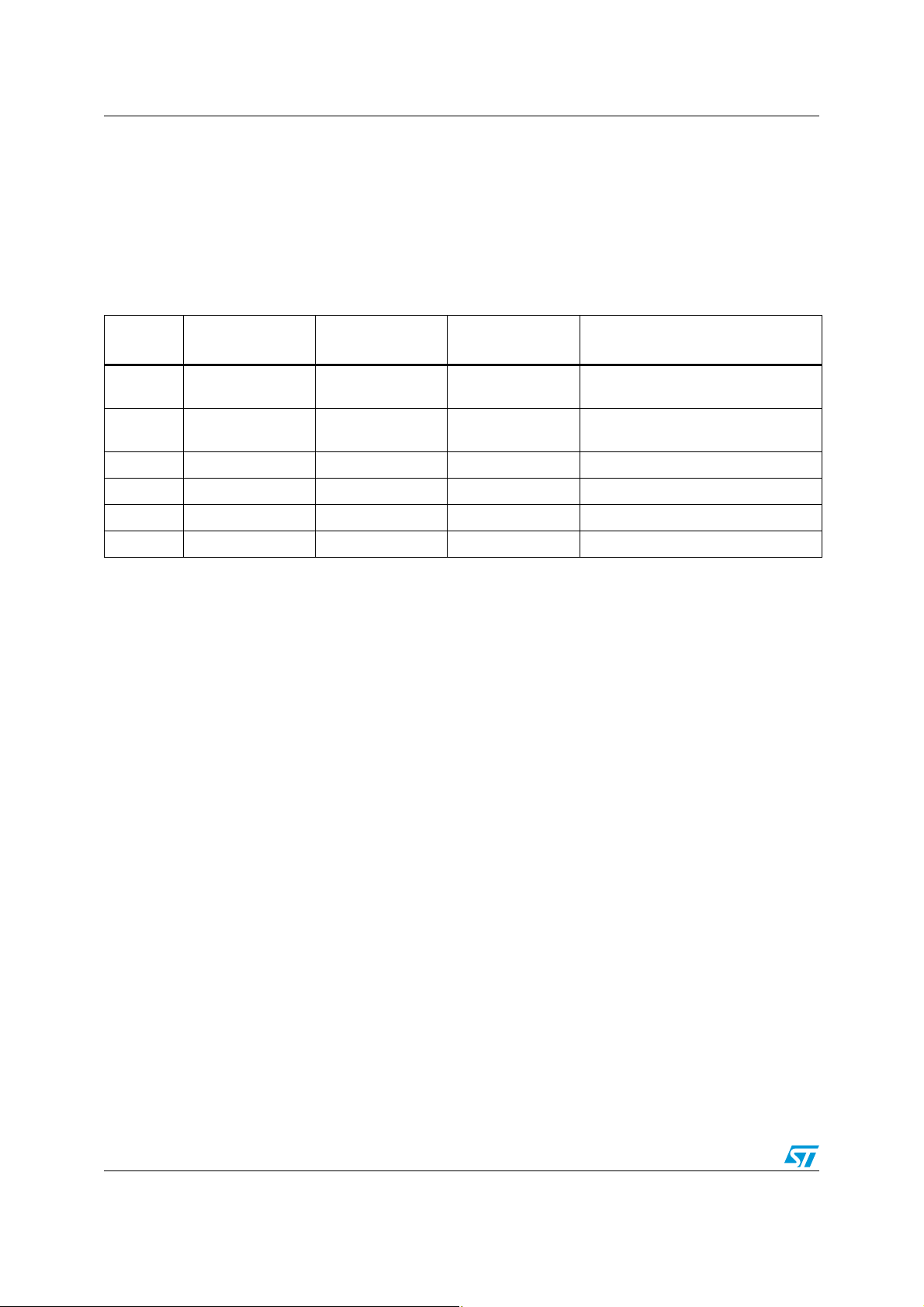

Table 2. STM32F10x and Smartcard connection

Smartcard

pins

C3: CLK USART3 CK: PB12 USART3 CK: PB12 USART3 CK: PD10

C7: IO USART3_TX: PB10 USART3_TX: PB10 USART3_TX: PD08

C2: RST PB.11 PB.11 PD.09 Reset to card: output push-pull

C1: V

CC

OFF PE.14 PC.07 PE.07 Smartcard detect: input floating

3/5V PD.11 PB.00 PC.00 3 V or 5 V: output push-pull

STM3210B-EVAL STM3210E-EVAL STM3210C-EVAL Function

Smartcard clock: alternate function

push-pull

IO serial data: alternate function open

drain

PE.07 PC.06 PD.07 Supply voltage: output push-pull

8/40 Doc ID 13750 Rev 3

Page 9

AN2598 Smartcard reader hardware connection

Figure 2. Smartcard interface hardware connection

Doc ID 13750 Rev 3 9/40

Page 10

ISO 7816: protocol overview AN2598

ISO 7816-2

Governs the dimension and location of

the chip contacts

1-V

CC

2-RST

3-CLK

4-RFU RFU-8

I/O-7

VPP-6

GND-5

Only one location accepted by ISO since 1/1/93.

Chip can still be on the front or back of the card.

ai14617

3 ISO 7816: protocol overview

3.1 Introduction

"ISO 7816: Identification cards -- Integrated circuit(s) cards with contacts" provides the basis

to transition the relatively simple identification card from a token that can be compromised

through forgery, theft, or loss into a tamper-resistant and "intelligent" integrated circuit card

(ICC), more popularly known as a Smartcard. ISO 7816 includes at least six approved parts

and has several additional parts under review:

● Part 1: Physical characteristics

● Part 2: Dimensions and location of the contacts

● Part 3: Electrical interface and transmission protocols

● Part 3: Amendment 2-Revision of protocol type selection

● Part 4: Organization, security and commands for interchange

● Part 5: Registration of application providers

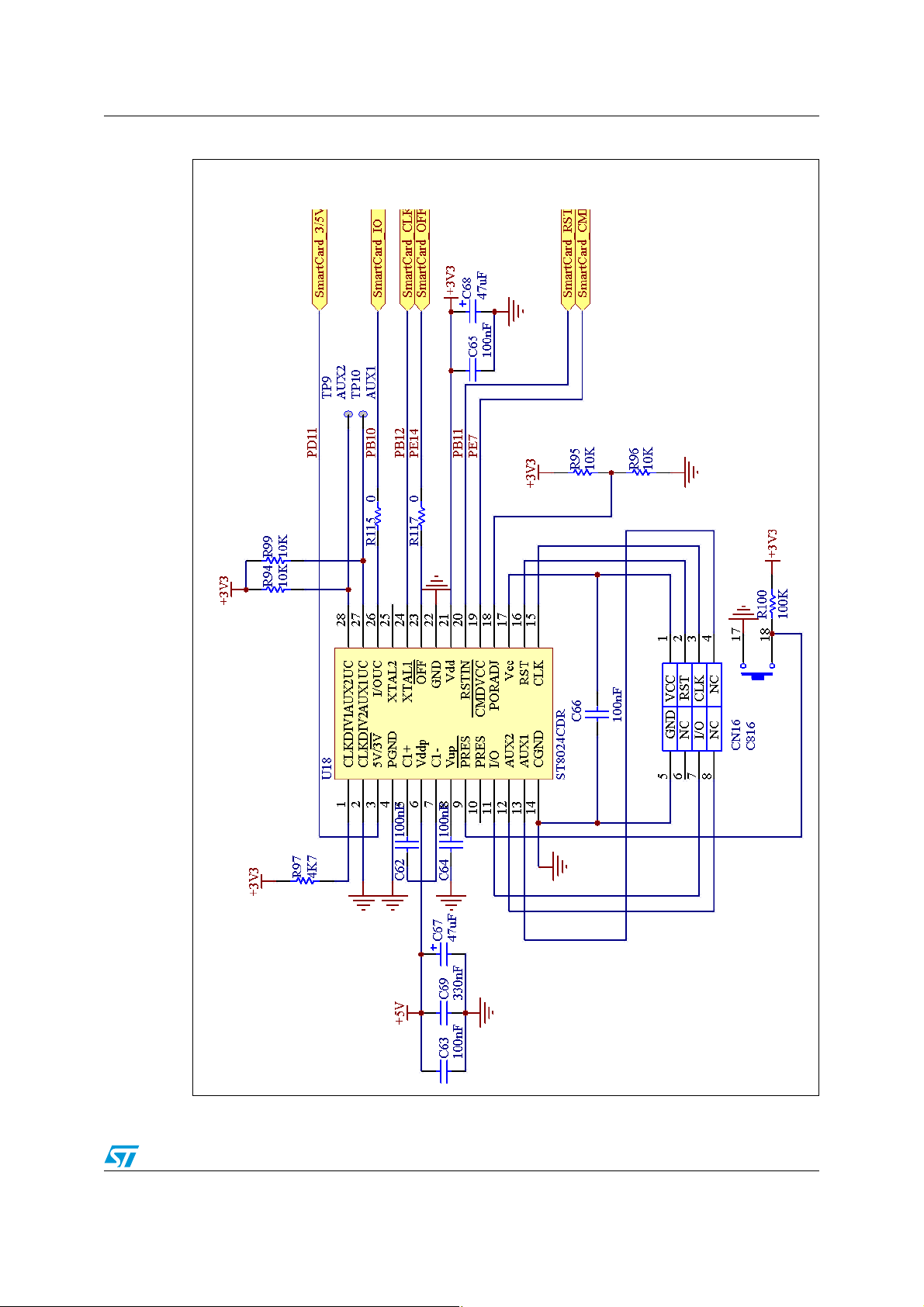

3.2 ISO 7816-2 – pin location

ISO 7816-2 specifies an ICC with eight electrical contacts present in a standardized position

on the front face of the card. These are referred to as C1 through C8. Some of these

contacts are electrically connected to the microprocessor chip embedded within the card;

some are not, having been defined to allow for enhancements but unused at the present

time. Figure 3 shows the contact positions.

Figure 3. Contact definitions for Smartcards

10/40 Doc ID 13750 Rev 3

Page 11

AN2598 ISO 7816: protocol overview

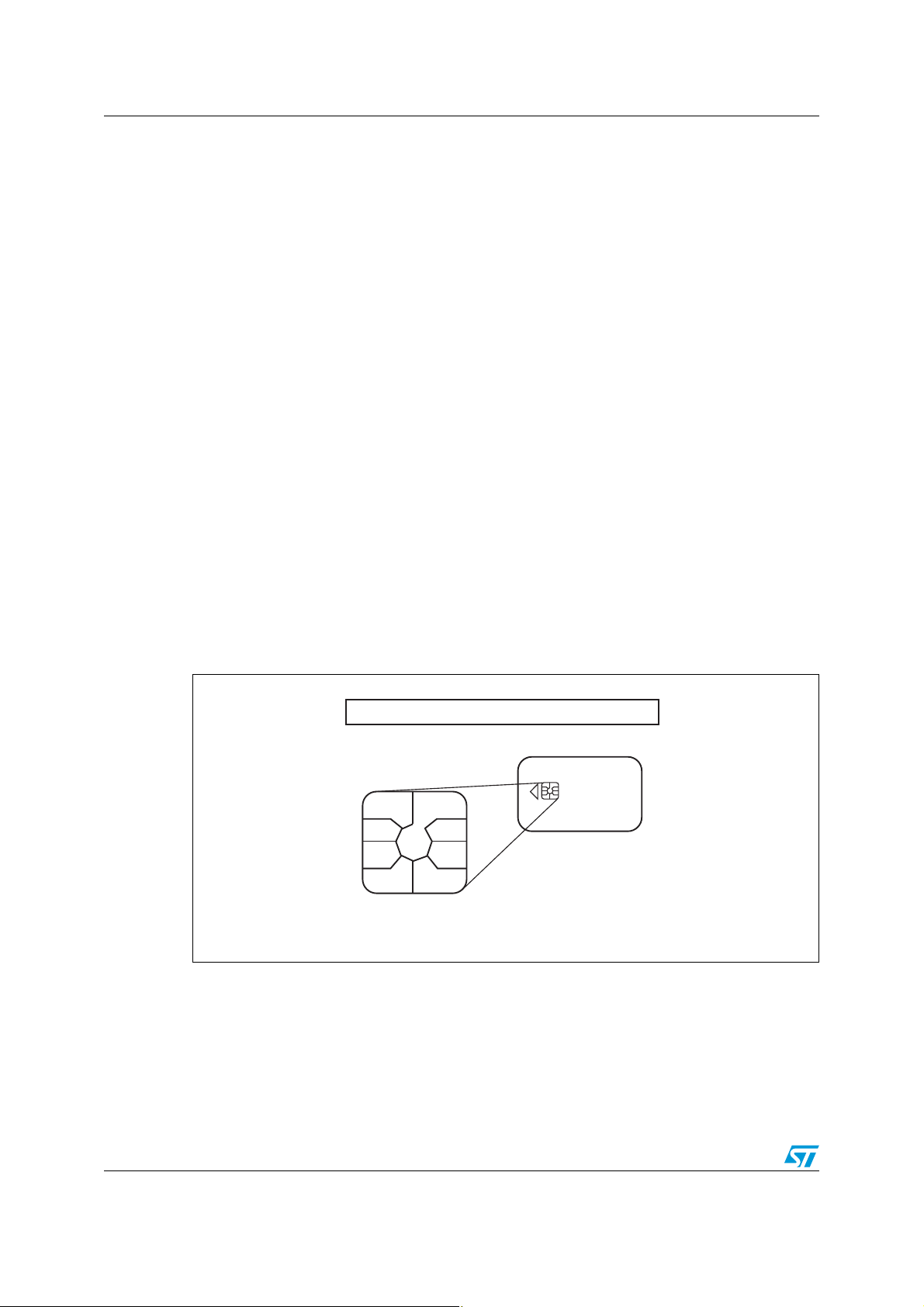

Table 3. Pin assignment

Pins Functions

C1 V

CC

C2 Reset

C3 Clock

C4 RFU

C5 GND

C6 V

PP

C7 I/O

C8 RFU

= 5 V or 3.3 V

Doc ID 13750 Rev 3 11/40

Page 12

ISO 7816-3 – Electronic signal and transmission protocol AN2598

Reader state diagram

Card removal

Reader

"idle"

Card insertion

Powe r

the cord

Protocol

negotiation

Protocol

fail

Card

removal

No ATR

Idle

command

Set protocol

Wait for

response

Command

completion

wait

Partial response

Send APDU to card

Request command

completion

Receive full

response

Powe r

off

Card reset

Prepare

AT R

APDU

dispatch

idle

APDU

processing

Dispatch APDU

to processor

Receive ATR

Issue ATR

Issue response

to reader

Card state diagram

ai14618

4 ISO 7816-3 – Electronic signal and transmission

protocol

ISO 7816-3 begins to delve into the specification of the "intelligent" aspects of the

Smartcard. This standard describes the relationship between the Smartcard and the reader

as one of "slave" (the Smartcard) and "master" (the reader). Communications are

established by the reader signaling to the Smartcard through the contacts noted previously

and are continued by the Smartcard responding accordingly.

Communication between the card and reader proceed according to various state transitions

illustrated in Figure 4.

Figure 4. Reader and card FSM

The communication channel is single-threaded; once the reader sends a command to the

Smartcard, it blocks until a response is received.

12/40 Doc ID 13750 Rev 3

Page 13

AN2598 ISO 7816-3 – Electronic signal and transmission protocol

GND

V

CC

CLK

RST

I/O

Card

inserted

Contacts

properly

positioned

T0

Reader not

listening

Reader listening

t3

(1)

ATR must come

from card here

(2)

ai14619

4.1 Card power-up and reset

When a card is inserted into a reader, no power is applied to any of the contacts. The chip

on the card could be seriously damaged by applying power to the wrong contacts, and this

situation could easily occur if a card were inserted across powered contact points. The

contacts remain unpowered until an edge detector determines that the card is properly

aligned with the contact points to within some acceptable (for the reader) mechanical

tolerance.

When the reader detects that the card is properly inserted, power is applied to the card.

First, the contacts are brought to a coherent idle state, as shown in Tab le 3 . A reset signal is

then sent to the card via the RST contact line. The idle state occurs when the power (V

contact is brought up to a normal, stable operating voltage of 5 V. An initial power setting of

5 V is always applied first, even though some microprocessor chips being introduced

operate at 3 V when in an I/O state. The I/O contact is set to a reception mode on the reader

side and a stable clock (CLK) is applied. The reset line is in a low state. It must remain in a

low state for at least 40 000 CLK cycles before a valid reset sequence can be started by the

reader, raising the reset line to a high state.

Figure 5. Answer to reset

CC

)

1. t3 = 40 000 clock cycles.

2. ATR must be issued by card between 400 clock cycles and 40 000 clock cycles after RST goes high.

Doc ID 13750 Rev 3 13/40

Page 14

ISO 7816-3 – Electronic signal and transmission protocol AN2598

4.2 Data transfer

Data transfer between the reader and the card occurs through the concerted action of two of

the contact lines: CLK and I/O. The I/O line conveys a single bit of information per unit of

time as defined by the CLK depending on its voltage relative to GND. A 1 bit can be

conveyed either through a +5 V value or through a 0 V value. The actual convention used is

determined by the card and is conveyed to the reader through the "initial character" of the

ATR, which is referenced as TS. To transfer 1 byte of information, 10 bits are actually moved

across the I/O line; the first is always a "start bit" and the last is always a parity bit used to

convey even parity. Considering that the I/O line can be (in one bit period) either in a high

(H) state or a low (L) state, the TS character of the form HLHHLLLLLLH signals that the card

wants to use the "inverse convention," meaning that H corresponds to a 0 and L

corresponds to a 1. A TS character of the form HLHHLHHHLLH signals that the card wants

to use the "direct convention," meaning that H corresponds to a 1 and L corresponds to a 0.

The direct convention and the inverse convention also control the bit ordering with each byte

transferred between the card and the reader. In the direct convention, the first bit following

the start bit is the low-order bit of the byte. Successively higher-order bits follow in

sequence. In the inverse convention, the first bit following the start bit is the high-order bit of

the byte. Successively lower-order bits follow in sequence. Parity for each byte transferred

should be even; this means that the total number of 1 bits in the byte, including the parity bit,

must be an even number.

The I/O line comprises a half-duplex channel; that is, either the card or the reader can

transmit data over the same channel, but they both cannot be transmitting at the same time.

So as part of the power-up sequence, both the reader and the card enter a receive state in

which they are listening to the I/O line. With the start of the reset operation, the reader

remains in the receive state while the card must enter a send state in order to send the ATR

back to the reader. From this point on, the two ends of the channel alternate between send

states and receive states. With a half-duplex channel, there is no reliable way for either end

to asynchronously change a state from send to receive or from receive to send. Rather, if

this is desired, that end must go into a receive state and allow a timeout of the operation in

progress; then a reader end will always try to re-establish a known sequence by re-entering

a send state. The CLK and I/O lines can support a wide variety of data transmission speeds.

The specific speed is defined by the card and is conveyed back to the reader through an

optional character in the ATR. The transmission speed is set through the establishment of

one bit time on the I/O line, which means that an interval is established at which the I/O line

may be sampled in order to read a bit and then each successive bit. This time is defined as

an elementary time unit (ETU) and is established through a linear relationship between

several factors. Note that the TS character is returned before any definition of the ETU can

be made. This is possible because the ETU during the ATR sequence is always specified to

be ETU0=372/(CLK frequency) where the CLK frequency is always between 1 MHz and 5

MHz; in fact, the frequency is almost always selected such that the initial data transfer rate is

9,600 bits per second.

14/40 Doc ID 13750 Rev 3

Page 15

AN2598 ISO 7816-3 – Electronic signal and transmission protocol

4.3 Answer to reset (ATR)

Once an RST signal is sent from the reader to the card, the card must respond with the first

character of the ATR within 40 000 CLK cycles. The card might not respond with an ATR for

a number of reasons, the most prevalent being that the card is inserted incorrectly into the

reader (probably upside down). In some instances, the card may not be functioning because

it has been damaged or broken. Whatever the case, if the ATR is not returned within the

prescribed time, the reader should begin a sequence to power down the card. During this

sequence, the reader sets the RST, CLK, and I/O lines low and drops voltage on the V

line to nominal 0 (that is, less than 0.4 V).

The ATR is a string of characters returned from the card to the reader following the

successful completion of the power-up sequence. As defined in ISO/IEC 7816-3, the ATR

consists of 33 or fewer characters comprising the following elements:

● TS - a mandatory initial character

● T0 - a mandatory format character

● TAi TBi TCi TDi - optional interface characters

● T1, T2,TK - optional historical characters

● TCK - a conditional check character

The historical characters can be defined at the discretion of the card manufacturer or the

card issuer. These characters are typically used to convey some type of designation of the

type, model, and use of this specific card. When used in this way, the historical characters

provide a mechanism through which systems can automatically detect the use of an

inserted card (within that system) and can initiate other actions (or software) accordingly.

The check character provides a mechanism through which the integrity of the ATR can be

measured; that is, whether a transmission error has occurred in sending the characters from

the card to the reader.

CC

The structure of the ATR is illustrated in Tab le 4 . As discussed previously, the initial TS

character is used to establish the bit-signaling and bit-ordering conventions between the

reader and the card. The T0 character is used to signal the presence or absence of

subsequent interface characters or historical characters. The interface characters are used

to tailor the characteristics of the I/O channel, including the specific protocol used by the

card and reader during subsequent exchange of commands (from the reader to the card)

and responses (from the card to the reader). The historical characters, if present, are used

to convey card-manufacturer-specific information from the card to the read, and hence to the

application system being served by the reader. There is really no established standard for

the information presented in the historical bits.

Doc ID 13750 Rev 3 15/40

Page 16

ISO 7816-3 – Electronic signal and transmission protocol AN2598

The total length of the ATR sequence is limited to 33 bytes and must adhere to the following

format:

Table 4. Answer-to-reset structure

Character ID Definition

Initial character section TS Mandatory initial character

Format character section T0 Indicator for presence of interface characters

TA1 Global, codes F1 and D1

TB1 Global, codes 11 and Pl1

TC1 Global, code N

TD1 Codes Y2 and T

TA 2 S pe c i fi c

Interface character section

TB2 Global, code Pl2

TC2 Specific

TD2 Codes Y3 and T

TA3 TAi, TBi and TCi are specific

..TDi Codes Yi+1 and T

T1 Card specific information

Historical character section ...TKi (Maximum of 15 characters)

Check character section TCK Optional check character

16/40 Doc ID 13750 Rev 3

Page 17

AN2598 ISO 7816-4 – Smartcard commands

5 ISO 7816-4 – Smartcard commands

The previous chapter discussed the answer-to-reset (ATR) mechanism, which establishes a

basic communication channel between the Smartcard and the reader. This channel is a halfduplex physical channel. This chapter investigates the use of more complex protocols on top

of this physical channel.

A link-level communication protocol resides directly on top of the physical channel, providing

error-free communication between the reader and the Smartcard. Once this link-level

protocol is established, application-level protocols can be defined. ISO 7816-4 defines two

such application-level protocols:

● File system API providing a set of functions to manipulate files (for example read, write,

select, etc.).

● Security service API allowing the Smartcard and the reader to mutually authenticate

themselves and also to encrypt data to be exchanged between the card and the reader.

ISO 7816-4 defines a protocol message structure to support the application protocol APIs.

This message structure consists of application protocol data units (APDUs) which are

exchanged between the reader application and the Smartcard application by the link-level

protocol. This chapter will provide an overview of the file access and security APIs.

5.1 T0 protocol

The T0 protocol is a byte-oriented protocol where a character is transmitted across the

channel between the reader and the card. In addition, error handling is performed on each

byte by looking at the parity bit. If the actual parity bit does not correspond to the parity of

the transmitted data, then an error must have occurred. In the T0 protocol, the receiving side

signals that it requires the byte to be retransmitted in the case of detecting a parity error.

This is done by holding the I/O line low (normally the I/O line is set high preceding the

transfer of a byte). When the transmitting side detects this, it resends the byte that was not

received correctly.

The reader and the Smartcard exchange data structures known as transmission protocol

data units (TPDUs). It consists of two distinct structures:

● a command that is sent from the reader to the card

● a response that is sent from the card to the reader

The command header includes the following five fields each of one byte in length:

● CLA: class designation of the command set to establish a collection of instructions

● INS: specifies a specific instruction from within the set of instructions

● P1: used to specify the addressing used by the [CLA, INS] instruction

● P2: also used to specify the addressing used by the [CLA, INS] instruction

● P3: specifies the number of data bytes transferred to or from the card as part of the

[CLA, INS] instruction execution.

Each value of CLA defines an application-specific set of instructions. Table 5. below lists

values for some sets of instructions.

Doc ID 13750 Rev 3 17/40

Page 18

ISO 7816-4 – Smartcard commands AN2598

Table 5. CLA instruction set definitions

CLA byte Instruction set

0x ISO 7816-4 instructions (files and security)

10 to 7F Reserved for future use

8x or 9x ISO 7816-4 instructions

Ax Application/vendor specific instructions

B0 to CF ISO 7816-4 instructions

D0 to FE Application/vendor specific instructions

FF Reserved for protocol type selection

The INS byte is used to identify a specific instruction within a class of instructions identified

by the value of CLA.Tab l e 6 . lists the instructions in the ISO 7816-4 standard used to access

file system and security functions.

Table 6. ISO 7816-4 INS codes

INS value Command name INS value Command name

0E Erase Binary C0 Get Response

20 Verify C2 Envelope

70 Manage Channel CA Get Data

82 External Authenticate D0 Write Binary

84 Get Challenge D2 Write Record

88 Internal Authenticate D6 Update Binary

A4 Select File DA Put Data

B0 Read Binary DC Update Record

B2 Read Record(s) E2 Append Record

The parameters P1 and P2 are defined at the link level but are actually dependent on the

specific instruction (application level). They provide control or addressing parameters for the

various application-specific instructions. For example, in the Select File instruction, P1 is

used to indicate how the file will be referred to (by identifier, name, path etc.) and P2 offers

further refinement as to which file is to be selected. P3 defines the number of bytes to be

transmitted during the execution of the INS specified instruction. The convention used to

indicate movement of data is card-centric that is, outgoing refers to data moving from the

card to the reader and incoming refers to data moving from the reader to the card.

For each command TDPU sent from the reader, a response TPDU is sent by the card. The

response includes three mandatory fields and one optional field (all one byte in length):

● ACK: indicates that the card has received the [CLA, INS] command

● NULL: used for flow control on the I/O channel by the card. It signals (to the reader) that

the card is still processing the command and so the reader must wait before sending

another command

● SW1: status response of the current command

● SW2: (optional) also conveys a status response to the reader

18/40 Doc ID 13750 Rev 3

Page 19

AN2598 ISO 7816-4 – Smartcard commands

Application

ai14620

APDU

Reader

Response

Card

Command

Response

APDU

Response

APDU

processor

Specific functions,

e.g. Select File, Read file, etc.

T0 or T1 link protocol

The ACK byte is a repeat of the INS byte from the command TPDU. If the response does not

reach the reader within a specified time, the reader may initiate an RST sequence to restart

the protocol between the reader and the card. This can be prevented if the reader receives

at least one NULL byte from the card. SW1 informs the reader of the result of the requested

instruction. The values allowed for SW1 are defined as part of the application protocol.

Some instructions require the card to send data to the reader. In this case SW2 is returned

to the reader, triggering the reader to execute a GetResponse command. The card will then

return the data bytes generated by the execution of the previous command.

5.2 Application-level protocols

The ISO 7816-4 standard addresses two areas of functionality for application software:

● File system: a set of functions is provided in the form of an API. By using this API

application software on the reader side can access files in the file system.

● Security functions: these can be used to limit access to application software or to files

on the card.

The T0 protocol is used to support application-level protocols between the Smartcard

application and the reader application. These application protocols exchange data

structures called application protocol data units (APDUs). The following diagram illustrates

this architecture:

Figure 6. Application communication architecture

The APDU structure defined by ISO 7816-4 is very similar to the TPDU structure used in the

T0 protocol. In fact, when an APDU is transported by the T0 protocol, the elements of the

APDU directly overlay the elements of the TPDU.

Doc ID 13750 Rev 3 19/40

Page 20

ISO 7816-4 – Smartcard commands AN2598

ai14621

BodyHeader

CLA INS P1 P2 Lc field

Le field

Data field

ai14622

Body

Trailer

Data field SW1 SW2

5.2.1 The ISO 7816-4 APDU

There are two types of messages used to support the ISO 7816-4 application protocols: the

command APDU (sent from the reader to the card) and the response APDU (sent from the

card to the reader).

Figure 7. Command APDU structure

The command APDU consists of a header and a body (this can be seen in the diagram

above). The header includes CLA, INS, P1 and P2 fields. As in the T0 protocol, CLA and

INS specify an application class and instruction. P1 and P2 are used to qualify specific

instructions and are given specific definitions by each [CLA, INS] instruction. The body of

the APDU can vary in size and is used to transmit data to the card's APDU processor as

part of a command or to convey a response from the card to the reader. The Lc field

specifies the number of bytes to be transmitted to the card as part of the instruction, that is,

the length of the data field. The data field contains information that must be sent to the card

to allow its APDU processor to execute the command specified in the APDU. The Le field

specifies the number of bytes that will be returned to the reader in the response APDU.

The body of the APDU can take on four different forms:

● Case 1: No data is transferred to or from the card, so the APDU only contains the

header.

● Case 2: No data is transferred to the card, but data is returned from the card. The body

of the APDU only contains a non-null Le field.

● Case 3: Data is transferred to the card, but none is returned from it. The body of the

APDU includes the Lc and data fields.

● Case 4: Data is transferred to the card and is also returned from the card as a result of

the command. The body of the APDU includes the Lc, data and Le fields.

Figure 8. Response APDU structure

The response APDU has a much simpler structure than that of the command APDU. It

consists of a body and a trailer. The body is either null or it includes a data field - depending

on the specific command. The length of the data field is determined by the Le field in the

corresponding command APDU. The trailer consists of up to two fields of status information

called SW1 and SW2. These fields return a status code in which one byte is used to specify

20/40 Doc ID 13750 Rev 3

Page 21

AN2598 ISO 7816-4 – Smartcard commands

MF

EF

DF EF

EF

EF DF

EF

DF

ai14623

an error category and the other is used to specify a command-specific status or error

indication.

5.2.2 File system API

The file system is used on the non-volatile memory or EEPROM. It is defined as a simple

hierarchical structure (similar to conventional file systems). The file system may contain

three types of files (identified by a 2-byte identifier):

● Master file (MF)

● Dedicated file (DF)

● Elementary file (EF)

There is one master file found on each Smartcard and it is the root of the file system. A

master file may contain dedicated files or elementary files. The file identifier reserved for the

master file is 3F00. The directory file is essentially a container (or directory) for elementary

files - a DF may contain zero or more EFs. Dedicated files partition the Smartcard into an

ordered structure of elementary files. A dedicated file must be given a unique file identifier

within the dedicated file or master file that contains it - allowing for a unique path for each

file. A dedicated file can also be referenced by name (1-16 bytes long). The naming

convention can be found in ISO 7816-5. An elementary file is a leaf node in the hierarchy

and contains the actual data. An elementary file can be identified by a 5-bit identifier within a

dedicated file. This file system hierarchy is illustrated in Figure 9.

Figure 9. Smartcard file system architecture

1. MF = master file, DF = dedicated file, EF = elementary file.

(1)

There are four types of elementary files:

● Transparent file

● Linear, fixed-length record file

● Linear, variable-length record file

● Cyclic, fixed-length record file

A transparent file is essentially a string of bytes, that is an unstructured binary file.

Consequently a byte offset from the start of the file is required when data is to be read or

written to this type of file. In addition, a command to read or write to a transparent file will

contain the length of the byte string to be read or written to the file.

Fixed- and variable-length files contain records that are identified by a sequence number. In

a fixed-length record file, all the records contain the same number of bytes. In contrast, a

Doc ID 13750 Rev 3 21/40

Page 22

ISO 7816-4 – Smartcard commands AN2598

variable-length record file contains records that may vary in length. As a result, variablelength record files have a higher overhead in read/write access times as well as a higher

administrative overhead required by the file system.

A cyclic file allows applications to access records in a consistent and transparent manner. It

can be thought of as a ring of files. Write operations are performed on the next physical

record in the ring.

5.2.3 ISO 7816-4 functions

The few functions that are defined in ISO 7816-4 for selecting, reading and writing to files

will be briefly discussed below.

Select File

This command establishes a logical pointer to a particular file in the Smartcard's file system.

This pointer is required for any file manipulation operation. Access to the Smartcard's file

system is not multithreaded, however it is possible to have several file pointers defined at

any point in time. This is accomplished by the Manage Channel command, which

establishes multiple logical channels between the reader side application and the card. This

allows different files on the card to be in various states of access by the reader application at

the same time. The identification of the file can be provided in the following ways:

● file identifier (2-byte value)

● DF name (string of bytes)

● path (concatenation of file identifiers)

● short ID

Note that not all Smartcards support all four naming mechanisms.

Read Binary

This command is used by the application on the reader side to retrieve a part of an EF on

the card. However, the EF must be a transparent file (not record-oriented). If the Read

Binary command is attempted on a record-oriented EF, the command will abort with an error

indicator being returned from the card.

The Read Binary command takes two parameters: an offset pointer from the start of the file

to the initial byte to be read, and the number of bytes to be read and returned to the reader.

Write Binary

This command is used to insert data into a transparent EF on the card. This command can

be used to set a series of bytes in the EF (that is set selected bits within a specified byte to a

value of1), clear a series of bytes or perform a write of a series of bytes in the EF.

Update Binary

A reader-side application can utilize this command to directly erase and store a contiguous

sequence of bytes in a transparent EF on the card. It effectively functions as a write

command that is a string of bytes provided in the command are written into the EF on the

card. The input parameters consist of an offset pointer from the start of the file as well as the

number of bytes to be written.

22/40 Doc ID 13750 Rev 3

Page 23

AN2598 ISO 7816-4 – Smartcard commands

Erase Binary

The Erase Binary command is used to clear bytes within a transparent EF on a card.

Similarly to the previous commands, the input parameters comprise an offset from the start

of the EF to the segment of bytes to be erased as well as the number of bytes to be erased.

Read Record

This command is used to read and return the contents of one or more records in an EF on a

card. Unlike the previous command, the EF for the Read Record command must be a

record-oriented file. If it is applied to a transparent EF, the command will abort and an error

will be returned to the reader.

The following may be returned from this command, depending on the input parameters:

● A specified record

● All the records from the beginning of the file to a specific record

● All the records from a specific record to the end of the file

Write Record

This command is used to write a record into a record-oriented EF. As with the Write Binary

command, this command can be used to write a record into an EF, set or clear specific bits

within a specific record in an EF.

Append Record

The Append Record command is used to add a record to the end of a linear, record-oriented

EF or to write the first record to a cyclic, record-oriented EF on a card.

Update Record

This command writes a specific record into a record-oriented EF on a card. As with the

Update Binary command, the old record is erased and the new one is written into the EF.

Get Data

This command reads and returns the contents of a data object stored within the file system

on the card. The Get Data command is card-specific as the definition of a data object varies

between different cards.

Put Data

This command (as the name suggests) puts information into a data object on the card. As

with the previous command, this is a card-specific command.

5.2.4 Security API

Each component of the file system on a Smartcard has an associated list of access

properties. The access properties ensure that only authorized parties are allowed to access

the particular component of the file system. The authentication can be simple, such as

requiring the reader to provide a predefined personal identification number (PIN).

Alternatively, it may be more complicated, such as requiring the reader to prove that it

possesses some shared secret with the card (for example a key) by encrypting or decrypting

a string of bytes provided by the card.

A few of the functions provided by the security API are briefly discussed below.

Doc ID 13750 Rev 3 23/40

Page 24

ISO 7816-4 – Smartcard commands AN2598

Verify

This command is sent by the application on the reader side to the security system on the

card. Its purpose is to convince the card that the reader knows a password maintained by

the card in order to restrict access to sensitive information stored on the card. The

password-type information may be associated with a specific file or to some or all of the file

hierarchy. If the Verify command fails i.e. the reader provides an incorrect password, an error

is returned to the reader.

Internal Authenticate

This command allows the card to authenticate itself to the reader by proving that it

possesses a secret key shared with the reader. The reader application software first

generates a random number and encrypts it with some algorithm known to both card and

reader. This constitutes a challenge to the card. The card then decrypts this challenge with

the secret key (that is stored on the card) and sends the resulting data back to the reader. If

the data received by the reader matches the random number that it generated then the

reader application software is assured of the identity of the card.

External Authenticate

This command is used in conjunction with the Get Challenge command to enable the reader

application software to authenticate itself to the card. The reader receives challenge data (a

random number) from the card and encrypts it with a secret key. This is then sent to the card

using the External Authenticate command. The card decrypts the data and compares it to

the random number that it generated in the previous Get Challenge command. If there is a

match, then the card is assured of the identity of the reader application.

Get Challenge

This command is sent by the reader to the card. Its purpose is to provide the reader

application with a random number generated by the Smartcard. As previously described,

this number is used in the External Authenticate command.

Manage Channel

The Manage Channel command is used by the reader application to open and close the

logical communication channels between it and the card. Initially the card opens a basic

communication channel by establishing an application-level protocol with the reader

application through the completion of an ATR sequence. This channel is then used to open

or close additional logical channels through the Manage Channel command.

Envelope

This command supports the use of secure messaging using the T0 protocol. It enables an

APDU to be encrypted and then incorporated into the Envelope command's data section (of

its APDU). The APDU processor on the card can then extract and execute the command.

Get Response

As with the previous command, the Get Response command allows the use of the T0

protocol for transferring APDUs. The Case 4 type of APDU cannot be supported by the T0

protocol i.e. it is not possible to send a block of data to the card and then receive a block of

data in return. So when using the T0 protocol, the initial command results in a response

which indicates that more data is waiting to be sent by the card. The Get Response

command is then used to retrieve this data.

24/40 Doc ID 13750 Rev 3

Page 25

AN2598 Smartcard interface library: description

6 Smartcard interface library: description

The user may access a Smartcard using directly the application layer. It allows to

send/receive ADPU commands to/from the Smartcard using the following user interface:

6.1 File organization

Ta bl e 7 presents the Smartcard library modules:

Table 7. File library description

File Description

– Smartcard definitions, types definitions and function prototypes

smartcard.h, smartcard.c

6.2 Smartcard interface library functions

– T0 protocol management

– Physical layer

Ta bl e 1 5 lists the various functions of the Smartcard library.

Table 8. Smartcard library functions

Function name Description

SC_Handler

SC_PowerCmd Enables or disables the power to the Smartcard.

SC_Reset Sets or clears the Smartcard reset pin.

SC_ParityErrorHandler

SC_PTSConfig Configures the IO speed (BaudRate) communication.

6.2.1 SC_Handler function

It is described in Ta bl e 9 .

Table 9. SC_Handler

Function name SC_Handler

Function prototype

Behavior description

void SC_Handler(SC_State *SCState, SC_ADPU_Commands *SC_ADPU,

SC_ADPU_Responce *SC_Response)

Handles all Smartcard states and serves to send and receive all

communication data between Smartcard and reader.

Handles all Smartcard states and serves to send and receive all

communication data between Smartcard and reader.

Resends the byte that failed to be received (by the Smartcard)

correctly.

Input parameter1

Input parameter2

SCState: pointer to an SC_State enumeration that will contain the

Smartcard state.

SC_ADPU: pointer to an SC_ADPU_Commands structure that will be

initialized.

Doc ID 13750 Rev 3 25/40

Page 26

Smartcard interface library: description AN2598

Table 9. SC_Handler (continued)

Function name SC_Handler

Input parameter3

SC_Response: pointer to a SC_ADPU_Responce structure which will be

initialized.

Output parameter None

Return parameter None

Required preconditions None

Called functions None

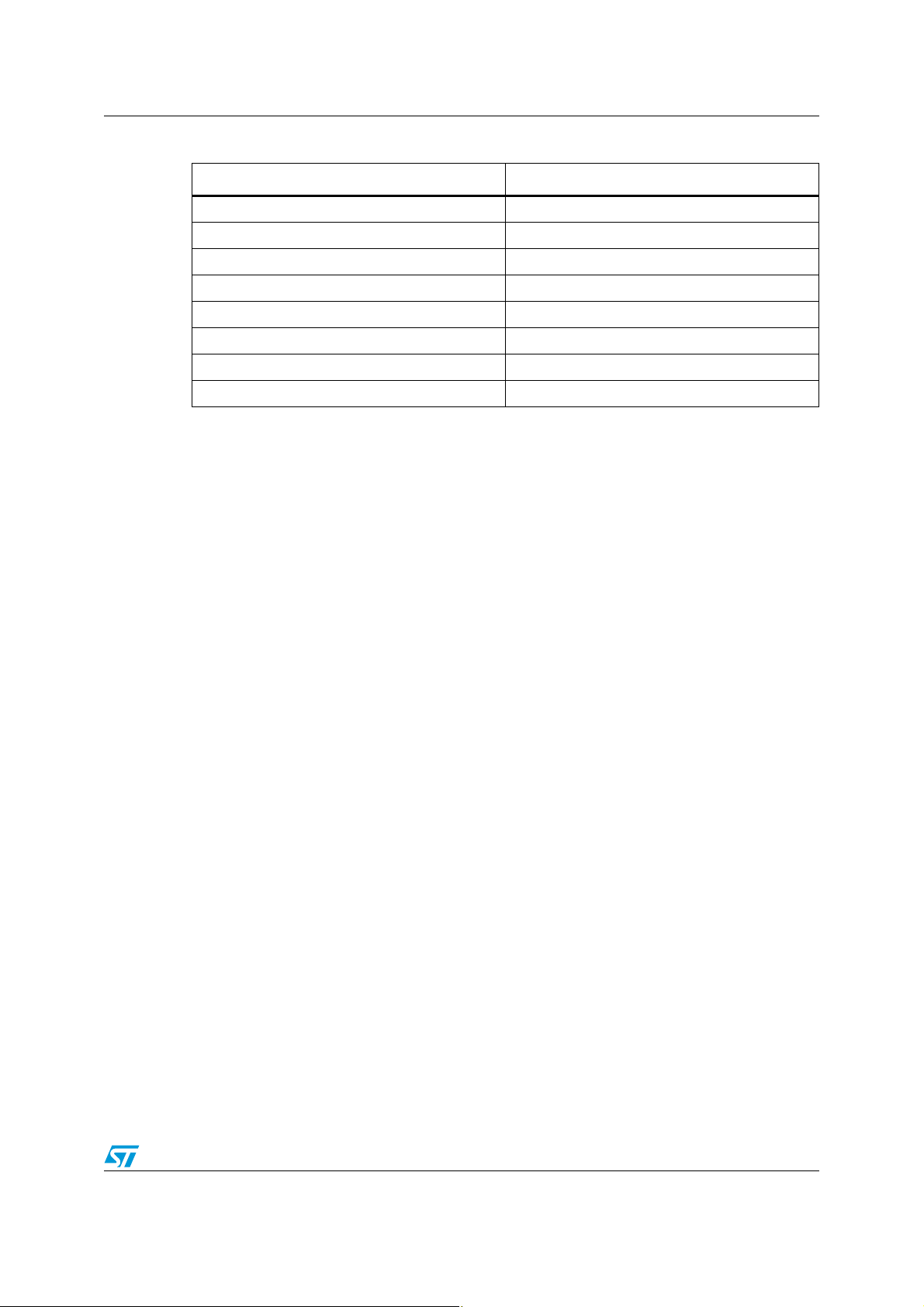

SCState

SCState informs the user about the Smartcard state and allows the user to power off the

Smartcard. It can assume one of the values defined in Tab le 1 0 below.

Table 10. SCState

SCState Meaning

SC_POWER_OFF

SC_POWER_ON

SC_RESET_LOW

No power is provided to the Smartcard (V

Smartcard interface is disabled. No clock is provided to the Smartcard.

The Smartcard peripheral is enabled and initialized; no power is provided to

the Smartcard; no clock is provided to the Smartcard.

In this state, the RST Smartcard pin (pin 2) is driven low (RST = 0). V

5 V is provided to the Smartcard; clock CLK is provided to the Smartcard.

Answer to reset (ATR) procedure begins. The reader waits for an ATR frame

from the Smartcard.

= 0); the STM32F10x

CC

CC

=

SC_RESET_HIGH

SC_ACTIVE

SC_ACTIVE_ON_T0

If no answer is received, the reader forces the reset pin RST high (RST = 1)

and holds it high until it receives an answer to reset.

If an answer to reset is received, the reader goes in active state and

decodes the ATR frame. It returns information about the used protocol.

If the used protocol is T0, the reader goes in SC_ACTIVE_ON_T0 state and

commands can then be sent to the Smartcard.

26/40 Doc ID 13750 Rev 3

Page 27

AN2598 Smartcard interface library: description

Power off

Power-up

User forces

power-up

Reset low

Active

Active on T0

Reset high

No ATR

received

No ATR

received

ATR received

with RST = 0

T0 protocol

ATR received

with RST = 1

ai14624

Figure 10. State machine for smartcard operation

SC_ADPU_Commands

The SC_APDU_Commands structure is defined in the smartcard.h file:

typedef struct

{

SC_Header Header;

SC_Body Body;

} SC_ADPU_Commands;

●

Header

Specifies the APDU command header. It is of the SC_Header type, which is defined in

the smartcard.h file:

typedef struct

{

u8 CLA; /* Command class */

u8 INS; /* Operation code */

u8 P1; /* Selection Mode */

u8 P2; /* Selection Option */

} SC_Header;

●

CLA

Specifies the class designation of the command set to establish a collection of

instructions.

● INS

Specifies a specific instruction from within the set of instructions.

● P1

Specifies the addressing used by the [CLA, INS] instruction.

● P2

Specifies the addressing used by the [CLA, INS] instruction.

● Body

Specifies the APDU command body. It is of the SC_Body type, which is defined in the

smartcard.h file:

Doc ID 13750 Rev 3 27/40

Page 28

Smartcard interface library: description AN2598

typedef struct

{

u8 LC; /* Data field length */

u8 Data[LCmax]; /* Command parameters */

u8 LE; /* Expected length of data to be returned */

} SC_Body;

●

LC

Specifies the number of data bytes transferred to the card as part of the [CLA, INS]

instruction execution.

● Data

Specifies the pointer to the data buffer transferred to the card.

● LE

Specifies the number of data bytes transferred from the card as part of the [CLA, INS]

instruction execution.

● SC_Response

Specifies the APDU command response. It is of SC_ADPU_Response type, defined in

the smartcard.h file:

typedef struct

{

u8 Data[LCmax]; /* Data returned from the card */

u8 SW1; /* Command Processing status */

u8 SW2; /* Command Processing qualification */

} SC_ADPU_Responce;

●

Data

Specifies the pointer to the data buffer which will contain the returned card data.

● SW1

Specifies the first status code byte. This byte stores the error category.

● SW2

Specifies the second status code byte. This byte stores a command-specific status or

error indication.

Example:

/* Select the Master Root MF */

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_SELECT_FILE;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x02;

for(i = 0; i < SC_ADPU.Body.LC; i++)

{

SC_ADPU.Body.Data[i] = MasterRoot[i];

}

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = 0;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

28/40 Doc ID 13750 Rev 3

Page 29

AN2598 Smartcard interface library: description

6.2.2 SC_PowerCmd

It is described in Ta bl e 1 1 .

Table 11. SC_PowerCmd

Function name SC_PowerCmd

Function prototype

Behavior description Enables or disables the power to the Smartcard.

Input parameter

Output parameter None

Return parameter None

Required preconditions None

Called functions None

Example:

/* Power ON the card */

SC_PowerCmd(ENABLE);

6.2.3 SC_Reset

It is described in Ta bl e 1 2 .

Table 12. SC_Reset

Function name SC_Reset

Function prototype

Behavior description Sets or clears the Smartcard reset pin.

void SC_PowerCmd(FunctionalState NewState);

NewState: new state of the Smartcard power supply. This parameter

can be: ENABLE or DISABLE.

void SC_Reset(BitAction ResetState);

ResetState: this parameter specifies the state of the Smartcard reset pin.

Input parameter

BitVal must be one of the BitAction enum values:

Bit_RESET: to clear the port pin.

Bit_SET: to set the port pin.

Output parameter None

Return parameter None

Required preconditions None

Called functions None

Example:

/* Set the Smartcard reset pin */

SC_Reset(Bit_SET);

Doc ID 13750 Rev 3 29/40

Page 30

Smartcard interface library: description AN2598

6.2.4 SC_ParityErrorHandler

It is described in Ta bl e 1 3 .

Table 13. SC_ParityErrorHandler

Function name SC_ParityErrorHandler

Function prototype

Behavior description Resends the byte that failed to be received correctly (by the Smartcard)

Input parameter None

Output parameter None

Return parameter None

Required preconditions None

Called functions None

Example:

/* Resend the byte to the Smartcard */

SC_ParityErrorHandler();

6.2.5 SC_PTSConfig

It is described in Ta bl e 1 4 .

Table 14. SC_PTSConfig

Function name SC_PTSConfig

Function prototype

Behavior description Configures the IO speed (BaudRate) communication.

Input parameter None

Output parameter None

void SC_ParityErrorHandler(void);

void SC_PTSConfig(void);

Return parameter None

Required preconditions Must be called just after the ATR sequence.

Called functions None

Example:

/* Configures the baudrate according to the card TA1 value */

SC_PTSConfig();

6.3 How to send APDU commands to the Smartcard

A detailed description on how to use the SC_Handler( ) function to send the ADPU

command to the Smartcard and retrieve the card response is described below. The user has

to update the SC_CLA and the Smartcard instruction values according to the Smartcard

specifications.

30/40 Doc ID 13750 Rev 3

Page 31

AN2598 Smartcard interface library: description

6.3.1 SC_GET_A2R

SC_ADPU.Header.CLA = 0x00;

SC_ADPU.Header.INS = SC_GET_A2R;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x00;

while(SCState != SC_ACTIVE_ON_T0)

{

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

}

●

SCState: It stores the current Smartcard state.

● SC_ATR_Table: Pointer to an array (filled in by the SC_Handler function) that

contains the Smartcard ATR frame.

6.3.2 SELECT_FILE

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_SELECT_FILE;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x02;

for(i = 0; i < SC_ADPU.Body.LC; i++)

{

SC_ADPU.Body.Data[i] = FileName[i];

}

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = 0;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

●

FileName: It contains the 16 bit file identifier.

● SCState: It stores the current Smartcard state.

● SC_Response->SW1 and SC_Response->SW2: they return the Smartcard response

to the SC_SELECT_FILE command.

6.3.3 SC_GET_RESPONSE

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_GETRESPONSE;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x00;

i = 0;

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = SC_Responce.SW2;

Doc ID 13750 Rev 3 31/40

Page 32

Smartcard interface library: description AN2598

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

SCState: It stores the current Smartcard state.

●

● SC_Response->SW1 and SC_Response->SW2: they return the Smartcard response

to the SC_GET_RESPONSE command.

● SC_Response->Data: It returns the Smartcard data response to the

SC_GET_RESPONSE command.

6.3.4 SC_READ_BINARY

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_READ_BINARY;

SC_ADPU.Header.P1 = OFFSET_MSB;

SC_ADPU.Header.P2 = OFFSET_LSB;

SC_ADPU.Body.LC = 0x00;

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = LENGTH;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

●

SCState: It stores the current Smartcard state.

● OFFSET_MSB: Most significant byte of offset for reading data.

● OFFSET_LSB: Least significant byte of offset for reading data.

● LENGTH: It contains size (in byte) of the area to read (valid only for the elementary

file).

● SC_Response->Data: It returns the Smartcard data to read.

● SC_Response->SW1 and SC_Response->SW2: they return the Smartcard response

to the SC_READ_BINARY command.

6.3.5 SC_CREATE_FILE

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_CREATE_FILE;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x10;

for(i = 0; i < SC_ADPU.Body.LC; i++)

{

SC_ADPU.Body.Data[i] = FileParameters[i];

}

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = 0;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

32/40 Doc ID 13750 Rev 3

Page 33

AN2598 Smartcard interface library: description

● FileParameters: It contains the 16 bytes file parameters (File ID, FILE Access

Conditions...).

● SCState: It stores the current Smartcard state.

● SC_Response->SW1 and SC_Response->SW2: they return the Smartcard response

to the SC_CREATE_FILE command.

6.3.6 SC_UPDATE_BINARY

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_UPDATE_BINARY;

SC_ADPU.Header.P1 = OFFSET_MSB;

SC_ADPU.Header.P2 = OFFSET_LSB;

SC_ADPU.Body.LC = LENGTH;

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = 0x00;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

●

SCState: It stores the current Smartcard state.

● OFFSET_MSB: Most significant byte of offset for reading data.

● OFFSET_LSB: Least significant byte of offset for reading data.

● LENGTH: It contains the size (in byte) of the area to write (valid only for the elementary

file).

● SC_Responce->Data: It contains the Smartcard data to write.

● SC_Responce->SW1 and SC_Responce->SW2: they return the Smartcard response

to the SC_UPDATE_BINARY command.

6.3.7 SC_VERIFY

SC_ADPU.Header.CLA = SC_CLA;

SC_ADPU.Header.INS = SC_VERIFY;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x08;

for(i = 0; i < SC_ADPU.Body.LC; i++)

{

SC_ADPU.Body.Data[i] = CHV1[i];

}

while(i < LCmax)

{

SC_ADPU.Body.Data[i++] = 0;

}

SC_ADPU.Body.LE = 0;

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

●

CHV1: It contains the 8-byte CHV1 code.

● SCState: It stores the current Smartcard state.

● SC_Responce->SW1 and SC_Responce->SW2: they return the Smartcard response

to the SC_VERIFY command.

Doc ID 13750 Rev 3 33/40

Page 34

Smartcard interface library: description AN2598

6.4 Parity error management

In the T0 protocol, error handling is performed on each byte by looking at the parity bit. If the

actual parity bit does not correspond to the parity of the transmitted data, then an error must

have occurred; the receiving side signals that it requires the byte to be retransmitted in the

case of detecting a parity error. This is done by holding the I/O line low (normally the I/O line

is set high preceding the transfer of a byte). When the transmitting side detects this, it

resends the byte that was not received correctly.

6.4.1 Data sent from card to reader

STM32F10x is able to detect a parity error on a received data via hardware, by pulling down

the data line during the stop bit.

6.4.2 Data sent from reader to card

Vice versa if the Smartcard pulls down the I/O line to signal that a parity error occurred, the

STM32F10x is able to detect a frame error via hardware. The Smartcard library uses the

SC_ParityErrorHandler() function to check whether a parity error has occurred and,

to manage the error if any.

Each time the SC_ParityErrorHandler function is called it resends the byte where the error

was detected.

After a byte is sent from the microcontroller to the card, the Smartcard captures the data

sent on the I/O line. If a parity error is detected from the card, the I/O line is pulled down

during the stop bits. A frame error event occurs and the related IRQ event invokes the

SC_ParityErrorHandler() function that resends the last data.

34/40 Doc ID 13750 Rev 3

Page 35

AN2598 Smartcard interface example

7 Smartcard interface example

An example is provided in conjunction with the Smartcard library in order to help the user

develop its custom application.

The example provides simple operations with an ISO 7816-3/4-compatible GSM11.11

Smartcard, such as file system exploration, pin1 enable/disable, read/write operation on

files and pin verify on protected files.

This example runs on the STM3210B-EVAL, STM3210E-EVAL and STM3210C-EVAL

STMicroelectronics evaluation boards. The boards provide all the hardware needed to

interface a Smartcard, and you can easily tailor them to any other hardware. To select the

STMicroelectronics evaluation board you wish to use to run the example, uncomment the

corresponding line in the platform_config.h file.

7.1 Firmware description

Three directories have been defined for the GSM Smartcard directory tree:

MasterRoot[3]={0x3F, 0x00};

GSMDir[3]={0x7F, 0x20};

TelecomDir[3]={0x7F, 0x10};

Figure 11. Smartcard example: file system description

At the end of the example:

● The ICCID file located under the MasterRoot directory is read

● The IMSI file, under GSMDir, that has a secure access through PIN1, is read

● The PIN1 is enabled/disabled

7.1.1 Smartcard startup: answer to reset (A2R)

The first action to perform when the reader wants to access a card is the answer-to-reset

procedure. To this aim the SC_Handler is invoked as follows:

SC_ADPU.Header.CLA = 0x00;

SC_ADPU.Header.INS = SC_GET_A2R;

SC_ADPU.Header.P1 = 0x00;

SC_ADPU.Header.P2 = 0x00;

SC_ADPU.Body.LC = 0x00;

while(SCState != SC_ACTIVE_ON_T0)

{

SC_Handler(&SCState, &SC_ADPU, &SC_Responce);

}

Doc ID 13750 Rev 3 35/40

Page 36

Smartcard interface example AN2598

When a card is detected, the A2R sequence is generated, received and decoded. If the

recognized protocol is the T0 protocol, the Smartcard state of the reader is active

(SC_ACTIVE_ON_T0) and the Smartcard is available for operations on the file system.

The procedure type selection (PTS) will be applied after the ATR using the SC_PTSConfig()

function. For the used GSM card, the PTS procedure is as follows:

PTSS = 0xFF

PTS0 = 0x10

PTS1 = 0x95

PCK = 0x7A

PTS1 = 0x95, F = 9 and D = 5, Fi = 512, Di = 16, BaudRate = 112500 baud.

7.1.2 Reading a file at a specified path

The specified reading path is assumed to be: MasterRoot/GSMDir/IMSI

To reach it, the following actions are performed:

● Select GSMDir using a SelectFile APDU command

● Select IMSI File using a SelectFile APDU command

The user has to get the file characteristics to check its access conditions. The IMSI file has a

CHV1(PIN1) read condition, so PIN1 has to be checked before reading it. The verify

command must be executed under the directory containing the file to be read, the GSMDir

must be selected in the example.

To get file characteristics:

● Select the file the characteristics of which are needed

● Get the data returned after issuing the SelectFile APDU command by sending a

GETRESPONSE command

The IMSI file has 9 data bytes, so to run correctly the READ_BINARY commands, the

following parameters are used:

● P1 = 0x00

● P2 = 0x00

● LE = 0x09

7.1.3 Enabling/disabling the PIN1 (CHV1) code

At the beginning of the application, the PIN1 (CHV1) status is checked. This can be done by

a GET_RESPONSE command after a successful MasterRoot selection.

In this example, the PIN1 status is checked. If it is enabled, the PIN1 will be disabled to give

access to all files that have a secure access conditions.

To check the PIN1 status, the procedure is the following:

● Select the MasterRoot directory using a SelectFile APDU command

● Get the data returned after issuing the MasterRoot SelectFile command by sending a

GETRESPONSE command.

● Check the bit8 of the 14 received bytes: if bit8 is 0: PIN1 is enabled else the PIN1 is

disabled.

To enable or disable PIN1, the CHV1 code must be sent to the card. The CHV1 code is 8byte long.

36/40 Doc ID 13750 Rev 3

Page 37

AN2598 Smartcard interface example

7.1.4 Verifying the PIN1 (CHV1) code

Some files have a restricted access conditions such as IMSI, CHV1 file, CHV2. The access

conditions of these files must be met for the user to be allowed to execute the restricted

operations (read, update, change CHV1).

To verify the PIN1 (CHV1) condition, the procedure is as follows:

● Go to the directory which contain the file to be accessed

● Use the Verify APDU command by presenting the CHV1 code

● Select the file and execute the selected operation

Doc ID 13750 Rev 3 37/40

Page 38

Conclusion AN2598

8 Conclusion

Thanks to the STM32F10x USART’s Smartcard mode that supports the ISO 7816-3/4

specification, the user can develop a Smartcard-based application with reduced firmware

and hardware resources.

38/40 Doc ID 13750 Rev 3

Page 39

AN2598 Revision history

9 Revision history

Table 15. Document revision history

Date Revision Changes

03-Aug-2007 1 Initial release.

Firmware updated to support STM32F10x High-density devices and

to run on the STM3210E-EVAL evaluation board:

30-May-2008 2

– Table 2: STM32F10x and Smartcard connection on page 8

updated.

– Section 7.1.2: Smartcard_AN folder on page 35 updated.

Small text changes.

27-Jul-2009 3

Updated for STM3210C-EVAL

Removed description of firmware package installation folders

Doc ID 13750 Rev 3 39/40

Page 40

AN2598

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

40/40 Doc ID 13750 Rev 3

Loading...

Loading...