Page 1

Introduction

Some industrial applications require a so called 'ultra-wide' input voltage range (between 90

and 450Vac). Due to the variations of the main, input voltages up to 450V ac are typical in threephase applications. A maximum input voltage of 450Vac requires the use of very high voltage

components, increasing cost, size, the weight and the overall complexity of the power supply .

Hence, the market is looking for solutions with low cost and good performance.

Thi document introduces a cost effective solution for low power high voltage power supplies.

The proposed solution consists of in an off-line SMPS and a low cost front-end regulation circuit

for input voltage limiting. Such a circuit allows proper operation of the power converter avoiding

the use of voltage over-rated components, both passive and active. The circuit is suitable for

any off-line SMPS topology since it includes a switching transistor connected between the input

rectifier and the DC bulk capacitor (STMicroelectronics patent pending). The series switch

limits the DC input voltage of the power converter by means of a suitable driving circuit; thus

the SMPS primary transistor can be selected as a standard part as well as a smart power

primary IC.

AN2264

APPLICATION NOT E

Three-Phase SMPS for low power applications

with VIPer12A

Typical end applications of this solution can be found in the industrial market in the range below

5W, such as three-phase and single phase power meter, industrial bias power supply and

auxiliary S MPS for high vo ltage stree t-lighti ng, where the input voltage can range between

90Vac and 450Vac and 1000V power MOSFETs are currently used.

As an example of industrial applications, a flyback converter for supplying an electronic power

meter is considered. The use of the proposed approach in a power converter designed for

265Vac maximum input voltage allows the operating input voltage to be extended up to 450Vac

or higher with no damages to the converter components. Thus, the major benefit of such

solution is a significant cost saving thanks to the reduction of components voltage rating.

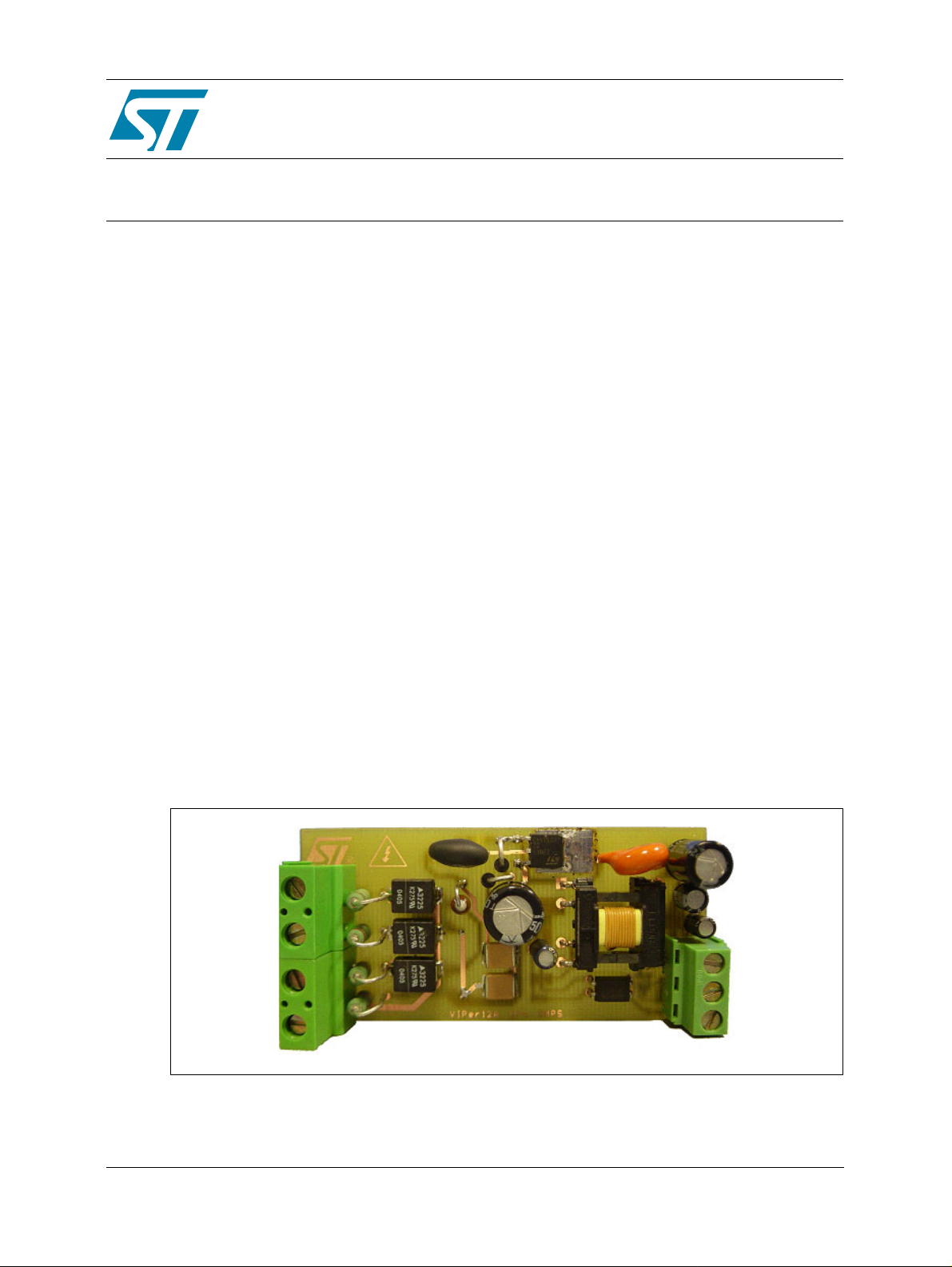

Figure 1. Board Prototype

Rev 1.0

AN2264/1105 1/42

www.st.com

42

Page 2

AN2264

Contents

1 Application Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Experimental Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Input Voltage Limiting Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Steady State Behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Line And Load Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 Hold-up Time Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5 Additional Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.6 Measurements At The Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Conducted Emissions Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 Thermal Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2/42

Page 3

AN2264

Figures

Figure 1. Board Prototype . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Circuit Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. PCB Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Flyback Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. MOSFET STD3NK50Z Operation at FULL LOA D and Vin = 450 Vrms . . 13

Figure 6. VIPer12AS Vds & Id at FULL LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. VIPer12AS Vds & Id at HALF LOAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 8. VIPer12AS Vds & Id at MINIMUM LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9. STD3NK50Z Vds & Id at FULL LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 10. Line Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 11. Load Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 12. Hold-up Time Capability at FULL LOAD. . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 13. Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 14. VIPer12AS and Outputs-Start-up at FULL LOAD . . . . . . . . . . . . . . . . . . . 31

Figu r e 1 5 . STD3N K 5 0 Z-1 St a r t-up at FULL LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 16. Start-up at MINIMUM LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 17. Conducted Emissions - at Vin=230Vac - FULL LOAD . . . . . . . . . . . . . . . 34

Figure 18. Conducted Emissions - at Vin=380Vac - FULL LOAD . . . . . . . . . . . . . . . 35

Figure 19. Thermal Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3/42

Page 4

AN2264

Tables

Table 1. Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. Three-Phase Electricity Meter Voltage Marking . . . . . . . . . . . . . . . . . . . . . 5

Table 3. B ill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Full Load (Iout ≈100mA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Half Load (Iout≈50mA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. Minimum Load (Iout=10mA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4/42

Page 5

AN2264 1 Application Description

1 Application Description

The present SMPS has been designed according to the following specifications:

Table 1. Operating conditions

Parameter Value

Input Voltage Range 90 to 450 V ac

Input Frequency Range 50/60 Hz

Output Voltage 1 V1=5V

Output Voltage 2 V2=3.3V

Output Current 1 I1=10mA

Output Current 2 I2=100mA

Output Power (peak) 550mW

Line Regulation +/- 1%

Load Regulation +/- 1%

Output Ripple Voltage 1 50mV

Hold-up capability > 40 ms (*)

Safety EN60950

EMI EN55022 class B

(*) Considering the STPM01 roll over time (31ms) and the Memory M95040 write time per data

(5ms).

In addition to the previous specs, the power supply has to be compliant also with the standards

of electricity meters, i.e. IEC 62052-11 and IEC 62053-21, since it has been specifically

developed for such an application. The main prescriptions are listed here below:

● Input connection and voltage marking (EN62052-11):

Table 2. Three-Phase Electricity Meter Voltage Marking

Meter Rated System Voltage (V)

Single-phase 2 wire 120V 120

Single-phase 3 wire 120V (120V to t he mid-wire) 240

Three-Phase 3 wire 2-element (230 V between phases) 400

Three-Phase 4 wire 3-element (230 V phase to neutral) 400

● Pulse Voltage Test (EN62052-11):

- Pulse waveform: according IEC 60060-1

- Voltage rise time: ±30%

- Voltage fall time: ±20%

5/42

Page 6

1 Application Description AN2264

- Source impedance: 500Ω ± 50Ω

- Source Energy: 0.5J ±0.05J

- Rated Pulse Voltage: 4000V

- Test Voltage Tolerance: +0 -10%

● Mean input power : 2W according to EN62053-21 (Switching power supplies with peak

power values exceeding the specified value are also permitted)

● Temperature Range: -25°C ± 3°C ÷ +70°C ± 2°C (EN 62052-11)

6/42

Page 7

AN2264 2 Circuit Description

2 Circuit Description

The schematic of the board is shown in Figure 2.

A 3-phase 4-wire bridge is used for mains rectification because the neutral rectification is

needed to ensure proper operation in case of missing neutral connection or neutral mis-wiring.

A varistor is connected between each line and neutral to guarantee pulse voltage test immunity

according to the EN62052-11 standard.

The input EMI filter is a simple undamped LC-filter for both differential and common mode noise

suppression.

The circuit for input voltage limiting is connected between the input EMI filter and the bulk

capacitor C4. Such a circuitry includes a Power MOSFET and a self driven control section.

The MOSFET Q1 is a standard N-Channel 500V 3.3Ω in D-PAK package, mounted on a small

copper area to improve thermal performance. The self driven control section consists of a

voltage divider and zener diodes. The resistors R1, R2 and R3 ensure the gate-source charge

for the switch, while the zener diodes D3 and D4 set t he maximum voltage val ue (360V) ac ross

the bulk capacitor.

An NTC limits the inrush current and ensures Q1 operation inside its safe operating area.

The flyback converter is based on VIPer12AS, a member of the VIPerX2A family, which

combines a dedicated current mode off-line PWM controller with a high voltage power

MOSFET on the same silicon chip. The switching frequency is fixed at 60kHz by the IC internal

oscillator allowing, to optimize the transformer size and cost. The transformer reflected voltage

has been set to 60V, providing enough margin for the leakage inductance voltage spike and no

snubber circuit is needed with a consequent cost saving.

As soon as the voltage is applied on the input of the converter the high voltage start-up current

source connected to the drain pin is activated and starts to charge the V

a constant current of 1mA. When the voltage across this capacitor reaches the V

(about 14V) the VIPer12AS starts to switch. During normal operation the smart power IC is

powered by the auxiliary win ding of the transforme r via the diode D7. No spike killer fo r the

auxiliary vo ltage fluctu ations is needed thanks to the wide range of the V

primary current is measured using the integrated current sensing for current mode operation.

The output rectifier D6 has been chosen in accordance with the maximum reverse voltage and

power dissipation; in particular a 0.5A-80V Schottky diode, type TMBAT49, has been selected.

The output voltage regulation is performed by secondary feedback on the 5V output dedicated

to the display, while the 3.3V output, dedicated to the logic part and the microcontroller, is

linearly post-regulated from the 5V output. This operation is performed by a very low drop

voltage regulator, L4931ABD33, in SO-8 package. The voltage regulator delivers up to 100mA,

ensuring good reliability with no heat sink. The feedback netw ork ensures the requir ed

insulation between the primary and secondary sections. The optotransistor directly drives the

VIPer12AS feedback pin which controls the IC operation.

A small LC filter has been added to the 5V output in order reduce the high frequency ripple with

reasonable output capacitors value.

capacitor C8 through

dd

pin (9-38V). The

dd

threshold

ddon

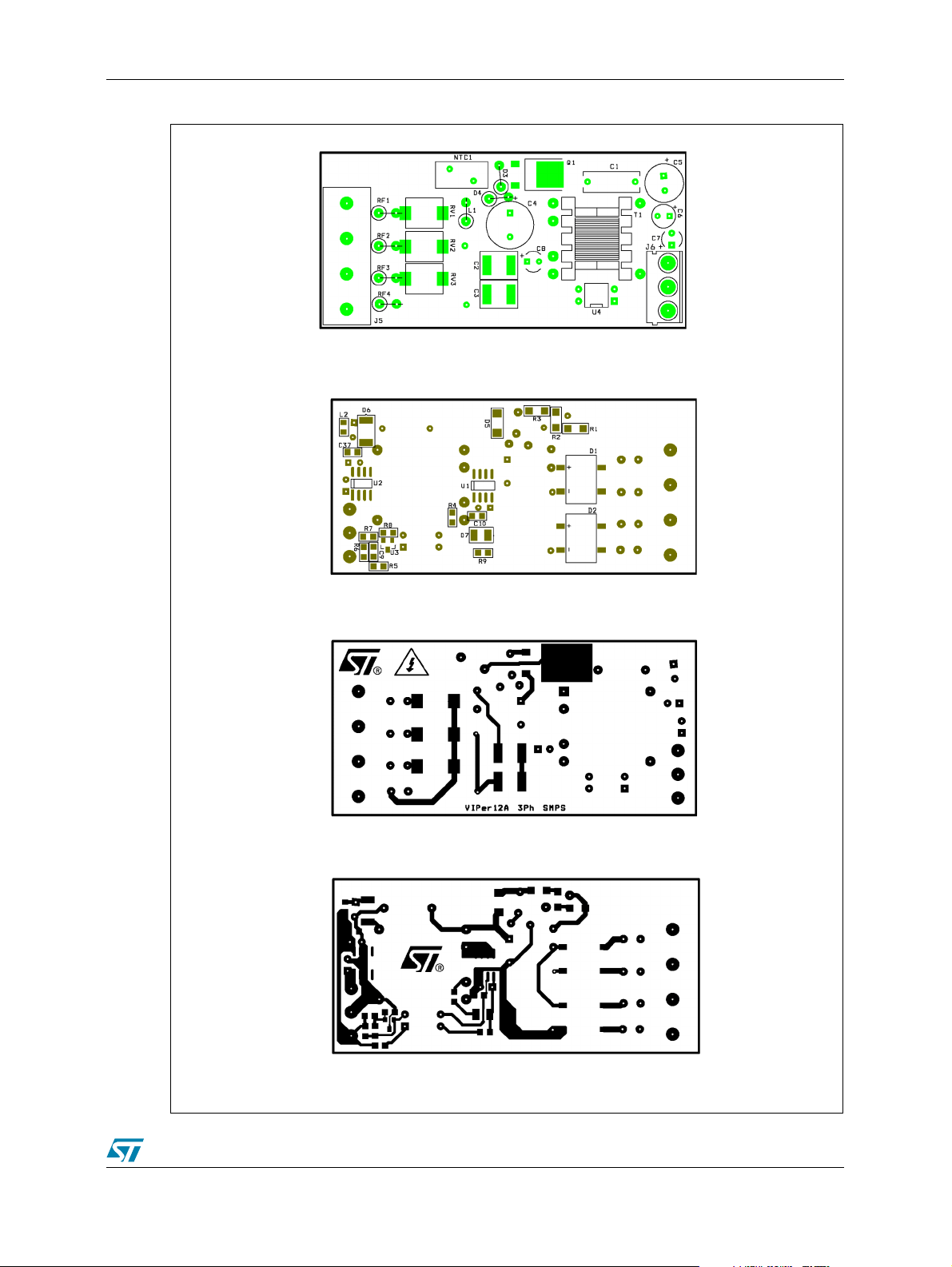

The flyback transformer is a layer type based on E13 core and N27 ferrite, manufactured by

Pulse Eldor, and ensures safety insulation in accordance with the EN60950. Figure 4. shows

the main features of the transformer.

7/42

Page 8

2 Circuit Description AN2264

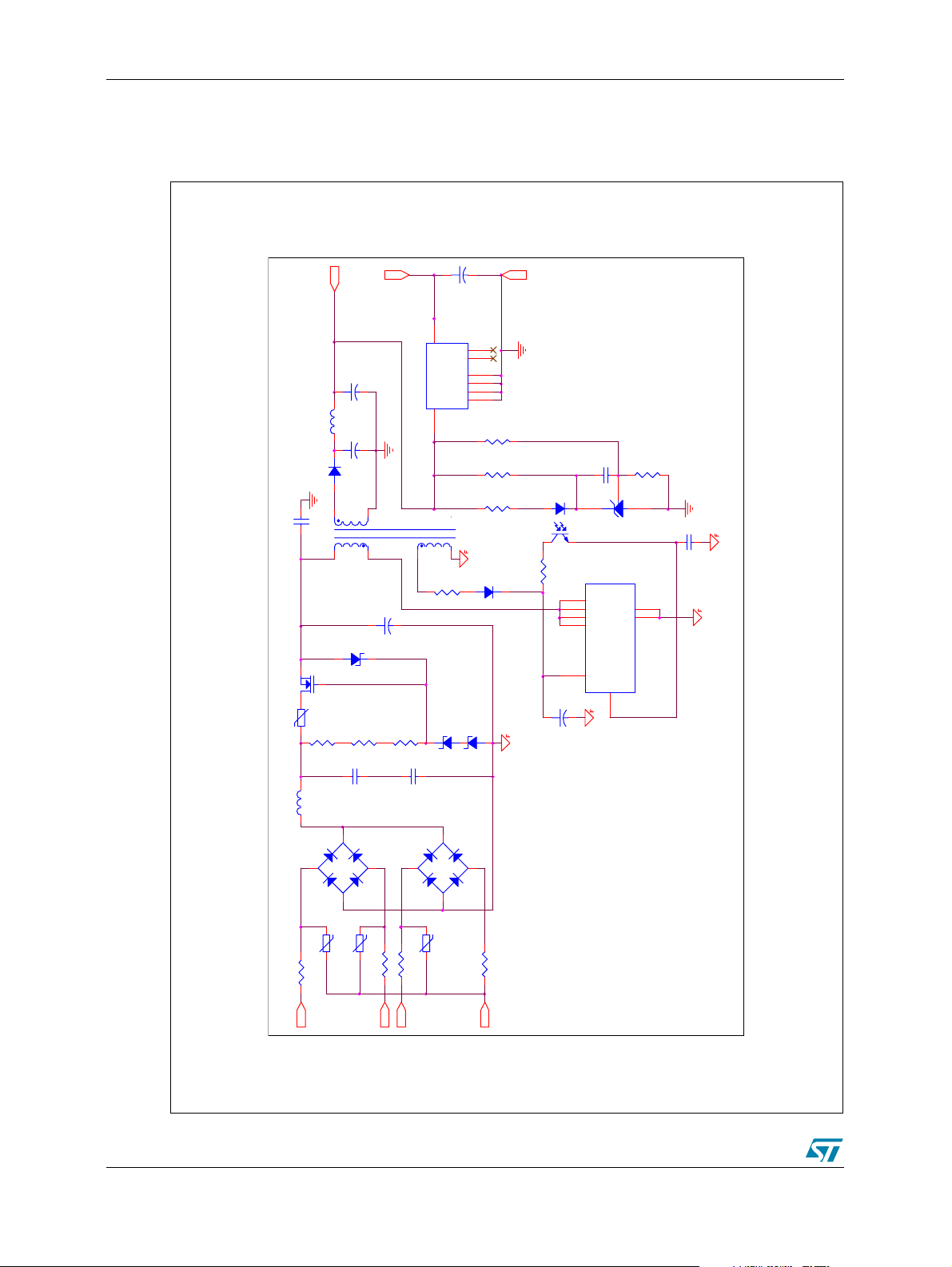

The whole power supply has been realized on a double side 35um PCB in FR-4, measuring 78

x 38 mm.

Figure 2. Circuit Sc hemati c

3.3V@100mA

1

U2 L4931ABD33

8

4

+

R7

R6

R5

LL4148

GND

4.7K

SMD

1K

SMD

12

U4

PC817

43

220E SMD

R9

C8

50V

SMD

R8

C9

100nF

U3

5.6K SMD

D

8

D

7

D

6

D

5

U1

4

+

10uF 50V

4.7K SMD

3

TS2431

2 1

C10

47nF

50V

SMD

S

1

S

2

VIPer12AS

Vdd

FB

3

C7

2.2uF 25V

INH

5

NC

4

VOUT

GND

7

GND

6

GND

3

GND

2

VIN

5

D7

R4

10E

SMD

D4

180V

D3

180V

VDD

5V@10mA

L2

10uH 100mA SMD

D6

TMBAT 49

C1

Q1

NTC1

10

2.2nF/ 2k V (Y1)

T1

1

D5

1

STD3NK50Z

2 3

50E

R1

3.3V

+

C6

22uF 25V

+

C5

330uF 25V

6

2

2.2uF450V

+

C4

SOD-80

ZMM 1 5

R3

330K SMD

330K SMD

R2

330K SMD

D1

2

RV1

SO5K275/275V

P1

C2

220nF

3

-+

4

RV2

SO5K275/275V

L1

1mH

RF1

22E 0.75W

630V

SMD

BRIDGE

RF2

1

22E 0.75W

P2NP3

C3

630V

SMD

220nF

3

D2

2

-+

4

RV3

SO5K275/275V

RF3

22E 0.75W

8/42

BRIDGE

1

RF4

22E 0.75W

Layout Hin ts: Q1 mounted on 1cm x 0.8cm copper

area. C8&C 10 have to be c losed to the VI Per12AS.

GND Pins f or U2 have to b e soldered to a unique

Note:

copper are a.

Page 9

AN2264 2 Circuit Description

Figure 3. PCB La yout

Top side-silk screen (in scale)

Bottom side- silk screen (in scale)

Top side-copper tracks (in scale)

Bottom side-copper tracks (in scale)

9/42

Page 10

2 Circuit Description AN2264

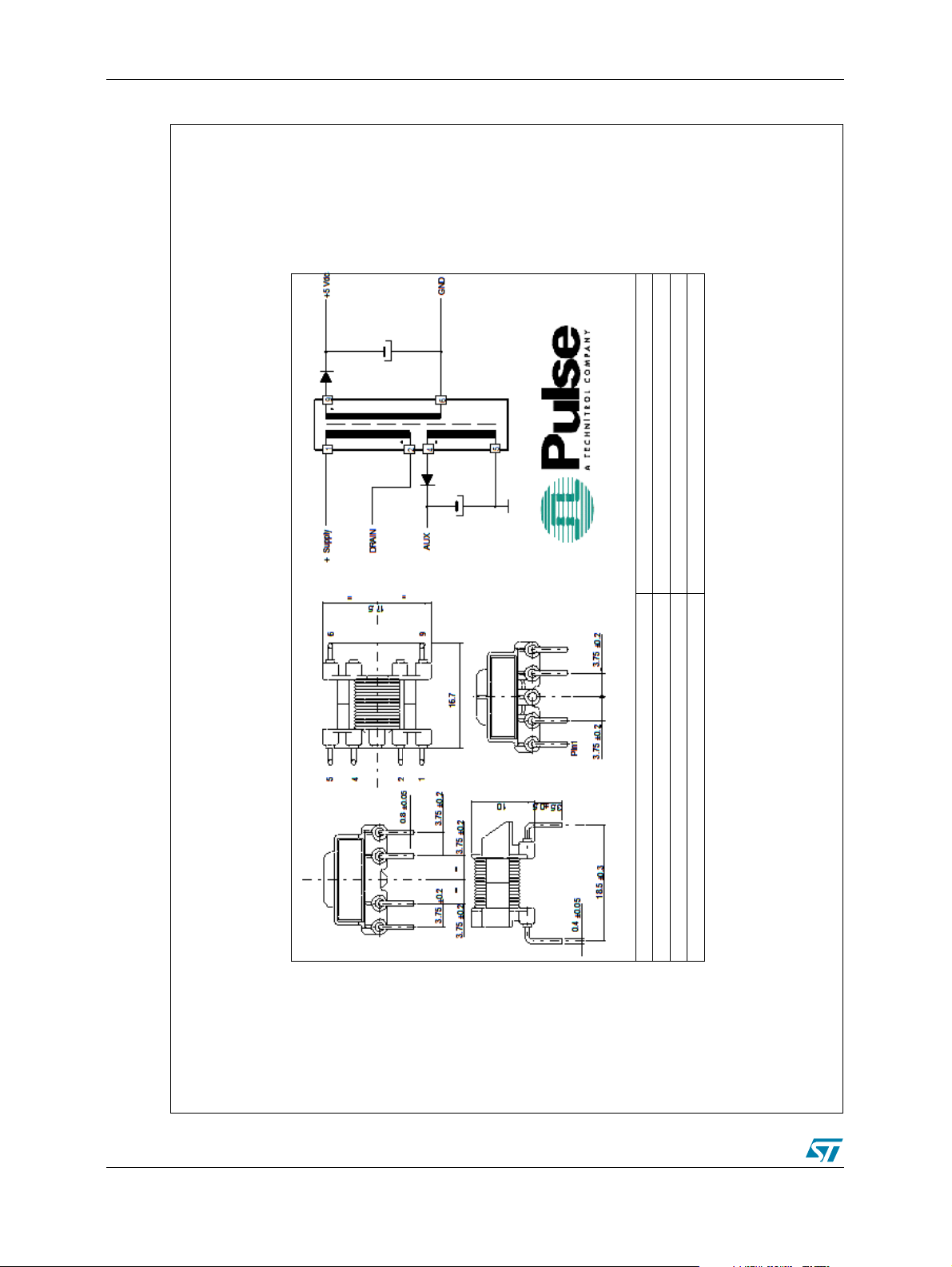

Figure 4. Flyback Tran sformer

< 2%

11

3

):

p

Primary Inductance: 2.2mH ±20%

Primary Leakage Inductance (%L

Primary to secondary turn ratio:

Auxiliary to secondary turn ratio:

10/42

Page 11

AN2264 2 Circuit Description

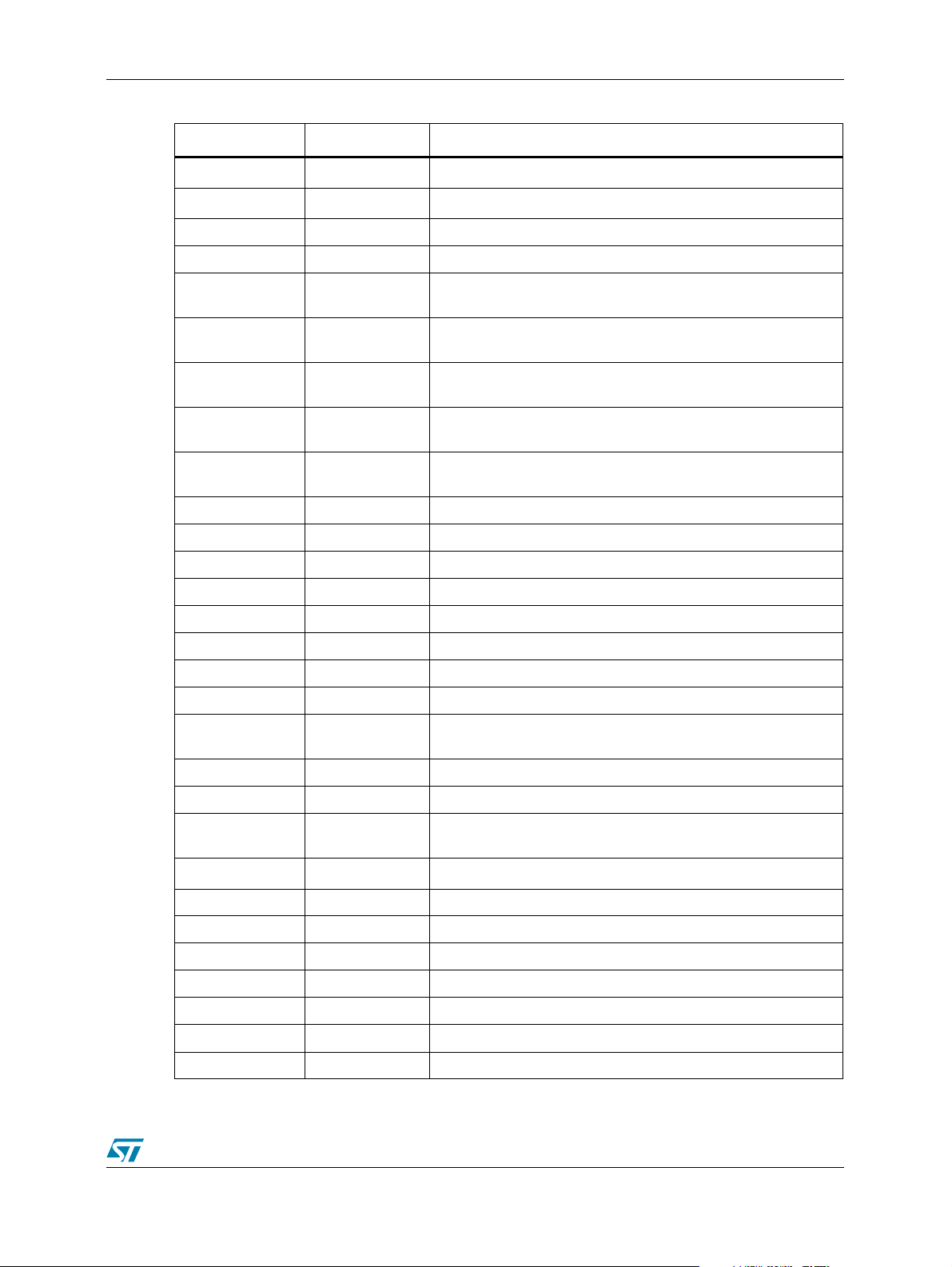

Table 3. Bill of Materials

Reference Value Description

CON1, CON2

CON3

Hartmann/ptr, 2 poles, type PK 7402, 380V

Hartmann/ptr, 3 poles, type PK 3503, 380V

AC

AC

16A

16A

C1 2.2nF/2kV Cera-Mite Corporation 44LD 22 Y1 Ceramic Capacitor 20%

C2, C3 220nF 630V TDK C5750X7R2J224M SMD Ceramic Capacitor 20%

C4 2.2uF450V

C5 330uF 25V

C6 22uF 16V

C7 2 .2uF 50V

C8 10uF 50V

Rubycon Aluminium Radial Lead El ectrolytic Capacitor YK

Series 29mA 20%

Rubycon Aluminium Radial Lead El ectrolytic Capacitor ZL

Series 56mR 995mA 20%

Rubycon Aluminium Radial Lead El ectrolytic Capacitor ZA

Series 270mR 350mA 20%

Panasonic ECA1HHG2R2 NHG-A Radial Lead Electrolytic

Capacitor 18mA 20%

Panasonic ECA1HHG100 NHG-A Radial Lead Electrolytic

Capacitor 39mA 20%

C9 100nF 50V muRata GRM40X7R104Z50 SMD Ceramic Capacitor 20%

C10 47nF 50V muRata GRM40X7R473Z50 SMD Ceramic Capacitor 20%

D1, D2 BRIDGE General Instrument s DF 10S SMT Diode Bridge 1000V 1A

D3, D4 ZY180V DO-41 Zener Diode 180V 2W 5%

D5 ZMM 15/SOD-80 Mini-Melf Zener Diode 15V 0.5W 5%

D6

TMBAT49 STMicroelectronics Small Signal Schottky Diode 80V 0.5A

D7 LL4148/SOD-80 SOD-80 General Purpose Rectifier 75V 200mA

L1 1mH Epcos B78108-S1105J , Bobbin Core BC 130mA 13R 10%

L2 10uH

TDK GLF2012T100M SMD Signal-Use SMD Inductor 125mA

20%

NTC1 50E UEI 10SP050L Inrush Current Suppr essor 50R 2A 10%

Q1

RF1, RF2, RF3,

RF4

RV1, RV2, R V 3 SO5K275/275V

STD3NK50Z STMicroelectronics N -Channel Mosfet 500V 2.3A 3.3R

22E 0.75W Ya geo R esi stor, wire wound, fusible, 22R 0.75W 5%

Epcos B72650M271K72 SMD Varistor 275V

AC

8.6J

R1, R2, R3 330K SMD Resistor, Metal Film 0.25W 5%

R4 10E SMD Resistor, Metal Film 0.25W 5%

R5 220E SMD Resistor, Metal Fil m 0.25W 5%

R6 1K SMD Resistor, Metal Film 0.25W 5%

R7 4.7K SMD Resistor, Metal Fil m 0.25W 5%

R8 4.7K SMD Resistor, Metal Film 0.25W 5%

R9 5.6K SMD Resistor, Metal Film 0.25W 5%

11/42

Page 12

2 Circuit Description AN2264

Table3. Bill of Materials (Continued)

Reference Value Description

T1 2432.0015C E13 TIW Pulse Eldor Switch Mode Transformer

U1

U2

U3

U4 PC817 Sharp Optocoupler 5kV

VIPer12AS

L4931ABD33

TS2431

STMicroelectronics

27R

STMicroelectronics

3.3V 300mA 1%

STMicroelectronics

Reference 1%

Off Line SMPS Primary IC 730V 0.4A

Very Low Drop Voltage Regulator

Programmable Shunt V ol tage

12/42

Page 13

AN2264 3 Experimental Results

3 Experimental Results

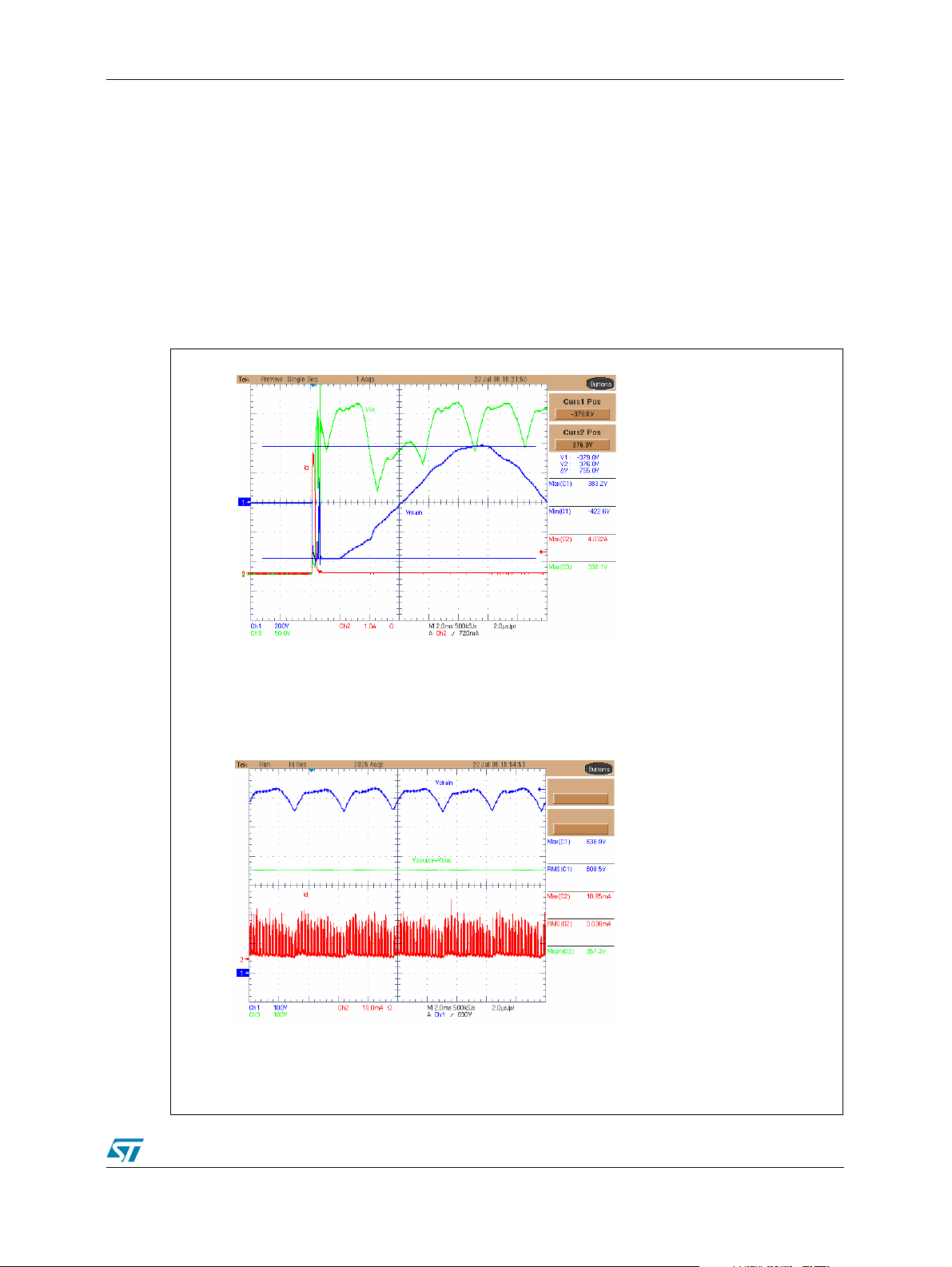

3.1 Input Voltage Limiting Circuit

The main waveforms of the input voltage limiting circuit are shown in Figure 5. In particular the

waveforms refer to the start-up and the steady-state operations at 450Vac and full load ,which

are the worst conditions for the device. The advantages of this solution are evident. It limits the

DC voltage at the given reference value, in this case 360V, and avoides the use of over-rated

components compared to the standard off-line power supply.

Figure 5. MOSFET STD3NK50Z Operati on at FULL LOAD and Vin = 450 Vrms

Start-Up

CH1: INPUT VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

CH3: DRAIN-SOURCE VOLTAGE (Green)

CH1: DRAIN VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

CH3: SOURCE VOLTAGE (Green)

Steady State

13/42

Page 14

3 Experimental Results AN2264

3.2 Steady State Behaviour

Several measurements have been performed on the SMP S in steady state operation, for

different values of the main voltage and load condition. The measured values are:

- The peak Drain Current through the VIPer12A

- The peak Drain Voltage across the VIPer12A

- The Peak Drain Voltage across the input MOS

- The Peak Drain Current through the input MOS

- The Reverse Voltage across the output Diode

- The Output Voltage

- The input power consumption

Figure 6. shows some waveforms during the normal operation at full load:

Figure 6. VIPer12AS Vds & Id at FULL LOAD

Vin=90 Vrms - 50Hz

Vin = 110 Vrms - 50Hz

14/42

Page 15

AN2264 3 Experimental Results

f

t

t

n

s

e

d

Figure 6. VIPer12AS Vds & Id at FULL LOAD (continued)

Vin = 230 Vrms - 50Hz

Vin = 450 Vrms - 50Hz

CH1: DRAIN VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

Vin = 380 Vrms - 50Hz

Vin

Vdsmax(V) Idpk(mA)

(Vac)

90 210 122

110 236 120

230 398 138

380 438 152

450 444 148

The table lists the measured values o

the drain peak voltage and current a

minimum, nominal and maximum inpu

mains voltage, during normal operatio

at full load. The voltage peak, which i

444V, assures a reli able opera tion of th

VIPer12AS power switch with a goo

margin against the maximum B

VDSS

.

15/42

Page 16

3 Experimental Results AN2264

Table 4. Full Load (Iout ≈100mA)

Input

Vin [Vrm s]= 90

Iin [mArms ] = 10.7

Pin [W] = 0.93

Output

Vout [V] = 3.303 4.989

Iout [mA] = 100 1

Pout [W] = 0.5

EFF.=54%

Input

Vin [Vrm s]= 110

Iin [mArms ] = 9.2

Pin [W] = 0.93

Output

Vout [V] = 3.303 4.989

Iout [mA] = 100 1

Pout [W] = 0.5

EFF.=54%

Input

Vin [Vrms]= 230

Iin [mArms ] = 6.5

Pin [W] = 1.1 2

Output

Vout [V] = 3.303 4.989

Iout [mA] = 100 1

Pout [W] = 0.5

EFF.=45%

16/42

Page 17

AN2264 3 Experimental Results

Table 4. Full Load (Iout ≈100mA) (continued)

Input

Vin [Vrms]= 380

Iin [mArms ] = 4.4

Pin [W] = 1.6

Output

Vout [V] = 3.303 4.989

Iout [mA] = 100 1

Pout [W] = 0.5

EFF.=31%

Input

Vin [Vrms]= 450

Iin [mArms ] = 4.5

Pin [W] = 2.0

Output

Vout [V] = 3.303 4.989

Iout [mA] = 100 1

Pout [W] = 0.5

EFF.=25%

The same test has been performed on the board in half load condition, for the different values

of the input voltage. In Figure 7. some typical waveforms are shown.

17/42

Page 18

3 Experimental Results AN2264

Figure 7. VIPer12AS Vds & Id at HALF LOAD

Vin = 90 Vrms - 50Hz

Vin = 110 Vrms - 50Hz

Vin = 230 Vrms - 50Hz

18/42

Page 19

AN2264 3 Experimental Results

Figure 7. VIPer12AS Vds & Id at HALF LOAD (Continued)

Vin = 380 Vrms - 50Hz

Vin = 450 Vrms - 50Hz

CH1: DRAIN VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

Vin (Vac) Vdsmax(V) Idpk(mA)

90 198 100

110 226 92

230 396 128

380 436 142

450 438 136

The table lists the measured values of the drain peak voltage and current

at minimum, nominal and maximum input mains voltage, during normal

operation at full load. The voltage peak, which is 438V, assures a reliable

operation of the VIPer12AS power switch with a good margin against the

maximum BV

DSS

.

19/42

Page 20

3 Experimental Results AN2264

Table 5. Half Load (Iout≈50mA)

Input

Vin [Vrm s]= 90

Iin [mArms ] = 6.9

Pin [W] = 0.58

Output

Vout [V] = 3.303 4.989

Iout [mA] = 50 1

Pout [W] = 0.25

EFF.=43%

Input

Vin [Vrm s]= 110

Iin [mArms ] = 6.6

Pin [W] = 0.62

Output

Vout [V] = 3.303 4.989

Iout [mA] = 50 1

Pout [W] = 0.25

EFF.=40%

Input

Vin [Vrms]= 230

Iin [mArms ] = 4.8

Pin [W] = 0.7 7

Output

Vout [V] = 3.303 4.989

Iout [mA] = 50 1

Pout [W] = 0.25

EFF.=32%

20/42

Page 21

AN2264 3 Experimental Results

Table 5. Half Load (Iout≈50mA) (Continued)

Input

Vin [Vrms]= 380

Iin [mArms ] = 3.5

Pin [W] = 1.22

Output

Vout [V] = 3.303 4.989

Iout [mA] = 50 1

Pout [W] = 0.5

EFF.=20%

Input

Vin [Vrms]= 450

Iin [mArms ] = 3.5

Pin [W] = 1.5

Output

Vout [V] = 3.303 4.989

Iout [mA] = 50 1

Pout [W] = 0.25

EFF.=17%

21/42

Page 22

3 Experimental Results AN2264

Figure 8. shows the waveforms and the results of the steady state in minimum load condition.

Figure 8. VIPer12AS Vds & Id at MINIMUM LOAD

Vin = 90 Vrms - 50Hz

Vin = 110 Vrms - 50Hz

Vin = 230 Vrms - 50Hz

22/42

Page 23

AN2264 3 Experimental Results

Figure 8.VI Per12AS Vds & Id at MINIMUM LOAD (continued )

Vin = 380 Vrms - 50Hz

CH1: DRAIN VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

Also at minimum load condition, the drain

voltage peak (426V) ensures a good margin

against the maximum BV

burst mode operation is ensured, saving the

input power consumption.

Vin

(Vac)

90 189.2 80

110 217.2 78.4

230 396 128

380 424 115

. The VIPer12A

DSS

Vdsmax(V) Idpk(mA)

Vin = 450 Vrms - 50Hz

450 426 116

23/42

Page 24

3 Experimental Results AN2264

Table 6. Minimum Load (Iout=10mA)

Input

Vin [Vrm s]= 90

Iin [mArms ] = 4.1

Pin [W] = 0.29

Output

Vout [V] = 3.302 4.989

Iout [mA] = 10 1

Pout [W] = 0.05

EFF.=17%

Input

Vin [Vrm s]= 110

Iin [mArms ] = 3.8

Pin [W] = 0.31

Output

Vout [V] = 3.303 4.989

Iout [mA] = 10 1

Pout [W] = 0.05

EFF.=16%

Input

Vin [Vrms]= 230

Iin [mArms ] = 3.1

Pin [W] = 0.4 3

Output

Vout [V] = 3.3023 4.989

Iout [mA] = 10 1

Pout [W] = 0.05

EFF.=12%

24/42

Page 25

AN2264 3 Experimental Results

Table 6. Minimum Load (Iout=10mA) (Continued)

Input

Vin [Vrms]= 380

Iin [mArms ] = 2.9

Pin [W] = 0.7

Output

Vout [V] = 3.302 4.989

Iout [mA] = 10 1

Pout [W] = 0.05

EFF.=7%

Input

Vin [Vrms]= 450

Iin [mArms ] = 2.9

Pin [W] = 0.8 5

Output

Vout [V] = 3.302 4.989

Iout [mA] = 10 1

Pout [W] = 0.05

EFF.=6%

25/42

Page 26

3 Experimental Results AN2264

The steady state characterization has been made also for the input MOSFET, in terms of drainsource voltage and drain current, as shown in Figure 9.

Figure 9. STD3NK5 0Z Vds & Id at FULL LOAD

In the voltage range below the given reference voltage, the MOSFET is fully on.

Vin = 110 Vrms - 50Hz

CH1: DRAIN-SOURCE VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

Vin = 230 Vrms - 50Hz

26/42

Page 27

AN2264 3 Experimental Results

Figure 9. STD3NK50Z Vds & Id at FULL LOAD (continued)

Vin = 380 Vrms - 50Hz

CH1: DRAIN VOLTAGE (Blue)

CH2: DRAIN CURRENT (Red)

CH3: SOURCE VOLTAGE (Green)

Vin = 450 Vrms - 50Hz

As soon as the input rectified voltage is higher than the reference

voltage, the input MOSFET is accommodating the voltage drop

between the input and the regulated voltage. The peak of the drainsource voltage (around 280V) ensures a good margin against the Vds

of the device.

27/42

Page 28

3 Experimental Results AN2264

c

c

c

3.3 Line And Load Regulations

In this section the line and load regulations for 5V output are given, as shown in Figure 10. and

Figure 11. For the line regulation the input voltage is slowly increased from 90Vac to 450Vac;

For the load regulation the output current is slowly increased from the minimum load 10mA to

the maximum load100mA .

Figure 10. Line Re gulati on

5.5

5.375

5.25

5.125

5

4.875

5V O u tput [V dc]

4.75

4.625

4.5

70 90 110 130 150 180 230 280 300 330 350 380 400 430 450 470

Figure 11. Load Regulati on

5.5

5.375

5.25

5.125

5

4.875

5V Output [Vdc]

4.75

Full Load

Half Load

Minim um Load

Input Voltage [Vac]

Input Voltage 110Va

Input Voltage 230Va

Input Voltage 380Va

4.625

4.5

0 102030405060708090100

Output Current [mA]

As shown in the previous pictures, the board has a line and a load regulation of +/- 0.1%.

28/42

Page 29

AN2264 3 Experimental Results

t

t

3.4 Hold-up Time Capability

As listed in the specification table, the power supply has to guarantee at least 40mS of hold-up

in any line and load condition, in order to allow the STPM01 to safely store data in the memory.

As shown in Figure 12. the SMPS is compliant with the given specification.

Figure 12. Hold-up Time Capability at FULL LOAD

Vin = 90 Vrms - 50Hz

CH1: INPUT VOLTAGE (Blue)

CH3: 3.3V OUTPUT (Green)

Vin = 110 Vrms - 50Hz

Vin = 300 Vrms - 50Hz

The hold-up time capability is

shown. At the minimum inpu

voltage, which is the wors

condition, the measured time is

43ms.

29/42

Page 30

3 Experimental Results AN2264

E

D

3.5 Additional Considerations

Thanks to the voltage limiting circuit, the maximum voltage on the drain of the VIPer is well

below its maximum absolute rating, getting rid of the clamper circuit. Also the reverse voltage

across the output diode is kept low allowing the use of a low voltage diode, i.e. 80V .

Figure 13. Waveforms

CH1: OUTPUT DIODE VOLTAGE (Blue)

The peak reverse voltage of the diode has been

measured during the worst operat ing condition and

it is indicated on the right of the picture. The margin

against the maximum value is good enough to

ensure the diode reliability.

Vin = 300 Vrms - 50Hz at

OUTPUT DIODE REVERSE VOLTAG

Vin = 300 Vrms - 50Hz at FULL LOAD

VIPer12AS Vd s at St a rt-up

FULL LOA

CH1: VIPer12AS DRAIN VOLTAGE (Blue)

The picture gives the measurement of the peak drain voltage (540V) at the

start up with 300Vac input voltage in full load condition. Thanks to the

good coupling of the transformer, the measured value has a good margin

against the maximum BVDSS, avoiding the clamping circuit and improving

the cost effectiveness of the solution.

30/42

Page 31

AN2264 3 Experimental Results

3.6 Measurements At The Start-Up

In this section the typical waveforms during the start-up of the power supply are given. In

particular, the full load condition is considered since it represents the heaviest case in terms of

voltage and current stress, as well as the minimum load condit ion for loop stability and voltage

stress.

Figure 14. VIPer12AS and Outputs-Start-up at FULL LOAD

Vin = 90 Vrms - 50Hz

CH1: VIPer12AS DRAIN VOLTAGE (Blue)

CH2: VIPer12AS DRAIN CURRENT (Red)

CH3: 3.3V OUTPUT (Green);

CH4: 5V OUTPUT (Magenta)

Vin = 110 Vrms - 50Hz

Vin = 230 Vrms - 50Hz

Vin (Vac) Vdsmax(V) Idpk(mA)

90 193.5 343.9

110 218.8 344.6

230 391 360.5

31/42

Page 32

3 Experimental Results AN2264

Figure 15. STD3NK50Z-1 Start-up at FULL LOAD

CH2: STD3NK50Z DRAIN CURRENT (Red)

CH3: STD3NK50Z DRAIN VOLTAGE (Green)

The picture gives the measurement of the input MOSFET

peak drain current at the worst condition. (45 0Vac-full load).

The cross point between the drain voltage and the drain

current (120V-2.4A) is inside the safe operating area of the

device.

32/42

Page 33

AN2264 3 Experimental Results

Figure 16. Start-u p at MINIMUM LOAD

Vin = 90 Vrms - 50Hz

CH1: VIPer12AS DRAIN VOLTAGE (Blue)

CH2: VIPer12AS DRAIN CURRENT (Red)

CH3: 3.3V OUTPUT (Green)

CH4: 5V OUTPUT (Magenta)

Vin = 110 Vrms - 50Hz

Vin = 230 Vrms - 50Hz

Vin (Vac) Vdsmax(V) Idpk(mA)

90 184.3 342.7

110 218 346.3

230 407.9 468.7

33/42

Page 34

4 Conducted Emissions Test AN2264

R

P

L

1

d

S

S

S

R

R

P

L

1

d

S

S

S

R

R

P

L

1

d

S

S

S

R

R

P

L

1

d

S

S

S

R

4 Conducted Emissions Test

Conducted emissions have been measured in neutral and lines wires, using peak detector and

considering the EN55022 limits. The measurements have been performed at nominal values of

the input voltage, i.e. 230Vac and 380Vac, and fully loaded outputs. The results are shown in

Figure 17. Since the emission level is below both the Quasi-Peak and Average limits with

acceptable margin, the power supply passes the pre-compliance test.

Figure 17. Conducted Emiss ions - at Vin=230Vac - FULL LOAD

02:03:21 Jul 29, 2005

ef 75 dBµV#Atten 10 dB

eak

og

0

B/

1W2

3FC

AA

tart 150 kHz

es BW 9 kHz VBW 30 kHz

Phase L1-Peak Detector

02:07:36 Jul 29, 2005

ef 75 dBµV#Atten 10 dB

eak

og

0

B/

1W2

3FC

AA

tart 150 kHz

es BW 9 kHz VBW 30 kHz

S w ee p 88 1.3 ms (1905 pts)

Sweep 881.3 ms (1905 pts)

Sto p 30 MH z

Stop 30 MHz

2:04:1 3 Jul 29, 2005

0

ef 75 dBµV

eak

og

0

B/

1W2

3FC

A

A

tart 150 kHz

es BW 9 kHz VBW 30 kHz

Att e n 10 dB

#

Phase L2- Peak Detector

02:06:13 Ju l 29, 2005

ef 75 d BµV#Atten 10 dB

eak

og

0

B/

1W2

3FC

AA

tart 150 kHz

es BW 9 kHz VBW 30 kHz

Sweep 881.3 ms (1905 pts)

Sweep 88 1.3 ms (1905 p ts)

Stop 30 MHz

Stop 30 MHz

Phase L3- Peak Detector

Phase N- Peak Detector

UPPER LIMIT: EN5 5022BCQP LOWER LIMIT: EN55022BCAV

34/42

Page 35

AN2264 4 Conducted Emissions Test

R

P

L

1

d

W

S

S

R

R

P

L

1

d

W

S

S

R

R

P

L

1

d

W

S

S

R

R

P

L

1

d

W

S

S

R

Figure 18. Conducted Emiss ions - at Vin=380Vac - FULL LOAD

02:12:47 Jul 29, 2005

ef 75 dBµV#Atten 10 dB

eak

og

0

B/

1S2

3FC

AA

tart 150 kHz

es BW 9 kHz VBW 30 kHz

Phase L1 - Peak Detector

02:14:33 Jul 29, 2005

ef 75 dBµV#A tten 10 dB

eak

og

0

B/

1S2

3FC

AA

tart 150 kHz

es BW 9 kH z VBW 30 kH z

Sweep 881.3 ms (1905 pts)

Sweep 881.3 ms (1905 pts)

Stop 30 MHz

Stop 30 M Hz

2:13:19 Jul 29, 2005

0

ef 75 dBµV

eak

og

0

B/

1S2

3FC

A

A

tart 150 kHz

es BW 9 kH z VBW 30 kH z

Atten 10 dB

#

Phase L2- Peak Detector

02:13:43 Jul 29, 2005

ef 75 dBµV#A tten 10 dB

eak

og

0

B/

1S2

3FC

AA

tart 150 kHz

es BW 9 kH z VBW 30 kH z

Sweep 881.3 ms (1905 pts)

Sweep 881.3 ms (1905 pts)

Stop 30 M Hz

Stop 30 M Hz

Phase L3 - Peak Detector

UPPER LIMIT: EN5 5022BCQP

Phase N - Peak Detector

LOWER LIMIT: EN55022BCAV

35/42

Page 36

5 Thermal Measurements AN2264

5 Thermal Measurements

In order to check the reliability of the design, a thermal mapping by means of an IR camera has

been done. Here below the thermal measurements on both sides of the board, at minimum,

nominal, and maximum input voltage, at ambient temperature (27 °C) are shown.

Pointers 1-3 have been placed across some key components, which could affect the reliability

of the circ uit, which are:

● TOP SIDE

- PowerMOS - Q1

- Transformer- T1

● SMD COMPONENTS SIDE

- VIPer12AS - U1

- +5V diode - D6

- +3.3V regulator - U2

As shown in the thermal maps, all the other points of the board are within the temperature

limits, assuring reliable operation of the devices.

In fact, the highest temperature values have been measured on the MOSFET Q1, the

VIPer12A and the 3.3V regulator, while for the transformer the maximum temperature rise is

around 15° C.

36/42

Page 37

AN2264 5 Thermal Measurements

Figure 19. Thermal Measurements

TOP SIDE

BOTTOM SIDE

at 90VAC - FULL LOAD

at 110VAC - FULL LOAD

37/42

Page 38

5 Thermal Measurements AN2264

Figure 19. Thermal Measurement (continued)

at 230VAC - FULL LOAD

at 380VAC - FULL LOAD

at 450VAC - FULL LOAD

38/42

Page 39

AN2264 6 Conclusions

6 Conclusions

In this document an innovative power supply has been introduced and described in order to

overcome the very high voltage issue, with an optimum cost-performance trade-off.

In fact, despite the three-phase input voltage up to 450Vac, the design of the power supply has

been done using standard components for off-line single-phase applications.

This has been made possible thanks to a simple voltage limiting circuit (STMicroelectronics

patent pending) which always ensures no more than 400V on the DC bus. The proposed

solution has been specifically developed for electronic metering applica tions and can be used

in any low power (<5W) application where the input voltage can be as high as 450Vac or higher.

39/42

Page 40

7 Revision History AN2264

7 Revision History

Date Revision Changes

16-Nov-2005 1. 0 First edit io n

40/42

Page 41

AN2264 7 Revision History

41/42

Page 42

7 Revision History AN2264

I

s

o

d

b

ct

t

ot

a

nformation furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequence

f use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is grante

y implic ation or oth erwise under any patent or patent rights of STMicro el ectronics. Specifications mentioned in this publication are s ubje

o change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are n

uthoriz ed for use as crit ical components in life support devices or s ys tems without express wri tt en approval of STM i croelectronics.

The ST logo is a registered trademark of STMicroelec tronics.

All other nam es are the property of their respective owners

Austra l i a - Be l gi um - Brazil - C anada - China - Czech Republic - Finland - France - Germany - Hong Kon g - India - Israel - Italy - Japan -

Malaysi a - M al ta - Morocco - Singapore - Sp ai n - Sweden - Swi t zerland - Uni ted Kingdom - Uni ted States of America

© 2005 STMi croelectro ni cs - All rights res e rv ed

STMicroelectronics group of com panies

www.st.com

42/42

Loading...

Loading...