Page 1

AN-1006

APPLICATION NOTE

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Using the EVAL-ADUSB2EBZ

by Brett Gildersleeve

INTRODUCTION

The EVAL-ADUSB2EBZ features USB-to-I2C and SPI conversion.

It is compatible with 1.8 V and 3.3 V target devices and allows

for SigmaStudio™ integration for most SigmaDSP® processors.

Its on-board power regulators are capable of supplying the

target board, and it features a standard Aardvark-compatible

programming header. The EVAL-UDSUB2EBZ provides SPI

control of up to five slave devices with a low profile surfacemount USB miniature Type B connector, and it allows for plugand-play operation.

The EVAL-ADUSB2EBZ is ideal for downloading code

and register settings to SigmaDSP processors and codecs

with SigmaStudio. It can also be used for real-time tuning

of SigmaDSP production units with SigmaStudio.

GENERAL DESCRIPTION

The EVAL-ADUSB2EBZ, also known as the USBi, is a standalone

communications interface and programmer for SigmaDSPsystems.

It translates USB control commands from SigmaStudio to the I

and SPI communications protocols. The USBi is powered over

the USB cable; therefore, no external power supply is required.

2

C

The ribbon cable and 10-pin header form a bridge to the target

board to connect the communications signals to the target IC.

The ribbon cable also carries 5 V power from the USB hub, which

can be used to power the target board if desired.

The on-board regulators enable both 1.8 V and 3.3 V IOVDD

operation, allowing for increased compatibility with target

devices.

Up to five slave devices can be controlled by the USBi simultaneously. To control multiple SPI devices, additional latch signals

are provided, although they are not connected to the ribbon cable.

The USBi can be used to control SigmaDSP systems in real time

via SigmaStudio, and is capable of programming an EEPROM

in self-boot systems. It is an ideal solution for in-circuit programming and tuning of prototype systems.

The USBi only supports USB 2.0 interfaces; the USBi will not

work with PCs that only support USB Version 1.0 and USB

Version 1.1.

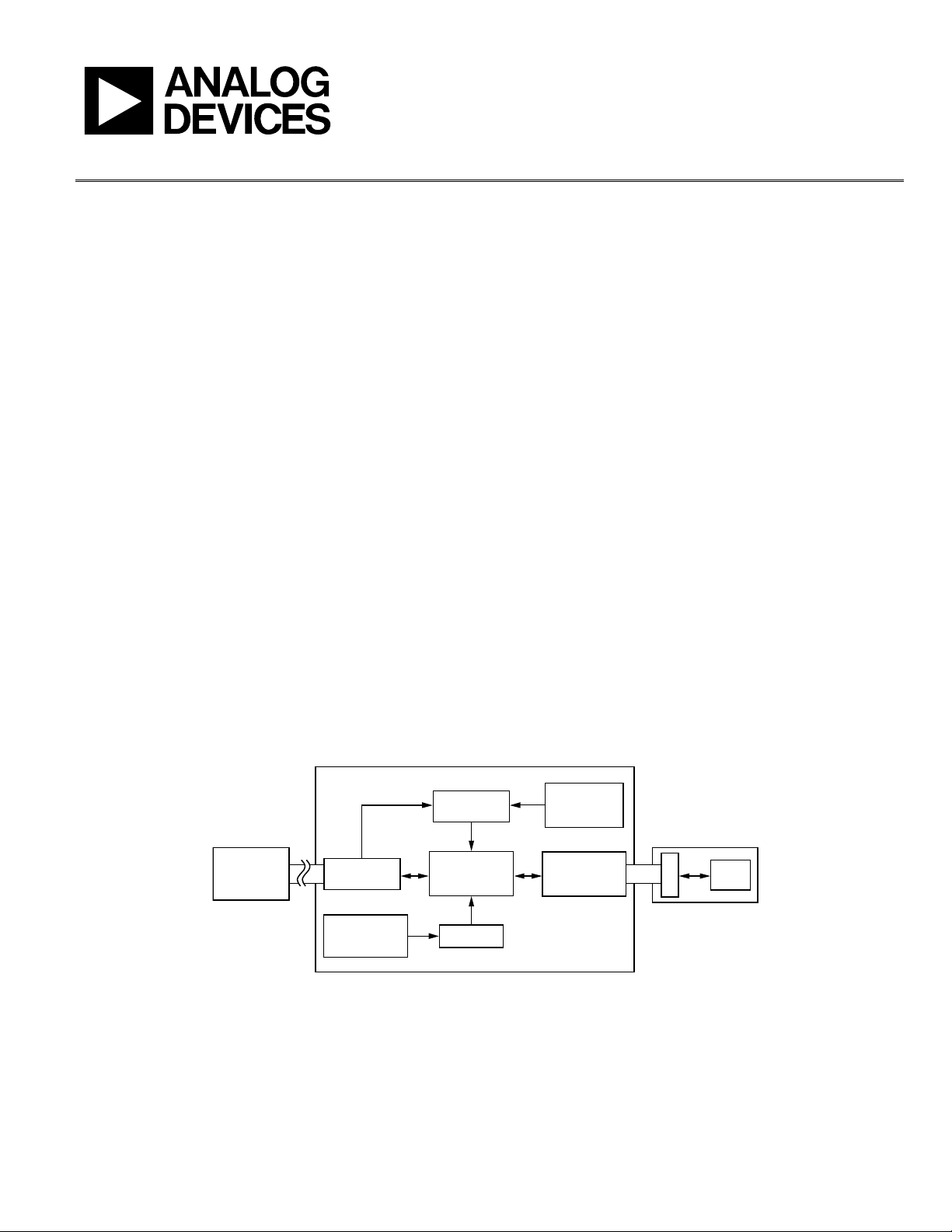

FUNCTIONAL BLOCK DIAGRAM

EVAL-ADUSB2 (USBi)

POWER

REGULATOR

HOST PC

SigmaStudio

USB

CONNECTOR

EEPROM

PROGRAMMING

HEADER

CYPRESS

USB INTERFACE

EEPROM

Figure 1.

Rev. A | Page 1 of 16

1.8V/3.3V

SELECTOR

SWITCH

PROGRAMMING

HEADER

TARGET

BOARD

SIGMA

DSP

08093-001

Page 2

AN-1006 Application Note

TABLE OF CONTENTS

Introduction ...................................................................................... 1

USB Connector ..............................................................................7

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Using the USB Interface with SigmaStudio ................................... 3

Installing the Drivers ................................................................... 3

Adding the USBi to a SigmaStudio Project ............................... 4

Configuring the USBi to Communicate with an IC ................ 4

Configuring the USBi to Communicate with Multiple ICs .... 4

Controlling the USBi .................................................................... 5

Monitoring the USBi .................................................................... 6

Using the USBi to Program a Self-Boot EEPROM .................. 6

Warning ......................................................................................... 6

Circuit Schematics ............................................................................ 7

REVISION HISTORY

4/10—Rev. 0 to Rev. A

Changes to General Description Section .......................................1

Added Warning Section ................................................................... 6

5/09—Revision 0: Initial Version

Power Regulator ............................................................................7

Cypress USB Interface ..................................................................8

Crystal Oscillator Schematic ........................................................8

LEDs ................................................................................................9

EEPROM ........................................................................................9

Target Board Power Switch ..........................................................9

Target Board Programming Header ...........................................9

Evaluation Board Schematics and Artwork ................................ 10

Schematics ................................................................................... 10

Board Layout ............................................................................... 12

Bill of Materials ............................................................................... 13

Rev. A | Page 2 of 16

Page 3

Application Note AN-1006

USING THE USB INTERFACE WITH SIGMASTUDIO

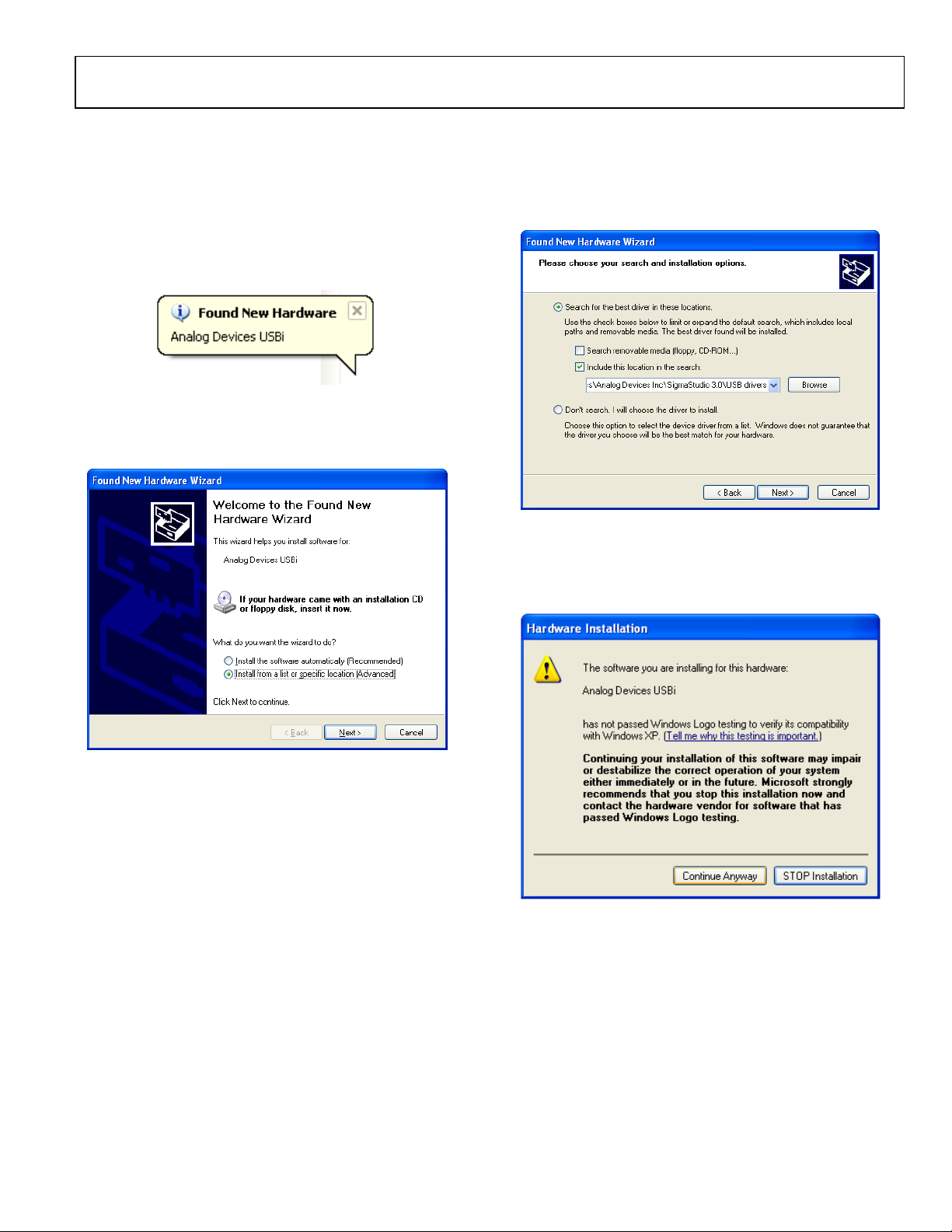

INSTALLING THE DRIVERS

SigmaStudio must be installed to use the USBi. Once

SigmaStudio has been properly installed, connect the USBi to

an available USB port with the included USB cable. At this

point, Windows® XP recognizes the device and prompts the

user to install drivers.

08093-002

Figure 2. Found New Hardware Notification

Select the Install from a list or specific location (Advanced)

option and click Next >.

Click Search for the best driver in these locations, then select

Include this location in the search. Click Browse to find the

SigmaStudio 3.0\USB drivers directory.

Figure 4. Windows Found New Hardware Wizard—Search and

Installation Options

08093-004

Figure 3. Found New Hardware Wizard—Installation

When the warning about Windows Logo testing appears on the

screen, click Continue Anyway.

8093-003

Figure 5. Windows Logo Testing Warning

08093-005

Rev. A | Page 3 of 16

Page 4

AN-1006 Application Note

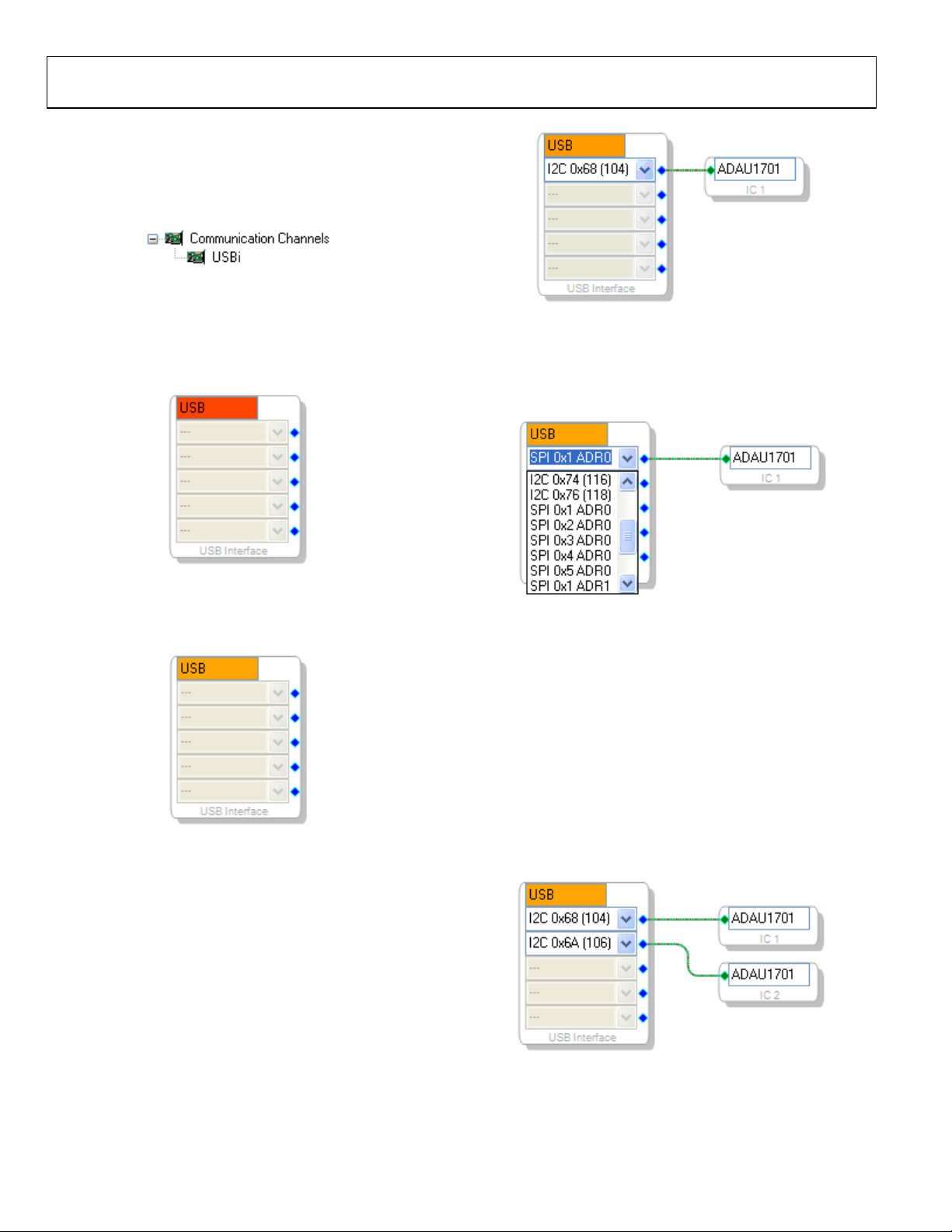

ADDING THE USBi TO A SIGMASTUDIO PROJECT

To use the USBi in conjunction with SigmaStudio, first select it

in the Communication Channels subsection of the toolbox in

the Hardware Configuration tab, and add it to the project space.

8093-006

Figure 6. Adding the USBi Communication Channel

If SigmaStudio cannot detect the USBi on the USB port of the

computer, then the background of the USB label will be red.

This may happen when the USBi is not connected or when the

drivers are incorrectly installed.

08093-009

Figure 9. Connecting the USBi to an IC

To change the communication mode and channel, click the

drop-down box and select the appropriate mode and channel

from the list.

08093-007

Figure 7. USBi Not Detected by SigmaStudio

If SigmaStudio detects the USBi on the USB port of the computer,

the background of the USB label changes to orange.

08093-008

Figure 8. USBi Detected by SigmaStudio

CONFIGURING THE USBi TO COMMUNICATE WITH AN IC

To use the USBi to communicate with the target IC, connect it

by click-dragging a wire between the blue pin of the USBi and

the green pin of the IC. The corresponding drop-down box of

the USBi automatically fills with the default mode and channel

for that IC.

08093-010

Figure 10. Selecting the Communications Mode and Channel

CONFIGURING THE USBi TO COMMUNICATE WITH MULTIPLE ICS

The USBi can communicate with up to five ICs simultaneously.

To communicate with more than one IC, add another IC to the

project and connect it to the next available pin of the USBi.

Multiple Address Operation with I2C

The USBi can support up to four identical devices on the same

bus if the I

dently set to four different addresses, matching the addresses in

the drop-down box in the Hardware Configuration tab of

SigmaStudio.

2

C address pins of the target devices are indepen-

Rev. A | Page 4 of 16

Figure 11. Multiple Address Operation with I

08093-011

2

C

Page 5

Application Note AN-1006

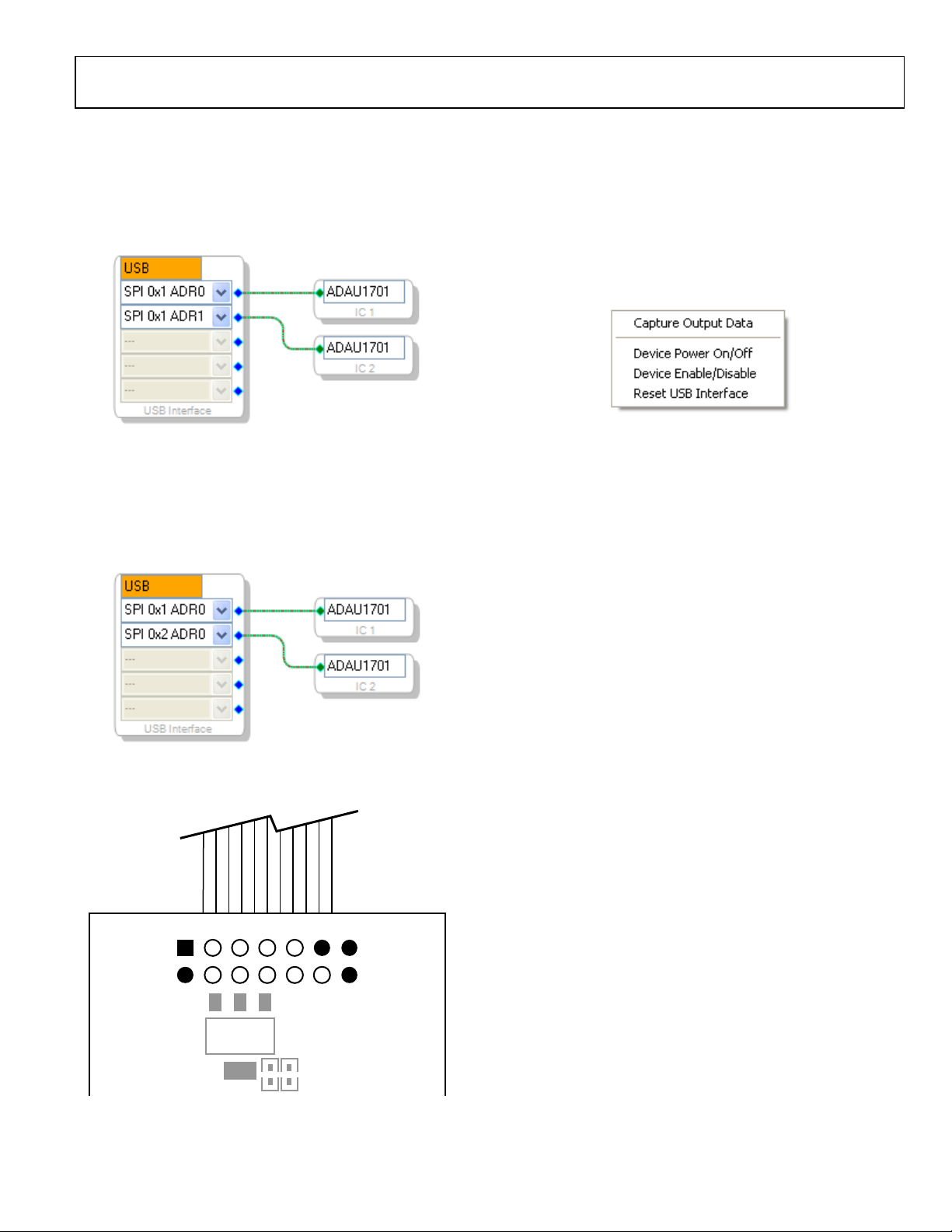

Multiple Address Operation with SPI Combined Multiple Latch and Multiple Address

The USBi can support up to two identical devices on the same

SPI latch if the SPI address pins of the target devices are independently set to two different addresses, matching the addresses in

the drop-down box in the Hardware Configuration tab of

SigmaStudio.

08093-012

Figure 12. Multiple Address Operation with SPI

Multiple Latch Operation with SPI

The USBi can support devices on five different SPI latches.

When multiple latches are used, the additional SPI latch signals

from the USBi that are not connected to the ribbon cable need

to be manually wired to the target.

Operation with SPI

A combination of multiple latch and multiple address schemes

can be used, but the total number of devices cannot exceed five.

CONTROLLING THE USBi

The USBi has several functions for controlling the target hardware.

The control options are accessed in SigmaStudio by right-clicking

on the USB Interface in the Hardware Configuration tab.

8093-015

Figure 15. USBi Control Menu

Capture Output Data

This option accesses the Capture Window, which displays a log

of all communication between the PC and the target IC

(see Figure 1

7).

Device Power On/Off

This option switches the line that supplies power to the target

board. By default, the device power is on.

08093-013

Figure 13. Multiple Latch Operation with SPI

The locations of extended SPI latch signals are shown in Figure 14.

0x02 0x04

0x03

Q1

0x01

0x05

Device Enable/Disable

For supported ICs, selecting this option switches the device to

low power mode.

Reset USB Interface

This function performs a software reset of the USB driver, and

causes the Cypress USB microcontroller to reload its firmware.

R12

Figure 14. Extended SPI Latch Signal Pinout (Bottom View of Board)

R11

08093-014

Rev. A | Page 5 of 16

Page 6

AN-1006 Application Note

MONITORING THE USBi

Using the Capture Window, it is possible to view all outgoing

communications transfers from the PC to the target IC. For

each write, the write mode, time of write, cell name (if applicable), parameter name, address, value, data (in decimal and

hexadecimal), and byte length are shown.

For block writes where more than one memory location is

written, only the first location is shown. The expand/collapse

button in the leftmost column allows the user to view the full

data write.

WARNING

The USBi has an EEPROM on the I2C bus at Address 0x51, which

it uses to indicate its Vendor ID and Product ID to the PC, as

well as boot its internal program. You should avoid having any

other EEPROMs in your system design at this address. This

EEPROM is not write-protected; therefore, if you attempt to

write to Address 0x51, you will overwrite the USBi's onboard

EEPROM, and the USBi will cease to function. The USBi cannot be

reprogrammed without returning the board to Analog Devices.

Most EEPROMs are set to Address 0x51 by setting its pins A0 = 1

and A1 = A2 = 0.

USING THE USBi TO PROGRAM A SELF-BOOT EEPROM

After compiling a project, the registers and RAM contents

can be written to a target EEPROM for self-boot. To use this

functionality, an EEPROM IC must be connected to the USBi

in the Hardware Configuration window. After verifying that

the EEPROM write protect pin is disabled on the target board,

right-click the target IC (SigmaDSP), and select Write L a t e st

Compilation to E2PROM.

Figure 16. Writing to the Self-Boot EEPROM

08093-017

08093-016

Figure 17. Output Capture Window

Rev. A | Page 6 of 16

Page 7

Application Note AN-1006

CIRCUIT SCHEMATICS

USB CONNECTOR

The connection between the host PC and the Cypress USB

interface device is via a standard USB cable that carries D+ and

D− signals for data communications, a 5 V power supply, and

ground. The D+ and D− lines are a one-wire communication

interface carried by half-duplex differential signals on a twisted

pair. The clock is embedded in the data using the nonreturn-tozero inverted (NRZI) line code. These signal lines connect

directly to pins on the Cypress USB interface.

POWER REGULATOR

The Cypress USB Interface I/O ports are capable of operating in

both 1.8 V and 3.3 V modes, depending on the target device in

the system. Two regulators, one for 5 V to 3.3 V regulation and

the other for 5 V to 1.8 V regulation, run simultaneously when

the board is powered. A switch (S1) is provided to easily switch

the IOVDD supply between the two regulators. LED D4 provides

visual feedback that the board is being supplied with 5 V power

from the PC USB port.

A surface-mounted USB miniature Type B jack was selected for

its low profile and increasing ubiquity in consumer electronics.

5V0DD

1

VCC

2

J3

D–

USB-MINI-B-SMD

GND

3

D+

4

Figure 18. USB Connector Schematic

5V0DD

D4

Red Diffused

R10

475R

+

C22

15uF

DMINUS

DPLUS

C21

1.0uF

C20

1.0uF

08093-018

ADP1711AUJZ-3.3-R7

1

IN5OUT

3

EN

BYP

GND

2

U8

ADP1711AUJZ-1.8-R7

1

IN5OUT

3

EN

BYP

GND

2

U7

10nF

4

4

C16

C18

10nF

The position of switch S1 should not be changed when the

board is connected to the USB bus.

3V3DD

+

C19

C14

1.0uF

10uF

IOVDD

C17

1.0uF

1V8DD

+

C13

10uF

3V3DD1V8DD

S1

3

2

1

SPDT

TP1

08093-019

Figure 19. Power Regulator Schematic

Rev. A | Page 7 of 16

Page 8

AN-1006 Application Note

CYPRESS USB INTERFACE

The Cypress USB interface is the core of the system, including

all of the necessary functionality to convert USB commands

into corresponding I

2

C or SPI read/write transfers, and acts as a

FIFO to route data between the host PC and the target device.

CRYSTAL OSCILLATOR SCHEMATIC

The Cypress USB interface is its own clock master, and the board

includes a crystal oscillator circuit with a 24 MHz piezoelectric

crystal resonator to provide stability to the oscillator circuit.

The crystal resonator is driven in parallel by the XTALOUT

and XTALIN pins of the Cypress USB interface.

IOVDD

1DD8V3DD3V

Figure 20. Crystal Oscillator Schematic

IOVDD

Local to 68053

C11

22pF

24.000MHz

C27

22pF

Y1

08093-021

C11

22pF

24.000MHz

C27

22pF

Y1

DMINUS

USB_CLK

DPLUS

SCL

SDA

IOVDD

100k

+

C9

0.10uF

VCC_IO

VCC_IO

VCC_D

PA0/INT0

PA1/INT1

PA2/SLOE

PA3/WU2

PA4/FIFOADR0

PA5/FIFOADR1

PA6/PKTEND

PA7/FLAGD/SLCS

PB0/FD[0]

PB1/FD[1]

PB2/FD[2]

PB3/FD[3]

PB4/FD[4]

PB5/FD[5]

PB6/FD[6]

PB7/FD[7]

PD0/FD[8]

PD1/FD[9]

PD2/FD[10]

PD3/FD[11]

PD4/FD[12]

PD5/FD[13]

PD6/FD[14]

PD7/FD[15]

GND

GND

GND

4A4B4C

7D

G

1

U3

VCC_A

8G

6G

8F

7F

6F

8C

7C

6C

3H

4F

4H

4G

5H

5G

5F

6H

8A

7A

6B

6A

3B

3A

3C

2A

GND

GND

8D

C6

0.10uF

2D

5A

5B7E8E5C

AVCC1DAVCC

VCC_IO

2E

DPLUS

1E

DMINUS

3F

SCL

3G

SDA

1A

RDY0/SLRD

1B

RDY1/SLWR

7H

CTL0/FLAGA

7G

CTL1/FLAGB

8H

CTL2/FLAGC

R15

2B

CLKOUT

2G

C1

1.0uF

2C

1C

7B

8B

IFCLK

XTALOUT

XTALIN

WAKEUP

RESET

49R9

R5

VCC_IO

CYPRESS_CY7C68053_56BAXI

AGND

AGND

GND

GND

2F

1F

1H

2H

GND

3V3DDIOVDD

475R

R6

USB_PWR_ON

C8

0.10uF

C10

0.10uF

CDATA

COUT

CLATCH2

CLATCH3

CLATCH4

CLATCH5

CCLK

C12

0.10uF

C15

15uF

10k0

R1

C4

0.10uF

C5

0.10uF

CLATCH1

IOVDD

IOVDD

IOVDD

2

2

A

2

A

1

A

VCCA

FXLP34P5X

1

GND

VCCA

3

1

5

GND

VCCA

3

FXLP34P5X

IOVDD

5

GND

3

5

VCCY

U5

Y

VCCY

U6

VCCY

U4

Y

3V3DD

4

10k0

R2

3V3DD

4

Y

3V3DD

4

FXLP34P5X

BRD_RESET

D1

YELLOW DIFFUSED

R7

475R

3V3DD

D2

D3

BLUE CLEAR

YELLOW DIFFUSED

R8

R9

475R

475R

8093-020

Figure 21. Cypress USB Interface Schematic

Rev. A | Page 8 of 16

Page 9

Application Note AN-1006

U

LEDS

The LEDs provide feedback to the user about the status of the

Cypress USB microcontroller.

3V3DD

D2

TO U3

IOVDD

IOVDD

IOVDD

2

A

2

A

1

2

A

1

VCCA

1

A

VCC

3

FXLP34P5X

GND

VCCA

3

5

GND

3

5

D

GN

VCCY

5

VCCY

Y

VCCY

U5

Y

U6

3V3DD

4

Y

U4

FXLP34P5X

3V3DD

4

FXLP34P5X

3V3DD

4

D1

YELLOW CLEAR

R7

475R

BLUE CLEAR

D3

YELLOW CLEAR

R8

R9

475R

475R

RED DIFFUSED

R10

475R

5V0DD

D4

8093-022

Figure 22. LEDs Schematic

Table 1. LED Functions

Reference

Designator Color Functionality

D1 Yellow I2C mode is active

D2 Blue GPIO LED, for firmware debug purposes

D3 Yellow SPI mode is active

D4 Red 5 V power being is supplied over the USB bus

EEPROM

The EEPROM is an important system element that identifies

the board to the host PC and stores the firmware for the

Cypress USB Interface. The EEPROM is programmed during

manufacturing via the J2 connector.

IOVDD

C3

1

A0

2

A1

3

A2

4

GND

24AA256-I/ST

0.10uF

U1

8

VCC

7

WP

6

SCL

5

SDA

10k0R410k0

R3

J2

1

2

3

SCL

SDA

8093-023

Figure 23. EEPROM Schematic

TARGET BOARD POWER SWITCH

The USBi is capable of supplying power to the target board after

the Cypress USB microcontroller has finished its boot up process.

The USB_PWR_ON signal connects to the base of Q2 and turns

on both transistors when driven high.

This circuit also enables a software-controlled target reset from

SigmaStudio.

C

4

3

USB_PWR_ON

5V0DD

10k0

R14

R13

1k50

FZT705TA

R12

100k

E

2k00

1

B

2

C

Q1

1

B

R11

C

3

Q2

MMBT3904LT1G

2

E

Figure 24. Target Power Switch Schematic

5V0DD_USB

8093-024

TARGET BOARD PROGRAMMING HEADER

To properly boot the Cypress USB microcontroller from the

EEPROM, it is necessary to remove all other devices from the

2

I

C bus. The ADG721BRMZ analog switch remains open,

isolating the I

completed.

2

C bus from the target, until the boot process has

5V0DD_USB

SCL

SB_PWR_ON

ADG721BRMZ

U2-A

S1

D1

CTRL

IN1

USB_PWR_ON

ADG721BRMZ

SDA

LOCAL FOR ADG721

S2

IN2

U2-B

CTRL

D2

3V3DD

CLATCH2

CLATCH1

CLATCH4

C2

0.10uF

COUT

CCLK

J1

2

1

4

3

6

5

8

7

10

9

111312

14

2X5 CUSTOM RIBBON

CLATCH3

USB_CLK

BRD_RESET

CDATA

CLATCH5

8093-025

Figure 25. Target Board Programming Header Schematic

Rev. A | Page 9 of 16

Page 10

AN-1006 Application Note

0

EVALUATION BOARD SCHEMATICS AND ARTWORK

SCHEMATICS

SCL

SDA

J2

123

R4

10k0

R3

10k0

IOVDD

8

7WP6

5

SCL

VCC

U1

1A02A13A24

SDA

24AA256-I/ST

GND

0.10uF

C3

5V0DD_USB

C

2

Q1

4

C

1

B

E

3

R12

FZT705TA

100k

5V0DD

Q2

MMBT3904LT1G

2

3

E

C

R11

2k00

1

B

R13

1k50

R14

10k0

C8

0.10uF

3V3DDIOVDD

C6

USB_PWR_ON

0.10uF

8093-028

LOCAL FOR FXLP34

3V3DD

BRD_RESET

R2

10k0

IOVDD

C5

0.10uF

C4

0.10uF

LOCAL TO 68053

C15

15uF

IOVDD

1DD8V3DD3V

IOVDD

+

C12

0.10uF

C10

0.10uF

C9

0.10uF

CLATCH1

R1

10k0

CLATCH3

CCLK

CLATCH4

CLATCH5

CLATCH2

COUT

CDATA

475R

USB_PWR_ON

R6

U3

8G

6G

8F

7F

6F

7C

6C

3H

VCC_A

1G

PA0/INT0

PA1/INT1

PA3/WU2

PA6/PKTEND

PA4/FI FOADR08CPA5/FI FOADR1

PA7/FLAGD/SLCS

RDY0/SLRD1BRDY1/SLWR7HCTL0/FLAGA7GCTL1/FLAGB8HCTL2/FLAGC2GIFCLK

SCL3GSDA

3F

1A

SCL

SDA

PB0/FD[0]4FPB1/FD[1]4HPB2/FD[2]4GPB3/FD[3]5HPB4/FD[4]5GPB5/FD[5]5FPB6/FD[6]6HPB7/FD[7]

PA2/SLOE

VCC_D

5C

VCC_IO

8E

VCC_IO

7E

VCC_IO

5B

VCC_IO

5A

AVCC

1D

AVCC

2D

DMINUS2EDPLUS

1E

DPLUS

DMINUS

8A

PD0/FD[8]7APD1/FD[9]

R15

49R9

USB_CLK

22pF

C11

6B

PD2/FD[10]6APD3/FD[11]3BPD4/FD[12]3APD5/FD[13]3CPD6/FD[14]2APD7/FD[15]

XTALIN2CXTALOUT2BCLKOUT

1C

IOVDD

24.000MHz

D3

D2

D1

CYPRESS_CY7C68053_56BAXI

WAKEUP

RESET

7B

8B

R5

100k

Y1

R9

475R

YELLOW CLEAR

R8

BLUE CLEAR

GND

GND

GND

GND

GND

GND

GND

AGND

AGND

C1

22pF

C7

475R

R7

475R

YELLOW CLEAR

4

3V3DD

1

IOVDD

8D

7D

4C

4B

4A

2H

1H

2F

1F

1.0uF

3V3DD

4

3V3DD

U4

VCCY

Y

5

GND

VCCA

A

2

GND

Y

5

3

FXLP34P5X

GND

VCCA

1

A

2

IOVDD

4

U5

FXLP34P5X

VCCY

3

U6

VCCY

Y

5

GND

3

FXLP34P 5X

VCCA

1

A

2

IOVDD

Figure 26. Board Schematics Page 1

Rev. A | Page 10 of 16

Page 11

Application Note AN-1006

5V0DD_USB

TESER_DRBTUOC

USB_CLK

CLATCH3

CDATA

246810

12

14

J1

13579

11

13

2X5 CUSTOM RIBBO N

CCLK

CLATCH2

CLATCH4 CLATCH5

CLATCH1

D2

CTRL

U2-B

S2

IN2

ADG721BRMZ

SDA

USB_PWR_ON

D1

CTRL

U2-A

S1

IN1

ADG721BRMZ

C2

0.10uF

3V3DD

LOCAL FOR ADG721

IOVDD

S1

SPDT

123

08093-029

SCL

USB_PWR_ON

3V3DD

5

OUT

IN

1

DMINUS

DPLUS

5V0DD

1

VCC

2D-3D+4

GND

J3

USB-MINI-B-SMD

5V0DD

ADP1711AUJZ-3.3-R7

3V3DD1V8DD

TP1

C14

10uF

+

C19

1.0uF

C18

10nF

4

U8

BYP

2

GND

EN

3

C21

1.0uF

D4

C13

10uF

+

1V8DD

C17

1.0uF

C16

10nF

4

5

U7

BYP

OUT

2

GND

EN

IN

3

1

ADP1711AUJZ-1.8-R7

C20

1.0uF

C22

15uF

+

R10

475R

RED DIFF U S E D

Figure 27. Board Schematics Page 2

Rev. A | Page 11 of 16

Page 12

AN-1006 Application Note

BOARD LAYOUT

08093-026

Figure 28. Board Layout—Top View

08093-027

Figure 29. Board Layout—Bottom View

Rev. A | Page 12 of 16

Page 13

Application Note AN-1006

BILL OF MATERIALS

Table 2.

Reference

Qty

Designator

5 C1, C17, C19

to C21

9 C2 to C6, C8

to C10, C12

2 C7, C11 22 pF, 5%, multilayer ceramic, 50 V, NP0 (0402) GRM1555C1H220JZ01D Digi-Key 490-1283-1-ND

2 C13, C14 10 μF, 20%, SMD tantalum capacitor, 0805, 6.3 V TCP0J106M8R Digi-Key 511-1447-1-ND

2 C15, C22 15 μF, 20%, SMD tantalum capacitor 0805 6.3 V TCP0J156M8R Digi-Key 511-1448-1-ND

2 C16, C18 10 nF, 5%, multilayer ceramic, 25 V, NP0 (0603) C1608C0G1E103J Digi-Key 445-2664-1-ND

2 D1, D3 LED, yellow clear, 6.0 mcd, 585 nm, 1206 SML-LX1206YC-TR Digi-Key 67-1358-1-ND

1 D2 LED, blue clear, 25 mcd, 470 nm, 1206 SML-LX1206USBC-TR Digi-Key 67-1701-1-ND

1 D4 LED, red diffused, 6.0 mcd, 635 nm, 1206 SML-LX1206IW-TR Digi-Key 67-1003-1-ND

1 J1 Header, 10-way, custom ribbon cable, install

1 J2 3-way socket, 2 mm, single row, 1 × 3 25630301RP2 Digi-Key 2563S-03-ND

1 J3 USB, mini Type B receptacle SMD 54819-0572 Digi-Key WM17116CT-ND

1 Q1 PNP Darlington transistor, SOT223 FZT705TA Digi-Key FZT705CT-ND

1 Q2 NPN general-purpose transistor MMBT3904LT1G Digi-Key MMBT3904LT1GOSCT-ND

4 R1 to R4 10.0 kΩ chip resistor, 1%, 63mW, thick film, 0402 MCR01MZPF1002 Digi-Key RHM10.0KLCT-ND

2 R5, R12 100 kΩ chip resistor, 1%, 63 mW, thick film, 0402 MCR01MZPF1003 Digi-Key RHM100KLCT-ND

5 R6 to R10 475 Ω chip resistor, 1%, 63 mW, thick film, 0402 CRCW0402475RFKED Digi-Key 541-475LCT-ND

1 R11 2.00 kΩ chip resistor, 1%, 63 mW, thick film, 0402 ERJ-2RKF2001X Digi-Key P2.00KLCT-ND

1 R13 1.50 kΩ chip resistor, 1%, 63 mW, thick film, 0402 ERJ-2RKF1501X Digi-Key P1.50KLCT-ND

1 R14 10.0 kΩ chip resistor, 1%, 63 mW, thick film, 0402 MCR01MZPF1002 Digi-Key RHM10.0KLCT-ND

1 R15 49.9 Ω chip resistor, 1%, 63 mW, thick film, 0402 MCR01MZPF49R9 Digi-Key RHM49.9LCT-ND

1 S1 SPDT slide switch SMD J hook CAS-120TA Digi-Key CAS120JCT-ND

1 TP1 Mini test point white 0.040 inch hole diameter,

1 U1 256 kb I2C, CMOS serial EEPROM 24AA256-I/ST Digi-Key 24AA256-I/ST-ND

1 U2 CMOS, low voltage, 4 Ω dual SPST switch ADG721BRMZ Analog

1 U3 USB microcontroller, I2C (3) 8-bit ports CY7C68053-56BAXI Arrow

3 U4 to U6 Translator, 1-bit, unidirect SC70-5 FXLP34P5X Digi-Key FXLP34P5XCT-ND

1 U7 Adjustable, low dropout voltage regulator, 1.0% ADP1711AUJZ-1.8-R7 Analog

1 U8 Adjustable, low dropout voltage regulator, 1.0% ADP1711AUJZ-3.3-R7 Analog

1 Y1 Crystal, 24.000 MHz, SMT 18 pF, 3.2 mm × 2.5 mm ABM8-24.000MHZ-B2-T Digi-Key 535-9138-1-ND

Description

1.0 μF, 10%, multilayer ceramic, 16 V, X7R (0603) EMK107B7105KA-T Digi-Key 587-1241-1-ND

0.10 μF, 10%, multilayer ceramic, 16 V, X7R (0402) ECJ-0EX1C104K Digi-Key PCC13490CT-ND

centered on 14-way footprint

0.10 inch × 0.020 inch

Manufacturer

Part Number

RCC-2184-ND Digi-Key RCC-2184-ND

5002 Digi-Key 5002K-ND

Vendor Vendor Order No.

ADG721BRMZ

Devices

CY7C68053-56BAXI

Electronics

ADP1711AUJZ-1.8-R7

Devices

ADP1711AUJZ-3.3-R7

Devices

Rev. A | Page 13 of 16

Page 14

AN-1006 Application Note

NOTES

Rev. A | Page 14 of 16

Page 15

Application Note AN-1006

NOTES

Rev. A | Page 15 of 16

Page 16

AN-1006 Application Note

NOTES

I2C refers to a communications protocol originally developed by Philips Semiconductors (now NXP Semiconductors).

©2009–2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

AN08093-0-4/10(A)

Rev. A | Page 16 of 16

Loading...

Loading...