Datasheet AMMCL004AWP-150I, AMMCL004AWP-150, AMMCL002AWP-150I Datasheet (AMD Advanced Micro Devices)

Page 1

PRELIMINARY

AmMCL00XA

2 or 4 Megabyte 3.0 Volt-only Flash Miniature Card

DISTINCTIVE CHARACTERISTICS

■ 2 or 4 Mbytes of addressable Flash memory

■ 2.7 V to 3.6 V, single power supply operation

— Write and read voltage: 3.0 V –10/+20%

— No additional supply current required for V

■ Fast access time

— 150 ns maximum access time

■ CMOS low power consumption

— Typical active read current:

35 mA (word mode)

— Typical active erase/write current:

40 mA (word mode)

— Typical standby current:

10 µA (4 Mbyte); 5 µA (2 Mbyte)

■ High write endurance

— Guaranteed minimum 100,000 write/erase

cycles per card

— More than 1,000,000 cycles per card typical

■ Uniform sector architecture

— 64K byte individually useable sectors

— Erase Suspend/Resume increases system level

performance

— BUSY# and RESET# signals

■ Zero data retention power

— No power required to retain data

PP

■ Available in industrial temperature grade

(–40°C to +85°C)

■ Miniature Card standard form factor

— True interchangeability

— 60-pad elastomeric connector

— Supports multiple technologies

— Sonic welded stainless steel case

— PCMCIA Type II adapter available

— Selectable byte- or word-wide configuration

— Small Form Factor (38 mm x 33 mm x 3.5 mm)

■ 60 connection bus

— 16-bit data bus

— 25-bit address bus

— Easy system integration

— Low cost implementation

— Low cost card s

■ Consumer-friendly mechanicals

— User can easily insert and remove card, upgrade

memory, and add applications

■ Voltage level keying

— Does not allow a 3 V card to plug into a 5 V

system and vice versa

— Single power supply design

— System does not need a separate program

voltage supply; only one is necessary to read

and write

GENERAL DESCRIPTION

The Miniature Card is an expansion card that provides a low cost, low power, high-performance, small

form factor solution for data and file storage to the

portable, handheld market, which includes audio,

digital film, wireless, and PDA (Por table Digital

Assistant) applications.

Miniature cards can be e asily “snappe d” into the back

of an electronic system and can be readily removed

and replaced by end users. AMD’s 3 V Flash Miniature

Cards are manufactured using AMD’s industry leading

3.0 volt-only, single-power-supply Am29LV081 Flash

This document contains information on a product under development at Advanced Micro Devices. The information

is intended to help you evaluate this product. AMD re serves the right to cha nge or discontinue work o n this proposed

product without notice.

Memory device, ensuring h igh reliability and excellent

performance. The Miniature Card is less than 30% of

the size of a PCMCIA memory card. Applications

include digital voice recorders, pocket P Cs and intelligent organizers, smart ce llular telephones, voice and

data messaging pagers, digital still came ras and portable instrumentation equipment.

The Miniature Card sp ecification will be defined by

PCMCIA as of October 1997. The participating association members include major Flash memory vendors

and leading consumer electronics OE Ms. The goal of

the Miniature Card specification is to promote an open,

Publication# 21138 Rev: E Amendment/0

Issue Date: September 1997

Page 2

PRELIMINARY

interoperable small-form-factor memory card standard.

For more information on the Miniatu re Card specification, visit the PCMCIA web site at

http://www.pc-card.com.

AMD Flash Miniature Cards can be read in either a

byte-wide or word-wide mode, which allows for flexible

integration into various system platforms. Compatibility

is assured at the hardware interface and software interchange specification.

The Miniature Card is also designed with low-cost and

rugged handling in mind. The card contains virtually no

control logic, which keeps cost and power consumption

to a minimum. The Miniature Card is packaged in a

sonic welded, stainless steel case that guarantees

durability, provides good ESD protection and ease of

handling.

The Miniature Card has extensive third-party support,

including socket and connector solutions, software

Table 1. Miniature Card Definitions

Term Meaning

support from the major FTL software vendors, and

PCMCIA adapter solutions and programmer support.

AMD's Miniature Flash cards can be used for both code

and data stor age. Since fas t random access is possible, code can be direct ly executed from the card,

reducing the amount of system RAM required. In addition. AMD’s Flash technology offers unsurpassed

endurance, data retention and reliability, eliminating

the need for complex error correctio n an d de fect ma nagement hardware and software. Each Flash sector

provides a min imum of 100,00 0 cycles, and a typ ical

card life of one million or more cycles.

For more informat ion, please contact yo ur local AMD

sales office or visit our Web site at

http://www.amd.com/html/products/nvd/nvd.html.

DEFINITIONS

Table 1 lists the terms and definitions that may be used

in conjunction with Miniature Card specifications.

AIS

ESD Acronym for Electrostatic Discharge. ESD is part of the Miniature Card physical test.

FAT

Flash

Host Any system that incorporates a Miniature Card socket.

Insertion, Cold

Insertion, Hot

Insertion, Pseudo Hot

Acronym for Attribute Informati on Stru cture. AIS is a Miniature Card sp ecifi cation for stor ing

Miniature Card attribute information.

Acronym for File Alloca tion Table. Using an F AT is a common method for managing files in a

DOS-based system.

A type of non-volatil e me mory tha t is both read abl e and writea ble , but requir es th e media to

be erased before it is rewritten.

User Perception:

Host State:

host is non-op erati onal by the user. The user inserts the Miniature Card and then presses a

button to turn the host on before the syste m is operational.

User Perception:

Host State:

operational by the user. The user inserts the card, the host recognizes it, and the host

continues to be operation al. Note: Ho t insert ion ma y require bu ff ering on the host sy stem for

proper operation.

User Perception:

Host State:

operational by th e user . The user in serts the card, the ho st immediately powers off be fore the

Miniature Card makes contac t with the host’s intern al bus. The user would then need to press

a button to turn the host on for it to become operational.

Insertion of the Miniature Card when the host is of f.

The host would be either off or in sleep mode, no bus activity is occurring, the

Insertion of a Miniature Card when the host is running.

The host would be in running mode, bus activity is occurring, the host is

Insertion of a Miniature Card when the host is running.

The host would be in running mode, bus activity is occurring, the host is

Interface Signals Miniature Card signals that make connection through the 60-pad connector area.

JEDEC Acronym for Joint Electronic Device Engineering Council.

Miniature Card Backside

Miniature Card Bottomside

The side of the Miniature Card that contains the latching mechanism. The backside is

opposite the frontside.

The side of the Min iature Card that conta ins the in terface signals . The bottomside i s opposite

the topside.

2 AmMCL00XA

Page 3

PRELIMINARY

Table 1. M iniature Card Definitions (Continued)

Term Meaning

Miniature Card Frontside

Miniature Card Topside

PC Card A memory or I/O card compatible with the PC Card Standard.

PC Card Adapter

Power/Insertion Signals

Pull-Ups Resistors used to ensure that signals do not float when no device is driving them.

Removal, Cold

Removal, Hot

Removal, Pseudo Hot

The side of the Miniature Card that contains power, insertion, ground, voltage keys, and

alignment notch. The frontside is opposite the backside.

The side of the Mini ature Card that co ntains the Mi niature Card labe l. The topsi de is opposite

the bottomside.

The hardware that connects the Miniature Card 60 contact bus to the PC Card 68 pin bus.

This hardware can be mechanically implemented by following the PC Card Type II

specification.

The three signals on the frontside of the Minia ture Card that provide grou nd, power and early

detection of insertio n.

User Perception:

Host State:

host is non-opera tion al by the use r. User would turn off the host, then remove the Miniature

Card and then press a button to turn the host on for it to become operational again.

User Perception:

Host State:

operational by th e user. User removes the card, the host reco gnize s the ev ent, and th e ho st

continues to be operati ona l.

User Perception:

Host State:

operational by the user. User removes the card, the host recognizes the event, the hos t

immediately powers off before the Miniature Card removes contact with the host’s internal

bus. The user would then need to press a button to turn the host on for it to be operational

again.

Removal of a Miniature Card when the host is off.

The host would either be off or in sleep mode, no bus activity is occurring, the

Removal of the Miniature Card when the host is running.

The host would be in running mode, bus activity is occurring, the host is

Removal of the Miniature Card when the host is running.

The host would be in running mode, bus activity is occurring, the host is

Sector Usually 64 KBytes. In word mode, a sector is 64 Kwords .

Tuple

User Insertable

User Removable

User Non-Removable

XIP

An element of the PC Ca rd Standard CIS that provides card at trib ute information, and a link

to the next tuple in a string of tuples.

All Miniature Cards should be inserted into the host by the user without the need for any

special tools.

This type of Miniature Card can be removed by the user withou t the need for any specia l

tools. It conta ins progra ms and data that users may want to switch ofte n. The use o f this typ e

of card is similar to a floppy disk.

This type of Miniature Card must be removed by the user with a special tool. It contains

memory upgrades or boot prog ram that us ers switc he s onl y whe n they require an upgrade.

The use of this type of card is similar to a SIMM memory expansion or boot hard disk.

Acronym for eXecute-In-Place, which refers to code that executes directly from a Miniature

Card.

AmMCL00XA 3

Page 4

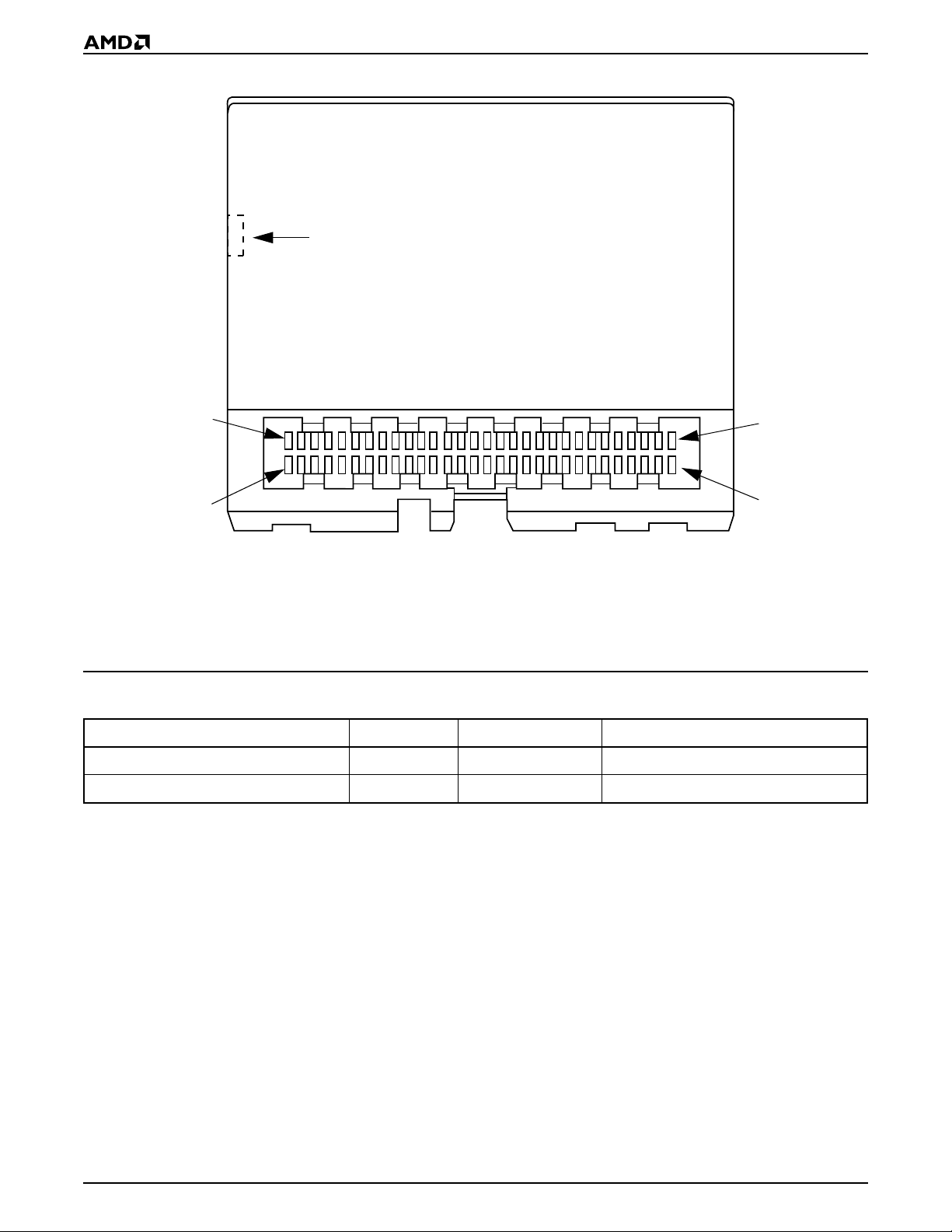

PRELIMINARY

Write Protect Switch (optional)

Pad 60 Pad 31

Pad 30 Pad 1

Key

Alignment

Notch

CINS# GND

21138E-1

V

CC

3V/5V

Figure 1. Miniature Card Connector (Card Bottom View)

Note: Refer to the Physical Dimens ions section for more information. Als o refer to the MCIF spe cification for det ailed mechan ical

information, available on the Web at http://www.mcif.org.

Table 2. AMD Flash Miniature Cards and Flash Devices

Family Part Number Density No. of Flash Devices AMD Flash Memory

AmMCL002AWP 2 Mbyte 2 Am29LV081

AmMCL004AWP 4 Mbyte 4 Am29LV081

4 AmMCL00XA

Page 5

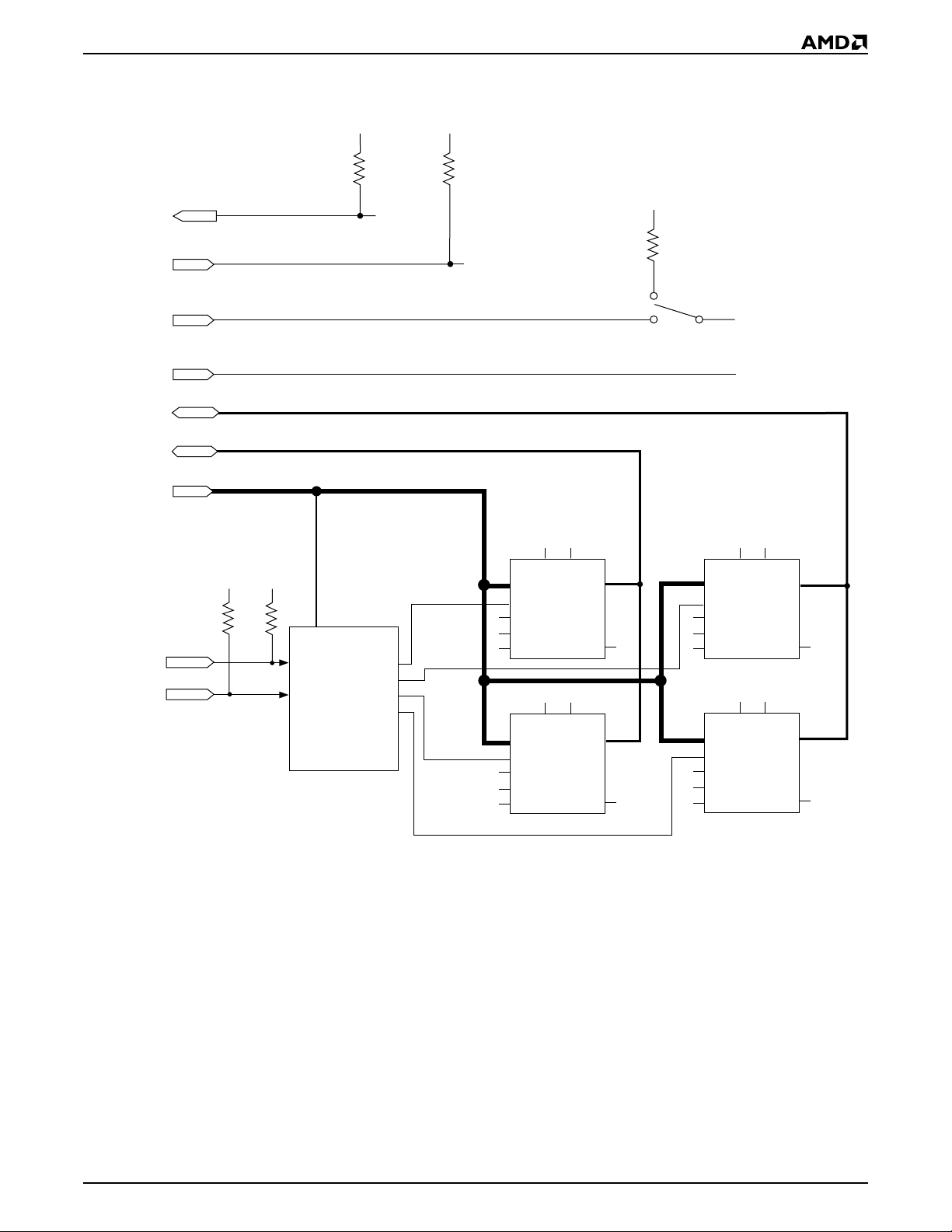

BLOCK DIAGRAM

PRELIMINARY

BUSY#

RESET#

WE#

OE#

D8-D15

D0-D7

A0-A20

CEL#

CEH#

100K

V

CCVCC

100K

A20

Decoder*

V

CC

RY/BY#

CEL0#

CEH0#

CEL1#

CEH1#

V

CC

100K100K

V

CC

10K

RESET# to all Flash devices

WE# to all Flash devices

Write Protect

Switch

OE# to all Flash devices

V

A0-A19

CE#

WE#

OE#

RESET#

V

A0-A19

CE#

WE#

OE#

RESET#

SSVCC

D0-D7

S0**

RY/BY#

SSVCC

D0-D7

S2**

RY/BY#

V

A0-A19

CE#

WE#

OE#

RESET#

V

A0-A19

CE#

WE#

OE#

RESET#

SSVCC

D8-D15

S1**

RY/BY#

SSVCC

D8-D15

S3**

RY/BY#

21138E-2

* 4 Mbyte card only. Not used on 2 Mbyte card.

** 2 Mbyte card: Two Am29LV081 devices, S0 and S1

4 Mbyte card: Four Am29LV081 devices, S0...S3

Note: On the 2 Mbyte card, A20–A24 are not connected. On the 4 Mbyte card, A21– A24 are not co nne cte d. Connections not

shown in this diagram are not connected internally.

AmMCL00XA 5

Page 6

PRELIMINARY

MINIATURE CARD PAD ASSIGNMENTS

A0–A24

Address A0 to A24 are the address bus lines that can

address up to 32 Mwords (64 Mbytes ). The address

lines are word addressed. The Miniat ure Card specification does not requ ire the Miniature Card to decode

the upper address lines. A 2 Mbyte Miniature Card that

does not decode the upper address lines would repeat

its address space every 2 Mbytes. Address 0h would

access the same ph ysical location as 200000h,

400000h, 600000h, etc. On t he 2 Mbyte cards, A20–

A24 are not connected. On the 4 Mbyte cards,

A21–A24 are not connected.

D0–D15

Data lines D0 through D15 constitute the data bus. The

data bus is composed of two bytes; the low byte is

D0–D7 and the hig h byte is D8–D15. Th ese lines are

tristated when OE# is high.

OE#

OE# indicates to the card that the current bus cycle is

a read cycle. The output enable access time (t

delay from the falling edge of OE# to val id data at the

output pins (assuming the addresses have been stable

for at least t

– tOE time).

ACC

OE

) is the

WE#

WE# indicates to the card tha t th e current bus cy cle is

a write cycle. The falling edge of WE# (or CE#), whichever occurs later, latches address information and the

rising edge of WE# (or CE#), whichever occurs first

latches data/command information.

VS1#

Voltage Sense 1 signal. This signal is grounded.

VS2#

Voltage Sense 2 signal. This signal is left open or no t

connected.

CEL#

CEL# enables the low byte of the data bus (D0–D7) on

the card.

CEH#

CEH# enables the high byte of the data bus (D8–D15)

on the card.

RESET#

RESET# controls card initializ ation. When RESET#

transitions from a low state to a high state, the Miniature Card resets to the Read state after a maximum

delay of 20 µs.

BUSY#

BUSY# is a signal generated by the card to indicate the

status of operations within the Miniature Card. When

BUSY# is high, the Mini ature Card is ready to accept

the next command from the host. When BUSY# is low,

the Miniature Card is busy and unable t o accept most

data operations from the host. In Flash Miniature Cards

the BUSY# si gnal is ti ed to the co mponents’ RY/B Y#

signal.

CD#

CD# is a groun ded inte rface signa l. After a Mi niature

Card has been inserted, CD# will be forced low. T he

card detect signal is located in the center of the second

row of interface signals, and shou ld be one of the last

interface signals to connect to the host. Do not confuse

CD# with CINS#.

CINS#

CINS# is a grounded signal on the front of the Miniature

Card that is used for early detection of a card insertion.

CINS# makes contact on the host when the front of the

card is inserted into the socket, before the interface

signals connect.

BS8#

The BS8# (Bus size 8) signal indi cates to the Miniature Card that the host has an 8-bit bus. AMD F lash

Miniature Cards ignore this signal ( no internal connection). An 8-bit host m ust connect its D0–D7 data

lines to D8–D15 on the Mi niatur e Card to retr ieve the

upper (odd) byte.

GND

Ground

V

CC

Vcc is used to supply power to the card.

NC

No connect

RFU

Reserved for future use

6 AmMCL00XA

Page 7

PRELIMINARY

ORDERING INFORMATION

Standard Products

AMD standard products are available in several packages and operating ranges. The order number (Valid Combination) is

formed by a combination of the following:

AM MC 004 WP

L

A

-150

I

TEMPERATURE RANGE

Blank = Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

SPEED OPTION

WRITE PROTECT SWITCH OPTION

WP = Switch installed

REVISION LEVEL

MEMORY CARD DENSITY

002 = 2 Megabyte Card

004 = 4 Megabyte Card

3 V, SINGLE SUPPLY OPERATION

2.7 V to 3.6 V, extended

operating voltage

MINIA TURE CARD

AMD

AmMCL00XA 7

Page 8

PRELIMINARY

INTERFACE SIGNAL ASSIGNMENTS

Pad Number Signal Name Pad Number Signal Name Pad Number Signal Name

1 A18 21 D12 41 A4

2 A16 22 D10 42 CEL#

3 A14 23 D9 43 A1

4NC24D044NC

5 CEH# 25 D2 45 NC

6 A11 26 D4 46 CD#

7 A9 27 RFU 47 A21

8 A8 28 D7 48 BUSY#

9 A629NC49WE#

10 A5 30 NC 50 D14

11 A3 31 A19 51 RFU

12 A2 32 A17 52 D11

13 A0 33 A15 53 VS2#

14 NC 34 A13 54 D8

15 A24 35 A12 55 D1

16 A23 36 RESET# 56 D3

17 A22 37 A10 57 D5

18 OE# 38 VS1# 58 D6

19 D15 39 A7 59 RFU

20 D13 40 BS8# 60 A20

Note: NC = No Connect; RFU = Reserved for Future Use.

FLASH MINIATURE CARD OPERATIONS

Voltage Sensing

AMD Miniature Cards provide two voltage sense

signals for hosts that support multiple voltages. The

multivolta ge host can s ense the volt age level o f the

Miniature Card and power up the card at that voltage.

See Table 3 for a description of the voltage

sense signal s.

In addition to th e voltage sens e pins, there are a lso

mechanical voltage keys on the Miniature Card that

ensure the card can only be inserted into host systems

that can su pply the prop er voltage le vels to the card.

Refer to Section 4.1.2 in the Min iature Card specification for more information on mechanical keying.

Table 3. Voltage Sense Signals

Miniature Card

Power-Up Voltage VS1# VS2#

3 volt-only Gnd Open

8 AmMCL00XA

Page 9

PRELIMINARY

Data Accesses

The Miniatur e Card has a 16-bit data bu s that can

accommodate word or byte a ccesses. By individually

asserting CEL# and CEH#, a host can access either

byte. However, byte swapping (moving the high byte

data to the low byte) is not supported.

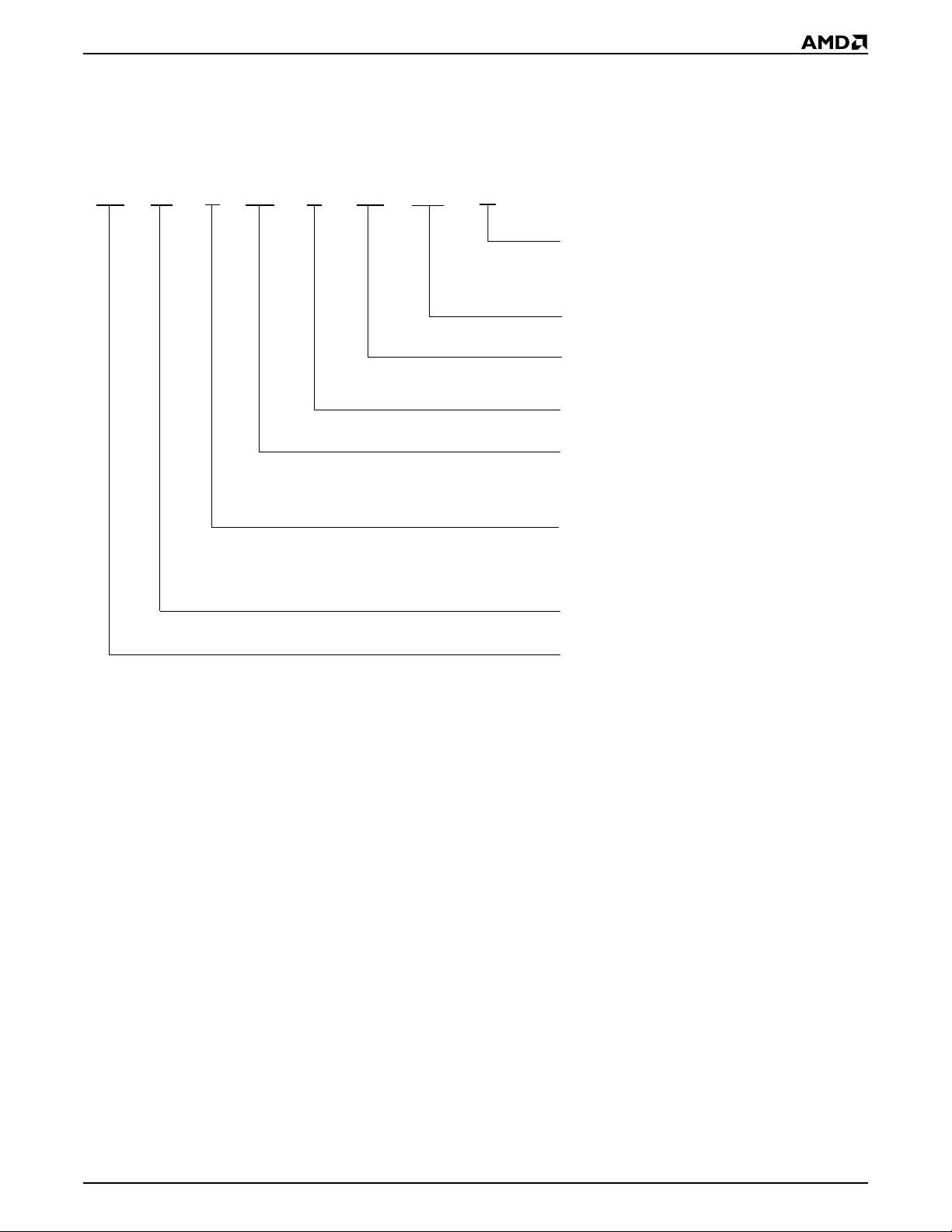

Figure 2 shows the connections betw een t he h ost and

Miniature Card. The host system address lines range

from A0–A25, whereas the Miniatur e Card address

Host Bus

A22

A21

A25

A24

A23

lines range f rom A0–A24. On the host, A0 and the

byte/word line are sent to a decoder and output to

CEL# and CEH# on the Miniature Card. These two bits

enable a single devi ce for byte accesses and two

devices for word accesses, as shown by the decoder

truth table in Figure 2. Again, the Miniature Card

address lines do not receive input from host address bit

A0. In this document, all address references are

addresses

, unless otherwise noted. T able 4 shows the

card

read/write modes for Miniature Cards.

Byte/Word

A0

Decoder

Decoder Truth Table

Input Output

A0 B/W CEL# CEH#

0000

0101

1000

A2

A1

1110

60-Pad Connector

A23*A24*

A22*

A21*

A20**

Card Bus

* Not connected

** Not connected on 2 Mbyte card

Figure 2. Host/Card Address Connections

Word-Wide Operations

The AMD Miniature Card provide the flexibility to

operate on data in a byte-wide or word-wide format. In

word-wide operations, the low bytes are controlled with

CEL#. The high bytes are controlled with CEH#. Refer to

the block diagram for more information.

Byte-Wide Operations

Byte-wide data is available for read and write operations (CEL# = 0, CEH# = 1). Even and odd bytes are

stored in separate memory devices (for example, S0

and S1) and are accessed by controlling CEL# and

CEH#. The even byte is the low order byte and the odd

byte is the high order byte of a 16-bit word.

Each memory sector or device pair must be addressed

separately for erase operations. Refer to the block

diagram for more information.

A1

CEH#CEL#A0

21138E-3

Card Detection

Each CD# (output) pin should be detected by the host

system to determine if the memory card is adequately

seated in the socket. CD# and CINS# are internally tied

to ground. If both bits are not d etected, the system

should indicate that the card must be re-inserted.

Data Protection

An optional mechanical write protect switch provides

user-initiated write protection. When this switch is acti-

WE# is internally forced high. The Flash memory

vated,

command register is disabled from accepting any write

commands. This prevents the card from responding to

any commands (for example, an Autoselect command). See Figure 3.

AmMCL00XA 9

Page 10

PRELIMINARY

Write Enabled

Write Disabled

Figure 3. Write Protect Switch

21138E-1

(Card Right Side View)

In addition to card-level data protection, AMD Flash

Miniature Cards offer several device-level data protection features.

Device-Level Data Protection

AMD Flash memory devices offer protection against

accidental erasure or programming caused by spurious

system level signals that may exist during pow er transitions. During power up, each device automatically

resets the internal state machine to the read mode. The

control register architectur e allows alteration of the

memory contents only occurs after successful completion of specific multi-bus cycle command sequences.

AMD Flash memory devices also incorporates the following features to prevent inadvertent write cycles

resulting from V

tions or system noise.

Low V

Write Inhibit

CC

To avoid initiation of a write cycle during V

and power-down, the AMD memory devices in the Miniature Card lock out write cycles for V

“DC Characteristics” on page 22 for voltages). When

< V

V

CC

LKO

internal program/erase circuits are disabled, and the

device resets to the read mode. The memory devices

ignore all write s until V

power-up and power-down transi-

CC

power-up

CC

CC

< V

LKO

(see

, the command register is disabled, all

CC

> V

. The user must

LKO

ensure that the control pins are in the correct logical

state when V

CC

> V

to prevent unintentional writes.

LKO

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#, CE# ,

or WE# will neither initiate a write cycle nor change the

command registers.

Logical Inhibit

Writing is inhibited by holding any one of OE# = V

CE# = V

, or WE# = VIH. To initiate a write cycle CE#

IH

IL

and WE# must be a lo gical ze ro whil e OE# is a logical

one.

Power-Up Write Inhibit

Power-up of the device with CE# = WE# = V

will not accept command s on the rising ed ge of

= V

IH

and OE#

IL

WE#. The internal state machine is automatically reset

to the read mode on power-up.

Read Mode

Two Card Enable (CE#) pin s are available on th e

memory card. Both CE # pins must be active low f or

word-wide read accesses. Only one CE# is required for

byte-wide accesses. The CE# pins select and determine when to appl y power to the high-byte and

low-byte memory devices. The Output Enable (OE#)

controls gating accessed data from the memory device

outputs. Refer to Table 4.

The Miniature Car d automatically power s up in the

read/reset state. In this case, a command sequence is

not required to read data. Standard microprocessor

read cycles will retrieve arra y data. This default state

ensures that no spurious alteration of the memory

content occurs during the power transition. Refer to the

AC Read Characteristics and Waveforms for the specific timing parameters.

Output Disable

Data outputs from th e card are di sabled when OE # is

at a logic-high level. Und er this conditio n, outputs are

in the high-impedance state.

,

10 AmMCL00XA

Page 11

PRELIMINARY

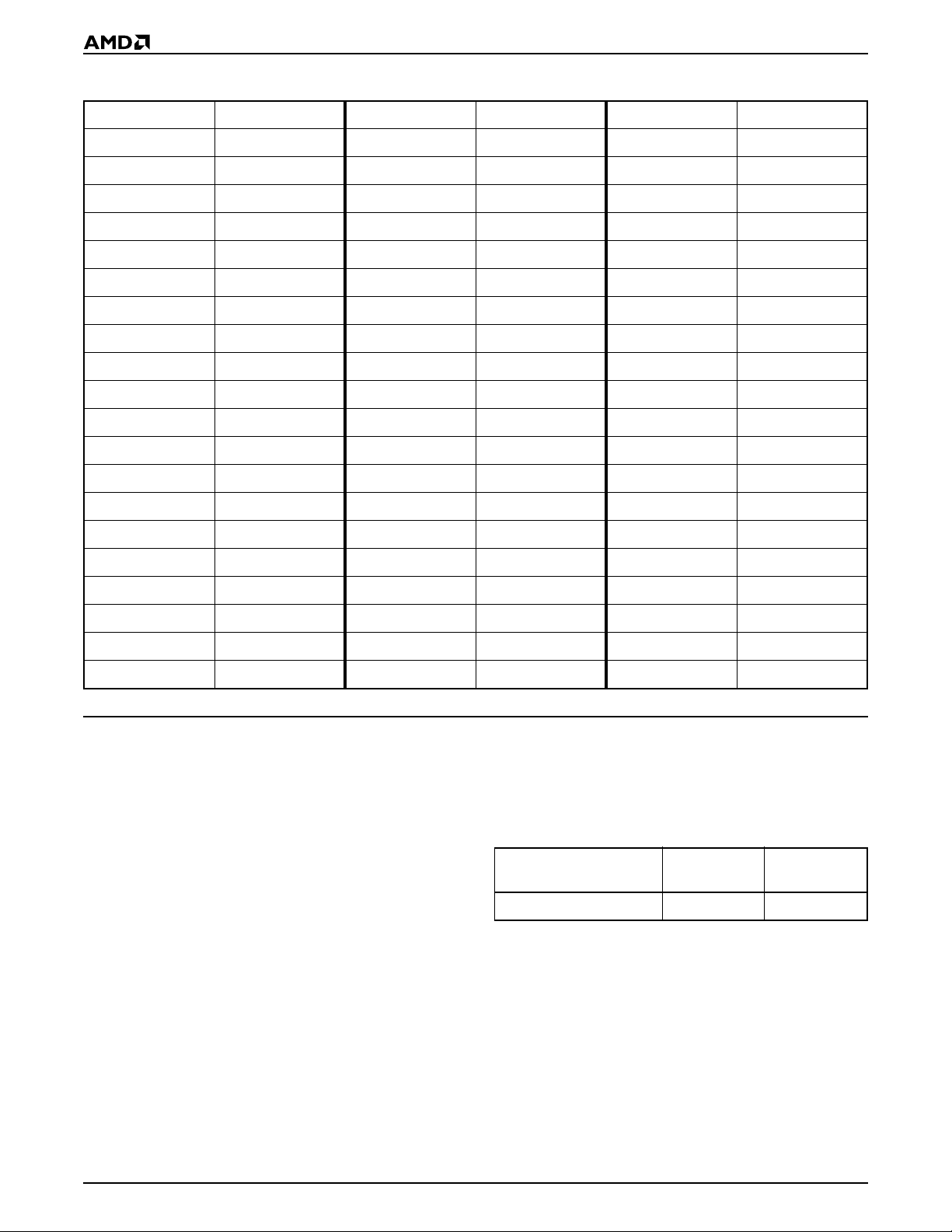

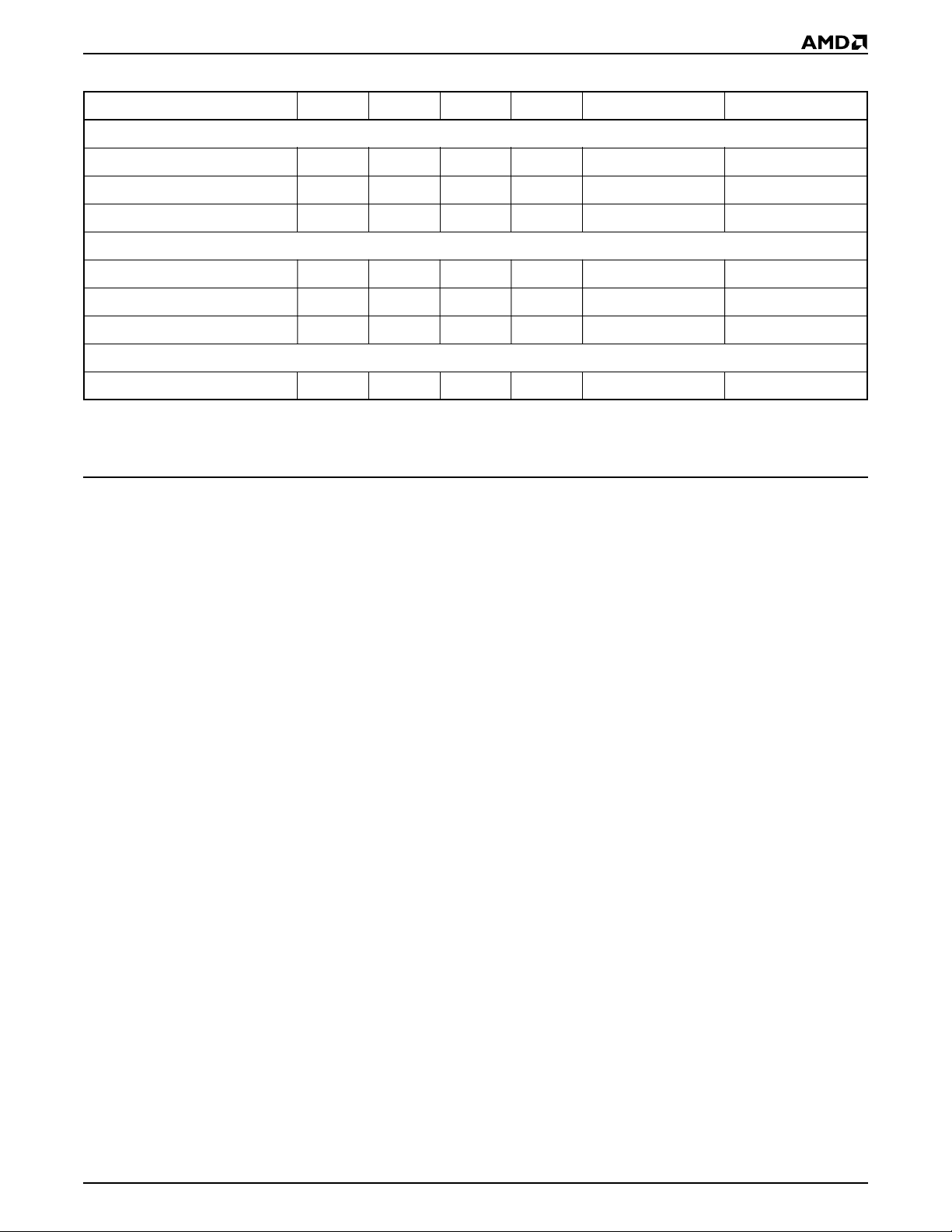

Table 4. Miniature Card Read/Write Modes

Function CEH# CEL# WE# OE# D8–D15 D0–D7

Read Mode

Word Access L L H L High Byte Data Low Byte Data

Low Byte Access H L H L High-Z Low Byte Data

High Byte Access L H H L High Byte Data Hi gh-Z

Write Mode

Word Access L L L H High Byte Data Low Byte Data

Low Byte Access H L L H High-Z Low Byte Data

High Byte Access L H L H High Byte Data Hi gh-Z

Standby Mode

Standby H H X X High-Z High-Z

Notes:

1. Unlisted access combinations are invalid and may return unexpected results.

2. X indicates a don’t care value.

Erase Operations

The AMD Flash Miniature Card is organized as an

array of individual devices. Each Am29LV081 device

contains sixteen 64 KByte sectors, for a total of 1 Mbyte

of memory space per device.

Flash technology allows any logical “1” data bit to be programmed to a log ica l “0 ”. T he on ly wa y t o r ese t bit s t o a

logical “1” is to erase that entire memory sector or

memory device. Once a memory s ector or memory

device is erased, any address location may be programmed. Two or more de vi ces m ay be er ase d co nc urrently when additional I

However, erasing more than two devices concurrently is

not typical in battery-powered applications, but may take

place during procedures such as card testing.

Erase operations can be performed in several ways:

■ Erase a single sector or multiple sectors in a device

■ Erase a sector pair

■ Erase multiple device pairs*

■ Erase the entire card*

* This operation is only feasible in solutions capable of

supplying more than the specified miniature card

supply current requirement (150mA) per system. Each

AMD Flash memory device pair can accept a

maximum of 120mA supply current.

The common memory space data contents are altered

in a similar ma nner to writing to individua l Flash

memory devices. An on-card address decoder activates the appropriate Flash device in the memory

current is supplied to the card.

CC

array. Each device internally latches address and data

during write cycles. Refer to Table 4.

Standby Mode

The AMD flash devices are designed to accommodate

low standby power consumption. In order to achieve

standby mode, the CE# line must be deselected. In

addition, while in the standby mode, data I/O pins

remain in the high impedance state independent of the

voltage level applied to the OE# input. See the DC

Characteristics section for more details on Standby

Modes.

Deselecting CE# (CE# and RE SET# = V

puts the device into the I

standby mode. If the

CC3

device is deselected during an Embedded Algorithm

operation, it continues to draw active power (I

to entering the standby mode, until the operation is

complete. When t he de vice is agai n selec ted (CE # =

), a c t i v e o p e r a t i on s occur in accordance with th e

V

IL

AC timing specifications.

Automatic Sleep Mode

Advanced power management features such as the

automatic sleep mode minimize Flash device energy

consumption. This is extremely important in battery-powered applications. The AMD memory devices

automatically enable the low-power, automatic sleep

mode when addresses remain stable for 300 ns. Automatic sleep mode is independent of the CE#, WE#, and

OE# control signals. Typical sleep mode current draw

from each device is < 1 µA. Standard address access

timings provide new data when addresses are

± 0.3 V)

CC

CC2

) prior

AmMCL00XA 11

Page 12

PRELIMINARY

changed. While in sleep mode, output data is latched

and always available to the system.

Command Definitions

Each memory device contains a command register,

which is a latch that saves address, commands, and

data information used by the state machine and

memory array. The state machine is active when V

greater than V

(2.3 - 2.5 V). This is required for valid

LKO

program and erase operations.

When Write Enable (WE#) and appropriate CE#

signals are at a logic-low level, and Output Enable

(OE#) is at a logic-high, the command register is

enabled for write ope rations. The fa lling edge of WE#

or CE#, whichever occurs later, latches address information and the rising e dge of W E# or CE# , which ever

occurs first, latches data/command information.

Commands are accomplished by writing non-specific

address and specific data sequences into the command register of accessed Flash memory devices.

Writing incorrect address and data values or writ-

CC

is

ing them in the improper sequence will reset the

device to the read mode.

The byte-wide comma nds are defined in Tables 6 and

7; word-wide com mands are defined i n Tab le 5. Note

that the Erase Suspend (B0h) and Erase Resume

(30h) commands are valid only while the Sector Erase

operation is in progress.

Autoselect Operation

A host system or external card reader/writer can determine the on-card manufacturer and device I.D. codes.

Codes are available after writing the 90h command to

the command register of a memory device, as shown in

Tables 5 throu gh 7. When the autoselect comman d is

issued to card address 00000h, the Miniature Card

returns the manufacturer I .D. If the autoselect

command is issued to card address 00001h, the Miniature Card provides the device I.D.

To term ina te th e autoselect operation, the Read/Reset

command sequence must be written to the same

device. The Autoselect command op erates only if the

card is not write protected.

12 AmMCL00XA

Page 13

PRELIMINARY

Table 5. Word Command Definitions

Bus Cycles (Notes 2–9)

Embedded Command

Sequence (Note 1)

Read 1 RA RW

Reset 1 XXXX F0F0

Autoselect Manufacturer ID

(Note 4)

Autoselect Device ID

(Note 4)

Word Write 4 XXXX AAAA XXXX 5555 XXXX A0A0 PA PW

Device Erase 6 XXXX AAAA XXXX 5555 XXXX 8080 XXXX AAAA XXXX 5555 XXXX 1010

Sector Erase 6 XXXX AAAA XXXX 5555 XXXX 8080 XXXX AAAA XXXX 5555 SA 3030

Sector Erase Suspend (Note 7) 1 XXXX B0B0

Sector Erase Resume (Note 8) 1 XXXX 3030

4 XXXX AAAA XXXX 5555 XXXX 9090 XX00 0101

4 XXXX AAAA XXXX 5555 XXXX 9090 XX01 3838

First Second Third Fourth Fifth Sixth

Cycles

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Legend:

X = Don’t care

RA = Address of the memory location to be read.

RW = Data read from location RA during read operation.

PA = Address of the memory location to be programmed.

PW = Data to be programmed at loc ation PA. Data is latched

on the rising edge of WE#.

SA = Address of th e secto r to be eras ed. Refer to Table 8 for

sector addresses.

Addresses are latched on the falling edge of the WE# pulse.

Notes:

1. Write protect must n ot be en abled for p roper op eration of

all commands. No command required for reading array

data, and can thus be done with write protect enabled.

2. During word addressing, CEL# = 0, CEH# = 0, and

address is applied to Memory De vice Pair 0 (S0 and S1).

On 4 Mbyte cards, address for Memory Device Pair 1 =

(Addr) + 200000h, and address is applied to Memory

Device Pair 1 (S2 and S3). For host-to-card address bit

connections, see Figure 2.

3. All values are in hexadecimal.

4. The last bus cycle in an autoselect command sequence is

a read operation.

5. Word = high byte + low byte.

6. Address bits = X = Don’t Care for all command s except for

Read Address (RA), Program Address (PA), and Sector

Address (SA).

7. The Erase Suspend command is valid only during a

sector erase operation . Refer to “Sector Eras e Suspen d”.

8. The Erase Resume command is valid only during the

Erase Suspend mode.

9. See Table 4 for bus operations.

AmMCL00XA 13

Page 14

PRELIMINARY

Table 6. E ven Byte Command Definitions

Bus Cycles (Notes 2–8)

Embedded Command Sequence

(Note 1)

Read 1 RA RD

Reset 1 XXXX XXF0

Autoselect Manufacturer ID (Note 4) 4

Device ID (Note 4) 4 XXXX XXAA XXXX XX55 XXXX XX90 XX01 XX38

Byte Write 4 XXXX XXAA XXXX XX55 XXXX XXA0 PA PD

Device Erase 6

Sector Erase 6

Sector Eras e Su s pe n d ( N ot e 6) 1 XXXX XXB0

Sector Erase Resume (Note 7) 1 XXXX XX30

First Second Third Fourth Fifth Sixth

CyclesCycles

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

XXXX XXAA XXXX XX55 XXXX XX90 XX00 XX01

XXXX XXAA XXXX XX55 XXXX XX80 XXXX XXAA XXXX XX5 5 XXXX XX10

XXXX XXAA XXXX XX55 XXXX XX80 XXXX XXAA XXXX XX55 SA XX30

Note for Table 6: During even (low) byte accesses, CEL# = 0, CEH# = 1. Address is applied to Memo ry Device 0 (S0). On 4 Mbyte

cards, address for Memory Device 2 (S2) = (Addr) + 20000 0h.

Table 7. Odd Byte Command Definitions

Bus Cycles (Notes 2–8)

Embedded Command Sequence

(Note 1)

Read 1 RA RD

Reset 1 XXXX XXF0

Autoselect Manufacturer ID (Note 4) 4

Autoselect Device ID (Note 4) 4 XXXX AAXX XXXX 55XX XXXX 90XX XX01 38XX

Byte Write 4 XXXX AAXX XXXX 55XX XXXX A0XX PA PDXX

Device Erase 6

Sector Erase 6

Sector Eras e Su s pe n d ( N ot e 6) 1 XXXX XXB0

Sector Erase Resume (Note 7) 1 XXXX XX30

First Second Third Fourth Fifth Sixth

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

XXXX AAXX XXXX 55XX XXXX 90XX XX00 01XX

XXXX AAXX XXXX 55XX XXXX 80XX XXXX AAXX XXXX 55XX XXX X 10XX

XXXX AAXX XXXX 55XX XXXX 80XX XXXX AAXX XXXX 55XX SA 30XX

Note for Table 7: During odd (high) byte accesses, CEL#= 1, CEH# = 0, and address is applied to Memory Device 1 (S1). On 4 Mbyte

cards, address for Memory Device 3 (S3) = (Addr) + 20000 0h + 1000 00h .

Legend for Tables 6 and 7:

X = Don’t care

RA = Address of the memory location to be read.

RW = Data read from location RA during rea d opera tion .

PA = Address of the memory location to be programmed.

PW = Data to be programmed at location PA. Data is latched on

the rising edge of WE#.

SA = Address of the sector to be eras ed. Refer to Table 8 for

sector addresses.

Addresses are latche d on the falling edge of the WE# pulse.

Notes for Tables 6 and 7:

1. Write protect must not be enabled for proper operation of all

commands. No comm a nd r equ ired for read in g ar ra y data ,

and can thus be done with write prote ct ena bled.

2. For host- to-card addres s bit c onn ect i ons, see Figur e 2.

3. All values are in hexadecim al.

6. The Erase Suspend com man d is va lid only dur ing a sect or

erase operation. Refe r to “S ect or Erase Susp en d” .

7. The Erase Resume command is valid only during the Erase

Suspend mode.

8. See Table 4 for bus operat io n s .

4. The last bus cycle in an autoselect command sequence is a

read oper at ion.

5. Address bits = X = Don’t Care for al l comm an ds ex ce pt for

Read Address (R A) , Progr am A d dr es s (PA), and Sector

Address (SA).

14 AmMCL00XA

Page 15

PRELIMINARY

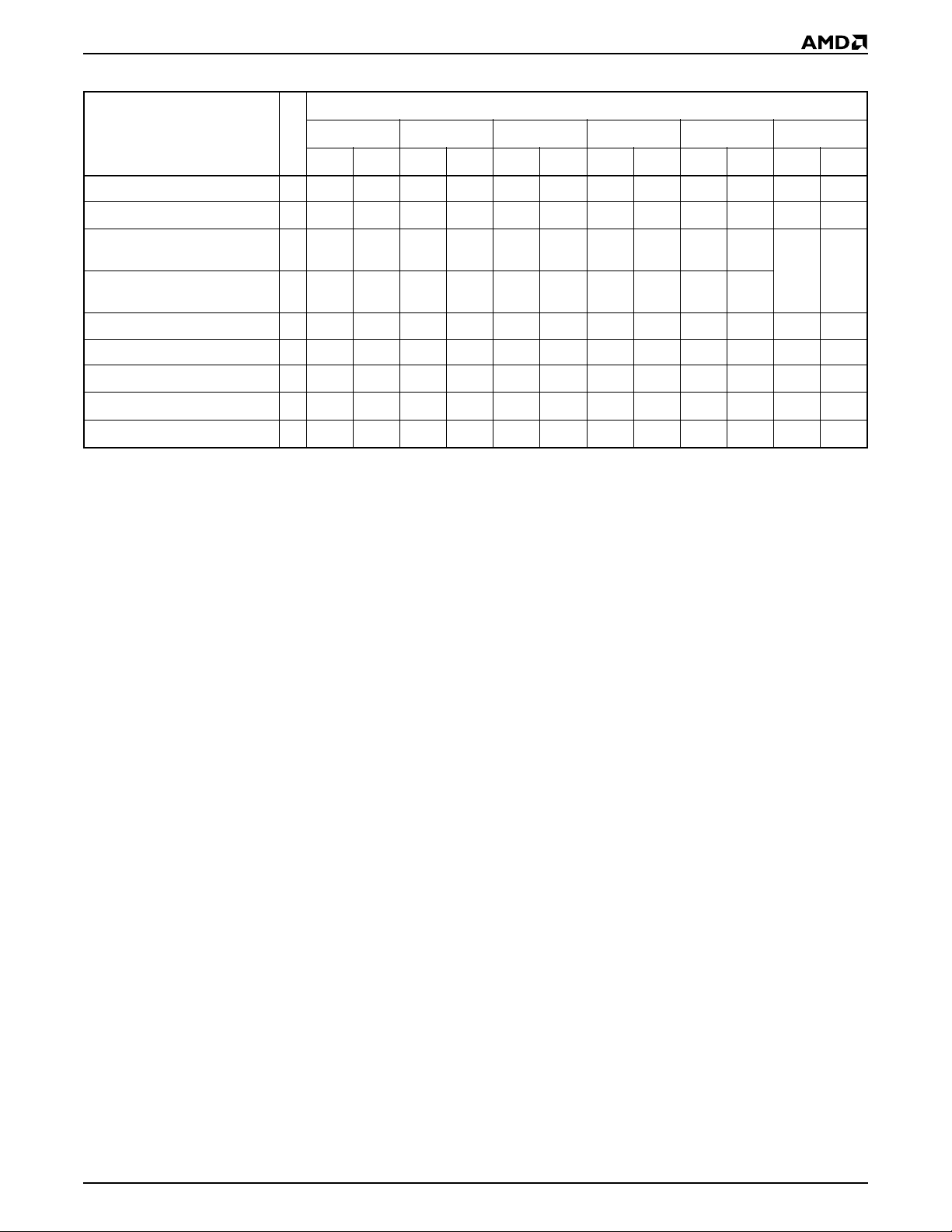

Table 8. Memory Sector Addresses

Card Address Bits Device 0 and/or 1 (Note 1) Device 2 and/or 3 (Note 1)

Sector

0 0 0 0 0 00000h–0FFFFh 100000h–10FFFFh

1 0 0 0 1 10000h–1FFFFh 110000h–11FFFFh

2 0 0 1 0 20000h–2FFFFh 120000h–12FFFFh

3 0 0 1 1 30000h–3FFFFh 130000h–13FFFFh

4 0 1 0 0 40000h–4FFFFh 140000h–14FFFFh

5 0 1 0 1 50000h–5FFFFh 150000h–15FFFFh

6 0 1 1 0 60000h–6FFFFh 160000h–16FFFFh

7 0 1 1 1 70000h–7FFFFh 170000h–17FFFFh

8 1 0 0 0 80000h–8FFFFh 180000h–18FFFFh

9 1 0 0 1 90000h–9FFFFh 190000h–19FFFFh

10 1 0 1 0 A0000h–AFFFFh 1A0000h–1AFFFFh

11 1 0 1 1 B0000h–BFFFFh 1B0000h–1BFFFFh

12 1 1 0 0 C0000h–CFFFFh 1C0000h–1CFFFFh

13 1 1 0 1 D0000h–DFFFFh 1D0000h–1DFFFFh

14 1 1 1 0 E0000h–EFFFFh 1E0000h–1EFFFFh

15 1 1 1 1 F0000h–FFFFFh 1F0000h–1FFFFFh

A19 A18 A17 A16 Card Address Range Card Address Range

Notes:

1. For word addressing, devices 0 and 1 (S0 and S1) together form Memory Device Pair 0; devices 2 and 3 (S2 and S3) form

Memory Device Pair 1. Refer to the block diagram for device connections.

2. Card address bits range from A0 to A19. Host ad dress bits rang e from A0 to A20. Hos t address bit A0 is used for co ntrolli ng

the CEL# and CEH# inputs to the card. Refer to Figure 2 for host-to-card address bit connections.

AmMCL00XA 15

Page 16

PRELIMINARY

AMD FLASH MEMORY PROGRAM AND

ERASE OPERATIONS

To simplify prog ram a nd erase ope ratio ns, AMD Fla sh

Memory devices include Embedded Algorithms

(Embedded Erase Algorithm and Embedded Program

Algorithm) that allow the host to simply issue a command, after which it is free to perform other tasks. The

host then only needs to monitor appropriate status bits

to determine when the operation is complete.

Embedded Erase Algorithm

When erasing a sector or device, the Embedded Erase

algorithm does not require the host to first entirely

pre-program the device. Upon executing the

Embedded Erase comman d seq uence , the addr essed

memory sector or memory device automa tically wri tes

and verifies the entire memory device or memory

sector for an all “0” data pattern. The system is not

required to provide any controls or ti mi ng during these

operations.

When the memory sector or memory dev ice is automatically verified to contain an all “0” pattern, a

self-timed chip erase-and-verify begins. The erase and

verify operations are complete when the data on D7

(D15 on the odd byte) of the memory sector or memory

device is “1” (see Write Operation Status section), at

which time the device returns to the read mode. The

system is not required to provide any control or timing

during these operations. If a Reset command is issued

while the erase operation is in progress, the erase

operation will stop, and the data in that device will be

undefined. In that case, restart the erase on that sector

and allow it to complete.

When using the Embedded Erase algorithm, the erase

automatically terminates when adequate erase margin

has been achieved for the memory array (no erase

verify command is required).

The Embedded Erase command sequence is a

command only operation that stages the memory

sector or memo ry device for automatic electrical

erasure of all bytes in the array. The automatic erase

begins on the rising edge of the

when the data on D7 (D15 on the odd byte) of the

memory sector or memory device is “1” (see Write

Operation Status section) at which time the device

returns to the Read mode. Please no te that for the

memory device or memory sector erase operation,

Data Polling may be performed at any address in that

device or sector.

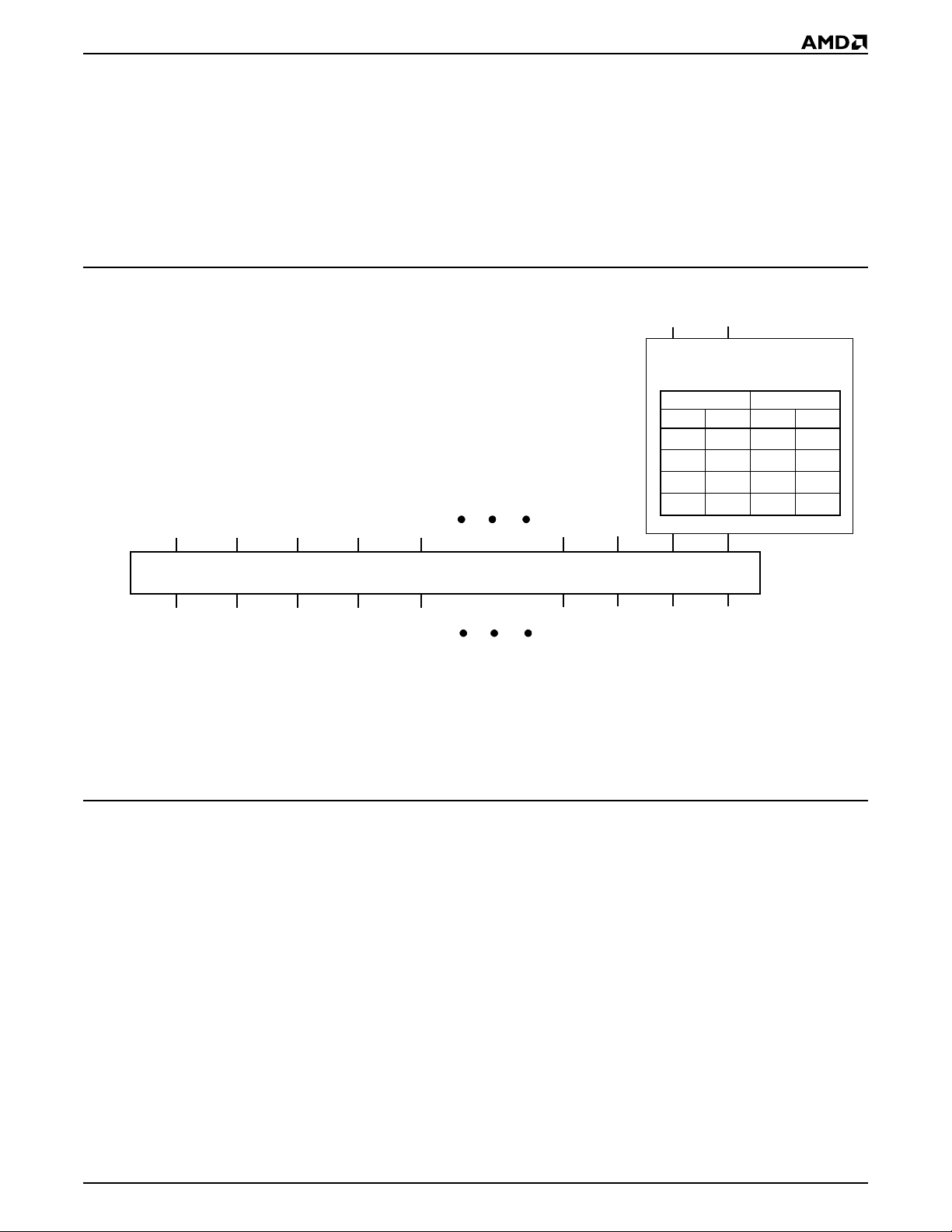

Figure 4 and Table 9 illustrate the Embedded Eras e

Algorithm, a typical command string and bus operations.

As described earlier, once the memory sector in a

device or memory device completes the Embedded

Erase operatio n, it returns to the Read mo de and

addresses are no longer latched. Therefore, the device

WE# and terminates

requires that a valid address input to the device is

supplied by the system at this particular instant of time.

Otherwise, the system will never read a “1” on D7 (D15

on the odd byte). A system designer has the follo wing

choices to impleme nt the Embedded Era se algorithm :

1. The host may keep the sector address (with in any

of the sectors being erased) valid during the entire

Embedded Erase operation.

2. Once the system executes the Embedded Erase

command sequence, the h ost may remove t he address from the device and perform other tasks. The

host is required to keep track of the valid sector address by loading it into a temporary regi ster. When

the host comes back to Data Poll the device, it must

reassert the same address.

3. The host may monitor BUSY# (RY/BY#) to determine the status of the Embedded Algorithm in

progress. A “0” indicates that the d evice is busy; a

“1” indicates that the algorithm is complete.

Sector Erase

Sector erase is a six bus cycle operation. There are two

“unlock” write cycles. These are followed by writing the

“set-up” command. Two more “unlock” write cycles are

then followed by the sector erase command. The

sector address (any address location within the desired

sector) is latched on the falling e dge of WE# (or CE #),

whichever occurs later, while the data is latched on the

rising edge of WE# (or CE#) pulse, whichever occurs

first. A time-out of 80 µs from the rising edge of the last

sector erase command will initiate the sector erase

command.

Multiple sectors can be specified for erase by writing

the six bus cycle operation as described above and

then following it by additional writes of the Sector Erase

command to addresses of ot her sectors to be erased.

The time between Sector Erase command writes must

be less than 80 µs, otherwise that command will not be

accepted. It is recommended th at processor int errupts

be disabled during this time to guarantee this condition.

The interrupts can be re-enabled after the last Sector

Erase command is written. A time-out of 80 µs from the

rising edge of the last WE# (or CE#) will initiate the execution of the Sector Erase command(s). If another

falling edge of the WE# (or CE #) occurs within the 80

µs time-out window, the timer is reset. During the 80 µs

window, any command other than Sector Erase or

Erase Suspend written to the de vice will reset the de vice back to Read mode. Once the 80 µs w indow has

timed out, only t he E ra se s usp end co mm and is r e cognized. Note that although the Reset command is not

recognized in the Erase Suspend mo de, the device is

available for read or program operations in sectors that

are not erase suspended. The Erase Suspende d and

Erase Resume commands may be writt en as often as

required during a sector erase operation. Hen ce , once

erase has begun, i t must ultimately c omplete unless

16 AmMCL00XA

Page 17

PRELIMINARY

Hardware Reset is initiated. Loading th e sector erase

registers may be done in any sequence and wi th any

number of sectors (0 to 15).

A Reset command issued after the device ha s begun

execution stops the erase operation, but the data in the

sector will be undefined. In that case, restart the erase

on that sector and allow it to complete.

The automatic sector erase begins after the 80 µs time

out from the rising edge of th e

WE# (or CE#) pulse for

the last sector erase command pulse and terminates

when the data on D7 is “1” (see Write Operation Status

section) at which time the device returns to read mode.

Data Polling must be performed at an address within

any of the sectors being erased.

If DATA Polling or the Toggle Bit indicates the device

has been written with a valid Sector Erase command ,

D3 may be used to determi ne if the sect or erase tim er

window is still open. If D3 is high (‘1’), the internally

controlled erase cycle has begun; attempts to write

subsequent commands to the d evice will be ignored

until the erase operation is co mpleted as indi cated by

the DATA Polling or Toggl e Bit. If D3 is low (‘0’), the

device will accept additional sector erase comman ds.

To be certain the c ommand has bee n accepted, t he

software should check th e status of D3 fol lowin g each

Sector Erase command. If D3 was hig h on the second

status check, the c ommand may not have been

accepted.

It is recomm ended that th e user guaran tee the time

between sector erase command writes be less than 80

µs by disabling the processor interrupts just for the

duration of the Sector Erase (30H) commands. This

approach will ensure that sequential sector erase

command writes will be written to the device whi le the

sector erase timer window is still open.

Figure 4 illustrates the Embedded Erase Algori thm

using typical command strings and bus operations.

Table 9. Embedded Erase Algorithm

Bus

Operation Command Com ments

Standby Wait for V

Write

Read

Embedded Erase

command sequence

6 bus cycle operation

Data Poll or check

BUSY# (RY/BY#)

to verify erasure

CC

ramp

Start

Write Embedded Erase

Command Sequence

(See Tables 5–7)

Data Poll from Device

or wait for BUSY#

(RY/BY#)

Erasure Complete

21138E-5

Figure 4. Embedded Erase Algorithm

Note: The latest release of the software drivers for AMD

Miniature Cards and devices may be downloaded from the

AMD web site at http://www.amd.com.

Embedded Program Algorithm

The Embedded Program setup is a four bus cycle operation that stages the addressed memory location or

memory device for automatic programming.

Once the Embedded Program setup ope ration is performed, the next

active programming operation. Addresses are internally latched on the falling edge of the

pulse. Data i s internally la tched on the rising edge o f

WE# pulse. The rising edge of WE# also begins the

the

programming operation. The system is not required to

provide further control or timing. The d evice will automatically pro vide an adequate internally genera ted

write pulse and verify margin. The autom ati c prog ramming operation is completed when the data on D7 of

the addressed memory secto r or memory device is

equivalent to data written to this bi t (see Write Operation Status section) at which time the device returns to

the Read mode (no write verify command is required).

Addresses are latched on the falling edge of

CE#) during the Embedded Program command execu-

tion and hence the system is not required to keep the

addresses stable during the entire Programming operation. However, once the device completes the

Embedded Program operation, it returns to the Read

mode and addresse s are no longer latched. Since a

verify valid d ata must occur on D7, at this particu lar

instant, the system is requ ired to sup pl y a valid ad dress

input to the device. A system designer has th ree choices

to implement the Embed de d Pro g ram min g a lgor ith m:

WE# pulse causes a transition to an

WE# (or CE#)

WE# (or

AmMCL00XA 17

Page 18

PRELIMINARY

1. The system (CPU) keeps the address valid during

the entire Embedded Programmin g operati on, or

2. Once the system execu tes the Embedded Programming command sequence, the CPU takes

away the address from the device and becomes

free to do other tasks. In this case, the CPU is required to keep track of the valid address by loading

it into a temporary register. When the CPU comes

back for performing Data Polling, it shou ld reassert

the same address.

3. The host may monitor BUSY# (RY/BY#) to determine the status of the Embedded Algorithm in

progress. A “0” indicates that the device i s busy; a

“1” indicates that the algorithm is complete.

However, since the Embedded Programming operation

takes only 9 µs typically, it may be easier for the CPU

to keep the address stable during the entire Embedded

Programming operation instead of reasserting the valid

address during Data Polling. Any commands written to

the device during this peri od will be ignored. Figure 5

and Table 10 illustrate the Embedded Program Algorithm, a typical command string, and bus operation.

Increment

Address

Start

Write Embedded Write Command

Sequence per Tables 5–7

Data Poll Device

or wait for BUSY# (RY/BY#)

N

Y

Y

N

Verify

Data

Last

Address

Completed

Table 10. Embedded Program Algorithm

Bus

Operation Command Comments

Standby Wait for V

Write

Write

Read

Embedded Program

command sequence

Program

Address/Data

3 bus cycle operation

1 bus cycle operation

Data Poll or check

BUSY# (RY/BY#) to

verify program

CC

ramp

21138E-6

Figure 5. Embedded Program Algorithm

Reset Command

The device will autom atically po wer up in the rea d/reset state. In this case, a command sequence is not required to read data. Standard microprocessor cycles

will retrieve array data. This default value ensures that

no spurious alteration of the memory content occurs

during the power transition. Refer to the AC Characteristics section for the specific timing parameters.

The reset operation is initiated by writing the read/reset

command sequence into the command register. Microprocessor read cycles retrieve array data from the

memory. The device remains enabled for reads until

the command register contents are altered.

Sector Erase Suspend

The Erase Suspend command allows the user to interrupt a Sector Erase operation and then perform data

read or programs in a sector not being e rased. This

command is applicable only during the Sector Erase

operation, which includes the time-out period for Sector

Erase. The Erase Suspend command will be ignored if

written during the exe cution of the Chip E rase operation or Embedded Program Algorithm (but will reset the

chip if written improperly dur ing the command sequences.) Writing the Erase Suspend command during

the Sector Erase time-out results in immediate termination of the time-out period and suspension of the erase

operation. Once in Erase Suspend, the device is avail-

18 AmMCL00XA

Page 19

PRELIMINARY

able for read (note that in the Erase Suspend mode, the

Reset/Read command is no t required for read ope rations and is ignored) or pro gram operatio ns in sectors

not being erased. Any other command written during

the Erase Suspend mode will be ignored, except for the

Erase Resume comman d. Writing the Erase Re sume

command resumes the sector erase operation. The addresses are “don’t cares” when writing the Erase Suspend or Erase Resume command.

When the Erase Suspend command is written during a

Sector Erase operati on, the chip wi ll take between 0.1

µs and 20 µs to actually suspend the operation and go

into erase suspended read mode (pseudo-read mode),

at which time the user can read or program from a sector that is not erase suspended. Re ading data in this

mode is the s ame as readi ng from th e standard re ad

mode, except that the data must be read from sectors

that have not been erase suspended.

Successively reading from the erase-suspended sector while the device is in the erase-suspend-read mode

will cause D2 to toggle. Polling D2 on successive reads

from a given sector provides t he system the ability to

determine if a sector is in Erase Suspend.

After entering the erase-suspend -read mode , the user

can program the device by writing the appropriate command sequence for Byte Program. This program mode

is known as the erase suspend-program mode. Again,

programming in this mode is the same as programming

in the regular Byte Program mode, except that the data

must be programmed to sectors that are not erase suspended. Successively reading from the erase suspended sector while the device is in the erase

suspend-program mode wi ll cause D 2 to tog gle . Completion of the erase suspend operation can be determined two ways:

■ Checking the status of the toggle bit D2

■ Checking the status of the RY/BY# pin

To resume t he o perat ion of Secto r Erase, the Resume

command (30H) should be written. Any further writes of

the Resume command at this point will be ignored.

However, another Erase Susp end command can be

written after the device has resumed sector erase operations.

Write Operation Status

Table 11 shows the status bit states for device program

and erase operations.

ded Program Algorithm, an attem pt to rea d th e device

will produce the true data last writ ten to D7. Note that

just at the instant w hen D7 switches to true d ata, the

other bits, D6–D0, may not yet b e true data . H owever,

they will all be true data on the next read from the device. Please note that Data Polling (D7) may give an

inaccurate result when an attempt is made to write

to a protected sector. During an Embedded Erase Al-

gorithm, an attempt to read the device will produce a ‘0’

at the D7 output. Upon completion of the Embedded

Erase Algorithm, an attempt to read

the device will produce a ‘1’ at D7.

START

DQ7 = Data?

No

No

Note: D7 is rechecked even if D5 = 1 because D7 may

change simulta neo us ly with D5.

DQ5 = 1?

Yes

DQ7 = Data?

No

FAIL PASS

Yes

Yes

21138E-7

Figure 6. Data Polling Algorithm

Data Polling—D7 (D15 on Odd Byte)

The Miniature card features DATA Polling as a method

to indicate to the host system that the embedded algorithms are in progress or completed.

During the Embedded P rogram Algorithm , an attempt

to read the device wil l produce the compliment o f the

data last written to D7. Upon completion of the Embed-

AmMCL00XA 19

Page 20

PRELIMINARY

Table 11. Hardware Sequence Flags

Status D7 D6 D5 D3 D2

Byte Program in Embedded Program Algorithm D7 Toggle 0 0 1

Embedded Erase Algorithm 0 Toggle 0 1 Toggle

Erase Suspend Read

In Progress

Erase Suspended Mode

Byte Program in Embedded Program Algorithm D7 Toggle 1 0 1

Exceeded

Time Limits

Notes:

1. Performing successive read operations from the erase-suspended sector will cause D2 to toggle.

2. Performing successive read operations from any address will cause D6 to toggle.

3. Reading the byte address being programmed while in the erase-suspend program mode will indicate logic “1” at the D2 bit.

However, successive reads from the erase-suspended sector will cause D2 to toggle.

Program/Erase in Embedded Erase Algorithm 0 Toggle 1 1 N/A

Erase Suspended Mode

BUSY# (RY/BY#—Ready/Busy)

The BUSY# signal indicates to the host the status of

operations with in the Miniature Card. Th e BUSY#

signal is tied to the components’ RY/BY# pins.

The RY/BY# signal from AMD Flash devices in

the Miniature Card indicate that the Emb ed de d Algo rithms are eit her in pro gress or have been co mpleted.

If the output is low, the device is busy with either a

program or erase operation. If the output is high, the

device is ready to accept any read/write or erase operation. When the RY/BY# pin is low, the device will

not accept any additi onal program or erase commands with the ex ception o f the Er ase Suspen d command. If a Flash device is placed in an Erase

Suspend mode, the R Y/BY# output will be high. Refer

to the section “Se cto r Er a se Susp end” fo r mo re i nf ormation.

(Erase Suspended Sector)

Erase Suspend Read

(Non-Erase Suspended Sector)

Erase Suspend Program

(Non-Erase Suspended Sector)

Erase Suspend Program

(Non-Erase Suspended Sector)

WORD-WIDE PROGRAMMING

The Word-Wide Programming sequence will be as

usual per Table 5. The Program word command is

A0A0H. Each byte is inde pendently pro grammed. For

example, if the high byte of the word indicates

the successfu l completion of programming via one of

its write status bits such as D15, software polling

should con tinue to monitor the low byte for write co mpletion and data verifica tion, or vice versa. During the

Embedded Programming operations the device executes programming pulses in 9 µs increments.

WORD-WIDE SECTOR ERASING

The Word-Wide Sector Erasing of a memory device

pair is similar to word-wide programming. The erase

word command is a six-bus-cycle command sequence

(see T able 5). Each sector is independently erased and

1100

Data Data Data Data Data

D7

D7 Toggle 1 1 N/A

Toggle

(Note 2)

01

Toggle

(Note 1)

1

(Note 3)

verified. Word-wide erasure reduces total erase time

when compared to byte erasure. Each Flash memory

device in the card may erase at different rates. Therefore, each device (byte) must be verified separately.

20 AmMCL00XA

Page 21

PRELIMINARY

ABSOLUTE MAXIMUM RATINGS

Storage Temperature . . . . . . . . . . . . . –40°C to +90°C

Ambient Temperature

with Power Applied . . . . . . . . . . . . . . –40°C to +85°C

Vo ltage at All Pins (Note 1) . . . . –0.5 V to V

V

(Note 1) . . . . . . . . . . . . . . . . . . . .–0.5 V to 3.6 V

CC

Output Short Circuit Current (Note 2) . . . . . . 200 mA

Notes:

1. Minimum DC voltage on input or I/O pin s is –0.5 V . During

voltage transitions, inputs may overshoot V

for periods of up to 20 ns. Max imum DC voltage on output

and I/O pins is VCC + 0.5 V. During voltage transitions,

outputs may overshoot to V

20ns.

2. No more than one output shorted at a time. Duration of

the short circuit should not be greater than one second.

Conditions equal V

These values are chosen to avoid test problems caused

= 0.5 V or 3.6 V, VCC = V

OUT

+ 2.0 V for periods up to

CC

CC

to –2.0 V

SS

+0.5 V

CCmax

.

by tester ground d egrada tion. Th is paramete r is sample d

and not 100% tested , but guarante ed by charac terization.

3. Stresses above those listed under “Absolute Maximum

Ratings” may cause perman ent damage to the devi ce.

This is a stre ss ra ting on ly; fu nct ion al ope ration of th e device at these or any other condit ion s abo ve those indicated in the operational sections of this specification is

not implied. Exposu re of the device to absolute maximu m

rating conditions for extended periods may affect device

reliability.

OPERATING RANGES

Commercial Devices

Case Temperature (T

Industrial (I) Devices

Case Temperature (T

V

Supply Voltages

CC

AmMCL00XAWP-150 . . . . . . . . . . . . +2.7 V to +3.6 V

Operating ranges define those limi ts betwe en whic h the

functionality of the device is gua ranteed.

). . . . . . . . . . . . . .0°C to +70°C

C

). . . . . . . . . . . .–40°C to +85°C

C

AmMCL00XA 21

Page 22

PRELIMINARY

DC CHARACTERISTICS

Parameter

Symbol Parameter Description Test Conditions Min Max Unit

I

V

Notes:

1. V

I

I

LO

CCS

I

CC

V

V

V

V

LKO

CC

LI

IL

IH

OL

OH

Input Leakage Current VIN = VSS to V

Output Leakage Current VIN = VSS to V

CEL#, CEH#, RESET# = VCC ± 0.3

VCC Standby Current

VCC Supply Current, word

mode (Note 2)

V

= 3.6V; VIN = VSS or V

V

CC

RESET# = VIH; CEL# and CEH# =

V

IL

CC, VCC

CC, VCC

= V

= V

CC max

CC max

CC

2 Mbyte 30 µA

4 Mbyte 40 µA

Read 40 mA

Write 60 mA

Input Low Voltage –0.5 0.8 V

Input High Voltage 0.7 V

Output Low Voltage I

Output High Voltage I

= 5.8 mA 0.45 V

OUT

= –2.0 mA 0.85 V

OUT

CCVCC

CC

Low VCC Lock-Out Voltage 2.3 2.5 V

2. Supply current is a max RMS value. Read frequ ency = 5

= 2.7 V to 3.6 V.

MHz.

±5 µA

±5 µA

+ 0.5 V

CONNECTOR DC SPECIFICATIONS

Parameter Min Max Units

Interface Signal Resistance (Note 2) 2.0 Ω

V

Interface Signal Current (Notes 1, 2) 125 mA

Power/Insertion Signal Resistance 0.060 Ω

Power/Insertion Signal Current (Note 1) 500 mA

Notes:

1. This current is a minimum that the connector should withstand, and a maximum that the host should provide.

2. On the host, these specifications must be met for one conducting channel on elastomeric connectors.

CARD AND PAD CAPACITANCE

Parameter Symbol Parameter Description Test Conditions Max Unit

C

CARD

C

HOST

C

I/O Capacitance D0-D15 40 pF

I/O

Notes:

1. Sampled, not 100% tested.

2. Test conditions TA = 25°C, f = 1.0 MHz.

Card Input Capacitance 40 pF

System Load Capacitance 120 pF

22 AmMCL00XA

Page 23

AC CHARACTERISTICS

Read-only Operations

Parameter Symbol

Parameter Description -150 UnitJEDEC Standard

PRELIMINARY

t

AVAV

t

ELQV

t

AVQV

t

GLQV

t

ELQX

t

EHQZ

t

GLQX

t

GHQZ

t

AXQX

t

RC

t

CE

t

ACC

t

OE

t

LZ

t

DF

t

OLZ

t

DF

t

OH

t

Ready

Read Cycle Time Min

150

ns

Chip Enable Access Time Max 150 ns

Address Access Time Max 150 ns

Output Enable Access Time Max 50 ns

Chip Enable to Output in Low-Z Min 5 ns

Chip Disable to Output in High-Z Max 30 ns

Output Enable to Output in Low-Z Min 5 ns

Output Disable to Output in High-Z Max 30 ns

Output Hold from First of Address, CE#, or OE# Change Min 5 ns

RESET# Pin Low to Read Mode Max 20 µs

AmMCL00XA 23

Page 24

AC CHARACTERISTICS

Write Operations (Erase/Program)

Parameter Symbols

Parameter Description -150 UnitJEDEC Standard

PRELIMINARY

t

AVAV

t

WLWH

t

ELGL

t

ELWL

t

AVGL

t

AVWL

t

DVWH

t

WHDX

t

WHAX

t

WHEH

t

WHWH1

t

WHWH2

t

WC

t

RP

t

BUSY

Write Cycle Time Min 150 ns

WE# pulse width Min 50 ns

CE# setup time to WE# or OE# active Min 0 ns

Address setup time to WE# or OE# active Min 0 ns

Data setup time to WE# inactive Min 50 ns

Data hold time from WE# inactive Min 0 ns

Address hold time from WE# inactive Min 0 ns

CE# hold time from WE# inactive Min 0 n s

RESET# Pulse Width Min 500 ns

Program/Erase Valid to RY/BY# Delay Min 90 ns

Typ 9

Programming Operation

Max 300 µs

Typ 1.5

Sector Erase Operation

Max 15 s

24 AmMCL00XA

Page 25

KEY TO SWITCHING WAVEFORMS

WAVEFORM INPUTS OUTPUTS

PRELIMINARY

SWITCHING WAVEFORMS

Must be

Steady

May

Change

from H to L

May

Change

from L to H

Don’t Care,

Any Change

Permitted

Does Not

Apply

Will be

Steady

Will be

Changing

from H to L

Will be

Changing

from L to H

Changing,

State

Unknown

Center

Line is HighImpedance

“Off” State

KS000010

A0–A25

CEL#/CEH#

OE#

D0–D15

t

AVGL

t

ELGL

t

ELQNZ

t

AVQV

t

t

GLQNZ

ELQV

t

AVAV

t

GLQV

Valid Data

t

AXQX

t

EHQX

t

GHQZ

t

GHQX

Figure 7. AC Waveforms for Read Operations

AmMCL00XA 25

21138E-8

Page 26

SWITCHING W AVEFORMS

PRELIMINARY

A0–A25

CEL#/CEH#

WE#

D0–D15

t

AVAV

t

AVWL

t

ELWL

t

WLWH

t

DVWH

t

Valid Data

Figure 8. AC Waveforms for Write Operations

t

WHAX

t

WHEH

WHDX

21138E-9

t

CE#

OE#

WE#

D7

D0–D6

CH

t

OEH

t

OE

t

CE

t

WHWH1 or tWHWH2

D7#

D0–D6=Invalid

*D7=Valid Data (The device has completed the Embedded operation).

*

t

OH

D7=

Valid Data

D0–D7

Valid Data

t

DF

High Z

21138E-10

Figure 9. AC Waveforms for Data Polling During Embedded Algorithm Operations

26 AmMCL00XA

Page 27

SWITCHING W AVEFORMS

CE#

PRELIMINARY

The rising edge of the last WE# signal

WE#

Entire programming

or erase operations

RY/BY#

t

BUSY

Figure 10. RY/BY# Timing Diagram During Program/Erase Operations

RESET#

t

RP

t

Ready

Figure 11. RESET# Timing Diagram

21138E-11

21138E-12

AmMCL00XA 27

Page 28

PRELIMINARY

AC CHARACTERISTICS-ALTERNATE CE# CONTROLLED WRITES

Write/Erase/Program Operations

Parameter Symbols

Parameter Description -150 UnitJEDEC Standard

t

AVAV

t

AVEL

t

ELAX

t

DVEH

t

EHDX

t

GLDV

t

GHEL

t

WLEL

t

EHWH

t

ELEH

t

EHEL

t

EHEH3

t

EHEH4

t

VCS

t

WC

t

AS

t

AH

t

DS

t

DH

t

OEH

t

WS

t

WH

t

CP

t

CPH

Write Cycle Time Min 150 ns

Address Setup Time Min 10 ns

Address Hold Time Min 50 ns

Data Setup Time Min 50 ns

Data Hold Time Min 0 ns

Output Enable Hold Time for Embedded Algorithm Min 10 ns

Read Recovery Time before Write Min 0 µs

WE# Setup Time before CE# Min 0 ns

WE# Hold Time Min 0 ns

CE# Pulse Width Min 50 ns

CE# Pulse Width HIGH (Note 3) Min 20 ns

Embedded Programming Operation (Notes 3,4)

Embedded Erase Operati on for each 64K byte Memo ry

Sector (Notes 1, 2)

VCC Setup Time to Write Enable LOW Min 50 µs

Typ 9

Max 300 µs

Typ 1.5

Max 15 s

Notes:

≤

1. Rise/fall time

10 ns.

2. Maximum specification not needed due to the internal stop timer that will stop any erase or write operation that exceed the

device specification.

3. Card Enable Controlled Programming:

Flash Programming is controlled by the valid combination of the Card Enable (CE1#, CE2#) and Write Enable (WE#) signals.

For systems that use the Card Enable sign al(s) to define the wri te pulse width, all setup, hold, and in active write enab le timing

should be measured relative to the Card Enable signal(s).

°

4. Under worst case condition of 90

C, Vcc = 2.7 V , 100 ,000 cycles. Excludes sy ste m level overhead, the time require d to

execute the four bus cycle command necessary to program each byte.

28 AmMCL00XA

Page 29

PRELIMINARY

Addresses

t

WC

XXXXh

t

AS

PA PA

t

AH

WE#

t

WH

OE#

t

GHEL

t

CE#

Data

V

CC

t

VCS

t

WS

A0h

CP

t

CPH

t

DS

t

DH

PD

t

Notes:

1. PA is address of the memory location to be programmed.

2. PD is data to be programmed at byte address.

3. D7 is the complement of the data written to the device.

4. D

is the data written to the device.

OUT

5. Figure indicates last two bus cy cl es of four bus cyc le seq ue nce.

6. These waveforms are for the x16 mode.

Figure 12. Alternate CE# Controlled Write Operation Timings

Data# Polling

EHEH3_or_4

DQ7# D

OUT

21138E-13

AIS MEMORY MAP

The AIS (Attribute Information Structure) is an area of

memory used for storing informa tion a bout the co nfiguration of the Miniature Card. The AIS is recommended

to be stored in the first sector of the first device of the

Flash array. As this area is not explicitly protected , the

AIS information must b e reloaded o nto the card in the

event that the information is erased.

The AIS has five unique information areas:

1. Identification Data: This data includes Manufacturer

information (Manufacturer and card name).

2. Compatibility Data: This data spe cifies basic information about the card (memo ry size, access time,

memory type, power, etc.)

3. Burst Data (not applicable)

4. DRAM Data (not applicable)

5. Reserved Data: This data area is reserved for future use.

AmMCL00XA 29

The AIS supports up to four different memory technologies on a card. Some of the information areas are

repeated in the memory map in order to specify different technologies (see Table 12). The Technology

Count field in the Identification Data section defines the

number of different technologies on a card. The first

memory technology is defined in the AIS memory map

from address 40H through 7FH. The second memory

technology is defined from 80H through BFH. The third

memory technology is d efined from C0 H to DFH. Th e

fourth memory technology is defined from E0H to FFH.

The AIS is stored as bytes within the 16-bit Miniature

Card data word. The even byte D0–D 7 stores the AIS

data, and the odd byte D8–D15 is reserved by the card

manufacturer for manufact uring informa tion.

Page 30

PRELIMINARY

Table 12. Miniature Card AIS Memory Assignments

Card Address Sectio n Description

00h–0Fh PC Card Compatibility Area* Reserved for PC Card Tuples

10h–1Fh Identification Data Identifies Card Type

20h–2Fh Identification Data Identifies Card Type

30h–3Fh Identification Data Identifies Card Type

40h–4Fh Compatibility Data (Area 1) Memory Technology #1

50h–5Fh Burst Data (not applicable)

60h–6Fh DRAM Data (not applicable)

70h–7Fh Reserved for future use

80h–8Fh Compatibility Data (not applicable) (Memory Technology #2)

90h–9Fh Burst Data (not applicable)

A0h–AFh DRAM Data (not applicable)

B0h–BFh Reserved for future use

C0h–CFh Compatibility Data (not applicable) (Memory Technology #3)

D0h–DFh Reserved for future use

E0h–EFh Compatibility Data (not applicable) (Memory Technology #4)

F0h–FFh Reserved for future use

* For more information on PC Card Compatibility refer to table 13 or the Miniature Card PC Compatibility Guide.

Note: “Not applicable” indic ate s the add res s spa ce does not app ly to AMD Flash Miniat ure Cards , but is defin ed by MCIF.

30 AmMCL00XA

Page 31

PRELIMINARY

Table 13. PC Card Compatibility Memory Assignments

Address Values Description

00h 01h TPL_CODE CISTPL_DEVICE

01h 03h TPL_LINK

02h 53 Device ID

03h 2 MB = 7C, 4 MB = FC Device Size

04h FF End of CISTPL_DEVICE

05h 1Ch TPL_CODE CISTPL_DEVICE_OC

06h 03h TPL_LINK

07h 53h Device ID

08h 2MB = 7C; 4MB = FC Device Size

09h FFh End of CISTPL_DEVICE_OC

0Ah 00h CISTPL_NULL

0Bh 00h CISTPL_NULL

0Ch 00h CISTPL_NULL

0Dh 00h CISTPL_NULL

0Eh 80h TPL_CODE CISTPL_MINI

0Fh F0h TPL_LINK

AmMCL00XA 31

Page 32

PRELIMINARY

Identification Data

The identificati on data provides b asic identification

information about the card . This data section is

required on all cards. Table 14 shows the Identification

Data for AMD’s 3 volt-only Miniature cards.

Compatibility Data

The compatibility data provides basic compatibility

across all cards. Thi s data section is requ ired on all

cards. The addresses in parentheses are specified for

cards with more than one memory technology on the

card. Table 15 shows the compatibility data for AMD

3-volt only Miniature Cards

Table 14. AMD Identification Data

Card Address Value Description

10h 99h

11h 11h

12h 78h or 76h

13h 41h

Miniature Card Identifier: Fix ed value for a host to ident ify an inse rted

Miniature Card

Level of Compliance: Defines the level of AIS supported. The

Miniature Cards described in this document are rev 1.1 compliant.

AIS Checksum: The modulo-25 6 sum of all even bytes from 10h–FFh.

A valid checksum sums to 00H (2’s complemen t).

9

2 Mbyte card: 88h + 78h = 00h

4 Mbyte card: 8Ah + 76h = 00h

Manufacturer Name: 13h–26h. String of ASCII characters at

addresses 13H to 26H to identify the manufacturer of the Miniature

Card.

ASCII character “A”

14h 4Dh ASCII character “M”

15h 44h ASCII character “D”

16h 20h ASCII character - SPACE

17h 49h ASCII character - “I”

18h 4Eh ASCII character - “N”

19h 43h ASCII character - “C”

1Ah 00h ASCII character - NULL

1Bh 00h ASCII character - NULL

1Ch–26h 00h Unused space in manufacturer name field

Card Name: (addresses 27h–3Ah). String of ASCII characters to

27h 33h

28h 56h ASCII character “V”

29h 4Dh ASCII character “M”

2Ah 43h ASCII character “C”

2Bh 20h ASCII character - SPACE

2Ch 53h ASCII character “S”

identify the card name.

ASCII character “3”

2Dh 65h ASCII character “e”

2Eh 72h ASCII character “r”

2Fh 69h ASCII character “i”

30h 65h ASCII character “e”

32 AmMCL00XA

Page 33

PRELIMINARY

Table 14. AMD Identification Data (Continued)

Card Address Value Description

31h 73h ASCII character “s”

32h 00h ASCII character - NULL

33h–3Ah 00h Unused space in card name field

Technology Count: Defines the number of different memory

3Bh 01h

3Ch–3Fh 00h Reserved space set to 00h; for future use

technologies on the Miniature Card.

Technology count set to 1

.

Table 15. AMD Compatibility Data

Card Address Value Description

40h 00h Defines the type of memory technology; Flash = 000 Binary

41h 01h Device JEDEC Manufacturer ID

42h 38h Device JEDEC Component ID: Am29LV081 = 38h

43h 01h or 03h Memory array size: 02 = 2 Mbyte, 04 = 4 Mbyte

44h 00h N/A

45h 0Fh 3.3V access time: 150 ns

46h 00h N/A

47h 00h N/A

48h 24h Typi cal read/ write current at 3.3V : 20 mA read, 40 mA wri te (word mod e)

49h 00h N/A

4Ah 00h Typical card standby current: 10 µA for 2 Mbyte, 40 µA for 4 Mbyte

4Bh–4Fh, 8Ch–8Fh,

CCh–CFh, ECh–EFh

80h–8Bh, C0–CBh,

E0h–EBh

100h 18h TPL_CODE CISTPL_JEDEC_C

101h 02h TPL_LINK

102h 01h Manufacturer ID

103h 38h Device ID

104h 1Eh TPL_CODE CISTPL_DEVICEGEO