Datasheet Am29SL800CT150WBIB, Am29SL800CT150WBI, Am29SL800CT150WBCB, Am29SL800CT150WBC, Am29SL800CT150FIB Datasheet (AMD Advanced Micro Devices)

...Page 1

PRELIMINARY

Am29SL800C

8 Megabi t (1 M x 8-Bit/51 2 K x 16-Bit)

CMOS 1.8 Volt-only Super Low Volta ge Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single p ower supply operation

— 1.8 to 2.2 V for read, program, and erase

operations

— Ideal for battery-powered applications

■ Manufactured on 0.32 µm process technology

— Compatible with 0.35 µm Am29SL800B device

■ High performance

— Access times as fast as 100 ns

■ Ultra low power consumption (typical values at

5 MHz)

— 65 nA Automatic Sleep Mode current

— 65 nA standby mode current

— 5 mA read current

— 10 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

fifteen 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

fifteen 32 Kword sectors (word mode)

— Supports full chip erase

— Sector Protection features:

A hardwar e me tho d of lockin g a sec to r to

prevent any program or erase operations wi thin

that sector

Sectors can be locked in-system or via

programming equipment

T emporary Sector Unprotect feature allows code

changes in previously locked sectors

■ Unlock Bypass Program Command

— Reduces overall programming time when

issui ng mult iple program command sequences

■ Top or bottom boot block configurations

available

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Minimum 1,000,000 write cycle guarantee per

sector

■ Package option

— 48-pin TSOP

— 48-ball FBGA

■ Compatibility with JEDEC standards

— Pinout and software compatible with single-

power supply Flash

— Superior inadvertent write protection

■ Data# Polling a nd toggle bits

— Provides a software method of detecting

program or erase operation completion

■ Ready/Bu sy # pin (RY/BY#)

— Provides a hardware method of detecting

program or erase cycle completion

■ Erase Sus pe nd /Er as e R es ume

— Suspends an erase operation to read data from,

or program data to, a sector th at is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the device to reading

array data

This do c um ent contains information on a product under d evel opment at A dvanced Mi c r o Devices. The inform ation

is intended to help you evaluate this product. AMD reserves the right to change or discontinue work on this proposed

product without notice.

Refer to AMD’s Website (www.amd.com) for the latest information.

Publication# 22230 Rev: A Amendment/0

Issu e Dat e: August 1998

Page 2

PRELIMINARY

GENERAL DESCRIPTION

The Am 29SL 800C i s an 8 M bit, 1.8 V vol t-only Flas h

memory organized as 1,048,576 bytes or 524,288

words. The d evice is offe red in 48 -pin TSOP and 48 ball FBGA packages. The word-wide data (x16)

appears on DQ15–DQ0; the byte-wide (x8) data

appear s on DQ7– DQ0. T his de vice is d esigne d to be

programmed and erased in-system with a single 1.8

volt V

The device c an also be program med in standard

EPROM programmers.

The standard device offers access times of 100, 120,

and 150 ns, allowing high speed microprocessors to

operate without wait states. To eliminate bus contention

the device has separate chip enable (CE#), write

enable (WE#) and output enable (OE#) controls.

The de vi ce re q ui r es on l y a single 1.8 volt power sup-

ply for both read and write functions. Internally generated and regulated voltage s are provided for th e

program and erase operations.

The device is entirely command set compatible with the

JEDEC single-power-supply Flash standard. Commands are written to the command register using

standard microprocessor write timings. Register contents serve as input to an internal state-machine that

controls the erase and programming circuitr y. Write

cycles also internally latch addresses and data needed

for the programming and erase operations. Reading

data ou t of the d evice is simi lar to re ading fr om othe r

Flash or EPRO M devices .

Device pro gram m ing oc cu rs by executing the program

command sequence. This initiates the Embedded

Program algorithm—an internal algorithm that automatically times the program pulse widths and verifies

proper cell margin. The Unlock Bypass mode facilitates faster programming times by requiring only two

write cycles to program data instead of four.

Device erasure occurs by ex ecuting the erase command

sequence. This initiates the Embedded Erase algorithm—an i nternal algo rithm tha t automatically prep rograms the array (if it is not already programmed) before

executing the erase operation. During erase, the device

automatically times the erase pulse widths and verifies

proper cell margin.

supply. No VPP is for wr ite or era se oper ations .

CC

The ho st system ca n detect whe ther a progra m or

erase op eration is co mp lete by ob ser vin g t he RY/BY#

pin, or by reading the DQ7 (Data# Polling) and DQ6

(toggle ) st atus bit s. After a program or erase cycle has

been completed, the device is ready to read array data

or accept another command.

The sector erase architecture allows memory sectors

to be erased and reprogrammed without affecting the

data contents of other sectors. The device is fully

eras ed when shipped f r om the factory.

Hardware data protection measures includ e a low

V

detector that auto matically inhibits write opera-

CC

tions during power transitions. The hardware sector

protection feature disables both program and erase

operatio ns in any com binatio n of the s ectors of m emory. This can be achieved in-system or via programming equipment.

The Erase Suspend feature enables the user to put

erase on ho ld for any pe r i od of tim e to rea d da ta fr om ,

or program d ata to, any secto r that is not se lected for

erasure. True background erase can thus be achieved.

The hardware RESET# pin terminates any operation

in progress and resets the internal state machine to

reading array data. T he RESET# pin ma y b e tied to t he

system rese t circuitr y. A system reset would thus a lso

reset the device, enabling the system micropr ocessor

to read the boot-up firmware from the Flash memory.

The device offers two power-saving features. When addresses have been stable for a specified amount of

time, the device enters the automatic sleep mode.

The system can also place the device into the standby

mode. Power consumption is greatly reduced in both

these modes.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability and cost effectiveness. The device electrically erases all bit s with in

a sector simultaneously via Fowler-Nordheim tunneling. The data is programmed using hot electron

injection.

2 Am29SL800C

Page 3

PRELIMINARY

PRODUCT SELECTOR GUIDE

Family Part Number Am29SL800C

Speed Options 100 120 150

Max access time, ns (t

Max CE# access time, ns (tCE) 100 120 150

Max OE# access time, ns (tOE) 35 50 65

) 100 120 150

ACC

Note: See “AC Characteristics” for full specifications.

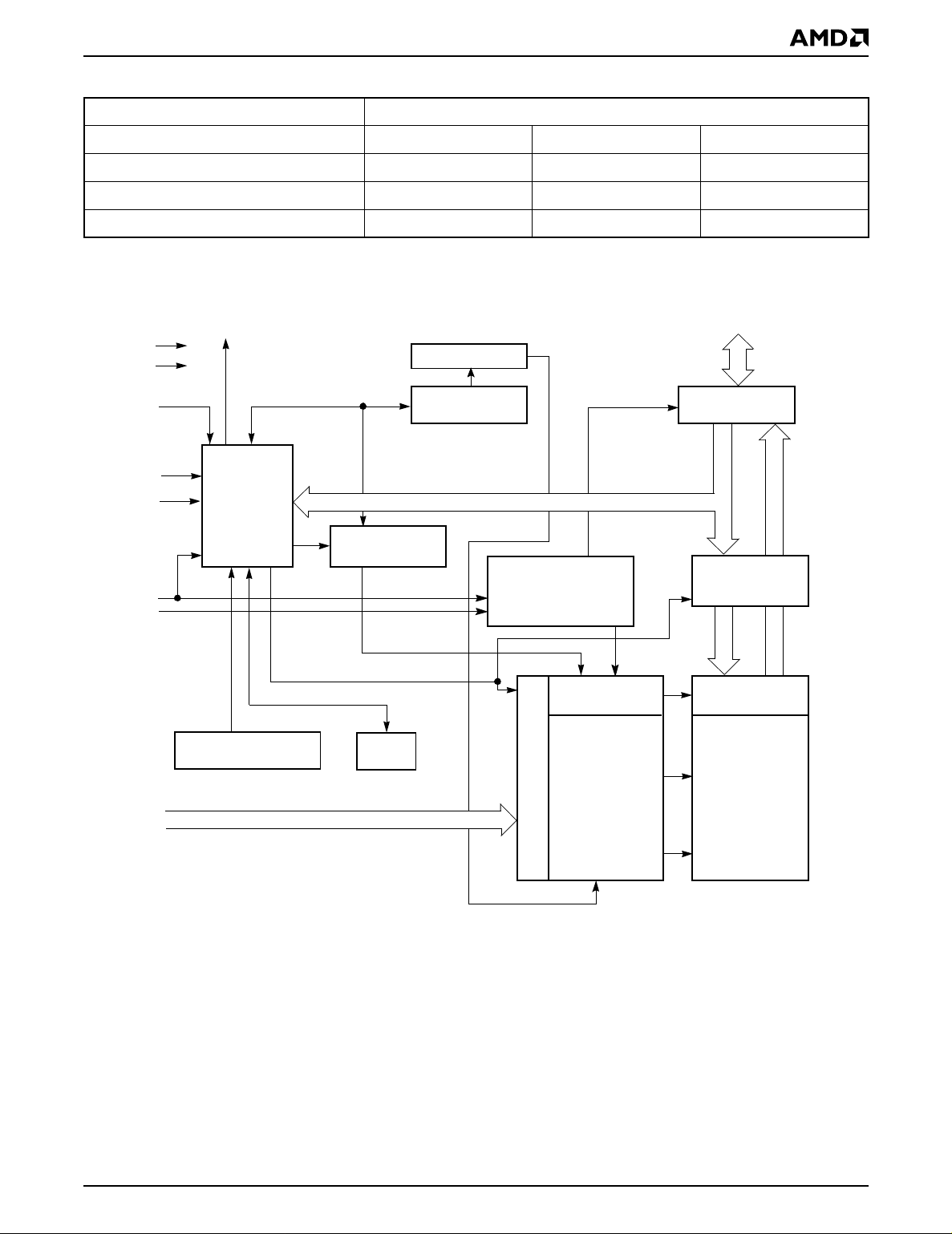

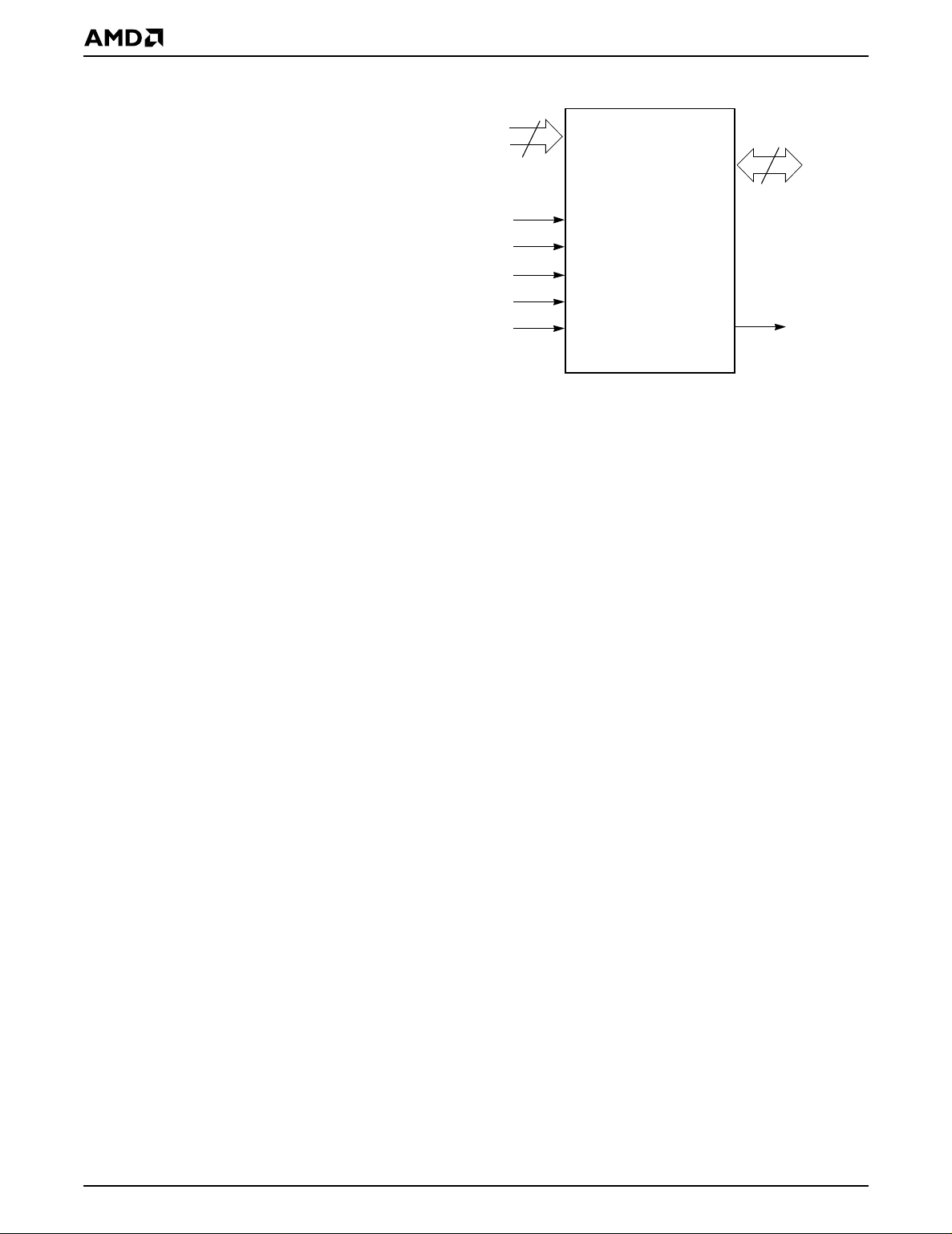

BLOCK DIAGRAM

DQ0

–

DQ15 (A-1)

Input/Output

Buffers

Data

Latch

V

CC

V

SS

RESET#

WE#

BYTE#

CE#

OE#

RY/BY#

State

Control

Command

Register

PGM Voltage

Generator

Sector Switches

Erase Voltage

Generator

Chip Enable

Output Enable

Logic

STB

A0–A18

VCC Detector

Timer

STB

Address Latch

Y-Decoder

X-Decoder

Y-Gating

Cell Matrix

22230A-1

Am29SL800C 3

Page 4

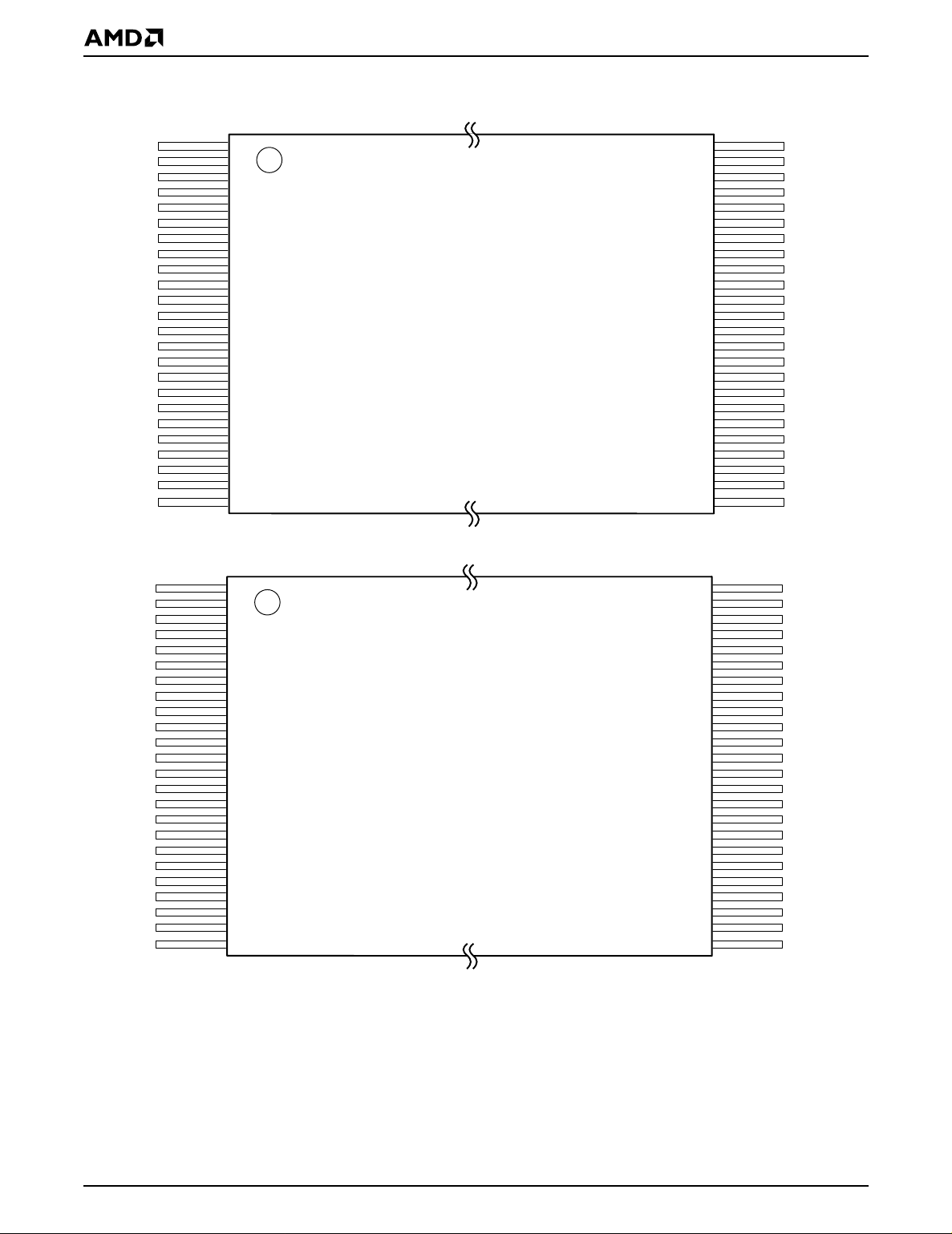

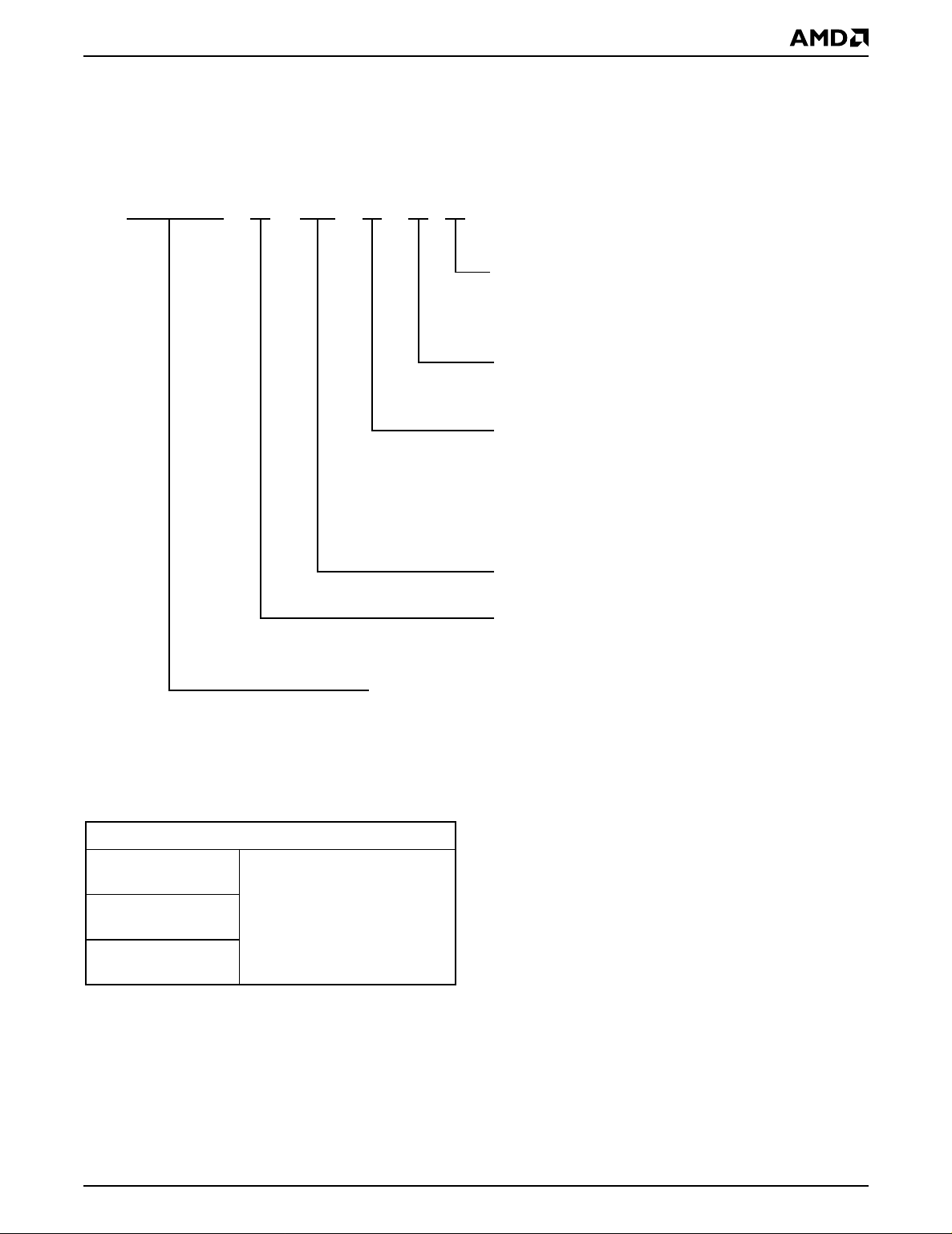

CONNECTION DIAGRAMS

PRELIMINARY

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

4 Am29SL800C

22230A-2

Page 5

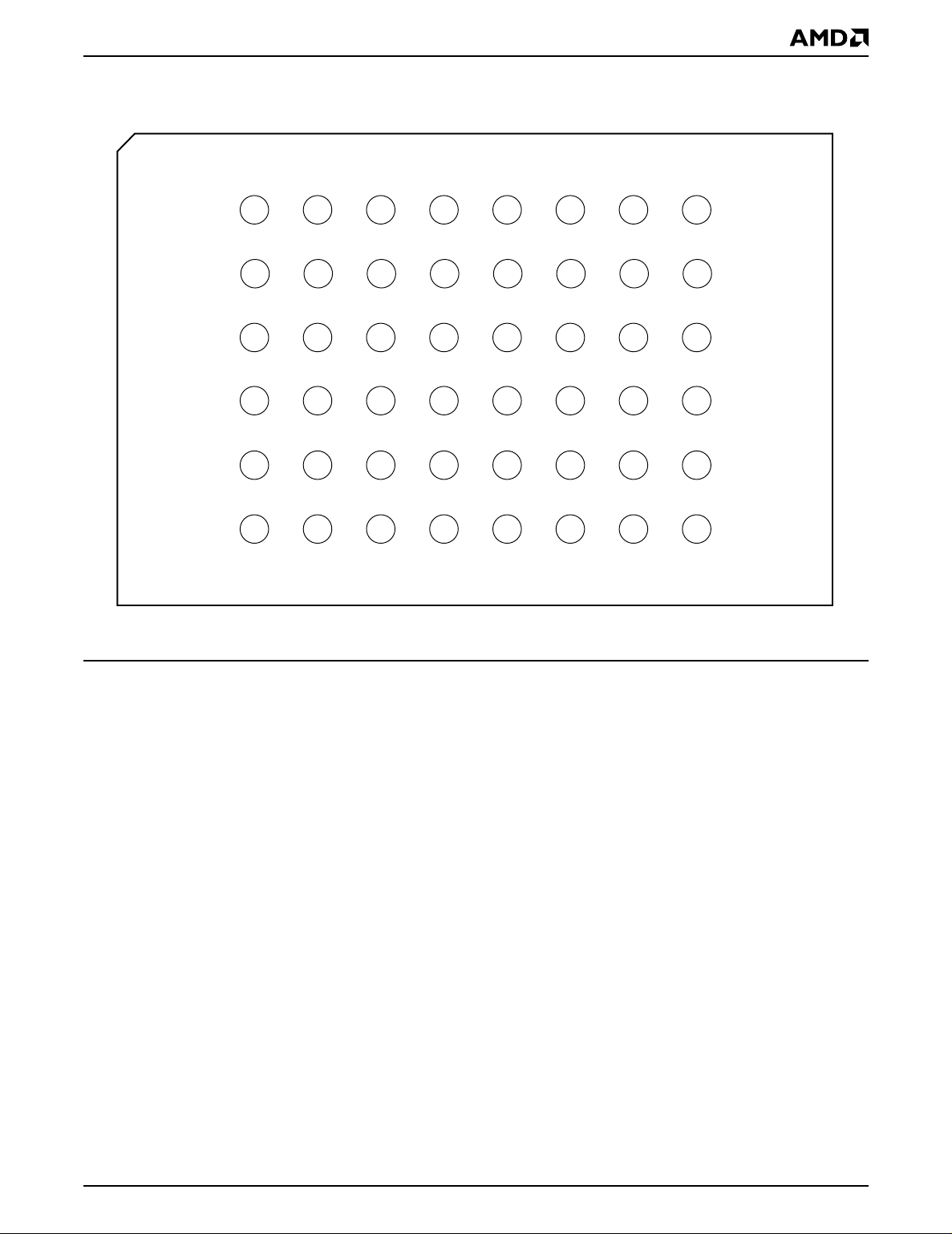

CONNECTION DIAGRAMS

A1 B1 C1 D1 E1 F1 G1 H1

PRELIMINARY

48-Ball FBGA (Bottom View)

A2 B2 C2 D2 E2 F2 G2 H2

A3 B3 C3 D3 E3 F3 G3 H3

A4 B4 C4 D4 E4 F4 G4 H4

A5 B5 C5 D5 E5 F5 G5 H5

A6 B6 C6 D6 E6 F6 G6 H6

Special Handling Instructions for FBGA Packages

Special handling is required for Flash Memory products

in FBGA packages.

CE#A0A1A2A4A3

BYTE#A16A15A14A12A13

OE# V

DQ9 DQ1DQ8DQ0A5A6A17A7

DQ11 DQ3DQ10DQ2NCA18NCRY/BY#

V

CC

DQ13 DQ6DQ14DQ7A11A10A8A9

DQ15/A-1 V

SS

DQ4DQ12DQ5NCNCRESET#WE#

SS

22230A-3

Flash memory devices in FBGA packages may be

damaged if exposed to ultrasonic cleaning methods.

The package and/or data integrity may be compromised

if the package body is exposed to temperatures above

150°C for prolonged periods of time.

Am29SL800C 5

Page 6

PRELIMINARY

PIN CONFIGURATION

A0–A18 = 19 addresse s

DQ0–DQ14 = 15 data inputs/out pu ts

DQ15/A-1 = DQ15 (data input/output, word mode),

A-1 (LSB addre s s input, byte mode)

BYTE# = Selects 8-bit o r 16-bit mode

CE# = Chip enable

OE# = Output enable

WE# = Write en able

RESET# = Hardware reset pin, active low

RY/BY# = Ready/Busy# output

V

= 1.8–2.2 V single power supply

CC

V

SS

NC = Pin not connected internally

= Device ground

LOGIC SYMBOL

19

A0–A18

CE#

OE#

WE#

RESET#

BYTE# RY/BY#

16 or 8

DQ0–DQ15

(A-1)

22230A-4

6 Am29SL800C

Page 7

PRELIMINARY

ORDERING INFORMATION

Standard Products

AMD stan dard produc ts ar e available in several pack ages an d opera ting ranges. Th e orde r numbe r (Valid Comb ination) is formed by a combination of the elements below.

CE100Am29SL800C T

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-in

(Contact an AMD representative for more information)

TEMPERATURE RANGE

C=Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

PACKAGE TYPE

E = 48-Pin Thin Small Outline Package (TSOP)

Standard Pinout (TS 048)

F = 48-Pin Thin Small Outline Package (TSOP)

Reverse Pinout (TSR048)

WB = 48-ball Fine-Pitch Ball Grid Array (FBGA)

0.80 mm pitch, 6 x 9 mm package

Am29SL800CT100,

Am29SL800CB100

Am29SL800CT120,

Am29SL800CB120

Am29SL800CT150,

Am29SL800CB150

Valid Combinations

EC, EI, FC, FI, WBC, WBI

SPEED OPTION

See Product Selector Guide and Valid Combinations

BOOT CODE SECTOR ARCHITECTURE

T = Top Sector

B = Bottom Sector

DEVICE NUMBER/DE SCRIP TION

Am29SL800C

8 Megabit (1 M x 8-Bit/512 K x 16-Bit) CMOS Flash Memory

1.8 Volt-only Read, Program, and Erase

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales

office to confirm availability of specific valid combinations and

to check on newly released combinations.

Am29SL800C 7

Page 8

PRELIMINARY

DEVICE BUS OPERATIONS

This section describes the requirements and use of the

device bus operat ions, whi ch are init iated thro ugh the

internal command register. The command register itself does not occupy any addressable memory location. The register is composed of latches that store the

comman ds, along with the add ress an d data infor mation needed to execute the command. The contents of

Table 1. Am29SL800C Device Bus Operations

Operation CE# OE# WE# RESET#

Read L L H H A

Write L H L H A

V

±

Standby

Output Disable L H H H X High-Z High-Z High-Z

Reset X X X L X High-Z High-Z High-Z

Sector Protect (Note 2) L H L V

Sector Unprotect (Note 2) L H L V

Temporary Sector Unprotect X X X V

Legend:

L = Logic Low = V

Notes:

1. Addresses are A18:A0 in word mode (BYTE# = V

2. The sector protect and sector unprotect functions may also be implemented via programming equipment. See the “Sector

Protection/Unprotection” section.

, H = Logic High = VIH, VID = 10 ± 1.0 V, X = Don’t Care, AIN = Address In, DIN = Data In, D

IL

CC

0.3 V

XX

VCC ±

0.3 V

ID

ID

ID

), A18:A-1 in byte mode (BYTE# = VIL).

IH

the register serve as inputs to the internal state machine. The state machine outputs dictate the function of

the device. Table 1 lists th e d evice bus o pe ratio ns, th e

inputs and control lev els they require, and the resulting

output. The following s ubsections describe each of

these operations in further detail.

DQ8–DQ15

Addresses

(Note 1)

IN

IN

X High-Z High-Z High-Z

Sector Address,

A6 = L, A1 = H,

A0 = L

Sector Address,

A6 = H, A1 = H,

A0 = L

A

IN

DQ0–

DQ7

D

OUT

D

IN

D

IN

D

IN

D

IN

BYTE#

= V

IH

D

OUT

D

IN

XX

XX

D

IN

BYTE#

= V

IL

DQ8–DQ14 = High-Z,

DQ15 = A-1

High-Z

= Data Out

OUT

W ord/Byte Configuration

The BY TE# p in contr ol s whethe r the device data I/O pins

DQ15–DQ0 operate in the byte or word configuration. If the

BYTE# pin is set at logic ‘1’, the device is in word configuration, DQ 15–DQ0 are ac tive and con trolled by CE # and

OE#.

If the BYTE# pin is set at logic ‘0’, the device is in byte configuration, and only data I/O pins DQ0–DQ7 are active and

controlled by CE# and OE#. The data I/O pins DQ8–DQ14

are tri-stated, and the DQ15 pin is used as an input for the

LSB (A-1) address function.

Requirements for Reading Array Data

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This ensures that no spurious alteration of the memory content occurs during the power transition. No co mmand is

necessary in this mode to obtain array data. Standard microproce ssor read cy cles tha t asse rt valid ad dresse s on

the device address inputs produce valid data on the device

data outputs. The device remains enabled for read access

until the command register contents are altered.

See “Reading Array Data” for m ore informati on. Refer to

the AC Read Operations table for timing specifications and

to Figure 13 for the timing diagram. I

teristics table represents the active current specification for

reading array data.

To read array data from the outputs, the system must driv e

the CE# and OE# pins to V

selects the device. OE# is the output control and gates

array data to the ou tput pins. W E# shoul d rem ain at V

The BYTE# pin determines whether the device outputs

array data in words or bytes.

. CE# is the power control and

IL

Writing Commands/Command Sequences

To write a command or command seque nce (whic h in-

.

IH

cludes programming data to the device and erasing sectors

of memory), the syste m must drive WE# and CE# to V

and OE# to V

8 Am29SL800C

in the DC Charac-

CC1

,

.

IH

IL

Page 9

PRELIMINARY

For program operatio ns, the BYTE# pin deter mines

whether the dev ice accepts program data in bytes or

words. Refer to “Word/Byte Configuration” for more information.

The device features an Unlock Bypass mode to facilitate

faster programming. Once the device enters the Unlock

Bypass mode, only two write cycles are required to program a word or byte, instead of four. The “Word/Byte Program Command Sequence” section has details on

programming data to the device using bo th stand ard and

Unlock Bypass command sequences.

An erase operation can erase one sector, multiple sectors,

or the enti re device. Tables 2 and 3 indica te the add ress

space that eac h sector oc cup ie s. A “s ector addr ess ” co nsists of the address bits required to uniquely select a sector.

The “Command Definitions” section has details on erasing

a sector or the entire chip, or suspending/resuming the

erase operation.

After the system writes the autoselect command sequence, the device enters the autoselect mode. The system can then read autoselect codes from the internal

register (whic h is separate from the me mory array) on

DQ7–DQ0. Standard read cycle timings apply in this mode.

Refer to the Autoselect Mode and Autoselect Command

Sequence sections for more information.

I

in the DC Characteristics table repres ents the active

CC2

current speci fic ation fo r the w rite mode . T he “ AC Ch aracteristics” section contains timing specification tables and

timing diagrams for write operations.

Program and Erase Operation Status

During an erase or program operation, the system may

check the status of the operation by reading the status bits

on DQ7–DQ0. Standard read cycle timings and I

CC

read

specificat ions ap ply. Refer to “Write Opera tion Status” for

more information, and to “AC Characteristics” for timing diagrams.

Standby Mode

When the system is not reading or writing to the device, it

can plac e t he device in th e stan dby mo de. In th is m ode,

current consumption is greatly reduced, and the outputs

are placed in the high impedance state, independent of the

OE# input.

The device enters the CMOS standby mode when the CE#

and RESET# pins are both held at V

this is a more restricted voltage range than V

RESET# are held at V

, but not within V

IH

vice will be in the standby mode, but the standby current will

be greater. The device requires standard access time (t

for re ad ac ces s when th e devic e is i n ei ther of t hese

standby modes, before it is ready to read data.

The device also enters the standby mode when the RESET# pin is driven low. Ref er to the next section, RESET#:

Hardware Reset Pin.

± 0.3 V. (Note that

CC

.) If CE# and

IH

± 0.3 V, the de-

CC

CE

If the device is deselected during erasure or programming,

the de vice dra w s act ive cur r e nt unt i l the o p er a t io n is completed.

I

in the DC Characteristics table represents the standby

CC3

current specification.

Aut oma ti c S lee p Mod e

The automatic sleep mode minimizes Flash device energy

consumption. The device automatically enables this mode

when addresses remain stable for t

ACC

automatic sleep mode is independent of the CE#, WE#,

and OE# control signals. Standard address access timings

provide new data when addresses are changed. Whi le in

sleep mode, output data is latched and always a vailable to

the system. I

in the DC Characteristics table represents

CC4

the automatic sleep mode current specification.

RESET#: Hardware Rese t Pi n

The RESET# pin provides a hardware method of resetting

the device to reading array data. When the RESET# pin is

driven low for at l east a p er io d o f t

ately terminates any operation in progress, tristates all

output pins, and ignores all read/write commands for the

duration of the RESET# pulse. The device also resets the

internal state machine to reading array data. The operation

that was interrupted should be reinitiated once the device is

ready to accept another command sequence, to ensure

data integrity.

Current is reduced for the duration of the RESET# pulse.

When RESET# is held at V

CMOS standby current (I

not within V

±0.3 V, the standby current will be greater.

SS

SS

). If RESET# is held at VIL but

CC4

The RESET# pin may be tied to the system reset circuitry.

A system reset woul d thus also rese t the Fla sh memor y,

enabling the system to read the boot-up firmware from the

Flash m e mory.

If RESET# is asserted during a program or erase operation, the RY/BY# pin remains a “0” (busy) until the internal

reset operation is complete, which requires a time of

t

(during Embedded Algorithms). The system can

READY

thus monitor RY/BY# to determine whether the reset operation is complete. If RESET# is asserted when a program

or erase operation is not executing (RY/BY# pin is “1”), the

reset operation is completed within a time of t

during Embedded Algorithms). The system can read data

t

after the RESET# pin returns to VIH.

RH

Refer to the AC Characteristics tables for RESET# parameters and to Figure 14 for the timing diagram.

Output Disable Mode

)

When the OE# input is at VIH, output from the device is disabled. The out put pi ns are plac ed in the high impedan ce

state.

, the device immedi-

RP

±0.3 V, the device draws

+ 50 ns. The

(not

READY

Am29SL800C 9

Page 10

PRELIMINARY

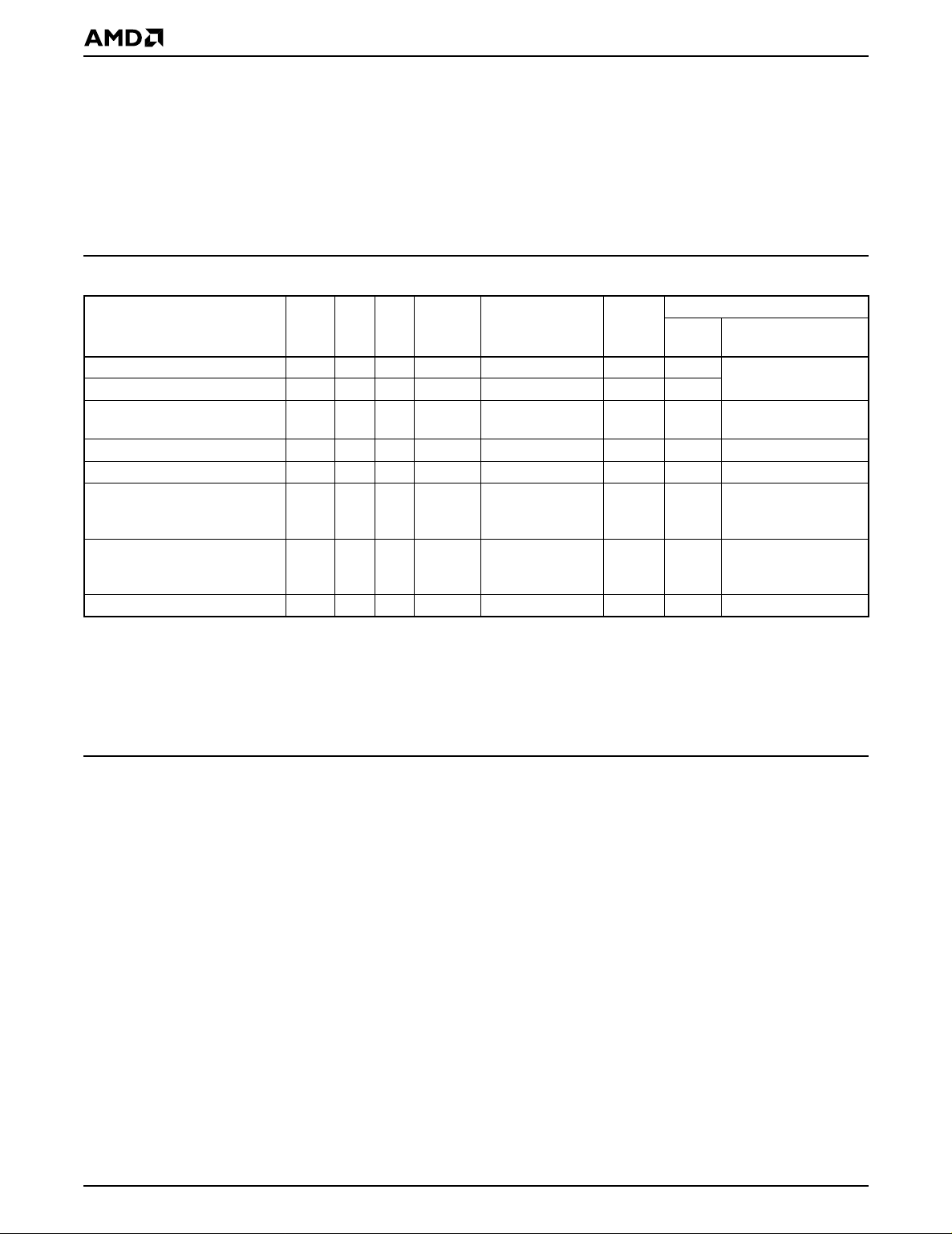

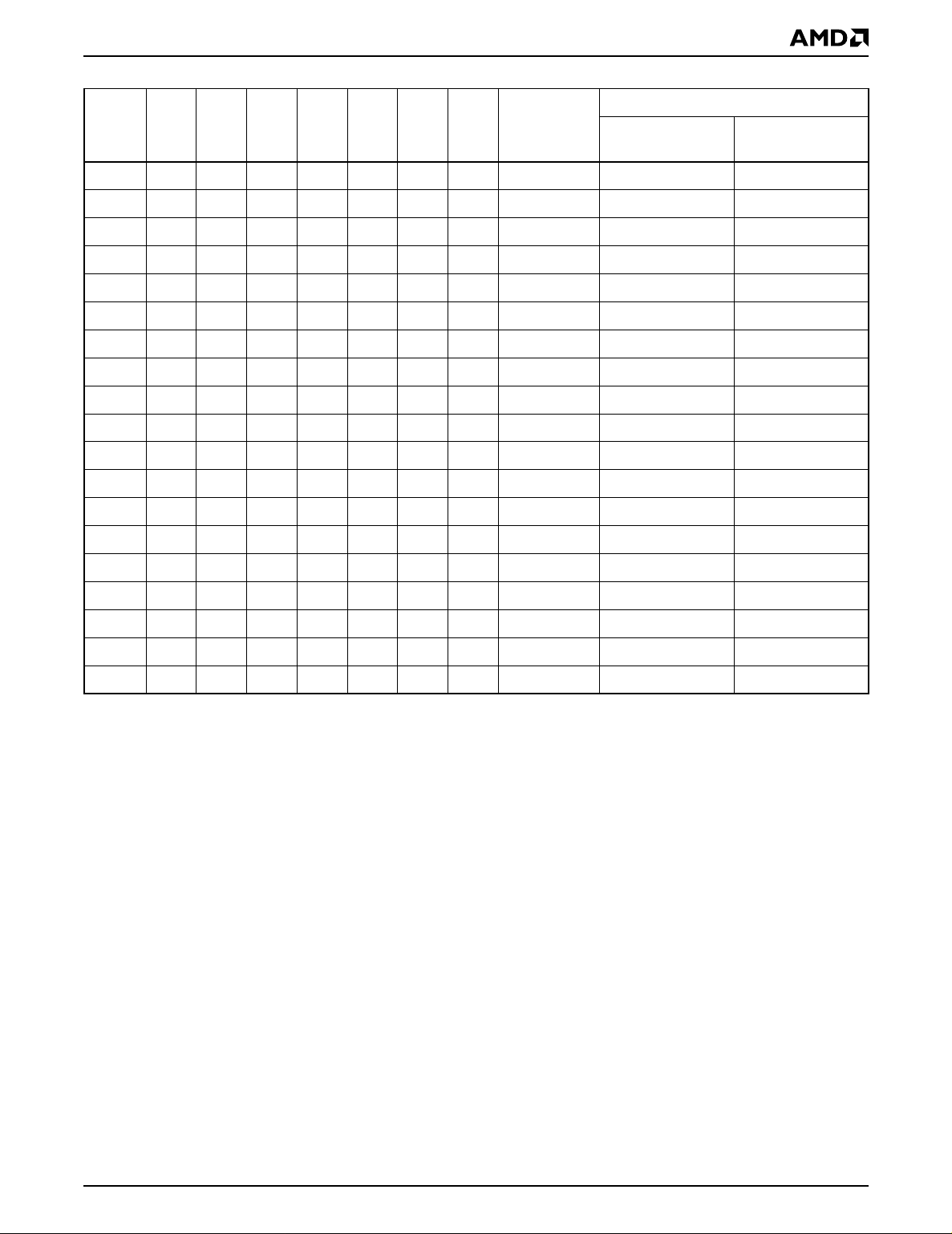

Table 2. Am29SL800CT Top Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A18 A17 A16 A15 A14 A13 A12

SA00000XXX 64/32 00000h–0FFFFh 00000h–07FFFh

SA10001XXX 64/32 10000h–1FFFFh 08000h–0FFFFh

SA20010XXX 64/32 20000h–2FFFFh 10000h–17FFFh

SA30011XXX 64/32 30000h–3FFFFh 18000h–1FFFFh

SA40100XXX 64/32 40000h–4FFFFh 20000h–27FFFh

SA50101XXX 64/32 50000h–5FFFFh 28000h–2FFFFh

SA60110XXX 64/32 60000h–6FFFFh 30000h–37FFFh

SA70111XXX 64/32 70000h–7FFFFh 38000h–3FFFFh

SA81000XXX 64/32 80000h–8FFFFh 40000h–47FFFh

SA91001XXX 64/32 90000h–9FFFFh 48000h–4FFFFh

SA10 1010XXX 64/32 A0000h–AFFFFh 50000h–57FFFh

SA11 1011XXX 64/32 B0000h–BFFFFh 58000h–5FFFFh

SA12 1100XXX 64/32C0000h–CFFFFh 60000h–67FFFh

SA13 1101XXX 64/32D0000h–DFFFFh 68000h–6FFFFh

Kwords)

Address Range (in hexadecimal)

(x8)

Address Range

(x16)

Address Range

SA14 1110XXX 64/32 E0000h–EFFFFh 70000h–77FFFh

SA15 11110XX 32/16 F0000h–F7FFFh 78000h–7BFFFh

SA16 1111100 8/4 F8000h–F9FFFh 7C000h–7CFFFh

SA17 1111101 8/4 FA000h–FBFFFh 7D000h–7DFFFh

SA18 111111X 16/8 FC000h–FFFFFh 7E000h–7FFFFh

10 Am29SL800C

Page 11

PRELIMINARY

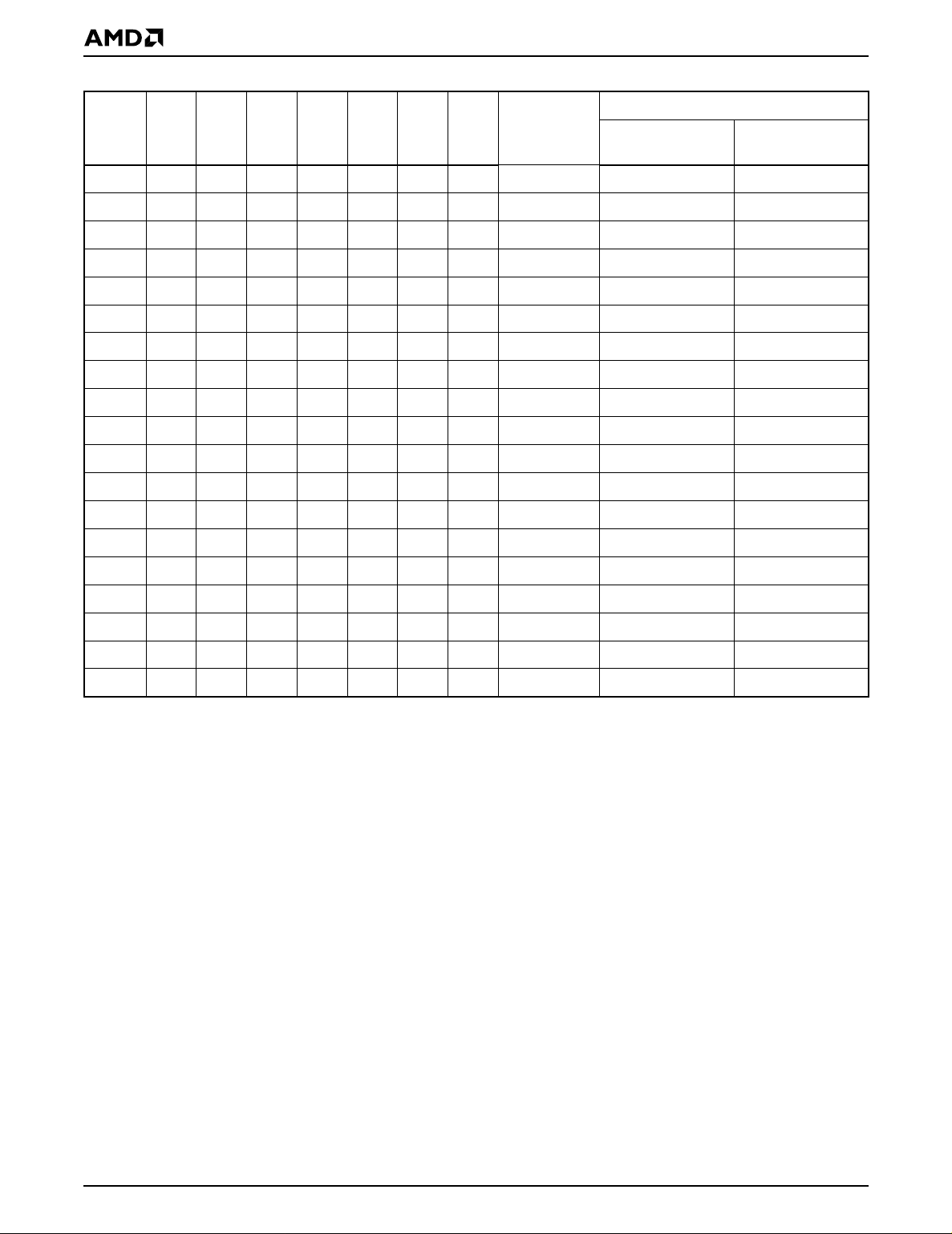

Table 3. Am29SL800CB Bottom Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A18 A17 A16 A15 A14 A13 A12

SA0000000X 16/8 00000h–03FFFh 00000h–01FFFh

SA10000010 8/4 04000h–05FFFh 02000h–02FFFh

SA20000011 8/4 06000h–07FFFh 03000h–03FFFh

SA300001XX 32/16 08000h–0FFFFh 04000h–07FFFh

SA40001XXX 64/32 10000h–1FFFFh 08000h–0FFFFh

SA50010XXX 64/32 20000h–2FFFFh 10000h–17FFFh

SA60011XXX 64/32 30000h–3FFFFh 18000h–1FFFFh

SA70100XXX 64/32 40000h–4FFFFh 20000h–27FFFh

SA80101XXX 64/32 50000h–5FFFFh 28000h–2FFFFh

SA90110XXX 64/32 60000h–6FFFFh 30000h–37FFFh

SA10 0111XXX 64/32 70000h–7FFFFh 38000h–3FFFFh

SA11 1000XXX 64/32 80000h–8FFFFh 40000h–47FFFh

Kwords)

Address Range (in hexadecimal)

(x8)

Address Range

(x16)

Address Range

SA12 1001XXX 64/32 90000h–9FFFFh 48000h–4FFFFh

SA13 1010XXX 64/32 A0000h–AFFFFh 50000h–57FFFh

SA14 1011XXX 64/32 B0000h–BFFFFh 58000h–5FFFFh

SA15 1100XXX 64/32C0000h–CFFFFh 60000h–67FFFh

SA16 1101XXX 64/32D0000h–DFFFFh 68000h–6FFFFh

SA17 1110XXX 64/32 E0000h–EFFFFh 70000h–77FFFh

SA18 1111XXX 64/32 F0000h–FFFFFh 78000h–7FFFFh

Note for Tables 2 and 3: Address range is A18:A-1 in byte mode and A18:A0 in word mode. See “Word/Byte Configuration”

section for more information.

Am29SL800C 11

Page 12

PRELIMINARY

Autoselect Mode

The autoselect mode provides manufacturer and device identification, and sector protection verification,

through identifier codes output on DQ7–DQ0. This

mode is primarily intended for programming equipment

to automatically match a device to be programmed with

its correspo nding programmi ng algorithm . However,

the aut osel ect co des can also be a cces sed in -sy stem

through the command register.

When using programming equipment, the autoselect

mode requires V

A1, and A 0 must be a s shown i n Table 4. In addi tion,

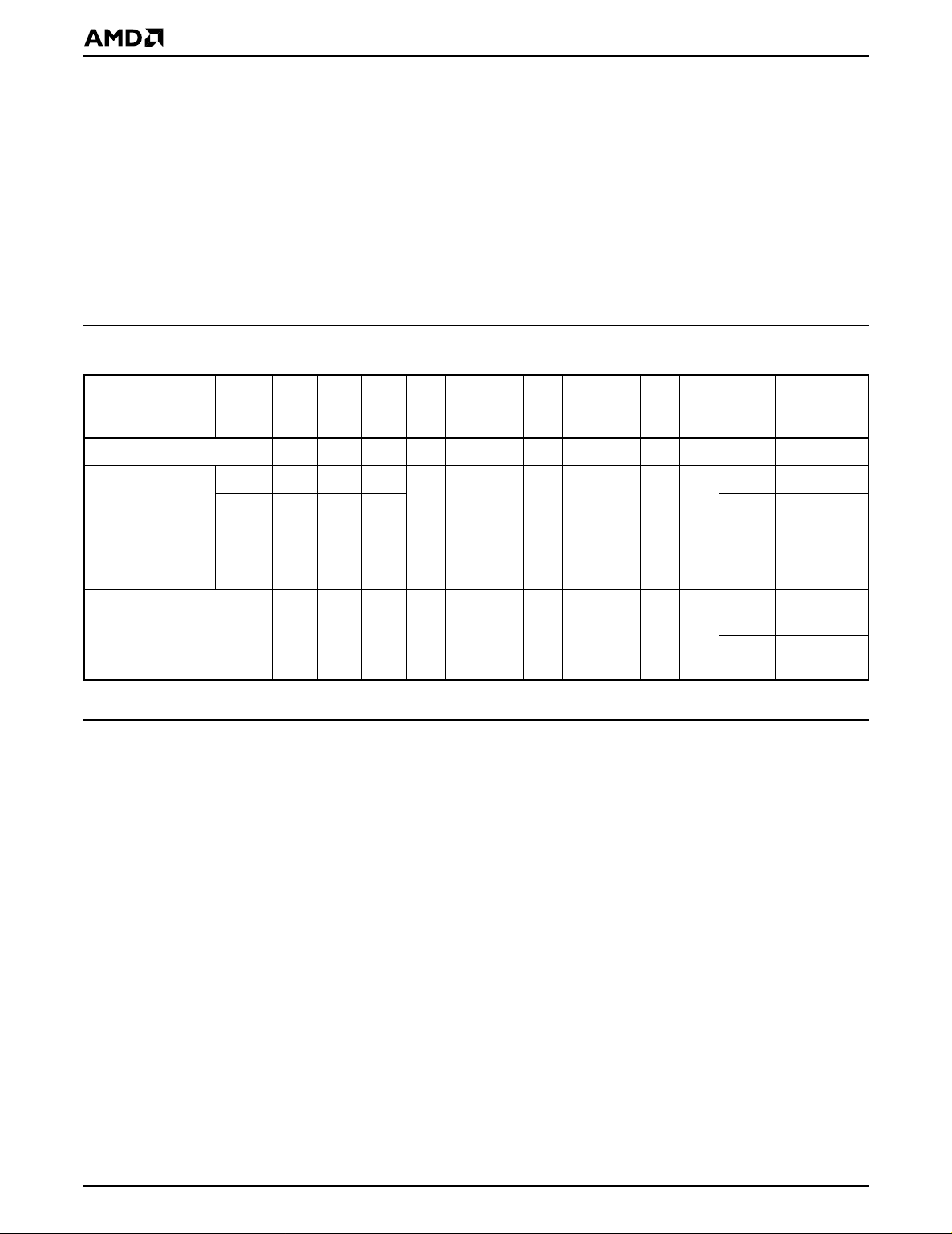

Description Mode CE# OE# WE#

Manufacturer ID: AMD L L H X X V

Device ID:

Am29SL800C

(Top Boot Block)

on address pin A9. Address pins A6,

ID

Table 4. Am29SL800C Autoselect Codes (High Voltage Method)

A11

A18

to

to

A10 A9

A12

Word L L H

Byte L L H X EAh

XXV

when verifying sector protection, the sector address

must appear on the app ropri ate highest or der addres s

bits (see Tables 2 and 3). Table 4 shows the remaining

address bits that are don’t care. When all necessary bits

have been set as required, the programming equipment

may then read the corresp onding identifier cod e on

DQ7–DQ0.

To access the autoselect codes in-system, the host

system can issue the autoselect command via the

comma nd reg ister, as s hown in Table 5. T his meth od

does not require V

. See “Command Definitions” for

ID

details on using the autoselect mode.

A8

to

A7 A6

XLXLL X 01h

ID

XLXLH

ID

A5

to

A2 A1 A0

DQ8

to

DQ15

22h EAh

DQ7

to

DQ0

Device ID:

Am29SL800C

(Bottom Boot Block)

Sector Protection V erification L L H SA X V

L = Logic Low = VIL, H = Logic High = VIH, SA = Sector Address, X = Don’t care.

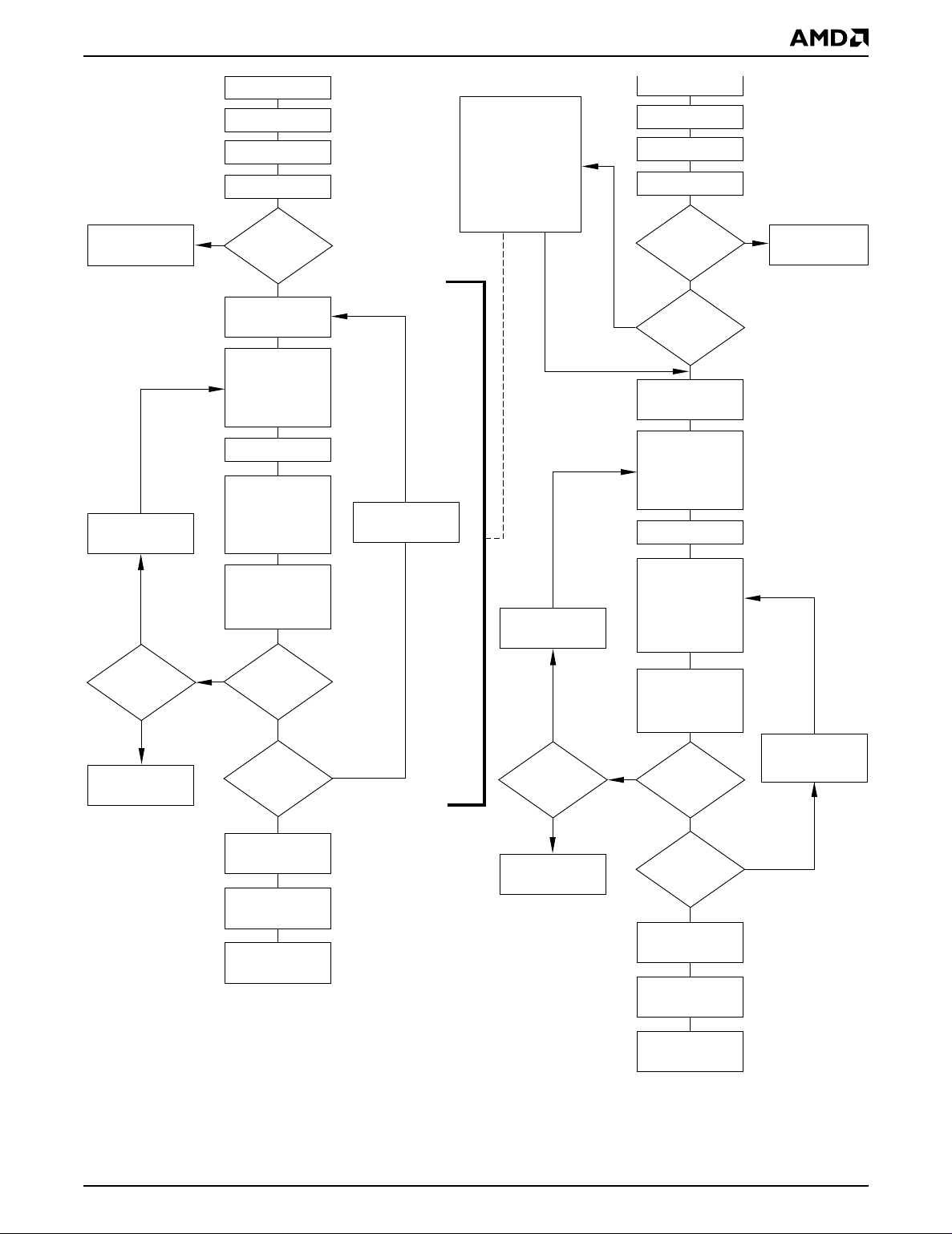

Sector Protection/Unprotection

The h ardwar e sect or p rotec tion fe ature disabl es bot h

program and erase operations in any sector. The hardware sect or unp rotecti on feature r e-enables both p rogram and erase operations in previously protected

sectors. Sector protection/unprotection can be implemente d via two method s.

The primary method requires V

only, and can be implemented either in-system or via

Word L L H

Byte L L H X 6Bh

XXV

XLXLH

ID

XLXHL

ID

an AMD represe ntative to request the doc ument containing further details.

The device i s shipped wit h all sector s unprotected .

AMD offers the option of program ming and protectin g

sectors at its factory prior to shipping the device

through AMD’s ExpressFlash™ Service. Contact an

AMD representative for details.

on the RESET# pin

ID

It is possible to determine whether a sector is protected

or unprotected. See “Autoselect Mode” for detail s.

programming equipment. Figure 1 shows the algorithm s and Fig ure 23 shows the ti ming diagram . Thi s

method uses standard microprocessor bus cycle timing. For sector unprotect, all unprotected sectors must

first be protected prior to the first sector unprotect write

cycle.

The alternate method intended only for programming

equipment requires V

on address pin A9 and OE#.

ID

This method is compatible with programmer routines

writte n for ea rli er 3 . 0 v o l t- o nly AMD fl a sh d evice s . Pu blication number 21622 contains further details. Contact

Temporary Sector Unprotect

This feature allows temporary unprotection of previously protected sectors to change data in-system. The

Sector U n pr ot ect m ode i s activated by s ett ing th e RESET# pi n to V

sectors can be programmed or erased by selecting the

sector ad dresses. Once V

SET# pin, all the previously protected sectors are

protected a gain. Figure 2 sh ows the algorithm, a nd

Figure 22 shows the timing diagrams, for this feature.

22h 6Bh

X

X

. During thi s mode, for me rly pr otecte d

ID

is rem oved from th e RE-

ID

01h

(protected)

00h

(unprotected)

12 Am29SL800C

Page 13

PRELIMINARY

Temporary Sector

Unprotect Mode

Increment

PLSCNT

No

PLSCNT

= 25?

Yes

Device failed

Sector Protect

Algorithm

START

PLSCNT = 1

RESET# = V

Wait 1 µs

No

First Write

Cycle = 60h?

Set up sector

address

Sector Protect:

Write 60h to sector

address with

A6 = 0, A1 = 1,

A0 = 0

Wait 150 µs

Verify Sector

Protect: Write 40h

to sector address

with A6 = 0,

A1 = 1, A0 = 0

Read from

sector address

with A6 = 0,

A1 = 1, A0 = 0

No

Data = 01h?

Protect another

sector?

Remove V

from RESET#

Write reset

command

Sector Protect

complete

Yes

Yes

No

START

Protect all sectors:

The indicated portion

of the sector protect

ID

Reset

PLSCNT = 1

Yes

ID

algorithm must be

performed for all

unprotected sectors

prior to issuing the

first sector

unprotect address

Increment

PLSCNT

No

PLSCNT

= 1000?

Yes

Device failed

Sector Unprotect

PLSCNT = 1

RESET# = V

Wait 1 µs

First Write

Cycle = 60h?

No

All sectors

protected?

Set up first sector

address

Sector Unprotect:

Write 60h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Wait 15 ms

Verify Sector

Unprotect: Write

40h to sector

address with

A6 = 1, A1 = 1,

A0 = 0

Read from

sector address

with A6 = 1,

A1 = 1, A0 = 0

No

Data = 00h?

Last sector

verified?

Remove V

from RESET#

Yes

Yes

Yes

Yes

ID

No

Temporary Sector

Unprotect Mode

Set up

next sector

address

No

ID

Algorithm

Write reset

command

Sector Unprotect

complete

Figure 1. In-System Sector Protect/Unprotect Algorithms

Am29SL800C 13

22230A-5

Page 14

PRELIMINARY

START

RESET# = V

(Note 1)

Perform Erase or

Program Operations

RESET# = V

Temporary Sector

Unprotect Completed

(Note 2)

Notes:

1. All protected sectors unprotected.

2. All previously protected sectors are protected once

again.

ID

IH

22230A-6

Figure 2. Temporary Sector Unprotect Operation

Hardware Data Protection

The command sequence requirement of unlock cycles

for programming or erasing provides data protection

against inadvertent wr ites (refer to Table 5 for com-

mand definitions). In addition, the following hardware

data protection measures prevent accidental erasure

or programming, which might otherwise be caused by

spurious system level signals during V

power -up and

CC

power-down transitions, or from system noise.

Low V

When V

cept any write cycles. This protects data during V

Write I nhibit

CC

is less than V

CC

, the device does not ac-

LKO

CC

power-up and power-down. The command register and

all in ternal prog ram /er ase circ uits are dis ab le d, and t he

devi c e r ese t s . Sub seq ue nt w rit es ar e ig n or ed un til V

is greate r than V

. The s ystem mus t provide th e

LKO

CC

proper signals to the control pins to prevent unintentional writes when V

is greater than V

CC

LKO

.

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#, CE# or

WE# do not initiate a write cycle.

Logical Inhibit

Write cycles are inhibited by holding any one of OE#

= V

, CE# = VIH or WE# = VIH. To initi a te a write c y -

IL

cle, CE# and WE# must be a logical zero while OE#

is a logical one.

Power-Up Write Inhibit

If WE# = CE# = V

and OE# = VIH during power

IL

up, the device d oes not accept comman ds on th e

rising edge of WE#. The intern al state ma chine is

automatically reset to reading array data on

power-up.

COMMAND DEFINITIONS

Writing specific address and data commands or sequences into the command register initiates device operations. Table 5 defines the valid register command

sequences. W riting incorrect address and data val-

ues or writing them in the improper sequence resets

the device to reading array data.

All addresses are latched on the falling edge of WE# or

CE#, whichever happens later. All data is latched on

the rising edge of WE# or CE#, whichever happens

first. Refer to the appropriate timing diagrams in the

“AC Characteristics” section.

Reading Array Data

The device is automatically set to reading array data

after device power-u p. No commands are requir ed to

retrieve data. The device is also ready to read array

data after completing an Embedded Program or Embedded Erase algorithm.

After the device accepts an Erase Suspend command, the device enters the Erase Suspend mode.

The system can read array data using the standard

read timings, except that if it reads at an address

within erase-sus pended sectors, the device outputs

status data. After completing a programming operation in the Erase Suspend mode, the system may

once again read array data with the same exception.

See “Erase Suspend/Erase Resume Commands” for

more information on this mode.

The system

must

issue the reset command to re-enable the device for rea din g array data if DQ5 goe s hi gh ,

or while in the autoselect mode. See the “Reset Command” section, next.

See also “Requirements for Reading Array Data” in the

“Device Bus Operations” section for more information.

The Read Operations table provides the read parameters, and Figure 13 shows the timing diagram.

Reset Command

Writing the reset command to the device resets the device to reading ar ray da ta. Address bits are don’t car e

for this command.

14 Am29SL800C

Page 15

PRELIMINARY

The reset command may be written between the sequence cy cles in a n era se c o mm an d se quence before

erasing begins. This resets the device to reading array

data. Once e rasure begins, however, the device ignores reset commands until th e operation is complet e.

The reset command may be written between the sequence cycles in a program command sequence before programmin g begins. This res ets the device to

reading array data (also applies to programming in

Erase Su spend mod e). Once programmin g begins,

however, the device i g no re s reset co mm ands until th e

operation is complete.

The reset command may be written between the sequence cycles in an autoselect command sequence.

Once in the autoselect mode, the reset command

be written to return to reading array data (also applies

to autoselect during Erase Suspend).

If DQ5 goes high during a program or erase operation,

writin g the re set c omm and re tur ns the d evice to re ading array data (also applies during Erase Suspend).

must

Autoselect Command Sequence

The autoselec t command sequence a llows the host

system to access the manufacturer and devices codes,

and determine whether or not a sector is protected.

T able 5 shows the address and data requirements. This

method is an alternative to that shown in T able 4, which

is in tended for PROM p rogram mers and r equi res V

on address bit A9.

The autoselect command sequence is initiated by writing two unlock cycles, followed by the autoselect command. The device then enters the autoselect mode,

and the sys tem m ay read a t any ad dres s any numbe r

of times, without initiating another command sequence.

A read cycle at address XX00h retrieves the manufacturer code. A r ead cycle at addr ess 01h in word m od e

(or 02h in byte mode) retur ns the devic e code. A read

cycle containing a sector address (SA) and the address

02h in word mode (or 04h in byte mode) returns 01h if

that sector is protected, or 00h if it is unprotected. Refer

to Tables 2 and 3 f or valid sector addr esses.

The system must write the reset command to exit the

autoselect mode and return to reading array data.

ID

Word/Byte Program Command Sequence

The system may program the device by word or byte,

depending on the state of the BYTE# pin. Programming is a four- bus-cycle o pe ratio n. The pr ogra m c om mand sequence is initiated by writing two unlock write

cycles, followed by th e pr ogra m se t- up c o mm a nd . Th e

program address and data are written next, which in

turn in itiate the Em bedded Program algorithm . The

system is

ings. The device a utoma tica lly ge nerat es t he pro gram

pulses and verifies the progra m med cell mar gin . Table

not

required to provide further controls or tim-

5 shows the address and data re quirements for the

byte program command sequence.

When the Embedded Program algorithm is complete,

the device then returns to reading array data and addresses are no longer latched. The system can determine t he s tat us of th e pr ogr am o per atio n b y us ing DQ7,

DQ6, or RY/BY#. See “Wr ite Operatio n Status ” for information on these status bits.

Any commands written to the device during the Embedded Program Algorithm are ignored. Note that a

hardware reset immediately t ermi nates th e program ming opera tion. The Byte Pro gram command sequence should be reinitiated once the device has reset

to reading array data, to ensure data integrity.

Programming is allowed in any sequence and across

sector boundaries. A bit cannot be programmed

from a “0” back to a “1”. Attempting to do so may halt

the oper ation and se t DQ5 to “1”, or caus e the Data #

Polling algorithm to indi cate the operation was suc cessful. However, a succeeding read will show that the

data is s ti l l “0 ”. On ly er a se oper a t i on s ca n c on vert a “0”

to a “1”.

Unlock B ypass Command Sequence

The unlock bypass feature allows the system to program b y te s or w or ds to t he device fast er th an us in g t he

standard program command sequence. The unlock bypass command sequence is initiated by first writing two

unlock cycles. This is followed by a third write cycle

containi ng th e unlo ck bypass comm and , 20h. T he de vice then enter s t he u nlo ck bypass m o de. A two-cy cle

unlock byp ass program co mm an d s eq ue nce i s al l tha t

is required to pro gram in this mode. The first cycle in

this sequ ence cont ains the unl ock bypass program

command, A0h; the second cycle contains the program

address and data. Additional data is programmed in

the same manner. This mode dispenses with the initial

two unlock cycles required in the standard pro gram

comman d sequen ce, result ing in faste r total prog ramming time. Table 5 shows the requirements for the command sequence.

During the unlock bypass mode, only the Unlock Bypass Program and Unlock Bypass Reset commands

are valid. To exit the unlock bypa ss m ode, th e sys tem

must issue the two-cycle unlock bypass reset command se quen ce. The fi rst cy cle mu st co ntai n the data

90h; the second cycle th e data 00h. Addresses are

don’t cares. The device then returns to reading array

data.

Figure 3 illustrates the algorithm for the program operation. Se e the E rase/P rogram Op era tions t able in “AC

Characteristics” for parameters, and to Figure 17 for

timing diagrams.

Am29SL800C 15

Page 16

Embedded

Program

algorithm

in progress

PRELIMINARY

START

Write Program

Command Sequence

Data Poll

from System

Verify Data?

Yes

No

The system can determine the status of the erase operation by using DQ7, DQ6, DQ2, or RY/BY#. See

“Write Operati on Status ” for infor mation on these status bits. W h en th e E m be dd ed E ras e alg or ithm is complete, th e device r eturns to readin g array data and

addresses are no longer latched.

Figure 4 illustrates the algorithm for the erase operation. See th e Era se/Pr ogram Operat ions tabl es in “ AC

Characteristics” for parameters, and to Figure 18 for

timing diagrams.

Sector Erase Command Sequence

Sector erase is a six bus cycle operation. The sector

erase command sequence is initiated by writing two unlock cycles, followed by a set-up command. Tw o additional unlock write cycles are then followed by the

address of the sector to be erased, and the sector

erase com mand . Table 5 shows the address and data

requirements for the sector erase command sequence.

Increment Address

Note: See Table 5 for program command sequence.

No

Last Address?

Yes

Programming

Completed

22230A-7

Figure 3. Program Oper ation

Chip Erase Command Sequence

Chip erase is a six bus cycle operation. The chip erase

command sequence is initiated by writing two unlock

cycles, followed by a set- up com mand . Two additional

unlock write cycles are then follow ed by t he chip erase

comman d, w hich i n t urn invokes the Emb ed ded Erase

algorithm. The device does

preprogram prior to erase. The Embedded Erase algorithm automatically preprograms and verifies the entire

memory for an all zero data pattern prior to electrical

erase. Th e sys tem is n ot requ ired to provi de any controls or timings during these operations. Table 5 shows

the addr ess and da ta require ments for the chip eras e

command sequence.

Any command s writte n to the chip during th e Embedded Erase algorithm are ignored. Note that a hardw are

reset during the c h ip e rase operation i m me diately terminates the operation. The Chip Erase command sequence should be reinitiated once the device has

returned to reading array data, to ensure data integrity.

not

require the system to

The device does

not

require the system to preprogram

the memory prior to erase. The Embedded Erase algorithm automatically programs and verifies the sector for

an all zero data pattern prior to electrical erase. The

syste m is not require d to provide any c ontrols or ti mings during these operations.

After the command sequence is written, a sector erase

time-out of 50 µs begins. During the time-out period,

additi onal secto r addresse s and sect or erase c ommands may be written. Loading the sector erase buffer

may be done in any sequence, and the number of sectors may be from one sector to all sectors. The time between these additional cycles must be less than 50 µs,

otherwise the last address and command might not be

accepte d, and eras ure may begin. It is recomm ended

that processor interrupts be disabled during this time to

ensure all commands are accepted. The interrupts can

be re-enabled after the last Sector Erase command is

written. If the time b etween additi onal sector era se

commands can be assumed to be less than 50 µs, the

system need not monitor DQ3. Any command other

than Sector Erase or Erase Suspend during the

time-out period resets the device to reading array

data. The system must rewrite the command sequence

and any additional sector addresses and commands.

The sys t em c an mo nit o r DQ 3 to d et ermin e if t he sec t or

erase timer has timed out. (See the “DQ3: Sector Erase

Timer” sect ion.) The time-out begi ns from the r ising

edge of the final WE# pulse in the command sequence.

Once the sector erase operation has begun, only the

Erase Sus p en d co mma nd i s valid. All ot he r co mma n ds

are ignored. Note that a hardware reset dur ing the

sector era s e o pe ratio n i m me dia t ely t erminates the operation. T he S ec tor E rase com mand sequ en ce s h ou ld

be reinitiated once the device has r eturn ed to rea ding

array data, to ensure data integrity.

16 Am29SL800C

Page 17

PRELIMINARY

When the Embedded Erase algorithm is complete, the

device returns to reading array data and addresses are

no longe r latc hed. The sy stem can d eter mi ne the status of the erase operation by using DQ7, DQ6, DQ2, or

RY /BY#. (Re f er to “Write O per ati on St atu s” for inf o rmation on these status bits.)

Figure 4 illustrates the algorithm for the erase operation. Refer to the Era se/Program Operati ons tables in

the “AC Characteristics” section for parameters, and to

Figure 18 for timing diagrams.

Erase Suspend/Erase Resume Commands

The Erase Suspend command allows the system to interrupt a sector erase operation an d then read data

from, or program data to, any sector not selected for

erasure. This command is valid only during the sector

erase operation, including the 50 µs time-out period

during the sect or erase command sequenc e. The

Erase Suspend command is ignored if written during

the chip erase operation or Embedded Program algorithm. Writing the Erase Suspend command during the

Sector Erase time-out immediately terminates the

time-o ut pe riod an d s u spe nd s t h e er a se o pe r at io n. Addresses are “don’t-cares” whe n w riting the E ras e S us pend command.

When the Erase Suspend command is written during a

sector erase operation, the device requires a maximum

of 20 µs t o suspend the erase ope ration. However,

when the Erase Suspend command is written during

the secto r erase time-out, the device im media tely ter minates the time-out period and suspends the erase

operatio n.

the Erase S uspend mode, an d is ready for ano ther

valid operatio n. See “Autoselect Command Sequence”

for more information.

The system must write the Erase Resume command

(address bits are “don’t care”) to exit the erase suspend

mode an d co nt in u e t he s ec tor er a s e ope r at ion . Fu rther

writes of the R esum e comma nd are ig nored. Anothe r

Erase Sus pend c omm and can be wr itt en afte r the de vice has resume d erasing.

START

Write Erase

Command Sequence

Data Poll

from System

No

Data = FFh?

Erasure Completed

Yes

Embedded

Erase

algorithm

in progress

After the erase ope ration has been susp ended, the

system can read array data from or program data to

any sector not selected for erasure. (The device “erase

suspends” all sec tors selected for erasure.) Norm al

read and write timings and command definitions apply.

Reading at any address within erase-suspended sectors produces status data on DQ7–DQ0. The system

can use DQ7, or DQ6 and DQ2 together, to determine

if a sector is actively erasing or is erase-suspended.

See “Wr ite Ope ration Stat us” for i nform ation on t hese

status bits.

After an erase-suspended program operation is complete, the system can once again read array data within

non-suspended sectors. The system can determine

the statu s of the pr ogram ope ration us ing the DQ 7 or

DQ6 statu s b its, j u st a s i n th e s tandard pr ogra m op er ation. See “Write Operation Status” for more information.

The system may also write the autoselect command

sequence when the device is in the Erase Suspe nd

mode. The device allows reading autoselect codes

even at addresses within erasing s ectors, since the

codes are not stored in the memory array. When the

device exits the autoselect mode, the device reverts to

22230A-8

Notes:

1. See Table 5 for erase command sequence.

2. See “DQ3: Sector Erase Timer” for more information.

Figure 4. Erase Operation

Am29SL800C 17

Page 18

PRELIMINARY

Table 5. Am29SL800C Command Definitions

Command

Sequence

(Note 1)

Read (Note 6) 1 RA RD

Reset (Note 7) 1 XXX F0

Manufacturer ID

Device ID,

Top Boot Block

Device ID,

Bottom Boot Block

Autoselect (Note 8)

Sector Protect Verify

(Note 9)

Program

Unlock Bypass

Unlock Bypass Program (Note 10) 2 XXX A0 PA PD

Unlock Bypass Reset (Note 11) 2 XXX 90 XXX 00

Chip Erase

Sector Erase

Erase Suspend (Note 12) 1 XXX B0

Erase Resume (Note 13) 1 XXX 30

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555

Legend:

X = Don’t care

RA = Address of the memory location to be read.

RD = Data read from location RA during read operation.

PA = Address of the memory location to be programmed.

Addresses latch on the falling edge of the WE# or CE# pulse,

whichever happens later.

First Second Third Fourth Fifth Sixth

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Cycles

555

4

555

4

555

4

555

4

555

4

555

3

555

6

555

6

AA

AA

AA

AA

AA

AA

AA

AA

2AA

2AA

2AA

2AA

2AA

2AA

2AA

2AA

Bus Cycles (Notes 2-5)

55

55

55

55

55

55

55

55

555

555

555

555

555

555

555

555

90 X00 01

X01 22EA

90

X02

EA

X01 226B

90

X02

(SA)

X02

90

(SA)

X04

A0 PA PD

20

555

80

555

80

6B

XX00

XX01

00

01

AA

AA

2AA

2AA

555

55

55 SA 30

PD = Data to be programmed at location P A. Data latches on the

rising edge of WE# or CE# pulse, whichever happens first.

SA = Address of the sector to be verified (in autoselect mode) or

erased. Address bits A18–A12 uniquely select any sector.

10

Notes:

1. See Table 1 for description of bus operations.

9. The data is 00h for an unprotected sector and 01h for a

2. All values are in hexadecimal.

3. Except when reading array or autoselect data, all bus cycles

are write operations.

4. Data bits DQ15–DQ8 are don’t cares for unlock and

command cycles.

10. The Unlock Bypass command is required prior to the Unlock

11. The Unlock Bypass Reset command is required to return to

5. Address bits A18–A11 are don’t cares for unlock and

command cycles, unless SA or PA required.

6. No unlock or command cycles required when reading array

12. The system may read and program in non-erasing sectors, or

data, unless SA or PA required.

7. The Reset command is required to return to reading array

data when device is in the autoselect mode, or if DQ5 goes

high (while the device is providing status data).

13. The Erase Resume command is valid only during the Erase

8. The fourth cycle of the autoselect command sequence is a

read cycle.

18 Am29SL800C

protected sector. See “Autoselect Command Sequence” for

more information.

Bypass Program command.

reading array data when the device is in the unlock bypass

mode.

enter the autoselect mode, when in the Erase Suspend

mode. The Erase Suspend command is valid only during a

sector erase operation.

Suspend mode.

Page 19

PRELIMINARY

WRITE OPERATION STATUS

The device provides several bits to determine the status of a write operatio n: DQ2, DQ 3, DQ5, DQ 6, DQ7,

and RY/BY#. Table 6 and the following subsections describe the functions of these bits. DQ7, RY/BY#, and

DQ6 each offer a method for determining whether a

program or erase operation is complete or in progress.

These three bits are discussed first.

DQ7: Data# Polling

The Data# Polling bit, DQ7, indicates to the host s ystem

whether an Embedded Algorithm is in progress or completed, o r whether the device is in Erase Suspend.

Data# Polling is valid after the rising edge of the final

WE# pulse in the program or erase command sequence.

Table 6 show s the outpu ts for Data# Polling on DQ7.

Figure 5 shows the Data# Polling algorithm.

START

Read DQ7–DQ0

Addr = VA

During the Embedded Program algorithm, the device

outputs on DQ7 the c ompleme nt of the da tum programmed to DQ7. Thi s DQ7 status also applies to programming during Erase Suspend. When the

Embedde d Pr ogram a lgor ithm is co mplete, the devic e

outputs the datum programmed to DQ7. The system

must provi d e th e p ro gram ad dr es s to r ea d val id status

information on DQ7. If a program address falls within a

protected sector, Data# Polling on DQ7 is active f or approximately 1 µs, then the device returns to reading

array data.

During the Embedded Erase algor ithm, Data# Polling

produces a “0” on DQ7. When the Embedded Erase algorith m is com plete, or if the device en ters the Erase

Suspend mode, Data# Polling produces a “1” on DQ7.

This is analogous to the complement/true datum output

described for the Embedded Program algorithm: the

erase function changes all the bits in a sector to “1”;

prior to this, the device outputs the “complement,” or

“0.” The system must provide an address within any of

the sectors selected for erasure to read valid status informatio n on DQ7 .

After an e ra se co mm an d se qu en c e is w rit t en , if a ll s e ctors selec ted for erasing are protected, Data# Polling

on DQ7 i s ac t ive for appr oximat e ly 10 0 µs , th en t he d evice returns to reading array data. If not all selected

sectors are protected, the Embedded Erase algorithm

erases the unprotected sectors, and ignores the selected sectors that are protected.

When the sys tem det ects DQ7 h as changed from the

complement to true data, it can read valid data at DQ7–

DQ0 on the

following

read cycles. This is because DQ7

may change asynchronously with DQ0–DQ6 while

Output Enable (OE#) is asserted low. Figure 19, Data#

Polling Timings (During Embedded Algorithms), in the

“AC Characteristics” section illustrates this.

DQ7 = Data?

No

No

Notes:

1. VA = Valid address for programming. During a sector

erase operation, a valid address is an address within any

sector selected for erasure. During chip erase, a valid

address is any non-protected sector address.

2. DQ7 should be rechecked even if DQ5 = “1” because

DQ7 may change simultaneously with DQ5.

DQ5 = 1?

Yes

Read DQ7–DQ0

Addr = VA

DQ7 = Data?

No

FAIL

Yes

Yes

PASS

22230A-9

Figure 5. Data# Polling Algori thm

Am29SL800C 19

Page 20

PRELIMINARY

RY/ BY#: Read y/Bu sy#

The RY/BY# is a de di ca ted , open-drain o utp ut pin that

indicates whether an Embedded Algorithm is in

progress or complete. The RY/BY# status is valid after

the rising edge of the final WE# pulse in the command

sequence. Since RY/BY# is an open-drain output, several RY/BY# pins can be tied together in parallel with a

pull-up resistor to V

If the output is low (Busy), the device is actively erasing

or programming. (T his includes programming in the

Erase Suspend mode.) If the output is high (Ready),

the device is ready to read array data (including during

the Erase Suspend mode), or i s in the standb y mode.

Table 6 shows the ou tputs for RY/BY#. F igures 14, 17

and 18 shows RY/BY# for reset, program, and erase

operations, respectively.

CC

.

DQ6: Toggle Bit I

Toggle Bit I on DQ6 indicates whether an Embedded

Program or Erase algorithm is in progress or complete,

or whether the device has entered the Erase Suspend

mode. Toggle B it I m ay b e re ad at a ny add ress, and is

valid after the rising edge of the final WE# pulse in the

command sequence (prior to the program or erase operation), and during the sector erase time-out.

During an Embed ded Program or E ra se algor i thm op eration, successive read cycles to any address cause

DQ6 to toggle (The system may use either OE# or CE#

to control the read cycles). When the operation is complete, DQ6 stops toggling.

After an e ra se co mm an d se qu en c e is w rit t en , if a ll s e ctors selected for erasing are protected, DQ6 toggles for

approximately 100 µs, then returns to readi ng array

data. If n ot all selected se cto rs ar e pro te c ted , the Em bedded Erase algorithm erases the unprotected sectors, and ignores the selected sectors that are

protect ed.

The system can use DQ6 an d DQ2 togethe r to determine wh ethe r a sect or is a ctivel y erasing or is erase suspended. When the device is actively erasing (that is,

the Embedded Erase algorithm is in progress), DQ6

toggles. When the device enters the Erase Suspend

mode, DQ6 stops toggling. However, the system must

also use DQ2 to determine which sectors are erasing

or erase-suspended. Alternatively, the system can use

DQ7 (see the subsection on DQ7: Data# Polling).

If a program address falls within a protected sector,

DQ6 toggl es for approximate ly 1 µs after th e program

command sequence is written, then returns to reading

array data.

DQ6 also toggles during the erase-suspend-program

mode, and stops to ggling once the E mbedded Pro gram algorithm is complete.

Table 6 shows the outputs for Togg le Bit I on DQ6. Figure 6 sh ows the togg le bit alg orit hm. Figu re 20 in th e

“AC Characteristics” section shows the toggle bit timing

diagrams. Figure 21 shows the differences between

DQ2 and D Q 6 in gra phi c al for m. Se e als o the subsec tion on DQ2: Toggle Bit II.

DQ2: Toggle Bit II

The “Toggle Bit II” on DQ2, when used with DQ6, indicates whether a particular s ector is actively erasing

(that is, the Embedded Erase algorithm is in progress),

or whethe r that sect or is erase- suspende d. Toggle Bit

II is valid after the rising edge of the final WE# pulse in

the command sequence. The device toggles DQ2 with

each O E# or CE# read cycle.

DQ2 toggles when the system reads at addresses

within tho se sector s that have been selecte d for erasure. But D Q2 ca nnot dist ingu ish w hethe r the sec tor is

actively erasing or is erase-suspended. DQ6, by comparison, indicates whether the device is actively erasing, or is in Erase Suspend, but cannot distinguish

which sectors are selected for erasure. Thus, both status bits are required for sector and mode information.

Refer to T able 6 to compare outputs for DQ2 and DQ6.

Figure 6 shows the toggle bit algorithm in flowchar t

form, and the section “DQ2: Toggle Bit II” explains the

algor ithm. Se e also the DQ6: Toggle Bit I sub section .

Figure 20 shows the toggle bit timing diagram. Figure

21 shows the differences between DQ2 and DQ6 in

graphical form.

Reading Toggle Bits DQ6/DQ2

Refer to Figure 6 for the follo wing discussion. Whenev er

the system initially begins reading toggle bit status, it

must read DQ7–DQ0 at least twice in a row t o determine

whether a toggle bit is toggling. Typically, the system

would note and store the value of the toggle bit after the

first read. After the second read, the system would compare the new value of the toggle bit with the first. If the

toggle bit is not toggling, the device has completed the

program or erase operation. The system can read arra y

data on DQ7–DQ0 on the following read cycle.

However, if after the initial two read cycles, the system

determines t hat the to ggle bit is still toggling , the sy stem also should note whether the value of DQ5 is high

(see the section on DQ5). If it is, the system should

then de termin e agai n whet her t he togg le bi t is to ggli ng,

since the to ggle bit may have stop ped tog gling j ust as

DQ5 went high. I f the tog gle bi t is no long er togg ling,

the device has successfully completed the program or

erase operation. If it is still toggling, the device did not

complete d the opera tion suc cessful ly, and the system

must wr ite the reset co mmand to return to readin g

array data.

20 Am29SL800C

Page 21

PRELIMINARY

The remaining scenario is that the system initially determines that the toggle bit is toggling and DQ5 has not

gone high. The system may continue to monitor the

toggle bit and DQ5 through successive read cycles, determining the status as described in the previous paragraph. Alterna tively, it may choose to perfor m other

system tasks. In this case, the system must start at the

beginn i ng of th e a l go rit hm wh en i t re turns t o de term ine

the status of the operation (top of Figure 6).

START

Read DQ7–DQ0

(Note 1)

Read DQ7–DQ0

No

(Notes

1, 2)

No

Program/Erase

Operation Complete

No

Toggle Bit

= Toggle?

Yes

DQ5 = 1?

Yes

Read DQ7–DQ0

Twice

Toggle Bit

= Toggle?

Yes

Program/Erase

Operation Not

Complete, Write

Reset Command

DQ5: Exceeded Timing Limits

DQ5 in dic ates whether the pr ogra m or e rase time ha s

exceeded a specified inter nal pulse count lim it. Under

these co ndi tions DQ5 produ ce s a “1 .” Th is is a failur e

condition that indicates the program or erase cycle was

not successfully completed.

The DQ5 failure condition may appear if the system

tries to progr am a “1” t o a locati on tha t is pre vious ly program med to “ 0.” Onl y an er ase op era tion c an c hange

a “0” back to a “1.” Under this condition, the device

halts the operation, and when the operation has ex-

ceeded the timing limits, DQ5 produces a “1.”

Under both th ese cond itio ns , t he syst em m ust issu e t he

reset command to return the device to reading array

data.

DQ3: Sector Erase Timer

After writing a sector erase command sequence, the

system may read DQ3 to determine whether or not an

erase operation has be gun. (The sector erase ti mer

does not apply to the chip erase command.) If additional

sectors are selected for erasure, the entire time-out also

applies after each additional sector erase command.

When the time-out is complete, DQ3 switches from “0” to

“1.” If the time between additional sector erase commands from the system can be assumed to be less than

50 µs, the system need not monitor DQ3. See also the

“Sector Erase Command Sequence” section.

After the sector erase command sequence is written,

the system should read the status on DQ7 (Data# Polling) or DQ6 (Toggle Bit I) to ensur e th e devic e has ac cepted the command sequenc e, and then read DQ3. If

DQ3 is “1”, t h e int e rnal ly c ont r ol le d er a s e cyc le ha s b egun; all further commands (other than Erase Suspend)

are ignored until the erase ope ration is complete. If

DQ3 is “0”, the device will accept additional sector

erase commands. To ensure the command has been

accept ed , t he sy s tem so f t war e sh ou ld ch ec k t he sta t us

of DQ3 pri or to and followin g each sub sequent sector

erase co mmand . If DQ 3 is hig h on th e seco nd statu s

check, the last command might not have been accepted. Table 6 shows the outputs for DQ3.

Notes:

1. Read toggle bit twice to determine whether or not it is

toggling. See text.

2. Recheck toggle bit because it may stop toggling as DQ5

changes to “1” . See text.

22230A-10

Figure 6. Toggle Bit Algorithm

Am29SL800C 21

Page 22

PRELIMINARY

Table 6. Write Operation Status

DQ7

Standard

Mode

Erase

Suspend

Mode

Operation

Embedded Program Algorithm DQ7# Toggle 0 N/A No toggle 0

Embedded Erase Algorithm 0 Toggle 0 1 Toggle 0

Reading within Erase

Suspended Sector

Reading within Non-Erase

Suspended Sector

Erase-Suspend-Program DQ7# Toggle 0 N/A N/A 0

(Note 2) DQ6

1 No toggle 0 N/A Toggle 1

Data Data Data Data Data 1

Notes:

1. DQ5 switches to ‘1’ when an Embedded Program or Embedded Erase operation has exceeded the maximum timing limits.

See “DQ5: Exceeded Timing Limits” for more information.

2. DQ7 and DQ2 require a valid address when reading status information. Refer to the appropriate subsection for further details.

DQ5

(Note 1) DQ3

DQ2

(Note 2) RY/BY#

22 Am29SL800C

Page 23

PRELIMINARY

ABSOLUTE MAXIMUM RATINGS

Storage Temperature

Plastic Packages . . . . . . . . . . . . . . . –65°C to +150°C

Ambient Temperature

with Power Applied. . . . . . . . . . . . . . –65°C to +125°C

Voltage with Respect to Ground

V

(Note 1) . . . . . . . . . . . . . . . .–0.5 V to +2.5 V

CC

A9, OE#,

and RESET# (Note 2) . . . . . . . .–0.5 V to +11.0 V

All other pins (Note 1) . . . . . –0.5 V to V

Output Short Circuit Current (Note 3) . . . . . . 100 mA

Notes:

1. Minimum DC voltage on input or I/O pins is –0.5 V. During

voltage transitions, input or I/O pins may overshoot V

–2.0 V for periods of up to 20 ns. See Figure 7. Maximum

DC voltage on input or I/O pins is V

voltage transitions, input or I/O pins may overshoot to V

+2.0 V for periods up to 20 ns. See Figure 8.

2. Minimum DC input voltage on pins A9, OE#, and RESET#

is –0.5 V. During voltage transitions, A9, OE#, and

RESET# may overshoot V

20 ns. See Figure 7. Maximum DC input voltage on pin A9

is +11.0 V which may overshoot to 12.5 V for periods up

to 20 ns.

3. No more than one output may be shorted to ground at a

time. Duration of the short circuit should not be greater

than one second.

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. This is

a stress rating only; functional operation of the device at

these or any other conditions above those indicated in the

operational sections of this data sheet is not implied.

Exposure of the device to absolute maximum rating

conditions for extended periods may affect device reliability.

to –2.0 V for periods of up to

SS

+0.5 V. During

CC

CC

+0.5 V

to

SS

CC

20 ns

0.0 V

–0.5 V

–2.0 V

20 ns

20 ns

22230A-11

Figure 7 . Maximum Negative Overshoot

Waveform

20 ns

V

CC

+2.0 V

V

CC

+0.5 V

2.0 V

20 ns

20 ns

22230A-12

Figure 8. Maximum Positive Overshoot

Waveform

OPERATING RANGES

Commercial (C) Devices

Ambient Temperature (T

Industrial (I) Devices

Ambient Temperature (T

V

Supply Voltages

CC

V

, all speed options . . . . . . . . . . . .+1.8 V to +2.2 V

CC

Operating ranges define those limits between which the functionality of the device is guaranteed.

) . . . . . . . . . . . 0°C to +70°C

A

) . . . . . . . . . –40°C to +85°C

A

Am29SL800C 23

Page 24

PRELIMINARY

DC CHARACTERISTICS

CMOS Compatible

Parameter Description Test Conditions Min Typ Max Unit

V

= VSS to VCC,

IN

V

= VCC

CC

CC max

= VSS to VCC,

V

OUT

V

= V

CC

CC max

CE# = V

IL,

Byte Mode

CE# = V

IL,

Word Mode

max

±1.0 µA

; A9 = 11.0 V 35 µA

±1.0 µA

OE#

= VIH,

5 MHz 5 10

1 MHz 1 3

OE#

= VIH,

5 MHz 5 10

1 MHz 1 3

I

I

LI

I

LIT

I

LO

CC1

Input Load Current

A9 Input Load Current VCC = V

Output Leakage Current

VCC Active Read Current

(Notes 1, 2)

mA

I

CC2

I

CC3

I

CC4

I

CC5

V

IL

V

IH

V

ID

V

OL1

V

OL2

V

OH1

V

OH2

V

LKO

VCC Active Write Current

(Notes 2, 3, 5)

CE# = V

IL,

OE#

= VIH

VCC Standby Current (Note 2) CE#, RESET# = VCC±0.3 V 1 5 µA

VCC Reset Current (Note 2) RESET# = V

Automatic Sleep Mode

(Notes 2, 3)

VIH = V

V

= V

IL

CC

SS

± 0.3 V 1 5 µA

SS

± 0.3 V;

± 0.3 V

Input Low Voltage –0.5 0.2 x V

Input High Voltage 0.8 x V

Voltage for Autoselect and

Temporary Sector Unprotect

Output Low Voltage

Output High Voltage

Low VCC Lock-Out Voltage

(Note 4)

V

= 2.0 V 9.0 11.0 V

CC

= 2.0 mA, VCC = V

I

OL

IOL = 100 µA, VCC = V

= –2.0 mA, VCC = V

I

OH

IOH = –100 µA, VCC = V

CC min

0.1

CC min

0.7 x V

CC min

VCC–0.1

CC min

1.2 1.5 V

Notes:

1. The I

2. The maximum I

3. I

current listed is typically less than 1 mA/MHz, with OE# at VIL. Typical VCC is 2.0 V.

CC

specifications are tested with V

CC

active while Embedded Erase or Embedded Program is in progress.

CC

= VCCmax.

CC

4. Automatic sleep mode enables the low power mode when addresses remain stable for t

5. Not 100% tested.

CC

CC

ACC

20 25 mA

15µA

CC

VCC + 0.3 V

0.25 V

+ 50 ns.

V

V

24 Am29SL800C

Page 25

PRELIMINARY

DC CHARACTERISTICS (Continued)

Zero Power Flash

20

15

10

5

Supply Current in mA

0

0 500 1000 1500 2000 2500 3000 3500 4000

Time in ns

Note: Addresses are switching at 1 MHz

Figure 9. I

Current vs. Time (Showing Active and Automatic Sleep Currents)

CC1

10

8

6

4

Supply Current in mA

2

0

1 2345

22230A-13

2.2 V

1.8 V

Frequency in MHz

Note: T = 25 °C

Figure 10. Typical I

Am29SL800C 25

vs. Frequency

CC1

22230A-14

Page 26

TE S T CONDITIONS

Device

Under

Test

PRELIMINARY

Table 7. Test Specifications

Test Condition 100 120, 150 Unit

Output Load 1 TTL gate

Output Load Capacitance, C

(including jig capacitance)

C

L

Input Rise and Fall Times 5 ns

Input Pulse Levels 0.0–2.0 V

L

30 100 pF

Figure 11 . Test Se tup

KEY TO SWITCHING WAVEFORMS

WAVEFORM INPUTS OUTPUTS

Don’t Care, Any Change Permitted Changing, State Unknown

Does Not Apply Center Line is High Impedance State (High Z)

22230A-15

Input timing measurement

reference levels

Output timing measurement

reference levels

Steady

Changing from H to L

Changing from L to H

1.0 V

1.0 V

2.0 V

0.0 V

1.0 V 1.0 V

Figure 12. Input Waveforms and Measurement Level s

26 Am29SL800C

KS000010-PA L

OutputMeasurement LevelInput

22230A-16

Page 27

AC CHARACTERISTICS

Read Operations

PRELIMINARY

Parameter

JEDEC Std Test Setup 100 120 150 Unit

t

AVAV

t

AVQV

t

ELQV

t

GLQV

t

EHQZ

t

GHQZ

t

Read Cycle Time (Note 1) Min 100 120 150 ns

RC

t

Address to Output Delay

ACC

t

Chip Enable to Output Delay OE# = V

CE

t

Output Enable to Output Delay Max 35 50 65 ns

OE

t

Chip Enable to Output High Z (Note 1) Max 50 60 60 ns

DF

t

Output Enable to Output High Z (Note 1) Max 50 60 60 ns

DF

Description

CE# = V

OE# = V

IL

Max 100 120 150 ns

IL

Max 100 120 150 ns

IL

Speed Option

Read Min 0 ns

Output Enable

OEH

Hold Time (Note 1)

Toggle and

Data# Polling

Output Hold Time From Addresses, CE# or

t

OH

OE#, Whichever Occurs First (Note 1)

Min 30 ns

Min 0 ns

t

AXQX

t

Notes:

1. Not 100% tested.

2. See Figure 11 and Table 7 for test specifications.

t

RC

Addresses

CE#

OE#

WE#

Outputs

RESET#

RY/BY#

0 V

Addresses Stable

t

ACC

t

OE

t

OEH

t

CE

HIGH Z

Output Valid

Figure 13. Read Operations Timings

t

DF

t

OH

HIGH Z

22230A-17

Am29SL800C 27

Page 28

AC CHARACTERISTICS

Hardware Reset (RESET#)

Parameter

PRELIMINARY

Description All Speed OptionsJEDEC Std Test Setup Unit

t

READY

t

READY

RESET# Pin Low (During Embedded

Algorithms) to Read or Write (see Note)

RESET# Pin Low (NOT During Embedded

Algorithms) to Read or Write (see Note)

t

RESET# Pulse Width Min 500 ns

RP