Datasheet AM29LV200T-150EI, AM29LV200T-150EEB, AM29LV200T-150EE, AM29LV200T-150ECB, AM29LV200T-150EC Datasheet (AMD Advanced Micro Devices)

...Page 1

PRELIMINARY

Am29LV200

2 Megabit (256 K x 8-Bit/128 K x 16-Bit)

CMOS 3.0 Volt-onl y Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single power supply operation

— Full voltage range: 2.7 to 3.6 volt read and write

operations for battery-powered applications

— Regulated voltage range: 3.0 to 3.6 volt read and

write operations and for compatibility with high

performance 3.3 volt microprocessors

■ High performance

— Full voltage range: access times as fast as 100

ns

— Regulated voltage range: access times as fast as

90 ns

■ Ultra low power consumption (typical v alues at 5

MHz)

— 200 nA Automatic Sleep mode current

— 200 nA standby mode current

— 10 mA read current

— 20 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

three 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

three 32 Kword sectors (word mode)

— Supports full chip erase

— Sector Protection features:

A hardware method of locking a sector to prevent

any program or erase operations within that

sector

Sectors can be locked via programming

equipment

Temporary Sector Unprotec t feature allows code

changes in previously locked sectors

■ Top or bottom boot block configurations

available

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Typical 1,000,000 write cycles per sector

(100,000 cycles minimum guaranteed)

■ Package option

— 48-pin TSOP

— 44-pin SO

■ Compatibility with JEDEC standards

— Pinout and software compatible with single-

power supply Flash

— Superior inadvertent write protection

■ Data# Polling and toggle bits

— Provides a software method of detecting program

or erase operation completion

■ Ready/Busy# pin (RY/BY#)

— Provides a hardware method of detecting

program or erase cycle completion

■ Erase Suspend/Erase Resume

— Suspends an erase operation to read data from,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the device to reading

array data

Publication# 20513 Rev: D Amendment/+1

Issue Date: March 1998

Page 2

PRELIMINARY

GENERAL DESCRIPTION

The Am29LV200 is a 2 Mbit, 3.0 volt-only Flash

memory organized as 262,144 bytes or 131,072 words.

The device is offer ed in 44-pin S O and 48-pin TSO P

packages. The word-wide data (x16) appears on

DQ15–DQ0; the byte-wide (x8) data appears on DQ7–

DQ0. This device is designed to be programmed insystem using only a single 3.0 volt V

is required for write or erase operations. The device

can also be programmed i n standard EPROM programmers.

The standard device offers access times of 90, 100,

120, and 150 ns, allowing high speed microprocessors

to operate without wait states. To eliminate bus contention the device has separate chip enable (CE#), write

enable (WE#) and output enable (OE#) controls.

The device requires only a single 3.0 volt power sup-

ply for both read and write functions. Internally generated and regulated voltages are provided for the

program and erase operations.

The device is entirely command set compatible with the

JEDEC single-power-supply Flash standard. Commands are written to the command register using

standard micropr ocessor write ti mings. Register c ontents serve as input to an i nternal state-machine that

controls the erase and programming circuitry. Write

cycles also internally latch addresses and dat a needed

for the programming and erase operations. Reading

data out of the device is similar to reading from other

Flash or EPROM devices.

Device programming occurs by executing the program

command sequence. This initiates the Embedded

Program algorithm—an internal algorithm that automatically times the program pulse widths and verifies

proper cell margin.

Device erasure occurs by executing the erase command sequence. This initiates the Embedded Erase

algorithm—an internal algorithm that automatically preprograms the array (if it is not already programmed) before executing the erase operation. During erase, the

device automatically times the erase pulse widths and

verifies proper cell margin.

supply. No V

CC

PP

The host system can detect whether a program or

erase operation is complete by observing the RY/BY#

pin, or by re ading the DQ7 (D ata# Polling) and DQ6

(toggle) status bits. After a program or erase cycle

has been completed, the device is ready to read array

data or accept another command.

The sector erase architecture allows memory sectors

to be erased and reprogrammed without affecting the

data contents of other sectors. The device is fully

erased when shipped from the factory.

Hardware data protection measures include a low

detector that automatically inhibits write opera-

V

CC

tions during p ower transitions. The hardware sector

protection feature disables both program and erase

operations in any combination of the sectors of memory. This can be achieved via programming equipment.

The Erase Sus pend feature enables the user to put

erase on hold for any period of time to read data from,

or program data to, any sector that is not selected for

erasure. True background erase can thus be achieved.

The hardware RESET# pin terminates any operation

in progress and resets the internal state machine to

reading array data. The RESET# pin may be tied to the

system reset circuitry. A system reset would thus also

reset the device, enabling the system microprocessor

to read the boot-up firmware from the Flash memory.

The device offers two pow er-saving features. When

addresses have been stable for a specified amount of

time, the device enters the automatic sleep mode.

The system can also place the device into the standby

mode. Power consumption is greatly reduced in both

these modes.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability and cost effectiveness. The device e lectrically erases a ll b its wit hin

a sector simultaneously via Fowler-Nordheim tunneling. The data is programmed using hot electron

injection.

Am29LV200 2

Page 3

PRELIMINARY

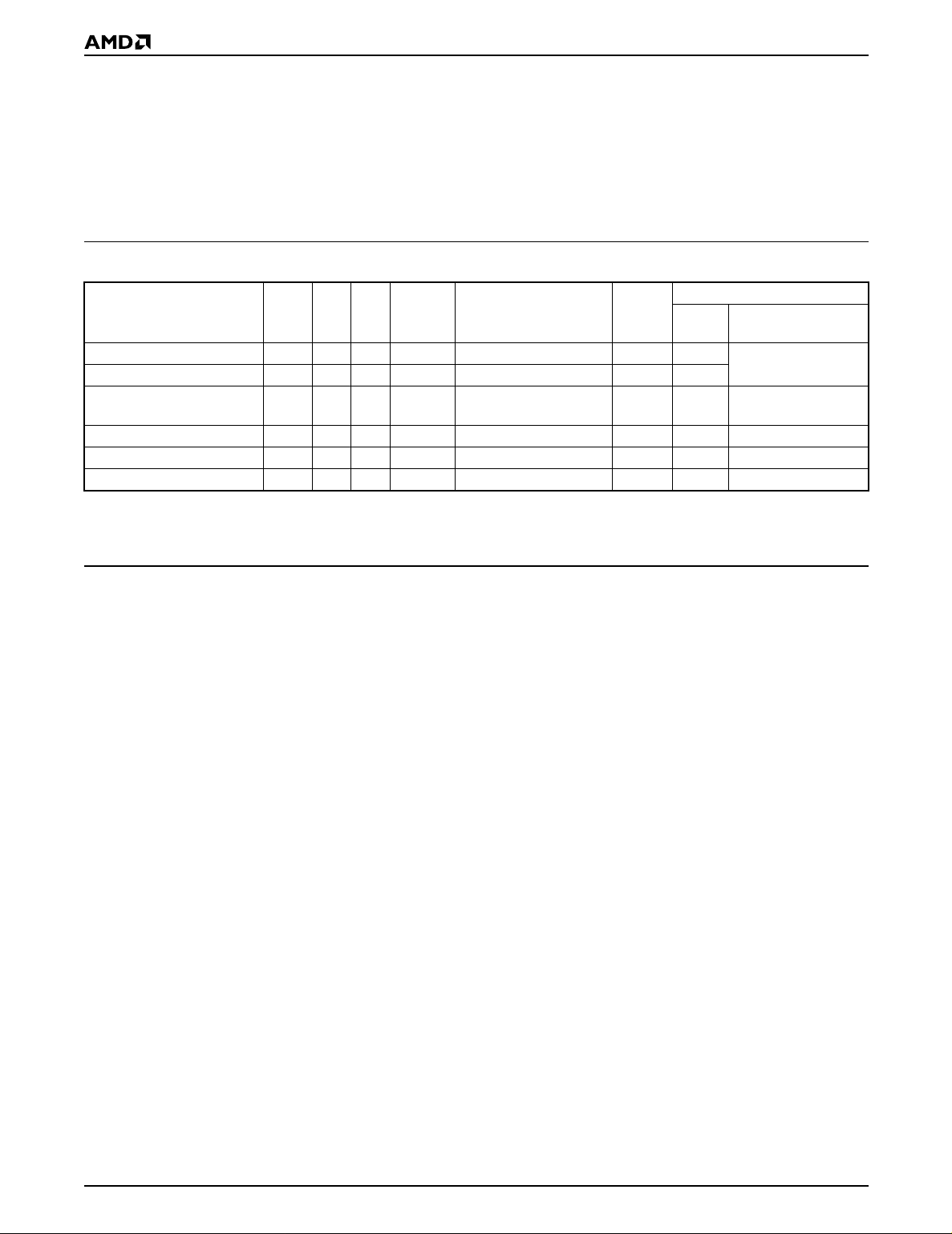

PRODUCT SELECTOR GUIDE

Family Part Number Am29LV200

Speed Options

Max access time, ns (t

Max CE# access time, ns (tCE) 90 100 120 150

Max OE# access time, ns (tOE) 40 40 50 55

Regulated Voltage Range: VCC =3.0–3.6 V -90R

Full Voltage Range: VCC = 2.7–3.6 V -100 -120 -150

) 90 100 120 150

ACC

Note: See “AC Characteristics” for full specifications.

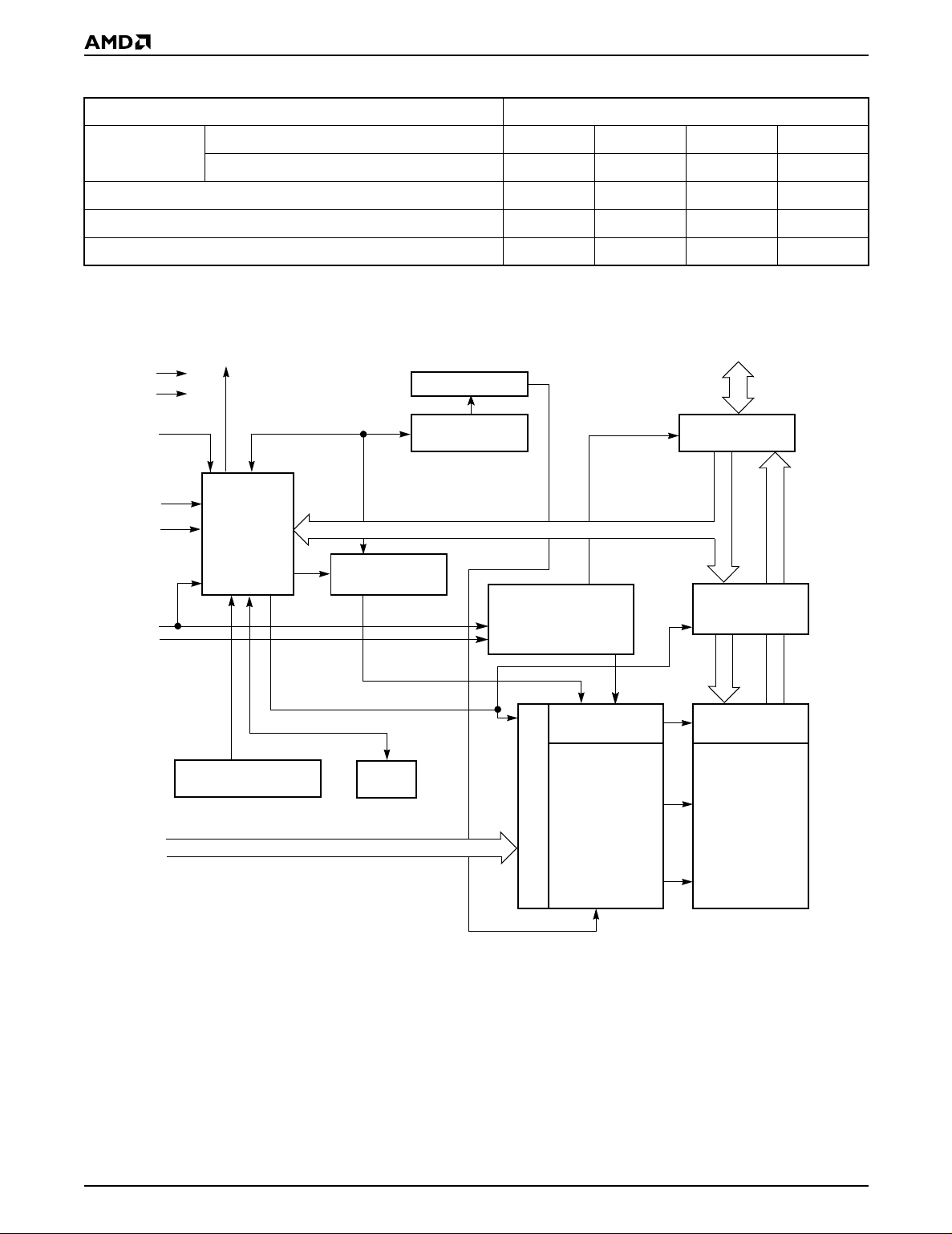

BLOCK DIAGRAM

DQ0

DQ15 (A-1)

–

Input/Output

Buffers

Data

Latch

V

CC

V

SS

RESET#

WE#

BYTE#

CE#

OE#

RY/BY#

State

Control

Command

Register

PGM Voltage

Generator

Sector Switches

Erase Voltage

Generator

Chip Enable

Output Enable

Logic

STB

A0–A16

VCC Detector

Timer

STB

Address Latch

Y-Decoder

X-Decoder

Y-Gating

Cell Matrix

20513D-1

3 Am29LV200

Page 4

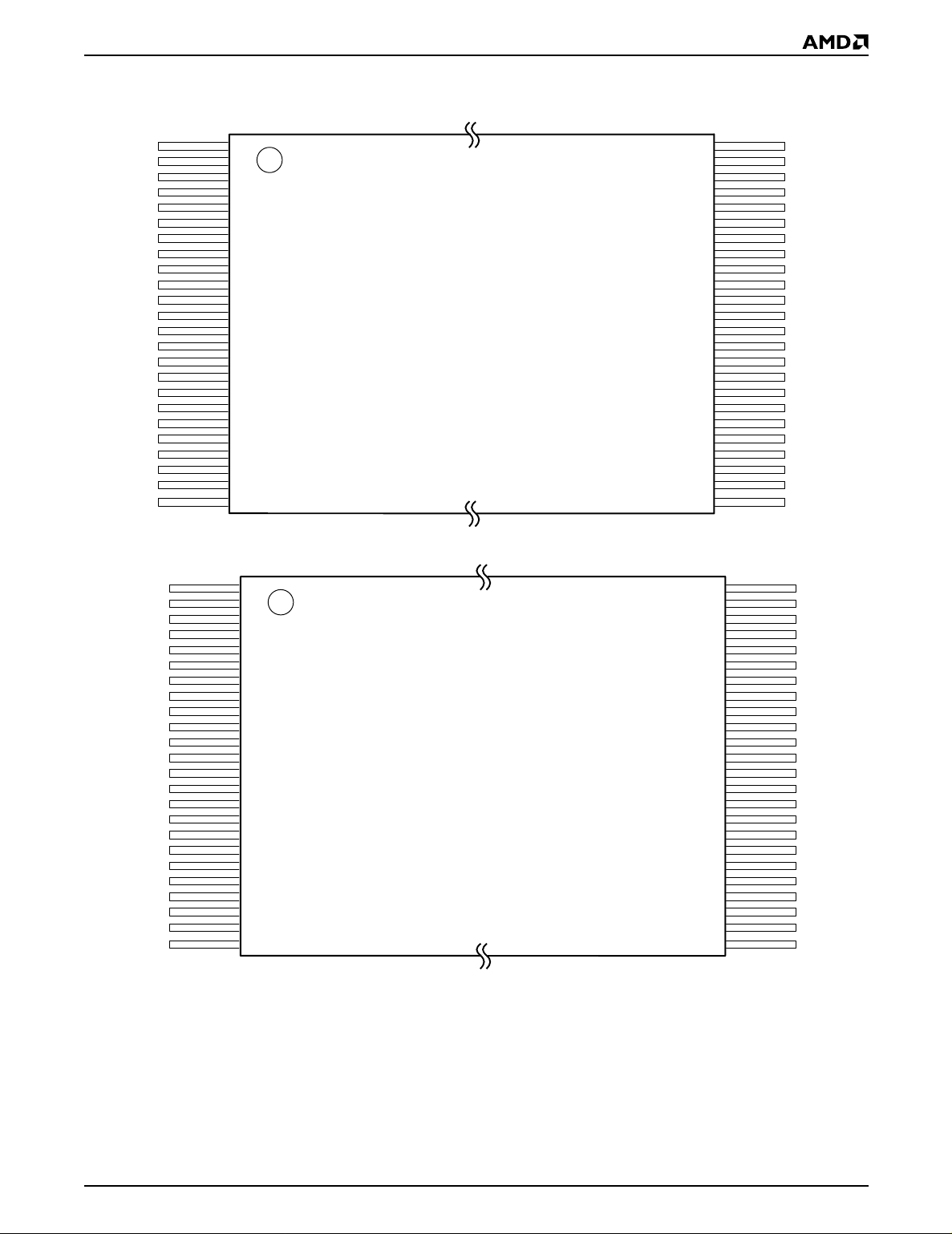

CONNECTION DIAGRAMS

PRELIMINARY

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

NC

NC

A7

A6

A5

A4

A3

A2

A1

A16

BYTE#

V

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

CE#

SS

CC

SS

A0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

NC

NC

A7

A6

A5

A4

A3

A2

A1

20513D-2

Am29LV200 4

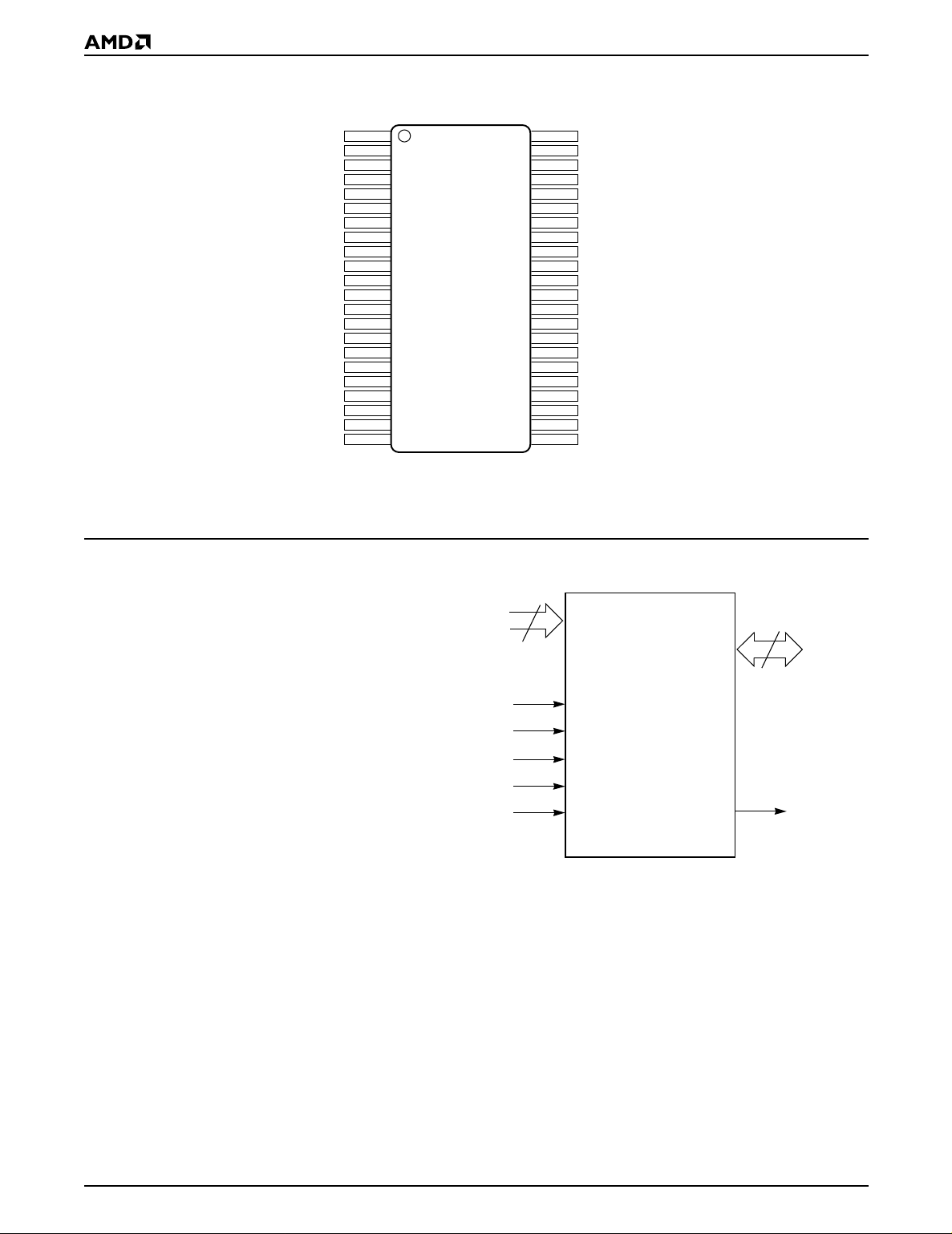

Page 5

CONNECTION DIAGRAMS

PRELIMINARY

1

NC

NC

A7

A6

A5

A4

A3

A2

A1

A0

CE#

V

SS

OE#

DQ0

DQ8

DQ1

DQ9

DQ2

DQ3

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

RY/BY#

DQ10

DQ11

PIN CONFIGURATION

A0–A16 = 17 addresses

DQ0–DQ14 = 15 data inputs/outputs

DQ15/A-1 = DQ15 (data input/output, word mode),

A-1 (LSB address input, byte mode)

SO

44

RESET#

43

WE#

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

A15

34

A16

33

BYTE#

32

V

SS

DQ15/A-1

31

DQ7

30

DQ14

29

DQ6

28

DQ13

27

DQ5

26

DQ12

25

DQ4

24

V

23

CC

LOGIC SYMBOL

17

A0–A16

20513D-3

16 or 8

DQ0–DQ15

(A-1)

BYTE# = Selects 8-bit or 16-bit mode

CE# = Chip enable

OE# = Output enable

WE# = Write enable

RESET# = Hardware reset pin, active low

RY/BY# = Ready/Busy# output

= 3.0 volt-only single power supply

V

CC

(see Product Selector Guide for speed

options and voltage supply tolerances)

V

SS

= Device ground

NC = Pin not connected internally

CE#

OE#

WE#

RESET#

BYTE# RY/BY#

20513D-4

5 Am29LV200

Page 6

PRELIMINARY

ORDERING INFORMATION

Standard Pr od ucts

AMD standard products are available in several packages and operating ranges. The order number (Valid Combination) is formed by a combination of the elements below.

CE-90RAm29LV200 T

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-in

(Contact an AMD representative for more information)

TEMPERATURE RANGE

C=Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

E = Extended (–55°C to +125°C)

PACKAGE TYPE

E = 48-Pin Thin Small Outline Package (TSOP)

Standard Pinout (TS 048)

F = 48-Pin Thin Small Outline Package (TSOP)

Reverse Pinout (TSR048)

Am29LV200T-90R,

Am29LV200B-90R

Am29LV200T-100,

Am29LV200B-100

Am29LV200T-120,

Am29LV200B-120

Am29LV200T-150,

Am29LV200B-150

Valid Combinations

EC, EI, FC, FI, SC, SI

EC, EI, EE,

FC, FI, FE,

SC, SI, SE

SPEED OPTION

See Product Selector Guide and Valid Combinations

BOOT CODE SECTOR ARCHITECTURE

T = Top Sector

B = Bottom Sector

DEVICE NUMBER/DESCRIPTION

Am29LV200

2 Megabit (256 K x 8-Bit/128 K x 16-Bit) CMOS Flash Memory

3.0 Volt-only Read, Program, and Erase

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales

office to confirm availability of specific valid combinations and

to check on newly released combinations.

Am29LV200 6

Page 7

PRELIMINARY

DEVICE BUS OPERATIONS

This section describes the re quirements and us e of the

device bus operations, which are initiated through the

internal command register . The command register itself

does not occupy any ad dressable memory locatio n.

The register is composed of latches that store the commands, along with the address and data information

needed to execute the command. The contents of the

Table 1. Am29LV200 Device Bus Operations

Operation CE# OE# WE# RESET#

Read L L H H A

Write L H L H A

±

V

CC

Standby

Output Disable L H H H X High-Z High-Z High-Z

Reset X X X L X High-Z High-Z High-Z

T emporary Sector Unprotect X X X V

Legend:

L = Logic Low = V

Note: Addresses are A16:A0 in word mode (BYTE# = V

, H = Logic High = VIH, VID = 12.0 ± 0.5 V , X = Don’t Care, AIN = Addresses In, DIN = Data In, D

IL

0.3 V

XX

VCC ±

0.3 V

ID

), A16:A-1 in byte mode (BYTE# = VIL).

IH

register serve as inputs to the internal state machine.

The state machine outputs d ictate the function of the

device. Table 1 lists the device bus operations, the inputs and control levels they require, and the resulting

output. The following subsections describe each of

these operations in further detail.

DQ8–DQ15

OUT

D

D

BYTE#

= V

IH

D

OUT

D

IN

IN

IN

D

IN

Addresses

(See Note)

IN

IN

X High-Z High-Z High-Z

A

IN

DQ0–

DQ7

D

BYTE#

= V

DQ8–DQ14 = High-Z,

DQ15 = A-1

High-Z

= Data Out

OUT

IL

Word/Byte Configuration

The BYTE# pin controls whether the device data I/O

pins DQ15–DQ0 operate in the byte or word configuration. If the BYTE# pin is set at logic ‘1’, the device is in

word configuration, DQ15–DQ0 are active an d c ontrolled by CE# and OE#.

If the BYTE# pin is set at logic ‘0’, the device is in byte

configuration, and only data I/O pins DQ0–DQ7 ar e active and controlled by CE# and OE#. The data I/O pins

DQ8–DQ14 are tri-stated, and the DQ15 pin is used as

an input for the LSB (A-1) address function.

Requirements for Reading Array Data

To read array data from the outputs, the system must

drive the CE# and OE# pins to V

control and selects the device. OE# is the output control and gates array data to the output pins. WE#

should remain at V

. The BYTE# pin determines

IH

whether the device outputs array data in words or

bytes.

The internal state machine is set for reading array data

upon device power-up, or after a hardware reset. This

ensures that no spurious alteration of the memory content occurs during the power transition. No command is

necessary in this mode to obtain array data. Standard

microprocessor read cycles that assert valid addr esses

on the device address inputs produce valid data on the

device data outpu ts. The device rem ains enabled for

. CE# is the power

IL

read access until the command register contents are

altered.

See “Reading Array Data” for more information. Refer

to the AC Read Operations table for timing specifications and to Figure 12 for the timing diagram. I

CC1

in

the DC Characteristics table represents the active current specification for reading array data.

Writing Commands/Command Sequences

To write a command or command sequence (which includes programming data to the device and erasing

sectors of memory), the system must drive WE# and

CE# to V

For program op erations, the BYTE# pin deter mines

whether the device accepts program data in bytes or

words. Refer to “Word/Byte Configuration” for more information.

An erase operation can erase one sector, multiple sectors, or the entire device. Tables 2 and 3 indicate the

address space that each sector occupies. A “sector address” consists of the address b its requ ired to uni quely

select a sector. See the “Command Definitions” section

has details on erasing a sector or the entire chip, or

suspending/resuming the erase operation.

After the system writes the autoselect command sequence, the device enters the autoselect mode. The

system can then read autoselect codes from the inter-

, and OE# to VIH.

IL

7 Am29LV200

Page 8

PRELIMINARY

nal register (which is separate from the memory array)

on DQ7–DQ0. Standard read cycle timings apply in this

mode. Refer to the “Autoselect Mode” and “Autoselect

Command Sequence” sections for more information.

in the DC Characteristics table represents the ac-

I

CC2

tive current specification for the write mode . The “AC

Characteristics” section contains timing specification

tables and timing diagrams for write operations.

Program and Erase Operation Status

During an erase or program operation, t he system may

check the status of the operation by reading the status

bits on DQ7–DQ0. Standard read cycle timings and I

CC

read specificat ions apply. Refer to “Write Operation

Status” for more information, and to “AC Characteristics” for timing diagrams.

Standby Mode

When the system is not reading or writing to the device,

it can place the device in the standby mo de. In this

mode, current consumption is greatly reduced, and the

outputs are placed in the high impedance state, independent of the OE# input.

The device enters the CMOS standby mode when the

CE# and RESET# pins are both held at V

CC

± 0.3 V.

(Note that this is a more restricted voltage range than

.) If CE# and RESET# are held at VIH, but not within

V

IH

± 0.3 V , t he device will be in the standby mode, but

V

CC

the standby current will be greater . The devi ce requires

standard access time (t

) for read access when the

CE

device is in either of these standby modes, before it is

ready to read data.

If the device is deselected during erasure or programming, the device draws active current until the

operation is completed.

In the DC Characteristics table, I

CC3

and I

CC4

repre-

sents the standby current specifications.

Automatic Sleep Mode

The automatic sleep mode minimizes Flash device

energy consumption. The device automatically

enables this mode when addresses rema in stable for

+ 30 ns. The automatic sleep mode is inde-

t

ACC

pendent of the CE#, WE#, and OE# control signals.

Standard address access timings provide new data

when addresses are changed. While in sleep mode,

output data is latched and always available to the

system. I

in the DC Characteristics table represents

CC5

the automatic sleep mode current specification.

RESET#: Hardware Reset Pin

The RESET# pin provides a hardware method of resetting the device to reading array data. When the

RESET# pin is driven to V

for at least a period of tRP,

IL

the device immediately terminates any operation in

progress, tristates all output pins, and ignores all

read/write commands for the duration of the RESET#

pulse. The device also resets the internal state

machine to reading array data. The operation that was

interrupted should be reinitiated once the device is

ready to accept another command sequence, to

ensure data integrity.

Current is reduced for the duration of the RESET#

pulse. When RESET# is held at V

draws CMOS standby current (I

but not within VSS±0.3 V , the standby current will

at V

IL

±0.3 V, the device

SS

). If RESET# is held

CC4

be greater.

The RESET# pin may be tied to the system reset cir-

cuitry. A system reset would thus also reset the Flash

memory, enabling the system to read the boot-up

firmware from the Flash memory.

If RESET# is asserted during a program or erase operation, the RY/BY# pin remains a “0” (busy) until the internal reset operation is complete, which re quires a

time of t

(during Embedded Algorithms). The

READY

system can thus monitor RY/BY# to determine whether

the reset operation is co mplete. If RESET# is asserted

when a program or erase operation is not executing

(RY/BY# pin is “1”), the reset opera tion is completed

within a time of t

READY

rithms). The system can read data t

SET# pin returns to V

(not during Embedded Algo-

after the RE -

.

IH

RH

Refer to the AC Characteristics tables for RESET# parameters and to Figure 13 for the timing diagram.

Output Disable Mode

When the OE# input is at VIH, output from the device is

disabled. The output pins are placed in the high impedance state.

Am29LV200 8

Page 9

PRELIMINARY

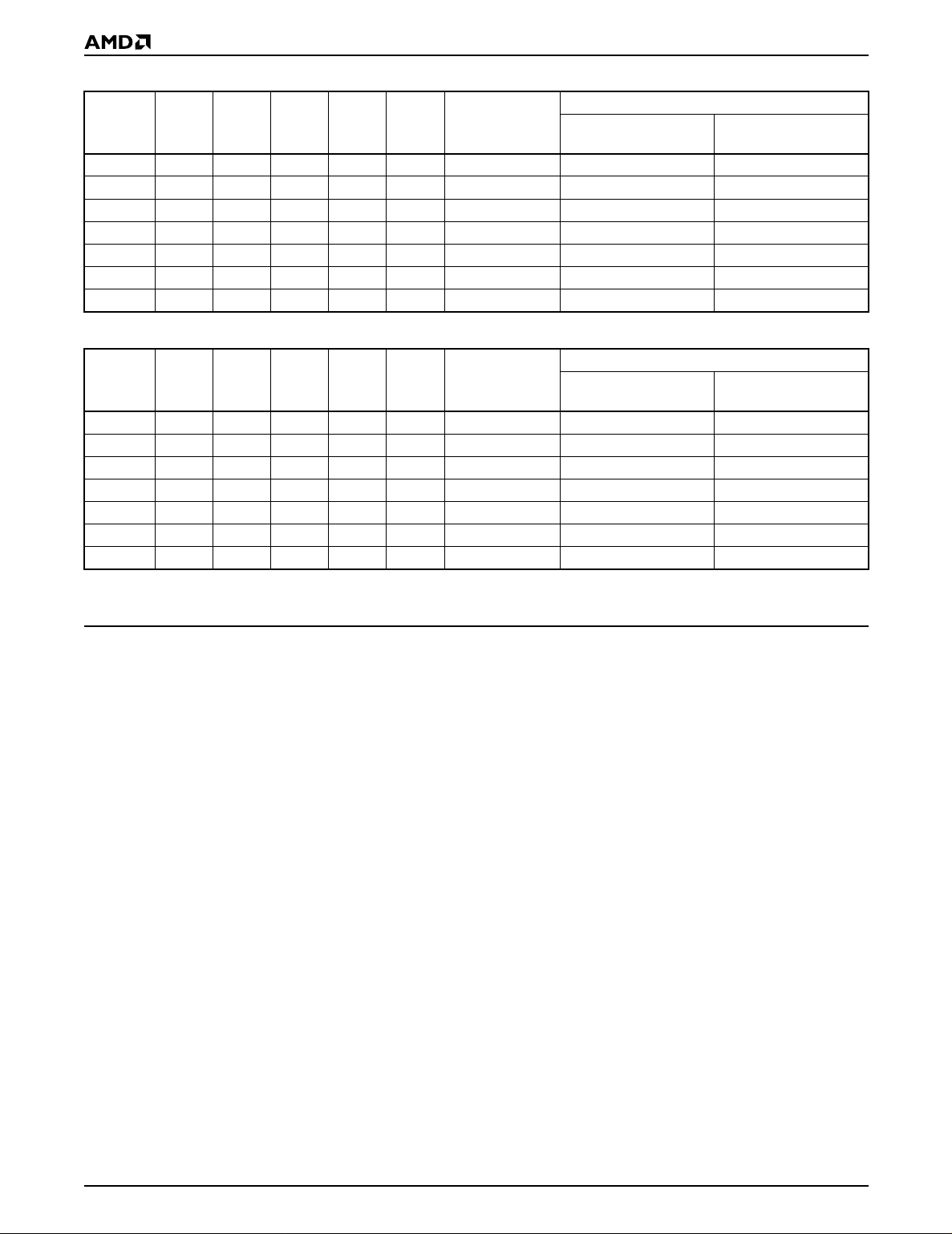

Table 2. Am29LV200T Top Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A16 A15 A14 A13 A12

SA0 0 0 X X X 64/32 00000h–0FFFFh 00000h–07FFFh

SA1 0 1 X X X 64/32 10000h–1FFFFh 08000h–0FFFFh

SA2 1 0 X X X 64/32 20000h–2FFFFh 10000h–17FFFh

SA3 1 1 0 X X 32/16 30000h–37FFFh 18000h–1BFFFh

SA4 1 1 1 0 0 8/4 38000h–39FFFh 1C000h–1CFFFh

SA5 1 1 1 0 1 8/4 3A000h–3BFFFh 1D000h–1DFFFh

SA6 1 1 1 1 X 16/8 3C000h–3FFFFh 1E000h–1FFFFh

Kwords)

Address Range (in hexadecim al )

(x8)

Address Range

Address Range

(x16)

Table 3. Am29LV200B Bottom Boot Block Sector Address Table

Sector Size

(Kbytes/

Sector A16 A15 A14 A13 A12

SA0 0 0 0 0 X 16/8 00000h–03FFFh 00000h–01FFFh

SA1 0 0 0 1 0 8/4 04000h–05FFFh 02000h–02FFFh

SA2 0 0 0 1 1 8/4 06000h–07FFFh 03000h–03FFFh

SA3 0 0 1 X X 32/16 08000h–0FFFFh 04000h–07FFFh

SA4 0 1 X X X 64/32 10000h–1FFFFh 08000h–0FFFFh

SA5 1 0 X X X 64/32 20000h–2FFFFh 10000h–17FFFh

SA6 1 1 X X X 64/32 30000h–3FFFFh 18000h–1FFFFh

Kwords)

Address Range (in hexadecim al )

(x8)

Address Range

Address Range

(x16)

Note for Tables 2 and 3: Address range is A16:A-1 in byte mode and A16:A0 in word mode. See “Word/Byte Configuration”

section for more information.

Autoselect Mode

The autoselect mode provides manu facturer and device identification, and sector protection verification,

through identifier codes output on DQ7–DQ0. This

mode is primarily intended for programming equipment

to automatically match a device to be programmed with

its corresponding progra mming algorithm. However,

the autoselect codes can also be accessed in-system

through the command register.

When using programming equipment, the autoselect

mode requires V

(11.5 V to 12.5 V) on address pin

ID

A9. Address pins A6, A1, and A0 must be as shown in

Table 4. In addition, when verifying sector protection,

the sector address must appear on the appropriate

highest order address bits (see Tables 2 and 3). Table

4 shows the remaining address bits that are don’t care.

When all necessary bits have be en set as required, the

programming equipment may then read the corresponding identifier code on DQ7–DQ0.

To access the autoselect codes in-system, the host

system can issue the autoselect command via the

command register, as shown in Table 5. This method

does not require V

. See “Command Definitions” for

ID

details on using the autoselect mode.

9 Am29LV200

Page 10

Table 4. Am29LV200 Autoselect Codes (High Voltage Method)

Description Mode CE# OE# WE#

PRELIMINARY

A16

to

A12

A11

to

A10 A9

A8

to

A7 A6

A5

to

A2 A1 A0

DQ8

to

DQ15

DQ7

to

DQ0

Manufacturer ID: AMD L L H X X V

Device ID:

Am29LV200

(Top Boot Block)

Device ID:

Am29LV200

(Bottom Boot

Block)

Sector Protection Verification L L H SA X V

L = Logic Low = VIL, H = Logic High = VIH, SA = Sector Address, X = Don’t care.

Word L L H

XXV

Byte L L H X 3Bh

Word L L H

XXV

Byte L L H X BFh

XLXLL X 01h

ID

XLXLH

ID

XLXLH

ID

XLXHL

ID

Sector Protection/Unprotection

The hardware sector protection feature disables both

program and erase operations in any sec tor. The hardware sector unprotection feature re-enables both program and erase operations in pre viously protected

sectors.

Sector protection/unprotection must be implemented

using programming equipment.The procedure requires

a high voltage (V

tails on this method are provided in a supplement, publication number 21226. Contact an AMD representative

to request a copy.

The device is shipped with all sectors unprotected.

AMD offers the option of programming and protecting

sectors at its factory prior to shipping the device

through AMD’s ExpressFlash™ Service. Contact a n

AMD representative for details.

) on address pin A9 and OE#. De-

ID

22h 3Bh

22h BFh

X

X

START

RESET# = V

(Note 1)

Perform Erase or

Program Operations

RESET# = V

Temporary Sector

Unprotect Completed

(Note 2)

ID

IH

01h

(protected)

00h

(unprotected)

It is possible to determine whether a sector is protected

or unprotected. See “Autoselect Mode” for details.

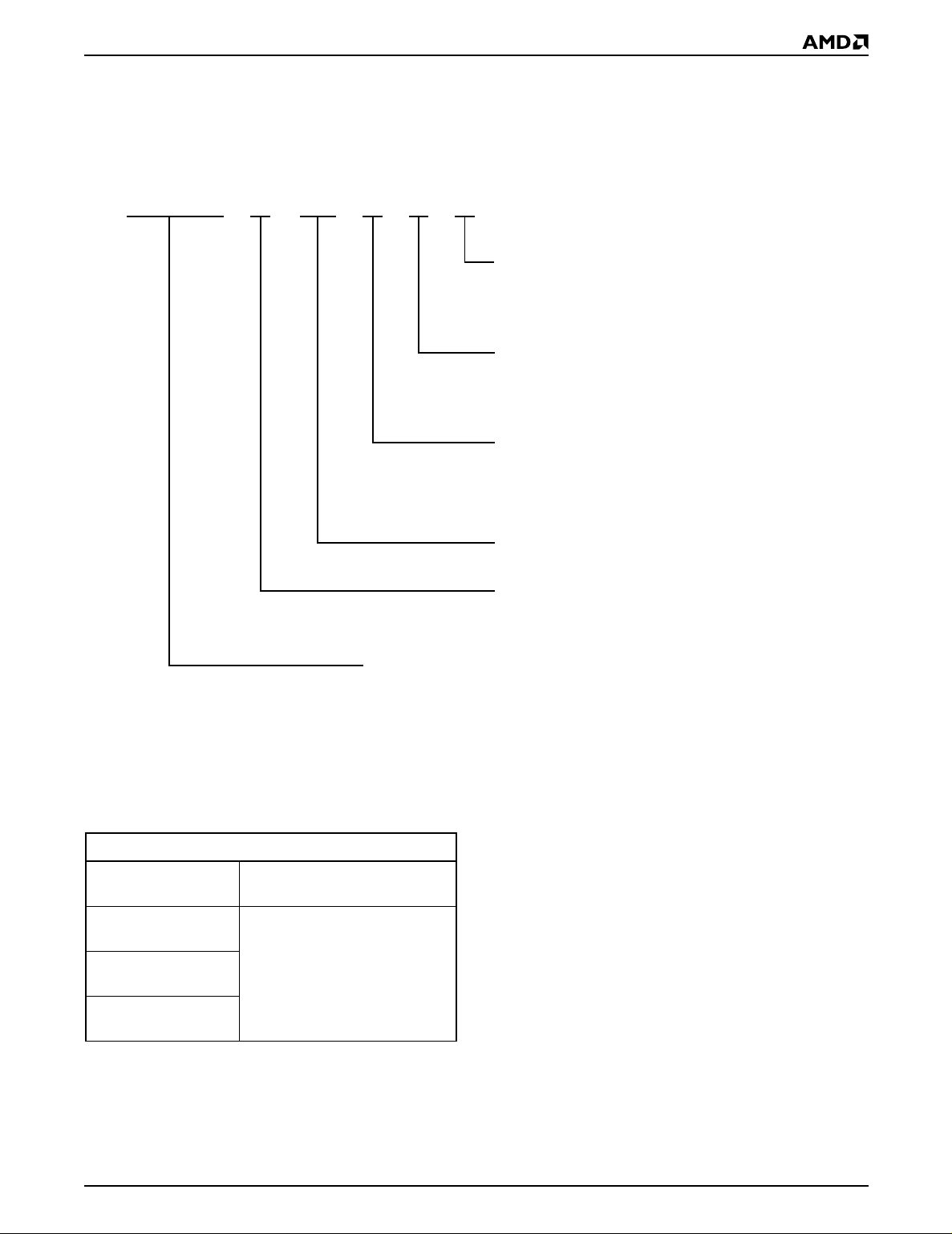

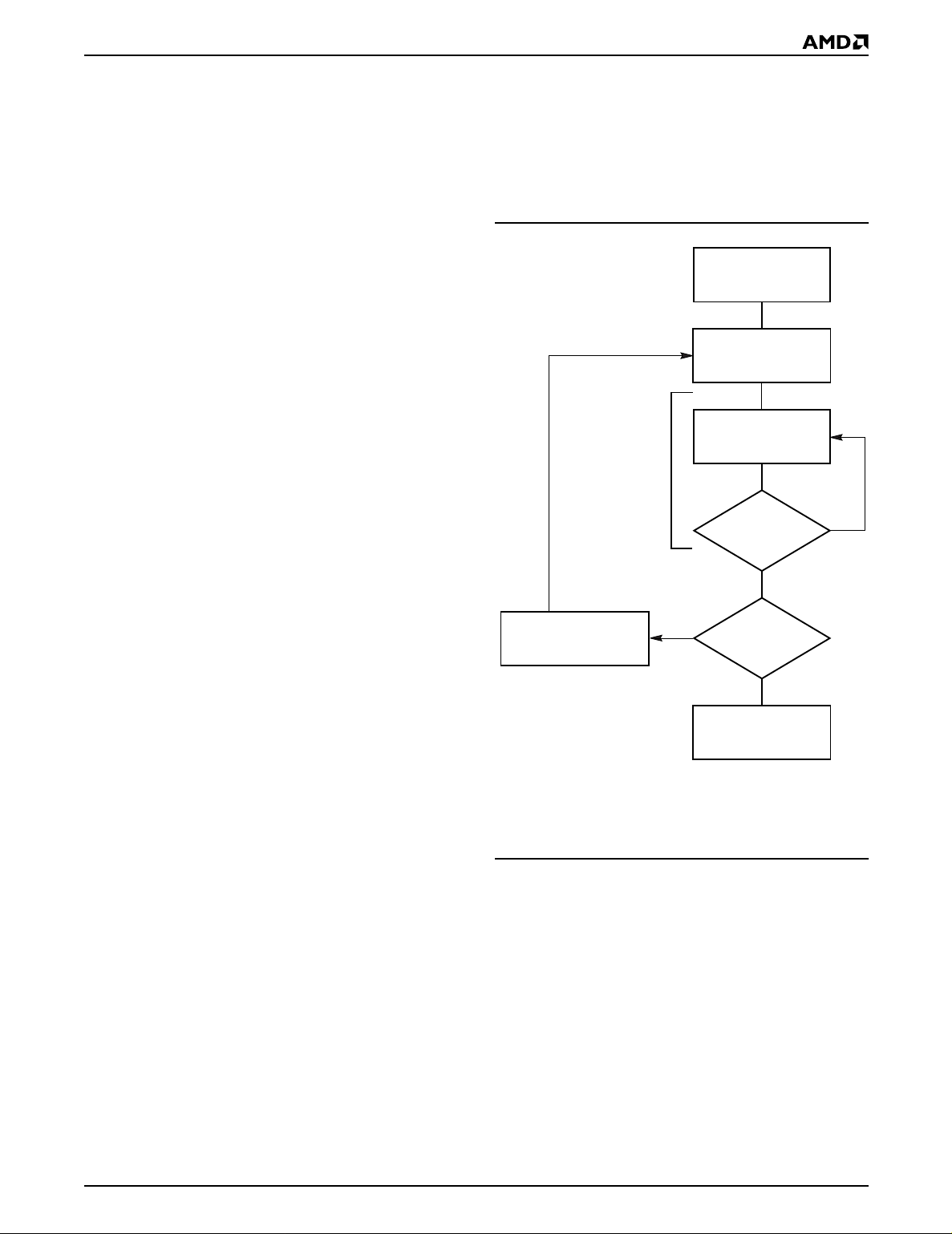

Temporary Sector Unprotect

This feature allows temporary unp rotection of previously protected sectors to change data in-system. The

Sector Unprotect mode is activated by setting the RESET# pin to V

sectors can be programmed or erased by selecting the

sector addres ses. Once V

SET# pin, all the previously protected sectors are

protected again. Figure 1 shows the algorithm, and

Figure 21 shows the timing diagrams, for this feature.

. During this mode, formerly protected

ID

is removed from the RE-

ID

Am29LV200 10

Notes:

20513D-5

1. All protected sectors unprotected.

2. All previously protected sectors are protected once

again.

Figure 1. Temporary Sector Unprotect Operation

Page 11

PRELIMINARY

Hardware Data Protection

The command sequence requirement of unlock cycles

for programming or erasing provides data protection

against inadvertent writes ( refer to Table 5 for command definitions). In add ition, the following hardwar e

data protection measures preve nt accidental erasure

or programming, which might otherwise be caused by

spurious system level signals during V

power-up

CC

and power-down transitions, or from system noise.

Low V

When V

cept any write cycles. This protects data during V

Write Inhibit

CC

is less than V

CC

, the device does not ac-

LKO

CC

power-up and power-down. The command register and

all internal program/erase circuits are disabled, and the

device resets. Subsequent writes are ignored until V

is greater than V

. The system must provide the

LKO

CC

proper signals to the control pins to prevent unintentional writes when V

is greater than V

CC

LKO

.

COMMAND DEFINITIONS

Writing specific address and data command s or sequences into the command register initiates device operations. Table 5 defines the valid register command

sequences. Writing incorrect address and data val-

ues or writing them in the improper sequence resets

the device to reading array data.

All addresses are latched on the falling edge of WE# or

CE#, whichever happens later. All data is latched on

the rising edge of WE# or CE#, whichever happens

first. Refer to the appropriate timing diagrams in the

“AC Characteristics” section.

Reading Array Data

The device is a utomatically set to reading array data

after device power-up. No commands are required to

retrieve data. The device is also ready to read array

data after completing an Em bedded Program or Embedded Erase algorithm.

After the device accepts an Erase Suspend command,

the device enters the Erase Suspend mode. The system can read array data using the standard read timings, except that if it reads at an address within erasesuspended sectors, the device outputs status data.

After completing a programming operation in the Erase

Suspend mode, the system may once again read array

data with the same exception. See “Erase Suspend/Erase Resume Commands” for more information

on this mode.

must

The system

ble the device for reading array data if DQ5 goes high,

or while in the autoselect mode. See the “Reset Command” section, next.

issue the reset command to re-ena-

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#, CE# or

WE# do not initiate a write cycle.

Logical Inhibit

Write cycles are inhibited by holding any one of OE# =

, CE# = VIH or WE# = VIH. To initiate a write cycle,

V

IL

CE# and WE# must be a logical zero wh ile OE# is a

logical one.

Power-Up Write Inhibit

If WE# = CE# = V

and OE# = VIH during power up, the

IL

device does not accept commands on the rising edge

of WE#. The internal state machin e is automatically

reset to reading array data on power-up.

See also “Requirements for Reading Array Data” in the

“Device Bus Operations” section for more information.

The Read Operations table provides the read parameters, and Figure 12 shows the timing diagram.

Reset Command

Writing the reset command to the device resets the device to reading array data. Address bits are don’t care

for this command.

The reset command may be written between the sequence cycles in an erase command sequence before

erasing begins. This resets the device to reading array

data. Once erasure begins, however, the device ignores reset commands until the operation is complete.

The reset command may be written between the sequence cycles in a program command sequence before programming begins. This resets the device to

reading array data (also applies to programming in

Erase Suspend mode). Once programming begins,

however, the device ignores reset commands until the

operation is complete.

The reset command may be written between the sequence cycles in an autoselect command sequence.

Once in the autoselect mode, the reset command

be written to return to reading array data (also applies

to autoselect during Erase Suspend).

If DQ5 goes high during a program or erase operat ion,

writing the reset command returns the device to reading array data (also applies during Erase Suspend).

must

11 Am29LV200

Page 12

PRELIMINARY

Autoselect Command Sequence

The autoselect command sequence allows the host

system to access the manufacturer and devices codes,

and determine whether or not a sector is protected.

Table 5 shows the address and data requirements.

This method is an alternative to that shown in Table 4,

which is intended for PROM programmers and requires

on address bit A9.

V

ID

The autoselect command sequence is initiated by writing two unlock cycles, followed by the autoselect command. The device then enters the autoselect mode,

and the system may read at any address any number

of times, without initiating another command sequence.

A read cycle at address XX00h retrieves the manufacturer code. A read cycle at address XX01h in word

mode (or 02h in byte mode) returns the device code. A

read cycle containing a sector address (SA) and the

address 02h in wor d mode (or 04h i n byte mode) returns 01h if that sector is protected, or 00h if it is unprotected. Refer to Tables 2 and 3 for valid sector

addresses.

The system must write the reset command to exit the

autoselect mode and return to reading array data.

Word/Byte Program Command Sequence

The system may program the device by word or byte,

depending on the state of the BYTE# pin. Programming is a four-bus-cycle operation. The program command sequence is initiated by writing two unlock write

cycles, followed by the program set-up command. The

program addre ss and data are writte n next, which in

turn initiate the Embedded Program algorithm. The

not

system is

ings. The device automatically provides internally generated program pulses and verifies the programmed

cell margin. Table 5 shows the address and data requirements for the byte program command sequence.

When the Embedded Program algorithm is complete,

the device then returns to reading array data and addresses are no longer latched. The system can determine the status of th e program operation by usin g

DQ7, DQ6, or RY/BY#. See “Write Operation Status”

for information on these status bits.

Any commands written to the device during the Embedded Program Algorithm are ignored. Note that a

hardware reset immediately terminates the programming operation. The program command sequence

should be reinitiated once the device has reset to reading array data, to ensure data integrity.

Programming is allowed in any s equence and across

sector boundaries. A bit cannot be programmed

from a “0” back to a “1”. Attempting to do so may halt

the operation and set DQ5 to “1”, or cause the Data#

Polling algorithm to indicate the operation was suc -

required to provide further controls or ti m-

cessful. However, a succeeding read will show that the

data is still “0”. Only erase operations can convert a “0”

to a “1”.

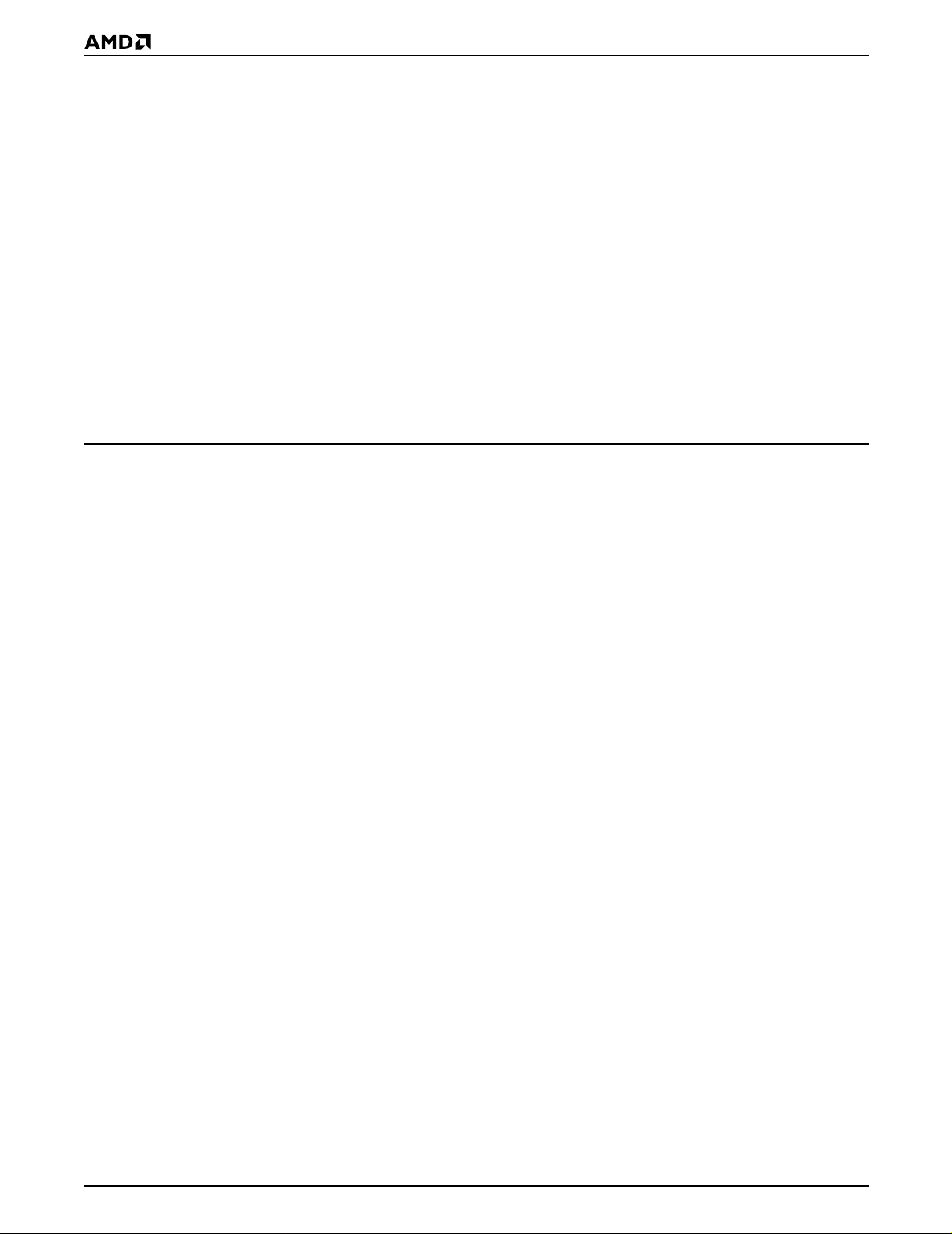

Figure 2 illustrates the algorithm for the program operation. See the Erase/Program Operations table in “AC

Characteristics” for parameters, and to Figure 16 for

timing diagrams.

START

Write Program

Command Sequence

Data Poll

Embedded

Program

algorithm

in progress

Increment Address

Note: See Table 5 for program command sequence.

No

from System

Verify Data?

Yes

Last Address?

Yes

Programming

Completed

No

20513D-5

Figure 2. Program Operation

Chip Erase Command Sequence

Chip erase is a six bus cycle operation. The chip erase

command sequence is ini tiated by writing two unlock

cycles, followed by a set-up command. Two additional

unlock write cycles are then followed by the chip erase

command, which in turn invokes the Embedded Erase

not

algorithm. The device does

preprogram prior to erase. The Embedded Erase algorithm automatically preprograms and verifi es the entire

memory for an all zero data pattern prior to electrical

erase. The system is not required to provide any controls or timings during these operations. Table 5 shows

the address and data requirements for the chip erase

command sequence.

require the system to

Am29LV200 12

Page 13

PRELIMINARY

Any commands written to the chip during the Embedded Erase algorithm are ignored. Note that a har dware

reset during the chip erase operation immediately terminates the operation. The Chip Erase command sequence should be reinitiated once the device has

returned to reading array data, to ensure data int egrity.

The system can determine the status of the erase operation by using DQ7, DQ6, DQ2, or RY/BY#. See

“Write Operation Status” for information on these status bits. When the Embedded Erase algorithm is complete, the device returns to reading array data and

addresses are no longer latched.

Figure 3 illustrates the algorithm for the erase operation. See the Erase/Program Operations tables in “AC

Characteristics” for parameters, and to Figure 17 for

timing diagrams.

Sector Erase Command Sequence

Sector erase is a six bus c ycle operation. The sector

erase command sequence is initiated by writing two

unlock cycles, followed by a set-up command. Two additional unlock write cycles are then followed b y the address of the sector to be erased, and the sector erase

command. Table 5 shows the address and data requirements for the sector erase command sequence.

not

The device does

the memory prior to erase. The Embedded Erase algorithm automatically programs and verifies the sector for

an all zero data pattern prior to electrical erase. The

system is not required to provide any c ontrols or timings during these operations.

After the command sequence is written, a sector erase

time-out of 50 µs begins. During the time-out period,

additional sector addresses and sector erase commands may be written. Loading the sect or er ase buf fer

may be done in any sequence, and the number of sectors may be from one sector to all s ectors. The time between these additional cycles must be less than 50 µs,

otherwise the last address and command might not be

accepted, and erasure may begin. It is recommended

that processor interrupts be disabled during t his time to

ensure all commands are accepted. The interrupts can

be re-enabled after the last Sector Erase command is

written. If the time between additional sector erase

commands can be assumed to be less than 50 µs, the

system need not monitor DQ3. Any command other

than Sector Erase or Erase Suspend during the

time-out period resets the device to reading array

data. The system must rewrite the command sequence

and any additional sector addresses and commands.

require the system to preprogram

Once the sector erase operation has begun, only the

Erase Suspend command is valid. All other commands

are ignored. Note that a hardware reset during the

sector erase operation immediately terminates the operation. The Sector Erase command sequence should

be reinitiated once the device has returned to reading

array data, to ensure data integrity.

When the Embedded Erase algorithm is complete, the

device returns to reading array data and addresses are

no longer latched. The system can determine the status of the erase operation by u sing DQ7, DQ6, DQ2, or

RY/BY#. (Refer to “Write Operation Status” for information on these status bits.)

Figure 3 illustrates the algorithm for the erase operation. Refer to the Erase/Program Operations tables in

the “AC Characteristics” section for parameters, and to

Figure 17 for timing diagrams.

Erase Suspend/Erase Resume Commands

The Erase Suspend command allows the system to interrupt a sector erase operatio n and then read data

from, or program data to, any sector not selected for

erasure. This command is valid only during the sector

erase operation, including the 50 µs time-out period

during the sector erase com mand sequence. The

Erase Suspend com mand is ignored if written during

the chip erase operation or Embedded Program algorithm. Writing the Erase Suspend command during the

Sector Erase time-out immediately terminates the

time-out period and suspends the erase operation. Addresses are “don’t-cares” when writing the Erase Suspend command.

When the Erase Suspend command is written during a

sector erase operation, the device requires a maximum

of 20 µs to suspend the erase operation. However,

when the Erase Suspend command is written during

the sector erase time-out, the device immediately terminates the time-out period and suspends the erase

operation.

After the erase operation has been suspended, the

system can read array data from or program data to

any sector not selected for erasure. (The device “erase

suspends” all sectors selected for erasure.) Normal

read and write timings and command definitions apply.

Reading at any address within erase-suspended sectors produces status data on DQ7–DQ0. The system

can use DQ7, or DQ6 and DQ2 together, to determine

if a sector is actively erasing or is erase-suspended.

See “Write Operation Status” for information on these

status bits.

The system can monitor DQ3 to determine if the sector

erase timer has timed out. (See the “DQ3: Sector

Erase Timer” section.) The time-out begins from the rising edge of the final WE# pulse in the command sequence.

13 Am29LV200

After an erase-suspended program operation is complete, the system can once again read array data within

non-suspended sectors. The system can determine the

status of the program operation us ing the DQ7 or DQ6

Page 14

PRELIMINARY

status bits, just as in the standard program operation.

See “Write Operation Status” for more information.

The system may also write the autoselect command

sequence when the devic e is in the Erase Suspend

mode. The device allows reading autoselect codes

even at addresses within erasing secto rs, since the

codes are no t stored in the memory array. When the

device exits the autoselect mode, the device reverts to

the Erase Suspend mode, and is ready for another

valid operation. See “Auto select Command Sequence ”

for more information.

The system must write the Erase Resume command

(address bits are “don’t care”) to exit the erase suspend

mode and continue the sector erase operation. Further

writes of the Resume command are ignored. Another

Erase Suspend command can be written after the device has resumed erasing.

START

Write Erase

Command Sequence

Data Poll

from System

No

Data = FFh?

Erasure Completed

Embedded

Erase

algorithm

in progress

Yes

20513D-6

Notes:

1. See Table 5 for erase command sequence.

2. See “DQ3: Sector Erase Timer” for more information.

Figure 3. Erase Operation

Am29LV200 14

Page 15

PRELIMINARY

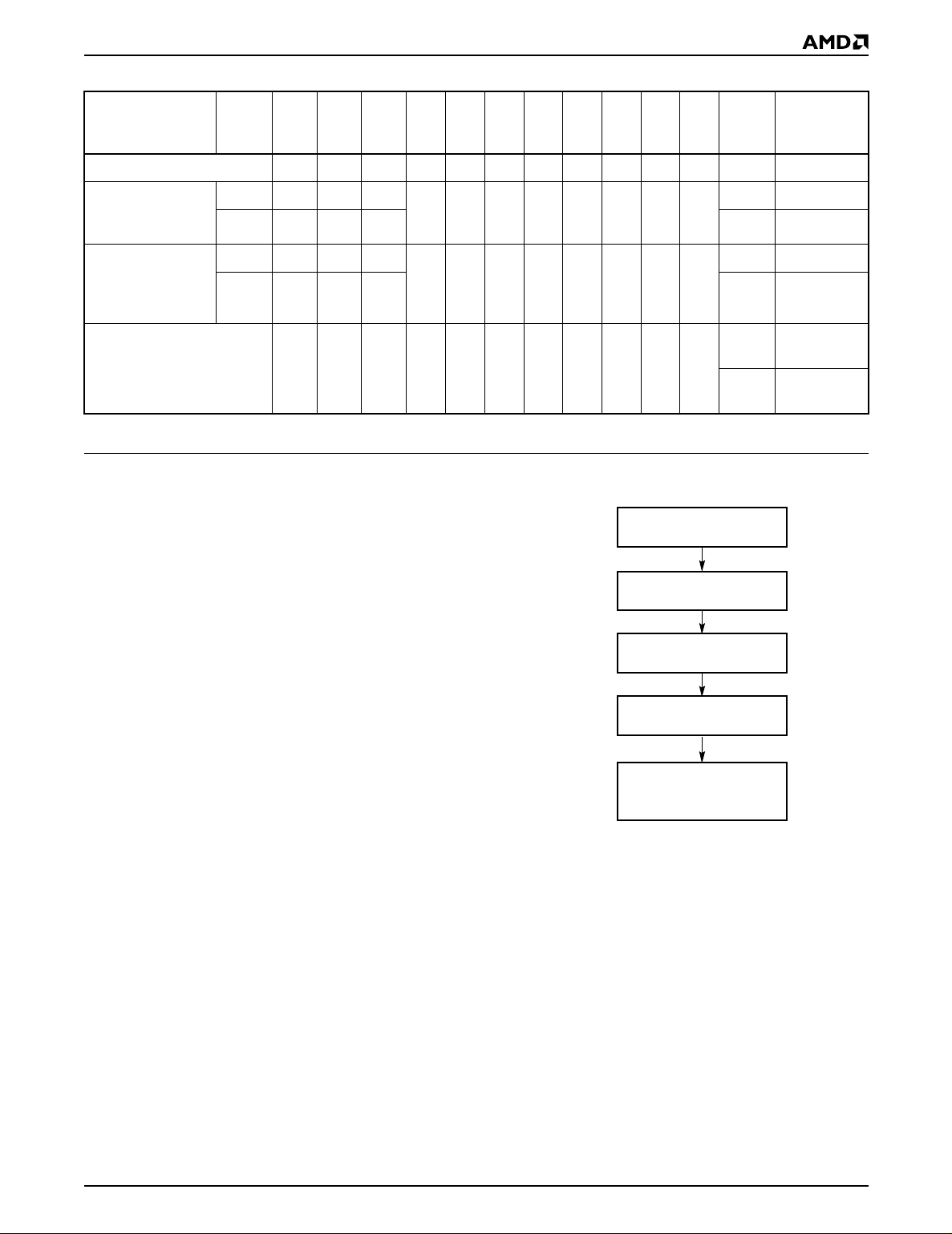

Table 5. Am29LV200 Command Definitions

Command

Sequence

(Note 1)

Read (Note 6) 1 RA RD

Reset (Note 7) 1 XXX F0

Manufacturer ID

Device ID,

Top Boot Block

Device ID,

Bottom Boot Block

Autoselect (Note 8)

Sector Protect Verify

(Note 9)

Program

Chip Erase

Sector Erase

Erase Suspend (Note 10) 1 XXX B0

Erase Resume (Note 11) 1 XXX 30

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555 AAA

Word

Byte AAA 555 AAA AAA 555

Legend:

X = Don’t care

RA = Address of the memory location to be read.

RD = Data read from location RA during read operation.

PA = Address of the memory location to be programmed.

Addresses latch on the falling edge of the WE# or CE# pulse,

whichever happens later.

First Second Third Fourth Fifth Sixth

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Cycles

555

4

555

4

555

4

555

4

555

4

555

6

555

6

AA

AA

AA

AA

AA

AA

AA

2AA

2AA

2AA

2AA

2AA

2AA

2AA

Bus Cycles (Notes 2–5)

55

55

55

55

55

55

55

555

555

555

555

555

555

555

90 X00 01

X01 223B

90

X02

X01 22BF

90

X02 BF

(SA)

X02

90

(SA)

X04

A0 PA PD

555

80

555

80

3B

XX00

XX01

00

01

AA

AA

2AA

2AA

555

55

55 SA 30

PD = Data to be programmed at location PA. Data latches on the

rising edge of WE# or CE# pulse, whichever happens first.

SA = Address of the sector to be verified (in autoselect mode) or

erased. Address bits A16–A12 uniquely select any sector.

10

Notes:

1. See Table 1 for description of bus operations.

8. The fourth cycle of the autoselect command sequence is a

2. All values are in hexadecimal.

3. Except when reading array or autoselect data, all bus cycles

9. The data is 00h for an unprotected sector and 01h for a

are write operations.

4. Data bits DQ15–DQ8 are don’t cares for unlock and

command cycles.

10. The system may read and program in non-erasing sectors, or

5. Address bits A16–A11 are don’t cares for unlock and

command cycles, unless SA or PA required.

6. No unlock or command cycles required when reading array

data.

11. The Erase Resume command is valid only during the Erase

7. The Reset command is required to return to reading array

data when device is in the autoselect mode, or if DQ5 goes

high (while the device is providing status da ta).

15 Am29LV200

read cycle.

protected sector. See “Autoselect Command Sequence” for

more information.

enter the autoselect mode, when in the Erase Suspend

mode. The Erase Suspend command is valid only during a

sector erase operation.

Suspend mode.

Page 16

PRELIMINARY

WRITE OPERATION STATUS

The device provides several bits to determine the status of a write operation: DQ2, DQ3, DQ5, DQ6, DQ7,

and RY/BY#. Table 6 and the following subsections describe the functions of these bits. DQ7, RY/BY#, and

DQ6 each offer a method for determining whether a

program or erase operation is complete or in progress.

These three bits are discussed first.

DQ7: Data# Polling

The Data# Polling bit, DQ7, indicates to the host system whether an Embedded Algorithm is in progress or

completed, or whether the device is in Erase Suspend.

Data# Polling is valid after the rising edge of the final

WE# pulse in the program or erase command sequence.

During the Embedded Program algorithm, the device

outputs on DQ7 the complement of the datum programmed to DQ7. This DQ7 status also applies to programming during Erase Suspend. When the

Embedded Program algorithm is complete, the device

outputs the datum programmed to DQ7. The system

must provide the program address to read valid status

information on DQ7. If a program address falls within a

protected sector , Data# Polling on DQ7 is active for approximately 1 µs, then the device returns to reading

array data.

No

START

Read DQ7–DQ0

Addr = VA

DQ7 = Data?

No

DQ5 = 1?

Yes

Read DQ7–DQ0

Addr = VA

Yes

During the Embedded Erase algorithm, Data# Polling

produces a “0” on DQ7. When the Embedded Erase algorithm is complete, or if the device enters the Erase

Suspend mode, Data# Polling produces a “1” on DQ7.

This is analogous to the complement/true da tum output

described for the Embedded Program algorithm: the

erase function changes al l the bits in a sector to “1”;

prior to this, the device outputs the “complement,” or

“0.” The system must provide an address within any of

the sectors selected for erasure to read valid status information on DQ7.

After an erase command sequence is written, if all sectors selected for erasing are p rotected, Data# Polling

on DQ7 is active for approximately 100 µs, t hen the device returns to reading array data. If not all selected

sectors are protected, the Embedded Erase algorithm

erases the unprotected sectors, and ignores the selected sectors that are protected.

When the system detects DQ7 has changed from the

complement to true data, it can read valid data at DQ7–

DQ0 on the

following

read cycles. This is because DQ7

may change asynchronously with DQ0–DQ6 while

Output Enable (OE#) is asserted low. Figure 18, Data#

Polling Timings (During Embedded Algorithms), in the

“AC Characteristics” section illustrates this.

DQ7 = Data?

No

FAIL

Notes:

1. VA = Valid address for programming. During a sector

erase operation, a valid address is an address within any

sector selected for erasure. During chip erase, a valid

address is any non-protected sector address.

2. DQ7 should be rechecked even if DQ5 = “1” because

DQ7 may change simultaneously with DQ5.

Yes

PASS

20513D-7

Figure 4. Data# Polling Algorithm

Table 6 shows the outputs for Data# Polling on DQ7.

Figure 4 shows the Data# Polling algorithm.

Am29LV200 16

Page 17

PRELIMINARY

RY/BY#: Ready/Busy#

The RY/BY# is a dedicated, open-drain output pin that

indicates whether an Embedded Algorithm is in

progress or complete. The RY/BY# status is valid af ter

the rising edge of the final WE# pulse in the command

sequence. Since RY/BY# is an open-drain output, several RY/BY# pins can be tied together in parallel with a

pull-up resistor to V

If the output is low (Busy), the device is actively erasing

or programming. (T his includes programmin g in the

Erase Suspend mode.) If the output is high (Ready),

the device is ready to read array data (including during

the Erase Suspend mode), or is in the standby mode.

Table 6 shows the outputs for RY/BY#. Figures 12, 13,

16 and 17 shows RY/BY# for read, reset , program, and

erase operations, respectively.

CC

.

DQ6: Toggle Bit I

Toggle Bit I on DQ6 indicates whe ther an Embedded

Program or Erase algorithm is in progress or complete,

or whether the device has entered the Erase Suspend

mode. Toggle Bit I may be read at any address, and is

valid after the rising edge of the final WE# pulse in the

command sequence (prior to the program or erase operation), and during the sector erase time-out.

During an Embedded Program or Erase algorithm operation, successive read cycles to any address cause

DQ6 to toggle. (The system may use either OE# or

CE# to control the read cycles.) When the operation is

complete, DQ6 stops toggling.

Table 6 shows the outputs for Toggle Bit I on DQ6.

Refer to Figure 5 for the toggle bit algorithm and to Figure 19 in the “AC Characteristics” section for the toggle

bit timing diagrams. Figure 20 shows the differences

between DQ2 and DQ6 in graphical form. See also the

subsection on “DQ2: Toggle Bit II”.

DQ2: Toggle Bit II

The “Toggle Bit II” on DQ2, when used with DQ6, indicates whether a pa rticular sector is ac tively erasing

(that is, the Embedded Erase algorithm i s in progress),

or whether that sector is erase-suspended. Toggle Bit

II is valid after the rising edge of the final WE# pulse in

the command sequence.

DQ2 toggles w hen the system reads at addresses

within those sectors that have been selected for erasure. (The system may use either OE# or CE# to control

the read cycles.) But DQ2 cannot distinguish whether

the sector is actively erasing or is erase-suspended.

DQ6, by comparison, i ndicates whether the device is

actively erasing, or is in Erase Suspend, but cannot

distinguish which sectors are selected for erasure.

Thus, both status bits are required for sector and mode

information. Refer to Table 6 to compare outputs for

DQ2 and DQ6.

Figure 5 sho ws the toggle bit alg orithm in flowchart

form, and the section “DQ2: Toggle Bit II” explains the

algorithm. See also the “DQ6: Toggle Bit I” subsection.

Refer to Figure 19 shows the toggle bit timing diagram.

Figure 20 shows the differences between DQ2 and

DQ6 in graphical form.

After an erase command sequence is written, if all sectors selected for erasing are protected, DQ6 toggles for

approximately 100 µs, the n returns to reading array

data. If not all selected sectors are protected, the Embedded Erase algorithm erases the unprotected sectors, and ignores the selected sectors that are

protected.

The system can use DQ6 and DQ2 together to determine whether a sector is actively erasing or is erasesuspended. When the device is actively erasing (that

is, the Embedded Erase algorithm is in progress), DQ6

toggles. When the device enters the Erase Suspend

mode, DQ6 stops toggling. However, the system must

also use DQ2 to determine which sectors are erasing

or erase-suspended. Alternatively, the system can use

DQ7 (see the subsection on “DQ7: Data# Polling”).

If a program address falls within a protected sector,

DQ6 toggles for approximately 1 µs after the program

command sequence is written, then returns to reading

array data.

DQ6 also toggl es during the e rase-suspend-pro gram

mode, and stops toggling once the Embedded Program algorithm is complete.

Reading Toggle Bits DQ6/DQ2

Refer to Figure 5 for th e following discussion. W henever the system initially begins reading toggle bit status, it must read DQ7–DQ0 at least twice in a row to

determine whether a toggle bit is toggling. Ty pically , the

system would note and store the value of the togg le bit

after the first read. After the second read, the system

would compare the new value of the toggle bi t with the

first. If the toggle bit is not toggling, the device has completed the program or erase operation. The system can

read array data on DQ7–DQ0 on the following read cycle.

However, if af ter the initial two read cycles, the system

determines that the toggle bit is still toggling, the system also should note whether the value of DQ5 is high

(see the section on DQ5). If it is, the system should

then determine again whether the toggle bit is toggling,

since the toggle bit may have stopped toggling just as

DQ5 went high. If the toggle bit is no longer toggling,

the device has successfully completed the program or

erase operation. If it is still toggling, the device did not

completed the operation successfully, and the system

must write the reset command to return to reading

array data.

17 Am29LV200

Page 18

PRELIMINARY

The remaining scenario is that the system initially determines that the toggle bit is toggling and DQ5 has not

gone high. The system may continue to mo nitor the

toggle bit and DQ5 through successive read cycles, determining the status as described in the previous paragraph. Alternatively, it may choose to perform other

system tasks. In this case, the system must start at the

beginning of the algorithm when it returns to determine

the status of the operation (top of Figure 5).

START

Read DQ7–DQ0

(Note 1)

DQ5: Exceeded Timing Limits

DQ5 indicates whether the program or erase time has

exceeded a specified internal pulse count limit. Under

these conditions DQ5 produces a “1.” This is a failure

condition that indicates the program or erase cycle was

not successfully completed.

The DQ5 failure condition may appear if the system

tries to program a “1” to a location that is previously

programmed to “0.” Only an erase op eration can

change a “0” back to a “1.” Under this condition, the

device halts the operation, and when the operation has

exceeded the timing limits, DQ5 produces a “1.”

Under both these conditions, the system must issue

the reset command to return the device to readin g

array data.

DQ3: Sector Erase Timer

After writing a sector erase command sequence, the

system may read DQ3 to determine whether or not an

erase operation has begun. (The sector erase time r

does not apply to the chip erase command.) If additional sectors are selected for erasure, the entire timeout also applies after each additional sector erase command. When the time-out is complete, DQ3 switches

from “0” to “ 1.” The system may ignore DQ3 if the system can guarantee that the time between additional

sector erase commands will alw ays be less than 50

µs. See also the “Sector Erase Command Sequence”

section.

After the sector erase command sequ ence is written,

the system should read the status on DQ7 (Data# Polling) or DQ6 (Toggle Bit I) to ensure the device has accepted the command sequence, and then read DQ3. If

DQ3 is “1”, the internally controlled erase cycle has begun; all further commands (other than Erase Su spend)

are ignored until the erase ope ration is complete. If

DQ3 is “0”, the device will accept additional sector

erase commands. To ensure the command h as been

accepted, the system software should check the s tatus

of DQ3 prior to and following each subsequent sector

erase command. If DQ3 is high on the second status

check, the last co mmand might not hav e been accepted. Table 6 shows the outputs for DQ3.

Read DQ7–DQ0

Toggle Bit

= Toggle?

Yes

No

Notes:

1. Read toggle bit twice to determine whether or not it is

toggling. See text.

2. Recheck toggle bit because it may stop toggling as DQ5

changes to “1” . See text.

DQ5 = 1?

Yes

Read DQ7–DQ0

Twice

Toggle Bit

= Toggle?

Yes

Program/Erase

Operation Not

Complete, Write

Reset Command

No

(Notes

1, 2)

No

Program/Erase

Operation Complete

20513D-8

Figure 5. Toggle Bit Algorithm

Am29LV200 18

Page 19

PRELIMINARY

Table 6. Write Operation Status

DQ7

Standard

Mode

Erase

Suspend

Mode

Operation

Embedded Program Algorithm DQ7# Toggle 0 N/A No toggle 0

Embedded Erase Algorithm 0 Toggle 0 1 Toggle 0

Reading within Erase

Suspended Sector

Reading within Non-Erase

Suspended Sector

Erase-Suspend-Program DQ7# Toggle 0 N/A N/A 0

(Note 2) DQ6

1 No toggle 0 N/A Toggle 1

Data Data Data Data Data 1

Notes:

1. DQ5 switches to ‘1’ when an Embedded Program or Embedded Erase operation has exceeded the maximum timing limits.

See “DQ5: Exceeded Timing Limits” for more information.

2. DQ7 and DQ2 require a valid address when reading status information. Refer to the appropriate subsection for further details.

DQ5

(Note 1) DQ3

DQ2

(Note 2) RY/BY#

19 Am29LV200

Page 20

PRELIMINARY

ABSOLUTE MAXIMUM RATINGS

Storage Temperature

Plastic Packages . . . . . . . . . . . . . . . –65°C to +150°C

Ambient Temperature

with Power Applied . . . . . . . . . . . . . –65°C to +125°C

Voltage with Respect to Ground

(Note 1) . . . . . . . . . . . . . . . .–0.5 V to +4.0 V

V

CC

A9, OE#, and

RESET# (Note 2). . . . . . . . . . . .–0.5 V to +12.5 V

All other pins (Note 1) . . . . . –0.5 V to V

Output Short Circuit Current (Note 3) . . . . . . 200 mA

Notes:

1. Minimum DC voltage on input or I/O pins is –0.5 V . During

voltage transitions, input or I/O pins may undershoot V

to –2.0 V for periods of up to 20 ns. Maximum DC voltage

on input or I/O pins is V

transitions, input or I/O pins may overshoot to V

for periods up to 20 ns. See Figure 6 and Figure 7.

2. Minimum DC input voltage on pins A9, OE#, and RESET#

is –0.5 V. During voltage transitions, A9, OE#, and

RESET# may undershoot V

to 20 ns. See Figure 6. Maximum DC input voltage on pin

A9 is +12.5 V which may overshoot to 14.0 V for periods

up to 20 ns.

3. No more than one output may be shorted to ground at a

time. Duration of the short circuit should not be greater

than one second.

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. This is

a stress rating only; functional operation of the device at

these or any other conditions above those indicated in the

operational sections of this data sheet is not implied.

Exposure of the device to absolute maximum rating

conditions for extended periods may affect device reliability.

+0.5 V. During voltage

CC

to –2.0 V for periods of up

SS

CC

CC

+0.5 V

SS

+2.0 V

20 ns

+0.8 V

–0.5 V

–2.0 V

20 ns

Figure 6. Maximum Negative Overshoot

20 ns

20513D-9

Waveform

20 ns

V

CC

+2.0 V

V

CC

+0.5 V

2.0 V

20 ns

20 ns

20513D-10

Figure 7. Maximum Positive Overshoot

Waveform

OPERATING RANGES

Commercial (C) Devices

Ambient Temperature (TA) . . . . . . . . . . . 0°C to +70°C

Industrial (I) Devices

Ambient Temperature (T

Extended (E) Devices

Ambient Temperature (T

Supply Voltages

V

CC

VCC for regulated voltage range. . . . .+3.0 V to +3.6 V

for full voltage range. . . . . . . . . .+2.7 V to +3.6 V

V

CC

Operating ranges define those limits between which the functionality of the device is guaranteed.

) . . . . . . . . . –40°C to +85°C

A

) . . . . . . . . –55°C to +125°C

A

Am29LV200 20

Page 21

PRELIMINARY

DC CHARACTERISTICS

CMOS Compatible

Parameter Description Test Conditions Min Typ Max Unit

= VSS to VCC,

V

IN

V

= VCC

CC

CC max

= VSS to VCC,

V

OUT

V

= V

CC

CC max

CE# = V

IL,

Byte Mode

CE# = V

IL,

Word Mode

max

±1.0 µA

; A9 = 12.5 V 35 µA

±1.0 µA

OE#

= VIH,

5 MHz 10 16

1 MHz 2 4

OE#

= VIH,

5 MHz 9 16

1 MHz 2 4

I

I

I

CC1

I

LIT

LO

LI

Input Load Current

A9 Input Load Current VCC = V

Output Leakage Current

VCC Active Read Current

(Note 1)

mA

V

V

V

I

CC2

I

CC3

I

CC4

I

CC5

V

V

V

V

IL

IH

ID

OL

OH1

OH2

LKO

VCC Active Write Current

(Notes 2 and 4)

VCC Standby Current

VCC Standby Current During

Reset

Automatic Sleep Mode (Note 3)

Input Low Voltage –0.5 0.8 V

Input High Voltage 0.7 x V

Voltage for Autoselect and

Temporary Sector Unprotect

Output Low Voltage IOL = 4.0 mA, VCC = V

Output High Voltage

Low VCC Lock-Out Voltage

(Note 4)

CE# = V

V

CC

CE#, RESET# = V

VCC = V

RESET# = V

V

IH

V

IL

= V

= V

= V

IL,

CC max

CC max

CC

± 0.3 V

SS

OE#

= VIH

;

;

± 0.3 V

SS

± 0.3 V;

CC

±0.3 V

VCC = 3.3 V 11.5 12.5 V

0.45 V

CC min

I

= –2.0 mA, VCC = V

OH

IOH = –100 µA, VCC = V

CC min

CC min

0.85 V

VCC–0.4

2.3 2.5 V

Notes:

1. The I

2. I

current listed is typically less than 2 mA/MHz, with OE# at VIH. Typical VCC is 3.0 V.

CC

active while Embedded Erase or Embedded Program is in progress.

CC

3. Automatic sleep mode enables the low power mode when addresses remain stable for t

4. Not 100% tested.

CC

CC

ACC

20 30 mA

0.2 5 µA

0.2 5 µA

0.2 5 µA

VCC + 0.3 V

V

+ 30 ns.

21 Am29LV200

Page 22

DC CHARACTERISTICS (continued)

Zero Power Flash

25

20

15

10

Supply Current in mA

5

0

0 500 1000 1500 2000 2500 3000 3500 4000

PRELIMINARY

Time in ns

Note: Addresses are switching at 1 MHz

Figure 8. I

Current vs. Time (Showing Active and Automatic Sleep Currents)

CC1

15

10

5

Supply Current in mA

0

1 2345

3

Frequency in MHz

V

6

.

V

7

2.

20513D-11

Note: T = 25 °C

Figure 9. Typical I

Am29LV200 22

vs. Frequency

CC1

20513D-12

Page 23

TEST CONDITIONS

Device

Under

Test

C

L

6.2 kΩ

PRELIMINARY

3.3 V

2.7 kΩ

Table 7. Test Specifications

-90R,

Test Condition

Output Load 1 TTL gate

Output Load Capacitance, C

(including jig capacitance)

Input Rise and Fall Times 5 ns

Input Pulse Levels 0.0–3.0 V

-100

L

30 100 pF

-120,

-150 Unit

Note: Diodes are IN3064 or equivalent

Figure 10. Test Setup

KEY TO SWITCHING WAVEFORMS

WAVEFORM INPUTS OUTPUTS

Don’t Care, Any Change Permitted Changing, State Unknown

Does Not Apply Center Line is High Impedance State (High Z)

20513D-13

Input timing measurement

reference levels

Output timing measurement

reference levels

Steady

Changing from H to L

Changing from L to H

1.5 V

1.5 V

KS000010-PAL

3.0 V

0.0 V

1.5 V 1.5 V

Figure 11. Input Waveforms and Measurement Levels

23 Am29LV200

OutputMeasurement LevelInput

20513D-14

Page 24

AC CHARACTERISTICS

Read Operations

PRELIMINARY

Parameter

JEDEC Std Test Setup

t

AVAV

t

AVQV

t

ELQV

t

GLQV

t

EHQZ

t

GHQZ

Description

t

Read Cycle Time (Note 1) Min 90 100 120 150 ns

RC

t

Address to Output Delay

ACC

t

Chip Enable to Output Delay OE# = V

CE

t

Output Enable to Output Delay Max 40 40 50 55 ns

OE

t

Chip Enable to Output High Z (Note 1) Max 30 30 30 40 ns

DF

t

Output Enable to Output High Z (Note 1) Max 30 30 30 40 ns

DF

CE# = V

OE# = V

IL

IL

IL

Read Min 0 ns

Output Enable

t

OEH

Hold Time (Note 1)

Toggle and

Data# Polling

Output Hold Time From Addresses, CE# or

t

AXQX

t

OH

OE#, Whichever Occurs First (Note 1)

Notes:

1. Not 100% tested.

2. See Figure 10 and Table 7 for test specifications.

t

RC

Speed Option

-90R -100 -120 -150 Unit

Max 90 100 120 150 ns

Max 90 100 120 150 ns

Min 10 ns

Min 0 ns

Addresses

CE#

OE#

WE#

Outputs

RESET#

RY/BY#

0 V

Addresses Stable

t

ACC

t

OE

t

OEH

t

CE

HIGH Z

Output Valid

Figure 12. Read Operations Timings

t

DF

t

OH

HIGH Z

20513D-15

Am29LV200 24

Page 25

AC CHARACTERISTICS

Hardware Reset (RESET#)

Parameter

Description All Speed OptionsJEDEC Std Test Setup Unit

PRELIMINARY

READY

READY

t

RP

t

RH

t

RPD

t

RB

RESET# Pin Low (During Embedded

Algorithms) to Read or Write (See Note)

RESET# Pin Low (NOT During Embedded

Algorithms) to Read or Write (See Note)

RESET# Pulse Width Min 500 ns

RESET# High Time Before Read (See Note) Min 50 ns

RESET# Low to Standby Mode Min 20 µs

RY/BY# Recovery Time Min 0 ns

t

t

Note: Not 100% tested.

RY/BY#

CE#, OE#

RESET#

t

RP

t

Ready

Max 20 µs

Max 500 ns

t

RH

RY/BY#

CE#, OE#

RESET#

Reset Timings NOT during Embedded Algorithms

Reset Timings during Embedded Algorithms

t

Ready

t

RP

Figure 13. RESET# Timings

t

RB

20513D-16

25 Am29LV200

Page 26

AC CHARACTERISTICS

Word/Byte Configuration (BYTE#)

Parameter

PRELIMINARY

-90R -100 -120 -150JEDEC Std. Description Unit

t

ELFL/tELFH

t

FLQZ

t

FHQV

BYTE#

Switching

from word

to byte

mode

CE# to BYTE# Switching Low or High Max 5 ns

BYTE# Switching Low to Output HIGH Z Max 30 30 30 40 ns

BYTE# Switching High to Output Active Min 90 100 120 150 ns

CE#

OE#

BYTE#

t

DQ0–DQ14

DQ15/A-1

ELFL

t

ELFH

Data Output

(DQ0–DQ14)

DQ15

Output

t

FLQZ

Data Output

(DQ0–DQ7)

Address

Input

BYTE#

BYTE#

Switching

from byte

to word

DQ0–DQ14

Data Output

(DQ0–DQ7)

mode

DQ15/A-1

Address

Input

t

FHQV

Figure 14. BYTE# Timings for Read Operations

CE#

The falling edge of the last WE# signal

WE#

BYTE#

t

SET

(tAS)

t

HOLD

(tAH)

Note: Refer to the Erase/Program Operations table for tAS and tAH specifications.

Figure 15. BYTE# Timings for Write Operations

Data Output

(DQ0–DQ14)

DQ15

Output

20513D-17

20513D-18

Am29LV200 26

Page 27

AC CHARACTERISTICS

Erase/Program Operations

Parameter

t

t

AVAV

t

AVWL

t

WLAX

t

DVWH

t

WHDX

t

t

GHWL

t

ELWL

t

WHEH

t

WLWH

t

WHWL

t

WHWH1tWHWH1

t

GHWL

t

Write Cycle Time (Note 1) Min 90 100 120 150 ns

WC

t

Address Setup Time Min 0 ns

AS

t

Address Hold Time Min 50 50 50 65 ns

AH

t

Data Setup Time Min 50 50 50 65 ns

DS

t

Data Hold Time Min 0 ns

DH

Output Enable Setup Time Min 0 ns

OES

Read Recovery Time Before Write

(OE# High to WE# Low)

t

CE# Setup Time Min 0 ns

CS

t

CE# Hold Time Min 0 ns

CH

t

Write Pulse Width Min 50 50 50 65 ns

WP

Write Pulse Width High Min 30 30 30 35 ns

WPH

Programming Operation (Note 2)

PRELIMINARY

-90R -100 -120 -150JEDEC Std. Description Unit

Min 0 ns

Byte Typ 9

µs

Word Typ 11

t

WHWH2tWHWH2

t

t

BUSY

Sector Erase Operation (Note 2) Typ 1 sec

VCC Setup Time (Note 1) Min 50 µs

VCS

Recovery Time from RY/BY# Min 0 ns

t

RB

Program/Erase Valid to RY/BY# Delay Min 90 ns

Notes:

1. Not 100% tested.

2. See the “Erase and Programming Performance” section for more information.

27 Am29LV200

Page 28

AC CHARACTERISTICS

Program Command Sequence (last two cycles)

PRELIMINARY

Read Status Data (last two cycles)

Addresses

CE#

OE#

WE#

Data

RY/BY#

V

CC

t

VCS

t

WC

555h

t

GHWL

t

CS

t

WP

t

DS

A0h

t

AS

PA PA

t

AH

t

CH

t

WHWH1

t

WPH

t

DH

PD

t

BUSY

PA

Status

D

OUT

t

RB

Notes:

1. PA = program address, PD = program data, D

2. Illustration shows device in word mode.

Figure 16. Program Operation Timings

is the true data at the program address.

OUT

20513D-19

Am29LV200 28

Page 29

AC CHARACTERISTICS

Erase Command Sequence (last two cycles) Read Status Data

PRELIMINARY

Addresses

CE#

OE#

WE#

Data

RY/BY#

V

CC

t

VCS

t

WC

2AAh SA

555h for chip erase

t

GHWL

t

CH

t

WP

t

t

CS

t

DS

t

WPH

DH

55h

t

AS

t

AH

30h

10 for Chip Erase

t

BUSY

t

WHWH2

VA

In

Progress

VA

Complete

t

RB

Notes:

1. SA = sector address (for Sector Erase), VA = Valid Address for reading status data (see “Write Operation Status”).

2. Illustration shows device in word mode.

Figure 17. Chip/Sector Erase Operation Timings

20513D-20

29 Am29LV200

Page 30

AC CHARACTERISTICS

Z

Z

Addresses

t

CE#

t

CH

OE#

t

OEH

WE#

DQ7

ACC

t

CE

t

RC

VA

t

OE

PRELIMINARY

t

DF

t

OH

Complement

VA VA

Complement

True

Valid Data

High

DQ0–DQ6

t

BUSY

Status Data

Status Data

True

Valid Data

High

RY/BY#

Note: VA = Valid address. Illustration shows first status cycle after command sequence, last status read cycle, and array data

read cycle.

20513D-21

Figure 18. Data# Polling Timings (During Embedded Algorithms)

t

RC

Addresses

CE#

OE#

WE#

DQ6/DQ2

RY/BY#

t

CH

t

BUSY

t

OEH

High Z

t

ACC

VA

t

CE

t

OE

t

DF

t

OH

(first read) (second read) (stops toggling)

VA VA

Valid Status

VA

Valid DataValid StatusValid Status

Note: V A = Valid address; not required for DQ6. Illustration shows first two status cycle after command sequence, last status read

cycle, and array data read cycle.

20513D-22

Figure 19. Toggle Bit Timings (During Embedded Algorithms)

Am29LV200 30

Page 31

PRELIMINARY

AC CHARACTERISTICS

Enter

Embedded

Erasing

WE#

DQ6

DQ2

Note: The system may use OE# and CE# to toggle DQ2 and DQ6. DQ2 toggles only when read at an address within an

erase-suspended sector.

Erase

Erase

Suspend

Erase Suspend

Enter Erase

Suspend Program

Read

Figure 20. DQ2 vs. DQ6

Erase

Suspend

Program

Erase Suspend

Read

Erase

Resume

Erase

Erase

Complete

20513D-23

Temporary Sector Unprotect

Parameter

All Speed OptionsJEDEC Std. Description Unit

t

VIDR

t

RSP

Note: Not 100% tested.

12 V

RESET#

0 or 3 V

CE#

WE#

RY/BY#

VID Rise and Fall Time (See Note) Min 500 ns

RESET# Setup Time for Temporary Sector

Unprotect

Min 4 µs

0 or 3 V

t

VIDR

t

VIDR