Datasheet AM29F400AT-90FIB, AM29F400AT-90FI, AM29F400AT-90FCB, AM29F400AT-90FC, AM29F400AT-90EIB Datasheet (AMD Advanced Micro Devices)

...Page 1

5.0 V-only Flash

■

■

■

■

■

■

■

■

■

■

■

■

■

PRELIMINARY

■

■

■

Am29F400AT/Am29F400AB

4 Megabit (524,288 x 8-Bit/262,144 x 16-Bit) CMOS 5.0 Volt-only,

Sector Erase Flash Memory

DISTINCTIVE CHARACTERISTICS

5.0 V ± 10% for read and write operations

— Minimizes system level power requirements

Compatible with JEDEC-standards

— Pinout and software compatible with

single-power-supply flash

— Superior inadvertent write protection

Package options

— 44-pin SO

— 48-pin TSOP

Minimum 100,000 write/erase cycles guaranteed

High performance

— 60 ns maximum access time

Sector erase architecture

— One 16 Kbyte, two 8 Kbytes , one 32 Kbyte, and

seven 64 Kbytes

— Any combination of sectors can be erased. Also

supports full chip erase.

Sector protection

— Hardware method that disables any combination

of sectors from write or erase operations.

Implemented using standard PROM

programming equipment.

Embedded Erase Algorithms

— Automatically preprograms and erases the chip

or any sector

Embedded Program Algorithms

— Automatically programs and verifies data at

specified address

Data

Polling and Tog gle Bit feature for detection

of program or erase cycle completion

Ready/Busy output (RY/BY)

— Hardware method for detection of program or

erase cycle completion

Erase Suspend/Resume

— Supports reading data from a sector not being

erased

Low power consumption

— 20 mA typical active read current for Byte Mode

— 28 mA typical active read current for Word Mode

— 30 mA typical program/erase current

Enhanced power management for standby

mode

—1 µ A typical standby current

Boot Code Sector Architecture

— T = Top sector

— B = Bottom sector

Hardware RESET

— Resets internal state machine to the read mode

pin

GENERAL DESCRIPTION

The Am29F400A is a 4 Mbit, 5.0 V olt-only Flash memory

organized as 512 Kbytes of 8 bits each or 256 Kwords

of 16 bits each. The 4 Mbits of data is divided into 11

sectors of one 16 Kbyte, two 8 Kbyte, one 32 Kbyte,

and seven 64 Kbytes, for flexible erase capability. The

8 bits of data will appear on DQ0–DQ7 or 16 bits on

DQ0–DQ15. The Am29F400A is offered in 44-pin SO

and 48-pin TSOP packages. This device is designed

to be programmed in-system with the standard system

5.0 Volt V

program or erase operations. The de vice can also be reprogrammed in standard EPROM programmers .

This document contains information on a product under development at Advanced Micro Devices. The information

is intended to help you evaluate this product. AMD reserves the right to change or discontinue work on this proposed

product without notice.

supply. 12.0 Volt V

CC

is not required for

PP

The standard Am29F400A offers access times of

60 ns, 70 ns, 90 ns, 120 ns and 150 ns, allowing high

speed microprocessors to operate without wait states.

To eliminate bus contention the device has separate chip enable (CE

enable (OE) controls.

The Am29F400A is entirely command set compatible

with the JEDEC single-power-supply Flash standard.

Commands are written to the command register using

standard microprocessor write timings. Register contents serve as input to an internal state-machine

which controls the erase and programming circuitry.

), write enable (WE) and output

Publication# 20380 Rev: B Amendment/0

Issue Date: April 1997

Page 2

■

■

■

PRELIMINARY

Write cycles also internally latch addresses and data

needed for the programming and erase operations.

Reading data out of the device is similar to reading

from 12.0 Volt Flash or EPROM devices.

The Am29F400A is programmed by executing the program command sequence. This will invoke the Embedded Program Algorithm which is an internal algorithm

that automatically times the program pulse widths and

verifies proper cell margin. Erase is accomplished by

executing the erase command sequence. This

will invoke the Embedded Erase Algorithm which is an

internal algorithm that automatically preprograms the

array if it is not already programmed before executing

the erase operation. During erase , the de vice automatically times the erase pulse widths and verifies proper

cell margin.

This device also features a sector erase architecture.

This allows for sectors of memory to be erased and reprogrammed without affecting the data contents of

other sectors. A sector is typically erased and verified

within 1.5 seconds. The Am29F400A is erased when

shipped from the factory.

The Am29F400A device also features hardw are sector

protection. This feature will disable both program and

erase operations in any combination of eleven sectors

of memory.

AMD has implemented an Erase Suspend feature that

enables the user to put erase on hold for any period of

time to read data from a sector that was not being

erased. Thus, true backg round erase can be achieved.

The device features single 5.0 Volt power supply operation for both read and write functions. Internally generated and regulated voltages are provided for the

program and erase operations. A low V

detector au-

CC

tomatically inhibits write operations during power transitions. The end of program or erase is detected by the

pin. Data Polling of DQ7, or by the Toggle Bit

RY/BY

(DQ6). Once the end of a program or erase cycle has

been completed, the device automatically resets to the

read mode.

The Am29F400A also has a hardware RESET pin.

When this pin is driven low, execution of any Embedded Program Algorithm or Embedded Erase Algorithm

will be terminated. The internal state machine will then

be reset into the read mode. The RESET pin may be

tied to the system reset circuitry. Therefore, if a system

reset occurs during the Embedded Program Algorithm

or Embedded Erase Algorithm, the device will be automatically reset to the read mode and will have erroneous data stored in the address locations being

operated on. These locations will need rewriting after

the Reset. Resetting the device will enable the system’s microprocessor to read the boot-up firmware

from the Flash memory.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability and cost effectiveness. The Am29F400A memory electrically erases all

bits within a sector simultaneously via

Fowler-Nordhiem tunneling. The bytes/words are programmed one byte/word at a time using the EPROM

programming mechanism of hot electron injection.

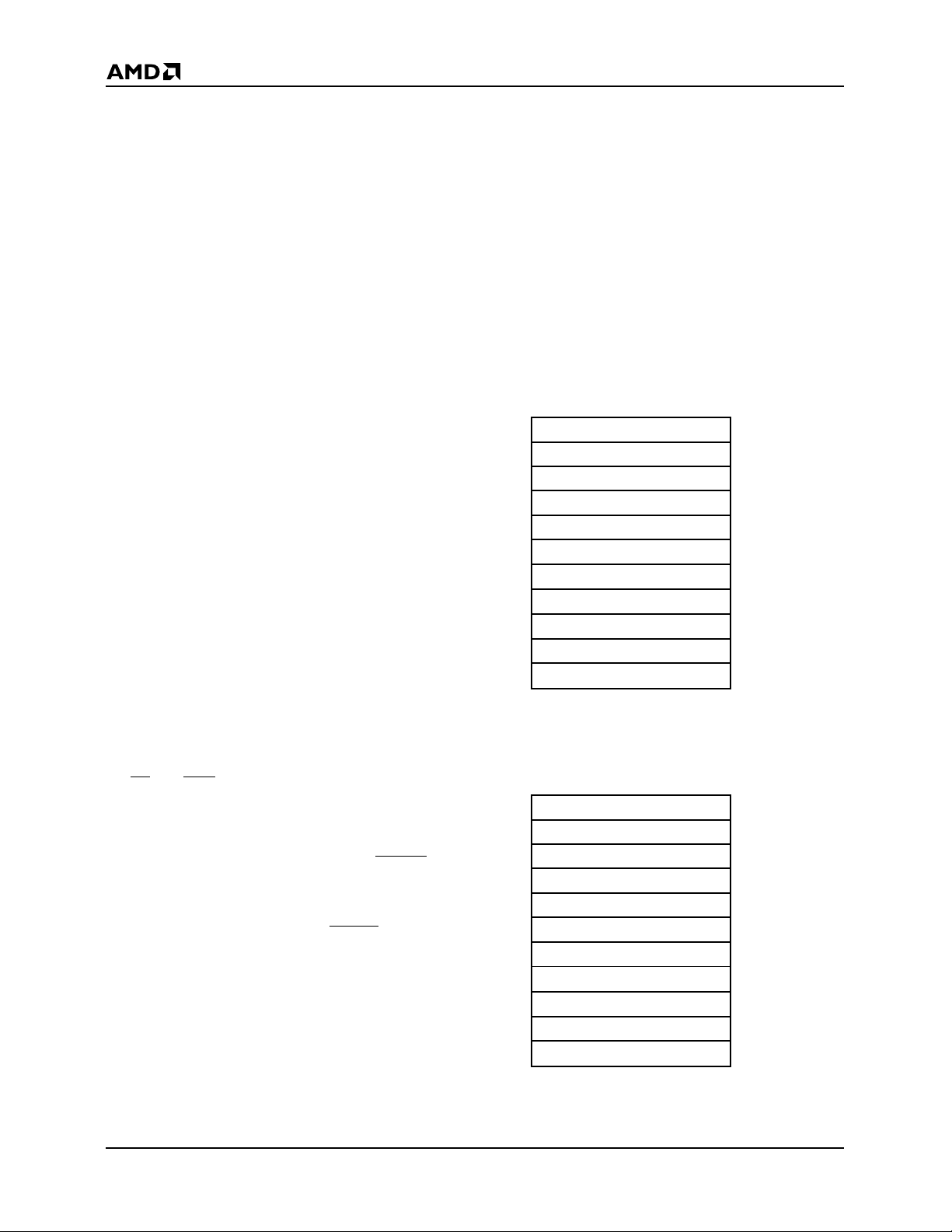

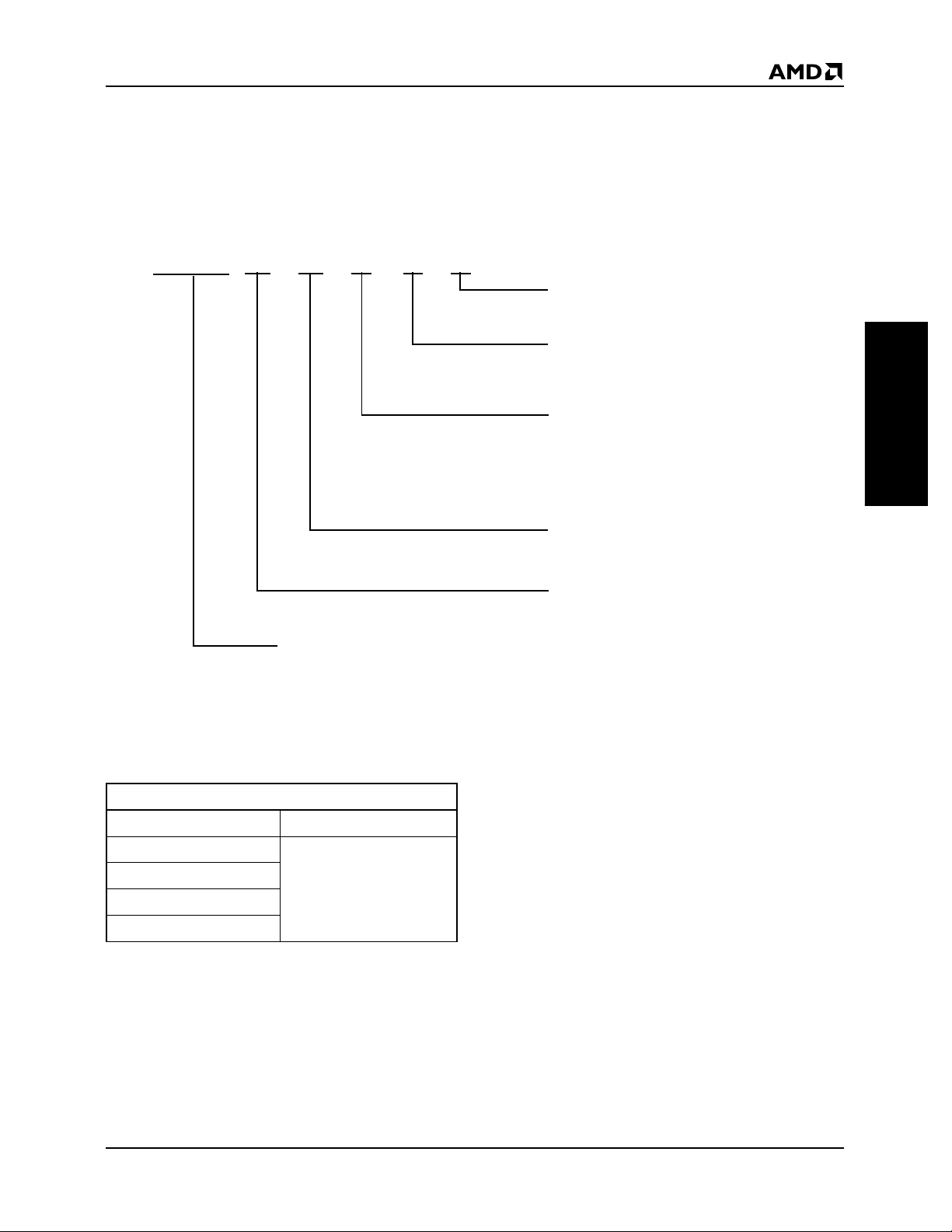

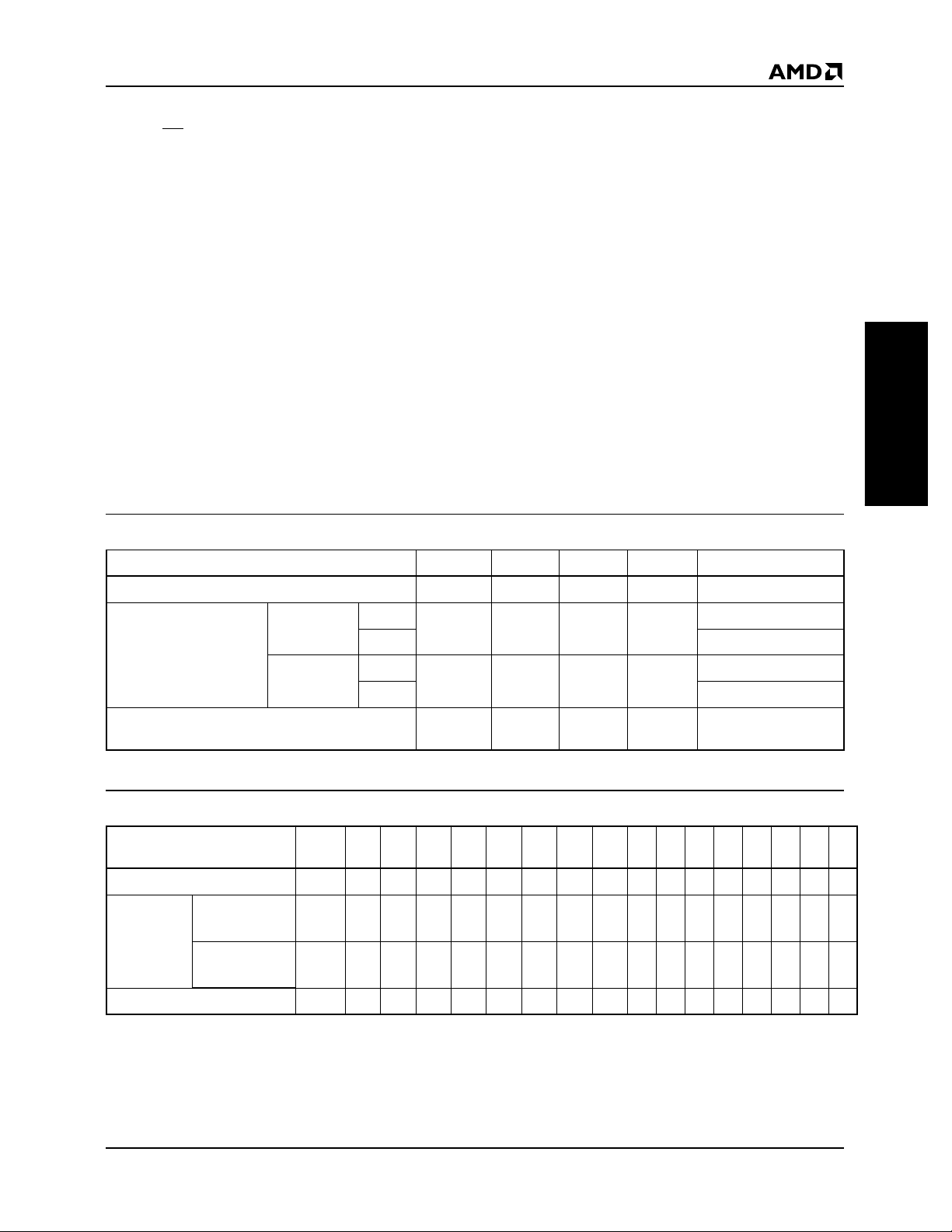

Flexible Sector-Erase Architecture

One 16 Kbyte, two 8 Kbytes, one 32 Kbyte, and

seven 64 Kbyte sectors

Individual-sector or multiple-sector erase capability

Sector protection is user definable

(x8) (x16)

7FFFFh 3FFFFh

7BFFFh 3DFFFh

79FFFh 3CFFFh

77FFFh 3BFFFh

6FFFFh 37FFFh

5FFFFh 2FFFFh

4FFFFh 27FFFh

3FFFFh 1FFFFh

2FFFFh 17FFFh

1FFFFh 0FFFFh

0FFFFh 07FFFh

00000h 00000h

20380B-1

(x8) (x16)

7FFFFh 3FFFFh

6BFFFh 37FFFh

5FFFFh 2FFFFh

4FFFFh 27FFFh

3FFFFh 1FFFFh

2FFFFh 17FFFh

1FFFFh 0FFFFh

0FFFFh 07FFFh

07FFFh 03FFFh

05FFFh 02FFFh

03FFFh 01FFFh

00000h 00000h

20380B-2

SA10

SA9

SA8

SA7

SA6

SA5

SA4

SA3

SA2

SA1

SA0

SA10

SA9

SA8

SA7

SA6

SA5

SA4

SA3

SA2

SA1

SA0

16 Kbyte

8 Kbyte

8 Kbyte

32 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

Am29F400AT Sector Architecture

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

64 Kbyte

32 Kbyte

8 Kbyte

8 Kbyte

16 Kbyte

Am29F400AB Sector Architecture

2 Am29F400AT/Am29F400AB

Page 3

5.0 V-only Flash

%

PRELIMINARY

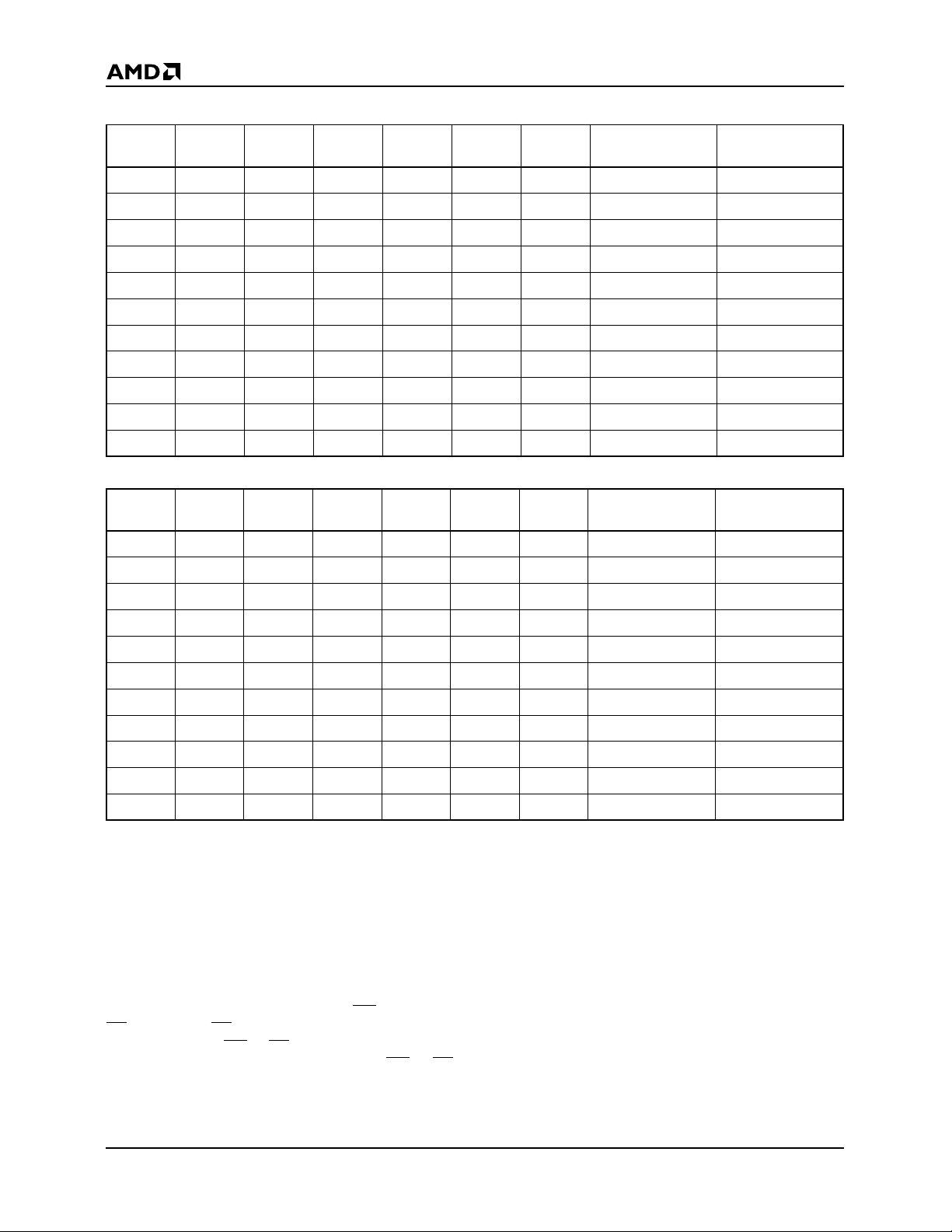

PRODUCT SELECTOR GUIDE

Family Part No: Am29F400A

Ordering Part No:V

Max Access Time (ns) 60 70 90 120 150

CE

(E) Access (ns) 60 70 90 120 150

OE (G) Access (ns) 30 30 35 50 55

= 5.0 V ±

CC

V

= 5.0 V ± 10%

CC

5

-65

-70 -90 -120 -150

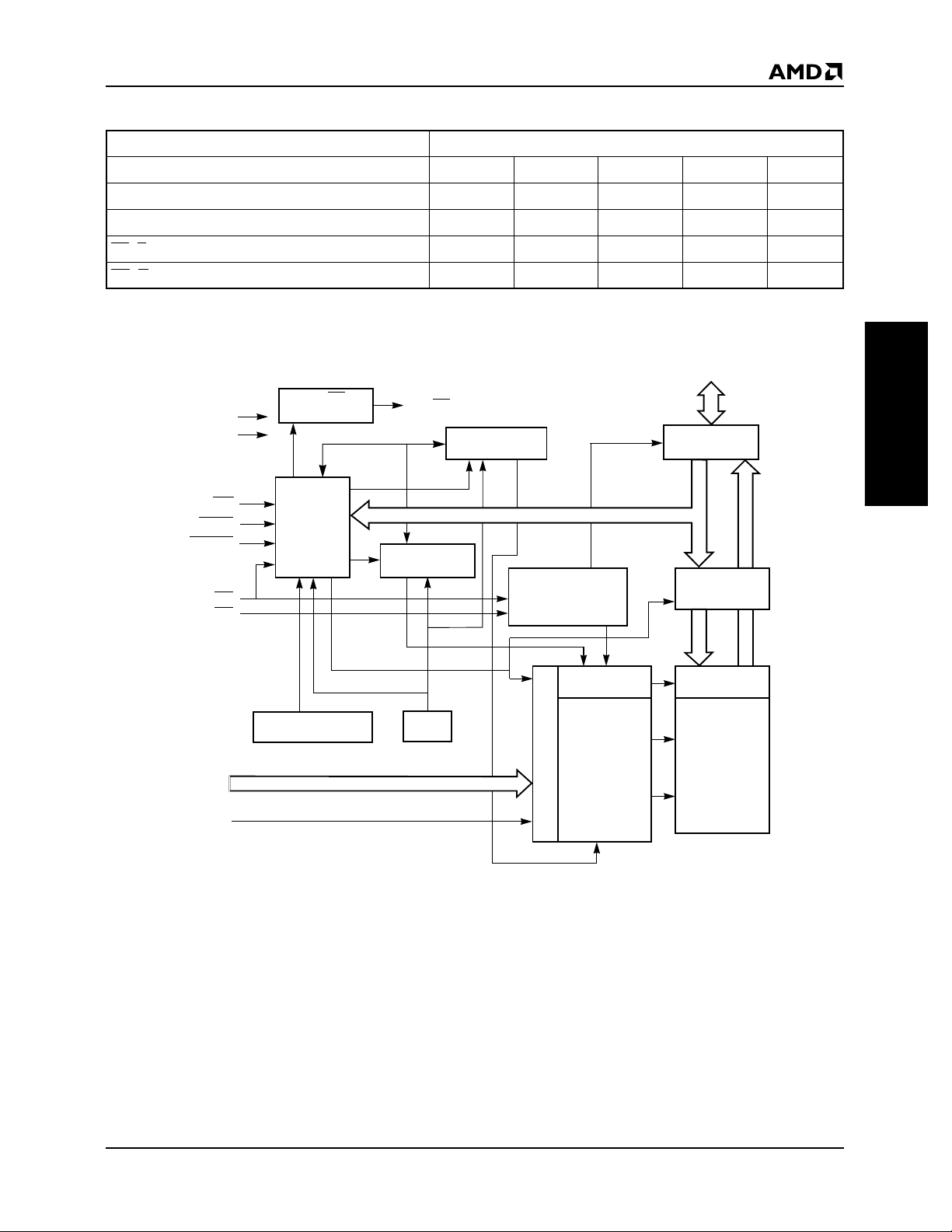

BLOCK DIAGRAM

DQ0–DQ15

V

V

WE

BYTE

RESET

A0-A17

A-1

CC

SS

CE

OE

RY/BY

Buffer

State

Control

Command

Register

V

Detector

CC

RY/BY

PGM V oltage

Generator

Timer

Erase V oltage

Generator

STB

Chip Enable

Output Enable

Logic

Y-Decoder

Address Latch

STB

Input/Output

Buffers

Data

Latch

Y-Gating

Cell MatrixX-Decoder

20380B-3

Am29F400AT/Am29F400AB 3

Page 4

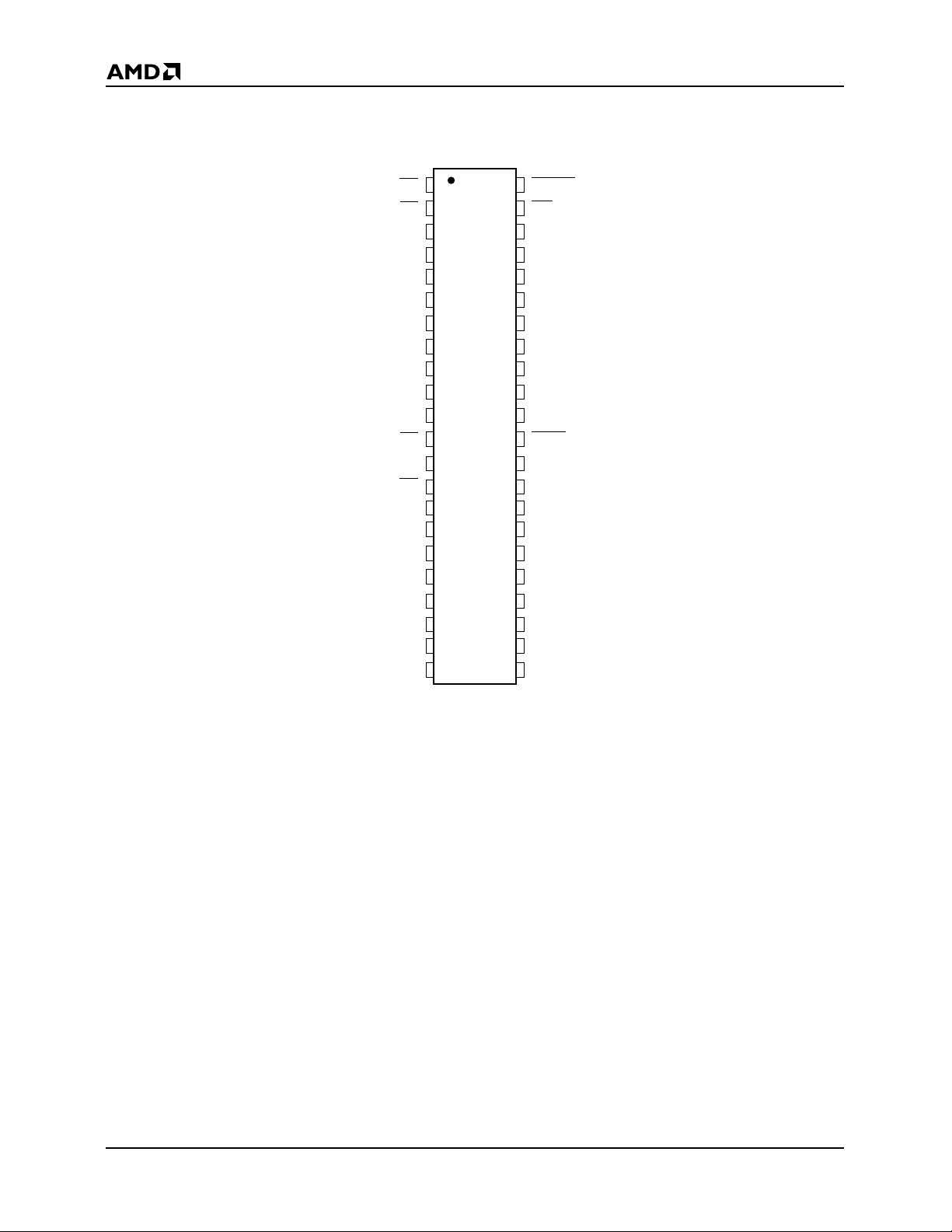

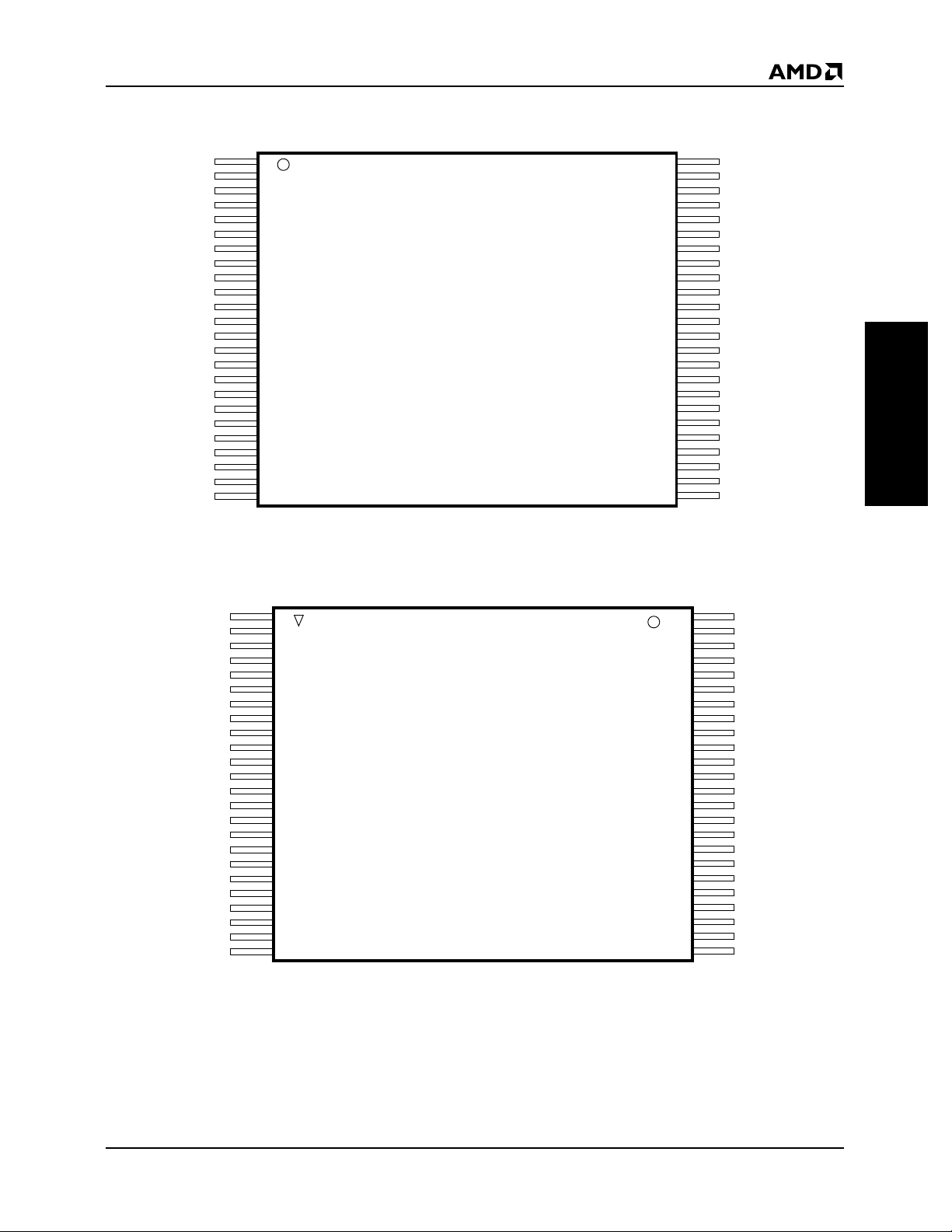

CONNECTION DIAGRAMS

PRELIMINARY

SO

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

RESET

WE

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

NC

RY/BY

A17

A7

A6

A5

A4

A3

A2

A1

A0

CE

V

SS

OE

DQ0

DQ8

DQ1

DQ9

DQ2

DQ10

DQ3

DQ11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

20380B-4

4 Am29F400AT/Am29F400AB

Page 5

5.0 V-only Flash

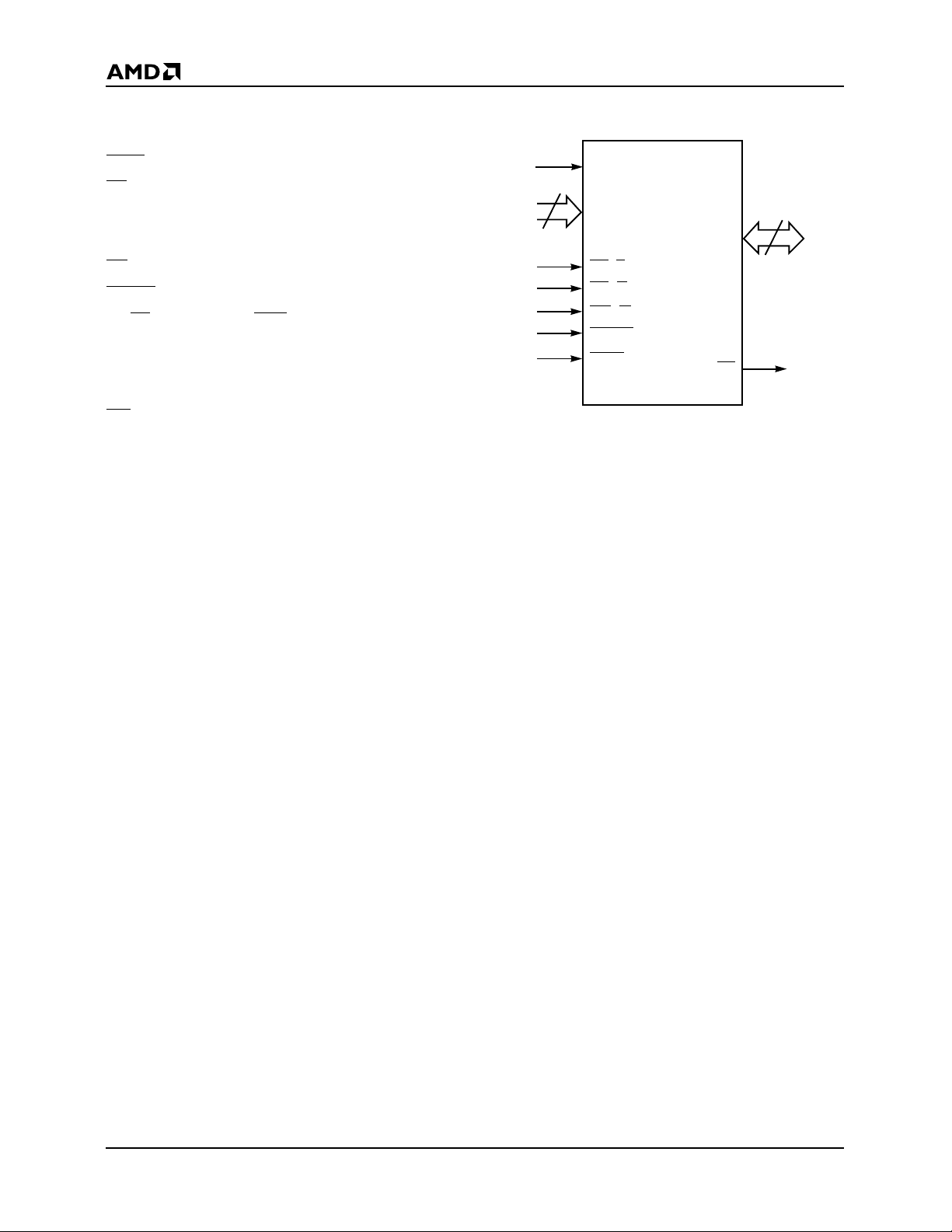

CONNECTION DIAGRAMS

PRELIMINARY

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE

RESET

NC

NC

RY/BY

NC

A17

A7

A6

A5

A4

A3

A2

A1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE

V

SS

CE

A0

20380B-5

A16

BYTE

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE

V

SS

CE

A0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE

RESET

NC

NC

RY/BY

NC

A17

A7

A6

A5

A4

A3

A2

A1

20380B-6

Am29F400AT/Am29F400AB 5

Page 6

PRELIMINARY

PIN CONFIGURATION

A1, A0–A17 = 18 Addresses

BYTE

CE = Chip Enable

DQ0–DQ15 = 16 Data Inputs/Outputs

NC = Pin Not Connected Internally

OE = Output Enable

RESET = Hardware Reset Pin, Active Low

RY/BY = Ready/Busy Output

V

SS

V

SS

WE

= Selects 8-bit or 16-bit mode

= +5.0 V olt Single-Power Supply

( ± 10% for -90, -120, -150) or ( ± 5% for -75)

= Device Ground

= Write Enable

LOGIC SYMBOL

A-1

18

A0–A17

CE

(E)

(G)

OE

WE

(W)

RESET

BYTE

16 or 8

DQ0–DQ15

RY/BY

20380B-7

6 Am29F400AT/Am29F400AB

Page 7

5.0 V-only Flash

PRELIMINARY

ORDERING INFORMATION

Standard Products

AMD standard products are available in several packages and operating ranges. The order number (Valid Combination) is formed by a combination of the following:

AM29F400A -65 E C

T

DEVICE NUMBER/DESCRIPTION

Am29F400A

4 Megabit (512K x 8-Bit/256K x 16-Bit) CMOS Flash Memory

5.0 Volt-only Program and Erase

B

OPTIONAL PROCESSING

Blank = Standard Processing

B = Burn-In

TEMPERATURE RANGE

C = Commercial (0

I = Industrial (-40

PACKAGE TYPE

E = 48-Pin Thin Small Outline Package

(TSOP) Standard Pinout (TS 048)

F = 48-Pin Thin Small Outline Package

(TSOP) Reverse Pinout (TSR048)

S = 44-Pin Small Outline Package (SO 044)

SPEED OPTION

See Product Selector Guide and

Valid Combinations

BOOT CODE SECTOR ARCHITECTURE

T = Top sector

B = Bottom sector

°C to +70°C)

°C to +85°C)

AM29F400AT/B-65 EC, EI, FC, FI, SC, SI

AM29F400AT/B-70

AM29F400AT/B-90

AM29F400AT/B-120

AM29F400AT/B-150

Valid Combinations

EC, EI, EE, EEB,

FC, FI, FE, FEB,

SC, SI, SE, SEB

Valid Combinations

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales

office to confirm availability of specific valid combinations and

to check on newly released combinations.

Am29F400AT/Am29F400AB 7

Page 8

PRELIMINARY

±

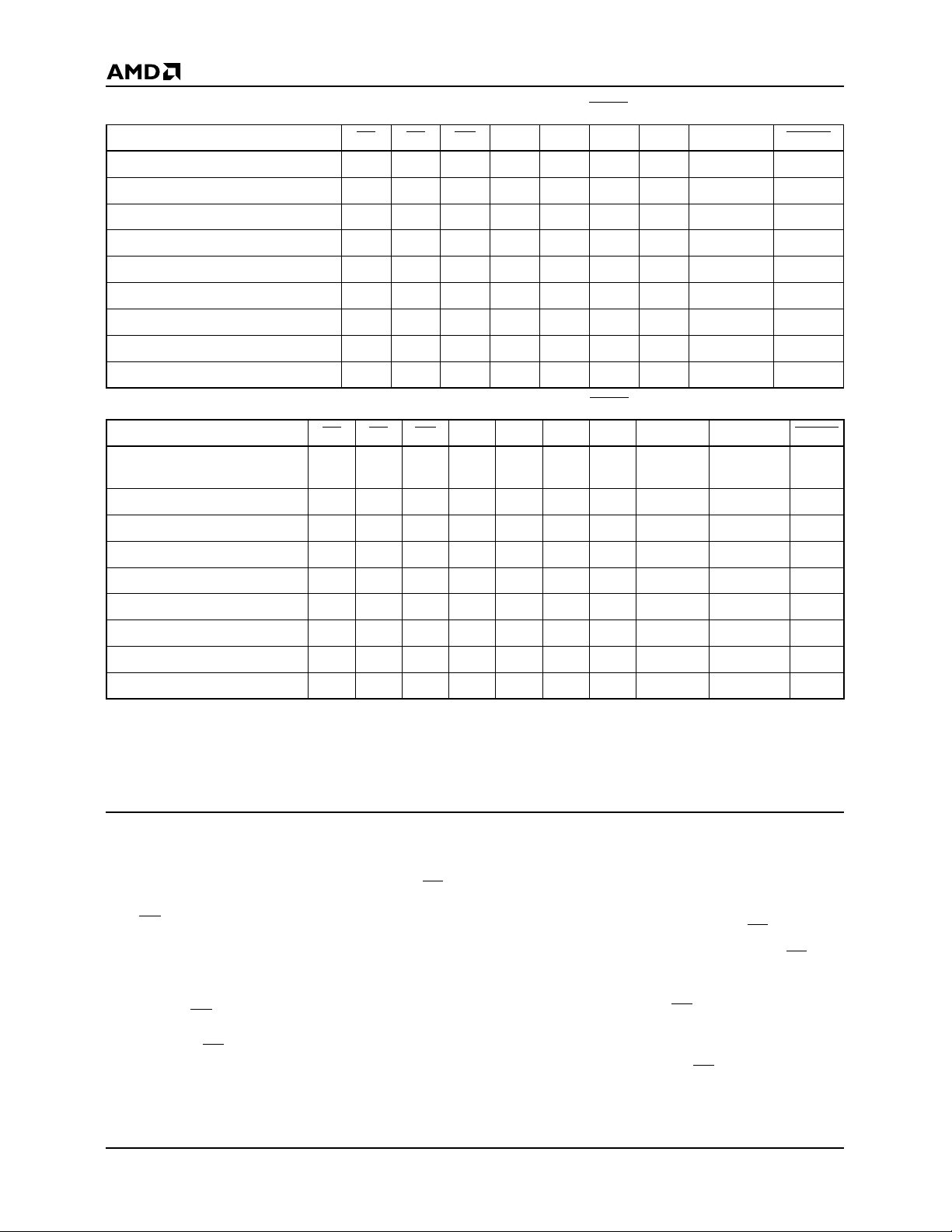

Table 1. Am29F400A User Bus Operations (BYTE = V

Operation CE

Autoselect, AMD Manuf. Code (Note 1) L L H L L L V

Autoselect Device Code (Note 1) L L H H L L V

Read L L H A0 A1 A6 A9 D

Standby H XXXXXXHIGH Z H

Output Disable L H H XXXXHIGH Z H

Write L H L A0 A1 A6 A9 D

Verify Sector Protect (Note 2) L LHLHLV

Temporary Sector Unprotect XXXXXXX X V

Hardware Reset XXXXXXXHIGH Z L

OE WE A0 A1 A6 A9 DQ0–DQ15 RESET

Table 2. Am29F400A User Bus Operations (BYTE

Operation CE

Autoselect, AMD Manuf. Code

(Note 1)

Autoselect Device Code (Note 1) L L H H L L V

Read L L H A0 A1 A6 A9 D

Standby H XXXXXXHIGH Z HIGH Z H

Output Disable L H H XXXXHIGH Z HIGH Z H

Write L H L A0 A1 A6 A9 DIN HIGH Z H

Verify Sector Protect (Note 2) L LHLHLVIDCode HIGH Z H

Temporary Sector Unprotect XXXXXXX X HIGH Z V

Hardware Reset XXXXXXXHIGH Z HIGH Z L

OE WE A0 A1 A6 A9 DQ0–DQ7 DQ8–DQ15 RESET

LLHLLLV

ID

ID

)

IH

ID

ID

ID

= V

)

IL

Code HIGH Z H

Code HIGH Z H

OUT

Code H

Code H

OUT

IN

Code H

HIGH Z H

H

H

ID

ID

Legend:

L = logic 0, H = logic 1, X = Don’t Care. See Characteristics for voltage levels.

Notes:

1. Manufacturer and device codes may also be accessed via a command register write sequence. Refer to Table 4.

2. Refer to the section on Sector Protection.

Read Mode

The Am29F400A has two control functions which must

be satisfied in order to obtain data at the outputs. CE

the power control and should be used for de vice selection. OE is the output control and should be used to

gate data to the output pins if a device is selected.

Address access time (t

) is equal to the delay from

ACC

stable addresses to valid output data. The chip enable

access time (t

and stable CE

) is the delay from stable addresses

CE

to valid data at the output pins.

The output enable access time is the delay from the

falling edge of OE to valid data at the output pins (as-

is

suming the addresses have been stable for at least

t

-t

OE

time).

ACC

Standby Mode

There are two ways to implement the standb y mode on

the Am29F400A device, both using the CE

A CMOS standby mode is achieved with the CE input

held at V

typically reduced to less than 5 µ A. A TTL standby

mode is achieved with the CE

this condition the current is typically reduced to 1 mA.

In the standby mode the outputs are in the high impedance state, independent of the OE

0.5 V. Under this condition the current is

CC

pin held at V

input.

8 Am29F400AT/Am29F400AB

pin.

IH

. Under

Page 9

PRELIMINARY

5.0 V-only Flash

Output Disable

With the OE input at a logic high level (VIH), output from

the device is disabled. This will cause the output pins to

be in a high impedance state.

Autoselect

The autoselect mode allows the reading of a binary

code from the device and will identify its manufacturer

and type. This mode is intended for use by programming equipment for the purpose of automatically

matching the device to be programmed with its corresponding programming algorithm. This mode is functional over the entire temperature range of the device.

To activate this mode, the programming equipment

must force V

Two identifier bytes may then be sequenced from the

device outputs by toggling address A0 from VIL to VIH.

All addresses are don’t cares except A0, A1, and A6

(see T ab le 3).

The manufacturer and device codes may also be read

via the command register, for instances when the

(11.5 V to 12.5 V) on address pin A9.

ID

Table 3. Am29F400A Sector Protection Verify Autoselect Codes

Am29F400A is erased or programmed in a system

without access to high voltage on the A9 pin. The command sequence is illustrated in Table 4 (see Autoselect

Command Sequence).

Byte 0 (A0 = V

) represents the manufacturer’s code

IL

(AMD=01H) and byte 1 (A0 = VIH) the device identifier

code (Am29F400AT = 23H and Am29F400AB = ABH

for x8 mode; Am29F400AT = 2223H and Am29F400AB

= 22ABH for x16 mode). These two bytes/words are

given in the table below. All identifiers for manufacturer

and device will exhibit odd parity with DQ7 defined as

the parity bit. In order to read the proper device codes

when executing the Autoselect, A1 must be V

(see Tables 3 and 4).

The autoselect mode also facilitates the determination

of sector protection in the system. By perf orming a read

operation at the address location XX02H with the

higher order address bits A12–A17 set to the desired

sector address, the device will return 01H for a protected sector and 00H for a non-protected sector.

IL

Type A12-A17 A6 A1 A0 Code (HEX)

Manufacturer Code-AMD X V

Am29F400AT

Am29F400A Device

Am29F400AB

Sector Protection

*Outputs 01H at protected sector addresses

Byte

XVILV

Word 2223H

Byte

XVILV

Word 22ABH

Sector

Address

IL

V

IL

V

IL

IL

IL

V

IH

V

IL

V

IH

V

IH

V

IL

01H

23H

ABH

01H*

Table 4. Expanded Autoselect Code Table

DQ15DQ14DQ13DQ12DQ11DQ10DQ9DQ8DQ7DQ6DQ5DQ4DQ3DQ2DQ1DQ

23H

A-10HI-Z0HI-Z1HI-Z0HI-Z0HI-Z0HI-Z1HI-Z0000011000000111

A-10HI-Z0HI-Z1HI-Z0HI-Z0HI-Z0HI-Z1HI-Z0110011001100111

ABH

0

1

1

(W)

(W)

Code

2223H

22ABH

Type

Manufacturer Code-AMD 01H 0000000000000001

Am29F400AT(B)

Am29F400A

Device

Sector Protection 01H 0000000000000001

Am29F400AB(B)

B) - Byte mode

(W) - Word mode

Am29F400AT/Am29F400AB 9

Page 10

PRELIMINARY

Table 5. Sector Address Tables (Am29F400AT)

(x8) Address

A17 A16 A15 A14 A13 A12

SA0 0 0 0 X X X 00000h-0FFFFh 00000h-07FFFh

SA1 0 0 1 X X X 10000h-1FFFFh 08000h-0FFFFh

SA2 0 1 0 X X X 20000h-2FFFFh 10000h-17FFFh

SA3 0 1 1 X X X 30000h-3FFFFh 18000h-1FFFFh

SA4 1 0 0 X X X 40000h-4FFFFh 20000h-27FFFh

SA5 1 0 1 X X X 50000h-5FFFFh 28000h-2FFFFh

SA6 1 1 0 X X X 60000h-6FFFFh 30000h-37FFFh

SA71110XX70000h-77FFFh 38000h-3BFFFh

SA811110078000h-79FFFh 3C000h-3CFFFh

SA91111017A000h-7BFFFh 3D000h-3DFFFh

SA10 11111X7C000h-7FFFFh 3E000h-3FFFFh

Range

(x16) Address

Range

Table 6. Sector Address Tables (Am29F400AB)

(x8) Address

A17 A16 A15 A14 A13 A12

SA000000X00000h-03FFFh 00000h-01FFFh

SA100001004000h-05FFFh 02000h-02FFFh

SA200001106000h-07FFFh 03000h-03FFFh

SA30001XX08000h-0FFFFh 04000h-07FFFh

SA4 0 0 1 X X X 10000h-1FFFFh 08000h-0FFFFh

SA5 0 1 0 X X X 20000h-2FFFFh 10000h-17FFFh

SA6 0 1 1 X X X 30000h-3FFFFh 18000h-1FFFFh

SA7 1 0 0 X X X 40000h-4FFFFh 20000h-27FFFh

SA8 1 0 1 X X X 50000h-5FFFFh 28000h-2FFFFh

SA9 1 1 0 X X X 60000h-6FFFFh 30000h-37FFFh

SA10 1 1 1 X X X 70000h-7FFFFh 38000h-3FFFFh

Range

(x16) Address

Range

Write

Device erasure and programming are accomplished via

the command register. The contents of the register serve

as inputs to the internal state machine. The state machine outputs dictate the function of the device.

The command register itself does not occupy any addressable memory location. The register is a latch used

to store the commands, along with the address and data

information needed to execute the command. The command register is written to by bringing WE

to VIL, while

CE is at VIL and OE is at VIH. Addresses are latched on

the falling edge of WE or CE, whichever happens later;

while data is latched on the rising edge of WE or CE,

whichever happens first. Standard microprocessor write

timings are used.

10 Am29F400AT/Am29F400AB

Refer to AC Write Characteristics and the Erase/Programming Waveforms for specific timing parameters.

Sector Protection

The Am29F400A features hardware sector protection.

This feature will disable both program and erase operations in any combination of ten sectors of memory. The

sector protect feature is enabled using programming

equipment at the user’s site. The device is shipped with

all sectors unprotected. Alternatively , AMD ma y program

and protect sectors in the factory prior to shipping the

device (AMD’ s ExpressFlash Service).

Page 11

PRELIMINARY

5.0 V-only Flash

It is possible to determine if a sector is protected in the

system by writing an Autoselect command. Performing

a read operation at the address location XX02H, where

the higher order address bits A12–A17 is the desired

sector address, will produce a logical “1” at DQ0 for a

protected sector. See Table 3 for Autoselect codes.

Temporary Sector Unprotect

This feature allows temporary unprotection of previously protected sectors of the Am29F400A device in

order to change data in-system. The Sector Unprotect

mode is activated by setting the RESET pin to high v oltage (12 V). During this mode, formerly protected sectors can be programmed or erased by selecting the

sector addresses. Once the 12 V is taken away from

the RESET pin, all the previously protected sectors will

be protected again. Refer to Figures 16 and 17.

Command Definitions

Device operations are selected by writing specific address and data sequences into the command register.

Writing incorrect address and data values

or writing them in the improper sequence will reset

the device to the read mode. Table 7 defines the valid

register command sequences. Note that the

Erase Suspend (B0H) and Erase Resume (30H) commands are valid only while the Sector Erase operation

is in progress. Moreover, both Reset/Read commands

are functionally equivalent, resetting the device to the

read mode.

Am29F400AT/Am29F400AB 11

Page 12

PRELIMINARY

Table 7. Am29F400A Command Definitions (Notes 1–7)

Bus

Command

Sequence

Read/Reset

Reset/Read 1 XXXXH F0H

Reset/

Read

Autoselect

Program

Chip Erase

Sector

Erase

Erase Suspend 1 XXXXH B0H

Erase Resume 1 XXXXH 30H

Write

Cycles

Req’ d

Word

Byte AAAAH 5555H AAAAH

Word 3 5555H AAH 2AAAH 55H 5555H 90H 01H 2223H

Byte AAAAH 5555H AAAAH 23H

Word

/Byte

Word 4 5555H AAH 2AAAH 55H 5555H A0H PA PD

Byte AAAAH 5555H AAAAH

Word 6 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H 5555H 10H

Byte AAAAH 5555H AAAAH AAAAH 5555H AAAAH

Word 6 5555H AAH 2AAAH 55H 5555H 80H 5555H AAH 2AAAH 55H SA 30H

Byte AAAAH 5555H AAAAH AAAAH 5555H

First Bus

Write Cycle

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

5555H AAH 2AAAH 55H 5555H

3

Second Bus

Write Cycle

Third Bus

Write Cycle

F0H RA RD

Fourth Bus

Read/Write Cycle

(T Device ID)

22ABH

(B Device ID)

(T Device ID)

ABH

(B Device ID)

01H (T/B

00H

Manuf. ID)

Fifth Bus

Write Cycle

Sixth Bus

Write Cycle

Notes:

1. Bus operations are defined in Tables 1 and 2.

2. RA = Address of the memory location to be read.

PA = Address of the memory location to be programmed. Addresses are latched on the falling edge of the WE

SA = Address of the sector to be erased. The combination of A17–A12 will uniquely select any sector.

3. RD = Data read from location RA during read operation.

PD = Data to be programmed at location PA. Data is latched on the rising edge of WE

4. Reading from non-erasing sectors is allowed in the Erase Suspend mode.

5. Address bits A17–A15 are don’t care for unlock and command cycles.

6. The system should generate the following address patterns:

Word Mode: 5555H or 2AAAH to addresses A0–A14

Byte Mode: AAAAH or 5555H to addresses A-1–A14.

Read/Reset Command

The read or reset operation is initiated by writing the

read/reset command sequence into the command register. Microprocessor read cycles retrieve array data

from the memory. The device remains enabled for

reads until the command register contents are altered.

The device will automatically power-up in the read/

reset state. In this case, a command sequence is not

required to read data. Standard microprocessor read

cycles will retrieve array data. This default value ensures that no spurious alteration of the memory content

occurs during the power transition. Refer to the AC

Read Characteristics and Waveforms for the specific

.

timing parameters.

pulse.

12 Am29F400AT/Am29F400AB

Page 13

PRELIMINARY

5.0 V-only Flash

Autoselect Command

Flash memories are intended for use in applications

where the local CPU can alter memory contents. As

such, manufacture and device codes must

be accessible while the device resides in the target

system. PR OM prog r ammers typically access the signature codes by raising A9 to a high voltage. How ev er ,

multiplexing high voltage onto the address lines is not

generally a desirable system design practice.

The device contains an autoselect command operation

to supplement traditional PROM programming methodology. The operation is initiated by writing the autoselect command sequence into the command register.

Following the command write, a read cycle from address XX00H retrieves the manuf acture code of 01H. A

read cycle from address XX01H returns the device

code (Am29F400AT = 23H and Am29F400AB = ABH

for x8 mode; Am29F400AT = 2223H and Am29F400AB

= 22ABH for x16 mode) (see Tables 3 and 4).

All manufacturer and device codes will exhibit odd parity with DQ7 defined as the parity bit.

Furthermore, the write protect status of sectors can be

read in this mode. Scanning the sector addresses

(A17, A16, A15, A14, A13, and A12) while (A6, A1, A0)

= (0, 1, 0) will produce a logical “1” at device output

DQ0 for a protected sector.

To terminate the operation, it is necessary to write the

read/reset command sequence into the register.

Byte/Word Programming

The device is programmed on a byte-by-byte (or

word-by-word) basis. Programming is a four bus cycle

operation. There are two “unlock” write cycles. These

are followed by the program setup command and data

write cycles. Addresses are latched on the falling edge

of CE or WE, whichever happens later and the data is

latched on the rising edge of CE or WE, whichev er happens first. The rising edge of CE or WE (whichev er happens first) begins programming using the Embedded

Program Algorithm. Upon executing the algorithm, the

system is

ings. The device will automatically pro vide adequate internally generated program pulses and verify the

programmed cell margin.

The automatic programming operation is completed

when the data on DQ7 (also used as Data Polling) is

equivalent to the data written to this bit at which time

the device returns to the read mode and addresses are

no longer latched (see Table 8, Write Operation Status). Theref ore , the device requires that a v alid address

to the device be supplied by the system at this particular instance of time for Data Polling operations. Data

Polling must be performed at the memory location

which is being programmed.

not

required to provide further controls or tim-

Any commands written to the chip during the Embedded Program Algorithm will be ignored. If a hardware

reset occurs during the programming operation, the

data at that particular location will be corrupted.

Programming is allowed in any sequence and across

sector boundaries. Beware that a data “0” cannot be

programmed back to a “1”. Attempting to do so may

cause the device to exceed programming time limits

(DQ5 = 1) or result in an apparent success according

to the data polling algorithm but a read from reset/read

mode will show that the data is still “013”. Only erase

operations can convert “0”s to “1”s.

Figure 1 illustrates the Embedded Programming Algorithm using typical command strings and

bus operations.

Chip Erase

Chip erase is a six bus cycle operation. There are two

“unlock” write cycles. These are followed by writing the

“setup” command. Two more “unlock” write cycles are

then followed by the chip erase command.

Chip erase does

device prior to erase. Upon executing the Embedded

Erase Algorithm command sequence the device will

automatically program and verify the entire memory for

an all zero data pattern prior to electrical erase. The

erase is performed sequentially on all sectors at the

same time (see Table “Erase and Programming Performance”). The system is not required to provide any

controls or timings during these operations.

The automatic erase begins on the rising edge of the

last WE pulse in the command sequence and terminates when the data on DQ7 is “1” (see Write Operation

Status section) at which time the device returns to read

the mode.

Figure 1 illustrates the Embedded Erase Algorithm

using typical command strings and bus operations.

not

require the user to program the

Sector Erase

Sector erase is a six bus cycle operation. There are two

“unlock” write cycles. These are followed by writing the

“set-up” command. Two more “unlock” write cycles are

then followed b y the sector erase command. The sector

address (any address location within the

desired sector) is latched on the falling edge of WE,

while the command (30H) is latched on the rising edge

of WE. After a time-out of 100 µs from the rising edge

of the last sector erase command, the sector erase operation will begin.

Multiple sectors may be erased sequentially by writing

the six bus cycle operations as described above. This

sequence is followed with writes of the Sector Erase

command to addresses in other sectors desired to be

sequentially erased. The time between writes must be

less than 100 µs otherwise that command will not be

Am29F400AT/Am29F400AB 13

Page 14

PRELIMINARY

accepted and erasure will start. It is recommended that

processor interrupts be disabled during this time to

guarantee this condition. The interrupts can be

re-enabled after the last Sector Erase command

is written. A time-out of 100 µs from the rising edge of

the last WE will initiate the execution of the Sector

Erase command(s). If another falling edge of the WE

occurs within the 100 µs time-out window the timer is

reset. (Monitor DQ3 to determine if the sector erase

timer window is still open, see section DQ3, Sector

Erase Timer.) Any command other than Sector Erase

or Erase Suspend during this period will reset the device to the read mode, ignoring the previous command

string. In that case, restart the erase on those sectors

and allow them to complete.

(Refer to the Write Operation Status section for DQ3,

Sector Erase Timer operation.) Loading the sector

erase buffer may be done in any sequence and with

any number of sectors (0 to10).

not

Sector erase does

require the user to program the

device prior to erase. The device automatically programs all memory locations in the sector(s) to be

erased prior to electrical erase. When erasing a sector

or sectors the remaining unselected sectors are not affected. The system is

not

required to provide any con-

trols or timings during these operations.

The automatic sector erase begins after the 100 µs

time out from the rising edge of the WE pulse for the

last sector erase command pulse and terminates when

the data on DQ7, Data Polling, is “1” (see Write Operation Status section) at which time the device returns to

the read mode. Data Polling must be performed at an

address within any of the sectors being erased.

Figure 1 illustrates the Embedded Erase Algorithm

using typical command strings and bus operations.

Erase Suspend

The Erase Suspend command allows the user to interrupt a Sector Erase operation and then perform data

reads from a sector not being erased. This command is

applicable ONLY during the Sector Erase operation

which includes the time-out period for sector erase. The

Erase Suspend command will be ignored if written during the Chip Erase operation or Embedded

Program Algorithm. Writing the Erase Suspend command during the Sector Erase time-out results in immediate termination of the time-out period and suspension

of the erase operation.

Any other command written during the Erase Suspend

mode will be ignored except the Erase

Resume command. Writing the Erase Resume command resumes the erase operation. The addresses are

“don’t-cares” when writing the Erase Suspend or Erase

Resume command.

When the Erase Suspend command is written during

the Sector Erase operation, the device will take a maximum of 15 µs to suspend the erase operation. When

the device has entered the erase-suspended mode,

DQ6 will stop toggling. The user must use the address

of a sector being erased for reading DQ6 to determine

if the erase operation has been suspended. Further

writes of the Erase Suspend command are ignored.

When the erase operation has been suspended, the

device defaults to the erase-suspend-read mode.

Reading data in this mode is the same as reading from

the standard read mode except that the data must be

read from sectors that have not been

erase-suspended.

To resume the operation of Sector Erase, the Resume

command (30H) should be written. Any further writes of

the Resume command at this point will be ignored. Another Erase Suspend command can be written after the

chip has resumed erasing.

Write Operation Status

Table 8. Write Operation Status

Status DQ7 DQ6 DQ5 DQ3

In Progress

Exceeded

Time Limits

Notes:

1. D8–D15 = Don’t Care for x16 mode.

2. DQ4 for AMD internal use only.

14 Am29F400AT/Am29F400AB

Auto-Programming DQ7 Toggle 0 0

Program/Erase in Auto-Erase 0 Toggle 0 1

Auto-Programming DQ7 Toggle 1 0

Program/Erase in Auto-Erase 0 Toggle 1 1

Page 15

PRELIMINARY

5.0 V-only Flash

DQ7

Data Polling

The Am29F400A device features Data Polling as a

method to indicate to the host that the embedded algorithms are in progress or completed. During

the Embedded Program Algorithm an attempt to read

the device will produce the complement of the data last

written to DQ7. Upon completion of the Embedded Program Algorithm, an attempt to read the device will produce the true data last written to DQ7. During the

Embedded Erase Algorithm, an attempt to read

the device will produce a “0” at the DQ7 output.

Upon completion of the Embedded Erase Algorithm an

attempt to read the device will produce a “1” at the DQ7

output. The flowchart for Data

in Figure 2.

For chip erase, the Data Polling is valid after the rising

edge of the sixth WE pulse in the six write pulse sequence. For sector erase, the Data Polling is valid after

the last rising edge of the sector erase WE pulse. Data

Polling must be performed at sector addresses within

any of the sectors being erased and not a protected

sector. Otherwise, the status may not be valid.

Just prior to the completion of Embedded Algorithm

operations DQ7 may change asynchronously while

the output enable (OE) is asserted low. This means

that the device is driving status information on DQ7 at

one instant of time and then that byte’s valid data at

the next instant of time. Depending on when the system samples the DQ7 output, it may read the status or

valid data. Even if the device has completed the Embedded Algorithm operations and DQ7 has a valid

data, the data outputs on DQ0–DQ6 may be still invalid. The valid data on DQ0–DQ7 will be read on the

successive read attempts.

The Data Polling feature is only active during the Embedded Programming Algorithm, Embedded Erase Algorithm, or sector erase time-out (see Table 7).

See Figure 10 for the Data P olling timing specifications

and diagrams.

DQ6

Toggle Bit

The Am29F400A also features the “Toggle Bit” as a

method to indicate to the host system that the embedded algorithms are in progress or completed.

During an Embedded Program or Erase Algorithm cycle, successive attempts to read (OE toggling) data

from the device at any address will result in DQ6 toggling between one and zero. Once the Embedded Program or Erase Algorithm cycle is completed, DQ6 will

stop toggling and valid data will be read on

successive attempt. During programming, the Toggle

Bit is valid after the rising edge of the fourth WE pulse

in the four write pulse sequence. For chip erase, the

Polling (DQ7) is shown

the next

Toggle Bit is valid after the rising edge of the sixth WE

pulse in the six write pulse sequence. F or Sector erase,

the Toggle Bit is valid after the last rising edge of the

sector erase WE pulse. The Toggle Bit is active during

the sector time-out.

Either CE or OE toggling will cause DQ6 to toggle. In

addition, an Erase Suspend/Resume command will

cause DQ6 to toggle. See Figure 11 for the Toggle Bit

timing specifications and diagrams.

DQ5

Exceeded Timing Limits

DQ5 will indicate if the program or erase time has exceeded the specified limits (internal pulse count).

Under these conditions DQ5 will produce a “1”. This is

a failure condition which indicates that the program or

erase cycle was not successfully completed. Data

ing is the only operating function of the device under

this condition. The CE circuit will partially power down

the device under these conditions (to approximately 2

mA). The OE and WE pins will control the output disable functions as described in Table 1.

The DQ5 failure condition will also appear if a user tries

to program a 1 to a location that is previously programmed to 0. In this case the device locks out and

never completes the Embedded Program Algorithm.

Hence, the system never reads a valid data on DQ7 bit

and DQ6 never stops toggling. Once the de vice has e xceeded timing limits, the DQ5 bit will indicate a “1.”

Please note that this is not a device failure condition

since the device was incorrectly used. If this occurs,

reset the device.

DQ3

Sector Erase Timer

After the completion of the initial sector erase command sequence the sector erase time-out will begin.

DQ3 will remain low until the time-out is complete. Data

Polling and Toggle Bit are valid after the initial sector

erase command sequence.

If Data Polling or the Toggle Bit indicates the device has

been written with a valid erase command, DQ3 may be

used to determine if the sector erase timer window is

still open. If DQ3 is high (“1”) the internally controlled

erase cycle has begun; attempts to write subsequent

commands (other than Erase Suspend) to the device

will be ignored until the erase operation is completed as

indicated by Data Polling or Toggle Bit. If DQ3 is low

(“0”), the device will accept additional sector erase

commands. To insure the command has been accepted, the system software should check the status of

DQ3 prior to and following each subsequent sector

erase command. If DQ3 were high on the second status check, the command may not have been accepted.

Refer to Table 8: Write Operation Status.

Poll-

Am29F400AT/Am29F400AB 15

Page 16

PRELIMINARY

RY/BY

Ready/Busy

The Am29F400A provides a RY/BY open-drain output

pin as a way to indicate to the host system that the Embedded Algorithms are either in progress or have been

completed. If the output is low, the device is busy with

either a program or erase operation. If the output is

high, the device is ready to accept any read/write or

erase operation. When the R Y/BY pin is low, the device

will not accept any additional program or erase commands with the exception of the Erase Suspend command. If the Am29F400A is placed in an Erase

Suspend mode, the RY/BY

During programming, the RY/BY pin is driven low after

the rising edge of the fourth WE pulse. During an erase

operation, the RY/BY pin is driven low after the rising

edge of the sixth WE pulse. The RY/BY pin should be

ignored while RESET is at VIL. Refer to Figure 12 for a

detailed timing diagram.

Since this is an open-drain output, sever al RY/BYpins

can be tied together in parallel with a pull-up resistor

to VCC.

RESET

Hardware Reset

The Am29F400A device may be reset by driving the

RESET pin to VIL. The RESET pin must be kept low

(VIL) for at least 500 ns. Any operation in progress will

be terminated and the internal state machine will be

reset to the read mode 20 µs after the RESET pin is

driven low. Furthermore, once the RESET pin goes

high, the device requires an additional 50 ns before it

will allow read access. When the RESET pin is low, the

device will be in the standby mode for the duration of

the pulse and all the data output pins will be tri-stated.

If a hardware reset occurs during a program or erase

operation, the data at that particular location will

be indeterminate.

The RESET pin may be tied to the system reset input.

Therefore, if a system reset occurs during the Embedded Program or Erase Algorithm, the device will be automatically reset to read mode and this will enable the

system’s microprocessor to read the boot-up firmware

from the Flash memory.

output will be high.

Byte/Word Configuration

The BYTE pin selects the byte (8-bit) mode or word

(16 bit) mode for the Am29F400A device. When this

pin is driven high, the device operates in the word (16

bit) mode. The data is read and programmed

at DQ0–DQ15. When this pin is driven low, the device operates in byte (8 bit) mode. Under this mode,

the DQ15/A-1 pin becomes the lowest address bit

and DQ8–DQ14 bits are tri-stated. However, the

command bus cycle is always an 8-bit operation and

hence commands are written at DQ0–DQ7 and the

DQ8–DQ15 bits are ignored. Refer to Figures 14 and

15 for the timing diagram.

Data Protection

The Am29F400A is designed to offer protection against

accidental erasure or programming caused by spurious

system level signals that ma y e xist during power transitions. During power up the device automatically resets

the internal state machine in the Read mode. Also , with

its control register architecture, alteration of the memory contents only occurs after successful completion of

specific multi-bus cycle command sequences.

The device also incorporates several features to prevent inadvertent write cycles resulting from V

power-up and power-down tr ansitions or system noise.

CC

Low VCC Write Inhibit

To av oid initiation of a write cycle during VCC power-up

and power-down, the Am29F400A locks out write cycles for VCC < V

voltages). When VCC < V

disabled, all internal program/erase circuits

are disabled, and the device resets to the read mode.

The Am29F400A ignores all writes until VCC > V

The user must ensure that the control pins are in the

correct logic state when VCC > V

tentional writes.

(see DC Characteristics section for

LKO

, the command register is

LKO

to prevent unin-

LKO

LKO

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE, CE, or

WE will not initiate a write cycle.

Logical Inhibit

Writing is inhibited by holding any one of OE = VIL,CE

= VIH, or WE = VIH. To initiate a write cycle CE and WE

must be a logical zero while OE is a logical one.

Power -Up Write Inhibit

Power-up of the device with WE = CE = VIL and OE =

VIH will not accept commands on the rising edge of WE.

The internal state machine is automatically reset to the

read mode on power-up.

.

16 Am29F400AT/Am29F400AB

Page 17

5.0 V-only Flash

EMBEDDED ALGORITHMS

PRELIMINARY

Start

Increment Address

Program Command Sequence (Address/Command):

Write Program Command Sequence

(see below)

Data

Poll Device

No

Last Address

?

Yes

Programming Completed

5555H/AAH

2AAAH/55H

5555H/A0H

Program Address/Program Data

20380B-8

Figure 1. Embedded Programming Algorithm

Am29F400AT/Am29F400AB 17

Page 18

EMBEDDED ALGORITHMS

PRELIMINARY

Start

Write Erase Command Sequence

Chip Erase Command Sequence

(Address/Command):

5555H/AAH

2AAAH/55H

5555H/80H

5555H/AAH

(see below)

Polling or Toggle Bit

Data

Successfully Completed

Erasure Completed

Individual Sector/Multiple Sector

Erase Command Sequence

(Address/Command):

5555H/AAH

2AAAH/55H

5555H/80H

5555H/AAH

2AAAH/55H

5555H/10H

2AAAH/55H

Sector Address/30H

Sector Address/30H

Sector Address/30H

Additional sector

erase commands

are optional

20380B-9

Note:

To insure the command has been accepted, the system software should check the status of DQ3 prior to and f ollowing each subsequent sector erase command. If DQ3 were high on the second status check, the command may not have been accepted.

Figure 2. Embedded Erase Algorithm

18 Am29F400AT/Am29F400AB

Page 19

PRELIMINARY

5.0 V-only Flash

Start

No

Read Byte

(DQ0-DQ7)

Addr=VA

DQ7=Data

?

No

DQ5=1

?

Yes

Read Byte

(DQ0-DQ7)

Addr=VA

DQ7=Data

?

No

VA=Byte address for programming

=any of the sector addresses within the

sector being erased during sector erase

operation

=Valid address equals any non-protected

sector group address during chip erase

Yes

Yes

Pass

Note:

DQ7 is rechecked even if DQ5 = “1” because DQ7 may change simultaneously with DQ5.

Fail

20380B-10

Figure 3. Data Polling Algorithm

Am29F400AT/Am29F400AB 19

Page 20

PRELIMINARY

Start

Read Byte

(DQ0–DQ7)

Addr=Don’t Care

DQ6=Toggle

No

?

Yes

No

DQ5=1

?

Yes

Read Byte

(DQ0–DQ7)

Addr=Don’t Care

DQ6=Toggle

No

?

Yes

Pass

Fail

Note:

DQ6 is rechecked even if DQ5 = “1” because DQ6 may stop toggling at the same time as DQ5 changing to “1”.

20380B-11

Figure 4. Toggle Bit Algorithm

20 ns

+0.8 V

-0.5 V

-2.0 V

20 ns

20 ns

Figure 5. Maximum Negative Overshoot Waveform

20 ns

+ 2.0 V

V

CC

V

+ 0.5 V

CC

2.0 V

20 ns 20 ns

Figure 6. Maximum Positive Overshoot Waveform

20 Am29F400AT/Am29F400AB

20380B-12

20380B-13

Page 21

PRELIMINARY

5.0 V-only Flash

ABSOLUTE MAXIMUM RATINGS

Storage Temperature

Plastic Packages . . . . . . . . . . . . . . . -65°C to +125°C

Ambient T emper ature

with Power Applied. . . . . . . . . . . . . . -55°C to +125°C

Voltage with Respect to Ground

All pins except A9, OE and RESET

(Note 1) . . . . . . . . . . . . . . . . . . . . . . . -2.0 V to +7.0 V

VCC (Note 1). . . . . . . . . . . . . . . . . . . . -2.0 V to +7.0 V

A9, OE, and RESET (Note 2). . . . . . -2.0 V to +13.0 V

Output Short Circuit Current (Note 3) . . . . . . 200 mA

Notes:

1. Minimum DC v oltage on input or I/O pins is -0.5 V. During

voltage transitions, input or I/O pins ma y undershoot V

to -2.0 V f or periods of up to 20 ns. Maximum DC voltage

on input or I/O pins is

transitions, input or I/O pins may ov ershoot to V

for periods up to 20 ns. See Figure 7 and Figure 8.

2. Minimum DC input v oltage on pins A9, OE

-0.5 V. During voltage transitions, A9, OE

may undershoot V

Maximum DC input voltage on pin A9 is +12.5 V which

may overshoot to 14.0 V for periods up to 20 ns. See

Figure 7 and Figure 8.

3. No more than one output may be shorted to ground at a

time. Duration of the short circuit should not be greater

than one second.

4. Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only; functional operation of the

device at these or any other conditions above those

indicated in the operational sections of this data sheet is

not implied. Exposure of the de vice to absolute maximum

rating conditions for extended periods may affect device

reliability.

V

+0.5 V. During voltage

CC

, and RESET is

, and RESET

to -2.0 V for periods of up to 20 ns.

SS

CC

SS

+2.0 V

OPERATING RANGES

Commercial (C) Devices

Ambient T emper ature (TA). . . . . . . . . . . . 0˚C to +70˚C

Industrial (I) Devices

Ambient T emper ature (TA). . . . . . . . . . -40˚C to +85˚C

Extended (E) Devices

Ambient T emper ature (TA). . . . . . . . . -55˚C to +125˚C

VCC Supply Voltages

VCC for Am29F400T/B-65, . . . . . . +4.75 V to +5.25 V

VCC for Am29F400T/B-70, -90,

-120, -150 . . . . . . . . . . . . . . . . . . . +4.50 V to +5.50 V

Operating ranges define those limits between which the functionality of the device is guaranteed.

Am29F400AT/Am29F400AB 21

Page 22

PRELIMINARY

DC CHARACTERISTICS

TTL/NMOS Compatible

Parameter

Symbol Parameter Description Test Conditions Min Max Unit

I

LI

I

LIT

I

LO

I

CC1

I

CC2

I

CC3

V

IL

V

IH

V

ID

V

OL

V

OH

V

LKO

Notes:

1. The I

The frequency component typically is less than 2 mA/MHz, with OE

active while Embedded Program or Erase Algorithm is in progress.

2. I

CC

3. Not 100% tested.

Input Load Current VIN = VSS to VCC, VCC = VCC Max ±1.0 µA

A9, OE, RESET Input Load Current VCC = VCC Max, A9, OE, RESET = 12.5 V 50 µA

Output Leakage Current V

= VSS to VCC, VCC = VCC Max ±1.0 µA

OUT

Byte 40

VCC Active Read Current (Note 1) CE = VIL, OE = V

VCC Active Program/Erase Current

(Notes 2, 3)

CE

= VIL, OE = V

VCC Standby Current VCC = VCC Max, CE = VIH, OE = V

IH

IH

Word 50

IH

60 mA

1.0 mA

Input Low Voltage –0.5 0.8 V

Input High Voltage 2.0 VCC + 0.5 V

Voltage for Autoselect and

Temporary Sector Unprotect

= 5.0 V 11.5 12.5 V

V

CC

Output Low Voltage IOL = 5.8 mA, VCC = VCC Min 0.45 V

Output High Voltage IOH = -2.5 mA, VCC = VCC Min 2.4 V

Low VCC Lock-Out Voltage 3.2 4.2 V

current listed includes both the DC operating current and the frequency dependent component (at 6 MHz).

CC

at VIH.

mA

22 Am29F400AT/Am29F400AB

Page 23

PRELIMINARY

5.0 V-only Flash

DC CHARACTERISTICS (continued)

CMOS Compatible

Parameter

Symbol Parameter Description Test Conditions Min Typ Max Unit

I

LI

I

LIT

I

LO

I

CC1

I

CC2

I

CC3

V

V

IH

V

ID

V

OL

V

OH1

V

OH2

V

LKO

Notes:

1. The I

The frequency component typically is less than 2 mA/MHz, with OE

active while Embedded Program or Erase Algorithm is in progress.

2. I

CC

3. Not 100% tested.

4. I

CC3

Input Load Current VIN = VSS to VCC, VCC = VCC Max ±1.0 µA

V

A9, OE, RESET Input Load

Current

Output Leakage Current V

= VCC Max, A9, OE,

CC

= 12.5 V

RESET

= VSS to VCC, VCC = VCC Max ±1.0 µA

OUT

Byte 20 40

VCC Active Read Current (Note 1) CE = VIL, OE = V

VCC Active Program/Erase

Current (Notes 2, 3)

VCC Standby Current (Note 4)

Input Low Voltage -0.5 0.8 V

IL

CE

= VIL, OE = V

= VCC Max, CE = VIH,

V

CC

OE

= V

IH

Input High Voltage

Voltage for Autoselect and

Temporary Sector Unprotect

V

= 5.0 V 11.5 12.5 V

CC

IH

IH

Word 28 50

30 50 mA

15µA

0.7 x

V

CC

Output Low Voltage IOL = 5.8 mA, VCC = VCC Min 0.45 V

Output Low Voltage

IOH = –2.5 mA, VCC = VCC Min

0.85

V

CC

IOH = –100 µA, VCC = VCC Min VCC -0.4 V

Low VCC Lock-Out Voltage 3.2 4.2 V

current listed includes both the DC operating current and the frequency dependent component (at 6 MHz).

CC

at VIH.

= 20 µA max at extended temperatures (> +85°C).

50 µA

VCC +

0.3

mA

V

V

Am29F400AT/Am29F400AB 23

Page 24

PRELIMINARY

AC CHARACTERISTICS

Read-Only Operations Characteristics

Parameter

Symbols Speed Option (Notes 1 and 2)

JEDEC Standard Description Test Setup -65 -70 -90 -120 -150 Unit

t

AVAV

t

AVQV

t

ELQV

t

GLQVtOE

t

EHQZtDF

t

GHQZtDF

t

AXQXtOH

t

RC

t

ACC

t

CE

t

Ready

t

ELFL

t

ELFH

Notes:

1. Test Conditions (for -65 only)

Output Load: 1 TTL gate and 30 pF

Input Rise and Fall Times: 5 ns

Input Pulse Levels:0.0 V to 3.0 V

Timing Measurement Reference Level: 1.5 V input

and output

2. Test Conditions (for -70, -90, -120, -150)

Output Load: 1 TTL gate and 100 pF

Input Rise and Fall Times: 20 ns

Read Cycle Time (Note 4) Min 60 70 90 120 150 ns

= V

CE

Address to Output Delay

OE = V

IL

Max 60 70 90 120 150 ns

IL

Chip Enable to Output Delay OE = VILMax 60 70 90 120 150 ns

Output Enable to Output

Delay

Chip Enable to Output High Z

(Notes 3, 4)

Output Enable to Output

High Z (Notes 3, 4)

Max 30 30 35 50 55 ns

Max 20 20 20 30 35 ns

Max 20 20 20 30 35 ns

Output Hold Time From

Addresses, CE

or OE,

Min00000ns

Whichever Occurs First

RESET Pin Low to Read

Mode (Note 4)

CE to BYTE Switching Low

or High

Max 20 20 20 20 20 µs

Max55555ns

Input Pulse Levels: 0.45 V to 2.4 V

Timing Measurement Reference Level: 0.8 V and 2.0 V

input and output

3. Output Driver Disable Time

4. Not 100% tested.

5.0 V

IN3064

Device

or Equivalent

2.7 kΩ

Under

Test

C

L

6.2 kΩ

Notes:

For -65: C

For all others: C

= 30 pF including jig capacitance

L

= 100 pF including jig capacitance

L

Figure 7. Test Conditions

24 Am29F400AT/Am29F400AB

IN3064 or Equivalent

IN3064 or Equivalent

IN3064 or Equivalent

20380B-14

Page 25

5.0 V-only Flash

AC CHARACTERISTICS

Write (Erase/Program) Operations

PRELIMINARY

Parameter Symbols

JEDEC Standard -65 -70 -90 -120 -150 Unit

t

AVAV

t

AVWL

t

WLAX

t

DVWH

t

WHDX

t

GHWL

t

ELWL

t

WHEH

t

WLWH

t

WHDL

t

WC

t

AS

t

AH

t

DS

t

DH

t

OEH

t

GHWL

t

CS

t

CH

t

WP

t

WPH

Description

Write Cycle Time Min 60 70 90 120 150 ns

Address Setup Time Min 00000ns

Address Hold Time Min 45 45 45 50 150 ns

Data Setup Time Min 30 30 45 50 50 ns

Data Hold Time Min 00000ns

Output

Enable

Hold Time

Read Recovery Time Before Write

(OE

High to WE Low)

Read (Note 2) Min 00000ns

Toggle and Data

(Note 2)

Polling

Min 10 10 10 10 10 ns

Min00000ns

CE Setup Time Min 00000ns

CE Hold Time Min 00000ns

Write Pulse Width Min 35 35 45 50 50 ns

Write Pulse Width High Min 20 20 20 20 20 ns

Speed Option (Notes 1 and 2)

Byte Typ 77777µs

t

WHWH1tWHWH1

Programming Operation

Word Typ1414141414µs

Typ 1.0 1.0 1.0 1.0 1.0 sec

t

WHWH2tWHWH2

t

VCS

t

VIDR

t

OESP

t

RP

t

FLQZ

t

BUSY

t

RESSP

Sector Erase Operation (Note 1)

Max88888sec

VCC Setup Time (Note 2) Min 50 50 50 50 50 µs

Rise Time to VID (Notes 2, 3) Min 500 500 500 500 500 ns

OE Setup Time to WE Active

(Notes 2, 3)

Min44444µs

RESET Pulse Width Min 500 500 500 500 500 ns

BYTE Switching Low to Output High Z

(Notes 3, 4)

Program/Erase Valid to RY/BY Delay

(Note 2)

Max 20 20 30 30 30 ns

Min 30 30 35 50 55 ns

RESET Setup Time to WE Active Min 44444µs

Notes:

1. This does not include the preprogramming time.

2. Not 100% tested.

3. These timings are for Temporary Sector Unprotect operation.

4. Output Driver Disable Time.

Am29F400AT/Am29F400AB 25

Page 26

KEY TO SWITCHING WA VEFORMS

WAVEFORM INPUTS OUTPUTS

PRELIMINARY

SWITCHING W A VEFORMS

Addresses

Must Be

Steady

May

Change

from H to L

May

Change

from L to H

Don’t Care,

Any Change

Permitted

Does Not

Apply

t

RC

Addresses Stable

Will Be

Steady

Will Be

Changing

from H to L

Will Be

Changing

from L to H

Changing,

State

Unknown

Center

Line is HighImpedance

“Off” State

KS000010

CE

OE

WE

Outputs

t

ACC

t

OE

t

OEH

(tCE)

(tOH)

High Z High Z

Output Valid

(tDF)

Figure 8. AC Waveforms for Read Operations

20380B-15

26 Am29F400AT/Am29F400AB

Page 27

5.0 V-only Flash

SWITCHING W A VEFORMS

3rd Bus Cycle

PRELIMINARY

Data Polling

Addresses

5555H

t

WC

PA

t

AH

t

AS

CE

t

GHWL

OE

t

WHWH1

WE

Data

t

t

CS

DS

A0H

t

WPH

t

WP

t

DH

PD

5.0 V

Notes:

1. PA is address of the memory location to be programmed.

2. PD is data to be programmed at byte address.

3. DQ7

4. D

is the output of the complement of the data written to the device.

is the output of the data written to the device.

OUT

5. Figure indicates last two bus cycles of four bus cycle sequence.

6. These waveforms are for the x16 mode.

Figure 9. Program Operation Timings

DQ7

PA

t

RC

t

t

OE

D

OUT

t

CE

DF

t

OH

20380B-16

Addresses

Notes:

1. SA is the sector address for Sector Erase. Addresses = don’t care for Chip Erase.

2. These waveforms are for the x16 mode.

CE

OE

WE

Data

V

CC

t

VCS

t

GHWL

t

AH

5555H 5555H

t

WP

t

t

CS

t

DS

WPH

t

DH

AAH

2AAAH

t

AS

55H

5555H

AAH

Figure 10. AC Waveforms Chip/Sector Erase Operations

Am29F400AT/Am29F400AB 27

2AAAH

55H80H 10H/30H

SA

20380B-17

Page 28

SWITCHING W A VEFORMS

t

CE

OE

CH

t

OEH

PRELIMINARY

t

OE

t

DF

WE

DQ7

DQ0-DQ6

t

CE

t

WHWH 1 or 2

DQ7

DQ0-DQ6=Invalid

Note:

*DQ7=Valid Data (The device has completed the Embedded operation).

Figure 11. AC Waveforms for Data Polling During Embedded Algorithm Operations

CE

t

OEH

WE

*

t

OH

DQ7=

Valid Data

DQ0-DQ6

Valid Data

High Z

20380B-18

OE

Data

(DQ0-DQ7)

DQ6=T oggle

DQ6=T oggle

Note:

*DQ6 stops toggling (The device has completed the Embedded operation).

Figure 12. AC Waveforms for Toggle Bit During Embedded Algorithm Operations

28 Am29F400AT/Am29F400AB

*

t

OE

DQ6=

Stop T oggling

DQ0-DQ7

Valid

20380B-19

Page 29

5.0 V-only Flash

SWITCHING W A VEFORMS

CE

PRELIMINARY

The rising edge of the last WE

WE

RY/BY

Entire programming

or erase operations

t

BUSY

Figure 13. RY/BY Timing Diagram During Program/Erase Operations

RESET

t

RP

t

Ready

Figure 14. RESET

Timing Diagram

signal

20380B-20

20380B-21

Am29F400AT/Am29F400AB 29

Page 30

SWITCHING W A VEFORMS

CE

OE

BYTE

DQ0-DQ14

t

ELFL

t

ELFH

PRELIMINARY

Data Output

(DQ0-DQ14)

Data Output

(DQ0-DQ7)

DQ15/A-1

Figure 15. BYTE Timing Diagram for Read Operation

CE

WE

BYTE

Figure 16. BYTE

Address

Input

t

FLQZ

DQ15

Output

The falling edge of the last WE signal

t

SET

(tAS)

t

HOLD

(tAH)

Timing Diagram for Write Operations

20380B-22

20380B-23

30 Am29F400AT/Am29F400AB

Page 31

PRELIMINARY

5.0 V-only Flash

Start

RESET = V

(Note 1)

Perform Erase or

Program Operations

RESET

Temporary Sector Group

Unprotect Completed

(Note 2)

Notes:

1. All protected sectors unprotected.

2. All previously protected sectors are protected once again.

Figure 17. Temporary Sector Unprotect Algorithm

= V

ID

IH

20380B-24

5 V

RESET

RY/BY

CE

WE

12 V

t

VIDR

Program or Erase Command Sequence

Figure 18. Temporary Sector Unprotect Timing Diagram

20380B-25

Am29F400AT/Am29F400AB 31

Page 32

AC CHARACTERISTICS

Write/Erase/Program Operations

Alternate CE Controlled Writes

PRELIMINARY

Parameter Symbols

t

AVAV

t

AVEL

t

ELAX

t

DVEH

t

EHDX

t

GHEL

t

WLEL

t

EHWH

t

ELEH

t

EHEL

t

WHWH1tWHWH1

t

WHWH2tWHWH2

t

WC

t

AS

t

AH

t

DS

t

DH

t

OES

t

OEH

t

GHEL

t

WS

t

WH

t

CP

t

CPH

t

FLQZ

Speed Option (Notes 1 and 2)

Description

UnitJEDEC Standard -65 -70 -90 -120 -150

Write Cycle Time (Note 2) Min 60 70 90 120 150 ns

Address Setup Time Min 00000ns

Address Hold Time Min 45 45 45 50 50 ns

Data Setup Time Min 30 30 45 50 50 ns

Data Hold Time Min 00000ns

Output Enable Setup Time Min 00000ns

Read (Note 2) Min 00000ns

Output Enable

Hold Time

Toggle and Data

Polling (Note 2)

Min 10 10 10 10 10 ns

Read Recover Time Before Write Min 00000ns

WE Setup Time Min 00000ns

WE Hold Time Min 00000ns

CE Pulse Width Min 35 35 45 50 50 ns

CE Pulse Width High Min 20 20 20 20 20 ns

Byte T yp 77777µs

Programming Operation

Word Typ1414141414µs

Typ 1.0 1.0 1.0 1.0 1.0 sec

Sector Erase Operation (Note 1)

Max88888sec

BYTE Switching Low to Output High Z

(Note 2)

Max 20 20 30 30 30 ns

Notes:

1. This does not include the preprogramming time.

2. Not 100% tested.

32 Am29F400AT/Am29F400AB

Page 33

5.0 V-only Flash

SWITCHING W A VEFORMS

PRELIMINARY

Data Polling

Addresses

5555H

t

WC

PA

t

AH

t

AS

WE

t

GHEL

OE

t

CP

CE

Data

t

WS

t

DS

A0H

t

CPH

t

DH

PD

5.0 V olt

Notes:

1. PA is address of the memory location to be programmed.

2. PD is data to be programmed at byte address.

3. DQ7

4. D

is the output of the complement of the data written to the device.

is the output of the data written to the device.

OUT

5. Figure indicates last two bus cycles of four bus cycle sequence.

6. These waveforms are for the x16 mode.

Figure 19. Alternate CE Controlled Program Operation Timings

t

WHWH1

DQ7

PA

D

OUT

20380B-26

ERASE AND PROGRAMMING PERFORMANCE

Sector Erase Time 1.0 8 sec Excludes 00H programming prior to erasure

Chip Erase Time 11 88 sec Excludes 00H programming prior to erasure

Byte Programming Time 7 300 (Note 3) µs Excludes system-level overhead (Note 4)

Word Programming Time 14 600 µs Excludes system-level overhead (Note 4)

Chip Programming Time 3.6 10.8 (Notes 3, 5) sec Excludes system-level overhead (Note 4)

Notes:

1. 25

2. Although Embedded Algorithms allow for longer chip prog r am and erase time , the actual time will be consider ab ly less since

bytes program or erase significantly faster than the worst case byte.

3. Under worst case condition of 90

4. System-level overhead is defined as the time required to execute the four bus cycle command necessary to program each

byte. In the preprogramming step of the Embedded Erase algorithm, all bytes are programmed to 00H before erasure.

5. The Embedded Algorithms allow for 2.5 ms b yte program time. DQ5 = “1” only after a b yte takes the theoretical maximum time

to program. A minimal number of bytes ma y require significantly more progr amming pulses than the typical byte . The majority

of the bytes will program within one or two pulses. This is demonstrated by the Typical and Maximum Programming Times

listed above.

Parameter

°

C, 5.0 V VCC, 100,000 cycles.

Limits

°

C, 4.5 V VCC, 100,000 cycles.

Am29F400AT/Am29F400AB 33

Unit CommentsTyp (Note 1) Max

Page 34

PRELIMINARY

LATCHUP CHARACTERISTICS

Min Max

Input Voltage with respect to VSS on all I/O pins –1.0 V VCC + 1.0 V

VCC Current –100 mA +100 mA

Includes all pins except VCC. Test conditions: VCC = 5.0 V, one pin at a time.

TSOP PIN CAPACITANCE

Parameter

Symbol Parameter Description Test Setup Typ Max Unit

C

IN

C

OUT

C

IN2

Input Capacitance VIN = 0 6 7.5 pF

Output Capacitance V

= 0 8.5 12 pF

OUT

Control Pin Capacitance VIN = 0 8 10 pF

Notes:

1. Sampled, not 100% tested.

2. Test conditions T

= 25°C, f = 1.0 MHz.

A

SO PIN CAPACITANCE

Parameter

Symbol Parameter Description Test Setup Typ Max Unit

C

IN

C

OUT

C

IN2

Notes:

1. Sampled, not 100% tested.

2. Test conditions T

A

Input Capacitance VIN = 0 6 7.5 pF

Output Capacitance V

= 0 8.5 12 pF

OUT

Control Pin Capacitance VPP = 0 8 10 pF

= 25°C, f = 1.0 MHz.

DATA RETENTION

Parameter Test Conditions Min Unit

Minimum Pattern Data Retention Time

34 Am29F400AT/Am29F400AB

150°C 10 Years

125°C 20 Years

Page 35

PRELIMINARY

5.0 V-only Flash

REVISION SUMMARY

Distinctive Characteristics:

High Performance:

is now 60 ns.

Enhanced power management for standby mode:

Changed typical standby current to 1µA.

General Description:

First paragraph, first sentence should read, “...organized as 512 Kbytes of 8 bits each or 256

bits each.” Added 60 ns speed option.

Product Selector Guide:

Added -65 column (60 ns, ±5% V

±10% VCC) and deleted -75 speed option.

Ordering Information, Standard Products:

The -65 speed option is now listed in the example.

Valid Combinations:

75 speed options.

Tables 1 and 2, User Bus Operations:

Corrected WE for read operations; was don’t care (X),

is now H.

Standby Mode:

Corrected standby mode current; was 100 µA, is now

5 µA.

Table 5, Sector Address Tables (Am29F400AB):

Corrected x16 starting address for SA5; was 1C000h,

is now 28000h.

The fastest speed option available

Kwords

). Added -70 (70 ns ,

CC

Added -65 and -70, and deleted -

of 16

Erase Suspend:

Third paragraph, third sentence: Deleted the word “NOT.”

Operating Ranges:

VCC Supply Voltages:

options in the list. Changed A9 maximum to +13.0 V.

DC Characteristics:

CMOS Compatible:

Note 4 (refers to I

AC Characteristics:

Read Only Operations Characteristics:

column and test conditions.

Replaced -75 column with -70 column.

Test Conditions, Figure 7:

Changed speed option in first C

to -65.

AC Characteristics:

Added -65 and deleted -75 speed

Revised ICC specifications. Added

).

CC3

Added the -65

statement from -75

L

Write/Erase/Program Operations, Alternate CE Controlled Writes:

column with -70 column. Revised sector erase and

programming specifications.

Erase and Programming Performance:

Revised specifications in table. Clarified tab le and notes.

Table 7, Command Definitions

Revised Note 5 to cover all upper address bits that are

don’t care.

Deleted Note 6.

Added the -65 column. Replaced -75

Am29F400AT/Am29F400AB 35

Loading...

Loading...