Datasheet AM29F016B-120DWI1, AM29F016B-120DTI1, AM29F016B-120DTC1, AM29F016B-120DPI1, AM29F016B-120DPC1 Datasheet (AMD Advanced Micro Devices)

...Page 1

SUPPLEMENT

Am29F016B Known Good Die

16 Megabit (2 M x 8-Bit)

CMOS 5.0 Volt-only, Sector Erase Flash Memory—Die Revision 1

DISTINCTIVE CH AR ACTERISTICS

■ 5.0 V ± 10%, single power supply operation

— Minimizes system level power requirements

■ Manufactured on 0.35 µm process technology

■ High performance

— 120 ns access time

■ Low power consumption

— 25 mA typical active read current

— 30 mA typical program/erase current

—<1 µA typical standby current (standard access

time to active mode)

■ Flexible sector architecture

— 32 uniform sectors of 64 Kbytes each

— Any combination of sectors can be erased.

— Supports full chip erase

— Group sector protection:

A hardware method of locking sector groups to

prevent any program or erase operations within

that sector group

Temporary Sector Group Unprotect allows code

changes in previously locked sectors

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies bytes at specified addresses

■ Minimum 100,000 write/erase cyc les guaranteed

■ Compatible with JEDEC standards

— Pinout and software compatible with

single-power-supply Flash standard

— Superior inadvertent write protection

■ Data# Polling and toggle bits

— Provides a software method of detecting

program or erase cycle completion

■ Ready/Busy output (RY/BY#)

— Provides a hardware method for detecting

program or erase cycle completion

■ Erase Suspend/Resume

— Suspends a sector erase operation to read data

from, or program data to, a non-erasing sector,

then resumes the erase operation

■ Hardware reset pin (RESET#)

— Resets internal state machine to the read mode

■ Tested to datasheet specifications at

temperature

■ Quality and reliability levels equivalent to

standard packaged components

2/17/98 Publication# 21551 Rev: A Amendment/+1

Issue Date: February 1998

Page 2

SUPPLEMENT

GENERAL DESCRIPTION

The Am29F016B in Known Good Die (KGD) form is a

16 Mbit, 5.0 volt-only Flash memory . AMD defines KGD

as standard product in die form, tested for functionality

and speed. AMD KGD products have the same reliability and quality as AMD products in packaged form.

The sector erase architecture allows memory sectors

to be erased and reprogrammed without affecting the

data contents of other sectors. A sector is typically

erased and verified within one second. The device is

erased when shipped from the factory.

Am29F016B Features

The Am29F016B is a 16 Mbit, 5.0 volt-only Flash

memory organized as 2,097,152 bytes of 8 bits each.

The 2 Mbytes of data are divided into 32 sectors of 64

Kbytes each for flexible erase capability. The 8 bits of

data appear on DQ0–DQ7. The Am29F016B is manufactured using AMD’s 0.35 µm process technology.

This device is designed to be programmed in-system

with the standard system 5.0 volt V

volt V

is not required for program or erase

PP

operations. The dev ice can also be programmed in

standard EPROM programmers.

The standard device offers an access time of 120 ns,

allowing high-speed microprocessors to operate

without wait states. To eliminate bus contention, the

device has separate chip enable (CE#), w rite enable

(WE#), and output enable (OE#) controls.

The device is entirely command set compatible with the

JEDEC single -power-supply Flash standar d. Commands are written to the command register using

standard microprocessor write timings. Register

contents serve as input to an internal state machine

that controls the erase and programming circuitry.

Write cycles also internally lat ch addresses and data

needed for the programming and erase operations.

Reading data out of the device is similar to reading

from 12.0 volt Flash or EPROM devices.

The device is programmed by executing the program

command sequence. This invokes the Embedded

Program algorithm—an inter nal algorithm that a utomatically times the program pulse widths and verifies

proper cell margin. The device is erased by executing

the erase command sequence. This invokes the

Embedded Erase algorithm—an internal algorithm that

automatically preprograms the array (if it is not already

programmed) before executing the erase operation.

During erase, the device automatically times the erase

pulse widths and verifies proper cell margin.

supply. A 12. 0

CC

The hardware sector group protection feature disables

both program and erase operations in an y combination

of the eight sector groups of memory. A sector group

consists of four adjacent sectors.

The Erase Suspend feature enables the system to put

erase on hold for any period of time to read data from,

or program data to, a sector that is not being erased.

True background erase can thus be achieved.

The device requires only a single 5.0 volt po wer supply

for both read and write functions. Internally generated

and regulated voltages are provided for the program

and erase operations. A low V

detector automatically

CC

inhibits write operations during power transitions. The

host system can detect whether a program or erase

cycle is complete by using the RY/BY# pin, the DQ7

(Data# Polling) or DQ6 (toggle) status bits. After a

program or erase cycle h as been completed, the

device automatically returns to the read mode.

A hardware RESET# pin te rminates any ope ration in

progress. The internal stat e machine is reset to the

read mode. The RESET# pin may be tied to the system

reset circuitry. Therefore, if a system reset occurs

during either an Embedded Program or Embedded

Erase algorithm, the device is automatically reset to the

read mode. This enables the system’s microprocessor

to read the boot-up firmware from the Flash memory.

AMD’s Flash technology combines years of Flash

memory manufacturing experience to produce the

highest levels of quality, reliability, and cost

effectiveness. The device electrically erases all bits

within a sector simultaneously via Fowler-Nordheim

tunneling. The bytes are programmed one byte at a

time using the EPROM programming mechanism of hot

electron injection.

ELECTRICAL SPECIFICATIONS

Refer to the Am29F016B data sheet, PID 21444, for full

electrical specifications on the Am29F016B in KGD

form.

PRODUCT SELECTOR GUIDE

Family Part Number Am29F016B KGD

Speed Option (VCC = 5.0 V ± 10%) -120

Max Access Time, t

Max CE# Access, tCE (ns) 120

Max OE# Access, t

2 Am29F016B Known Good Die 2/17/98

(ns) 120

ACC

(ns) 50

OE

Page 3

DIE PHOTOGRAPH

Orientation

relative to top

left corner of

Gel-Pak

SUPPLEMENT

Orientation relative

to leading edge of

tape and reel

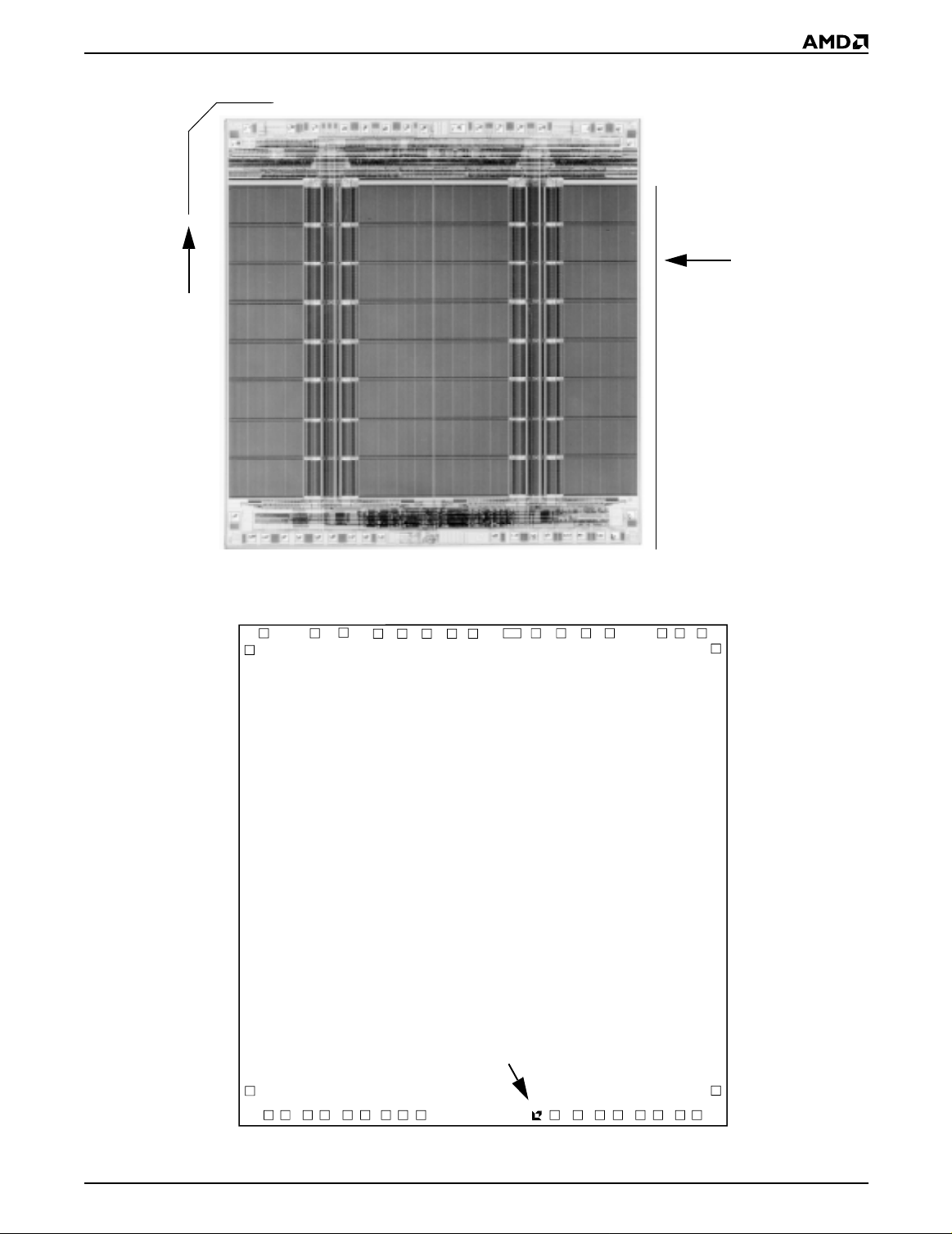

DIE PAD LOCATIONS

9

12345678

AMD logo location

31353637 323334

30

29

10

1112 13 14 15 16 17 19 20 21 22 23 24 25 26 27

18

28

2/17/98 Am29F016B Known Good Die 3

Page 4

SUPPLEMENT

PAD DESC RIPTION

Pad Signal

1V

CC

2DQ4–10.60 0.00 –0.27 0.00

3 DQ5 –24.00 0.00 –0.61 0.00

4 DQ6 –37.20 0.00 –0.94 0.00

5 DQ7 –50.50 0.00 –1.28 0.00

6 RY/BY# –68.90 0.00 –1.75 0.00

7 OE# –84.20 0.00 –2.14 0.00

8 WE# –111.80 0.00 –2.84 0.00

9 A20 –119.30 –8.50 –3.03 –0.22

10 A19 –119.30 –245.30 –3.03 –6.23

11 A18 –109.10 –258.20 –2.77 –6.56

12 A17 –100.20 –258.20 –2.55 –6.56

13 A16 –88.20 –258.20 –2.24 –6.56

14 A15 –79.00 –258.20 –2.01 –6.56

15 A14 –67.00 –258.20 –1.70 –6.56

16 A13 –57.80 –258.20 –1.47 –6.56

17 A12 –45.80 –258.20 –1.16 –6.56

18 CE# –36.60 –258.20 –0.93 –6.56

19 V

CC

20 RESET# 45.00 –258.20 1.14 –6.56

21 A11 57.20 –258.20 1.45 –6.56

22 A10 69.20 –258.20 1.76 –6.56

23 A9 78.40 –258.20 1.99 –6.56

24 A8 90.60 –258.20 2.30 –6.56

25 A7 99.80 –258.20 2.53 –6.56

26 A6 112.00 –258.20 2.84 –6.56

27 A5 121.10 –258.20 3.08 –6.56

28 A4 131.20 –245.30 3.33 –6.23

29 A3 131.20 –8.50 3.33 –0.22

30 A2 123.80 0.00 3.14 0.00

31 A1 111.90 0.00 2.84 0.00

32 A0 102.40 0.00 2.60 0.00

33 DQ0 74.40 0.00 1.89 0.00

34 DQ1 61.20 0.00 1.55 0.00

35 DQ2 47.90 0.00 1.22 0.00

36 DQ3 34.70 0.00 0.88 0.00

37 V

SS

Note: The coordinates above are relative to the center of pad 1 and can be used to operate wire bonding equipment.

Pad Center (mils) Pad Center (millimeters)

XYXY

0.00 0.00 0.00 0.00

–27.20 –258.20 –0.69 –6.56

21.70 0.00 0.55 0.00

4 Am29F016B Known Good Die 2/17/98

Page 5

SUPPLEMENT

ORDERING INFORMATION

Standard Products

AMD standard products are available in sev eral packages and operat ing ranges. The or der number (Valid Combin ation) is

formed by a combination of the following:

Am29F016B

-120

DP

C

1

DIE REVISION

This number refers to the specific AMD manufacturing

process and product technology reflected in this

document. It is entered in the revision field of AMD

standard product nomenclature.

TEMPERATURE RANGE

C = Commercial (0°C to +70°C)

I = Industrial (–40°C to +85°C)

PACKAGE TYPE AND

MINIMUM ORDER QUANTIT Y

DP = Waffle Pack

100 die per 5 tray stack

DG = Gel-Pak

294 die per 6 tray stack

DT = Surftape™ (Tape and Reel)

1600 per 7-inch reel

DW = Gel-Pak

Call AMD sales off ice for minimum order

quantity

SPEED OPTION

See Valid Combinations

®

Die Tray

®

Wafer Tray (sawn wafer on frame)

Am29F016B-120

Valid Combinations

DPC 1, DPI 1,

DGC 1, DGI 1,

DTC 1, DTI 1,

DWC 1, DWI 1

DEVICE NUMBER/DESCRIPTION

Am29F016B Known Good Die

16 Megabit (2 M x 8-Bit) CMOS Flas h Memory—Die Revi sion 1

5.0 Volt-only Read, Program, and Erase

Va lid Com bin at ions

Valid Combinations list configurations planned to be supported in volume for this device. Consult the local AMD sales

office to confirm av ailability o f specific va lid combination s and

to check on newly released combina ti ons.

2/17/98 Am29F016B Known Good Die 5

Page 6

SUPPLEMENT

PRODUCT TEST FLOW

Figure 1 provides an overview of AMD’s Known Good

Die test flow . F or more detailed inf ormation, refer to the

Am29F016B product qualification database supplement for KGD . AMD implements quality assurance procedures throughou t the product test flow. In addition,

Wafer Sort 1

an off-line quality monitoring program (QMP) further

guarantees AMD quality standards are met on Known

Good Die products. These Q A procedures also allow

AMD to produce KGD p roducts without requ iring or

implementing burn-in.

DC Parameters

Functionality

Programmability

Erasability

Bake

24 hours at 250°C

Wafer Sort 2

Wafer Sort 3

High Temperature

Packaging for Shipment

Data Retention

DC Parameters

Functionality

Programmability

Erasability

DC Parameters

Functionality

Programmability

Erasability

Speed

Incoming Inspection

Wafer Saw

Die Separation

100% Visual I nspection

Die Pack

Shipment

Figure 1. AMD KGD Product Test Flow

6 Am29F016B Known Good Die 2/17/98

Page 7

SUPPLEMENT

PHYSICAL SPECIFICATIONS

Die dimensions, X x Y . . . . . . . . . 267 mils x 280 mils

. . . . . . . . . . . . . . . . . . . . . . . . . . .6.78 mm x 7.11 mm

Die Thickness. . . . . . . . . . . . . . . . . . . . . . . . . ~20 mils

Bond Pad Size. . . . . . . . . . . . . X3.94 mils x 3.94 mils

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 µm x 100 µm

Pad Area Free of Passivation . . . . . . . . . .15.52 mils

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10,000 µm

Pads Per Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Bond Pad Metalization. . . . . . . . . . . . . . . . . . Al/Cu/Si

Die Backside . . . . . . . . . . . . . . . . . . . . . . . . No metal,

may be grounded (optional)

Passivation. . . . . . . . . . . . . . . . . . Nitride/SOG/Nitride

DC OPERATING CONDITIONS

VCC (Supply Voltage) . . . . . . . . . . . . . . .4.5 V to 5.5 V

Junction Temperature Under Bias . .T

Operating Temperature

Commercial . . . . . . . . . . . . . . . . . . . 0°C to +70°C

Industrial . . . . . . . . . . . . . . . . . . . –40°C to +85°C

(max) = 130°C

J

MANUFACTURING INFORMATION

Manufacturing . . . . . . . . . . . . . . . . . . . . . . . . . .FASL

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SDC

Manufacturing ID . . . . . . . . . . . . . . . . . . . . .98163DK

Preparation for Shipment . . . . . . . . Penang, Malaysia

Fabrication Process . . . . . . . . . . . . . . . . . . . . . .CS39

2

2

Die Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SPECIAL HANDLING INSTRUCTIONS

Processing

Do not expose KGD product s to ultraviolet light or

process them at temperatures greater than 250° C.

Failure to adhere to these handling instructions will

result in irreparable damage to the devices. For best

yield, AMD recommends assembly in a Class 10K

clean room with 30% to 60% relative humidity.

Storage

Store at a maximum temperature of 30°C in a nitrogenpurged cabinet or vacuum-sealed bag. Observe all

standard ESD handling procedures.

2/17/98 Am29F016B Known Good Die 7

Page 8

SUPPLEMENT

TERMS AND CONDITIONS OF SALE FOR AMD NON-VOLATILE MEMORY DIE

All transactions relating to AMD Products under this

agreement shall b e subject to AMD’s standard ter ms

and conditions of sale, or any revisions thereof, which

revisions AMD reserves the right to make at any time

and from time to time. In the event of conflict between

the provisions of AMD’s standard terms and conditions

of sale and this agreement, the terms of this agreement

shall be controlling.

AMD warrants ar ticles of its manufacture against

defective materials or workmanship for a period of

ninety (90) days from date of shipment. This warranty

does not extend beyond AMD’ s customer , and does not

extend to die which has been af fixed onto a board or

substrate of any kind. The liabi lity of AMD under this

warranty is limited, at AMD’s option, solely to repair or

to replacement with equivalent articles, or to make an

appropriate credit adjustment not to exceed the original

sales price, for articles returned to AMD, provided that:

(a) The Buyer promptly notifies AMD in writing of each

and ever y defect or nonconformity in any ar ticle for

which Buyer wishes to make a warranty claim against

AMD; (b) Buyer obtains authorization from AMD to

return the ar ticle; (c) the article is returned to AMD,

transportation charges paid by AMD , F.O .B . A MD’ s f actory; and (d) AMD’s examination of such article discloses to its satisfaction that such alleged de fect or

nonconformity actually exists and was not caused by

negligence, misuse, improper installation, accident or

unauthorized repair or alteration by an entity other than

AMD. The aforementioned pro visions do not e xtend the

original warranty period of any article which has either

been repaired or replaced by AMD.

THIS WARRANTY IS EXPRESSED IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING THE IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR P URPOSE, THE IMPLIED

WARRANTY OF MERCHANTABILITY AND OF ALL

OTHER OBLIGATIONS OR LIABILITIES ON AMD’S

PART, AND IT NEITH ER ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR AMD

ANY OTHER LIABILITIES. THE FOREGOING CON STITUTES THE BUYERS SOLE AND EXCLUSIVE

REMEDY FOR THE FURNISHING OF DEFECTIVE

OR NON CONFORMING ARTICLES AND AMD

SHALL NOT IN ANY EVENT BE LIABLE FOR

DAMAGES BY REASON OF FAILURE OF ANY

PRODUCT TO FUNCTION PROPERLY OR FOR ANY

SPECIAL, INDIRECT, CONSEQUENTIAL, INCIDENTAL OR EXEMPLARY DAMAGES, INCLUDING

BUT NOT LIMITED T O , LOSS OF PROFITS, LOSS OF

USE OR COST OF LABOR BY REASON OF THE

FACT THAT SUCH ARTICLES SHALL HAVE BEEN

DEFECTIVE OR NON CONFORMING.

Buyer agrees that it will make no warranty representations to its customers which exceed those given by

AMD to Buyer unless and until Buyer shall agree to

indemnify AMD in writing for any claims which exceed

AMD’s warranty. Buyer assumes all responsibility for

successful die prep, die attach and wire bonding processes. Due to the unprotected nature of the AMD Products which are the subject hereof, AMD assumes no

responsibility for environmental effects on die.

AMD products are not designed or authorized for use

as components in life suppor t appliances, devices or

systems where malfunction of a p roduct can reasonably be expected to result in a personal injury. Buyer’s

use of AMD products for use in lif e support applications

is at Buyer’s own risk and Buyer agrees to fully indemnify AMD for any damages resulting in such use or sale.

REVISION SUMMARY FOR AM29F016B KGD

Valid Combinations

Deleted designators in base part number to top and

bottom boot.

Trademarks

Copyright © 1998 Advanced Micro Devices, Inc. All rights reserved.

AMD, the AMD logo, and combinations thereof are registered trademark s of Advanced Micro Devices, Inc.

Product names used in this publication are for identification purposes only and may be trademarks of their respective companies.

8 Am29F016B Known Good Die 2/17/98

Physical Specifications

Clarified X and Y die dimensions

Manufacturing Information

Deleted references to top and bottom boot

Loading...

Loading...