Datasheet ALD1721SA, ALD1721PA, ALD1721ESA, ALD1721EPA, ALD1721EDA Datasheet (Advanced Linear Devices Inc)

...Page 1

ADVANCED

LINEAR

DEVICES, INC.

ALD1721E/ALD1721

EPAD™ MICROPOWER OPERATIONAL AMPLIFIER

KEY FEATURES

• EPAD ( Electrically Programmable Analog Device)

• User programmable V

trimmer

OS

• Computer-assisted trimming

• Rail-to-rail input/output

• Compatible with standard EPAD Programmer

• High precision through in-system circuit precision trimming

• Reduces or eliminates V

, PSRR, CMRR and TCVOS errors

OS

• System level “calibration” capability

• Application Specific Programming mode

• In-System Programming mode

• Electrically programmable to compensate for

external component tolerances

• Achieves 0.01pA input bias current and 35

µV

input offset voltage simultaneously

• Compatible with industry standard pinout

GENERAL DESCRIPTION

The ALD1721E/ALD1721 is a monolithic rail-to-rail precision CMOS

operational amplifier with integrated user programmable EPAD (Electrically Programmable Analog Device) based offset voltage adjustment. The

ALD1721E/ALD1721 operational amplifier is a direct replacement of the

ALD1701 operational amplifier, with the added feature of user-programmable offset voltage trimming resulting in significantly enhanced total

system performance and user flexibility. EPAD technology is an exclusive

ALD design which has been refined for analog applications where precision voltage trimming is necessary to achieve a desired performance. It

utilizes CMOS FETs as in-circuit elements for trimming of offset voltage

bias characteristics with the aid of a personal computer under software

control. Once programmed, the set parameters are stored indefinitely

within the device even after power-down. EPAD offers the circuit designer

a convenient and cost-effective trimming solution for achieving the very

highest amplifier/system performance.

The ALD1721E/ALD1721 operational amplifier features rail-to-rail input

and output voltage ranges, tolerance to over-voltage input spikes of

300mV beyond supply rails, capacitive loading up to 50pF, extremely low

input currents of 0.01pA typical, high open loop voltage gain, useful

bandwidth of 700KHz, slew rate of 0.7 V/µs, and low typical supply current

of 120 uA.

BENEFITS

• Eliminates manual and elaborate

system trimming procedures

• Remote controlled automated trimming

• In-System Programming capability

• No external components

• No internal chopper clocking noise

• No chopper dynamic power dissipation

• Simple and cost effective

• Small package size

• Extremely small total functional

volume size

• Low system implementation cost

• Micropower and Low Voltage

APPLICATIONS

• Sensor interface circuits

• Transducer biasing circuits

• Capacitive and charge integration circuits

• Biochemical probe interface

• Signal conditioning

• Portable instruments

• High source impedance electrode

amplifiers

• Precision Sample and Hold amplifiers

• Precision current to voltage converter

• Error correction circuits

• Sensor compensation circuits

• Precision gain amplifiers

• Periodic In-system calibration

• System output level shifter

PIN CONFIGURATION

VE2

VE1

1

8

ORDERING INFORMATION

-IN

+IN

V

2

3

-

4

Operating Temperature Range

-55°C to +125°C0°C to +70°C0°C to +70°C

8-Pin 8-Pin 8-Pin

CERDIP Small Outline Plastic Dip

Package Package (SOIC) Package

ALD1721E DA ALD1721E SA ALD1721E PA

ALD1721 DA ALD1721 SA ALD1721 PA

* Contact factory for industrial temperature range

© 1998 Advanced Linear Devices, Inc. 415 T asman Drive, Sunnyvale, California 94089 -1706 Tel: (408) 747-1155 Fax: (408) 747-1286 http://www .aldinc.com

2

TOP VIEW

DA, PA, SA PACKAGE

+

7

V

OUT

6

5

N/C

Page 2

FUNCTIONAL DESCRIPTION

The ALD1721E/ALD1721 uses EPADs as in-circuit elements

for trimming of offset voltage bias characteristics. Each

ALD1721E/ALD1721 has a pair of EPAD-based circuits

connected such that one circuit is used to adjust V

direction and the other circuit is used to adjust V

OS

OS

in one

in the

other direction.

Functional Description of ALD1721E

While each of the EPAD devices is a monotonically adjustable programmable device, the V

of the ALD1721E can be

OS

adjusted many times in both directions. Once programmed,

the set V

levels are stored permanently, even when the

OS

device power is removed.

The ALD1721E provides the user with an operational ampli-

fier that can be trimmed with user application-specific programming or in-system programming conditions. User application-specific circuit programming refers to the situation

where the Total Input Offset Voltage of the ALD1721E can be

trimmed with the actual intended operating conditions.

The ALD1721E is pre-programmed at the factory under

standard operating conditions for minimum equivalent input

offset voltage. It also has a guaranteed offset voltage

program range, which is ideal for applications that require

electrical offset voltage programming.

For example, an application circuit may have +6V and -2.5V

power supplies, and the operational amplifier input is biased

at +0.7V, and the average operating temperature is at 55

°C.

The circuit can be wired up to these conditions within an

environmental chamber, and the ALD1721E can be inserted

into a test socket connected to this circuit while it is being

electrically trimmed. Any error in V

conditions can be automatically zeroed out. The Total V

due to these bias

OS

OS

error is now limited only by the adjustable range and the

stability of V

amplifier. Therefore, this Total V

, and the input noise voltage of the operational

OS

error now includes V

OS

OS

as VOS is traditionally specified; plus the VOS error contributions from PSRR, CMRR, TCV

total V

error term (V

OS

OST

, and noise. Typically this

OS

) is approximately ±35µV for the

ALD1721E.

The V

contribution due to PSRR, CMRR, TCVOS and

OS

external components can be large for operational amplifiers

without trimming. Therefore the ALD1721E with EPAD trimming is able to provide much improved system performance

by reducing these other sources of error to provide significantly reduced V

OST.

In-System Programming refers to the condition where the

EPAD adjustment is made after the ALD1721E has been

inserted into a circuit board. In this case, the circuit design

must provide for the ALD1721E to operate in normal mode

and in programming mode. One of the benefits of in-system

programming is that not only is the ALD1721E offset voltage

from operating bias conditions accounted for, any residual

errors introduced by other circuit components, such as resistor or sensor induced voltage errors, can also be corrected.

In this way, the “in-system” circuit output can be adjusted to

a desired level eliminating other trimming components.

Functional Description of ALD1721

The ALD1721 is pre-programmed at the factory under standard operating conditions for minimum equivalent input offset

voltage. The ALD1721 offers similar programmable features

as the ALD1721E, but with more limited offset voltage program range. It is intended for standard operational amplifier

applications where little or no electrical programming by the

user is necessary.

USER PROGRAMMABLE Vos FEATURE

Each ALD1721E/ALD1721 has two pins named VE1 and

VE2 which are internally connected to an internal offset bias

circuit. VE1/VE2 have initial typical values of 1.2 /1.7 Volt.

The voltage on these pins can be programmed using the ALD

E100 EPAD Programmer and the appropriate Adapter Module. The useful programming range of VE1 and VE2 is 1.2

Volt to 3.0 Volts. VE1 and VE2 pins are programming pins,

used during programming mode. The Programming pin is

used during electrical programming to inject charge into the

internal EPADs. Increases of VE1 decrease the offset voltage while increases of VE2 increase the offset voltage of the

operational amplifier. The injected charge is permanently

stored and determines the offset voltage of the operational

amplifier. After programming, VE1 and VE2 terminals must

be left open to settle on a voltage determined by internal bias

currents.

During programming, the voltages on VE1 or VE2 are increased incrementally to set the offset voltage of the operational amplifier to the desired V

. Note that desired VOS can

OS

be any value within the offset voltage programmable ranges,

and can be either zero, a positive value or a negative value.

This V

value can also be reprogrammed to a different

OS

value at a later time, provided that the useful VE1 or VE2

programming voltage range has not been exceeded. VE1 or

VE2 pins can also serve as capacitively coupled input pins.

Internally, VE1 and VE2 are programmed and connected

differentially. Temperature drift effects between the two

internal offset bias circuits cancel each other and introduce

less net temperature drift coefficient change than offset

voltage trimming techniques such as offset adjustment with

an external trimmer potentiometer.

While programming, V+, VE1 and VE2 pins may be alternately pulsed with 12V (approximately) pulses generated by

the EPAD Programmer. In-system programming requires the

ALD1721E/ALD1721 application circuit to accommodate

these programming pulses. This can be accomplished by

adding resistors at certain appropriate circuit nodes. For

more information, see Application Note AN1700.

2 Advanced Linear Devices ALD1721E/ALD1721

Page 3

ABSOLUTE MAXIMUM RATINGS

Supply voltage, V

+

Differential input voltage range -0.3V to V

Power dissipation 600 mW

Operating temperature range PA,SA package 0°C to +70°C

DA package -55°C to +125°C

Storage temperature range -65°C to +150°C

Lead temperature, 10 seconds +260°C

13.2V

+

+0.3V

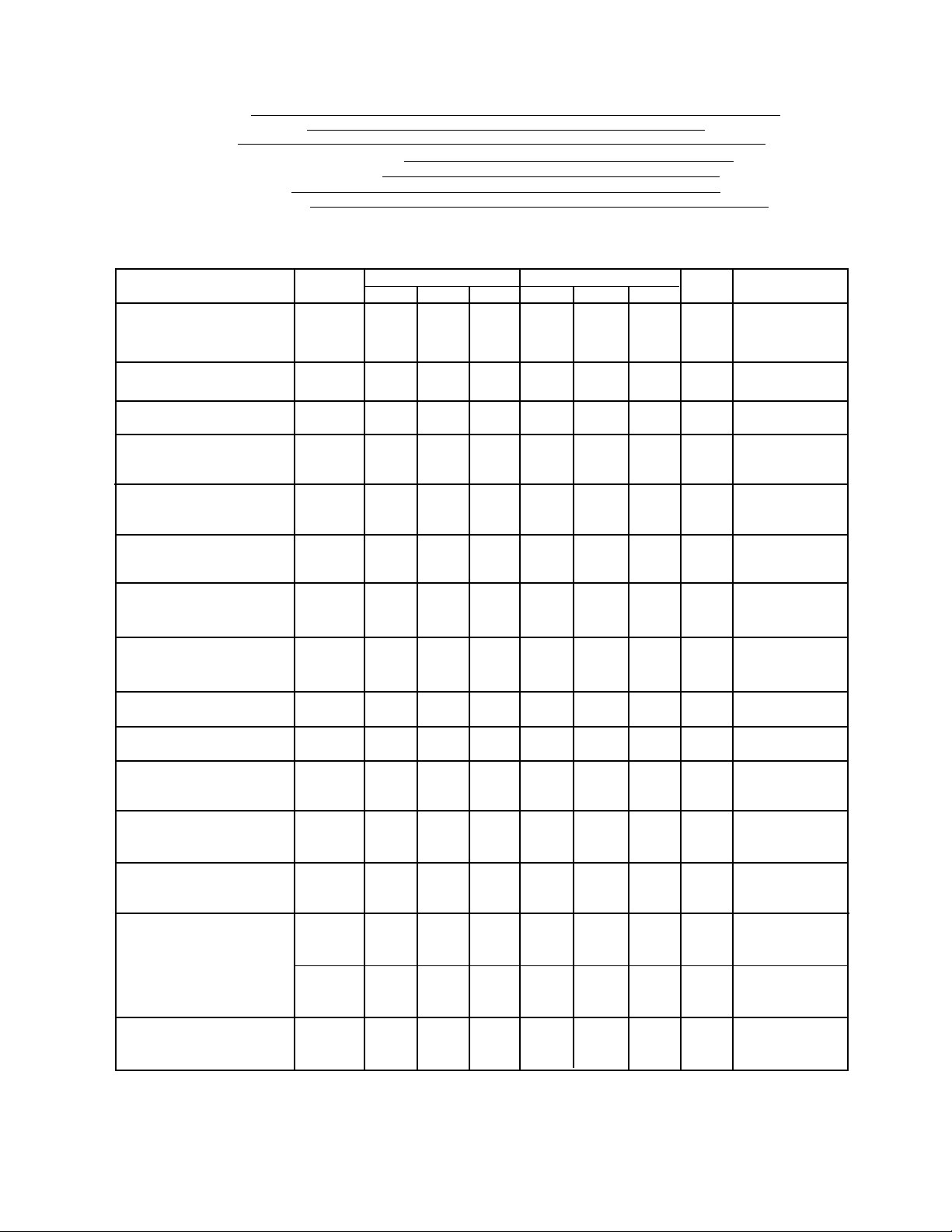

OPERATING ELECTRICAL CHARACTERISTICS

T

A

= 25

oC

V

= ±2.5V unless otherwise specified

S

1721E 1721

Parameter Symbol Min Typ Max Min Typ Max Unit Test Conditions

Supply Voltage V

Initial Input Offset Voltage

Offset Voltage Program Range

1

2

Programmed Input Offset V

Voltage Error

Total Input Offset Voltage

Input Offset Current

Input Bias Current

Input Voltage Range

3

4

5

5

6

V

V

∆V

V

I

I

V

OS

B

S

+

OS i

OS

OS

OST

IR

±1.0 ±5.0 ±1.0 ±5.0 V

2.0 10.0 2.0 10.0 V Single Supply

35 75 50 150 µVR

≤ 100KΩ

S

±10 ±15 ±1 ±5mV

50 90 50 150 µV At user specified

target offset voltage

50 90 50 150 µV At user specified

target offset voltage

0.01 10 0.01 10 pA TA = 25°C

240 240 pA 0°C ≤ TA ≤ +70°C

0.01 10 0.01 10 pA TA = 25°C

240 240 pA 0°C ≤ TA ≤ +70°C

-0.3 5.3 -0.3 5.3 V V+ = +5V

-2.8 +2.8 -2.8 +2.8 V VS = ±2.5V

Input Resistance R

Input Offset Voltage Drift

7

IN

TCV

OS

Initial Power Supply PSRR

Rejection Ratio

8

Initial Common Mode CMRR

Rejection Ratio

Large Signal Voltage Gain A

8

V

14

10

57µV/°CRS ≤ 100KΩ

i

i

80 80 dB RS ≤ 100KΩ

83 83 dB RS ≤ 100KΩ

32 100 32 100 V/mV RL =100KΩ

10

14

Ω

20 20 V/mV 0°C ≤ TA ≤ +70°C

VO low 0.001 0.01 0.001 0.01 V RL =1MΩ V+ = 5V

Output Voltage Range VO high 4.99 4.999 4.99 4.999 V 0°C ≤ TA ≤ +70°C

VO low -2.48 -2.40 -2.48 -2.40 V RL =100KΩ

VO high 2.40 2.48 2.40 2.48 V 0°C ≤ TA ≤ +70°C

Output Short Circuit Current I

\* NOTES 1 through 9, see section titled "Definitions and Design Notes".

SC

11mA

ALD1721E/ALD1721 Advanced Linear Devices 3

Page 4

OPERATING ELECTRICAL CHARACTERISTICS (cont'd)

oC

= 25

T

A

Parameter Symbol Min Typ Max Min Typ Max Unit Test Conditions

V

= ±2.5V unless otherwise specified

S

1721E 1721

Supply Current I

Power Dissipation P

Input Capacitance C

Maximum Load Capacitance C

Equivalent Input Noise Voltage e

Equivalent Input Current Noise i

Bandwidth B

Slew Rate S

Rise time t

Overshoot Factor 20 20 % RL = 100KΩ,

Settling Time t

S

D

IN

L

n

n

W

R

r

s

400 700 400 700 KHz

0.3 0.7 0.3 0.7 V/µsA

120 200 120 200 µAV

0.6 1.00 0.6 1.00 mW VS = ±2.5V

11

50 50 pF

55 55 nV/√Hz f = 1KHz

0.6 0.6 fA/√Hz f =10Hz

0.2 0.2 µsR

10 10 µs 0.1%

pF

= 0V

IN

No Load

= +1

V

RL = 10KΩ

= 10KΩ

L

CL = 50pF

AV = 1,RL=100KΩ

CL = 50pF

A

= 25

oC

VS = ±2.5V unless otherwise specified

T

1721E 1721

Parameter Symbol Min Typ Max Min Typ Max Unit Test Conditions

Average Long Term Input Offset ∆ V

Voltage Stability

Initial VE Voltage VE1 i, VE2

Programmable VE Range ∆VE1, ∆VE2 1.5 2.5 1.0 V

Programmed VE Voltage Error e(VE1-VE2) 0.1 0.1 %

VE Pin Leakage Current i

9

OS

∆ time 1000 hrs

i

eb

0.02 0.02 µV/

1.2 1.7 V

-5 -5 µA

4 Advanced Linear Devices ALD1721E/ALD1721

Page 5

V

= ±2.5V -55°C ≤ T

S

≤ +125°C unless otherwise specified

A

1721E 1721

Parameter Symbol Min Typ Max Min Typ Max Unit Test Conditions

Initial Input offset Voltage V

Input Offset Current I

Input Bias Current I

OS i

OS

B

Initial Power Supply PSRR

Rejection Ratio

8

Initial Common Mode CMRR

Rejection Ratio

Large Signal Voltage Gain A

8

V

i

i

15 50 15 50 V/mV RL = 100KΩ

0.5 0.8 mV RS ≤ 100KΩ

2.0 2.0 nA

2.0 2.0 nA

75 75 dB RS ≤ 100KΩ

83 83 dB RS ≤ 100KΩ

Output Voltage Range VO low -2.47 -2.40 -2.47 -2.40 V

VO high 2.35 2.45 2.35 2.45 V RL = 100KΩ

= 25

A

oC

VS = ±5.0V unless otherwise specified

T

1721E 1721

Parameter Symbol Min Typ Max Min Typ Max Unit Test Conditions

Initial Power Supply PSRR

Rejection Ratio

8

i

83 83 dB RS ≤ 100KΩ

Initial Common Mode CMRR

Rejection Ratio

Large Signal Voltage Gain A

8

V

i

83 83 dB RS ≤ 100KΩ

250 250 V/mV RL = 100KΩ

Output Voltage Range VO low -4.98 -4.90 -4.98 -4.90 V RL = 100KΩ

VO high 4.90 4.98 4.90 4.98

Bandwidth B

Slew Rate S

W

R

1.0 1.0 MHz

1.0 1.0 V/µsAV = +1, CL = 50pF

ALD1721E/ALD1721 Advanced Linear Devices 5

Page 6

TYPICAL PERFORMANCE CHARACTERISTICS

OUTPUT VOLTAGE SWING AS A FUNCTION

OF SUPPLY VOLTAGE

±6

±25°C ≤ TA ≤ +125°C

±5

R

= 100KΩ

L

±4

±3

±2

OUTPUT VOLTAGE SWING (V)

±1

0

±1 ±2 ±3 ±4 ±7±6±5

SUPPLY VOLTAGE (V)

INPUT BIAS CURRENT AS A FUNCTION

OF AMBIENT TEMPERATURE

1000

= ±2.5V

100

10

V

S

OPEN LOOP VOLTAGE GAIN AS A FUNCTION

OF SUPPLY VOLTAGE AND TEMPERATURE

1000

100

10

GAIN (V/mV)

OPEN LOOP VOLTAGE

1

0 ±2 ±4 ±6 ±8

SUPPLY VOLTAGE (V)

±55°C ≤ T

RL = 100KΩ

SUPPLY CURRENT AS A FUNCTION

OF SUPPLY VOLTAGE

500

400

300

INPUTS GROUNDED

OUTPUT UNLOADED

TA = -55°C

-25°C

≤ +125°C

A

+25°C

1.0

0.1

INPUT BIAS CURRENT (pA)

0.01

AMBIENT TEMPERATURE (°C)

ADJUSTMENT IN INPUT OFFSET VOLTAGE

AS A FUNCTION OF CHANGE IN VE1 AND VE2

10

8

6

4

(mV)

OS

2

0

-2

-4

VOLTAGE ∆V

-6

-8

CHANGE IN INPUT OFFSET

-10

0.0 0.25 0.5 0.75 1.0 1.25 1.50

CHANGE IN VE1 AND VE2 (V)

VE2

100-25 0 75 1255025-50

VE1

200

100

SUPPLY CURRENT (µA)

0

0 ±1 ±2 ±3 ±4 ±5 ±6

OPEN LOOP VOLTAGE GAIN

AS A FUNCTION OF FREQUENCY

120

100

80

60

40

GAIN (dB)

20

OPEN LOOP VOLTAGE

0

-20

1 10 100 1K 10K 1M 10M100K

SUPPLY VOLTAGE (V)

FREQUENCY (Hz)

+70°C

+125°C

VS = ±2.5V

T

= 25°C

A

6 Advanced Linear Devices ALD1721E/ALD1721

PHASE SHIFT IN DEGREES

0

45

90

135

180

Page 7

TYPICAL PERFORMANCE CHARACTERISTICS

COMMON MODE INPUT VOLTAGE RANGE

AS A FUNCTION OF SUPPLY VOLTAGE

±7

±6

±5

TA = 25°C

±4

±3

±2

VOLTAGE RANGE (V)

COMMON MODE INPUT

±1

0

0 ±1 ±2 ±3 ±4 ±5 ±6 ±7

SUPPLY VOLTAGE (V)

OPEN LOOP VOLTAGE GAIN AS A

FUNCTION OF LOAD RESISTANCE

1000

100

LARGE - SIGNAL TRANSIENT

RESPONSE

2V/div

500mV/div 5µs/div

VS = ±1.0V

TA = 25°C

RL = 100KΩ

CL = 50pF

SMALL - SIGNAL TRANSIENT

RESPONSE

100mV/div

= ±2.5V

V

S

T

= 25°C

A

R

= 100KΩ

L

C

= 50pF

L

10

GAIN (V/mV)

OPEN LOOP VOLTAGE

1

10K

100K 1M

LOAD RESISTANCE (Ω)

LARGE - SIGNAL TRANSIENT

RESPONSE

5V/div

2V/div 5µs/div

VS = ±2.5V

= 25°C

T

A

VS = ±2.5V

T

= 25°C

A

R

= 100KΩ

L

C

= 50pF

L

10M

100

EXAMPLE B:

V

AFTER EPAD

OST

80

PROGRAMMING

TARGET = -750µV

V

OST

60

40

PERCENTAGE OF UNITS (%)

20

0

-2000

-2500

20mV/div 2µs/div

DISTRIBUTION OF TOTAL INPUT OFFSET VOLTAGE

BEFORE AND AFTER EPAD PROGRAMMING

EXAMPLE A:

V

AFTER EPAD

OST

PROGRAMMING

TARGET = 0.0µV

V

OST

V

BEFORE EPAD

OST

PROGRAMMING

-1500

-500

-1000

TOTAL INPUT OFFSET VOLTAGE (µV)

500

0

1000 1500 2000 2500

ALD1721E/ALD1721 Advanced Linear Devices 7

Page 8

TWO EXAMPLES OF EQUIVALENT INPUT OFFSET VOLTAGE DUE TO

CHANGE IN SUPPLY VOLTAGE vs. SUPPLY VOLTAGE

500

PSRR = 80 dB

400

300

200

100

CHANGE IN SUPPLY VOLTAGE (µV)

EQUIVALENT INPUT OFFSET VOLTAGE DUE TO

0

0

1

EXAMPLE A:

V

EPAD PROGRAMMED

OS

AT V

2

SUPPLY

3

= +5V

4

SUPPLY VOLTAGE (V)

6

5

EXAMPLE B:

EPAD

V

OS

PROGRAMMED

AT V

789 10

SUPPLY

= +8V

THREE EXAMPLES OF EQUIVALENT INPUT OFFSET VOLTAGE DUE TO

CHANGE IN COMMON MODE VOLTAGE vs. COMMON MODE VOLTAGE

500

400

V

= ±5V

SUPPLY

CMRR = 80dB

300

EXAMPLE B:

EPAD

V

OS

PROGRAMMED

200

100

CHANGE IN COMMON MODE VOLTAGE (µV)

0

EQUIVALENT INPUT OFFSET VOLTAGE DUE TO

-5

AT V

= -4.3V

IN

-4

-3

EXAMPLE A:

EPAD PROGRAMMED

V

OS

= 0V

AT V

IN

-1

-2

COMMON MODE VOLTAGE (V)

0

EXAMPLE C:

EPAD PROGRAMMED

V

OS

= +5V

AT V

IN

1

2345

EXAMPLE OF MINIMIZING EQUIVALENT INPUT OFFSET VOLTAGE

FOR A COMMON MODE VOLTAGE RANGE OF 0.5V

50

40

30

20

CMRR = 80dB

10

COMMON MODE VOLTAGE RANGE OF 0.5V

VOS EPAD

PROGRAMMED

AT COMMON MODE

VOLTAGE OF 0.25V

CHANGE IN COMMON MODE VOLTAGE (µV)

0

EQUIVALENT INPUT OFFSET VOLTAGE DUE TO

-0.5

-0.4

-0.3

-0.2 -0.1

COMMON MODE VOLTAGE (V)

0.0

0.1

0.2 0.3 0.4 0.5

8 Advanced Linear Devices ALD1721E/ALD1721

Page 9

APPLICATION SPECIFIC / IN-SYSTEM PROGRAMMING

Examples of applications where accumulated total input offset voltage from various

contributing sources is minimized under different sets of user-specified operating conditions

TOTAL INPUT OFFSET VOLTAGE (µV)

2500

2000

1500

1000

500

-500

-1000

-1500

-2000

-2500

2500

2000

1500

1000

500

BUDGET AFTER

V

OS

EPAD PROGRAMMING

0

VOS BUDGET BEFORE

EPAD PROGRAMMING

EXAMPLE A

VOS BUDGET BEFORE

EPAD PROGRAMMING

2500

2000

1500

1000

500

TOTAL INPUT OFFSET VOLTAGE (µV)

-500

-1000

-1500

-2000

-2500

2500

2000

1500

1000

500

+

X

VOS BUDGET AFTER

EPAD PROGRAMMING

0

VOS BUDGET BEFORE

EPAD PROGRAMMING

EXAMPLE B

VOS BUDGET AFTER

EPAD PROGRAMMING

+

X

TOTAL INPUT OFFSET VOLTAGE (µV)

-500

-1000

-1500

-2000

-2500

0

VOS BUDGET AFTER

EPAD PROGRAMMING

EXAMPLE C

+

X

Device input V

PSRR equivalent V

+

CMRR equivalent V

TA equivalent V

Noise equivalent V

X

External Error equivalent V

OS

OS

OS

OS

OS

OS

0

-500

-1000

-1500

TOTAL INPUT OFFSET VOLTAGE (µV)

-2000

-2500

Total Input VOS

after EPAD

Programming

+

X

VOS BUDGET BEFORE

EPAD PROGRAMMING

EXAMPLE D

ALD1721E/ALD1721 Advanced Linear Devices 9

Page 10

DEFINITIONS AND DESIGN NOTES:

1. Initial Input Offset Voltage is the initial offset voltage of the

ALD1721E/ALD1721 operational amplifier when shipped from

the factory. The device has been pre-programmed and tested

for programmability.

2. Offset Voltage Program Range is the range of adjustment of

user specified target offset voltage. This is typically an adjustment in either the positive or the negative direction of the input

offset voltage from an initial input offset voltage. The input

offset programming pins, VE1 or VE2, change the input offset

voltage in the negative or positive direction, respectively. User

specified target offset voltage can be any offset voltage within

this programming range.

3. Programmed Input Offset Voltage Error is the final offset

voltage error after programming when the Input Offset Voltage

is at target Offset Voltage. This parameter is sample tested.

4. Total Input Offset Voltage is the same as Programmed Input

Offset Voltage, corrected for system offset voltage error. Usually this is an all inclusive system offset voltage, which also

includes offset voltage contributions from input offset voltage,

PSRR, CMRR, TCV

and noise. It can also include errors

OS

introduced by external components, at a system level. Programmed Input Offset Voltage and Total Input Offset Voltage is

not necessarily zero offset voltage, but an offset voltage set to

compensate for other system errors as well. This parameter is

sample tested.

5. The Input Offset and Bias Currents are essentially input

protection diode reverse bias leakage currents. This low input

bias current assures that the analog signal from the source will

not be distorted by it. For applications where source impedance

is very high, it may be necessary to limit noise and hum pickup

through proper shielding.

6. Input Voltage Range is determined by two parallel complementary input stages that are summed internally, each stage

having a separate input offset voltage. While Total Input Offset

Voltage can be trimmed to a desired target value, it is essential

to note that this trimming occurs at only one user selected input

bias voltage. Depending on the selected input bias voltage

relative to the power supply voltages, offset voltage trimming

may affect one or both input stages. For the ALD1721E/

ALD1721, the switching point between the two stages occur at

approximately 1.5V below positive supply voltage.

7. Input Offset Voltage Drift is the average change in Total Input

Offset Voltage as a function of ambient temperature. This

parameter is sample tested.

8. Initial PSRR and initial CMRR specifications are provided as

reference information. After programming, error contribution to

the offset voltage from PSRR and CMRR is set to zero under the

specific power supply and common mode conditions, and

becomes part of the Programmed Input Offset Voltage Error.

9. Average Long Term Input Offset Voltage Stability is based on

input offset voltage shift through operating life test at 125°C

extrapolated to T

A = 25 °C, assuming activation energy of

1.0eV. This parameter is sample tested.

ADDITIONAL DESIGN NOTES:

A. The ALD1721E/ALD1721 is internally compensated for unity

gain stability using a novel scheme which produces a single pole

role off in the gain characteristics while providing more than 70

degrees of phase margin at unity gain frequency. A unity gain

buffer using the ALD1721E/ALD1721 will typically drive 50pF of

external load capacitance.

B. The ALD1721E/ALD1721 has complementary p-channel

and n-channel input differential stages connected in parallel to

accomplish rail-to-rail input common mode voltage range. The

switching point between the two differential stages is 1.5V below

positive supply voltage. For applications such as inverting

amplifier or non-inverting amplifier with a gain larger than 2.5

(5V operation), the common mode voltage does not make

excursions below this switching point. However, this switching

does take place if the operational amplifier is connected as a railto-rail unity gain buffer and the design must allow for input offset

voltage variations.

C. The output stage consists of class AB complementary output

drivers. The oscillation resistant feature, combined with the railto-rail input and output feature, makes the ALD1721E/ALD1721

an effective analog signal buffer for high source impedance

sensors, transducers, and other circuit networks.

D. The ALD1721E/ALD1721 has static discharge protection.

Care must be exercised when handling the device to avoid

strong static fields that may degrade a diode junction, causing

increased input leakage currents. The user is advised to power

up the circuit before, or simultaneously with, any input voltages

applied and to limit input voltages not to exceed 0.3V of the

power supply voltage levels.

E. VE1 and VE2 are high impedance terminals, as the internal

bias currents are set very low to a few microamperes to

conserve power. For some applications, these terminals may

need to be shielded from external coupling sources. For example, digital signals running nearby may cause unwanted

offset voltage fluctuations. Care during the printed circuit board

layout to place ground traces around these pins and to isolate

them from digital lines will generally eliminate such coupling

effects. In addition, optional decoupling capacitors of 1000pF or

greater value can be added to VE1 and VE2 terminals.

F. The ALD1721E/ALD1721 is designed for use in low voltage,

micropower circuits. The maximum operating voltage during

normal operation should remain below 10 Volts at all times. Care

should be taken to insure that the application in which the device

is used do not experience any positive or negative transient

voltages that will cause any of the terminal voltages to exceed

this limit.

G. All inputs or unused pins except VE1 and VE2 pins should be

connected to a supply voltage such as Ground so that they do

not become floating pins, since input impedance at these pins

is very high. If any of these pins are left undefined, they may

cause unwanted oscillation or intermittent excessive current

drain. As these devices are built with CMOS technology, normal

operating and storage temperature limits, ESD and latchup

handling precautions pertaining to CMOS device handling

should be observed.

10 Advanced Linear Devices ALD1721E/ALD1721

Loading...

Loading...