Page 1

Ω

AIC3643

Built-in OVP White LED Step-Up Converter

FEATURES

Built-In Open Circuit Protection

Over Voltage Protection

Efficiency Up to 83% at VIN=4.2V, 3LEDs,

I

=20mA

LED

1.2MHz Fixed Switching Frequency

Drives Up to 5LEDs in series

2.5V to 5.5V Input Voltage

Low Supply Current: 150μA

Matches LED Current

Requires Tiny Inductor and Capacitors

TSOT-23-6, and SOT-23-6 Packages

DESCRIPTION

AIC3643 is a current-mode pulse-widthmodulation (PWM), step-up DC/DC converter

designed to drive white LEDs with a constant

current to provide backlight in hand-held devices.

Series connection of LEDs provides identical

LED currents resulting in uniform brightness.

This configuration eliminates the need of ballast

resistors. The built-in open load protection

prevents the damage resulting from an open

circuit condition. Also low 100mV feedback

voltage minimizes power loss in the current

setting resistor for better efficiency.

APPLICATIONS

Cellular Phones

PDAs

DSCs

Handheld Devices

White LED Display Backlighting

AIC3643 is a step-up PWM converter, which

includes an internal N-channel MOSFET switch

for high efficiency. The high switching frequency,

1.2MHz, allows the use of tiny external

components.

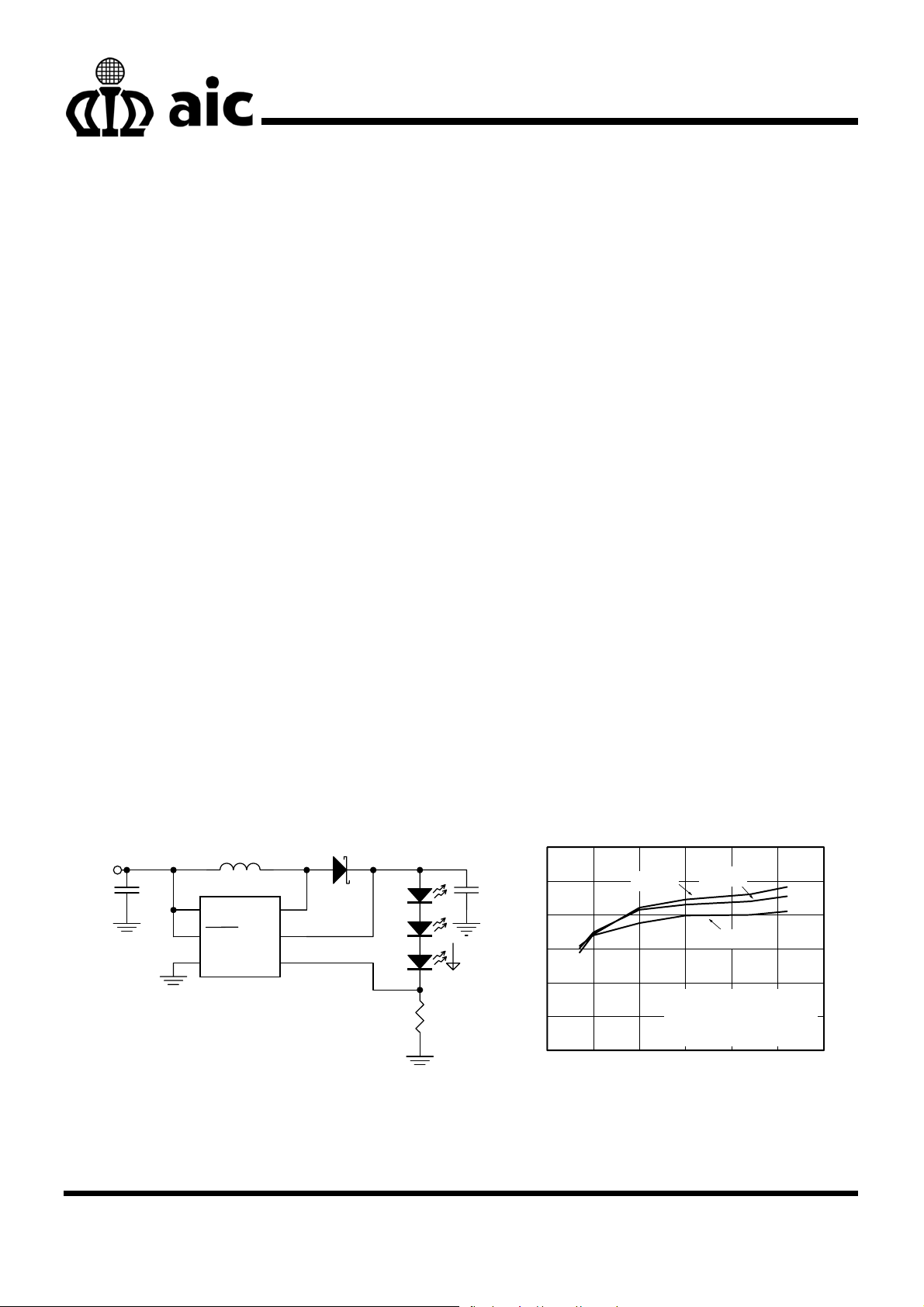

TYPICAL APPLICATION CIRCUIT

3.0~4.2V

C1

1μF

L1: GTSD31-6R8M, GOTREND

D1: SS0540, PAN JIT

C1: JMK107BJ105KA, TAIYO YUDEN

C2: GRM21BR61C335K, MURATA

L

6.8μH

VIN

SHDN

GND

AIC3643

SW

OVP

FB

Fig. 1 Li-Ion Powered Driver for Three White LEDs

D1

RFB

5

C2

3.3μF

20mA

AIC3643 is available in a space-saving TSOT23-6, and SOT-23-6 packages.

90

85

80

75

70

Efficiency (%)

65

60

0 5 10 15 20 25 30

VIN=4.2V

LED Current (mA)

VIN=3.6V

VIN=3V

3 LEDs, 6.8μH

L1: GTSD31-6R8M, GOTREND

D1: SS0540, PAN JIT

Test Circuit refer to Fig.1

Analog Integrations Corporation Si-Soft Research Center DS-3643G-01 20090820

3A1, No.1, Li-Hsin Rd. I, Science Park, Hsinchu 300, Taiwan, R.O.C.

TEL: 886-3-5772500 FAX: 886-3-5772510 www.analog.com.tw

1

Page 2

A

AIC3643

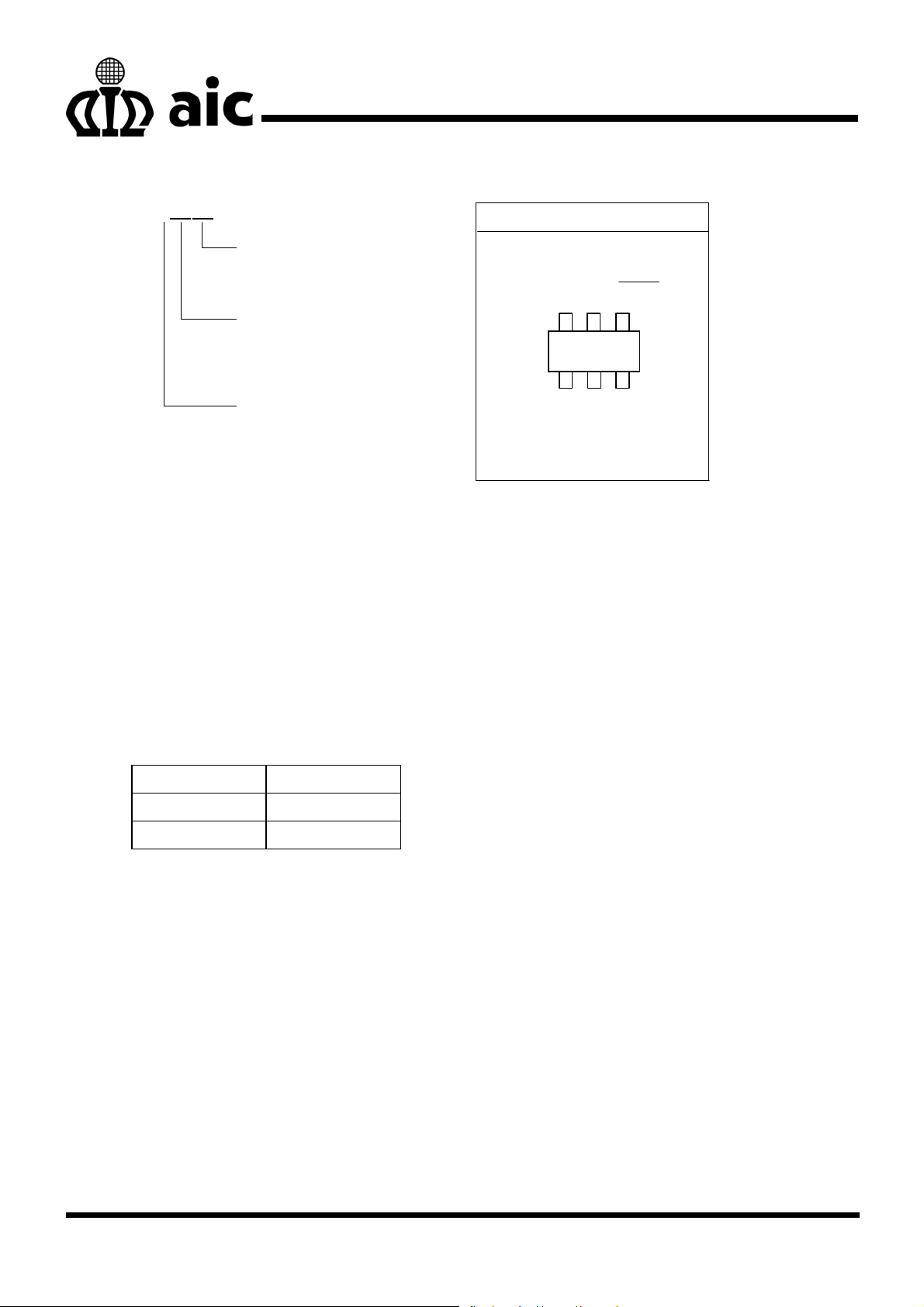

ORDERING INFORMATION

IC3643XXX XX

PIN CONFIGURATION

PACKING TYPE

TR: TAPE & REEL

BG: BAG

PACKAGE TYPE

G6: SOT-23-6

K6: TSOT-23-6

G: Green Package

Example: AIC3643GG6TR

in SOT-23-6 Green Package &

Tape & Reel Packing Type

SOT-23-6

TSOT-23-6

FRONT VIEW

OVP

5

2

GNDSW

SHDN

4

3

FB

VIN

6

3643G/3643K

1

Note: Pin1 is determined by orienting

the package marking as shown.

Marking

Part No. Marking

AIC3643GG6 3643G

AIC3643GK6 3643K

2

Page 3

AIC3643

ABSOLUTE MAXIMUM RATINGS

Input Voltage (VIN) 6V

SW Voltage

FB Voltage

SHDN

OVP Voltage

Operating Temperature Range

Storage Temperature Range

Maximum Junction Temperature

Lead Temperature (Soldering, 10 sec)

Thermal Resistance Junction to Case SOT-23-6

TSOT-23-6

Thermal Resistance Junction to Ambient SOT-23-6

TSOT-23-6

Absolute Maximum Ratings are those values beyond which the life of a device may be impaired.

Voltage 6V

–40°C to 85°C

–65°C to 150°C

33V

6V

34V

150°C

260°C

115°C/W

115°C/W

250°C/W

250°C/W

3

Page 4

AIC3643

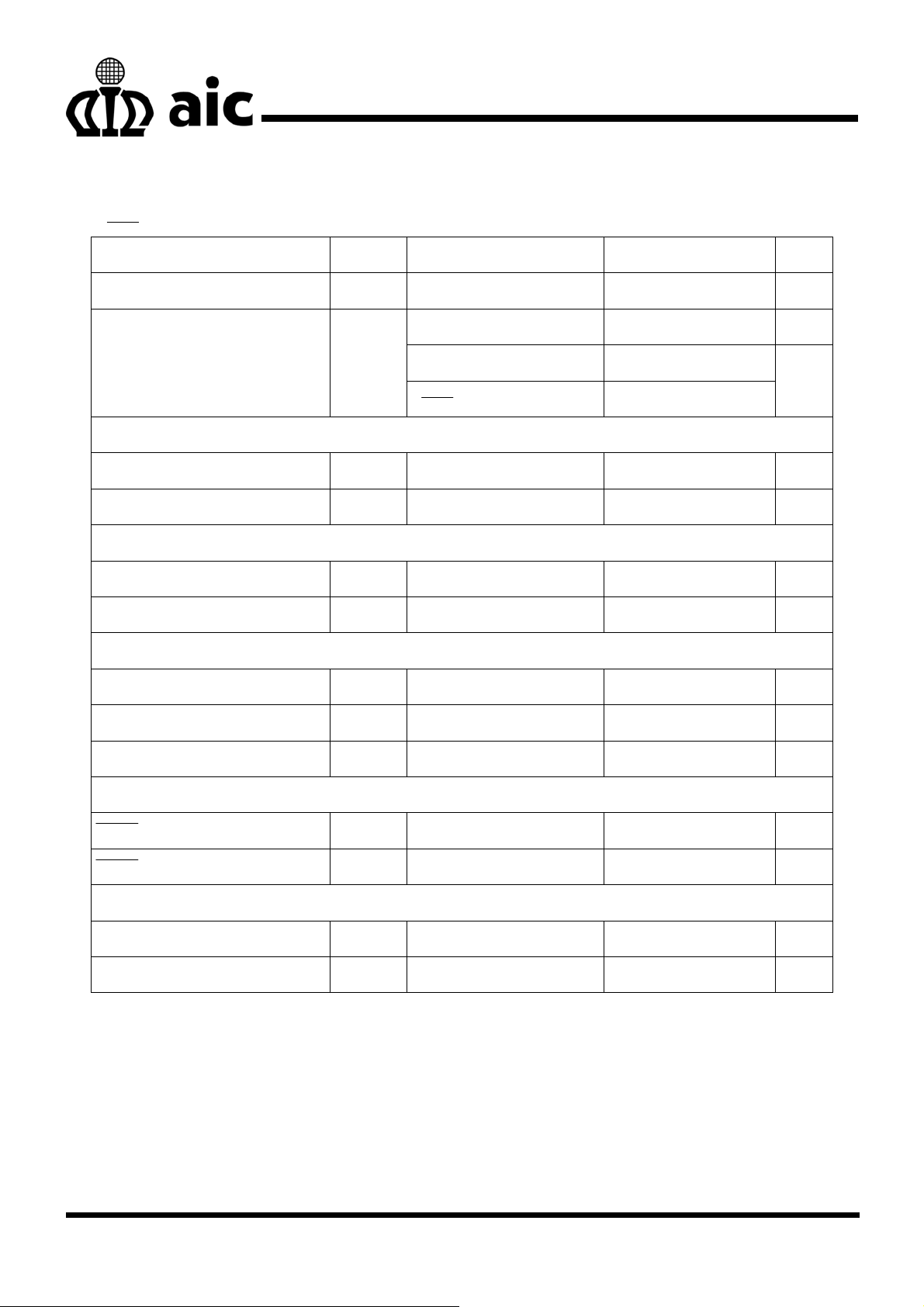

ELECTRICAL CHARACTERISTICS

(V

=1.5V, VIN=3V, TA=25°C, unless otherwise specified.) (Note 1)

SHDN

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

Operating Voltage VIN 2.5 5.5 V

Switching 1 3 mA

Supply Current IIN

Non switching 150 270

V

= 0V 0.1 1.0

SHDN

ERROR AMPLIFIER

V

Feedback Voltage

FB Input Bias Current

90 100 110 mV

FB

I

FB

V

FB

=100mV

1 nA

OSCILLATOR

Switching Frequency f

0.8 1.2 1.6 MHz

OSC

Maximum Duty Cycle D 91 94 %

μA

POWER SWITCH

SW ON Resistance R

Switch Leakage Current I

DS(ON)

SW(OFF)VSW

1.4 2.5 Ω

=33V 0.1 1 μA

Switch Current Limit IIL 0.65 1 A

CONTROL INPUT

SHDN Voltage High V

SHDN

Voltage Low V

ON 1.5 V

IH

OFF 0.3 V

IL

OVER VOLTAGE PROTECTION

OVP Input Resistance R

OVP Threshold V

0.8 1.2 1.6 MΩ

OVP

1V Hysteresis typical 22 28 32 V

OVP

Note 1: Specifications are production tested at TA=25°C. Specifications over the -40°C to 85°C operating

temperature range are assured by design, characterization and correlation with Statistical Quality

Controls (SQC).

4

Page 5

AIC3643

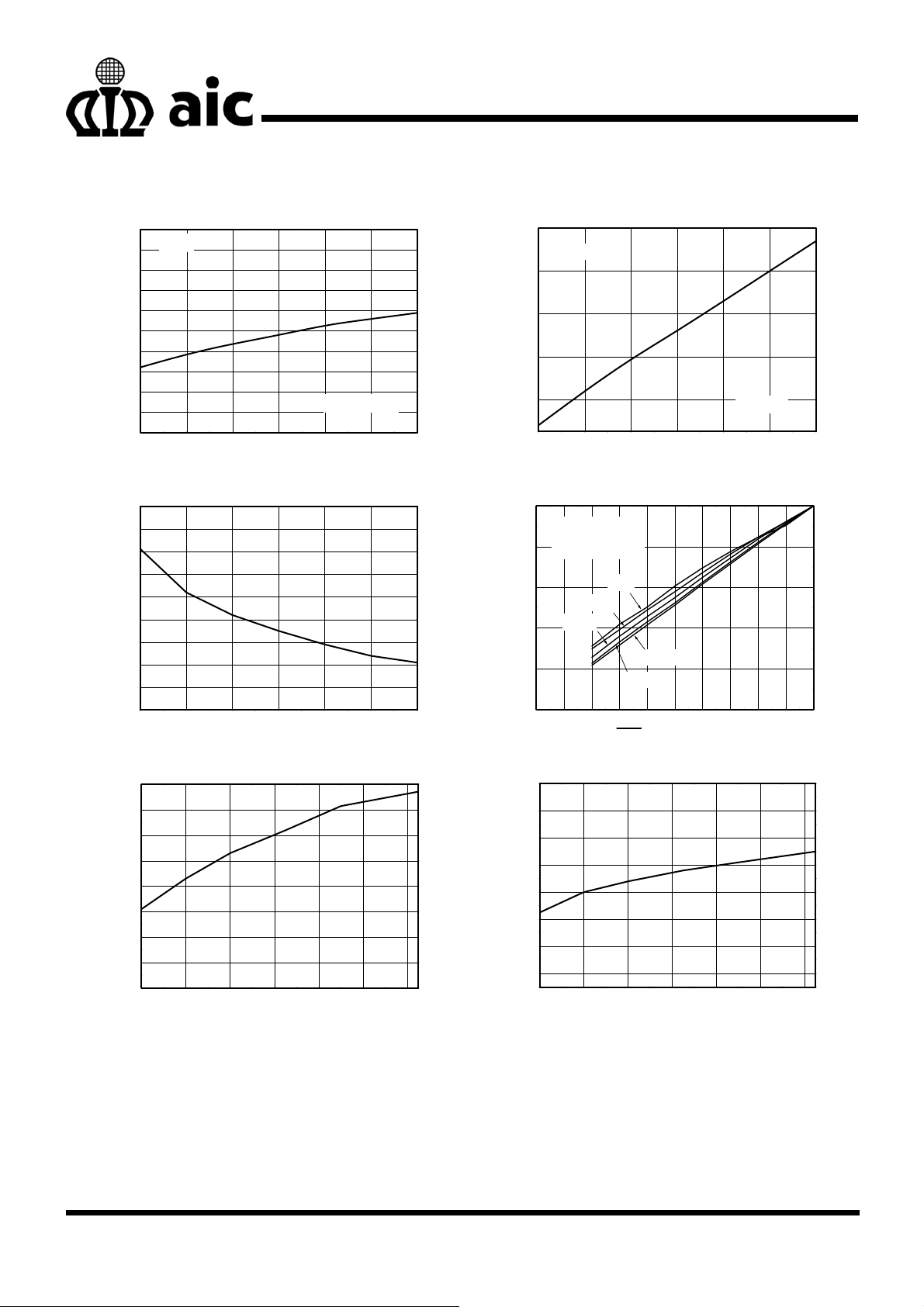

TYPICAL PERFORMANCE CHARACTERISTICS

200

FB=V

190

180

170

160

150

140

130

Supply Current (μA)

120

110

100

2.5 3.0 3.5 4.0 4.5 5.0 5.5

Fig. 2 Supply Current vs. Supply Voltage Fig. 3 Supply Current vs. Supply Voltage

IN

Non-Switching

Supply Voltage (V)

1600

FB=GND

1400

1200

1000

Supply Current (μA)

800

2.5 3.0 3.5 4.0 4.5 5.0 5.5

Supply Voltage (V)

Switching

1.7

1.6

1.5

1.4

1.3

(Ω)

1.2

DS-ON

R

1.1

1.0

0.9

0.8

2.53.03.54.04.55.05.5

Fig. 4 R

1.6

1.5

1.4

1.3

1.2

1.1

1.0

Switching Frequency (MHz)

0.9

0.8

-40-200 20406080

100

VIN=3.6V; L=6.8μH

C

=1μF; C

500Hz

=3.3μF

OUT

2kHz

1kHz

100Hz

200Hz

SHDN PIN PWM Duty (%)

Temperature (oC)

IN

80

3LEDs

60

(%)

LEDMAX

/I

40

LED_DUTY

I

20

0

0 102030405060708090100

Supply Voltage (V)

vs. Supply Voltage Fig. 5 Dimming Control by Shutdown Pin

DS_ON

Temperature (oC)

110

108

106

104

102

100

98

Feedback Voltage (mV)

96

-40-200 20406080

Fig. 6 Switching Frequency vs. Temperature Fig. 7 Feedback Voltage vs. Temperature

5

Page 6

AIC3643

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

24

23

22

LED Current (mA)

21

20

-40-200 20406080

VIN=4.2V

VIN=5.5V

VIN=3V

VIN=2.5V

Temperature (oC)

VIN=3.6V

V

, 2V/div

SHDN

I

, 200mA/div

INDUCTOR

V

, 2V/div

OUT

VIN=3V; 3LEDs; L=6.8μF; C

=3.3μF; I

OUT

LED

=20mA

Fig. 8 LED Current vs. Temperature Fig. 9 Start Up from Shutdown

V

, 5V/div

SW

, 200mA/div

I

INDUCTOR

Output Ripple, 50mV/div

VIN=3.6V; 3LEDs; L=6.8μF; C

OUT

=3.3μF; I

LED

=20mA

90

85

80

75

70

Efficiency (%)

65

60

0 5 10 15 20 25 30

VIN=4.2V

VIN=3.6V

VIN=3V

3 LEDs, 6.8μH

L1: GTSD31-6R8M, GOTREND

D1: SS0540, PAN JIT

Test Circuit refer to Fig.1

LED Current (mA)

Fig. 10 Operation Waveform Fig. 11 3LEDs Efficiency vs. LED Current

90

85

80

75

70

Efficiency (%)

65

60

0 5 10 15 20 25 30

VIN=4.2V

VIN=3V

4 LEDs, 6.8μH

L1: GTSD31-6R8M, GOTREND

D1: SS0540, PAN JIT

Test Circuit refer to Fig.1

LED Current (mA)

VIN=3.6V

90

85

VIN=4.2V

80

75

70

Efficiency (%)

65

60

0 5 10 15 20 25 30

VIN=3V

5 LEDs, 6.8μH

L1: GTSD31-6R8M, GOTREND

D1: SS0540, PAN JIT

Test Circuit refer to Fig.1

VIN=3.6V

LED Current (mA)

Fig. 12 4LEDs Efficiency vs. LED Current Fig. 13 5LEDs Efficiency vs. LED Current

6

Page 7

AIC3643

BLOCK DIAGRAM

OVP

100mV

VIN

FB

VREF

+

-

Error

AMP

28V

RC

CC

Over Voltage

Comparator

+

-

+

PWM

Comparator

Slope

Compensation

Current AMP.

PWM/PFM

Control

Control

Logic

1.2MHz

Oscillator

+

-

SHDN

SW

M1

Driver

RS

GND

PIN DESCRIPTIONS

PIN 1: SW - Switch pin. Connect

inductor/diode here. Minimize

trace area at this pin to reduce

EMI.

PIN 2: GND - Ground pin. Tie directly to local

ground plane.

PIN 3: FB - Feedback pin. Reference

voltage is 100mV. Connect

cathode of lowest LED and

resistor here. Calculate resistor

value to obtain LED current

according to the formula:

R

= 100mV/I

FB

LED

PIN 4:

SHDN

PIN 5: OVP - Overvoltage protection. When

PIN 6: VIN - Power input pin. Bypass VIN to

- Shutdown pin. Tie to higher than

1.5V to enable device, 0.3V or

less to disable device.

VOUT is greater than 28V, the

internal MOSFET turns off.

GND with a capacitor sitting as

close to VIN as possible.

7

Page 8

AIC3643

APPLICATION INFORMATION

Inductor Selection

A 6.8μH inductor is recommended for most

AIC3643 applications. Although small size and

high efficiency are major concerns, the inductor

should have low core losses at 1.2MHz and low

DCR (copper wire resistance). It is important to

ensure the inductor saturation current exceeding

the peak inductor current in application to prevent

core saturation. For CCM (Continuous Conduction

Mode) operation, the peak inductor current can be

calculated from:

DV

⋅

II

()

MAXINPEAK

=

+=

OSC

⋅

VI

OUT)MAX(LED

⋅η

V

+

)MIN(IN

)MAX()MIN(IN

Lf2

⋅×

DV

⋅

)MAX()MIN(IN

Lf2

⋅×

OSC

Capacitor Selection

The small size of ceramic capacitors makes them

ideal for AIC3643 applications. X5R and X7R

types are recommended because they retain their

capacitance over wider ranges of voltage and

temperature than other types, such as Y5V or

Z5U. 1

μF input capacitor with 3.3μF output

capacitor are sufficient for most AIC3643

applications.

Diode Selection

Schottky diodes, with their low forward voltage

drop and fast reverse recovery, are the ideal

choices for AIC3643 applications. The forward

voltage drop of an Schottky diode represents the

conduction losses in the diode, while the diode

capacitance (C

T or CD) r epresents the switching

losses. For diode selection, both forward voltage

drop and diode capacitance need to be

considered. In addition, the rating of selected

Schottky diode should be able to handle the

output voltage and the maximum peak diode

current.

LED Current Control

LED current is controlled by feedback resistor

(R

in Figure 1). The feedback reference voltage

FB

is 100mV. The LED current is 100mV/R

FB

. In

order to have accurate LED current, precision

resistors are preferred (1% recommended). The

formula for R

R =

FB

selection is shown below.

FB

mV100

I

LED

Open-Circuit Protection

In the cases of output open circuit, when the LEDs

are disconnected from the circuit or the LEDs fail,

the feedback voltage will be zero. AIC3643 will

then switch to a high duty cycle resulting in a high

output voltage, which may cause SW pin voltage

to exceed its maximum 33V rating. Connect builtin OVP (Over Voltage Protection) pin to output

terminal to prevent the damage resulting from an

open circuit condition.

Dimming Control

There are three different ways of dimming control

circuits as follows:

1. Using a PWM signal

PWM brightness control provides the widest

dimming range by pulsing the LEDs on and off at

full and zero current, respectively. The change of

average LED current depends on the duty cycle of

the PWM signal. Typically, a 0.1kHz to 2kHz

PWM signal is used. Two applications of PWM

dimming with AIC3643 are shown in Figure 14

and Figure 15. One, as Figure 14, uses PWM

signal to drive

control. The other, as Figure 15, employs PWM

signal going through a resistor to drive FB pin. If

the

SHDN pin is used, the increase of duty cycle

results in LED brightness enhancement. If the FB

pin is used, on the contrary, the increase of duty

cycle will decrease its brightness. In this

application, LEDs are dimmed by FB pin and

turned off completely by

2. Using a DC Voltage

For some applications, the preferred method of a

dimming control uses a variable DC voltage to

adjust LED current. The dimming control using a

DC voltage is shown in Figure 16. With a V

SHDN pin directly for dimming

SHDN.

DC

8

Page 9

μ

AIC3643

ranging from 0V to 5V, the selection of resistors in

Figure 16 results in dimming control of LED

current from 20mA to 0mA, respectively.

3. Using a Filtered PWM Signal

Filtered PWM signal can be considered as an

adjustable DC voltage. It can be used to replace

the variable DC voltage source in dimming

control. The circuit is shown in Figure 17.

Layout Consideration

In order to ensure a proper operation of AIC3643,

the following points should be managed

comprehensively.

1. The input capacitor and V

should be placed

IN

VIN

C1

1μF

PWM

6.8μH

VIN

SHDN

GND

AIC3643

L

SW

OVP

FB

as close as possible to each other to reduce

the input ripple voltage.

2. The output loop, which is consisted of the

inductor, the internal power switch, the

Schottky diode and the output capacitor,

should be kept as small as possible.

3. The routes with large current should be kept

short and wide.

4. Logically the large current on the converter

should flow at the same direction.

5. The FB pin should be connected to the

feedback resistors directly and the route

should be away from the noise sources.

D1

SS0540

C2

3.3μF

R

FB

5Ω

Fig. 14 Dimming Control with a PWM Signal

V

IN

C1

1μF

6.8

VIN

SHDN

GND

AIC3643

L

SW

OVP

FB

PWM

D1

SS0540

R2

49K

R1

1K

R

5Ω

C2

3.3μF

FB

Fig. 15 Dimming Control Using a PWM Signal

9

Page 10

μ

μ

Ω

Ω

AIC3643

V

IN

C1

1μF

L

6.8

H

SWVIN

OVPSHDN

D1

SS0540

C2

3.3

F

AIC3643

FB

V

DC

0~5V

R2

49K

R1

1K

R

5Ω

FB

GND

Fig. 16 Dimming Control Using a DC Voltage

VIN

C1

1μF

L

6.8μH

OVPSHDN

AIC3643

SWVIN

FBGND

PWM

Fig. 17Dimming Control Using a Filter PWM Signal

D1

SS0540

R3

5.1K

R2

49K

C3

0.1μF

R1

1K

C2

3.3μF

R

FB

5Ω

APPLICATION EXAMPLE

3.0~4.2V

C1

1μF

Fig. 18 Six White LEDs Application in Li-Ion Battery

L

6.8μH

VIN

SHDN

GND

AIC3643

SW

OVP

FB

D1

SS0540

C2

3.3μF

20mA

R

FB

5

R1

5

10

Page 11

AIC3643

PHYSICAL DIMENSIONS

SOT-23-6 PACKAGE OUTLINE DRAWING

AA

D

e

e1

(unit: mm)

E

E1

A

A2

A1

SEE VIEW B

b

WITH PLATING

c

BASE METAL

SECTION A-A

0.25

L1

VIEW B

L

θ

GAUGE PLANE

SEATING PLANE

Note : 1. Refer to JEDEC MO-178AB.

2. Dimension "D" does not include mold flash, protrusions

or gate burrs. Mold flash, protrusion or gate burrs shall not

exceed 10 mil per side.

3. Dimension "E1" does not include inter-lead flash or protrusions.

4. Controlling dimension is millimeter, converted inch

dimensions are not necessarily exact.

S

Y

M

B

O

L

A

A1

A2

b

c

D

E

E1

e

e1

L

L1

θ

MIN.

0.95

0.05

0.90

0.30

0.08

2.80

2.60

1.50

0.30

0°

SOT-23-6

MILLIMETERS

MAX.

1.45

0.15

1.30

0.50

0.22

3.00

3.00

1.70

0.95 BSC

1.90 BSC

0.60

0.42 REF

8°

11

Page 12

AIC3643

TSOT-23-6 PACKAGE OUTLINE DRAWING

D

E

E1

AA

e1

e

SEE VIEW B

b

WITH PLATING

A2

A

c

BASE METAL

SECTION A-A

A1

L

L1

VIEW B

Note : 1. Refer to JEDEC MO-193AA.

2. Dimension "D" does not include mold flash, protrusions

or gate burrs. Mold flash, protrusion or gate burrs shall not

exceed 6 mil per side.

3. Dimension "E1" does not include inter-lead flash or protrusions.

4. Controlling dimension is millimeter, converted inch

dimensions are not necessarily exact.

0.25

GAUGE PLANE

SEATING PLANE

θ

S

Y

M

B

O

L

A

A1

A2

b

c

D

E

E1

e

e1

L

L1

θ

MILLIMETERS

MIN.

-

0

0.70

0.30

0.08

2.80

2.60

1.50

0.30

0°

TSOT-23-6

MAX.

1.00

0.10

0.90

0.50

0.22

3.00

3.00

1.70

0.95 BSC

1.90 BSC

0.60

0.60 REF

8°

12

Page 13

AIC3643

Note:

Information provided by AIC is believed to be accurate and reliable. However, we cannot assume responsibility for use of any

circuitry other than circuitry entirely embodied in an AIC product; nor for any infringement of patents or other rights of third parties

that may result from its use. We reserve the right to change the circuitry and specifications without notice.

Life Support Policy: AIC does not authorize any AIC product for use in life support devices and/or systems. Life support devices or

systems are devices or systems which, (I) are intended for surgical implant into the body or (ii) support or sustain life, and whose

failure to perform, when properly used in accordance with instructions for use provided in the labeling, can be reaso nably expected

to result in a significant injury to the user.

13

Page 14

Loading...

Loading...