Page 1

AIC1802

µ

µ

*C

TC

*C

TD

1µF

M2

Q1

Two-Cell Lithium-Ion Battery Protection IC

n FEATURES

l Ultra-Low Quiescent Current at 10

VC=3.5V).

l Ultra-Low Power-Down Current at 0.2

=3.8V, VC=1.9V).

l Wide Supply Range: 2 to 18V.

l Precision Overcharge Protection Voltage

4.35V ± 30mV for the AIC1802A

4.30V ± 30mV for the AIC1802B

4.25V ± 30mV for the AIC1802C

l Built-in Delay Circuits for Overcharge, Over-

discharge and Overcurrent Protection.

l Overcharge and Overdischarge Delay Time

can be Extended by External Capacitors.

l Built-in Cell-balancing Bleeding Network under

Overcharge Condition.

n APPLICATIONS

l Protection IC for Two-Cell Lithium-Ion Battery

Pack.

A (VCC=7V,

A (V

CC

n DESCRIPTION

The AIC1802 battery protection IC is designed

to protect lithium-ion batteries from damage due

to overcharging, overdischarging, and

overcurrent for two series cells in portable

phones and laptop computers. It can be a part of

the low-cost charge control system within a twocell lithium-ion battery pack.

Safe and full utilization charging is ensured by

the accurate ±30mV overcharge detection.

Three different specification values for

overcharge protection voltage are provided for

various protection requirements. The very low

standby current drains little current from the

cells while in storage.

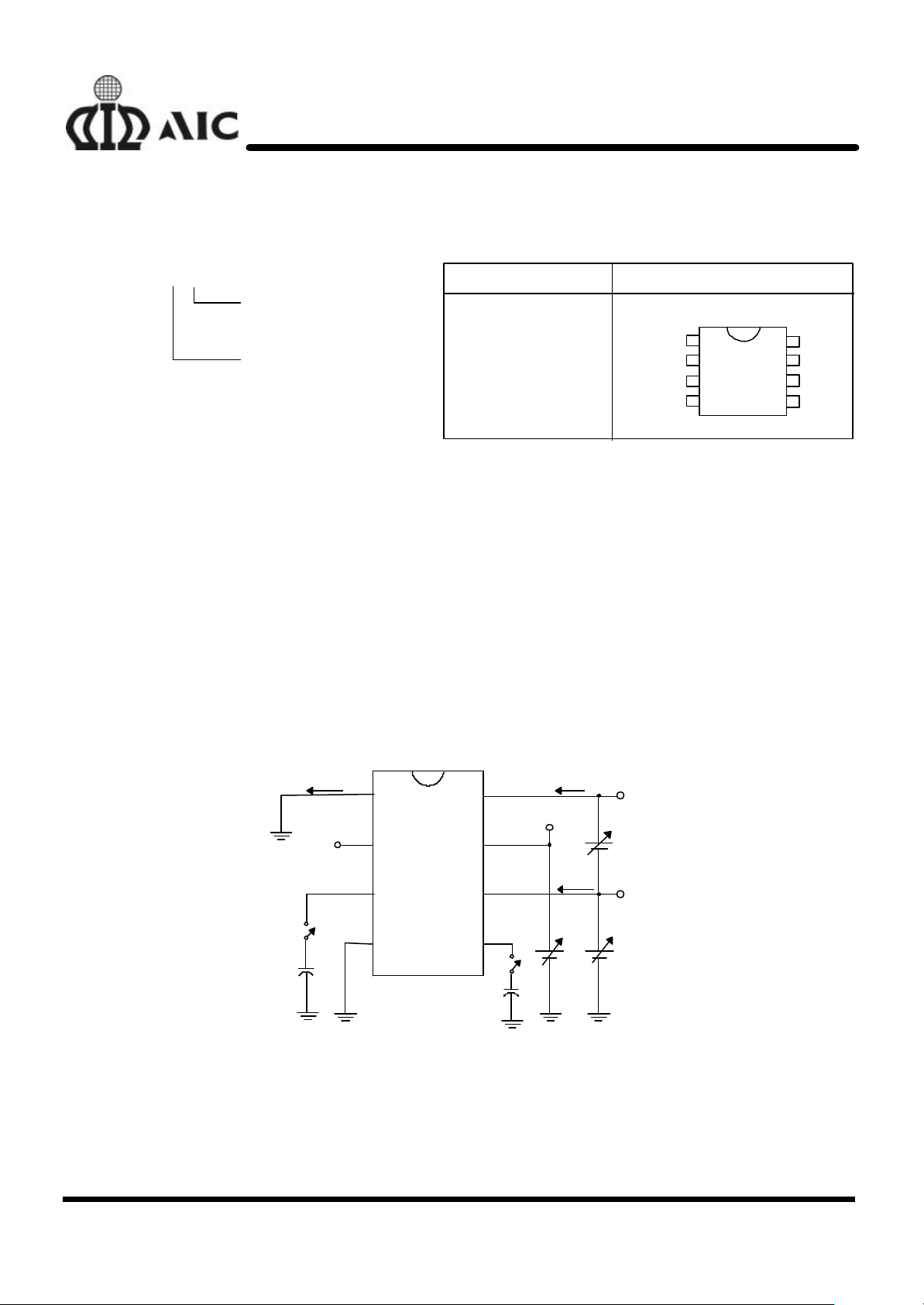

n TYPICAL APPLICATION CIRCUIT

**R1

C1

C2

BATTERY 2

M1

CEM9926

1µF

**R2

*CTC & CTD are optional for delay time adjustment.

**R1 & R2: Refer application informations.

Protection Circuit for Two-Cell Lithium-Ion Battery Pack

DS-1802-03 July 13, 00 www.analog.com.tw

8

VCC TC

6

VC TD

4

GND OC

2

OD CS

AIC1802

5

3

1

7

R6

1K

R3

1M

CEM9926

C3

0.01µF

V

+

BAT

R4

1M

R5

1M

V

-

BAT

1

Page 2

n ORDERING INFORMATION

AIC1

802ACS

VCVCODTD

GNDCSTC

OC13428657

+

+

V

V

432

1

I

V

CSCTC

V

COICC

AIC1802

AIC1802 XCX

PACKAGE TYPE

S: SOP-8

OVERCHARGE

PROTECTION VOLTAGE

A: 4.35V

B: 4.30V

C: 4.25V

ORDER NUMBER

AIC1802BCS

AIC1802CCS

(PLASTIC SO8)

PIN CONFIGURATION

TOP VIEW

n ABSOLUTE MAXIMUM RATINGS

Supply Voltage ....................................……………..................................................... 18V

DC Voltage Applied on VC, CS, OC, OD Pins ...............…………….............................. 18V

DC Voltage Applied on TC, TD Pins ...............…………………..…….............................. 5V

Operating Temperature Range .......................................….………….............. -40°C~85°C

Storage Temperature Range .........................…………………..................... - 65°C~150°C

n TEST CIRCUIT

I

OC VCC

OD CS

TD VC

GND TC

C

TD

AIC1802

8

7

6

5

CC

2

Page 3

AIC1802

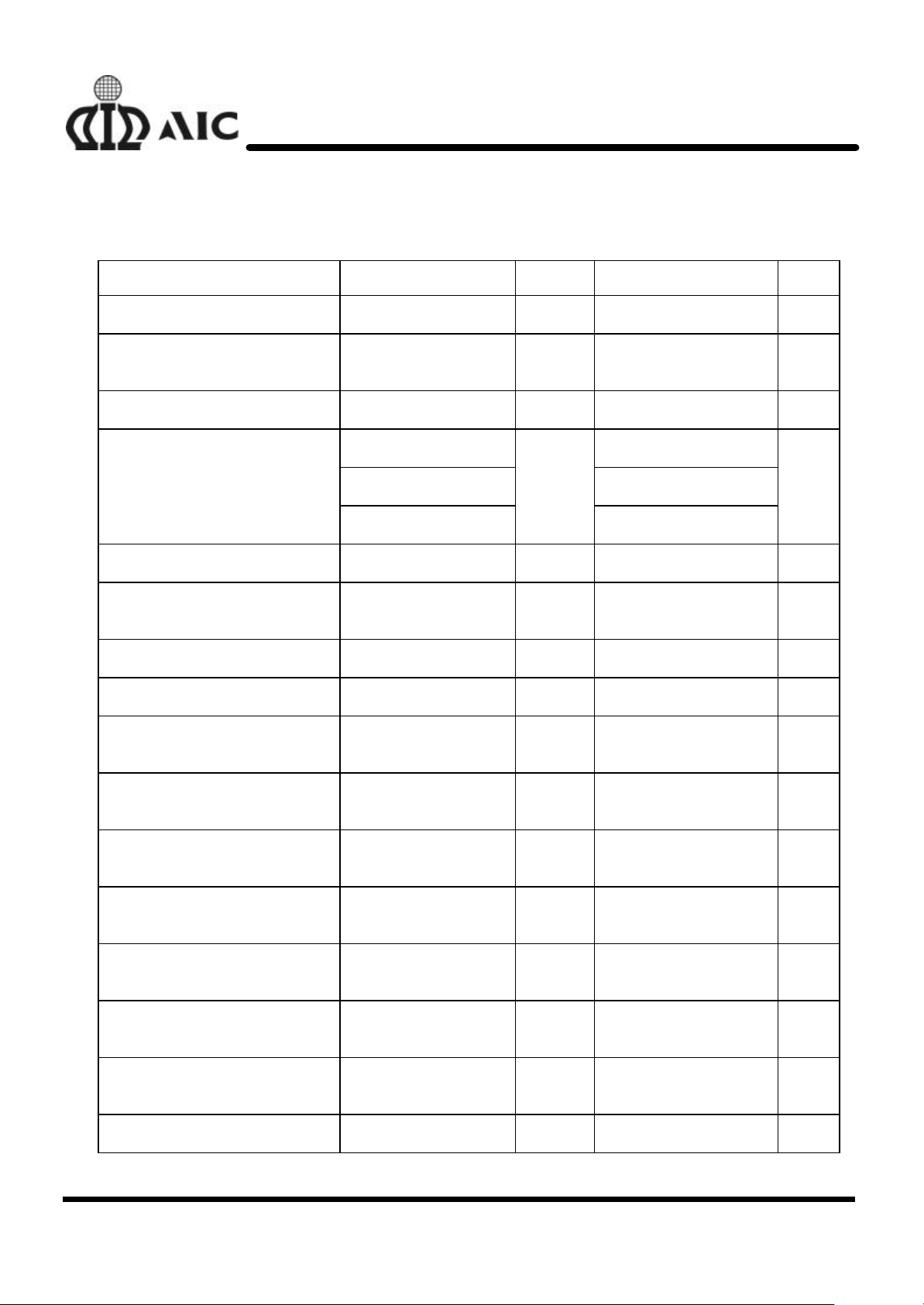

n ELECTRICAL CHARACTERISTICS (Ta=25 °C, unless otherwise specified.)

PARAMETER TEST CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

Supply Current in Normal Mode VCC=7V, VC=3.5V I

Supply Current in Power-Down

Mode

VCC=4.8V, VC=2.4V I

VC Pin Input Current VCC=7V, VC=3.5V I

AIC1802A 4.32 4.35 4.38

AIC1802B 4.27 4.30 4.33 Overcharge Protection Voltage

V

AIC1802C

Overcharge Release Voltage V

Overdischarge Protection

Voltage

V

Overdischarge Release Voltage V

Overcurrent Protection Voltage VCC=7V V

Overcharge Delay Time (1)

VCC=8.6V, VC=4.3V,

CTC=0µF

T

CC

PD

C

OCP

OCR

ODP

ODR

OIP

OC1

10 15 µA

0.8 1.2 µA

400 600 nA

V

4.22 4.25 4.28

3.85 4.0 4.15 V

2.25 2.4 2.55 V

2.85 3.0 3.15 V

135 150 165 mV

12 25 38 mS

Overcharge Delay Time (2)

Overdischarge Delay Time (1)

Overdischarge Delay Time (2)

Overcurrent Delay Time (1)

Overcurrent Delay Time (2)

OC Pin Source Current

VCC=8.6V, VC=4.3V,

CTC=0.47µF

VCC=4.8V, VC=2.4V,

CTD=0µF

VCC=4.8V, VC=2.4V,

CTD=0.47µF

VCC=7V, VC=3.5V,

VCS=0.15V

VCC=7V, VC=3.5V,

VCS=0.36V

VCC=8.6V, VC=4.3V,

OC Pin Short to GND

T

T

T

OD Pin Output “H” Voltage V

T

T

I

OC2

OD1

OD2

OI1

OI2

CO

DL

0.7 1.1 1.5 S

12 25 38 mS

0.7 1.1 1.5 S

4 9 14 mS

1.0 2.0 3.0 mS

270 400 530 µA

VCC-0.1 VCC-0.02 V

3

Page 4

n ELECTRICAL CHARACTERISTICS (Continued)

AIC1802

PARAMETER TEST CONDITIONS

SYMBOL

OD Pin Output “L” Voltage V

Charge Detection Threshold

VCC=4.8V V

Voltage

Unbalance Discharge Current VCC=8.3V, VC=4V I

TYPICAL PERFORMANCE CHARACTERISTICS

n

10.7

10.5

10.3

10.1

Supply Current vs. Supply Voltage

VC=1/2VCC

TA=25°C

0.8

0.65

0.5

MIN. TYP. MAX. UNIT

DH

CH

UD

Power-down Current vs. Supply Voltage

0.01 0.1 V

-0.55 -0.4 V

5.4 7.7 10 mA

VC=1/2VCC

TA=25°C

Supply Current (µA)

9.9

9.7

5.5 6.5 7.5 8.5

Supply Voltage (V)

Overcharge Protection Voltage vs. Temperature

4.32

4.315

AIC1802B

4.31

4.305

Overcharge Protection Voltage (V)

4.3

0 10 20 30 40 50 60 70-10-20

Temperature (°C)

0.35

Power-Down Current (µA)

0.2

3.8 4.3 4.8 5.3 5.8

Supply Voltage (V)

Overcurrent Protection Voltage vs. Temperature

150

VCC=7V

147.5

142.5

Overcurrent Protection Voltage (mV)

VC=3.5V

145

140

0 10 20 30 40 50 60 70-10-20

Temperature (°C)

4

Page 5

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

µ

(V)

Overcharge Release Voltage vs. Temperature

Overdischarge Release Voltage (V)

n

AIC1802

Supply Current vs. Temperature

12.5

A)

11.5

10.5

Supply Current (

9.5

8.5

0 10 20 30 40 50 60 70-10-20

Temperature (°C)

Overdischarge Protection Voltage vs. Temperature

2.420

2.415

2.410

2.405

VCC=7V

VC=3.5V

1.1

0.9

0.7

Power-Down Current (µA)

0.5

4.025

4.020

4.015

Power-Down Current vs. Temperature

VCC=4.8V

VC=2.4V

0 10 20 30 40 50 60 70-10-20

Temperature (°C)

2.400

Overdischarge Protection Voltage

2.395

-20 -10 0 10 20 30 40 50 60 70

Temperature (°C)

Overdischarge Release Voltage vs. Temperature

3.025

3.020

3.015

3.010

3.005

-20 -10 0 10 20 30 40 50 60 70

Temperature (°C)

4.010

Overcharge Release Voltage (V)

4.005

-20 -10 0 10 20 30 40 50 60 70

Temperature (°C)

70

5

Page 6

BLOCK DIAGRAM

VCC

VCC

DETECTOR

DETECTOR 2

DETECTOR 1

DETECTOR 1

DETECTOR 2

UP

DISCHARGE

n

AIC1802

8

6

VC

OD

4

2

GND

PIN DESCRIPTIONS

n

450

450

OVERCHARGE

OVERDISCHARGE

UNBALANCE

OVERCHARGE

OVERDISCHARGE

OVERCURRENT

DELAY CIRCUIT

OVERCURRENT

OVERCHARGE

DELAY CIRCUIT

OVERDISCHARGE

DELAY CIRCUIT

POWER-

LOGIC

CONTROL

TIMING

GENERATION

CHARGE

DETECTION

DOWN

WAKE-

5

TC

3

TD

1

OC

7

CS

PIN 1: OC - PMOS open drain output for

control of the charge control

MOSFET M2. When overcharge

occurs, this pin sources current to

switch the external NPN Q1 on,

and charging is inhibited by

turning off the charge control

MOSFET M2.

PIN 2: OD - Output pin for control of the

discharge control MOSFET M1.

When overdischarge occurs, this

pin goes low to turn off the

discharge control MOSFET M1

and discharging is inhibited.

PIN 3: TD - Overdischarge delay time setting

pin.

PIN 4: GND - Ground pin. This pin is to be

connected to the negative terminal

of the lower battery cell.

PIN 5: TC - Overcharge delay time setting

pin.

PIN 6: VC - To be connected to the positive

terminal of the lower cell and

the negative terminal of the

upper cell.

PIN 7: CS - Input pin for current sensing.

Using the drain-source voltage

of the discharge control

MOSFET M1 (voltage between

CS and GND), it senses

discharge current during normal

mode and detects whether

charging current is present

during power down mode.

PIN 8: VCC - Power supply pin. It is to be

connected to the positive

terminal of the upper cell.

6

Page 7

APPLICATION INFORMATIONS

n

AIC1802

THE OPERATION

Overcharge Protection

When the voltage of either of the battery cells

exceeds V

beyond the overcharge delay time period,

charging is inhibited by the turning-off of the

charge control MOSFET M2. The overcharge

delay time (TOC) defaults to 25mS and can be

extended by adding a capacitor CTC. Inhibition of

charging is immediately released when the

voltage of the overcharged cell becomes lower

than V

OCR

discharge.

Overdischarge Protection

When the voltage of either of the battery cells

goes below V

voltage) beyond the overdischarge delay time

period, discharging is inhibited by the turning-off

of the discharge control MOSFET M1. The

overdischarge delay time (TOD) defaults to 25mS

and can be extended by adding a capacitor CTD.

Inhibition of discharging is immediately released

when the voltage of the overdischarged cell

becomes higher than V

release voltage) through charging.

Power-Down after Overdischarge

When overdischarge occurs, the AIC1802 will go

into power-down mode, turning off all the timing

generation and detection circuitry to reduce the

quiescent current to 0.8µA (VCC=4.8V). In the

unusual case where one battery cell is

overdischarged while the other under overcharge

condition, the AIC1802 will turn off all the

(overcharge protection voltage)

OCP

(overcharge release voltage) through

(overdischarge protection

ODP

(overdischarge

ODR

detection circuits except the overcharge detection

circuit for the cell under overcharge condition.

Charge Detection after Overdischarge

When overcharge occurs, the discharge control

MOSFET M1 turns off and discharging is inhibited.

However, charging is still permitted through the

parasitic diode of M1. Once the charger is

connected to the battery pack, the AIC1802

immediately turns on all the timing generation and

detection circuitry and goes into normal mode.

Charging is determined to be in progress if the

voltage between CS and GND is below –0.4V

(charge detection threshold voltage VCH)

Overcurrent Protection

In normal mode, the AIC1802 continuously

monitors the discharge current by sensing the

voltage of CS pin. If the voltage of CS pin

exceeds V

beyond overcurrent delay time TOI period, the

overcurrent protection circuit operates and

discharging is inhibited by turning-off of the

discharge control MOSFET M1. Discharging must

be inhibited for at least 256mS after overcurrent

takes place to avoid damage to external control

MOSFETs due to rapidly switching transient

between V

overcurrent condition returns to the normal mode

when the load is released and the impedance

between the V

higher. For the sake of protection of the external

MOSFETs, the larger the CS pin voltage (which

means the larger discharge current) the shorter

the overcurrent delay time. The relationship

between voltage of CS pin and overcurrent delay

(overcurrent protection voltage)

OIP

and V

BAT+

and V

BAT+

BAT-

terminals. The

BAT-

terminals is 10MΩ or

7

Page 8

time TOI is tabulated as below.

V

(V) T

CS

OI

(S)

150m 9.0m

200m 5.6m

300m 2.8m

360m 2.0m

1V

3V

540µ

290µ

C

(F) T

TC

0µ

0.1µ

0.3µ

0.47µ

0.57µ

C

(F) T

TD

(S)

OC

25m

320m

890m

1.12

1.43

(S)

OD

AIC1802

5V

270µ

Unbalanced Discharge after Overcharge

When either of the battery cells is overcharged,

the AIC1802 will automatically discharge the

overcharged cell at about 7.7mA until the voltage

of the overcharged cell is equal to the voltage of

the other cell. If the voltage of the other cell is

below V

, the internal cell-balance “bleeding”

OCR

will proceed until the voltage of the overcharged

cell decreases to V

OCR

.

DESIGN GUIDE

Adjustment of Overcharge and

Overdischarge Delay Time

Both the overcharge and overdischarge delay

times default to 25mS and can be extended by

adding the external capacitors CTC and CTD,

respectively. Increasing the capacitance value will

increase the delay time. The relationship between

capacitance of the external capacitors and delay

time is tabulated as below:

0µ

0.1µ

0.3µ

0.47µ

0.57µ

25m

320m

820m

1.08

1.39

Selection of External Control MOSFETs

Because the overcurrent protection voltage is

preset, the threshold current for overcurrent

detection is determined by the turn-on resistance

of the discharge control MOSFET M1. The turnon resistance of the external control MOSFETs

can be determined by the equation: RON=V

OIP/IT

(IT is the overcurrent threshold current). For

example, if the overcurrent threshold current IT is

designed to be 5A, the turn-on resistance of the

external control MOSFETs must be 30mΩ. Users

should be aware that turn-on resistance of the

MOSFET changes with temperature variation due

to heat dissipation. It changes with the voltage

between gate and source as well. (Turn-on

resistance of a MOSFET increases as the voltage

between gate and source decreases). Once the

turn-on resistance of the external MOSFET

8

Page 9

AIC1802

changes, the overcurrent threshold current will

change accordingly.

Suppressing the Ripple and Disturbance

from Charger

To suppress the ripple and disturbance from

charger, connecting C1 to cell 1 and C2 to cell 2 is

necessary.

Controlling the Charge Control MOSFET

R3, R4, R5 and NPN transistor Q1 are used to

switch the charge control MOSFET M2. If

overcharge does not occur, no current flows out

from OC pin and Q1 are turned off, then M2 is

turned on. When overcharge occurs, current flows

out from OC pin and Q1 is turned on, which turns

off M2 in turn. High resistance for R3, R4, and R5

is recommended for reducing loading of the

batteries.

release voltage and bleeding function. The

relationship among Vrelease1,Vrelease2, R1, and

R2 is shown as following equations:

Vrelease1=V

Vrelease2=V

where

Vrelease1 is Battery 1, real overcharge release

voltage

Vrelease2 is Battery 2, real overcharge release

voltage

Therefore, resistance of R1 and R2 should not

higher than 30Ω. Otherwise, overcharge release

voltage would be higher than overcharge

protection voltage and the charging current may

oscillate. In addition, if overcharge protection

function occurs, AIC1802 will discharge the

overcharged cell and will stop bleeding function

even if the voltage is not equal to the other. The

recommended resistance of R1 and R2 is from 20

to 30Ω.

OCR+IUD

OCR+IUD

*R1

*R2

Latch-Up Protraction at CS Pin

R6 is used for latch-up protection when charger is

connected under overdischarge condition, and

also for overstress protection when charger is

connected in reverse. The charge detection

function after overdischarge is possibly disabled

by larger value of R6. Resistance of 1KΩ is

recommended.

Selection of R1 and R 2

R1 and R2 are used to avoid large current flow

through the battery pack under the situation of IC

damage or pin short. On the other hand,

resistance of R1 and R2 will affect overcharge

Effect of C3

C3 has to be applied to the circuit. Because C3

will keep AIC1802 to be charged after

overdischarge occurred. In addition, when the

differential voltage between charger and battery

pack is higher than 2.1V and overcharge

protection function work, C3 will avoid battery

pack from being charged even if the battery

voltage lower than 4V (To avoid battery pack from

being charged under charger malfunction

situation). The battery pack can be charged again

till remove it from charger.

9

Page 10

n PHYSICAL DIMENSIONS

e

A

E

L

l 8 LEAD PLASTIC SO (unit: mm)

AIC1802

D

SYMBOL MIN MAX

A 1.35 1.75

A1 0.10 0.25

H

B 0.33 0.51

C 0.19 0.25

D 4.80 5.00

E 3.80 4.00

e 1.27(TYP)

C

A1

B

H 5.80 6.20

L 0.40 1.27

10

Loading...

Loading...