Page 1

AIC1341

High Performance, Triple-Output, Auto-

Tracking Com bo Controller

Analog Integrations Corporation 4F, 9, Industry E. 9th Rd, Science Based Industrial Park, Hsinchu Taiwan, ROC

www.analog.com.tw

DS-1341-00 May 24, 01 TEL: 886-3-5772500 FAX: 886-3-5772510 1

n

FEATURES

l Provide Triple Accurate Regulated Voltages

l Optimized Voltage-Mode PWM Control

l Dual N-Channel MOSFET Synchronous Drivers

l Fast Transient Response

l Adjustable Over Current Protection using R

DS(ON)

.

No External Current Sense Resistor Required.

l Programmable Softstart Function

l 200KHz Free-Running Oscillator

l Robust Output s Auto-Tracking Characteristics

l Sink and Source Capabilities with External Circuit

n

APPLICATIONS

l Advanced PC Mboards

l Information PCs

l Servers and Workstations

l Internet Appliances

l PC Add-On Cards

l DDR Termination

n

GENERAL DESCRIPTION

The AIC1341 combines a synchronous voltage

mode PWM controller with two linear controllers

as well as the monitoring and protection functions

in this chip. The PWM controller regulates the

output voltage with a synchronous rectified stepdown converter. The built-in N-Channel MOSFET

drivers also help to simplify the design of stepdown converter. It is able to power CPUs, GPUs,

memories, chipset s and multi-voltage applications.

The PWM controller features over current protection using R

DS(ON)

. It improves efficiency and saves

cost, as there is no expensive current sense resistor required.

Two built-in adjustable linear controllers drive an

external MOSFETs to form two linear regulators

that regulates power for multiple system I/O. Output voltage of both linear regulators can also be

adjusted by means of the external resistor divider.

Both linear regulators feature current limit. For a

system I/O requires current less than 500mA, the

AIC1340 is recommended for saving one external

MOSFET.

The programmable soft-start design provodes a

controlled output voltage rise, which limits the current rate during power on time.

The shutdown function is also provided for disabling the combo controller.

Page 2

AIC1341

2

n

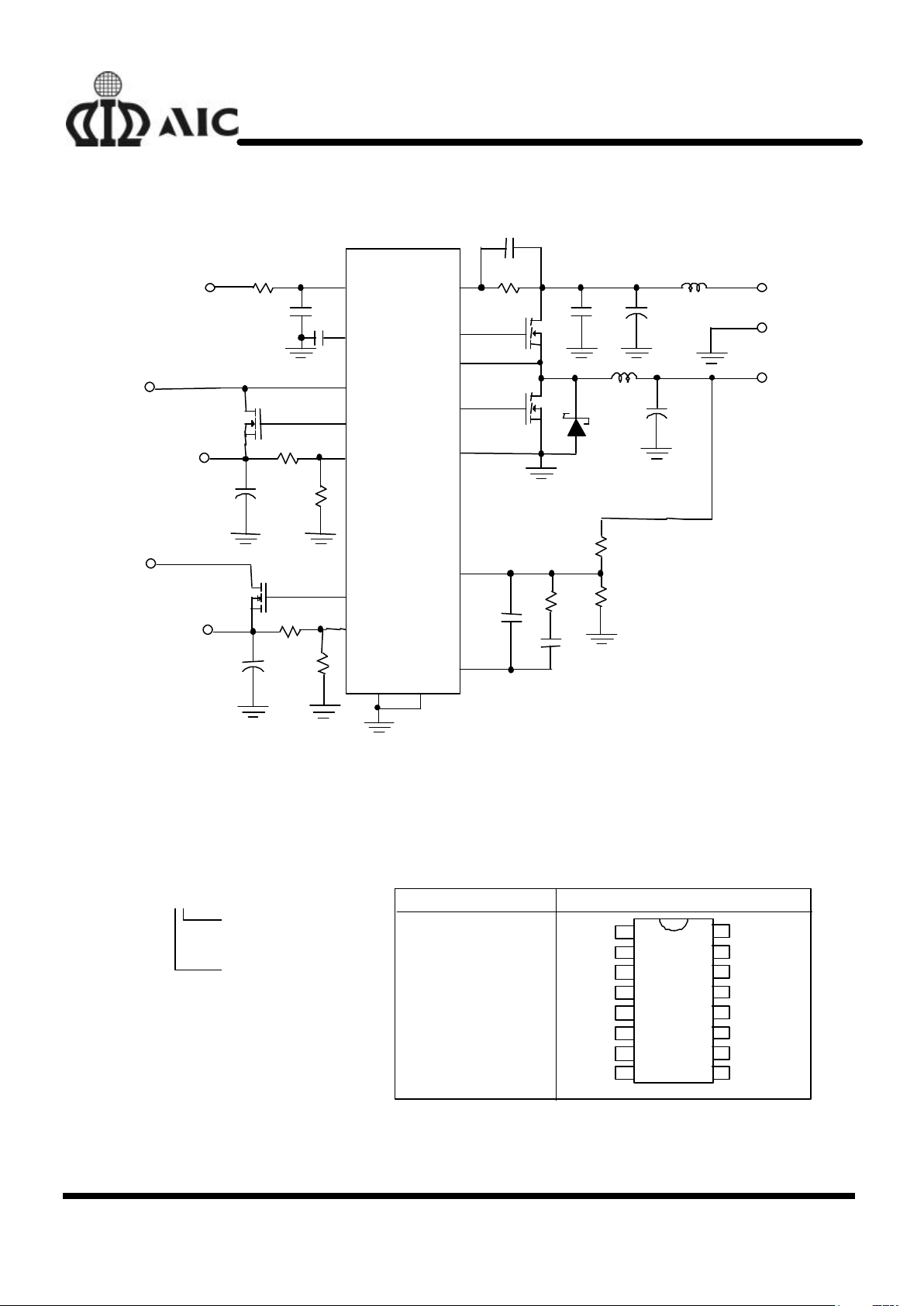

TYPICAL APPLICATION CIRCUIT

+

+

UGATE

PHASE

VIN2

LGATE

GATE3

PGNDFB3

GATE2

FB2

COMP1

SS

GND

+5VIN

VCC

+12VIN

15

OCSET

4

7

11

8

6

VOUT2

VOUT3

+3.3VIN

12

13

16

1

2

14

14

VOUT1

+

5

GND

FB1

3

SD

10

+

+3.3VIN

AIC1341CS

Q1

Q2

Typical Triple-Output Application

n

ORDERING INFORMATION

ORDER NUMBER

PIN CONFIGURATIONAIC1341-XX

AIC1341CS

(SO 16)

PACKAGING TYPE

S: SMALL OUTLINE

TEMPERATURE RANGE

C: O°C~+70°C

1

3

4

2

5

7

68FB2

UGATE

SD

VCC

PHASE

SS

VIN2

GATE2

OCSET

LGATE

PGND

FB3

FB1

COMP1

GATE3

GND

16

14

15

13

12

11

9

10

Page 3

AIC1341

3

n

ABSOLUTE MAXIMUM RATING

Absolute Maximum Ratings

Supply Voltage (VCC) .............................................................................................................. 15V

UGATE....................................................................................................GND - 0.3V to VCC + 0.3V

LGATE ....................................................................................................GND - 0.3V to VCC + 0.3V

Input Output and I/O Voltage .................................................................................GND - 0.3V to 7V

Operating Conditions

Ambient Temperature Range ........................................................................................0° C to 85°C

Maximum Operating Junction Temperature ............................................................................. 100°C

Supply Voltage, VCC .......................................................................................................15V±10%

Thermal Information

Thermal Resistance θJA (°C/W)

SOIC Package.......................................................................................................100°C/W

Maximum Junction Temperature (Plastic Package).................................................................. 150°C

Maximum Storage Temperature Range .......................................................................-65°C to 150°C

Maximum Lead Temperature (Soldering 10s)........................................................................... 300°C

n

TEST CIRCUIT

Refer to APPLICATION CIRCUIT.

n

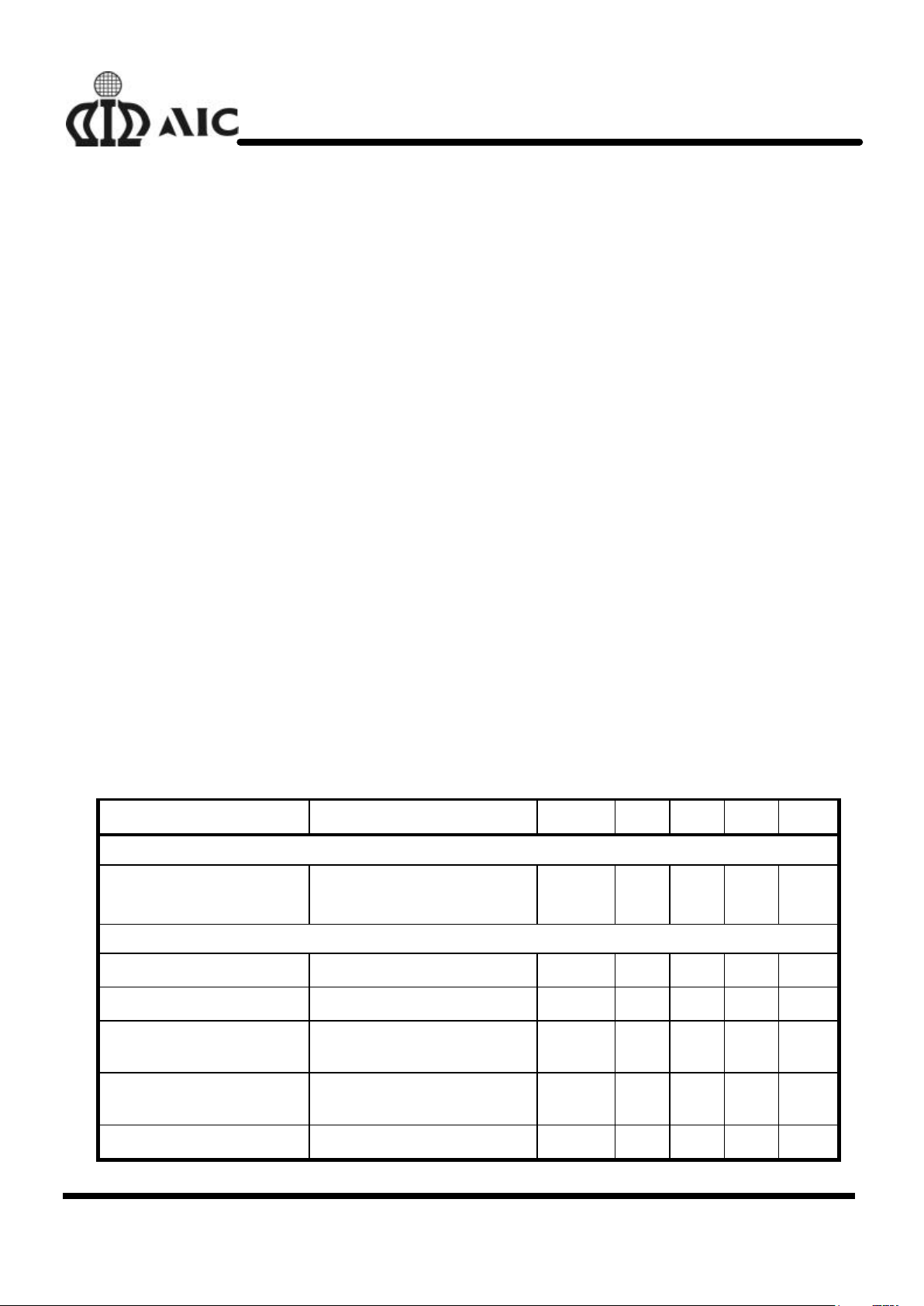

ELECTRICAL CHARACTERISTICS

(Vcc=12V, TJ=25°C, Unless otherwise

specified)

PARAMETER TEST CONDITIONS SYMBOL MIN. TYP. MAX. UNIT

VCC SUPPLY CURRENT

Supply Current UGATE, LGATE, GATE2 and

GATE3 open

I

CC

1.8 5 mA

POWER ON RESET

Rising VCC Threshold V

OCSET

=4.5V VCC

THR

8.6 9.5 10.4 V

Falling VCC Threshold V

OCSET

=4.5V VCC

THF

8.2 9.2 10.2 V

Rising VIN2 Under-Voltage

Threshold

VIN2

THR

2.5 2.6 2.7 V

VIN2 Under-Voltage Hysteresis

VIN2

HYS

130 mV

Rising V

OCSET1

Threshold V

OCSETH

1.3 V

Page 4

AIC1341

4

n

ELECTRICAL CHARACTERISTICS

(Continued)

PARAMETER TEST CONDITIONS

SYMBOL

MIN. TYP. MAX. UNIT

OSCILLATOR and REFERENCE

Free Running Frequency F 170 200 230 KHz

FB2 Reference Voltage V

REF2

1.245 1.270 1.295 V

FB3 Reference Voltage V

REF3

1.250 1.275 1.300 V

LINEAR CONTROLLER

Regulation 0 < I

GATE2/3

< 10mA -2.5 +2.5 %

Under-Voltage Level FB2/3 falling FB2/3

UV

70 80 %

PWM CONTROLLER ERROR AMPLIFIER

DC GAIN 76 dB

Gain Bandwidth Product GBWP 11 MHz

Slew Rate COMP1=10pF SR 6 V/µS

PWM CONTROLLER GATE DRIVER

Upper Drive Source VCC=12V, V

UGATE

=11V R

UGH

5.2 6.5 Ω

Upper Drive Sink VCC=12V, V

UGATE

=1V R

UGL

3.3 5 Ω

Lower Drive Source VCC=12V, V

LGATE

=11V R

LGH

4.1 6 Ω

Lower Drive Sink VCC=12V, V

LGATE

=1V R

LGL

3 5 Ω

PROTECTION

Soft-Start Current I

SS

11 µA

Chip Shutdown Soft Start

Threshold

1.0 V

Page 5

AIC1341

5

n

PIN DESCRIPTIONS

Pin 1: PHASE: Over-current detection pin. Con-

nect the PHASE pin to source of

the external high-side NMOSFET. This pin detects the

voltage drop across the high-side

N-MOSFET R

DS(ON)

for over-

current protection.

Pin 2: UGATE: External high-side N-MOSFET

gate drive pin. Connect UGATE

to gate of the external high-side

N-MOSFET.

Pin 3: SD: To shut down the system, active

high or floating. If connecting a

resistor to ground, keep the re-

sistor less than 4.7K Ω

Pin 4: VCC: The chip power supply pin. It also

provides the gate bias charge for

all the MOSFETs controlled by

the IC. Recommended supply

voltage is 12V.

Pin 5: SS: Soft-start pin. Connect a capaci-

tor from this pin to ground. This

capacitor, along with an internal

10µA (typically) current source,

sets the soft-start interval of the

converter.

Pulling this pin low will shut down

the IC.

Pin 6: FB2: Connect this pin to a resistor di-

vider to set the linear regulator

output voltage.

Pin 7: VIN2: This pin supplies power to the

internal regulator. Connect this

pin to a suitable 3.3V source.

Additionally, this pin is used to

monitor the 3.3V supply. If, following a start-up cycle, the voltage drops below 2.6V (typically),

the chip shuts down. A new softstart cycle is initiated upon re-

turn of the 3.3V supply above

the under-voltage thres hold.

Pin 8: GATE2: Linear Controller output drive pin.

This pin can drive either a Darlington NPN transistor or a Nchannel MOSFET.

Pin 9: GND: Signal GND for IC. All voltage

levels are measured with respect

to this pin.

Pin 10: GATE3: Linear Controller output drive pin.

This pin can drive either a Darlington NPN transistor or an Nchannel MOSFET.

Pin 11: FB3 Negative feedback pin for the

linear controller error amplifier

connect this pin to a resistor divider to set the linear controller

output voltage.

Pin 12: COMP1 External compensation pin. This

pin is connected to error amplifier output and PWM comparator.

A RC network is connected to

FB1 to compensate the voltage

control feedback loop of the converter.

Pin 13: FB1 The error amplifier inverting input

pin. The FB1 pin and COMP1 pin

are used to compensate the voltage-control feedback loop.

Pin 14: OCSET: Current limit sense pin. Connect

a resistor R

OCSET

from this pin to

the drain of the external high-side

N-MOSFET. R

OCSET

, an internal

200µA current source (I

OCSET

),

and the upper N-MOSFET onresistance (R

DS(ON)

) set the overcurrent trip point according to the

following equation:

I

I R

R

PEAK

OCSET OCSET

DS(ON)

=

×

Page 6

AIC1341

6

Pin 15: PGND: Driver power GND pin. PGND

should be connected to a low

impedance ground plane in close

to lower N-MOSFET source.

Pin 16: LGATE: Lower N-MOSFET gate drive pin.

n

TYPICAL PERFORMANCE CHARACTERISTICS

U

GATE

L

GATE

U

GATE

L

GATE

Fig.1 The gate drive waveforms

FAULT

SS

10A/div

Inductor Current

Over Load

Applied

VOUT1=3.5V

VOUT1=1.3V

V

OUT1

=2V

SS

Fig.2 Over-Current Operation on Inductor Fig.3 Soft start initiates PWM Output

Page 7

AIC1341

7

n

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

V

OUT1

5A to 12A Load Step

2.0V

DC

V

OUT3 (

2mV/div

)

1A to 2A Load Step

Fig.4 Transient Response of PWM Output Fig.5 Transient Response of Linear Controller

n

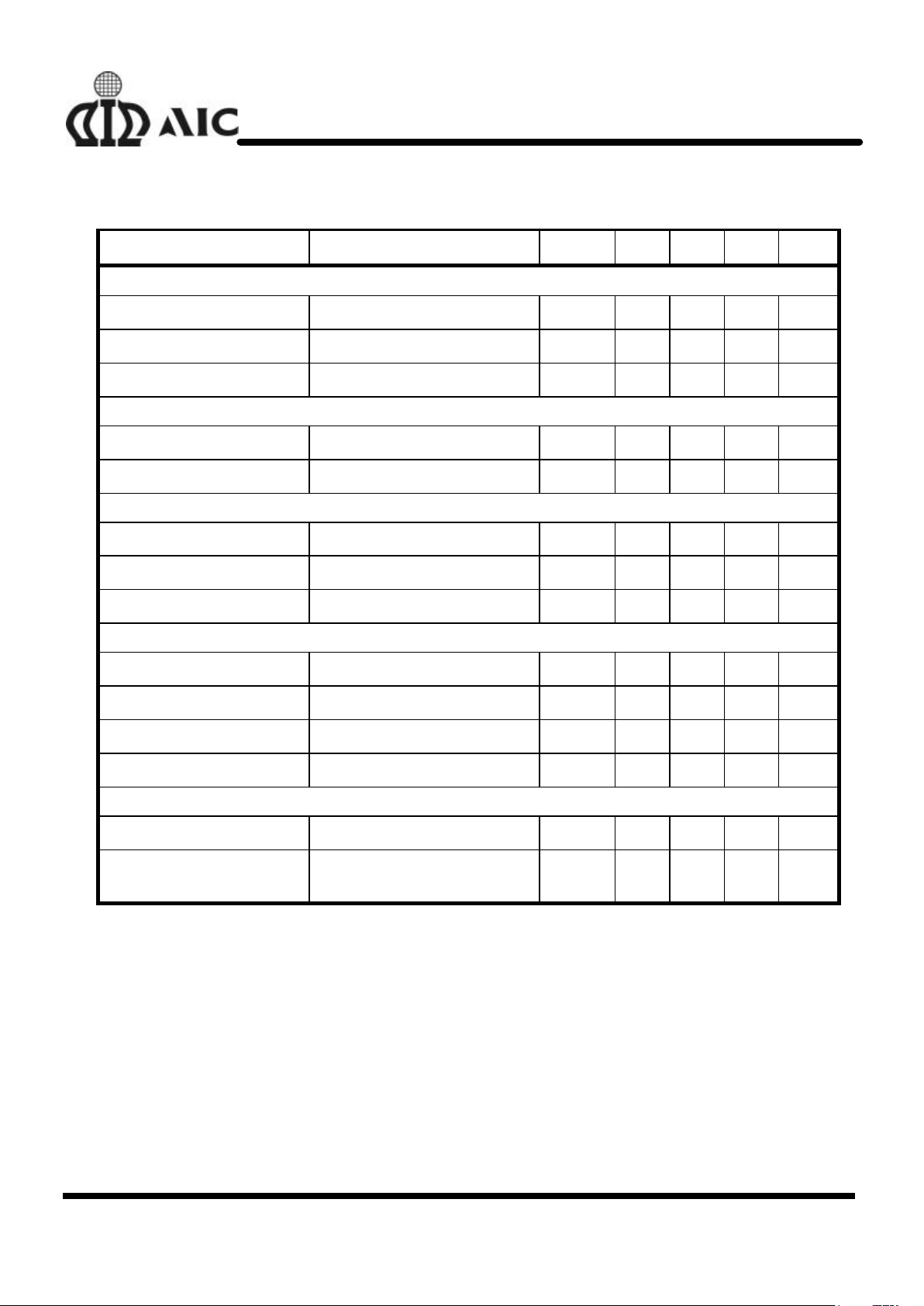

BLOCK DIAGRAM

+

+

++

+

+

+

+

+

+

SSSS

POR

5V

-

+

3.6V

QRS

QRS

-

+0.2V

5V

SD

POR

2.6V

COUNT 3

VIN2

VCC

1.3V

200uA

9.5V

FB2

GATE2

OCSET

COMP1

R

R

QS

1.3V

FB3

OSCILLATOR

GATE CONTROL

SS

SLOW DISCHARGE

FAST DISCHARGE

20uA

10uA

ERROR AMP

PWM COMP

200KHz

70K

4V

SS

INHIBIT

LUV

OC1

LUV

OC1

PHASE

UGATE

VCC

PGND

LGATE

VCC

0.3V

1.26V

FB1

GATE3

GND

Page 8

AIC1341

8

n

DESCRIPTION

The AIC1341 is designed for applications with

multiple voltage demand. This IC has one PWM

controller and two linear controllers. The PWM

controller is designed to regulate the voltage

(V

OUT1

) by driving 2 MOSFETs (By U

GATE

and

L

GATE

) in a synchronous rectified buck converter

configuration. The voltage is regulated to a level,

which is decided by a resistor devide network.

The Power-On Reset (POR) function continually

monitors the input supply voltage +12V at VCC

pin, the 5V input voltage at OCSET pin, and the

3.3V input at VIN2 pin. The POR function initiates

soft-start operation after all three input supply

voltage exceeds their POR thresholds.

Soft-Start

The POR function initiates the soft-start sequence.

Initially, the voltage on SS pin rapidly increases to

approximate 1V. Then an internal 10µA current

source charges an external capacitor (CSS) on the

SS pin to 4V. As the SS pin voltage slews from

1V to 4V, the PWM error amplifier reference input

(Non-inverting terminal) and output (COMP1 pin) is

clamped to a level proportional to the SS pin voltage. As the SS pin voltage slew from 1V to 4V,

the output clamp generates PHASE pulses of increasing width that charge the output capacitors.

Additionally both linear regulator’s reference inputs are clamped to a voltage proportional to the

SS pin voltage. This method provides a controlled

output voltage smooth rise.

Fig.3 shows the soft-start sequence for the typical

application. The internal oscillator’s triangular

waveform is compared to the clamped error amplifier output voltage. As the SS pin voltage increases, the pulse width on PHASE pin increases.

The interval of increasing pulse width continues

until output reaches sufficient voltage to transfer

control to the input reference clamp.

Each linear output (V

OUT2

and V

OUT3

) initially

follows a ramp. When each output reaches suffi-

cient voltage the input reference clamp slows the

rate of output voltage rise.

Over-Current Protection

All outputs are protected against excessive overcurrent. The PWM controller uses upper

MOSFET’s on-resistance, R

DS(ON)

to monitor the

current for protection against shorted outputs.

Both the linear regulator and controller monitor

FB2 and FB3 for under-voltage to protect against

excessive current.

When the voltage across Q1 (ID•R

DS(ON)

) ex-

ceeds the level (200µA•R

OCSET

), this signal inhibit all outputs. Discharge soft-start capacitor

(Css) with 10µA current sink, and increments the

counter. Css recharges and initiates a soft-start

cycle again until the counter increments to 3. This

sets the fault latch to disable all outputs. Fig. 2

illustrates the over-current protection until an over

load on OUT1.

Should excessive current cause FB2 or FB3 to fall

below the linear under-voltage threshold, the LUV

signal sets the over-current latch if Css is fully

charged. Cycling the bias input power off then on

reset the counter and the fault latch.

The over-current function for PWM controller will

trip at a peak inductor current (I

PEAK

) determined

by:

I

I R

R

PEAK

OCSET OCSET

DS(ON)

=

×

The OC trip point varies with MOSFET’s temperature. To avoid over-current tripping in the normal

operating load range, determine the R

OCSET

resis-

tor from the equation above with:

1. The maximum R

DS(ON)

at the highest junction.

2. The minimum I

OCSET

from the specification table.

3. Determine I

PEAK

> I

OUT(MAX)

+ (inductor ripple

current) /2.

Page 9

AIC1341

9

Shutdown

Compatible with the TTL logic level, by holding the

SD (pin3) pin low will activate the controller. If

connecting a resistor to ground, make sure the

resistor is less than 4.7K Ω for normal operation.

Layout Considerations

Any inductance in the switched current path generates a large voltage spike during the switching

interval. The voltage spikes can degrade efficiency,

radiate noise into the circuit, and lead to device

over-voltage stress. Careful component selection

and tight layout of critical components, and short,

wide metal trace minimize the voltage spike.

1) A ground plane should be used. Locate the

input capacitors (CIN) close to the power

switches. Minimize the loop formed by CIN,

the upper MOSFET (Q1) and the lower

MOSFET (Q2) as possible. Connections

should be as wide as short as possible to

minimize loop inductance.

2) The connection between Q1, Q2 and output

inductor should be as wide as short as practical. Since this connection has fast voltage

transitions will easily induce EMI.

3) The output capacitor (C

OUT

) should be located as close the load as possible. Because

minimize the transient load magnitude for high

slew rate requires low inductance and resistance in circuit board

4) The AIC1341 is best placed over a quiet

ground plane area. The GND pin should be

connected to the groundside of the output capacitors. Under no circumstances should

GND be returned to a ground inside the CIN,

Q1, Q2 loop. The GND and PGND pins

should be shorted right at the IC. This help to

minimize internal ground disturbances in the

IC and prevents differences in ground potential

from disrupting internal circuit operation.

5) The wiring traces from the control IC to the

MOSFET gate and source should be sized to

carry 1A current. Locate C

OUT2

close to the

AIC1341 IC.

6) The Vcc pin should be decoupled directly to

GND by a 1µF ceramic capacitor, trace

lengths should be as short as possible.

A multi-layer printed circuit board is recommended. Figure 6 shows the connections of the

critical components in the converter. The CIN and

C

OUT

could each represent numerous physical capacitors. Dedicate one solid layer for a ground

plane and make all critical component ground

connections with vias to this layer.

PWM Output Capacitors

The load transient for the microprocessor core requires high quality capacitors to supply the high

slew rate (di/dt) current demand.

The ESR (equivalent series resistance) and ESL

(equivalent series inductance) parameters rather

than actual capacitance determine the buck capacitor values. For a given transient load magnitude, the output voltage transient change due to

the output capacitor can be note by the following

equation:

∆ ∆

∆

∆

V ESR I ESL

I

T

OUT OUT

OUT

= × + × , where

∆

I

OUT is transient load current step.

Page 10

AIC1341

10

+

+

+

V

OUT

C

OUT

Q1

+3.3V

IN

+5V

IN

L

OUT

GATE3

C

IN

Q2

Css

SS

GATE2

PGND

LGATE

PHASE

UGATE

OCSETVIN2

GND

VCC

+12V

+

+

Q3

V

OUT3

C

OUT3

Power Plane Layer

Circuit Plane Layer

Via Connection to Ground Plane

+

Q4

V

OUT2

C

OUT2

Fig.6 Printed circuit board power planes and islands

After the initial transient, the ESL dependent term

drops off. Because the strong relationship between output capacitor ESR and output load transient, the output capacitor is usually chosen for

ESR, not for capacitance value. A capacitor with

suitable ESR will usually have a larger capacitance value than is needed for energy storage.

A common way to lower ESR and raise ripple current capability is to parallel several capacitors. In

most case, multiple electrolytic capacitors of

small case size are better than a single large

case capacitor.

Output Inductor Selection

Inductor value and type should be chosen based

on output slew rate requirement, output ripple requirement and expected peak current. Inductor

value is primarily controlled by the required current

response time. The AIC1341 will provide either 0%

or 85% duty cycle in response to a load transient.

The response time to a transient is different for the

application of load and remove of load.

t

L I

V V

RISE

OUT

IN OUT

=

×−∆

, t =

L I

V

FALL

OUT

OUT

×∆

.

Where

∆

I

OUT is transient load current step.

In a typical 5V input, 2V output application, a 3µH

inductor has a 1A/µS rise time, resulting in a 5µS

delay in responding to a 5A load current step. To

optimize performance, different combinations of

input and output voltage and expected loads may

require different inductor value. A smaller value of

inductor will improve the transient response at the

expense of increase output ripple voltage and inductor core saturation rating.

Peak current in the inductor will be equal to the

maximum output load current plus half of inductor

ripple current. The ripple current is approximately

equal to:

Page 11

AIC1341

11

I =

(V V ) V

L V

RIPPLE

IN OUT OUT

IN

−

×

× ×f

;

f = 200KHz oscillator frequency.

The inductor must be able to withstand peak current without saturation, and the copper resistance

in the winding should be kept as low as possible

to minimize resistive power loss

Input Capacitor Selection

Most of the input supply current is supplied by the

input bypass capacitor, the resulting RMS current

flow in the input capacitor will heat it up. Use a

mix of input bulk capacitors to control the voltage

overshoot across the upper MOSFET. The ceramic capacitance for the high frequency decoupling should be placed very close to the upper

MOSFET to suppress the voltage induced in the

parasitic circuit impedance. The buck capacitors

to supply the RMS current is approximate equal

to:

I (1 D) D I

112V D

f L

RMS

2

OUT

IN

2

= − × × + ×

×

×

, where D

V

V

OUT

IN

=

The capacitor voltage rating should be at least

1.25 times greater than the maximum input voltage.

PWM MOSFET Selection

In high current PWM application, the MOSFET

power dissipation, package type and heatsink are

the dominant design factors. The conduction loss

is the only component of power dissipation for the

lower MOSFET, since it turns on into near zero

voltage. The upper MOSFET has conduction loss

and switching loss. The gate charge losses are

proportional to the switching frequency and are

dissipated by the AIC1341. However, the gate

charge increases the switching interval, tSW, which

increase the upper MOSFET switching losses.

Ensure that both MOSFETs are within their

maximum junction temperature at high ambient

temperature by calculating the temperature rise

according to package thermal resistance specifications.

P I R D

I V t f

2

UPPER OUT

2

DS(ON)

OUT IN SW

= × × +

× × ×

P I R D)LOWER OUT

2

DS(ON)= × × −(1

The equations above do not model power loss due

to the reverse recovery of the lower MOSFET’s

body diode.

The R

DS(ON)

is different for the two previous equations even if the type devices is used for both.

This is because the gate drive applied to the upper

MOSFET is different than the lower MOSFET.

Logic level MOSFETs should be selected based

on on-resistance considerations, R

DS(ON)

should

be chosen base on input and output voltage, allowable power dissipation and maximum required

output current. Power dissipation should be calculated based primarily on required efficiency or

allowable thermal dissipation.

Rectifier Schottky diode is a clamp that prevent

the loss parasitic MOSFET body diode from conducting during the dead time between the turn off

of the lower MOSFET and the turn on of the upper

MOSFET. The diode’s rated reverse breakdown

voltage must be greater than twice the maximum

input voltage.

Linear Controller MOSFET Selection

The power dissipated in a linear regulator is :

)V(VIP OUTIN2 OUTLINEAR −×=

Select a package and heatsink that maintains

junction temperature below the maximum rating

Page 12

AIC1341

12

while operation at the highest expected ambient

temperature.

Linear Output Capacitor

The output capacitors for the linear controller

provide dynamic load current. The linear controller

uses dominant pole compensation integrated in

the error amplifier and is insensitive to output capacitor selection. C

OUT2

and C

OUT3

should be se-

lected for transient load regulation.

Notes

V

OUT1

- The PWM output

V

OUT2

- The linear controller dominated by FB2,

GATE2 and VIN2

V

OUT3

- The linear controller dominated by FB3

and

GATE3

All the designators mentioned above are refering

to the TYPICAL APPLICATION CIRCUIT in previous page.

Page 13

AIC1341

13

n

APPLICATION CIRCUIT

+

+

UGATE

PHASE

VIN2

LGATE

GATE3

PGNDFB3

GATE2

FB2

COMP1

SS

GND

+5VIN

VCC

+12VIN

15

OCSET

4

7

11

8

6

2.5V

3.3V

VOUT2

VOUT3

+5.0VIN

12

13

16

1

2

14

14

5V OUT

+

5

GND

FB1

3

SD

10

+

+5.0VIN

1000µF *5

0.1µF

1000µF*2

6030L

6030L

2K

24K

8.2K

91K

1000pF

33pF

3.9K

2.4K

2.4K

2.4K

1µH

7µH

1000pF

10

0.1µF

1µF

6030L

6030L

AIC1341CS

Circuit 1 Multiple Voltage Power application Circuit

Page 14

AIC1341

14

n

PACKAGE DIMENSIONS

l 16 LEAD PLASTIC SO (300 mil) (unit: mm)

SYMBOL MIN MAX

A 2.35 2.65

A1 0.10 0.30

B 0.33 0.51

C 0.23 0.32

D 10.10 10.50

E 7.40 7.60

e 1.27(TYP)

H 10.00 10.65

HE

e

B

c

A

A1

D

L L 0.40 1.27

Loading...

Loading...