Page 1

EP

388

EP-RELAYS

HIGH V OL T AGE AND

CURRENT CUT-OFF

CAPACITY IN A

COMPACT PACKAGE

150A 2 Form A

150A 1 Form A

60A

FEATURES

• Control of large voltages and currents

The relays have a sealed construction

that is filled with a hydrogen gas compound, and use a permanent magnet to

establish a magnetic path for the arc. This

allows them to switch high-level DC voltages of up to 400V DC.

• Compact size and light weight

The capsule contact construction is filled

with a gas that has excellent thermal dissipation and insulation characteristics.

Because of this we have been able to reduce the contact gap to one tenth that of

conventional relays, and produce a compact and light design.

• No arc space is required: size including arc space 1/9 (compared to conventional contactors)

The arc is not exposed to the outside,

therefore, no arc space is not required.

• Safety construction

The arc is not exposed, therefore, the

contactor is explosion proof and intrinsically safe.

• Quiet: operation noise 1/4 (compared

to conventional contactors).

Along with the above-mentioned miniaturization, the operation noise has been reduced to 70dB, and, in addition, the

operation noise remains unchanged

when a current of 1000A or more is interrupted.

• High contact reliability

The contact part is hermetically sealed,

hence the contact resistance remains stable regardless of the ambient conditions.

• Mounting direction is not specified

The weight of the movable parts is light,

and also the restoring force is large,

hence the contactor is relatively unaffected by gravity.

• Line-up of indicator types (150A T ype

only)

1 Form A and 1 Form B types with indicators for detecting welding of the main contacts are available.

• 12 and 24V DC coil voltage types are

available.

• Screw terminal blocks for easy wiring.

SPECIFICATIONS

Contact

Notes:

Same specifications as the 12 V type.

#1

Condition: Nominal switching 100cycles, each cut off 2,500A

#2

Conditions: Varistor used for coil surge absorption. Note: if a diode is used the life will be lower.

Type 150A type 60A type

Arrangement 1 Form A, 2 Form A 1 Form A

Rating

Nominal switching capacity

(resistive load)

150A 400V DC

150A 277V AC

60A 400V DC

60A 277V AC

Short term current 300A (10min)(harness wire: 40mm

2

) 120A (15min)(harness wire: 15mm

2

)

Max. cut-off current 2,500A 300V DC (3 cycles)

#1

600A 300V DC (5 cycles)

Overload opening/closing rating 600A 400V DC (Min. 1,000 cycles) 180A 400V DC (Min. 100 cycles)

#2

Reverse cut-off current –200A 200V DC (Min. 500 cycles) –60A 200V DC (Min. 1,000 cycles)

#2

Contact voltage drop (Max.) 0.1V (When current [is 150A per 1] contact set) 0.1V (When current [is 60A per 1] contact set)

Nominal operating power 35W (Inrush, approx 0.1s) 5W ( Stable ) Max. 5W

Expected life

(min.

operations)

Mechanical 10

5

2 ×

10

5

Electrical

3 × 10

3

150A 400V DC

(L/R

&

1ms)

3 × 10

3

60A 400V DC

(L/R

&

1ms

#2

)

Page 2

EP

389

Characteristics

Remarks:

*

1

Measurement at same location as "Initial breakdown voltage" section.

*

2

Detection current: 10mA.

*

3

Nominal voltage applied to the coil, excluding bounce time.

*

4

Nominal voltage applied to the coil.

*

5

Half-wave pulse of sine wave: 11 ms; detection time: 10 µ s.

*

6

Half-wave pulse of sine wave: 6 ms.

*

7

Detection time: 10 µ s .

*

8

3 directions, each 4 hours.

*

9

Storage: Max.85 ° C 185 ° F.

Initial insulation resistance Min. 100 M Ω (at 500 V DC)*

1

Initial breakdown voltage

Between open contacts AC 2,500 Vrms for 1 min.*

2

Between contact and coil AC 2,500 Vrms for 1 min.*

2

Operate time (at 20 ° C) (at nominal voltage) Max. 50ms*

3

Reset time (without diode) (at 20 ° C) (at nominal voltage) Max. 30ms*

4

Shock resistance

Functional Min. 196 m/s

2

{20 G}*

5

Destructive Min. 490 m/s

2

{50 G}*

6

Vibration resistance

Functional 43 m/s

2

{4.4 G} 10 to 200Hz*

7

Destructive 43 m/s

2

{4.4 G} 10 to 200 Hz*

8

Conditions for operation,

transport and storage

(Not freezing and condensing at low

temperature)

Ambient temperature

–40 ° C to +80 ° C*

9

–40 ° F to +176 ° F

Humidity 5 to 85% R.H.

Unit weight

150 A 1 Form A: 600 g 21.16oz

150 A 2 Form A: 1,100 g 38.80oz

60 A: 340 g 12.00oz

Indicator ratings

Note: Indicator type is only available for the 150 A type.

Arrangement 1 Form A 1 Form B

Material Gold-clad

Rating(resistive load) 0.1 A 30 V DC

Contact resistance Max. 100 m Ω

TYPICAL APPLICATIONS

• UPS (uninterruptible power supplies)

• Solar power generation systems

• Unmanned transport carts

• Battery inspection and testing equipment

• Welding equipment

ORDERING INFORMATION

Product Name

EP

Contact arrangement Contact rating Coil voltage

1: 1 Form A

2: 2 Form A

5: 150A

6: 60A

0: without indicator contact

1: a contact (150A type only)

3: b contact (150A type only)

Indicator contact

arrangement

12: 12V DC

24: 24V DC

Ex. A EP 1 5 0 12

Page 3

EP

390

TYPES AND COIL DATA (at 20 ° C 68 ° F)

Note: *Same coil data as Indicator type. When using a DC power supply use one that has a leeway of at least 150% current capacity.

Part No.

Coil voltage,

V DC

Pick-up voltage,

V DC (max.)

(at 20 ° C)

Drop-out voltage,

V DC (min.)

(at 20 ° C)

Nominal coil

current, mA ( ± 10%)

(at 20 ° C)

Operating power, W

(12 V DC, at 20 ° C)

Max. allowable

voltage, V DC

AEP25012*

12 V DC 9 V DC 1 V DC

2.8 A

(at peak)*

35W(Inrush,

approx. 0.1S)

5W(Stable)

16 V DCAEP15012*

AEP16012 0.415 A Max. 5W

AEP25024*

24 V DC 18 V DC 2 V DC

1.9 A

(at peak)*

35W(Inrush,

approx. 0.1S)

Max. 5W (1 F orm A)

Max. 6W (2 F orm A)

32 V DC

AEP15024*

2.2 A

(at peak)*

AEP16024 0.208 A Max. 5W

Packing quantity

Types Inner Outer

150A 2 Form A 1pc. 5pcs.

150A 1 Form A 1pc. 10pcs.

60A 1 Form A 1pc. 20pcs.

SPARE PARTS

Installing parts Part No. Packing Quantity

M8 nut with washer for

150A type

AEV801 2pcs.

M5 screw for 60A type AEV802 2pcs.

M4 screw for 30A type AEV803 2pcs.

Bus bar for 60A type AEV804 1pc.

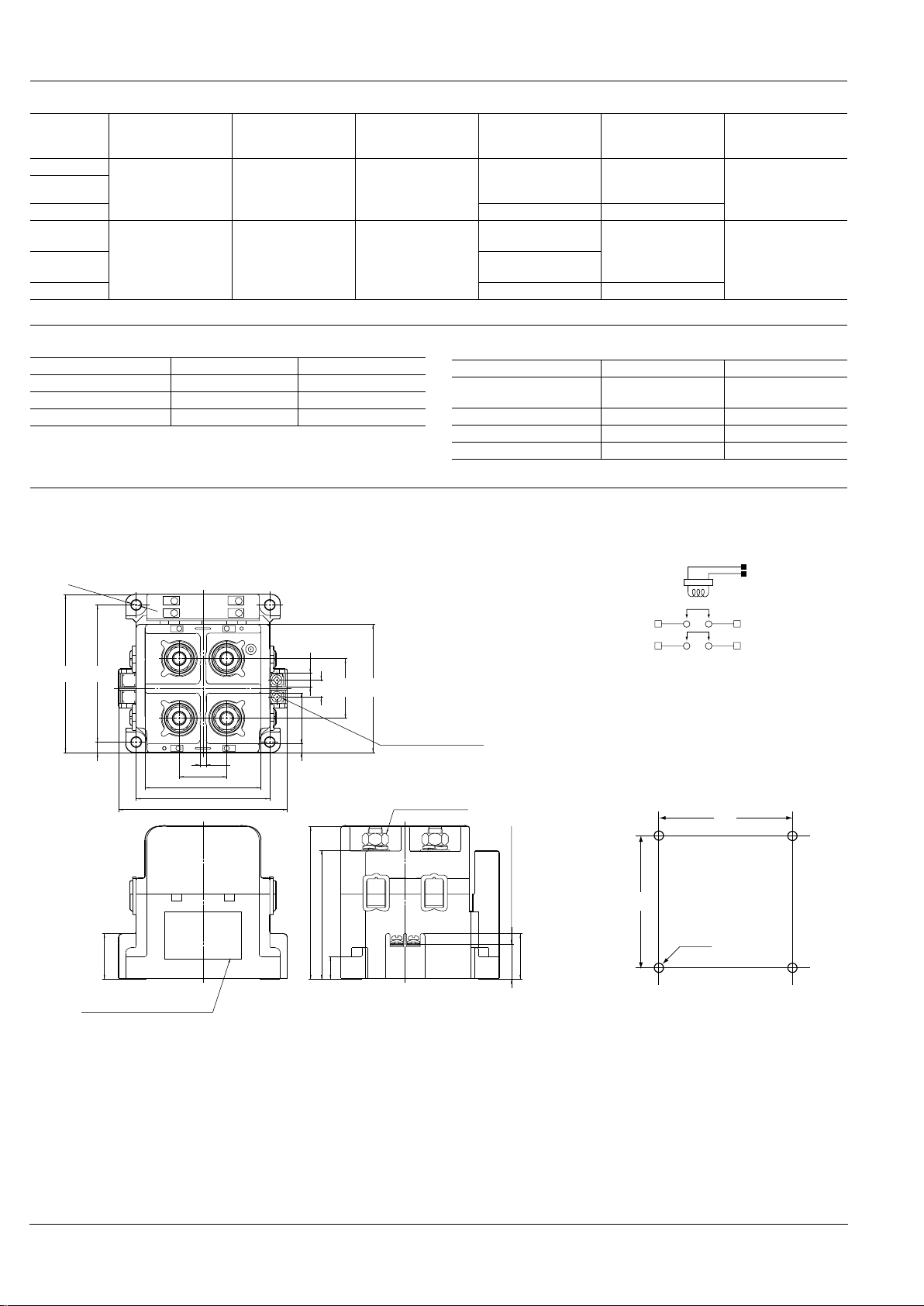

DIMENSIONS

150A 2 Form A

3.5

.138

27.0 1.063

66.0 2.598

96.0 3.780

±0.2

76.0

±.008

2.992

5

.197

29.0

1.142

7.7

.303

Coil input terminal (M3.5)

5 terminal: input (+) side

6 terminal: input (–) side

6

.236

26.0

1.024

Plate (Part No., rating,

schematic and Lot No.)

20.0 .787

(terminal height)

26.0

1.024

13.0

.512

73.5 2.894

(terminal height)

87.1

3.429

M8 nut; AEV801

3

-

+

1

4

2

-

+

3

-

4

+

6

7

8

9

9

X

Y

Z

1

9

2

3

4

5

65

2

-

+

1

87

4- 5.5

φ

±0.1

4- .217

φ

±.004

±0.2

78.0

±.008

3.071

90.0

3.543

9.5

.374

34.0

1.339

73.0

2.874

Schematic (TOP VIEW)

Mounting dimensions

6: Coil (–)

5: Coil (+)

2–

4+

1+

3–

Both input and load sides have polarities (+) and (–).

76

2.992

4- .217

φ

4- 5.5

φ

78

3.071

General tolerance:

less than 10 .394 ± 0.3 ± .012

10 .394 to 50 1.969 ± 0.6 ± .024

more than 50 1.969 ± 1.0 ± .039

mm inch

Page 4

EP

391

150A 2 Form A (Indicator Type)

3.5

.138

27.0 1.063

66.0 2.598

96.0 3.780

±0.2

76.0

±.008

2.992

5

.197

29.0

1.142

26.0

1.024

13.0

.512

87.1

3.429

3

+

1

4

2

-

+

3

-

4

+

6

7

8

9

9

X

Y

Z

1

9

2

3

4

5

65

2

-

+

1

87

9.5

.374

7.7

.303

6

.236

78.0

±0.2

3.071

±.008

90.0

3.543

26.0

1.024

Coil input terminal (M3.5)

5 terminal: input (+) side

6 terminal: input (–) side

Plate (Part No., rating,

schematic and Lot No.)

20.0 .787

(terminal height)

20.0 .787

(terminal height)

73.5 2.894

(terminal height)

M8 nut; AEV801

4- 5.5

φ

±0.1

4- .217

φ

±.004

Indicator input

terminal (M3.5)

7 terminal: NO or NC

8 terminal: COM

34.0

1.339

73.0

2.874

Schematic (TOP VIEW)

1 Form A

1 Form B

Mounting dimensions

6: Coil (–)

5: Coil (+)

8: Indicator: COM

7: Indicator: NO

2–

4+

1+

3–

Both input and load sides have polarities (+) and (–).

2–

4+

1+

3–

Both input and load sides have polarities (+) and (–).

6: Coil (–)

5: Coil (+)

8: Indicator: COM

7: Indicator: NC

76

2.992

4- .217

φ

4- 5.5

φ

78

3.071

General tolerance:

less than 10 .394 ± 0.3 ± .012

10 .394 to 50 1.969 ± 0.6 ± .024

more than 50 1.969 ± 1.0 ± .039

150A 1 Form A

3.5

.138

27.0 1.063

64.0 2.520

±0.2

76.0

±.008

2.992

94.0 3.701

19.5

.768

56.0

2.205

7.7

.303

9.5

.374

10.8

.425

6

.236

26.0

1.024

13.0

.512

87.1

3.429

M8 nut; AEV801

21.0

.827

1

+

2

-

1

+

-

2

56

5

6

7

8

9

X

Y

4

3

2

1

Z

99

87

Coil input terminal (M3.5)

5 terminal: input (+) side

6 terminal: input (–) side

Plate (Part No., rating,

schematic and Lot No.)

20.0 .787

(terminal height)

73.5 2.894

(terminal height)

2- 5.5

φ

±0.1

2- .217

φ

±.004

±0.2

44.0

±.008

1.732

29.0

1.142

Schematic (TOP VIEW)

Mounting dimensions

6: Coil (–)

5: Coil (+)

2–1+

Both input and load sides have polarities (+) and (–).

76

2.992

2- .217

φ

2- 5.5

φ

44

1.732

General tolerance:

less than 10 .394 ± 0.3 ± .012

10 .394 to 50 1.969 ± 0.6 ± .024

more than 50 1.969 ± 1.0 ±.039

mm inch

Page 5

EP

392

150A 1 Form A (Indicator Type)

3.5

27.0

64.0

±0.2

76.0

94.0

7.7

.303

9.5

.374

10.8

.425

6

.236

26.0

1.024

13.0

.512

87.1

3.429

1

+

2

-

1

+

-

2

Z

1

3

2

9

4

5

6

7

8

9

X

Y

9

65

21.0

.827

(

9.5

)

(

.374

)

87

Coil input terminal (M3.5)

5 terminal: input (+) side

6 terminal: input (–) side

Plate (Part No., rating,

schematic and Lot No.)

20.0 .787

(terminal height)

73.5 2.894

(terminal height)

2- 5.5

φ

±0.1

2- .217

φ

±.004

Indicator input

terminal (M3.5)

7 terminal: NO or NC

8 terminal: COM

M8 nut; AEV801

17.8

.701

19.5

.768

±0.2

44.0

±.008

1.732

29.0

1.142

56.0

2.205

15.0 .591

(terminal height)

Schematic (TOP VIEW)

1 Form A type

1 Form B type

Mounting dimensions

6: Coil (–)

5: Coil (+)

2–1+

Both input and load sides have polarities (+) and (–).

8: Indicator: COM

7: Indicator: NO

6: Coil (–)

5: Coil (+)

2–1+

Both input and load sides have polarities (+) and (–).

8: Indicator: COM

7: Indicator: NC

76

2.992

2- .217

φ

2- 5.5

φ

44

1.732

General tolerance:

less than 10 .394 ±0.3 ±.012

10 .394 to 50 1.969 ±0.6 ±.024

more than 50 1.969 ±1.0 ±.039

60A

2.5 .098

(17.9) (.705)

45.0 1.772

49.0 1.929

61.0

±0.2

2.402

±.008

76.0 2.992

13

.512

±0.2

26.0

±.008

1.024

30.2

1.189

38.0

1.496

7.7

.303

9.5

.374

6.55

.258

Coil input terminal (M3.5)

M4 screw: AEV803 (built-in)

63.9 2.516

79.9 3.146

M5 screw: AEV802

AEV804 (built-in)

Bus bar (15sq)

:

13.0

.512

71.0

2.795

26.0

1.024

+-

21

56

2- 5.5

φ

±0.1

2- .217

φ

±.004

Plate (Part No., rating,

schematic and Lot No.)

20.0 .787

(terminal height)

62.0 2.441

(terminal height)

Schematic (TOP VIEW)

Mounting dimension

6: Coil

5: Coil

2–1+

Load side has polarities (+) and (–).

61

2.402

26

1.024

2- .217

φ

2- 5.5

φ

General tolerance:

less than 10 .394 ±0.3 ±.012

10 .394 to 50 1.969 ±0.6 ±.024

more than 50 1.969 ±1.0 ±.039

mm inch

Page 6

EP

393

REFERENCE DATA

1-(1) Ambient temperature characteristics

(150 A type)

Sample: AEP15012, 3pcs

1-(2) Ambient temperature characteristics

Sample:AEP16012, 3pcs

2. Max. switching capacity

x

-

x

-

Pick up

voltage

Variation

ratio, %

Drop out

voltage

Ambient

temperature, °C °F

10

8

6

4

2

-40

-40

-20

-4

20

68

-6

-2

-4

-8

-10

60

110

40

74

80

146

0

32

x

-

x

-

40

30

20

10

-40

-40

-20

-4

20

68

-30

-10

-20

-40

60

110

40

74

80

146

0

32

Pick up

voltage

Variation

ratio, %

Drop out

voltage

Ambient

temperature °C °F

Contact voltage, V

Contact current, A

101

100 1000

1000

100

10

1

150A type

DC, AC 400V resistive load

60A type

DC, AC 400V resistive load

3. Switching life curve 4. Cut-off life curve 5. Carrying performance curve

Contact current, A

Life (×10

3

cycle)

10

100 1000

100

10

1

150A type

DC, AC 400V resistive load

60A type

DC, AC 400V resistive load

Cut-off current, A

100

1000

10000

1000

10

100

1

150A type

DC400V resistive load

60A type

DC400V resistive load

Life (cycle)

Carrying current, A

10

100 1000

10

5

10

4

10

100

1000

150A type

(Electric cable 40mm

2

)

60A type

(Electric cable 15mm

2

)

Time (sec)

NOTES

1. When installing the rela y , al ways use

washers to prevent loosening of the

screws.

Tighten each of the screws within the rated ranges given below. Exceeding the

maximum torque may result in breakage.

Mounting is possible in either direction.

• M8 screw (150 A main terminal): 8 to 10

N·m

• M5 screw (150 A, 60 A main unit mounting section): 2.5N·m to 3.6N·m

• M4 screw (60 A main terminal): 1.8 to

2.7 N·m

• M3.5 screw (Input terminal): 0.84 to 1.2

N·m

2. The coils (150 A type) and contacts

(60 A, 150 A) of the relay are polarized,

so follow the instructions in the connection schematic when connecting

the coils and contacts.

Type 150 A has contains a reverse surge

voltage absorption circuit;

therefore a surge protector is not needed.

We recommend installing a surge protector varistor (ZNR) for the 60 A types. A void

using a diode as this may result in decreased cut-off capability.

3. As a general rule, do not use a rela y

if it has been dropped.

4. Avoid mounting the relay in strong

magnetic fields (near a transformer or

magnet) or close to an object that radiates heat.

5. Electrical life

This relay is a high-voltage direct-current

switch. In its final breakdown mode, it ma y

lose the ability to provide the proper cutoff. Theref ore, do not exceed the indicated

switching capacity and life. (Please treat

the relay as a product with limited life and

replace it when necessary.)

In the event that the relay loses cut-off

ability, there is a possibility that burning

may spread to surrounding parts, so configure the layout so that the power is

turned off within one second.

6. Permeation life of internal gas

This relay uses a hermetically encased

contact (capsule contact) with gas inside.

The gas has a permeation life that is affected by the temperature inside the capsule contact (ambient temperature +

temperature rise due to flow of electrical

current). For this reason, make sure the

ambient operating temperature is between –40 and 80°C –40 and +176°F, and

the ambient storage temperature is between –40 and 85°C –40 and +185°F.

7. The case is designed so that it will

not come off with normal handling.

If you remove the case, the relay will not

function as intended, and its performance

cannot be guaranteed.

Page 7

EP

394

8. If the power is turned off and then

immediately on after applying the rated

voltage (current) continuously to the

relay's coil and contact, the resistance

of the coil will increase due to a rise in

the coil temperature. This causes the

pick-up voltage to rise, and possibly

exceed the rated pick-up voltage. In

these circumstances, take measures

such as reducing the load current, limiting the duration of current flow, and

applying a coil voltage higher than the

rated operating voltage (quick start).

9. The coil must only be supplied with

its rated voltage. The v oltage waveform

supplied to the coil should be rectangular.

10. Take steps to ensure that voltages

that exceed the maximum allowed v oltage for a coil are never continuously

applied.

11. Take steps to ensure that the rated

voltage and current values for the contacts are never exceeded.

12. The rated control capacity and life

are given as guides.

The contact life is heavily influenced by

the type of load and other related conditions, and these factors must be giv en due

consideration when using the relay.

13. Main contact ratings in the ratings

apply to when there is a resistive load.

14. If you are using an inductive load (L

load) such that L/R > 1 ms, add surge

protection in parallel with the inductive

load. If this is not done, the electrical

life will decrease and cut-off failure

may occur.

15. When using the 150 A type, mount

it as far away as possible from amateur

wireless transmitters or devices that

may generate large surges. To prevent

malfunctioning due to high emission

levels, it may be neccessary to take

measures for E.M.I., such as adding a

line noise filter or an electromagnetic

shield.

16. Since coil current control is performed, a slight amount of superimposed line noise may be generated in

the input line system. If this noise must

be removed, install a line noise filter.

17. Be careful that foreign matter and

oils do not stick to the main terminal

part. It is likely to cause a terminal part

to give off unusual heat. Use the following specifications for the harness

bus bar that the relay connects to:

• 150A type: nominal cross sectional area:

min. 38mm

2

.

• 60A type: nominal cross sectional area:

min. 14mm

2

.

18. A void excessive load applied to the

terminal in case of installing such as a

bus bar etc., because it might give bad

influence to the opening and closing

performance.

• M8 screw terminal (150A main terminal

part)

Terminal pulling up strength ; Max.100N per

terminal

The up-down rotation torque applied to the

terminal ; Max.15N·m

19. For AC cut-off there is no contact

polarity, but confirm the electrical life

using the actual load. In the case of DC

cut-off the contacts have polarity, so

take due care.

9/1/2000 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

Loading...

Loading...