Page 1

Fast Starting, ±20,000°/sec

F

V

FEATURES

High vibration rejection over wide frequency

Ultrafast startup: 3 ms

Measurement range extendable to ±50,000°/sec

10,000 g powered shock survivability

Ratiometric to referenced supply

5 V single-supply operation

Z-axis (yaw rate) response

−40°C to +105°C operation

Self-test on digital command

Ultrasmall and light (<0.15 cc, <0.5 gram)

Temperature sensor output

RoHS compliant

APPLICATIONS

Sports equipment

Industrial applications

Platform stabilization

High speed tachometry

Vibration Rejecting Rate Gyro

ADXRS649

GENERAL DESCRIPTION

The ADXRS649 is a complete angular rate sensor (gyroscope)

that uses the Analog Devices, Inc., patented high volume BiMOS

surface-micromachining process to make a complete gyro on

one chip. An advanced, differential, quad sensor design rejects

the influence of linear acceleration, enabling the ADXRS649

to offer rate sensing in harsh environments where shock and

vibration are present.

The output signal, RATEOUT (B1, A2), is a voltage proportional

to the angular rate about the axis normal to the top surface of

the package. The output is ratiometric with respect to a provided

reference supply. An external capacitor is used to set the bandwidth. The measurement range is extendable to ±50,000°/sec

by adding an external resistor.

Low power consumption (3.5 mA) enables very low power

consumption, and ultrafast startup (3 ms) allows for quick

power cycling of the gyro. At 10 samples per second, a pair of

CR2032 coin cells can power the ADXRS649 for three months.

A temperature output is provided for compensation techniques.

Two digital self-test inputs electromechanically excite the sensor

to test proper operation of both the sensor and the signal conditioning circuits. The ADXRS649 is available in a 7 mm × 7 mm ×

3 mm CBGA chip scale package.

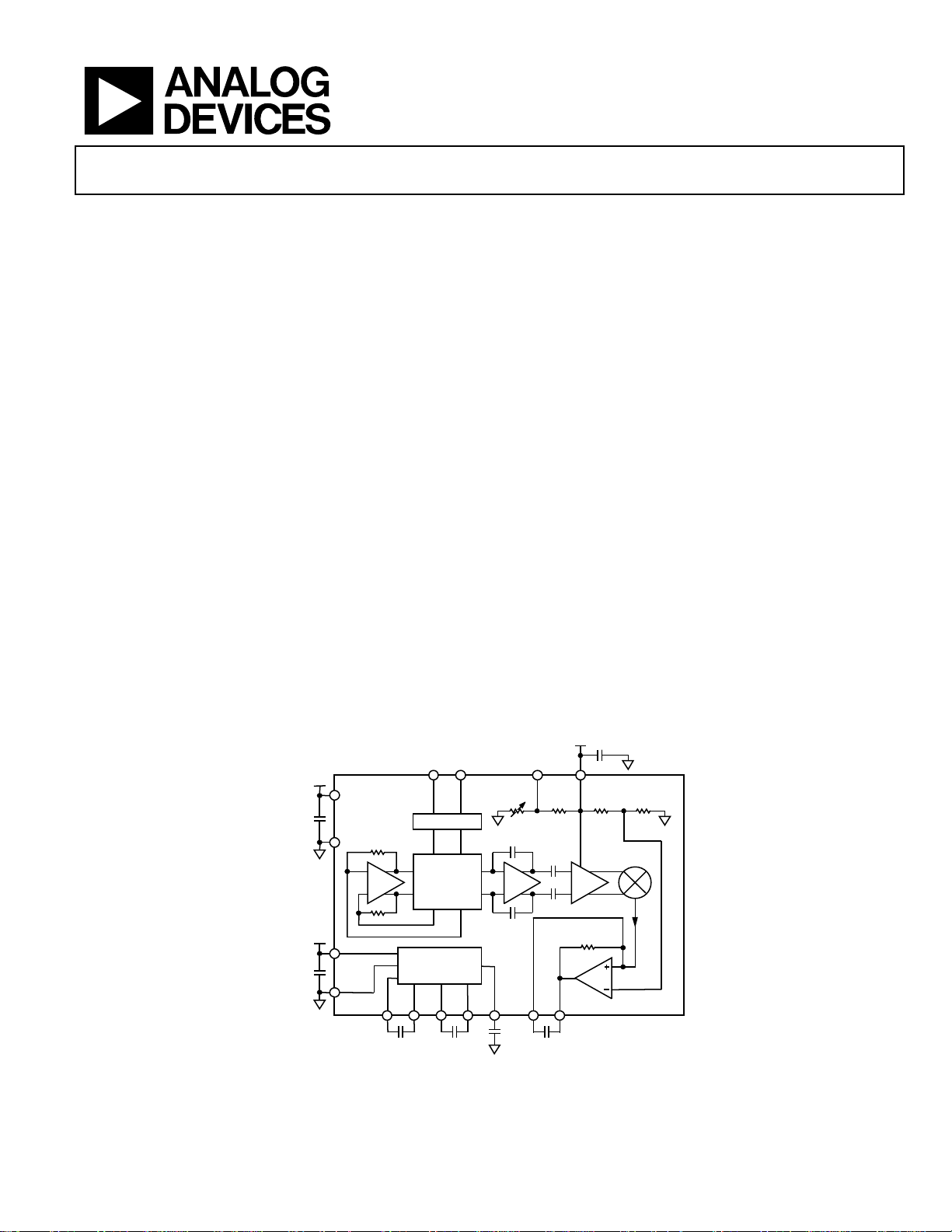

FUNCTIONAL BLOCK DIAGRAM

5V

AV

CC

100nF

AGND

5V

V

DD

100n

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

PGND

DRIVE

CP1

AMP

ST2 ST1

SELF-TEST

MECHANICAL

SENSOR

CHARGE PUMP

AND VOLTAG E

REGULATO R

CP2 CP3

22nF

CP4 CP5

22nF

5

(ADC REF)

TEMP

V

RATIO

25kΩ

25k

Ω

AT 25° C

AC

AMP

SUMJ RATEOUT

2.2nF

C

OUT

VGA

R

OUT

180kΩ ±1%

100nF

ADXRS649

DEMOD

09573-001

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010–2011 Analog Devices, Inc. All rights reserved.

Page 2

ADXRS649

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 4

Rate Sensitive Axis ....................................................................... 4

ESD Caution .................................................................................. 4

Pin Configuration and Function Descriptions ............................. 5

REVISION HISTORY

3/11—Rev. 0 to Rev. A

Changes to Ordering Guide ............................................................ 1

12/10—Revision 0: Initial Version

Typical Performance Characteristics ..............................................6

Theory of Operation .........................................................................9

Setting the Bandwidth ..................................................................9

Temperature Output and Calibration ...................................... 10

Modifying the Measurement Range ........................................ 10

Null Bias Adjustment ................................................................. 10

Self-Test Function ...................................................................... 10

Continuous Self-Test .................................................................. 10

Outline Dimensions ....................................................................... 11

Ordering Guide .......................................................................... 11

Rev. A | Page 2 of 12

Page 3

ADXRS649

SPECIFICATIONS

All minimum and maximum specifications are guaranteed. Typical specifications are not guaranteed.

T

= −40°C to +105°C, VS = AVCC = VDD = V

A

unless otherwise noted.

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

SENSITIVITY1 Clockwise rotation is positive output

Measurement Range2 Full-scale range over specifications range ±20,000 °/sec

Initial and over Temperature

−40°C to +105°C 0.08 0.1 0.12 mV/°/sec

Temperature Drift3 ±2 %

Nonlinearity Best fit straight line 0.1 % of FS

NULL BIAS1

Null Bias −40°C to +105°C 2.4 2.5 2.6 V

Calibrated Null Bias4 −40°C to +105°C ±5 °/sec

Linear Acceleration Effect Any axis 0.1 °/sec/g

Vibration Rectification 40 g rms, 50 Hz to 27 kHz 0.0006 °/sec/g2

NOISE PERFORMANCE

Rate Noise Density TA = 25°C 0.25 °/sec/√Hz

T

A

Resolution Floor TA = 25°C, 1 minute to 1 hour in-run 200 °/hr

FREQUENCY RESPONSE

Bandwidth

5

±3 dB user adjustable up to specification 2000 Hz

Sensor Resonant Frequency 16 18 20 kHz

SELF-TEST1

ST1 RATEOUT Response

ST1 pin from Logic 0 to Logic 1 −1300 °/sec

ST2 RATEOUT Response ST2 pin from Logic 0 to Logic 1 1300 °/sec

ST1 to ST2 Mismatch6

Logic 1 Input Voltage 3.3 V

Logic 0 Input Voltage 1.7 V

Input Impedance To common 40 50 100 kΩ

TEMPERATURE SENSOR1

V

at 25°C Load = 10 MΩ 2.3 2.4 2.5 V

OUT

Scale Factor7 T

Load to V

S

A

25 kΩ

Load to Common 25 kΩ

TURN-ON TIME4 Power on to ±90% of final output, CP5 = 2.2 nF 3 ms

OUTPUT DRIVE CAPABILITY

Current Drive For rated specifications 200 μA

Capacitive Load Drive 1000 pF

POWER SUPPLY

Operating Voltage (VS) 4.75 5.00 5.25 V

Quiescent Supply Current 3.5 mA

TEMPERATURE RANGE

Specified Performance −40 +105 °C

1

Parameter is linearly ratiometric with V

2

Measurement range is the maximum range possible, including output swing range, initial offset, sensitivity, offset drift, and sensitivity drift at 5 V supplies.

3

From +25°C to −40°C or +25°C to +105°C.

4

Based on characterization.

5

Adjusted by external capacitor, C

6

Self-test mismatch is described as (ST2 + ST1)/((ST2 − ST1)/2).

7

Scale factor for a change in temperature from 25°C to 26°C. V

.

RATIO

. Reducing bandwidth below 0.01 Hz does not result in further noise improvement.

OUT

= 5 V, angular rate = 0°/sec, bandwidth = 80 Hz (C

RATIO

= 0.01 μF), I

OUT

= 100 μA, ±1 g,

OUT

= 105°C 0.4 °/sec/√Hz

= 25°C, V

= 5 V 9 mV/°C

RATIO

is ratiometric to V

TEMP

. See the section for more information. Temperature Output and Calibration

RATIO

±2

%

Rev. A | Page 3 of 12

Page 4

ADXRS649

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Acceleration (Any Axis, 0.5 ms)

Unpowered 10,000 g

Powered 10,000 g

VDD, AV

CC

V

AVCC

RATIO

−0.3 V to +6.0 V

ST1, ST2 AVCC

Output Short-Circuit Duration

Indefinite

(Any Pin to Common)

Operating Temperature Range −55°C to +125°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under the Absolute Maximum

Ratings may cause permanent damage to the device. This is a

stress rating only; functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Drops onto hard surfaces can cause shocks of greater than

10,000 g and can exceed the absolute maximum rating of the

device. Care should be exercised in handling to avoid damage.

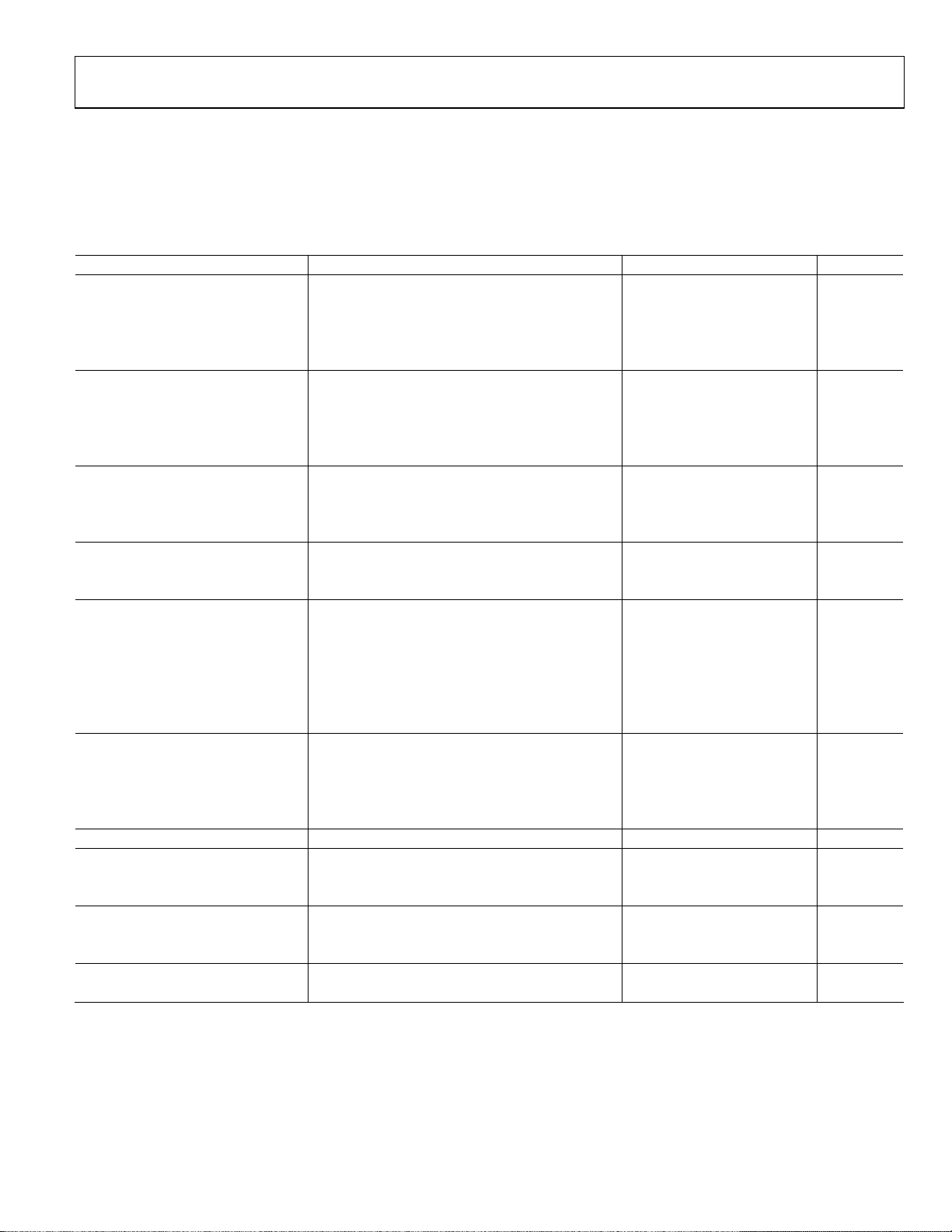

RATE SENSITIVE AXIS

The ADXRS649 is a z-axis rate-sensing device (also called a yaw

rate-sensing device). It produces a positive going output voltage

for clockwise rotation about the axis normal to the package top,

that is, clockwise when looking down at the package lid.

RATE

AXIS

LONGIT UDINAL

AXIS

ABCD G

A1

LATERAL AXIS

Figure 2. RATEOUT Signal Increases with Clockwise Rotation

EF

+

1

A

VCC=5V

7

V

GND

RATIO

RATEOUT

/2

4.75V

RATE IN

0.25V

09573-002

ESD CAUTION

Rev. A | Page 4 of 12

Page 5

ADXRS649

A

V

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

NC

CP3CP5

SUMJ

CP4

CP1

CP2

AV

CC

RATEOUT

7

6

5

4

3

2

1

9573-003

V

DD

RATIO

PGND

ST1

ST2

TEMP

GND

GF E D C BA

NOTES

1. NC = NO CO NNECT. DO NOT CONNE CT TO T HIS PIN.

Figure 3. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

D6, D7 CP5 High Voltage Filter Capacitor, 2.2 nF.

A6, B7 CP4 Charge Pump Capacitor, 22 nF.

C6, C7 CP3 Charge Pump Capacitor, 22 nF.

A5, B5 CP1 Charge Pump Capacitor, 22 nF.

A4, B4 CP2 Charge Pump Capacitor, 22 nF.

A3, B3 AVCC Positive Analog Supply.

B1, A2 RATEOUT Rate Signal Output.

C1, C2 SUMJ Output Amplifier Summing Junction.

D1, D2 NC Do not connect to these pins.

E1, E2 V

Reference Supply for Ratiometric Output.

RATIO

F1, G2 AGND Analog Supply Return.

F3, G3 TEMP Temperature Voltage Output.

F4, G4 ST2 Self-Test for Sensor 2.

F5, G5 ST1 Self-Test for Sensor 1.

G6, F7 PGND Charge Pump Supply Return.

E6, E7 VDD Positive Charge Pump Supply.

Rev. A | Page 5 of 12

Page 6

ADXRS649

R

A

A

A

A

A

TYPICAL PERFORMANCE CHARACTERISTICS

N > 1000 for all histograms, unless otherwise noted.

0

0

60

–3

–6

–9

TE RESPONSE (d B)

–12

–15

–18

0.1 11

FREQUENCY (kHz)

–30

–60

–90

PHASE (Deg rees)

–120

–150

–180

0

09573-004

Figure 4. Typical Rate and Phase Response vs. Frequency

(C

= 470 pF with a Series RC Low-Pass Filter of 3.3 kΩ and 22 nF)

OUT

4.0

3.5

3.0

2.5

2.0

TE OUT (V)

R

1.5

1.0

0.5

50

40

TION (%)

30

POPUL

20

10

0

2.401

2.434

2.467

2.500

2.533

2.566

2.418

2.451

2.484

2.517

NULL BIAS (V)

2.550

2.583

2.599

09573-007

Figure 7. Null Bias at 25°C

60

50

40

TION (%)

30

POPUL

20

10

0

0 0. 5 1.0 1.5 2.0 2.5 3.0 3.5 4. 0 4.5 5.0

TIME (ms)

Figure 5. Typical Start-Up Behavior at RATEOUT

10000

1000

DEGREES PER HOUR (°)

100

0.01 0.1 1 10 100 1000

TIME (Seconds)

Figure 6. Typical Root Allan Deviation at 25°C vs. Averaging Time

09573-005

09573-006

Rev. A | Page 6 of 12

0

0.081 0.085 0.089 0.093 0.097 0.101 0.105 0.109 0.113 0.117

SENSITIVITY (mV/°/sec)

Figure 8. Sensitivity at 25°C

100

80

60

TION (%)

40

POPUL

20

0

–100

–300

–500

–900

–1100

–1300

–1500

–700

DEGREES PER SECOND (°)

–1700

Figure 9. ST1 Output Change at 25°C (V

RATIO

–1900

= 5 V)

–2100

–2300

09573-008

09573-009

Page 7

ADXRS649

A

A

A

A

z

100

80

60

TION (%)

40

POPUL

20

0

100

300

500

900

1100

1300

1500

700

DEGREES PER SECOND (°)

1700

Figure 10. ST2 Output Change at 25°C (V

70

60

50

40

TION (%)

30

POPUL

20

10

0

–5–4–3–2–1012345

Figure 11. Self-Test Mismatch at 25°C (V

70

MISMATCH (%)

RATIO

RATIO

1900

= 5 V)

2100

= 5 V)

2300

09573-010

09573-011

30

25

20

TION (%)

15

POPUL

10

5

0

2.35 2.37 2.39 2.41 2.43 2.45 2. 47 2.49 2.51 2.53 2.55

OUTPUT (V)

V

TEMP

Figure 13. V

3.3

3.1

2.9

2.7

2.5

OUTPUT (V)

2.3

TEMP

2.1

V

1.9

1.7

1.5

–50 –25 0 25

Figure 14. V

Output over Temperature, 256 Parts (V

TEMP

Output at 25°C (V

TEMP

TEMPERATURE (° C)

= 5 V)

RATIO

50 75 100

RATIO

= 5 V)

09573-013

09573-014

30

25

20

TION (%)

15

POPUL

10

5

0

3.06

3.24

3.42

3.15

3.33

CURRENT CONS UMPTIO N (mA)

3.51

3.60

Figure 12. Current Consumption at 25°C (V

3.69

3.78

3.87

3.96

RATIO

4.05

= 5 V)

4.14

4.23

09573-012

Rev. A | Page 7 of 12

1

ACCELERATI ON

0.1

0.01

AND %/sec

g²/H

0.001

0.0001

100 1000 10000

FREQUENC Y (Hz)

GYRO OUT PUT

Figure 15. Typical Response to 25 g RMS Random Vibration, 50 Hz to 5 kHz

(Sensor Bandwidth = 1 kHz)

09573-015

Page 8

ADXRS649

10

1

0.1

RATEOUT (°/sec Peak)

0.01

0.001

100 1000 10000

VIBRATION INPUT FREQUENCY (Hz)

Figure 16. Typical Response to 10 g RMS Sinusoidal Vibration

(Sensor Bandwidth = 1 kHz)

09573-016

0.5

0.4

0.3

0.2

0.1

0

–0.1

NONLI NEARITY (%)

–0.2

–0.3

–0.4

–0.5

0 5000 10000 15000 20000

ANGULAR RATE (Deg ress per Second)

09573-017

Figure 17. Typical Nonlinearity (Four Typical Devices)

Rev. A | Page 8 of 12

Page 9

ADXRS649

THEORY OF OPERATION

The ADXRS649 operates on the principle of a resonator gyro.

Figure 18 shows a simplified version of one of four polysilicon

sensing structures. Each sensing structure contains a dither

frame that is electrostatically driven to resonance. This produces the necessary velocity element to produce a Coriolis force

when experiencing angular rate. The ADXRS649 is designed to

sense a z-axis (yaw) angular rate.

When the sensing structure is exposed to angular rate, the resulting Coriolis force couples into an outer sense frame, which

contains movable fingers that are placed between fixed pickoff

fingers. This forms a capacitive pickoff structure that senses

Coriolis motion. The resulting signal is fed to a series of gain

and demodulation stages that produce the electrical rate signal

output. The quad sensor design rejects linear and angular

acceleration, including external g-forces and vibration. This is

achieved by mechanically coupling the four sensing structures

such that external g-forces appear as common-mode signals

that can be removed by the fully differential architecture

implemented in the ADXRS649.

The electrostatic resonator requires 13 V to 15 V for operation.

Because only 5 V are typically available in most applications,

a charge pump is included on chip. If an external 13 V to 15 V

supply is available, the two capacitors on CP1 to CP4 can be

omitted, and this supply can be connected to CP5 (Pin D6,

Pin D7). CP5 should not be grounded when power is applied

to the ADXRS649. No damage occurs, but under certain conditions, the charge pump may fail to start up after the ground is

removed without first removing power from the ADXRS649.

SETTING THE BANDWIDTH

External Capacitor C

chip R

resistor to create a low-pass filter to limit the bandwidth

OUT

of the ADXRS649 rate response. The −3 dB frequency set by

and C

R

OUT

f

OUT

f

can be well controlled because R

OUT

is

OUT

= 1/(2 × π × R

during manufacturing to be 180 kΩ ± 1%. Any external resistor

applied between the RATEOUT pin (B1, A2) and the SUMJ pin

(C1, C2) results in

R

= (180 kΩ × R

OUT

In general, an additional filter (in either hardware or software)

is added to attenuate high frequency noise arising from demodulation spikes at the 18 kHz resonant frequency of the gyro. An

RC output filter consisting of a 3.3 kΩ series resistor and 22 nF

shunt capacitor (2.2 kHz pole) is recommended.

is used in combination with the on-

OUT

× C

OUT

EXT

)

OUT

OUT

)/(180 kΩ + R

has been trimmed

)

EXT

X

Y

Z

09573-018

Figure 18. Simplified Gyro Sensing Structure—One Corner

Rev. A | Page 9 of 12

Page 10

ADXRS649

V

TEMPERATURE OUTPUT AND CALIBRATION

It is common practice to temperature-calibrate gyros to improve

their overall accuracy. The ADXRS649 has a temperature proportional voltage output that provides input to such a calibration

method. The temperature sensor structure is shown in Figure 19.

The temperature output is characteristically nonlinear, and any

load resistance connected to the TEMP output results in decreasing

the TEMP output and its temperature coefficient. Therefore,

buffering the output is recommended.

The voltage at TEMP (F3, G3) is nominally 2.5 V at 25°C, and

V

= 5 V. The temperature coefficient is ~9 mV/°C at 25°C.

RATIO

Although the TEMP output is highly repeatable, it has only

modest absolute accuracy.

RATIO

R

FIXEDRTEMP

Figure 19. Temperature Sensor Structure

TEMP

09573-019

MODIFYING THE MEASUREMENT RANGE

The ADXRS649 scale factor can be reduced to extend the

measurement range to as much as ±50,000°/sec by adding a

single 120 kΩ resistor between the RATEOUT and SUMJ pins.

If an external resistor is added between RATEOUT and SUMJ,

C

must be proportionally increased to maintain correct

OUT

bandwidth.

NULL BIAS ADJUSTMENT

The nominal 2.5 V null bias is for a symmetrical swing range at

RATEOUT (B1, A2). However, a nonsymmetric output swing

may be suitable in some applications. Null bias adjustment is

possible by injecting a suitable current to SUMJ (C1, C2). Note

that supply disturbances may reflect some null bias instability.

Digital supply noise should be avoided, particularly in this case.

SELF-TEST FUNCTION

The ADXRS649 includes a self-test feature that actuates each of

the sensing structures and associated electronics in the same

manner, as if subjected to angular rate. The self-test is activated

by standard logic high levels applied to Input ST1 (F5, G5),

Input ST2 (F4, G4), or both. ST1 causes the voltage at RATEOUT

to change by approximately −0.15 V, and ST2 causes an opposite

change of +0.15 V. The self-test response follows the viscosity

temperature dependence of the package atmosphere,

approximately 0.25%/°C.

Activating ST1 and ST2 simultaneously does not damage the

part. ST1 and ST2 are fairly closely matched (±2%), but

actuating both simultaneously may result in a small apparent

null bias shift proportional to the degree of self-test mismatch.

ST1 and ST2 are activated by applying a voltage equal to V

RATIO

to the ST1 pin and the ST2 pin. The voltage applied to ST1 and

ST2 must never be greater than AV

.

CC

CONTINUOUS SELF-TEST

The on-chip integration of the ADXRS649 gives it higher reliability

than is obtainable with any other high volume manufacturing

method. In addition, it is manufactured under a mature BiMOS

process that has field-proven reliability. As an additional failure

detection measure, a power-on self-test can be performed. However, some applications may warrant continuous self-test while

sensing rate. Information about continuous self-test techniques

is also available in the AN-768 Application Note, Using the

ADXRS150/ADXRS300 in Continuous Self-Test Mode.

Rev. A | Page 10 of 12

Page 11

ADXRS649

3

OUTLINE DIMENSIONS

A1 BALL

CORNER

7.05

6.85 SQ

6.70

4.80

BSC SQ

0.80

BSC

76543

21

*

A

B

C

D

E

F

G

A1 CORNER

INDEX AREA

.80 MAX

TOP VIEW

DETAIL A

0.60 MAX

0.25 MIN

SEATING

PLANE

*

BALL A1 IDENTIFIER IS GOLD PLATED AND CONNECTED

TO THE D/A PAD INTERNALLY VIA HOLES.

BOTTOM VIEW

DETAIL A

0.60

0.55

0.50

BALL DIAMETER

3.20 MAX

2.50 MIN

COPLANARITY

0.15

10-26-2009-B

Figure 20. 32-Lead Ceramic Ball Grid Array [CBGA]

(BG-32-3)

Dimensions shown in millimeters

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

ADXRS649BBGZ-RL –40°C to +105°C 32-Lead Ceramic Ball Grid Array [CBGA] BG-32-3

ADXRS649BBGZ –40°C to +105°C 32-Lead Ceramic Ball Grid Array [CBGA] BG-32-3

EVAL-ADXRS649Z Evaluation Board

1

Z = RoHS Compliant Part.

Rev. A | Page 11 of 12

Page 12

ADXRS649

NOTES

©2010–2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D09573-0-3/11(A)

Rev. A | Page 12 of 12

Loading...

Loading...