Page 1

SELF-TEST

+V

S

2

25kV

5kV

ADXL150

GAIN

AMP

OFFSET

NULL

COM

0.1mF

BUFFER

AMP

DEMODULATORSENSOR

+V

S

TP

(DO NOT CONNECT)

V

OUT

9

CLOCK

SELF-TEST

5kV

25kV

ADXL250

GAIN

AMP

Y OFFSET

NULL

COM

0.1mF

BUFFER

AMP

DEMODULATOR

+V

S

TP

(DO NOT CONNECT)

25kV

5kV

GAIN

AMP

BUFFER

AMP

DEMODULATOR

V

OUT

Y

X OFFSET

NULL

SENSOR

+V

S

2

CLOCK

SENSOR

V

OUT

X

65 g to 650 g, Low Noise, Low Power,

a

Single/Dual Axis i

FEATURES

Complete Acceleration Measurement System

on a Single Monolithic IC

80 dB Dynamic Range

Pin Programmable 650

Low Noise: 1 m

g

g

or 625g Full Scale

/√Hz Typical

Low Power: <2 mA per Axis

Supply Voltages as Low as 4 V

2-Pole Filter On-Chip

Ratiometric Operation

Complete Mechanical & Electrical Self-Test

Dual & Single Axis Versions Available

Surface Mount Package

GENERAL DESCRIPTION

The ADXL150 and ADXL250 are third generation ± 50 g sur-

face micromachined accelerometers. These improved replacements for the ADXL50 offer lower noise, wider dynamic range,

reduced power consumption and improved zero g bias drift.

The ADXL150 is a single axis product; the ADXL250 is a fully

integrated dual axis accelerometer with signal conditioning on a

single monolithic IC, the first of its kind available on the commercial market. The two sensitive axes of the ADXL250 are

orthogonal (90°) to each other. Both devices have their sensitive

axes in the same plane as the silicon chip.

The ADXL150/ADXL250 offer lower noise and improved

signal-to-noise ratio over the ADXL50. Typical S/N is 80 dB,

allowing resolution of signals as low as 10 mg, yet still providing

a ±50 g full-scale range. Device scale factor can be increased

from 38 mV/g to 76 mV/g by connecting a jumper between

and the offset null pin. Zero g drift has been reduced to

V

OUT

0.4 g over the industrial temperature range, a 10× improvement

over the ADXL50. Power consumption is a modest 1.8 mA

per axis. The scale factor and zero g output level are both

MEM

S

Accelerometers

ADXL150/ADXL250

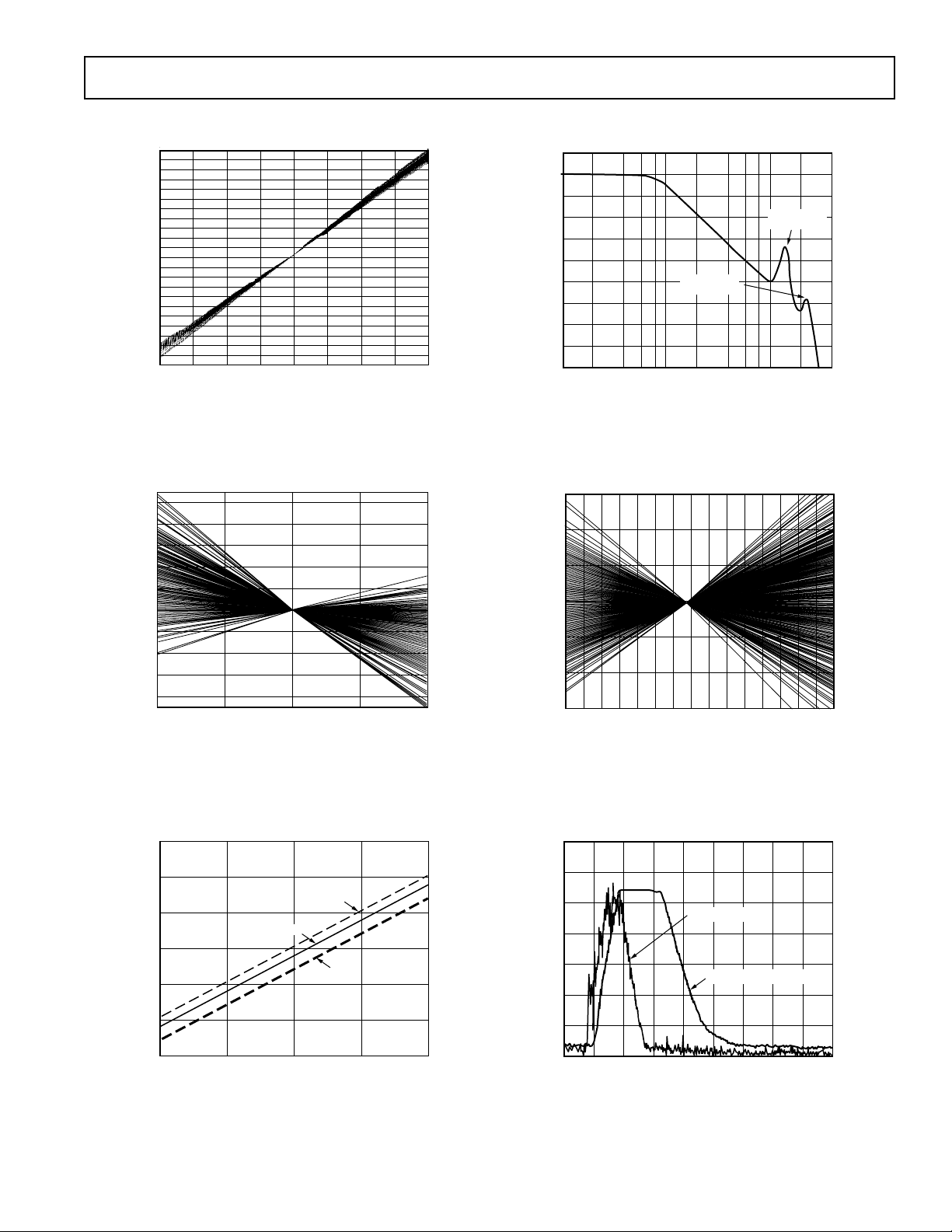

FUNCTIONAL BLOCK DIAGRAMS

ratiometric to the power supply, eliminating the need for a voltage reference when driving ratiometric A/D converters such as

those found in most microprocessors. A power supply bypass

capacitor is the only external component needed for normal

operation.

The ADXL150/ADXL250 are available in a hermetic 14-lead

surface mount cerpac package specified over the 0°C to +70°C

commercial and –40°C to +85°C industrial temperature ranges.

Contact factory for availability of devices specified over automotive and military temperature ranges.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

i

MEM

S

is a registered trademark of Analog Devices, Inc.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Page 2

(TA = +258C for J Grade, TA = –408C to +858C for A Grade,

ADXL150/ADXL250–SPECIFICATIONS

Parameter Conditions Min Typ Max Min Typ Max Units

SENSOR

Guaranteed Full-Scale Range ±40 ±50 ±40 ±50 g

Nonlinearity 0.2 0.2 % of FS

Package Alignment Error

Sensor-to-Sensor Alignment Error ±0.1 Degrees

Transverse Sensitivity

SENSITIVITY

Sensitivity (Ratiometric)

Sensitivity Drift Due to Temperature Delta from 25°C to T

ZERO g BIAS LEVEL

Output Bias Voltage

Zero g Drift Due to Temperature Delta from 25°C to T

ZERO-g OFFSET ADJUSTMENT

Voltage Gain Delta V

Input Impedance 20 30 20 30 kΩ

NOISE PERFORMANCE

Noise Density

5

Clock Noise 5 5 mV p-p

FREQUENCY RESPONSE

–3 dB Bandwidth 900 1000 900 1000 Hz

Bandwidth Temperature Drift T

Sensor Resonant Frequency Q = 5 24 24 kHz

SELF-TEST

Output Change

6

Logic “1” Voltage V

Logic “0” Voltage 1.0 1.0 V

Input Resistance To Common 30 50 30 50 kΩ

OUTPUT AMPLIFIER

Output Voltage Swing I

Capacitive Load Drive 1000 1000 pF

POWER SUPPLY (V

Functional Voltage Range 4.0 6.0 4.0 6.0 V

Quiescent Supply Current ADXL150 1.8 3.0 mA

TEMPERATURE RANGE

Operating Range J 0 +70 0 +70 °C

Specified Performance A –40 +85 –40 +85 °C

NOTES

1

Alignment error is specified as the angle between the true axis of sensitivity and the edge of the package.

2

Transverse sensitivity is measured with an applied acceleration that is 90 degrees from the indicated axis of sensitivity.

3

Ratiometric: V

doubled by connecting V

4

Ratiometric, proportional to VS/2. See Figure 21.

5

See Figure 11 and Device Bandwidth vs. Resolution section.

6

Self-test output varies with supply voltage.

7

When using ADXL250, both Pins 13 and 14 must be connected to the supply for the device to function.

Specifications subject to change without notice.

OUT

= V

1

2

3

Y Channel 33.0 38.0 43.0 mV/g

X Channel 33.0 38.0 43.0 33.0 38.0 43.0 mV/g

or T

MIN

MAX

4

or T

MIN

MAX

/Delta V

MIN

OUT

to T

MAX

OS PIN

ST Pin from Logic “0” to “1” 0.25 0.40 0.60 0.25 0.40 0.60 V

= ±100 µA 0.25 V

OUT

7

)

S

ADXL250 (Total 2 Channels) 3.5 5.0 mA

/2 + (Sensitivity × VS/5 V × a) where a = applied acceleration in gs, and V

S

to the offset null pin.

OUT

VS = +5.00 V, Acceleration = Zero g, unless otherwise noted)

ADXL150JQC/AQC ADXL250JQC/AQC

±1 ±1 Degrees

±2 ±2%

±0.5 ±0.5 %

VS/2 – 0.35 VS/2 VS/2 + 0.35 VS/2 – 0.35 VS/2 VS/2 + 0.35 V

0.2 0.3 g

0.45 0.50 0.55 0.45 0.50 0.55 V/V

1 2.5 1 2.5 mg/√Hz

50 50 Hz

– 1 VS – 1 V

S

– 0.25 0.25 VS – 0.25 V

S

= supply voltage. See Figure 21. Output scale factor can be

S

–2–

REV. 0

Page 3

ADXL150/ADXL250

TOP VIEW

(Not to Scale)

ADXL150

14

1

78

NC

NC

NC

NC

NC

COMMON

V

S

NC

NC

V

OUT

SELF-TEST

ZERO

g

ADJ

TP (DO NOT CONNECT)

NC = NO CONNECT

ZERO

g

ADJ Y

V

OUT

Y

NC

NC

COMMON

V

S

V

S

NC

NC

ZERO

g

ADJ X

SELF-TEST

V

OUT

X

TOP VIEW

(Not to Scale)

ADXL250

14

1

78

NC

TP (DO NOT CONNECT)

NOTE: WHEN USING ADXL250, BOTH PINS 13 AND 14 NEED

TO BE CONNECTED TO SUPPLY FOR DEVICE TO FUNCTION

NC

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . . 2000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . . . 500 g

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

+V

S

Output Short Circuit Duration

, V

(V

OUT

Terminals to Common) . . . . . . . . . . . Indefinite

REF

Operating Temperature . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Drops onto hard surfaces can cause shocks of greater than 2000 g

and exceed the absolute maximum rating of the device. Care

should be exercised in handling to avoid damage.

1

ADXL150

TOP VIEW

(Not to Scale)

78

14

A

X

1

ADXL250

TOP VIEW

(Not to Scale)

A

78

14

A

X

908

Y

Package Characteristics

Package u

JA

u

JC

Device Weight

14-Lead Cerpac 110°C/W 30°C/W 5 Grams

ORDERING GUIDE

Model Temperature Range

ADXL150JQC 0°C to +70°C

ADXL150AQC –40°C to +85°C

ADXL250JQC 0°C to +70°C

ADXL250AQC –40°C to +85°C

PIN CONNECTIONS

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL150/ADXL250 feature proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

POSITIVE A = POSITIVE V

POSITIVE A = POSITIVE V

OUT

OUT

Figure 1. ADXL150 and ADXL250 Sensitive Axis

Orientation

REV. 0

–3–

Page 4

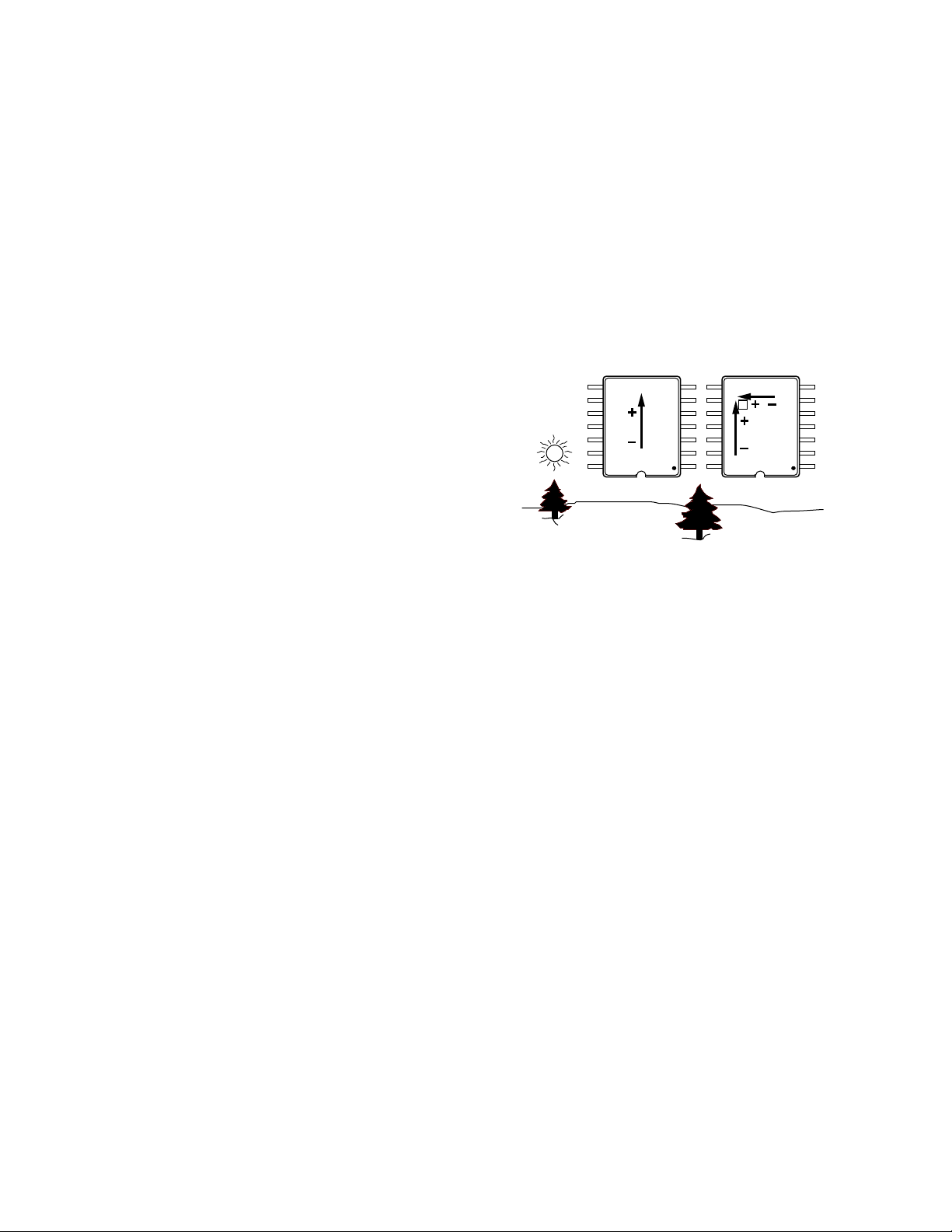

ADXL150/ADXL250

14

1

78

A

X

ADXL150

14

1

78

A

X

ADXL250

A

Y

GLOSSARY OF TERMS

Acceleration: Change in velocity per unit time.

Acceleration Vector: Vector describing the net acceleration

acting upon the ADXL150/ADXL250.

g: A unit of acceleration equal to the average force of gravity

occurring at the earth’s surface. A g is approximately equal to

32.17 feet/s

2

or 9.807 meters/s2.

Nonlinearity: The maximum deviation of the ADXL150/

ADXL250 output voltage from a best fit straight line fitted to a

plot of acceleration vs. output voltage, calculated as a % of the

full-scale output voltage (at 50 g).

Resonant Frequency: The natural frequency of vibration of

the ADXL150/ADXL250 sensor’s central plate (or “beam”). At

its resonant frequency of 24 kHz, the ADXL150/ADXL250’s

moving center plate has a slight peak in its frequency response.

Sensitivity: The output voltage change per g unit of accelera-

tion applied, specified at the V

pin in mV/g.

OUT

Total Alignment Error: Net misalignment of the ADXL150/

ADXL250’s on-chip sensor and the measurement axis of the

application. This error includes errors due to sensor die alignment to the package, and any misalignment due to installation

of the sensor package in a circuit board or module.

Transverse Acceleration: Any acceleration applied 90° to the

axis of sensitivity.

Transverse Sensitivity Error: The percent of a transverse

acceleration that appears at V

OUT

.

Transverse Axis: The axis perpendicular (90°) to the axis of

sensitivity.

Zero g Bias Level: The output voltage of the ADXL150/

ADXL250 when there is no acceleration (or gravity) acting

upon the axis of sensitivity. The output offset is the difference

between the actual zero g bias level and (V

S

/2).

Polarity of the Acceleration Output

The polarity of the ADXL150/ADXL250 output is shown in

Figure 1. When its sensitive axis is oriented to the earth’s gravity

(and held in place), it will experience an acceleration of +1 g.

This corresponds to a change of approximately +38 mV at the

output pin. Note that the polarity will be reversed if the package

is rotated 180°. The figure shows the ADXL250 oriented so that

its “X” axis measures +1 g. If the package is rotated 90° clock-

wise (Pin 14 up, Pin 1 down), the ADXL250’s “Y” axis will now

measure +1 g.

Figure 2. Output Polarity

Acceleration Vectors

The ADXL150/ADXL250 is a sensor designed to measure

accelerations that result from an applied force. It responds to

the component of acceleration on its sensitive X axis (ADXL150)

or on both the “X” and “Y” axis (ADXL250).

–4–

REV. 0

Page 5

ADXL150/ADXL250

TIME – 0.2ms/Div

OUTPUT RESPONSE

500g INPUT

600

g

500

g

400

g

300

g

200

g

100

g

0

g

60

g

50

g

40

g

30

g

20

g

10

g

0

g

Typical Characteristics

5.0

4.0

3.0

2.0

1.0

0

–1.0

–2.0

ERROR FROM IDEAL – %

–3.0

–4.0

–5.0

4.0 4.5 5.0 5.5 6.0

POWER SUPPLY VOLTAGE

(@+5 V dc, +258C with a 38 mV/g Scale Factor unless otherwise noted)

Figure 3. Typical Sensitivity Error from Ideal Ratiometric

Response for a Number of Units

2.5

2.0

1.5

1.0

0.5

0

ERROR – %

–0.5

–1.0

–1.5

–2.0

4.0 4.5 5.0 5.5 6.0

SUPPLY VOLTAGE

Figure 4. Offset Error of Zero g Level from Ideal

V

/2 Response as a Percent of Full-Scale for a Number

S

of Units

6

0

–6

–12

–18

–24

–30

–36

–42

TYPICAL OUTPUT RESPONSE IN dB

–48

100 1k

RESONANCE

FREQUENCY – Hz

BEAM

PACKAGE

RESONANCE

10k

Figure 6. Typical Output Response vs. Frequency of

ADXL150/ADXL250 on a PC Board that Has Been

Conformally Coated

30

20

10

0

DRIFT – mV

g

–10

ZERO

–20

–30

–40 –30 –20 –10 10 20 30 60

05040 80 90 100

TEMPERATURE – 8C

70

Figure 7. Typical Zero g Drift for a Number of Units

2.4

2.2

2

1.8

1.6

SUPPLY CURRENT – mA

1.4

1.2

464.5

SUPPLY VOLTAGE – Volts

Figure 5. Typical Supply Current vs. Supply Voltage

REV. 0

+1058C

+258C

–408C

5 5.5

Figure 8. Typical 500 g Step Recovery at the Output

–5–

Page 6

ADXL150/ADXL250

FREQUENCY – kHz

30

25

0

100 100001000

RMS BASEBAND ERROR – mV

20

15

10

5

20

15

10

5

0

–5

OUTPUT VOLTAGE – mV

g

–10

ZERO

–15

–20

02468101214161820

NOISE FROM INTERNAL CLOCK

TIME – ms

Figure 9. Typical Output Noise Voltage with Spikes

Generated by Internal Clock

SELF-TEST

OUTPUT

(0.2V/DIV)

1.6

1.4

Hz

/

g

1.2

1.0

RMS NOISE – m

0.8

0.6

4.0

4.5 5.5 6.0

SUPPLY VOLTAGE – Volts

5.0

Figure 12. Noise vs. Supply Voltage

SELF-TEST

INPUT

(2V/DIV)

02468101214161820

Figure 10. Typical Self-Test Response

2.50

2.25

2.00

1.75

1.50

1.25

1.00

rms

g

0.75

NOISE – m

0.50

0.25

TIME – ms

Figure 13. Baseband Error Graph

Figure 13 shows the mV rms error in the output signal if there is

a noise on the power supply pin of 1 mV rms at the internal

clock frequency or its odd harmonics. This is a baseband noise

and can be at any frequency in the 1 kHz passband or at dc.

2k10 100 1k

FREQUENCY – Hz

Figure 11. Noise Spectral Density

–6–

REV. 0

Page 7

ADXL150/ADXL250

THEORY OF OPERATION

The ADXL150 and ADXL250 are fabricated using a proprietary surface micromachining process that has been in high

volume production since 1993. The fabrication technique uses

standard integrated circuit manufacturing methods enabling all

the signal processing circuitry to be combined on the same chip

with the sensor.

The surface micromachined sensor element is made by depositing polysilicon on a sacrificial oxide layer that is then etched

away leaving the suspended sensor element. Figure 14 is a

simplified view of the sensor structure. The actual sensor has

42 unit cells for sensing acceleration. The differential capacitor

sensor is composed of fixed plates and moving plates attached to

the beam that moves in response to acceleration. Movement of

the beam changes the differential capacitance, which is measured

by the on chip circuitry.

The sensor has 12-unit capacitance cells for electrostatically

forcing the beam during a self-test. Self-test is activated by the

user with a logic high on the self-test input pin. During a logic

high, an electrostatic force acts on the beam equivalent to

approximately 20% of full-scale acceleration input, and thus a

proportional voltage change appears on the output pin. When

activated, the self-test feature exercises both the entire mechanical structure and the electrical circuitry.

BEAM

PLATE

CAPACITANCES

FIXED

PLATE

ANCHOR

UNIT CELL

ACCELERATION

Figure 14. Simplified View of Sensor Under Acceleration

All the circuitry needed to drive the sensor and convert the

capacitance change to voltage is incorporated on the chip requiring

no external components except for standard power supply decoupling. Both sensitivity and the zero-g value are ratiometric to

the supply voltage, so that ratiometeric devices following the

accelerometer (such as an ADC, etc.) will track the accelerometer if the supply voltage changes. The output voltage (V

OUT

) is

a function of both the acceleration input (a) and the power

supply voltage (V

) as follows:

S

V

= V

OUT

/2 – (Sensitivity ×

S

V

5V

S

× a)

Both the ADXL150 and ADXL250 have a 2-pole Bessel switchedcapacitor filter. Bessel filters, sometimes called linear phase

filters, have a step response with minimal overshoot and a maximally flat group delay. The –3 dB frequency of the poles is

preset at the factory to 1 kHz. These filters are also completely

self-contained and buffered, requiring no external components.

MEASURING ACCELERATIONS LESS THAN 50 g

The ADXL150/ADXL250 require only a power supply bypass

capacitor to measure ± 50 g accelerations. For measuring ±50 g

accelerations, the accelerometer may be directly connected to an

ADC (see Figure 25). The device may also be easily modified to

measure lower g signals by increasing its output scale factor.

The scale factor of an accelerometer specifies the voltage change

of the output per g of applied acceleration. This should not be

confused with its resolution. The resolution of the device is the

lowest g level the accelerometer is capable of measuring. Resolution is principally determined by the device noise and the measurement bandwidth.

The zero g bias level is simply the dc output level of the accelerometer when it is not in motion or being acted upon by the earth’s

gravity.

Pin Programmable Scale Factor Option

In its normal state, the ADXL150/ADXL250’s buffer amplifier

provides an output scale factor of 38 mV/g, which is set by an

internal voltage divider. This gives a full-scale range of ±50 g

and a nominal bandwidth of 1 kHz.

A factor-of-two increase in sensitivity can be obtained by connecting the V

pin to the offset null pin, assuming that it is

OUT

not needed for offset adjustment. This connection has the effect

of reducing the internal feedback by a factor of two, doubling

the buffer’s gain. This increases the output scale factor to 76 mV/g

and provides a ±25 g full-scale range.

Simultaneously, connecting these two pins also increases the

amount of internal post filtering, reducing the noise floor and

changing the nominal 3 dB bandwidth of the ADXL150/

ADXL250 to 500 Hz. Note that the post filter’s “Q” will also

be reduced by a factor of √2 from 0.58 (Bessel response) to a

much gentler “Q” value of 0.41. The primary effect of this

change in “Q” is only at frequencies within two octaves of the

corner frequency; above this the two filter slopes are essentially

the same. In applications where a flat response up to 500 Hz is

needed, it is better to operate the device at 38 mV/g and use an

external post filter. Note also that connecting V

to V

pin adds a 30 kΩ load from V

, this added load will consume ±60 µA of the ADXL150/

at V

OUT

OUT

/2. When swinging ±2 V

S

to the offset

OUT

ADXL250’s 100 µA (typical) output current drive.

REV. 0

–7–

Page 8

ADXL150/ADXL250

Increasing the

i

MEM

S

Accelerometer’s Output

Scale Factor

Figure 15 shows the basic connections for using an external

buffer amplifier to increase the output scale factor.

The output multiplied by the gain of the buffer, which is simply

the value of resistor R3 divided by R1. Choose a convenient

scale factor, keeping in mind that the buffer gain not only amplifies the signal, but any noise or drift as well. Too much gain can

also cause the buffer to saturate and clip the output waveform.

Note that the “+” input of the external op amp uses the offset

null pin of the ADXL150/ADXL250 as a reference, biasing the

op amp at midsupply, saving two resistors and reducing power

consumption. The offset null pin connects to the V

/2 reference

S

point inside the accelerometer via 30 kΩ, so it is important not

to load this pin with more than a few microamps.

It is important to use a single-supply or “rail-to-rail” op amp for

the external buffer as it needs to be able to swing close to the

supply and ground.

The circuit of Figure 15 is entirely adequate for many applications, but its accuracy is dependent on the pretrimmed accuracy

of the accelerometer and this will vary by product type and grade.

TP

(DO NOT CONNECT)

+V

0.1mF

5

14

S

C1

ADXL150

SENSOR

9

SELF-TEST

GAIN

AMP

CLOCK

DEMODULATOR

7

COM

+V

S

5kV

2

25kV

OFFSET

0.1mF

8

NULL

+V

C2

OUTPUT SCALE FACTOR = 38mV/g ––

Figure 15. Using an External Op Amp to Increase Output Scale Factor

For the highest possible accuracy, an external trim is recommended. As shown by Figure 20, this consists of a potentiometer, R1a, in series with a fixed resistor, R1b. Another option is

to select resistor values after measuring the device’s scale factor

(see Figure 17).

AC Coupling

If a dc (gravity) response is not required—for example in vibration measurement applications—ac coupling can be used between the accelerometer’s output and the external op amp’s

input as shown in Figure 16. The use of ac coupling virtually

eliminates any zero g drift and allows the maximum external

amp gain without clipping.

Resistor R2 and capacitor C3 together form a high pass filter

whose corner frequency is 1/(2 π R2 C3). This filter will reduce

the signal from the accelerometer by 3 dB at the corner frequency, and it will continue to reduce it at a rate of 6 dB/octave

(20 dB per decade) for signals below the corner frequency.

Capacitor C3 should be a nonpolarized, low leakage type.

If ac coupling is used, the self-test feature must be monitored at

the accelerometer’s output rather than at the external amplifier

output (since the self-test output is a dc voltage).

2

OP196

3

R3

C4

0.1mF

V

OUT

6

7

4

R3

+V

S

R1

BUFFER

S

2

AMP

R1

10

+V

S

0.1mF

TP

(DO NOT CONNECT)

5

14

C1

ADXL150

9

SELF-TEST

GAIN

AMP

DEMODULATORSENSOR

CLOCK

7

COM

TYPICAL COMPONENT VALUES FOR AC COUPLED CIRCUIT

BUFFER

FS RANGE

GAIN

2 625

4 612.5

5 610

g

1MV 0.15mF 0.05mF 0.015mF 0.0075mF

g

g

249kV 0.68mF 0.22mF 0.022mF 0.01mF

+V

S

2

5kV

C3

R2

10

V

25kV

OFFSET

NULL

0.1mF

R2

332kV 0.47mF 0.15mF 0.047mF 0.022mF

BUFFER

8

+V

S

2

C2

C3 VALUE FOR 3dB CORNER FREQ

1Hz 3Hz 10Hz 20Hz

OUT

AMP

+V

1MV

+V

S

C4

0.1mF

7

2

OP196

3

S

2

EXTERNAL AMP GAIN = ––––

6

4

OUTPUT

1MV

R2

Figure 16. AC Coupled Connection Using an External Op Amp

–8–

REV. 0

Page 9

ADXL150/ADXL250

TP

(DO NOT CONNECT)

5

+V

NOTES:

0g “QUICK” CALIBRATION METHOD USING RESISTOR R2 AND A +5V SUPPLY.

(a)

WITH ACCELEROMETER ORIENTED AWAY FROM EARTH’S

GRAVITY (i.e., SIDEWAYS), MEASURE PIN 10 OF THE ADXL150.

(b)

CALCULATE THE OFFSET VOLTAGE THAT NEEDS TO BE NULLED:

V

(

c)

R2 = ––––––––

(d)

FOR V

(e)

FOR V

14

S

C1

0.1mF

=(+2.5V – V

OS

2.5V (R3)

V

OS

10 > +2.5V, R2 CONNECTS TO GND.

PIN

10 < +2.5V, R2 CONNECTS TO +VS.

PIN

ADXL150

9

SELF-TEST

10)(R3/R1).

PIN

CLOCK

GAIN

AMP

COM

DEMODULATORSENSOR

7

OFFSET

NULL

C2

0.1mF

+V

2

25kV

S

Figure 17. “Quick Zero g Calibration” Connection

Adjusting the Zero g Bias Level

When a true dc (gravity) response is needed, the output from

the accelerometer

must be dc coupled to the external amplifier’s

input. For high gain applications, a zero g offset trim will also be

needed. The external offset trim permits the user to set the zero g

offset voltage to exactly +2.5 volts (allowing the maximum output

swing from the external amplifier without clipping with a +5

supply).

With a dc coupled connection, any difference between the zero g

output and +2.5 V will be amplified along with the signal. To

obtain the exact zero g output desired or to allow the maximum

output voltage swing from the external amplifier, the zero g offset

will need to be externally trimmed using the circuit of Figure 20.

The external amplifier’s maximum output swing should be

limited to ±2 volts, which provides a safety margin of ±0.25

volts before clipping. With a +2.5 volt zero g level, the maximum gain will equal:

2 Volts

38

mV/g Times the Max Applied Acceleration in g

+VS OR GND

5kV

BUFFER

AMP

8

+V

S

2

R2 (SEE NOTES)

R1

10

DESIRED

OUTPUT

SCALE FACTOR

g

76mV/

100mV/

g

200mV/

g

400mV/

g

R3

100kV

C4

+V

S

0.1mF

7

2

OP196

3

FS

RANGE

625g2.0 49.9kV

620g2.6 38.3kV

610g5.3 18.7kV

65

g

4

EXT

AMP

GAIN

10.5 9.53kV

6

R1

VALUE

V

OUT

The device scale factor and zero g offset levels can be calibrated

using the earth’s gravity, as explained in the section “calibrating

the ADXL150/ADXL250.”

Using the Zero g “Quick-Cal” Method

In Figure 18 (accelerometer alone, no external op amp), a trim

potentiometer connects directly to the accelerometer’s zero g

null pin. The “quick offset calibration” scheme shown in Figure

17 is preferred over using a potentiometer, which could change

its setting over time due to vibration. The “quick offset calibration” method requires measuring only the output voltage of

the ADXL150/ADXL250 while it is oriented normal to the

earth’s gravity. Then, by using the simple equations shown in

the figures, the correct resistance value for R2 can be calculated.

In Figure 17, an external op amp is used to amplify the signal. A

resistor, R2, is connected to the op amp’s summing junction.

The other side of R2 connects to either ground or +V

depend-

S

ing on which direction the offset needs to be shifted.

REV. 0

TP

(DO NOT CONNECT)

+V

S

C1

0.1mF

14

SENSOR

SELF-TEST

5

ADXL150

9

AT PIN 8

R

IN

30kV 610kV

GAIN

AMP

CLOCK

COM

DEMODULATOR

7

0.1mF

+V

S

2

5kV

V

10

OUT

BUFFER

8

OFFSET

NULL

AMP

+V

S

25kV

C2

200kV

Figure 18. Offset Nulling the ADXL150/ADXL250 Using a Trim Potentiometer

–9–

Page 10

ADXL150/ADXL250

DEVICE BANDWIDTH VS. MEASUREMENT RESOLUTION

Although an accelerometer is usually specified according to its

full-scale g level, the limiting resolution of the device, i.e., its

minimum discernible input level, is extremely important when

measuring low g accelerations.

g

100m

10m

g

NOISE LEVEL – rms

1m

g

10 1k100

3dB BANDWIDTH – Hz

660m

g

66m

g

NOISE LEVEL – Peak to Peak

6.6m

g

Figure 19.␣ ADXL150/ADXL250 Noise Level vs. 3 dB

Bandwidth (Using a “Brickwall” Filter)

The limiting resolution is predominantly set by the measurement noise “floor,” which includes the ambient background

noise and the noise of the ADXL150/ADXL250 itself. The level

of the noise floor varies directly with the bandwidth of the measurement. As the measurement bandwidth is reduced, the noise

floor drops, improving the signal-to-noise ratio of the measurement and increasing its resolution.

The bandwidth of the accelerometer can be easily reduced by

adding low-pass or bandpass filtering. Figure 19 shows the

typical noise vs. bandwidth characteristic of the ADXL150/

ADXL250.

The output noise of the ADXL150/ADXL250 scales with the

square root of the measurement bandwidth. With a single pole

roll-off, the equivalent rms noise bandwidth is π divided by 2 or

approximately 1.6 times the 3 dB bandwidth. For example, the

typical rms noise of the ADXL150 using a 100 Hz one pole post

filter is:

Noise rms

=1mg/ Hz × 100 1.6

()

=12.25mg

()

Because the ADXL150/ADXL250’s noise is, for all practical

purposes, Gaussian in amplitude distribution, the highest noise

amplitudes have the smallest (yet nonzero) probability. Peakto-peak noise is therefore difficult to measure and can only be

estimated due to its statistical nature. Table I is useful for estimating the probabilities of exceeding various peak values, given

the rms value.

Table I.

Nominal Peak-to- % of Time that Noise Will Exceed

Peak Value Nominal Peak-to-Peak Value

2.0 × rms 32%

4.0 × rms 4.6%

6.0 × rms 0.27%

6.6 × rms 0.1%

8.0 × rms 0.006%

RMS and peak-to-peak noise (for 0.1% uncertainty) for various

bandwidths are estimated in Figure 19. As shown by the figure,

device noise drops dramatically as the operating bandwidth is

reduced. For example, when operated in a 1 kHz bandwidth,

the ADXL150/ADXL250 typically have an rms noise level of

32 mg. When the device bandwidth is rolled off to 100 Hz, the

noise level is reduced to approximately 10 mg.

Alternatively, the signal-to-noise ratio may be improved considerably by using a microprocessor to perform multiple measurements and then to compute the average signal level.

Low-Pass Filtering

The bandwidth of the accelerometer can easily be reduced by using

post filtering. Figure 20 shows how the buffer amplifier can be

connected to provide 1-pole post filtering, zero g offset trimming,

and output scaling. The table provides practical component values

+V

S

C1

0.1mF

+V

S

R2

RT

R1a

75kV

SCALE

FACTOR

TRIM

(OPTIONAL)

Cf (mF)

100Hz

0.0082

0.0056

0.0033

0.0015

1MV

R1b

50kV

Cf (mF)

30Hz

0.027

0.022

0.010

0.0056

3

Cf (mF)

10Hz

0.082

0.056

0.033

0.015

2

Cf

+V

OP196

100kV

S

7

4

R3

0.1mF

6

(DO NOT CONNECT)

14

ADXL150

9

SELF-TEST

TP

5

CLOCK

GAIN

AMP

DEMODULATORSENSOR

7

COM

DESIRED

OUTPUT

SCALE FACTOR

76mV/

g

100mV/

200mV/

400mV/

+V

2

25kV

OFFSET

NULL

0.1mF

F.S.

RANGE

625g2.0 200kV

g

620g2.6 261kV

g

610g5.3 536kV

g

65

g

S

8

5kV

BUFFER

AMP

+V

S

2

EXT

AMP

GAIN

10.5 1MV

0

R3

VALUE

200kV

g

TRIM

10

Figure 20.␣ One-Pole Post Filter Circuit with SF and Zero g Offset Trims

–10–

V

OUT

REV. 0

Page 11

ADXL150/ADXL250

POWER SUPPLY VOLTAGE

2.65

2.50

2.35

5.25 5.20 5.15 5.10 5.05 5.00 4.95 4.90 4.85 4.80 4.75

2.60

2.55

2.45

2.40

40.25

38.00

35.75

SENSITIVITY

39.50

38.75

37.25

36.50

0

g

OFFSET

for various full-scale g levels and approximate circuit bandwidths. For bandwidths other than those listed, use the

formula:

Cf =

2π R3

()

Desired 3 dB Bandwidth in Hz

1

or simply scale the value of capacitor Cf accordingly; i.e., for an

application with a 50 Hz bandwidth, the value of Cf will need

to be twice as large as its 100 Hz value. If further noise reduction is needed while maintaining the maximum possible bandwidth, a 2- or 3-pole post filter is recommended. These provide

a much steeper roll-off of noise above the pole frequency. Figure 21 shows a circuit that provides 2-pole post filtering. Component values for the 2-pole filter were selected to operate the

first op amp at unity gain. Capacitors C3 and C4 were chosen

to provide 3 dB bandwidths of 10 Hz, 30 Hz, 100 Hz and

300 Hz.

The second op amp offsets and scales the output to provide a

+2.5 V ± 2 V output over a wide range of full-scale g levels.

APPLICATION HINTS

ADXL250 Power Supply Pins

When wiring the ADXL250, be sure to connect BOTH power

supply terminals, Pins 14 and 13.

Ratiometric Operation

Ratiometric operation means that the circuit uses the power

supply as its voltage reference. If the supply voltage varies, the

accelerometer and the other circuit components (such as an

ADC, etc.) track each other and compensate for the change.

Figure 22 shows how both the zero g offset and output sensitivity of the ADXL150/ADXL250 vary with changes in supply

voltage. If they are to be used with nonratiometric devices, such

as an ADC with a built-in 5 V reference, then both components

should be referenced to the same source, in this case the ADC

reference. Alternatively, the circuit can be powered from an

external +5 volt reference.

Figure 22. Typical Ratiometric Operation

Since any voltage variation is transferred to the accelerometer’s

output, it is important to reduce any power supply noise. Simply

following good engineering practice of bypassing the power supply

right at Pin 14 of the ADXL150/ADXL250 with a 0.1 µF ca-

pacitor should be sufficient.

+V

S

C1

0.1mF

TYPICAL FILTER VALUES

BW C3 C4

300Hz 0.027mF 0.0033mF

100Hz 0.082mF 0.01mF

30Hz 0.27mF 0.033mF

10Hz 0.82mF 0.1mF

DESIRED

OUTPUT

SCALE FACTOR

g

76mV/

100mV/

200mV/

400mV/

F.S.

RANGE

±25

±20

±10

±5

g

g

g

g

g

g

g

14

SENSOR

SELF-TEST

EXT

AMP

VALUE

GAIN

2.0 200kV

2.6 261kV

5.3 536kV

10.5 1MV

TP

(DO NOT CONNECT)

ADXL150

9

R5

5

CLOCK

GAIN

AMP

COM

DEMODULATOR

7

OFFSET

NULL

C2

0.1mF

+V

S

2

25kV

OUTPUT

5kV

8

+V

S

2

AMPLIFIER

BUFFER

AMP

SCALING

Figure 21. Two-Pole Post Filter Circuit

R3

82.5kV

C4

+V

S

2

OP296

3

1/2

0.1mF

8

2-POLE

FILTER

+V

S

200kV

0g TRIM

1

R2

R1

42.2kV

82.5kV

10

C3

+V

S

2

5

1/2

7

OP296

4

R5

R4

100kV

6

R6

1MV

REV. 0

–11–

Page 12

ADXL150/ADXL250

0

g

(a)

0

g

(b)

+1

g

(c)

–1

g

(d)

8

14

1

7

8

14

7

1

8

7

1

14

1

14

7

8

Additional Noise Reduction Techniques

Shielded wire should be used for connecting the accelerometer to

any circuitry that is more than a few inches away—to avoid 60 Hz

pickup from ac line voltage. Ground the cable’s shield at only one

end and connect a separate common lead between the circuits;

this will help to prevent ground loops. Also, if the accelerometer

is inside a metal enclosure, this should be grounded as well.

Mounting Fixture Resonances

A common source of error in acceleration sensing is resonance

of the mounting fixture. For example, the circuit board that the

ADXL150/ADXL250 mounts to may have resonant frequencies

in the same range as the signals of interest. This could cause the

CALIBRATING THE ADXL150/ADXL250

If a calibrated shaker is not available, both the zero g level and

scale factor of the ADXL150/ADXL250 may be easily set to fair

accuracy by using a self-calibration technique based on the 1 g

acceleration of the earth’s gravity. Figure 24 shows how gravity

and package orientation affect the ADXL150/ADXL250’s

output. With its axis of sensitivity in the vertical plane, the

ADXL150/ADXL250 should register a 1 g acceleration, either

positive or negative, depending on orientation. With the axis of

sensitivity in the horizontal plane, no acceleration (the zero g

bias level) should be indicated. The use of an external buffer

amplifier may invert the polarity of the signal.

signals measured to be larger than they really are. A common

solution to this problem is to damp these resonances by mounting the ADXL150/ADXL250 near a mounting post or by adding extra screws to hold the board more securely in place.

When testing the accelerometer in your end application, it is

recommended that you test the application at a variety of frequencies to ensure that no major resonance problems exist.

REDUCING POWER CONSUMPTION

The use of a simple power cycling circuit provides a dramatic

reduction in the accelerometer’s average current consumption.

In low bandwidth applications such as shipping recorders, a

simple, low cost circuit can provide substantial power reduction.

If a microprocessor is available, it can supply a TTL clock pulse

to toggle the accelerometer’s power on and off.

A 10% duty cycle, 1 ms on, 9 ms off, reduces the average cur-

rent consumption of the accelerometer from 1.8 mA to 180 µA,

providing a power reduction of 90%.

Figure 23 shows the typical power-on settling time of the

ADXL150/ADXL250.

V

5.0

4.5

4.0

3.5

3.0

2.5

2.0

VOLTAGE – Volts

1.5

1.0

0.5

0

0 0.04

0.08 0.12 0.16 0.20 0.24 0.28 0.32 0.36

TIME – ms

S

0.5V

V

– 50

g

OUT

V

= 0

g

OUT

V

+ 50

g

OUT

0.5V

Figure 23. Typical Power-On Settling with Full-Scale

Input. Time Constant of Post Filter Dominates the

Response When a Signal Is Present.

Figure 24. Using the Earth’s Gravity to SelfCalibrate the ADXL150/ADXL250

Figure 24 shows how to self-calibrate the ADXL150/ADXL250.

Place the accelerometer on its side with its axis of sensitivity

oriented as shown in “a.” (For the ADXL250 this would be the

“X” axis—its “Y” axis is calibrated in the same manner, but the

part is rotated 90° clockwise.) The zero g offset potentiometer

RT is then roughly adjusted for midscale: +2.5 V at the external

amp output (see Figure 20).

Next, the package axis should be oriented as in “c” (pointing

down) and the output reading noted. The package axis should

then be rotated 180° to position “d” and the scale factor poten-

tiometer, R1b, adjusted so that the output voltage indicates a

change of 2 gs in acceleration. For example, if the circuit scale

factor at the external buffer’s output is 100 mV per g, the scale

factor trim should be adjusted so that an output change of

200 mV is indicated.

Self-Test Function

A Logic “1” applied to the self-test (ST) input will cause an

electrostatic force to be applied to the sensor that will cause it to

deflect. If the accelerometer is experiencing an acceleration

when the self-test is initiated, the output will equal the algebraic

sum of the two inputs. The output will stay at the self-test level

as long as the ST input remains high, and will return to the

actual acceleration level when the ST voltage is removed.

Using an external amplifier to increase output scale factor may

cause the self-test output to overdrive the buffer into saturation.

The self-test may still be used in this case, but the change in the

output must then be monitored at the accelerometer’s output

instead of the external amplifier’s output.

Note that the value of the self-test delta is not an exact indication of the sensitivity (mV/g) and therefore may not be used to

calibrate the device for sensitivity error.

–12–

REV. 0

Page 13

ADXL150/ADXL250

MINIMIZING EMI/RFI

The architecture of the ADXL150/ADXL250, and its use of

synchronous demodulation, makes the device immune to most

electromagnetic (EMI) and radio frequency (RFI) interference.

The use of synchronous demodulation allows the circuit to

reject all signals except those at the frequency of the oscillator

driving the sensor element. However, the ADXL150/ADXL250

have a sensitivity to noise on the supply lines that is near its

internal clock frequency (approximately 100 kHz) or its odd

harmonics and can exhibit baseband errors at the output. These

error signals are the beat frequency signals between the clock

and the supply noise.

Such noise can be generated by digital switching elsewhere in

the system and must be attenuated by proper bypassing. By

inserting a small value resistor between the accelerometer and

its power supply, an RC filter is created. This consists of the

resistor and the accelerometer’s normal 0.1 µF bypass capacitor.

For example if R = 20 Ω and C = 0.1 µF, a filter with a pole at

80 kHz is created, which is adequate to attenuate noise on the

supply from most digital circuits, with proper ground and supply layout.

Power supply decoupling, short component leads, physically

small (surface mount, etc.) components and attention to good

grounding practices all help to prevent RFI and EMI problems.

Good grounding practices include having separate analog and

digital grounds (as well as separate power supplies or very good

decoupling) on the printed circuit boards.

INTERFACING THE ADXL150/ADXL250 SERIES

ACCELEROMETERS WITH POPULAR ANALOG-TODIGITAL CONVERTERS.

Basic Issues

i

MEM

S

The ADXL150/ADXL250 Series accelerometers were designed

to drive popular analog-to-digital converters (ADCs) directly.

In applications where both a ±50 g full-scale measurement range

and a 1 kHz bandwidth are needed, the V

accelerometer is simply connected to the V

terminal of the

OUT

terminal of the

IN

ADC as shown in Figure 25a. The accelerometer provides its

(nominal) factory preset scale factor of +2.5 V ±38 mV/g which

drives the ADC input with +2.5 V ±1.9 V when measuring a

50 g full-scale signal (38 mV/g × 50 g = 1.9 V).

As stated earlier, the use of post filtering will dramatically

improve the accelerometer’s low g resolution. Figure 25b shows

a simple post filter connected between the accelerometer and

the ADC. This connection, although easy to implement, will

require fairly large values of Cf, and the accelerometer’s signal

will be loaded down (causing a scale factor error) unless the

ADC’s input impedance is much greater than the value of Rf.

ADC input impedance’s range from less than 1.5 kΩ up to

greater than 15 kΩ with 5 kΩ values being typical. Figure 25c is

the preferred connection for implementing low-pass filtering

with the added advantage of providing an increase in scale

factor, if desired.

Calculating ADC Requirements

The resolution of commercial ADCs is specified in bits. In an

ADC, the available resolution equals 2

of bits. For example, an 8-bit converter provides a resolution of

8

whi ch equals 256. So the full-scale input range of the converter

2

n

, where n is the number

divided by 256 will equal the smallest signal it can resolve.

In selecting an appropriate ADC to use with our accelerometer

we need to find a device that has a resolution better than the

measurement resolution but, for economy’s sake, not a great

deal better.

For most applications, an 8- or 10-bit converter is appropriate.

The decision to use a 10-bit converter alone, or to use a gain

stage together with an 8-bit converter, depends on which is more

important: component cost or parts count and ease of assembly.

Table II shows some of the tradeoffs involved.

Table II.

8-Bit Converter and 10-Bit (or 12-Bit)

Op Amp Preamp Converter

Advantages:

Low Cost Converter No Zero g Trim Required

Disadvantages:

Needs Op Amp Higher Cost Converter

Needs Zero g Trim

Adding amplification between the accelerometer and the ADC

will reduce the circuit’s full-scale input range but will greatly

reduce the resolution requirements (and therefore the cost) of

the ADC. For example, using an op amp with a gain of 5.3

following the accelerometer will increase the input drive to the

ADC from 38 mV/g to 200 mV/g. Since the signal has been

gained up, but the maximum full-scale (clipping) level is still the

same, the dynamic range of the measurement has also been

reduced by 5.3.

Table III. Typical System Resolution Using Some Popular

ADCs Being Driven with and without an Op Amp Preamp

Converter SF FS System

Converter mV/Bit Preamp in Range Resolution

Type 2

8 Bit 256 19.5 mV None 38 ±50 0.51

10 Bit 1,024 4.9 mV None 38 ±50 0.13

12 Bit 4,096 1.2 mV None 38 ±50 0.03

n

(5 V/2n) Gain mV/g in g’s in g’s (p-p)

256 19.5 mV 2 76 ±25 0.26

256 19.5 mV 2.63 100 ±20 0.20

256 19.5 mV 5.26 200 ±10 0.10

1,024 4.9 mV 2 76 ±25 0.06

1,024 4.9 mV 2.63 100 ±20 0.05

1,024 4.9 mV 5.26 200 ±10 0.02

4,096 1.2 mV 2 76 ±25 0.02

4,096 1.2 mV 2.63 100 ±20 0.01

4,096 1.2 mV 5.26 200 ±10 0.006

Table III is a chart showing the required ADC resolution vs. the

scale factor of the accelerometer with or without a gain amplifier. Note that the system resolution specified in the table refers

REV. 0

–13–

Page 14

ADXL150/ADXL250

+V

S

V

OUT

XL

+V

S

ADC

V

OS

NULL PIN

0

g

OFFSET

ADJUST

+V

S

V

OUT

XL

+V

S

ADC

R

F

Cf

R1

to that provided by the converter and preamp (if used). It is

necessary to use sufficient post filtering with the accelerometer

to reduce its noise floor to allow full use of the converter’s resolution (see post filtering section).

The use of a gain stage following the accelerometer will normally require the user to adjust the zero g offset level (either by

trimming or by resistor selection—see previous sections).

For many applications, a modern “economy priced” 10-bit

converter, such as the AD7810 allows you to have high resolution without using a preamp or adding much to the overall

circuit cost. In addition to simplicity and cost, it also meets two

other necessary requirements: it operates from a single +5 V

supply and is very low power.

a. Direct Connection, No Signal Amplification or

Post Filtering

+V

S

R

XL

F

V

OUT

Cf

+V

S

ADC

INPUT

RESISTANCE

b. Single-Pole Post Filtering, No Signal Amplification

c. Single-Pole Post Filtering and Signal Amplification

Figure 25. Interfacing the ADXL150/ADXL250 Series

Accelerometers to an ADC

–14–

REV. 0

Page 15

OUTLINE DIMENSIONS

0.291 (7.391)

0.285 (7.239)

0.390 (9.906)

MAX

PIN 1

0.419 (10.643)

0.394 (10.008)

7

14 8

1

0.300 (7.62)

0.345 (8.763)

0.290 (7.366)

0.0125 (0.318)

0.009 (0.229)

0.050 (1.270)

0.016 (0.406)

88

08

SEATING

PLANE

0.020 (0.508)

0.004 (0.102)

0.020 (0.508)

0.013 (0.330)

0.050

(1.27)

BSC

0.195 (4.953)

0.115 (2.921)

0.215 (5.461)

0.119 (3.023)

Dimensions shown in inches and (mm).

14-Lead Cerpac

(QC-14)

ADXL150/ADXL250

C2949–8–4/98

REV. 0

PRINTED IN U.S.A.

–15–

Loading...

Loading...