Page 1

Low Cost ⴞ100 gSingle Axis

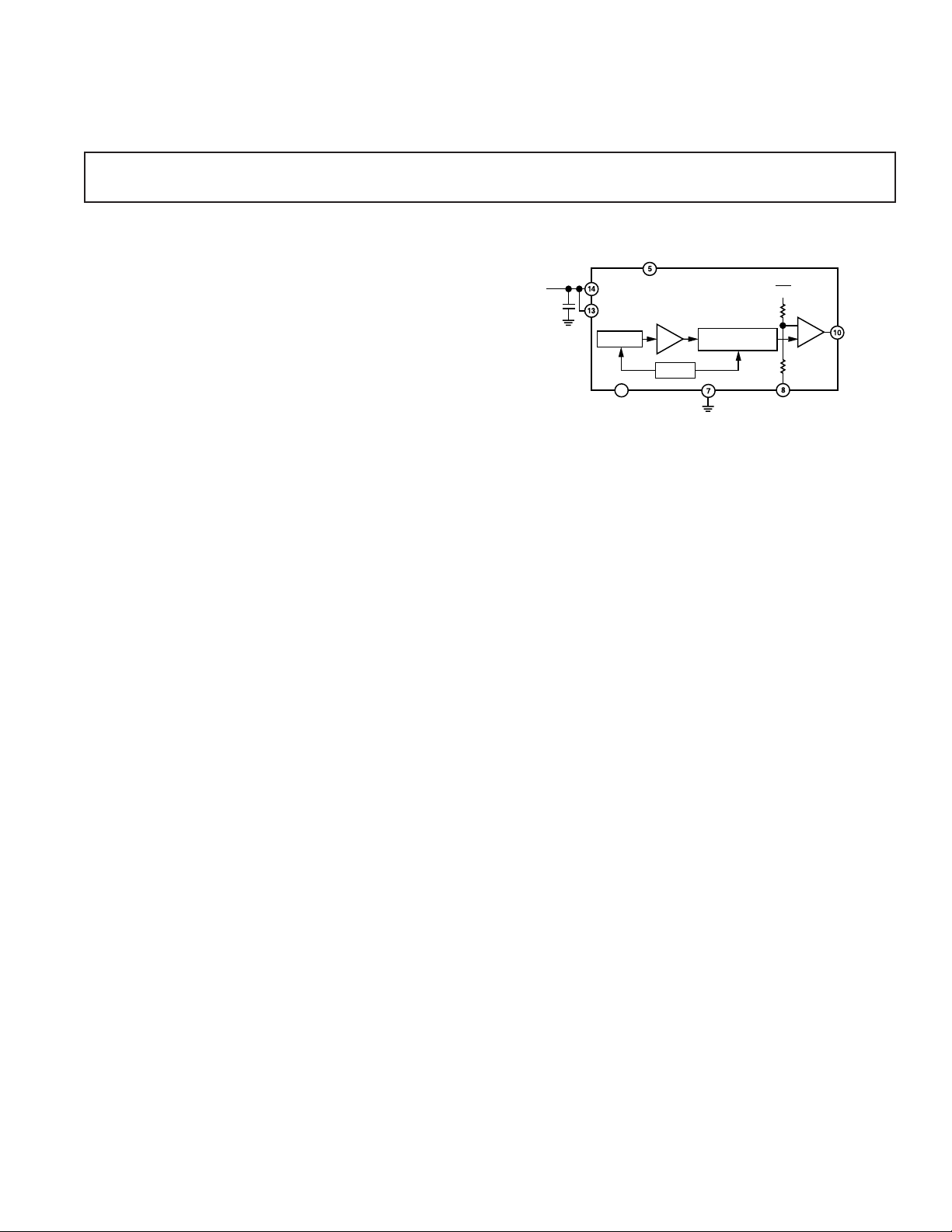

SELF-TEST

+V

S

2

25kV

5kV

ADXL190

GAIN

AMP

ZERO g ADJUST

COM

0.1mF

BUFFER

AMP

DEMODULATOR

SENSOR

+V

S

TP

(DO NOT CONNECT)

V

OUT

9

CLOCK

a

FEATURES

®

iMEMS

40 MilliLow Power 2 mA

400 Hz Bandwidth

+5.0 V Single Supply Operation

2000

APPLICATIONS

Shock and Vibration Measurement

Machine Health

Shipping Recorders

Military Fuze, Safe and Arm

GENERAL DESCRIPTION

Single Chip IC Accelerometer

g

Resolution

g

Shock Survival

Accelerometer with Analog Output

The ADXL190 is a complete acceleration measurement system

on a single monolithic IC. It contains a polysilicon surfacemicromachined sensor and signal conditioning circuitry to

implement an open-loop acceleration measurement architecture.

The ADXL190 is capable of measuring both positive and nega-

tive accelerations up to ±100 g, making it suitable for shock and

vibration measurement.

Typical noise floor is 4 mg/√Hz allowing signals below 40 milli-g

to be resolved. The ADXL190 can measure both dynamic accelerations, (typical of vibration) or static accelerations, (such as

inertial force or gravity).

The ADXL190 has a two-pole Bessel switched-capacitor filter.

Bessel filters, sometimes called linear phase filters, have a step

response with minimal overshoot and a maximally flat group

ADXL190*

FUNCTIONAL BLOCK DIAGRAM

delay. The –3 dB frequency of the poles is preset at the factory

to 400 Hz. These filters are also completely self-contained and

buffered, requiring no external components.

The product features a built-in self-test feature that exercises

both the mechanical structure and electrical circuitry. When

triggered by a logic high on the self-test pin, an electrostatic

force acts on the beam equivalent to approximately 20% of fullscale acceleration input, and thus a proportional voltage change

appears on the output pin. No external components other than a

decoupling capacitor are required.

The ADXL190 is available in a hermetic 14-lead surface mount

cerpak, specified over the –40°C to +105°C temperature range.

*Patent Pending.

i

MEM

S

is a registered trademark of Analog Devices, Inc.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

ADXL190–SPECIFICATIONS

(TA = T

MIN

to T

, VS = +5 V, Acceleration = 0 g unless otherwise noted)

MAX

ADXL190WQC

Parameter Conditions Min Typ Max Units

SENSOR INPUT

Dynamic Range

1, 2, 3

Without Zero-g Adjust ±105 g

Alignment Error ±1 Degrees

Nonlinearity 0.2 %

Cross Axis Sensitivity ±2%

SENSITIVITY

ZERO g BIAS LEVEL

4

Initial

Temperature Drift

2, 3

Initial

5

0 g Offset vs. Temperature

5

Ratiometric 16.5 18.0 19.5 mV/g

∆ from +25°C ±0.5 %

Ratiometric 2.3 2.5 2.7 V

∆ from +25°C 1.0 g

Zero g Adjustment Gain 0.45 0.50 0.55 ∆V

/∆V 0 g Adjust

OUT

Zero g Adjust Pin Input Impedance 20 30 40 kΩ

NOISE PERFORMANCE

Noise Density 4 12 mg/√Hz rms

FREQUENCY RESPONSE

3 dB Bandwidth 360 400 Hz

Sensor Resonant Frequency 24 kHz

SELF-TEST

Output Change

6

450 990 mV

Logic “1” Voltage 3.5 V

Logic “0” Voltage 1.0 V

Input Impedance 50 kΩ

ANALOG OUTPUT

Output Voltage Range I

= ±100 µA0.25 V

OUT

– 0.25 V

S

Capacitive Load Drive 1000 pF

POWER SUPPLY

Specified Performance 4.75 5.25 V

Quiescent Supply Current 2.0 5.0 mA

TEMPERATURE RANGE

Specified Performance –40 +105 °C

NOTES

1

Product is tested at ±50 g, and the combination of 0-g error, sensitivity error, and output voltage swing measurements provide the calculations for dynamic range.

2

0-g is nominally VS/2. Use of the 0-g adjustment pin is used to null the 0-g error, resulting in increased dynamic range. It can also be used to create an asymmetrical

dynamic range if so desired.

3

The output response is ratiometric and is described by the following equation. V

Where a = 0.2 V, b = 2.712 × 10–3 1/g , c = 0.178 × 10

4

Measured at 100 Hz, ±50 g.

5

Specification refers to the maximum change in parameter from its initial value at +25 °C to its worst case value at T

6

ST pin Logic “0” to “1”; ∆V

All min and max specifications are guaranteed. Typical specifications are not tested or guaranteed.

Specifications subject to change without notice.

OUT

= (∆V

@ 5 V) × (V

OUT

–3

1/g/V.

/5 V).

S

(accel, VS) = [V

OUT

/2 ±(a V

S

/5 V)] + [(accel) (b VS + c V

S

MIN

or T

MAX

.

2

)(1 ± 0.08)]

S

–2–

REV. 0

Page 3

ADXL190

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . . 2000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . .1000 g

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–0.3 V to +7.0 V

+V

S

Short Circuit Duration (Any Pin to Common) . . . . Indefinite

Operating Temperature . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Drops onto hard surfaces can cause shocks of greater than 2000 g

and exceed the absolute maximum rating of the device. Care

should be exercised in handling to avoid damage.

PIN FUNCTION DESCRIPTIONS

Pin No. Function

1, 2, 3, 4, 6, 11, 12 No Connect

5 Test Point (Do Not Connect)

7 Common

8 Zero g Adjust

9 Self-Test

10 V

13, 14 V

OUT

S

PACKAGE CHARACTERISTICS

Package

JA

JC

Device Weight

14-Lead Cerpak +110°C/W +30°C/W 5 Grams

PIN CONFIGURATION

NC

NC

NC

NC

TEST POINT

(DO NOT CONNECT)

NC

COMMON

1

2

3

ADXL190

4

TOP VIEW

(Not to Scale)

5

6

7

NC = NO CONNECT

14

13

12

11

10

9

8

V

S

V

S

NC

NC

V

OUT

SELF-TEST

g

ADJUST

ZERO

Figure 1 shows the response of the ADXL190 to the earth’s

gravitational field. The output values shown are nominal. They

are presented to show the user what type of response to expect

from each of the output pins due to changes in orientation with

respect to the earth.

PIN 1

PIN 1

1

7

814

TYPICAL OUTPUT AT

PIN 10 = 2.500V

1

PIN 1

TYPICAL OUTPUT AT

PIN 10 = 2.500V

1

TYPICAL OUTPUT AT

814

7

TYPICAL OUTPUT AT

EARTH'S SURFACE

14

7

8

PIN 10 = 2.482V

78

1

14

PIN 10 = 2.518V

PIN 1

1

g

Figure 1. ADXL190 Response Due to Gravity

ORDERING GUIDE

# Specified Temperature Package Package

Model Axis Voltage Range Description Option

ADXL190WQC 1 +5 V –40°C to +105°C 14-Lead Cerpak QC-14

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL190 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

–3–

Page 4

ADXL190

APPLICATIONS

All the circuitry needed to drive the sensor and convert the

capacitance change to voltage is incorporated on-chip requiring

no external components except for standard power supply decoupling. Both sensitivity and the zero-g value are ratiometric to

the supply voltage, so that ratiometric devices following the

accelerometer (such as an ADC, etc.) will track the accelerometer if the supply voltage changes. The output voltage (V

OUT

) is

a function of both the acceleration input (a) and the power

V

OUT

) as follows:

S

= V

/2 – (Sensitivity × VS/5 V × a)

S

supply voltage (V

Adjusting the 0 g Bias Level

In some cases the user may have an asymmetrical input or may

want to fine adjust the zero-g output level to obtain maximum

dynamic range. The zero-g level is adjusted by supplying a

voltage to the zero-g adjustment pin (see Figure 2).

+V

S

ADXL190

ACCELERATION

SIGNAL

C2

0.1mF

2

5kV

25kV

FILTER

ZERO g ADJUST

+V

200kV

GAIN = 3

S

V

OUT

Figure 2. Optional Zero-g Adjust Circuit Detail

Any voltage difference between the zero-g adjustment pin and

/2 is reduced by a factor of 6 by the internal resistor divider.

V

S

This is then gained by the factor of 3 in the output stage for a

total gain of 0.5 for the zero-g adjustment. (Note: The ratio of

the resistors in the divider is consistent from part-to-part; how-

ever, the absolute values can have a ±30% tolerance). The

zero-g adjustment voltage can be set up by a variety of methods

including a potentiometer (as shown in Figure 2), a PWM signal, or with a simple three-state output.

The simplest way is by adding a resistor between the ZERO g

ADJUST pin and V

where R is in kΩ and connected to V

or ground. The output will be offset by:

S

Offset (V) = (7.5 × V

Offset (V) = (–7.5 × V

)/(30 + R)

S

.

S

)/(30 + R)

S

where R is in kΩ and connected to ground.

Resistors may also be connected to microcontroller I/O pins as

shown in Figure 3. Using two I/Os that may be set to V

, ground,

S

or three-state, there are seven possibilities as shown in Table I

(one cannot set one I/O pin to V

and the other to ground).

S

Using such a system, any ADXL190 may be user trimmed to

output 2.5 V ± 35 mV at zero g.

Table I. Offsets Produced Using the Circuit in Figure 3 for V

S

= 5 V

Offset Voltage

P1 P0 Produced Offset in g

Three-State Three-State 0 mV 0

Three-State 0 –71 mV –4

0 Three-State –134 mV –7.4

0 0 –191 mV –10.6

Three-State 1 71 mV 4

1 Three-State 134 mV 7.4

1 1 191 mV 10.6

Another way to adjust the zero g offset is to supply a voltage to

the ZERO g ADJUST pin. The difference between V

/2 and

S

the voltage at the ZERO g ADJUST pin is reduced by a factor

of 6 (as a result of the internal 5 kΩ and 25 kΩ voltage divider)

and then multiplied by a factor of 3 in the output stage of the

ADXL190 resulting in a total gain of 0.5. Offset is thus described by the following equation:

Offset (V) = (Voltage at the ZERO g ADJUST Pin – V

/2)/2

S

This voltage may be produced by a variety of methods including a PWM signal from a microcontroller. Care must be taken

that the output impedance of this voltage source is less than

5 kΩ and that there is very little ripple (noise). Any noise at the

ZERO g ADJUST pin will cause output errors.

If an asymmetric range of acceleration is required (e.g., +75 g

to –125 g) a resistor may be connected between the ZERO g

ADJUST and ground or V

as described above. For example:

S

For a range of +75 g to –125 g the offset required is –25 g.

–25 g at 18 mV/g = 450 mV of offset is required.

Rearranging the offset equations above:

R = [(7.5 × V

)/offset] –30 = 53.3 kΩ connected to ground.

S

For asymmetric operation the g range midpoint may be shifted

up to ±80 g typically.

MICROCONTROLLER

250kV

P1

500kV

P0

ZERO

ADJUST

g

ADXL190

Figure 3. An Offset Adjustment Scheme

–4–

REV. 0

Page 5

OUTLINE DIMENSIONS

17

8

14

0.291 (7.391)

0.285 (7.239)

0.485 (12 .319)

MAX

PIN 1

0.300 (7 .62)

0.419 (10.643)

0.394 (10.008)

0.345 (8.763)

0.290 (7.366)

8

0

0.050 (1.270)

0.016 (0.406)

0.013 (0.318)

0.009 (0.229)

SEATING

PLANE

0.195 (4.953)

0.115 (2.921)

0.215 (5.461)

0.119 (3.023)

0.020 (0.508)

0.013 (0.330)

0.050

(1.27)

BSC

0.020 (0.508)

0.004 (0.102)

Dimensions shown in inches and (mm).

14-Lead Cerpak

(QC-14)

ADXL190

C3457–8–2/99

REV. 0

PRINTED IN U.S.A.

–5–

Loading...

Loading...