Page 1

61 g to 65 g Single Chip Accelerometer

a

FEATURES

g

5 milliNoise Level 123 Less than the ADXL50

User Selectable Full Scale from 61 g to 65

Output Scale Selectable from 200 mV/g to 1 V/

Complete Acceleration Measurement System on a

Self Test on Digital Command

+5 V Single Supply Operation

1000

APPLICATIONS

Low Cost Sensor for Vibration Measurement

Tilt Sensing with Faster Response than Electrolytic or

More Sensitive Alarms and Motion Detectors

Affordable Inertial Sensing of Velocity and Position

GENERAL DESCRIPTION

The ADXL05 is a complete acceleration measurement system

on a single monolithic IC. The ADXL05 will measure accelerations with full-scale ranges of ±5 g to ±1 g or less. Typical noise

Resolution

Single Chip IC

g

Shock Survival

Mercury Sensors

g

g

with Signal Conditioning

ADXL05*

floor is 500 µg/√Hz, (12× less than the ADXL50), allowing signals below 5 milli-g to be resolved. The ADXL05 is a force balanced capacitive accelerometer with the capability to measure

both ac accelerations (typical of vibration) or dc accelerations

(such as inertial force or gravity). Three external capacitors and

a +5 volt regulated power supply are all that is required to

measure accelerations up to ±5 g. Three resistors are used to

configure the output buffer amplifier to set scale factors from

200 mV/g to 1 V/g. External capacitors may be added to the

resistor network to provide 1 or 2 poles of filtering. No additional active components are required to interface directly to

most analog to digital converters (ADCs).

The device features a TTL compatible self-test function that

can electrostatically deflect the sensor beam at any time to verify

that the sensor and its electronics are functioning correctly.

The ADXL05 is available in a hermetic 10-pin TO-100 metal

can, specified over the 0°C to +70°C commercial, and –40°C to

+85°C industrial temperature ranges. Contact factory for availability of automotive grade devices.

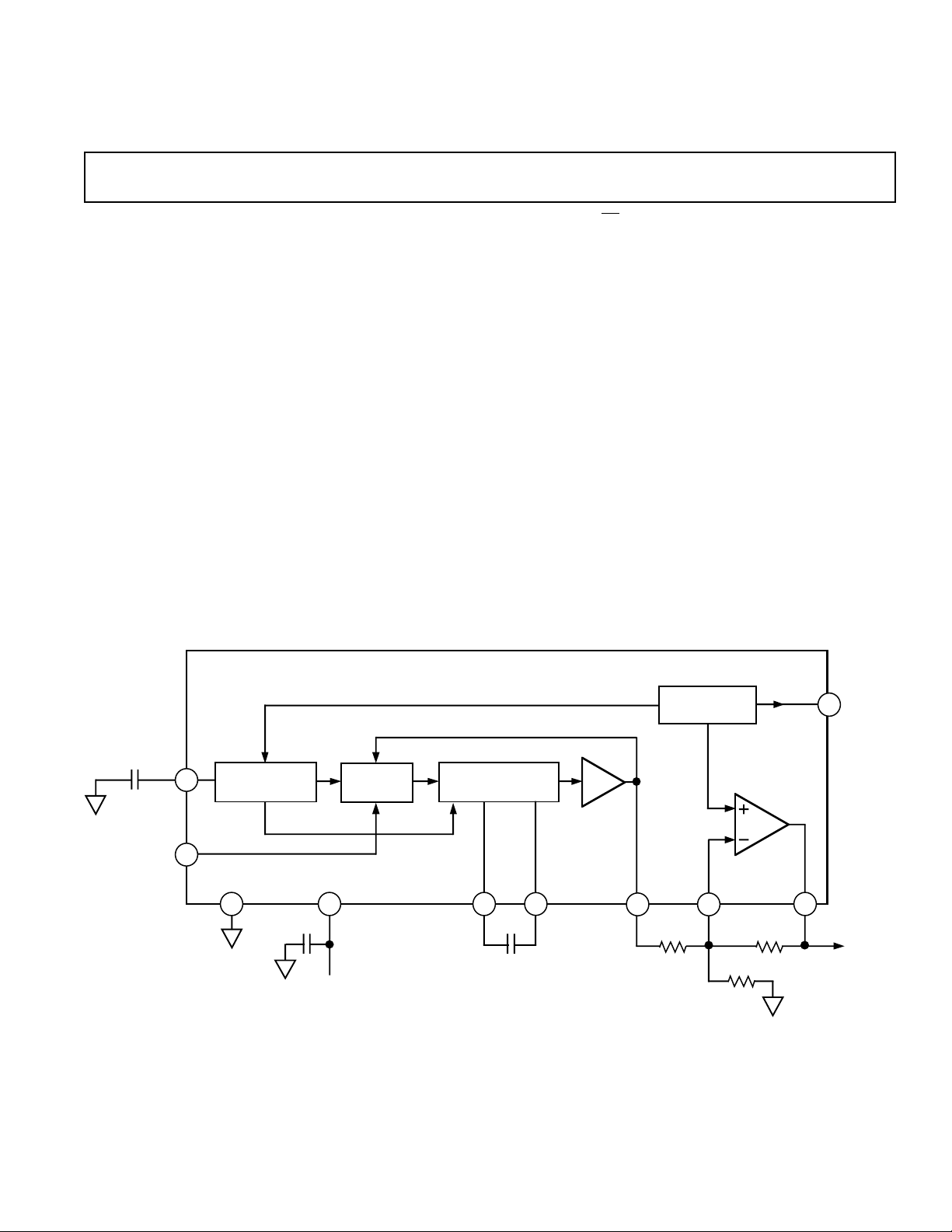

OSCILLATOR

DECOUPLING

CAPACITOR

C2

SELF-TEST

(ST)

*Patents pending.

4

7

COM

ADXL05

OSCILLATOR

C3

+5V

15

FUNCTIONAL BLOCK DIAGRAM

SENSOR

DEMODULATOR

C1

DEMODULATOR

CAPACITOR

32

C1

PREAMP

V

PR

8

REFERENCE

10

R1

+1.8V

V

IN–

BUFFER

AMP

R3

R2

+3.4V

V

REF

6

OUTPUT

9

V

OUT

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

ADXL05–SPECIFICA TIONS

(TA = T

MIN

to T

, TA = +258C for J Grade Only, VS = +5 V, @ Acceleration = 0 g,

MAX

unless otherwise noted)

Parameter Conditions Min Typ Max Units

ADXL05J/A

SENSOR INPUT

Measurement Range Guaranteed Full Scale –5 +5 g

Nonlinearity Best Fit Straight Line, 5 g FS 0.2 % of FS

Alignment Error

Transverse Sensitivity

1

2

± 1 Degrees

± 2%

SENSITIVITY

Initial Sensitivity at V

Initial Sensitivity at V

Temperature Drift

PR

OUT

3

ZERO g BIAS LEVEL at V

Initial Offset 1.50 1.80 2.10 V

vs. Temperature

3

+25°C 175 200 225 mV/g

+25°C, R3/R1 = 5 0.875 1.000 1.125 V/g

± 0.5 % of Reading

PR

± 25/40 mV

vs. Supply VS = 4.75 V to 5.25 V 10 32 mV/V

NOISE PERFORMANCE at V

PR

Voltage Noise Density BW = 4 Hz to 1 kHz 500 1000 µg/√Hz

Noise in 100 Hz Bandwidth 5mg rms

Noise in 10 Hz Bandwidth 1.6 mg rms

FREQUENCY RESPONSE

3 dB Bandwidth

3 dB Bandwidth

4

4

C1 = 0.022 µF (See Figure 9) 1000 1600 Hz

C1 = 0.010 µF 4 kHz

Sensor Resonant Frequency 12 kHz

SELF TEST INPUT

Output Change at V

5

PR

ST Pin from Logic “0” to “1” –0.85 –1.00 –1.15 V

Logic “1” Voltage 2.0 V

Logic “0” Voltage 0.8 V

Input Resistance To Common 50 kΩ

+3.4 V REFERENCE

Output Voltage 3.350 3.400 3.450 V

Output Temperature Drift

3

±5mV

Power Supply Rejection DC, VS = +4.75 V to +5.25 V 1 10 mV/V

Output Current Sourcing 500 µA

PREAMPLIFIER OUTPUT

Voltage Swing 0.25 VS – 1.4 V

Current Output Source or Sink 30 80 µA

Capacitive Load Drive 100 pF

BUFFER AMPLIFIER

Input Offset Voltage

6

Delta from Nominal 1.800 V ±10 ±25 mV

Input Bias Current 520nA

Open-Loop Gain DC 80 dB

Unity Gain Bandwidth 200 kHz

Output Voltage Swing I

= ±100 µA 0.25 VS – 0.25 V

OUT

Capacitive Load Drive 1000 pF

Power Supply Rejection DC, VS = +4.75 V to +5.25 V 1 10 mV/V

POWER SUPPLY

Operating Voltage Range 4.75 5.25 V

Quiescent Supply Current 8.0 10.0 mA

TEMPERATURE RANGE

Operating Range J 0 +70 °C

Specified Performance A –40 +85 °C

Automotive Grade* –40 +125 °C

NOTES

1

Alignment error is specified as the angle between the true and indicated axis of sensitivity, (see Figure 2).

2

Transverse sensitivity is measured with an applied acceleration that is 90° from the indicated axis of sensitivity. Transverse sensitivity is specified as the percent of

transverse acceleration that appears at the V

3

Specification refers to the maximum change in parameter from its initial at +25°C to its worst case value at T

4

Frequency at which response is 3 dB down from dc response assuming an exact C1 value is used. Maximum recommended BW is 6 kHz using a 0.010 µF capacitor, refer to

Figure 9.

5

Applying logic high to the self-test input has the effect of applying an acceleration of –5 g to the ADXL05.

6

Input offset voltage is defined as the output voltage differential from 1.800 V when the amplifier is connected as a follower. The voltage at this pin has a temperature drift

proportional to that of the 3.4 V reference.

*Contact factory for availability of automotive grade devices.

All min and max specifications are guaranteed. Typical specifications are not tested or guaranteed.

Specifications subject to change without notice.

output. This is the algebraic sum of the alignment and the inherent sensor sensitivity errors, (see Figure 2).

PR

MIN

to T

MAX

.

–2–

REV. B

Page 3

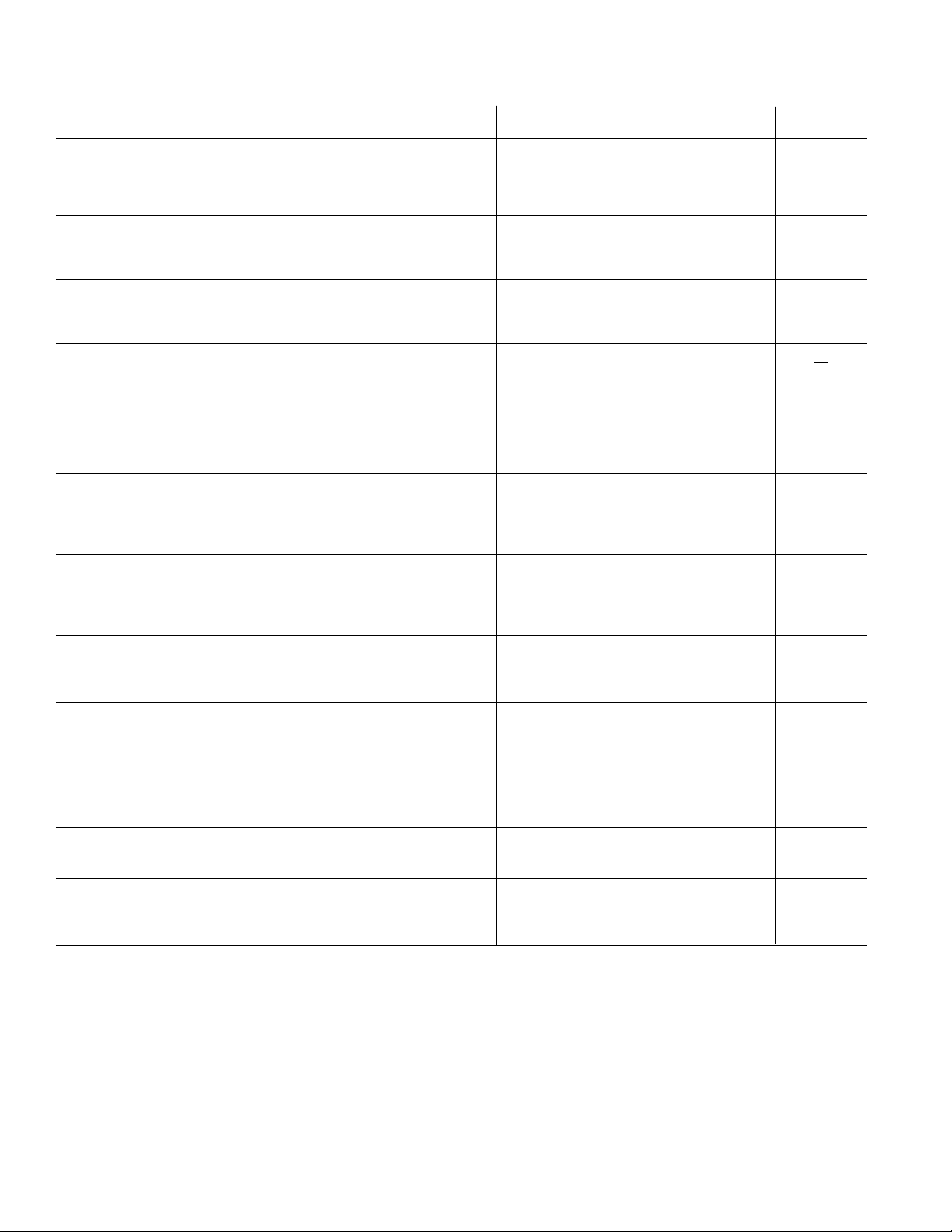

System Performance Specifications–ADXL05

0.022µF

0.022µF

COM

C2

4

ADXL05

C1

C1

2

3

5

+3.4V

REF

6

PRE-AMP

8

V

PR

C4

1.8V

10

V

R1

IN–

R2

BUFFER

AMP

R3

1

+5V

C3

0.1µF

9

V

OUT

NOMINAL VALUES:

R1 = 49.9kΩ

R3 = 249kΩ

R2 = 640kΩ

AC COUPLED CONNECTION (61.5 g Full Scale)

(@ V

Terminal (Pin 9), unless otherwise noted. 0 g Bias Level = +2.5 V, C1 = 0.022 mF, R2 = 2.57 R3

OUT

ADXL05J/A

Parameter Conditions Min Typ Max Units

Buffer Gain G = R3/R1* 5

FULL-SCALE RANGE –1.5 +1.5 g

SENSITIVITY @

Temperature Drift T

ZERO g BIAS LEVEL @ +25°C 2.5 V

Temperature Drift +25°C to T

FREQUENCY RESPONSE C4 = 3.3 µF, R1 = 49.9 kΩ 1 1000 Hz

*Note: Resistor tolerance will affect system accuracy. Use of ±1% (or better) metal film resistors is recommended.

+25°C 875 1000 1,125 mV/g

MIN

to T

MAX

MIN

or T

MAX

±0.5 % of Reading

2/5 mV

0.022µF

0.022µF

COM

C2

4

ADXL05

C1

C1

2

3

5

+3.4V

REF

6

PRE-AMP

8

V

PR

1.8V

10

V

R1

IN–

R2

BUFFER

AMP

R3

1

+5V

C3

0.1µF

9

V

OUT

NOMINAL VALUES:

R1 = 49.9kΩ

R3 = 100kΩ (G=2)

R2 = 255kΩ (G=2)

DC COUPLED CONNECTION (62 g Full Scale)

(@ V

Terminal (Pin 9), unless otherwise noted. 0 g Bias Level = +2.5 V, C1 = 0.022 mF, R2 = 2.57 R3)

OUT

ADXL05J/A

Parameter Conditions Min Typ Max Units

Buffer Gain G = R3/R1* 2

FULL-SCALE RANGE –2 +2 g

SENSITIVITY @

Temperature Drift T

ZERO g BIAS LEVEL @ +25°C 1.75 2.5 3.2 V

Temperature Drift +25°C to T

FREQUENCY RESPONSE dc 1000 Hz

*Note: Resistor tolerance will affect system accuracy. Use of ±1% (or better) metal film resistors is recommended.

+25°C 350 400 450 mV/g

MIN

to T

MAX

MIN

or T

MAX

±0.5 % of Reading

±50/80 mV

REV. B

–3–

Page 4

ADXL05

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . . 1000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . . . . 500 g

+V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

S

Package Characteristics

Package u

JA

10-Pin TO-100 130°C/W 30°C/W 5 Grams

Output Short Circuit Duration

(V

, V

, V

PR

OUT

Operating Temperature . . . . . . . . . . . . . . . . .–55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . .–65°C to +150°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only; the functional

operation of the device at these or any other conditions above those indicated in the

Terminals to Common) . . . . . . .Indefinite

REF

ORDERING GUIDE

Model Temperature Range

ADXL05JH 0°C to +70°C

ADXL05AH –40°C to +85°C

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL05 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

Drops onto hard surfaces can cause shocks of greater than 1000 g

and exceed the absolute maximum rating of the device. Care

should be exercised in handling to avoid damage.

u

JC

Device Weight

PIN DESCRIPTION

+5 V The power supply input pin.

C2 Connection for an external bypass capacitor (nominally 0.022 µF)

C1 Connections for the demodulator capacitor, nominally 0.022 µF.

COM The power supply common (or “ground”) connection.

V

ST The digital self-test input. It is both CMOS and TTL compatible.

V

V

V

used to prevent oscillator switching noise from interfering with

other ADXL05 circuitry. Please see the section on component

selection.

See the section on component selection for application information.

Output of the internal 3.4 V voltage reference.

REF

The ADXL05 preamplifier output providing an output voltage of

PR

200 mV per g of acceleration.

Output of the buffer amplifier.

OUT

The inverting input of the uncommitted buffer amplifier.

IN–

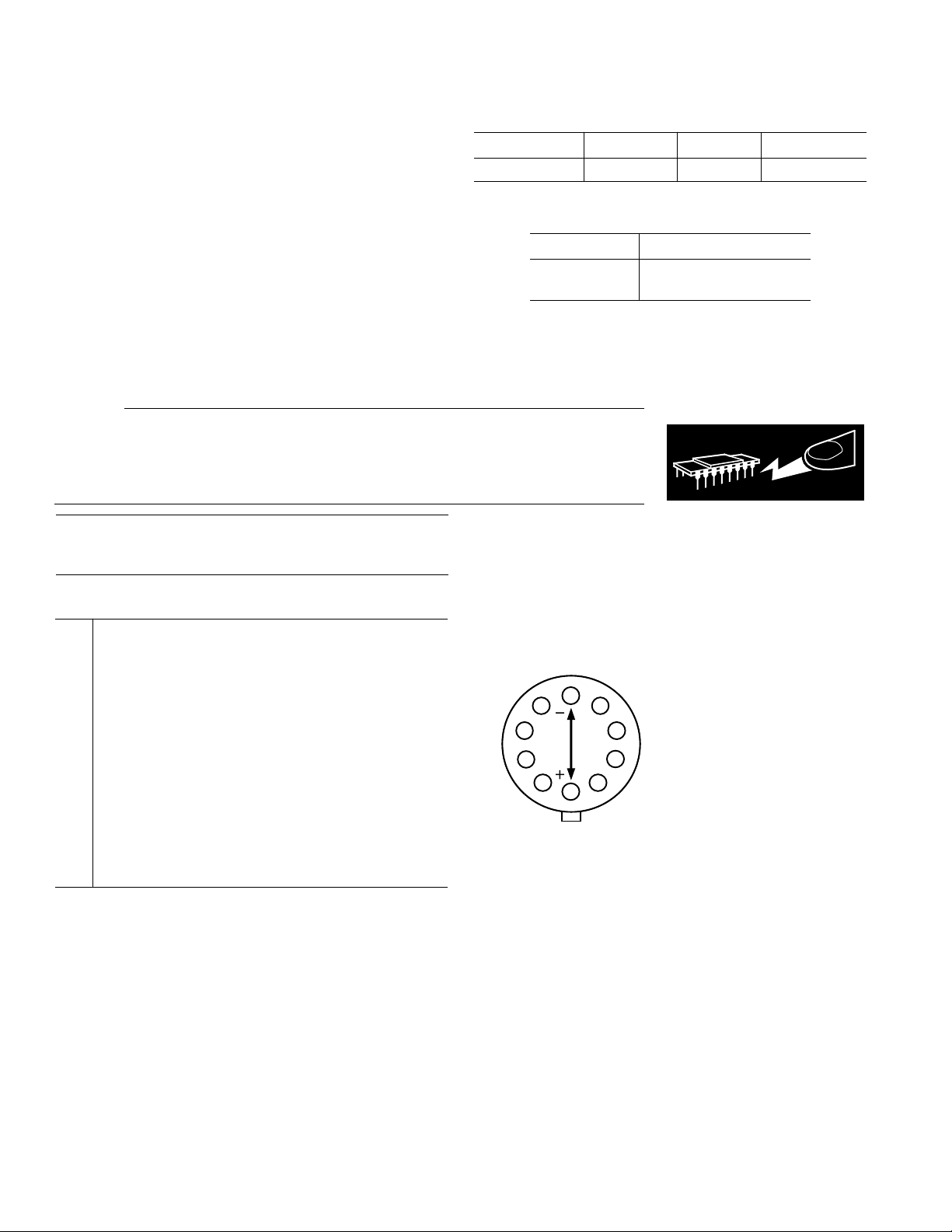

CONNECTION DIAGRAM

10-Header (TO-100)

TOP VIEW

OUT

COM

6

6

7

7

AXIS OF

AXIS OF

8

8

9

9

5

5

SENSITIVITY

SENSITIVITY

10

10

V

IN–

C2

4

4

C1

3

3

2

2

1

1

+5V

NOTES:

C1

AXIS OF SENSITIVITY IS ALONG A LINE

BETWEEN PIN 5 AND THE TAB.

THE CASE OF THE METAL CAN

PACKAGE IS CONNECTED TO PIN 5

(COMMON).

ARROW INDICATES DIRECTION OF

POSITIVE ACCELERATION ALONG AXIS

OF SENSITIVITY.

V

REF

ST

V

PR

V

–4–

REV. B

Page 5

ADXL05

+1g

INDICATED POLARITY IS THAT

OCCURRING AT V

PR

.

TAB

PIN 5

+

–

GLOSSARY OF TERMS

Acceleration: Change in velocity per unit time.

Acceleration Vector: Vector describing the net acceleration

acting upon the ADXL05 (A

XYZ

).

g: A unit of acceleration equal to the average force of gravity

occurring at the earth’s surface. A g is approximately equal to

32.17 feet/s

2

, or 9.807 meters/s2.

Nonlinearity: The maximum deviation of the ADXL05 output

voltage from a best fit straight line fitted to a plot of acceleration

vs. output voltage, calculated as a % of the full-scale output

voltage (@ 5 g).

Resonant Frequency: The natural frequency of vibration of

the ADXL05 sensor’s central plate (or “beam”). At its resonant

frequency of 12 kHz, the ADXL05’s moving center plate has a

peak in its frequency response with a Q of 3 or 4.

Sensitivity: The output voltage change per g unit of accelera-

tion applied, specified at the V

pin in mV/g.

PR

Sensitive Axis (X): The most sensitive axis of the accelerometer sensor. Defined by a line drawn between the package tab

and Pin 5 in the plane of the pin circle. See Figures 2a and 2b.

Sensor Alignment Error: Misalignment between the

ADXL05’s on-chip sensor and the package axis, defined by

Pin 5 and the package tab.

Total Alignment Error: Net misalignment of the ADXL05’s

on-chip sensor and the measurement axis of the application.

This error includes errors due to sensor die alignment to the

package, and any misalignment due to installation of the sensor

package in a circuit board or module.

Transverse Acceleration: Any acceleration applied 90° to the

axis of sensitivity.

Transverse Sensitivity Error: The percent of a transverse acceleration that appears at the V

output. For example, if the

PR

transverse sensitivity is 1%, then a +10 g transverse acceleration

will cause a 0.1 g signal to appear at V

(1% of 10 g). Trans-

PR

verse sensitivity can result from a sensitivity of the sensor to

transverse forces or from misalignment of the internal sensor to

its package.

Transverse Y Axis: The axis perpendicular (90°) to the pack-

age axis of sensitivity in the plane of the package pin circle. See

Figure 2.

Transverse Z Axis: The axis perpendicular (90°) to both the

package axis of sensitivity and the plane of the package pin

circle. See Figure 2.

Polarity of the Acceleration Output

The polarity of the ADXL05 output is shown in the Figure 1.

When oriented to the earth’s gravity (and held in place), the

ADXL05 will experience an acceleration of +1 g. This corresponds to a change of approximately +200 mV at the V

PR

output pin. Note that the polarity will be reversed to a negative

going signal at the buffer amplifier output V

, due to its

OUT

inverting configuration.

Figure 1. Output Polarity at V

PR

Acceleration Vectors in Three Dimensions

The ADXL05 is a sensor designed to measure accelerations that

result from an applied force. The ADXL05 responds to the

component of acceleration on its sensitive X axis. Figures 2a

and 2b show the relationship between the sensitive “X” axis and

the transverse “Z” and “Y” axes as they relate to the TO-100

Z

SIDE VIEW

X

PIN 5

TRANSVERSE Z AXIS

TAB

Z

X

SENSITIVE (X) AXIS

Figure 2a. Sensitive X and Transverse Z Axis

Y

TOP VIEW

X

PIN 5

TRANSVERSE Y AXIS

SENSITIVE (X) AXIS

TAB

X

REV. B

Y

Figure 2b. Sensitive X and Transverse Y Axis

–5–

Page 6

ADXL05

10

90

100

0%

0.5ms

package. Figure 2c describes a three dimensional acceleration

vector (A

component of interest. To determine A

of acceleration in the XY plane (A

) which might act on the sensor, where AX is the

XYZ

, first, the component

X

) is found using the cosine

XY

law:

A

= A

XY

A

Therefore: Nominal V

–Z AXIS

Y AXIS

(cosθXY) then

XYZ

= AXY (cosθX)

X

= 200 mV/g (A

PR

θxy

θx

Axy

) (cosθXY) cosθ

XYZ

Axyz

Ax

X

X AXIS

Figure 2c. A Vector Analysis of an Acceleration Acting

Upon the ADXL05 in Three Dimensions

Note that an ideal sensor will react to forces along or at angles

to its sensitive axis but will reject signals from its various transverse axes, i.e., those exactly 90° from the sensitive “X” axis.

But even an ideal sensor will produce output signals if the transverse signals are not exactly 90° to the sensitive axis. An acceleration that is acting on the sensor from a direction different

from the sensitive axis will show up at the ADXL05 output at a

reduced amplitude.

Table I shows the percentage signals resulting from various θ

X

angles. Note that small errors in alignment have a negligible

effect on the output signal. A 1° error will only cause a 0.02%

error in the signal. Note, however, that a signal coming 1° off of

the transverse axis (i.e., 89° off the sensitive axis) will still contribute 1.7% of its signal to the output. Thus large transverse

signals could cause output signals as large as the signals of

interest. Table I may also be used to approximate the effect of

the ADXL05’s internal errors due to misalignment of the die to

the package. For example: a 1 degree sensor alignment error will

allow 1.7% of a transverse signal to appear at the output.

Table I. Ideal Output Signals for Off Axis Applied

Accelerations Disregarding Device Alignment and

Transverse Sensitivity Errors

% of Signal Appearing Output in gs for a 5 g

θ

X

at Output Applied Acceleration

0 100% 5.000 (On Axis)

1° 99.98% 4.999

2° 99.94% 4.997

3° 99.86% 4.993

5° 99.62% 4.981

10° 98.48% 4.924

30° 86.60% 4.330

45° 70.71% 3.536

60° 50.00% 2.500

80° 17.36% 0.868

85° 8.72% 0.436

87° 5.25% 0.263

88° 3.49% 0.175

89° 1.7% 0.085

90° 0% 0.000 (Transverse Axis)

Mounting Fixture Resonances

A common source of error in acceleration sensing is resonance

of the mounting fixture. For example, the circuit board that the

ADXL05 mounts to may have resonant frequencies in the same

range as the signals of interest. This could cause the signals

measured to be larger than they really are. A common solution

to this problem is to dampen these resonances by mounting the

ADXL05 near a mounting post or by adding extra screws to

hold the board more securely in place.

When testing the accelerometer in your end application, it is

recommended that you test the application at a variety of frequencies in order to ensure that no major resonance problems

exist (refer to Analog Devices Application Note AN-379).

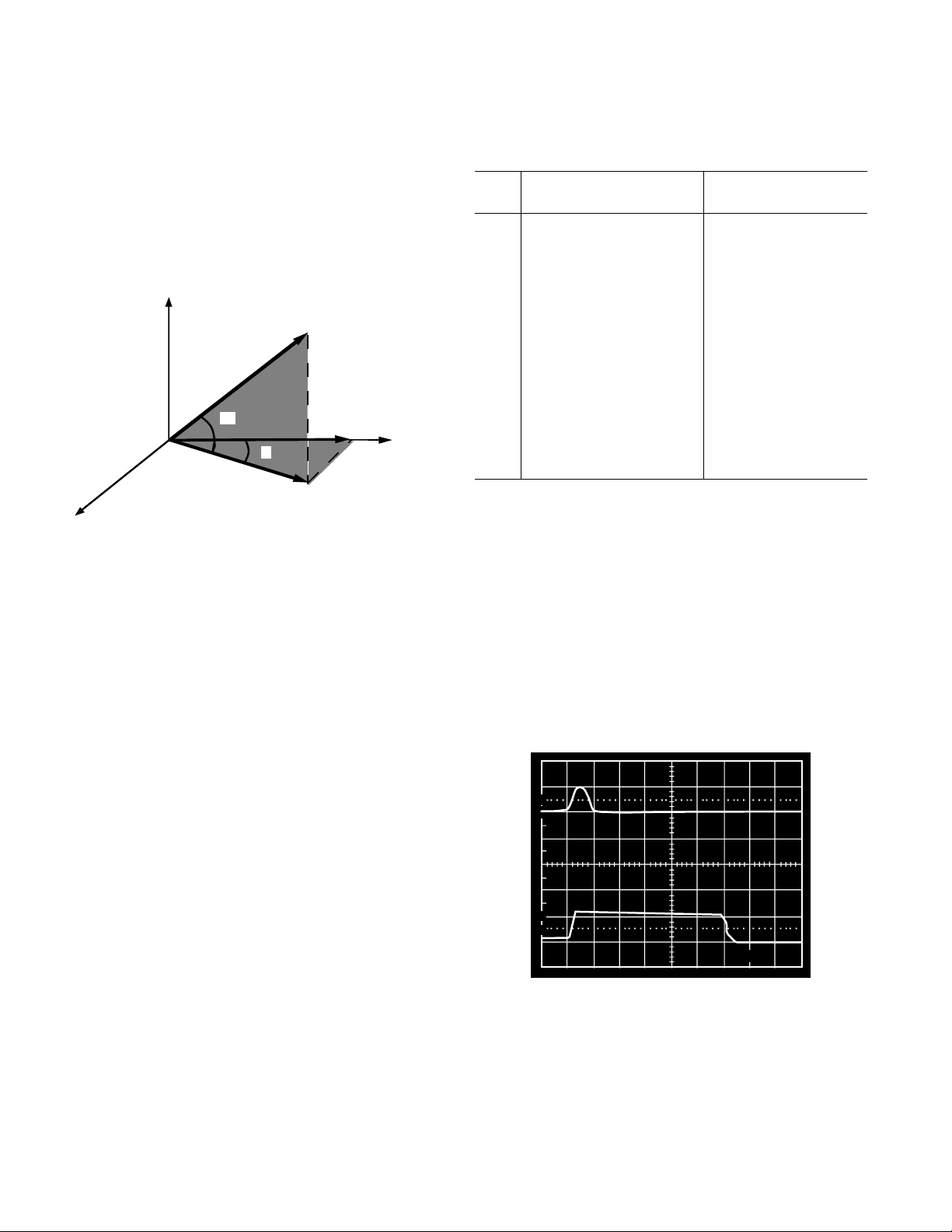

Figure 3. 500 g Shock Overload Recovery. Top Trace, PCB

Reference Accelerometer Output: 500 g/Vertical Division.

Bottom Trace, ADXL05 Output at V

–6–

PR

REV. B

Page 7

ADXL05

Typical Characteristics

9

6

3

0

–3

–6

–9

–12

–15

NORMALIZED SENSITIVITY – dB

–18

–21

1 10k10

FREQUENCY – Hz

(@ +258C, C1 = C2 = 0.022 mF, VS = +5 V unless otherwise noted)

100 1k

Figure 4. Normalized Sensitivity vs. Frequency

2

1

0

0.2

0.1

0

–0.1

NONLINEARITY IN % OF FULL SCALE

–0.2

05

1234

g LEVEL APPLIED

Figure 7. % Nonlinearity vs. g Level Applied

40

30

20

–1

–2

–3dB BANDWIDTH CHANGE – %

–3

–4

–50 1500 50 100

TEMPERATURE – °C

Figure 5. –3 dB Bandwidth vs. Temperature

0.30

0.20

0.10

0.00

–0.10

–0.20

–0.30

SENSITIVITY CHANGE – %

–0.40

–0.50

4.0 7.54.5 5.0 5.5 6.0 6.5 7.0

SUPPLY VOLTAGE – Volts

10

0

CHANGE IN NOISE – %

–10

–20

–50 1500 50 100

TEMPERATURE – °C

Figure 8. % Change in Noise from +25°C vs. Temperature

10k

1k

100

–3dB BANDWIDTH – Hz

10

0.01

DEMODULATOR CAPACITANCE – µF

10.1

Figure 6. Sensitivity Change at VPR vs. Supply Voltage

REV. B

Figure 9. –3 dB Bandwidth vs. Demodulator

Capacitance

–7–

Page 8

ADXL05

FREQUENCY – Hz

100

80

0

10 10k100 1k

60

40

20

TA = +25°C, ACL = 2

OUTPUT IMPEDANCE – Ω

Typical Characteristics

80

60

E

40

B

20

C

D

0

–20

A

CHANGE IN 0g BIAS LEVEL – mV

–40

–60

–40 120

04080

TEMPERATURE – °C

(@ +258C, C1 = C2 = 0.022 mF, VS = +5 V unless otherwise noted)

A

B

C

D

E

Figure 10. Change in 0 g Bias Level vs. Temperature

(Characteristic Curves from Five Typical Units)

40

30

80

TA = +25°C

= +5V + (0.5Vp-p)

V

S

60

PSRR – dB

REF

40

+3.4V V

20

1 100k10

Figure 13. +3.4 V V

100 1k 10k

FREQUENCY – Hz

PSRR vs. Frequency

REF

20

10

0 g PSRR – dB

PR

NOTE: AT THIS FREQUENCY, THE SIGNAL ON THE

0

V

POWER SUPPLY IS IN SYNCHRONISM WITH THE

ACCELEROMETER'S INTERNAL CLOCK OSCILLATOR

(SEE EMI/RFI SECTION)

–10

–20

10 1M100 1k 10k 100k

Figure 11. 0 g PSRR vs. Frequency

FREQUENCY – Hz

Figure 14. Buffer Amplifier Output Impedance vs.

Frequency

0.05

0

–0.05

–0.1

DRIFT FROM +25°C

–0.15

REF

% V

–0.2

–0.25

–50 1500 50 100

TEMPERATURE – °C

30

25

20

15

10

5

GAIN – dB

0

–5

–10

–15

–20

10 1M100

G =10

G = 2

1k 10k 100k

FREQUENCY – Hz

TA = +25°C

Figure 12. % V

Drift vs. Temperature

REF

–8–

Figure 15. Buffer Amplifier Closed-Loop Gain vs.

Frequency

REV. B

Page 9

ADXL05

BEAM

FIXED

OUTER

PLATES

UNIT CELL

CS1

<

CS2

TOP VIEW

APPLIED

ACCELERATION

CS1

CS2

DENOTES ANCHOR

CENTER PLATE

THEORY OF OPERATION

The ADXL05 is a complete acceleration measurement system

on a single monolithic IC. It contains a polysilicon surfacemicro machined sensor and signal conditioning circuitry which

implements a force-balance control loop. The ADXL05 is capable of measuring both positive and negative acceleration to a

maximum level of ±5 g.

Figure 16 is a simplified view of the ADXL05’s acceleration

sensor at rest. The actual structure of the sensor consists of 46

unit cells and a common beam. The differential capacitor sensor

consists of independent fixed plates and central plates attached

to the main beam that moves in response to an applied acceleration. The two capacitors are series connected, forming a

capacitive divider with a common movable central plate. The

sensor’s fixed capacitor plates are driven differentially by a

1 MHz square wave: the two square wave amplitudes are equal

but are 180° out of phase from one another. When at rest, the

values of the two capacitors are the same, and therefore, the

voltage output at their electrical center (i.e., at the center plate)

is zero.

BEAM

CENTER PLATE

FIXED

OUTER

PLATES

UNIT CELL

CS1

CS2

CS1 = CS2

DENOTES ANCHOR

Figure 16. A Simplified Diagram of the ADXL05

Sensor at Rest

Figure 17 shows the sensor responding to an applied acceleration. When this occurs, the common central plate or “beam”

moves closer to one of the fixed plates while moving further

from the other. This creates a mismatch in the two capacitances,

resulting in an output signal at the central plate. The output

amplitude of the signal varies directly with the amount of acceleration experienced by the sensor.

Figure 17. The ADXL05 Sensor Momentarily Responding

to an Externally Applied Acceleration

Figure 18 shows a block diagram of the ADXL05. The voltage

output from the central plate of the sensor is buffered and then

applied to a synchronous demodulator which is clocked, in

phase, with the same oscillator that drives the fixed plates

of the sensor. If the applied voltage is in sync and in phase

with the clock, a positive output will result. If the applied voltage is in sync but 180° out of phase with the clock, then the

demodulator’s output will be negative. All other signals will be

rejected. An external capacitor, C1, sets the bandwidth of the

demodulator.

REV. B

C2

EXTERNAL

OSCILLATOR

DECOUPLING

CAPACITOR

+5V

V

REF

+3.4V

DENOTES EXTERNAL

PIN CONNECTION

1MHz

OSCILLATOR

+5V

+5V

INTERNAL

REFERENCE

+3.4V +1.8V +0.2V

180

COMMON

COM

+3.4V

CS1

BEAM

CS2

+0.2V

V

+1.8V

IN–

BUFFER

AMPLIFIER

+1.8V

0

+3.4V

75Ω

°

°

SYNC

Figure 18. Functional Block Diagram

–9–

3MΩ

+5V

33kΩ

C1 C1

DEMODULATION

SYNCHRONOUS

DEMODULATOR

V

OUT

EXTERNAL

CAPACITOR

50kΩ

33kΩ

SELF–TEST

(ST)

PREAMP

+1.8V

LOOP GAIN = 10

RST

+3.4V

V

PR

INTERNAL

FEEDBACK

LOOP

Page 10

ADXL05

The output of the synchronous demodulator drives the

preamp—an instrumentation amplifier buffer which is referenced to +1.8 volts. The output of the preamp, V

, is fed back

PR

to the outer plate of the sensor through a 3 MΩ isolation resistor. The V

voltage electrostatically resets the sensor back to its

PR

0 g position and is a direct measure of the applied acceleration.

The output of the ADXL05’s preamplifier is 1.8 V ± 200 mV/g,

with an output range of ±1 V for a ±5 g input. An uncommitted buffer amplifier provides the capability to adjust the scale

factor and 0 g offset level over a wide range. An internal reference supplies the necessary regulated voltages for powering the

chip and +3.4 volts for external use.

A self-test is initiated by applying a TTL “high” level voltage

(> +2.0 V dc) to the ADXL05’s self-test pin, which causes the

chip to apply a deflection voltage to the beam which moves it an

ADXL05

OSCILLATOR

DECOUPLING

CAPACITOR

C2

0.022µF

4

OSCILLATOR

SENSOR

DEMODULATOR

amount equal to –5 g (the negative full-scale output of the device). Note that the ±15% tolerance of the self-test circuit is not

proportional to the sensitivity error, see Self-Test section.

BASIC CONNECTIONS FOR THE ADXL05

Figure 19 shows the basic connections needed for the ADXL05

to measure accelerations in the ±5 g range with an output scale

factor 400 mV/g, a 2.5 V 0 g level, a ± 2.0 V full-scale swing

around 0 g, and a 3 dB bandwidth of approximately 1.6 kHz.

Using the circuit of Figure 19, the overall transfer function is:

V

OUT

PREAMP

R3

=

1.8 V – V

()

()

R1

REFERENCE

PR

+1.8V

R3

+

(1.8)

6

+1.8 V

V

REF

OUTPUT

()

R2

+3.4V

SELF-TEST

(ST)

7

COM

5

C3

0.1µF

1

+5V

2

C1

0.022µF

DEMODULATOR

CAPACITOR

83

C1

V

R1

PR

49.9kΩ

10

V

IN–

R2

274kΩ

BUFFER

Figure 19. ADXL05 Application Providing an Output Sensitivity of 400 mV/g,

a +2.5 V 0 g Level and a Bandwidth of 1 kHz

AMP

R3

100kΩ

9

V

OUT

–10–

REV. B

Page 11

BUFFER

AMP

0.1µF

+5V

V

OUT

0.022µF

C1

C1

+3.4V

REF

COM

1.8V

6

8

9

10

1

2

3

4

0.022µF

C2

PRE-AMP

V

PR

R1b

R3

V

IN–

OUTPUT SCALE FACTOR = x V

PR

OUTPUT

V

PR

OUTPUT: 200mV/g

R3

(R1a + R1b)

5

ADXL05

R1a

USING THE INTERNAL BUFFER AMPLIFIER TO VARY

THE ACCELEROMETER’S OUTPUT SCALE FACTOR

AND 0 g BIAS LEVEL

The ADXL05 accelerometer has an onboard buffer amplifier

that allows the user to change the output scale factor and 0 g

bias level.

The output scale factor of an accelerometer is simply how many

volts output are provided per g of applied acceleration. This

should not be confused with its resolution. The resolution of the

device is the lowest g level the accelerometer is capable of measuring. Resolution is principally determined by the device noise

and the measurement bandwidth.

The 0 g bias level is simply the dc output level of the accelerometer when it is not in motion or being acted upon by the Earth’s

gravity.

Setting the Accelerometer’s Scale Factor

Figure 20 shows the basic connections for using the onboard

buffer amplifier to increase the output scale factor. The nominal

output level in volts from V

to the g forces applied to the sensor (along its sensitive axis)

times 200 mV/g. The use of the buffer is always recommended,

even if the preset scale factor is adequate, as the buffer helps

prevent any following circuitry from loading down the V

output.

0.022µF

In Figure 20, the output scale factor at Pin 9 (V

put at V

PR

of resistor R3 divided by R1. Choose a convenient scale factor,

keeping in mind that the buffer gain not only amplifies the signal but any noise or drift as well. Too much gain can also cause

the buffer to saturate and clip the output wave form.

The circuit of Figure 20 is entirely adequate for many applications, but its accuracy is dependent on the pretrimmed accuracy

of the accelerometer and this will vary by product type and

grade. For the highest possible accuracy, an external trim is recommended. As shown by Figure 21, this consists of a potentiometer, R1a, in series with a fixed resistor, R1b.

REV. B

(the preamplifier output) is equal

PR

PR

C2

4

0.022µF

C1

C1

COM

ADXL05

PRE-AMP

2

3

5

8

6

+3.4V

REF

OUTPUT SCALE FACTOR = x V

V

OUTPUT: 200mV/g

PR

1.8V

V

PR

10

V

R1

IN–

R3

R1

BUFFER

AMP

R3

OUTPUT

PR

1

+5V

C3

0.1µF

9

V

OUT

Figure 20. Basic Buffer Connections

) is the out-

OUT

times the gain of the buffer, which is simply the value

–11–

ADXL05

Figure 21. External Scale Factor Trimming

Setting the Accelerometer’s 0 g Bias Level, AC Coupled

Response

If a dc (gravity) response is not required—for example in motion

sensing or vibration measurement applications—ac coupling can

be used between the preamplifier output and the buffer input as

shown in Figure 22. The use of ac coupling between V

the buffer input virtually eliminates any 0 g drift and allows the

maximum buffer gain without clipping.

Resistor R1 and capacitor C4 together form a high pass filter

whose corner frequency is 1/(2 π R1 C4). This means that this

simple filter will reduce the signal from V

by 3 dB at the

PR

corner frequency, and it will continue to reduce it at a rate of

6 dB/octave (20 dB per decade) for signals below the corner

frequency.

Note that capacitor C4 should be a nonpolarized, low leakage

type. If a polarized capacitor is used, tantalum types are preferred, rather than electrolytic. With polarized capacitors, V

should be measured on each device and the positive terminal of

the capacitor connected toward either V

or VIN—whichever is

PR

more positive

The 0 g offset level of the ADXL05 accelerometer is preset at

+1.8 V. This can easily be changed to a more convenient level,

such as +2.5 V which, being at the middle of the supply voltage,

provides the greatest output voltage swing.

When using the ac coupled circuit of Figure 22, only a single resistor, R2, is required to swing the buffer output to +2.5 V.

Since the “+” input of the buffer is referenced at +1.8 V, its

summing junction, Pin 10, is also held constant at +1.8 V.

Therefore, to swing the buffer’s output to the desired +2.5 V

0 g bias level, its output must move up +0.7 V (2.5 V – 1.8 V =

0.7 V). Therefore, the current needed to flow through R3 to

cause this change, IR3, is equal to:

IR3 =

0.7 Volts

R3 inOhms

PR

and

PR

Page 12

ADXL05

BUFFER

AMP

0.1µF

+5V

V

OUT

0.022µF

C1

C1

+3.4V

REF

COM

1.8V

8

9

10

1

2

3

4

0.022µF

C2

PRE-AMP

V

PR

R1

R3

V

IN–

5

ADXL05

6

R2

100kΩ

0

g

LEVEL

TRIM

50kΩ

S.F. =

R3

R1

R1 ≥ 20kΩ

V

X

FULL

SCALE

±1

g

±2

g

±4

g

±5

g

mV

per

g

2000

1000

500

400

R1

kΩ

30.1

40.2

40.2

49.2

R3

kΩ

301

200

100

100

RECOMMENDED COMPONENT VALUES FOR

VARIOUS OUTPUT SCALE FACTORS

0.022µF

0.022µF

COM

C2

4

ADXL05

C1

C1

2

3

5

+3.4V

REF

6

PRE-AMP

8

V

PR

C4

1.8V

10

V

R1

IN–

R2

BUFFER

AMP

R3

1

+5V

C3

0.1µF

9

V

OUT

SCALE FACTOR =

1

C4 =

2πR1 FL

FOR A +2.5V 0g LEVEL,

IN AN AC COUPLED

CONFIGURATION,

R2 = 2.57 R3

R3

R1

RECOMMENDED COMPONENT VALUES

FULL

SCALE

RANGE

±2

g

±5

g

±2

g

±5

g

±5

g

SCALE

FACTOR

IN

mV/

g

1000

400

1000

400

400

DESIRED

LOW

FREQUENCY

LIMIT, F

L

30Hz

30Hz

3Hz

1Hz

0.1Hz

R1

IN

kΩ

49.9

127

49.9

127

127

CLOSEST

C4

VALUE

0.10µF

0.039µF

1.0µF

1.5µF

15µF

R3

kΩ

249

249

249

249

249

IN

R2 VALUE

IN kΩ FOR

+2.5V 0

LEVEL

640

640

640

640

640

g

Figure 22. Typical Component Values for AC Coupled

Circuit

In order to force this current through R3, the same current

needs to flow from Pin 10 to ground through resistor R2. Since

Pin 10 is always held at +1.8 V, R2 is equal to:

With a dc coupled connection, any difference between a nonideal +1.8 V 0 g level at V

and the fixed +1.8 V level at the

PR

buffer’s summing junction will be amplified by the gain of the

buffer. If the 0 g level only needs to be approximate and the

buffer is operated a low gain, a single fixed resistor, R2, can still

be used. But to obtain the exact 0 g output desired or to allow

the maximum output voltage swing from the buffer, the 0 g

offset will need to be externally trimmed using the circuit of Figure 23. Normally, a value of 100 kΩ is typical for R2.

The buffer’s maximum output swing should be limited to

±2 volts, which provides a safety margin of ±0.25 volts before

clipping. With a +2.5 volt 0 g level, the maximum gain the

buffer should be set to (R3/R1) equals:

200 mV/gTimes the Max Applied Acceleration ings

2Volts

Note that the value of R1 should be kept as large as possible,

20 kΩ or greater, to avoid loading down the V

output.

PR

The device scale factor and 0 g offset levels can be calibrated using the Earth’s gravity as explained in the section “calibrating

the ADXL05.”

1.8 Volts

R2 =

IR3

Therefore, for an ac coupled connection and a +2.5 V 0 g

output:

1.8 Volts × R3

R2 =

0.7Volts

= 2. 57 × R3

If ac coupling is used, the self-test feature must be monitored at

V

, rather than at the buffer output (since the self test output is

PR

a dc voltage).

Setting the Accelerometer’s 0 g Bias Level, DC Coupled

Response

When a true dc (gravity) response is needed, the output from

the preamplifier, V

For high gain applications, a 0 g offset trim will also be needed.

The external offset trim permits the user to set the 0 g offset

voltage to exactly +2.5 volts, since this is at the center of the +5

volt power supply it will allow the maximum output swing from

the buffer without clipping.

, must be dc coupled to the buffer input.

PR

Figure 23. Typical Component Values for Circuit with

External 0 g Trimming

–12–

REV. B

Page 13

ADXL05

DEVICE BANDWIDTH VS. MEASUREMENT

RESOLUTION

Although an accelerometer is usually specified according to its

full scale (clipping) g level, the limiting resolution of the device,

i.e., its minimum discernible input level, is extremely important

when measuring low g accelerations.

The limiting resolution is predominantly set by the measurement noise “floor” which includes the ambient background

noise and the noise of the ADXL05 itself. The level of the noise

floor varies directly with the bandwidth of the measurement. As

the measurement bandwidth is reduced, the noise floor drops,

improving the signal-to-noise ratio of the measurement and increasing its resolution.

The bandwidth of the accelerometer can be easily reduced by

adding low-pass or bandpass filtering. Figure 24 shows the typical noise vs. bandwidth characteristic of the ADXL05.

100mg

10mg

NOISE LEVEL – rms

1mg

10 1k100

3dB BANDWIDTH – Hz

660mg

66mg

NOISE LEVEL – Peak to Peak

6.6mg

Figure 24. Noise Level vs. 3 dB Bandwidth

The output noise of the ADXL05 scales with the square root of

the measurement bandwidth. With a single pole roll-off, the

equivalent rms noise bandwidth is π divided by 2 or approximately 1.5 times the 3 dB bandwidth. For example, the typical

rms noise of the ADXL05J using a 100 Hz one pole post filter is:

Noise(rms) = 500 µg/ Hz × 100(1.5) = 6,124 µgor6.1 mg rms

For the bandpass filter of Figure 27 where both ac coupling and

low pass filtering are used, the low frequency roll-off, F

termined by C4 and R1 and the high frequency roll-off, F

, is de-

L

, is

H

determined by the 1-pole post filter R3, C5.

The equivalent rms noise of the bandpass filter is equal to

500 µg/ Hz × (1.5 FH)–(FL/1.5).

For example, the typical rms noise of the ADXL05 using 1 pole

ac coupling with a bandwidth of 10 Hz and 1 pole low-pass

filter of 100 Hz is:

Noise (rms) = 500 µg/ Hz × 1. 5(100 ) – (10 /1.5)

= 5,987 µg rms or ≈ 5.9 mg rms

Because the ADXL05’s noise is for all practical purposes

Gaussian in amplitude distribution, the highest noise amplitudes

have the smallest (yet nonzero) probability. Peak-to-peak noise

is therefore difficult to measure and can only be estimated due

to its statistical nature. Table II is useful for estimating the

probabilities of exceeding various peak values, given the rms

value.

Table II.

Nominal Peak-to- % of Time that Noise Will Exceed

Peak Value Nominal Peak-to-Peak Value

2.0 × rms 32%

4.0 × rms 4.6%

6.0 × rms 0.27%

6.6 × rms 0.1%

8.0 × rms 0.006%

RMS and peak-to-peak noise (for 0.1% uncertainty) for various

bandwidths is estimated in Figure 24. As shown by the figure,

device noise drops dramatically as the operating bandwidth is

reduced. For example, when operated in a 1 kHz bandwidth,

the ADXL05 typically has an rms noise level of 19 mg. With

±5 g applied accelerations, this 19 mg resolution limit is nor-

mally quite satisfactory; but for smaller acceleration levels the

noise is now a much greater percentage of the signal. As shown

by the figure, when the device bandwidth is rolled off to 100 Hz,

the noise level is reduced to approximately 6 mg, and at 10 Hz it

is down to less than 2 mg.

Alternatively, the signal-to-noise ratio may be improved considerably by using a microprocessor to perform multiple measurements and then compute the average signal level. When using

this technique, with 100 measurements, the signal-to-noise ratio

will be increased by a factor of 10 (20 dB).

REV. B

–13–

Page 14

ADXL05

Low-Pass Filtering

The bandwidth of the accelerometer can easily be reduced by

using post filtering. Figure 25 shows how the buffer amplifier

can be connected to provide 1-pole post filtering, 0 g offset trimming, and output scaling. The table provides practical component values for various full-scale g levels and approximate circuit

bandwidths. For bandwidths other than those listed, use the

formula:

C4=

(2 πR3) Desired 3dBBandwidth in Hz

or simply scale the value of capacitor C4 accordingly, i.e., for an

application with a 50 Hz bandwidth, the value of C4 will need

to be twice as large as its 100 Hz value. If further noise reduction is needed while maintaining the maximum possible bandwidth, then a 2- or 3-pole post filter is recommended. These

provide a much steeper roll-off of noise above the pole frequency. Figure 26 shows a circuit that uses the buffer amplifier

to provide 2-pole post filtering. Component values for the 2pole filter were selected to operate the buffer at unity gain. Capacitors C3 and C4 were chosen to provide 3 dB bandwidths of

10 Hz, 30 Hz, 100 Hz, and 300 Hz.

In this configuration, the nominal buffer amplifier output will be

+1.8 V ± the 200 mV/g scale factor of the accelerometer. An

AD820 external op amp allows noninteractive adjustment of 0 g

offset and scale factor. The external op amp offsets and scales

the output to provide a +2.5 V ± 2 V output over a wide range

of full-scale g levels.

C2

4

ADXL05

PRE-AMP

2

3

5

8

6

V

PR

OPTIONAL SCALE

FACTOR TRIM

R2

COMPONENT VALUES FOR VARIOUS

mV

3dB

per

g

BW (Hz)

2000

10

1000

100

500

200

400

300

3dB BW =

0.022µF

0.022µF

C1

C1

COM

+3.4V

REF

g

0

LEVEL

50kΩ

TRIM

FULL-SCALE RANGES AND BANDWIDTHS

FULL

SCALE

g

±1

±2

g

±4

g

±5

g

1

1

+5V

1.8V

BUFFER

AMP

R1a

kΩ

10

10

10

10

R1b

*

R1b

kΩ

24.9

35.7

35.7

45.3

1

2π R3 C4

10

V

IN–

R3

C4

R2

R3

kΩ

kΩ

100

301

100

200

100

100

100

100

R1a

*TO OMIT THE OPTIONAL SCALE FACTOR

TRIM, REPLACE R1a AND R1b WITH A FIXED

VALUE 1% METAL FILM RESISTOR.

SEE VALUES SPECIFIED IN TABLES BELOW.

NOTE: FOR NONINTERACTIVE TRIMS,

SET SCALE FACTOR FIRST, THEN OFFSET.

9

C4

µF

0.056

0.0082

0.0082

0.0056

0.1µF

V

OUT

ADXL05

8

V

PR

R1

82.5kΩ

0.027

0.082

1.8V

10

V

C3µF

0.27

0.82

PRE-AMP

6

V

REF

2-POLE FILTER

COMPONENT VALUES

3dB

BW (Hz)

300

100

30

10

BUFFER

AMP

C4

IN–

R5

42.2kΩ

R3

C3

82.5kΩ

2-POLE FILTER

+3.4V

R6

40.2kΩ

20kΩ

R7

71.5kΩ

C4µF

0.0033

0.01

0.033

0.1

V

OUT

9

R4a

SCALE

FACTOR

0

g

LEVEL

TRIM

AMPLIFIER COMPONENT VALUES

FULL

SCALE

±1

g

±2

g

±4

g

±5

g

OPTIONAL CAPACITOR

FOR 3-POLE FILTERING

R5

+5V

R4b

2

AD820

mV

per

2000

1000

500

400

3

GAIN

10.00

4.98

2.50

2.00

R4a

kΩ

10

10

10

10

g

TRIM

OFFSET AND SCALING

0.01µF

7

6

4

OFFSET AND

SCALING

AMPLIFIER

R4b

kΩ

24.9

35.7

35.7

45.3

OUTPUT

R5

kΩ

301

200

100

100

Figure 26. Two-Pole Filtering Circuit with Gain and 0 g

Offset Adjustment

Bandpass Filtering

Figure 27 shows how the combination of ac coupling and lowpass filtering together form a bandpass filter that provides an

even greater improvement in noise reduction.

SCALE

FACTOR

IN

mV/

1000

200

1000

200

200

COMPONENT

VALUES ARE

APPROXIMATE.

DESIRED

LOW

FREQUENCY

LIMIT, F

g

30

30

3

1

0.1

ADXL05

PRE-AMP

V

PR

8

V

PR

CLOSEST

R1

VALUE

VALUE

IN kΩ

L

49.9

0.10µF

249

0.022µF

49.9

1.0µF

249

0.68µF

249

6.8µF

C4

C4

1.8V

10

V

R1

R2

DESIRED

HIGH

FREQUENCY

LIMIT, F

300

300

100

100

BUFFER

IN–

10

AMP

H

R3

C5

R3

IN

kΩ

249

249

249

249

249

V

OUT

9

CLOSEST

VALUE

0.002µF

0.002µF

0.0068µF

0.0068µF

0.068µF

VALUE

OF R2

C5

FOR +2.5V

0

g

LEVEL

640kΩ

640kΩ

640kΩ

640kΩ

640kΩ

Figure 25. Using the Buffer Amplifier to Provide 1-Pole

Post Filtering Plus Scale Factor and 0 g Level Trimming

–14–

Figure 27 AC Coupling and Low-Pass Filtering Used

Together to Provide a Bandpass Function

REV. B

Page 15

Additional Noise Reduction Techniques

Shielded wire should be used for connecting the accelerometer to

any circuitry that is more than a few inches away—to avoid 60 Hz

pickup from ac line voltage. Ground the cable’s shield at only one

end and connect a separate common lead between the circuits;

this will help to prevent ground loops. Also, if the accelerometer

is inside a metal enclosure, this should be grounded as well.

Methods for Reducing 0 g Offset Drift

When using any accelerometer with a dc (gravity sensing) response, the 0 g offset level will exhibit some temperature drift.

For very high accuracy applications, one very straightforward

approach is to use a low cost crystal oven to maintain the accelerometer at a constant temperature. These ovens are available in

a variety of different temperatures. After the circuit has been built

and is operating correctly, the crystal oven can be mounted over

the accelerometer and powered off the same +5 V power supply.

The ovens may be purchased from Isotemp Research, Inc., P.O.

Box 3389, Charlottesville, VA 22903, phone 804-295-3101. For

more details on crystal oven compensation, refer to application

note AN-385.

Other methods for 0 g drift compensation include using a low

cost temperature sensor such as the AD22100 to supply a microprocessor with the device temperature. If the drift curve of

the accelerometer is stored in the µP, then a software program

can be used to subtract out the drift. Alternatively, a simple 1st

order (straight line) correction circuit can be used to subtract

out the linear portion of the accelerometer’s drift by using a

temperature sensor and op amp to supply a small compensation

current. For more details on software and hardware drift compensation, refer to application note AN-380.

ACCELEROMETER APPLICATIONS

Popular applications for low g accelerometers tend to fall into

three categories: measurement of tilt and orientation, inertial

measurement of acceleration, velocity and distance, and vibration or shock measurement.

The ADXL05 is a “dc” accelerometer, meaning that it is capable of measuring static accelerations such as the Earth’s gravity. The ADXL05 differs from other acceleration measurement

technologies such as piezoelectric and piezofilm sensors which

can only respond to ac signals greater than approximately 1 Hz.

This dc capability is required for tilt and inertial measurement.

For ac shock or vibration the ADXL05 can measure frequencies

of up to 4 kHz and has the added benefit of measuring all the

way down to dc.

Using the ADXL05 in Tilt Applications

The ADXL05’s precision dc characteristics make it suitable for

tilt measurement. It can directly measure the Earth’s gravity and

use this constant force as a position reference to determine inclination. As shown in Figure 28, the accelerometer should be

mounted so that its sensitive axis is perpendicular to the force of

gravity, i.e., parallel to the Earth’s surface. In this manner, it

will be most sensitive to changes in orientation (when it is orientated 90° to the force of gravity). Its output can be then described by the sine function; a tilt occurring at an angle θ will

cause a voltage output equal to:

V

V

= Accelerometer Scale Factor

OUT

g

×sin

θ

×1g

()

+zero g output(V )

ADXL05

θ

1g

Figure 28. Two Possible Orientations for Tilt Measurement

Conversely, for a given acceleration signal and assuming no

other changes in the axis or interfering signals, the tilt angle is

proportional to the voltage output as shown in Figure 29. The

angle, θ can be calculated using:

θ

= arcsin 1g ×

500

400

300

200

g

100

0

@ 500mV/

–100

OUT

V

–200

–300

–400

–500

–90 90–70 –50 –30 –10

Figure 29. V

OUT

Scale Factor (V/g)

ANGLE OF TILT

vs. Tilt Angle

OUT

–zero g output(V)

V

The use of an accelerometer in tilt applications has several advantages over the use of a traditional tilt sensor. A traditional tilt

sensor consists of glass vial filled with a conductive liquid, typically a mercury or electrolytic solution. Besides being larger

than an XL05, it requires additional signal conditioning circuitry. The settling time and frequency response is limited by

the amount of time required for the liquid to stop sloshing

around in the vial. In high vibration environments, or where

high lateral accelerations may be present, it may not be possible

to resolve the tilt signal above the “slosh” noise. The accelerometer has faster frequency (up to 50 ×) response and settling time. Interfering vibrations may be filtered out if

necessary, an impossibility with a liquid tilt sensor, since one

cannot filter the liquid. Finally, in the presence of lateral accelerations, an accelerometer provides more useful information,

i.e., an acceleration signal, which if cleverly signal processed,

can provide both a tilt and an acceleration output. A single accelerometer can be used to measure tilt over a 180° range; two

accelerometers gives a complete 360° of measurement.

An important characteristic for an accelerometer used in a tilt

application is its 0 g offset stability over temperature. The

ADXL05 typically exhibits offsets that deviate no more than

0.1 g over the 0°C to +70°C temperature range, corresponding

θ

1g

10 30 50 70

REV. B

–15–

Page 16

ADXL05

0

g

(a)

0

g

(b)

–1

g

(c)

+1

g

(d)

INDICATED POLARITY IS THAT

OCCURRING AT V

PR

.

to a 5° tilt error over the entire temperature range. Straightforward calibration schemes discussed in this data sheet may be

used to reduce or compensate for temperature drift to improve

the absolute accuracy of the measurement.

Using the ADXL05 in Inertial Measurement Applications

Inertial measurement refers to the practice of measuring acceleration for the purpose of determining the velocity of an object

and its change in position, or distance traveled. This technique

has previously required expensive inertial guidance systems of

the type used in commercial aircraft and military systems. The

availability of a low cost precision dc accelerometer such as the

ADXL05 enables the use of inertial measurement for more cost

sensitive industrial and commercial applications.

Inertial measurement makes use of the fact that the integral of

acceleration is velocity and the integral of velocity is distance.

By making careful measurements of acceleration and mathematically integrating the signals, one can determine both velocity and the distance traveled. The technique is useful for

applications where a traditional speed and distance measurement is impractical, or where a non-contact, relative position

measurement must be made.

A practical inertial measurement system uses multiple accelerometers to measure acceleration in three axes, and gyroscopes to

measure rotation in three axes, the requirement for a 6 degree of

freedom system. For simpler systems where one or more of the

axes can be constrained, it is possible to build a system with

fewer accelerometers and gyros.

The measurement system must take the acceleration sensor and

calibrate out all static errors including any initial inaccuracy or

temperature drift. A mathematical model is used to describe the

performance of the sensor in order to calibrate it. If these errors

are not removed, then the process of double integration will

quickly cause any small error to dominate the result. Most practical systems use microprocessors for error correction and a temperature sensor for temperature drift compensation. Another

approach is to maintain all of the sensors at a controlled temperature. The microprocessors have the additional advantage of

providing a low cost method of performing the single and

double integration of the acceleration signal.

The stability and repeatability of the accelerometer is the most

important specification in an inertial system. The ADXL05 is

“well behaved” that is, its response and temperature characteristics are easy to model and correct, and once modeled they are

very repeatable. For example, temperature performance can be

adequately modeled using first order, (straight line) approximations for most applications, and other errors such as on-axis and

pendulous rectification are minimal. This greatly simplifies the

math required to correct the sensor.

Vibration and Shock Measurement Applications

The ADXL05 can measure shocks and vibrations from dc to

4 kHz. Typical signal processing for vibration signals includes

fast Fourier transforms, and single and double integration for

velocity and displacement. It is possible to build a single integrator stage using the ADXL05’s output buffer amplifier in

order to provide a velocity output.

The sensitivity of the accelerometer will typically vary only

±0.5% over the full industrial temperature range, making it one

of the most stable vibration measurement devices available. In

vibration measurement applications, mechanical mounting and

control of system and mounting resonances are critical to proper

measurement. Refer to the application note AN-379, available

from Analog Devices.

CALIBRATING THE ADXL05

If a calibrated shaker is not available, both the 0 g level and scale

factor of the ADXL05 may be easily set to fair accuracy by using

a self-calibration technique based on the 1 g (average) acceleration of the earth’s gravity. Figure 30 shows how gravity and

package orientation affect the ADXL05’s output. Note that the

output polarity is that which appears at V

; the output at V

PR

OUT

will have the opposite sign. With its axis of sensitivity in the

vertical plane, the ADXL05 should register a 1 g acceleration,

either positive or negative, depending on orientation. With the

axis of sensitivity in the horizontal plane, no acceleration (the

0 g bias level) should be indicated.

Figure 30. Using the Earth’s Gravity to Self-Calibrate the

ADXL05

To self-calibrate the ADXL05, place the accelerometer on its

side with its axis of sensitivity oriented as shown in “a.” The 0 g

offset potentiometer, Rt, is then roughly adjusted for midscale:

+2.5 V at the buffer output (see Figure 25).

Next, the package axis should be oriented as in “c” (pointing

down) and the output reading noted. The package axis should

then be rotated 180° to position “d” and the scale factor potentiometer, R1a, adjusted so that the output voltage indicates a

change of 2 gs in acceleration. For example, if the circuit scale

factor at the buffer output is 400 mV per g, then the scale factor

trim should be adjusted so that an output change of 800 mV is

indicated.

Adjusting the circuit’s scale factor will have some effect on its

0 g level so this should be readjusted, as before, but this time

checked in both positions “a” and “b.” If there is a difference in

the 0 g reading, a compromise setting should be selected so that

the reading in each direction is equidistant from +2.5 V. Scale

factor and 0 g offset adjustments should be repeated until both

are correct.

REDUCING POWER CONSUMPTION

The use of a simple power cycling circuit provides a dramatic

reduction in the ADXL05’s average current consumption. In

low bandwidth applications such as shipping recorders, this

simple, low cost circuit can provide substantial power reduction.

If a microprocessor is available, only the circuit of Figure 31 is

needed. The microprocessor supplies a TTL clock pulse to gate

buffer transistor Q1 which inverts the output pulse from the µP

–16–

REV. B

Page 17

ADXL05

so that the duty cycle is correct when the pulse is re-inverted

again by transistor, Q2, which cycles the accelerometer’s supply

voltage on and off.

+5V

FROM µP

OR

FIGURE 1b

10kΩ

100kΩ

Q1

2N2222

0.1µF

10kΩ

V

PR

58

BUFFER

2N3906

Q2

1

ADXL05

V

10

R1

IN–VOUT

9

R3

C

F

V

OUT

Figure 31. Basic Power Cycling Circuit

Figures 32 and 33 show typical waveforms of the accelerometer

being operated with a 10% duty cycle: 1 ms on, 9 ms off. This

reduces the average current consumption of the accelerometer

from 8 mA to 800 µA, providing a power reduction of 90%. The

µP should sample acceleration during the interval between the

time the 0 g level has stabilized (≈ 400 µs using a 0.022 µF

demod cap) and the end of the pulse duration. The measurement bandwidth of a power-cycled circuit will be set by the

clock pulse rate and duty cycle. In this example, 1 sample can

be taken every 10 ms which is 100 samples per second or 100

Hz. As defined by the “Nyquist criteria,” the best case measurement bandwidth is F

/2 or half the clock frequency. Therefore

S

50 Hz signals can be processed if adequate filtering is provided.

2V

100

90

10

0%

1V

200µs

Figure 32. Top Trace: Voltage at Pin 1;

Bottom Trace: Output at V

PR

Higher measurement bandwidths can be achieved by reducing

the size of the demodulation capacitor below 0.022 µF and in-

creasing the pulse frequency. A 0.01 µF capacitor was con-

nected across the feedback resistor of the ADXL05 buffer to

improve its transient characteristics. The optimum value for this

capacitor will change with buffer gain and the cycling pulse rate.

For more details, refer to application note AN-378.

2V

100

90

10

0%

500mV

200µs

Figure 33. Top Trace: Voltage at Pin 1; Bottom Trace:

Ω

Buffer Output With R1 = R3 = 100 k

, CF = 0.01 µF

COMPONENT SELECTION

LOAD DRIVE CAPABILITIES OF THE VPR AND BUFFER

OUTPUTS

The VPR and the buffer amplifier outputs are both capable of

driving a load to voltage levels approaching that of the supply

rail. However, both outputs are limited in how much current

they can supply, affecting component selection.

VPR Output

The VPR pin has the ability to source current up to 500 µA but

only has a sinking capability of 30 µA which limits its ability to

drive loads. It is recommended that the buffer amplifier be used

in most applications, to avoid loading down V

±5 g applications, the resistor R1 from V

mended to have a value greater than 20 kΩ to reduce loading

effects.

Capacitive loading of the V

capacitance between the V

pin should be minimized. A load

PR

pin and common will introduce an

PR

offset of approximately 1 mV for every 10 pF of load. The V

pin may be used to directly drive an A/D input or other source

as long as these sensitivities are taken into account. It is always

preferable to drive A/D converters or other sources using the

buffer amplifier (or an external op amp) instead of the V

Buffer Amplifier Output

The buffer output can drive a load to within 0.25 V of either

power supply rail and is capable of driving 1000 pF capacitive

loads. Note that a capacitance connected across the buffer

feedback resistor for low-pass filtering does not appear as a

capacitive load to the buffer. The buffer amplifier is limited to

sourcing or sinking a maximum of 100 µA. Component values

for the resistor network should be selected to ensure that the

buffer amplifier can drive the filter under worst case transient

conditions.

Self-Test Function

The digital self-test input is compatible with both CMOS and

TTL signals. A Logic “l” applied to the self-test (ST) input will

cause an electrostatic force to be applied to the sensor which

will cause it to deflect to the approximate negative full-scale

output of the device. Accordingly, a correctly functioning accelerometer will respond by initiating an approximate –1 volt

PR

to V

. In standard

PR

is recom-

IN–

PR

PR

pin.

REV. B

–17–

Page 18

ADXL05

output change at V

acceleration when the self-test is initiated, the V

. If the ADXL05 is experiencing an

PR

output will

PR

equal the algebraic sum of the two inputs. The output will stay

at the self-test level as long as the ST input remains high and

will return to the 0 g level when the ST voltage is removed.

A self-test output that varies more than ± 15% from the nominal

–1.0 V change indicates a defective beam or a circuit problem

such as an open or shorted pin or component.

Operating the ADXL05’s buffer amplifier at Gains > 2, to provide full-scale outputs of less than ± 5 g, may cause the self-test

output to overdrive the buffer into saturation. The self-test may

still be used in the case, but the change in the output must then

be monitored at the V

pin instead of the buffer output.

PR

Note that the value of the self-test delta is not an exact indication of the sensitivity (mV/g) of the ADXL05 and, therefore,

may not be used to calibrate the device for sensitivity error.

In critical applications, it may be desirable to monitor shifts in

the zero-g bias voltage from its initial value. A shift in the 0 g

bias level may indicate that the 0 g level has shifted which may

warrant an alarm.

Power Supply Decoupling

The ADXL05 power supply should be decoupled with a 0.1 µF

ceramic capacitor from +5 V pin of the ADXL05 to common

using very short component leads. For other decoupling considerations, see EMI/RFI section.

Oscillator Decoupling Capacitor, C2

An oscillator decoupling capacitor, C2, is used to remove

1 MHz switching transients in the sensor excitation signal, and

is required for proper operation of the ADXL05. A ceramic

capacitor with a minimum value of 0.022 µF is recommended

from the oscillator decoupling capacitor pin to common. Small

amounts of capacitor leakage due to a dc resistance greater than

1MΩ will not affect operation (i.e., a high quality capacitor is

not needed here). As with the power supply bypass capacitor,

very short component leads are recommended. Although

0.022 µF is a good typical value, it may be increased for reasons

of convenience, but doing this will not improve the noise performance of the ADXL05.

Demodulator Capacitor, C1

The demodulator capacitor is connected across Pins 2 and 3 to

set the bandwidth of the force balance control loop. This capacitor may be used to approximately set the bandwidth of the accelerometer. A capacitor is always required for proper operation.

The frequency response of the ADXL05 exhibits a single pole

roll-off response, see Figure 4.

A nominal value of 0.022 µF is recommended for C1. In gen-

eral, the design bandwidth should be set 40% higher than the

minimum desired system bandwidth due to the ± 40% tolerance,

to preserve stability C1 should be kept > 0.01 µF.

The demodulation capacitor should be a low leakage, low drift

ceramic type with an NPO (best) or X7R (good) dielectric.

In general, it’s best to use the recommended 0.022 µF capacitor

across the demodulator pins and perform any additional lowpass filtering using the buffer amplifier. The use of the buffer for

low-pass filtering generally results in smaller capacitance values

and better overall performance. It is also a convenient and more

precise way to set the system bandwidth. Post filtering allows

bandwidth to be controlled accurately by component selection

and avoids the ±40% demodulation tolerance. Note that signal

noise is proportional to the square root of the bandwidth of the

ADXL05 and may be a consideration in component selection—

see section on noise.

Care should be taken to reduce or eliminate any leakage paths

from the demodulator capacitor pins to common or to the +5 V

pin. Even a small imbalance in the leakage paths from these pins

will result in offset shifts in the zero-g bias level. As an example,

an unbalanced parasitic resistance of 30 MΩ from either demodulator pin to ground will result in an offset shift at V

PR

of

approximately 50 mV. Conformal coating of PC boards with a

high impedance material is recommended to avoid leakage problems due to aging or moisture.

MINIMIZING EMI/RFI

The architecture of the ADXL05 and its use of synchronous demodulation make the device immune to most electromagnetic

(EMI) and radio frequency (RFI) interference. The use of synchronous demodulation allows the circuit to reject all signals except those at the frequency of the oscillator driving the sensor

element. However, the ADXL05 does have a sensitivity to RFI

that is within ±5 kHz of the internal oscillator’s nominal frequency of 1 MHz and also to any odd harmonics of this frequency. The internal oscillator frequency will exhibit part to

part variation in the range of 0.5 MHz to 1.4 MHz.

In general the effect is difficult to notice as the interference must

match the internal oscillator within ±5 kHz and must be large

in amplitude. For example: a 1 MHz interference signal of

20 mV p-p applied to the +5 V power supply pin will produce a

200 mV p-p signal at the V

pin if the internal oscillator and

PR

interference signals are matched exactly or at odd harmonics. If

the same 20 mV interference is applied but 5 kHz above or below the internal oscillator’s frequency, the signal level at V

PR

will

only be 20 mV p-p in amplitude.

Power supply decoupling, short component leads (especially for

capacitors C1 and C2), physically small (surface mount, etc.)

components and attention to good grounding practices all help

to prevent RFI and EMI problems. Good grounding practices

include having separate analog and digital grounds (as well as

separate power supplies or very good decoupling) on the printed

circuit boards. A single ground line shared by both the digital

and analog circuitry can lead to digital pulses (and clock signals)

interfering with the sensor’s onboard oscillator. In extreme

cases, a low cost radio frequency choke (≈10 µH) may be

needed in series with the accelerometer’s power supply pin.

This, together with the recommended 0.1 µF power supply by-

pass capacitor, will form an effective RF filter. The use of an RF

choke is preferred over a resistor since any series resistance in

the power supply will “unregulate” the device from the supply,

degrade its power supply rejection and reduce its supply voltage.

–18–

REV. B

Page 19

0.335 (8.51)

0.305 (7.75)

0.370 (9.40)

0.335 (8.51)

0.185 (4.70)

0.165 (4.19)

0.040 (1.02) MAX

0.045 (1.14)

0.010 (0.25)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

REFERENCE PLANE

0.750 (19.05)

0.500 (12.70)

SEATING PLANE

0.115

(2.92)

BSC

0.230 (5.84)

BSC

5

4

3

0.160 (4.06)

0.110 (2.79)

6

2

1

0.034 (0.86)

0.027 (0.69)

7

ADXL05

8

0.045 (1.14)

0.027 (0.69)

9

10

REV. B

–19–

Page 20

C2028b–5–3/96

–20–

PRINTED IN U.S.A.

Loading...

Loading...