Page 1

PRELIMINARY TECHNICAL DATA

Simultaneous Sampling

a

Preliminary Technical Data

FEATURES

Four 10-Bit Video DACs (4:2:2, YCrCb, RGB I/P

Supported)

10-Bit Video Rate Digitization at Up to 54 Mhz

AGC Control (ⴞ6 dB)

Front-End 3-Channel Clamp Control

Up to Five CVBS Input Channels, Two Component YUV,

Three S-Video, or a combination of the above. Simul-

taneous Digitization of Two CVBS Input Channels.

Aux 8-Bit SAR ADC @ 843 kHz Sampling Giving up to

Eight General Purpose Inputs

2

C and SPI Compatible Interface with I2C Filter

I

RGB Inputs for Picture-on-Picture of the RGB DACs

APPLICATIONS

Picture-on-Picture Video Systems

Simultaneous Video Rate Processing

Hybrid Set-Top Box TV Systems

Direct Digital Synthesis/I-Q Demodulation

Image Processing

Video Rate Codec

ADV7202

GENERAL DESCRIPTION

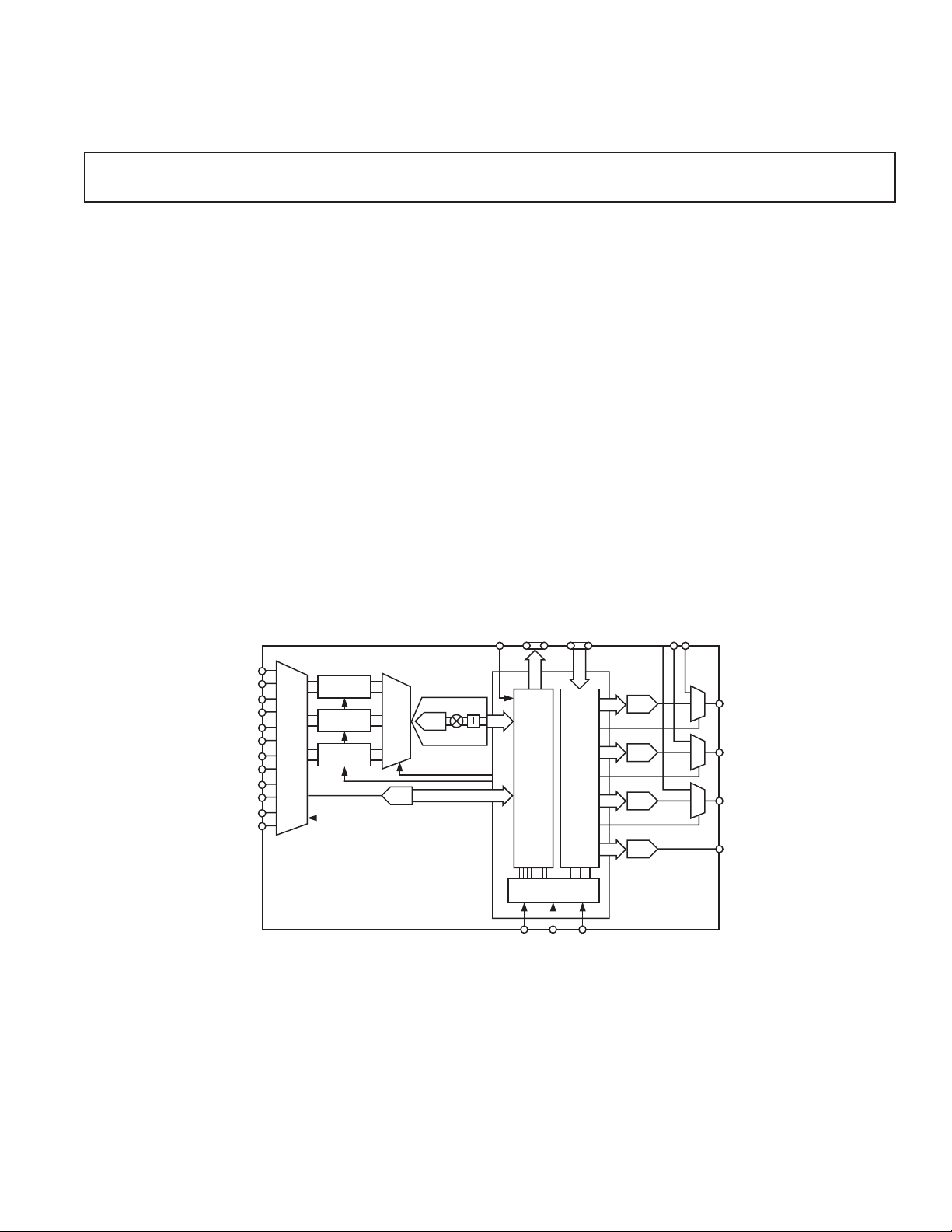

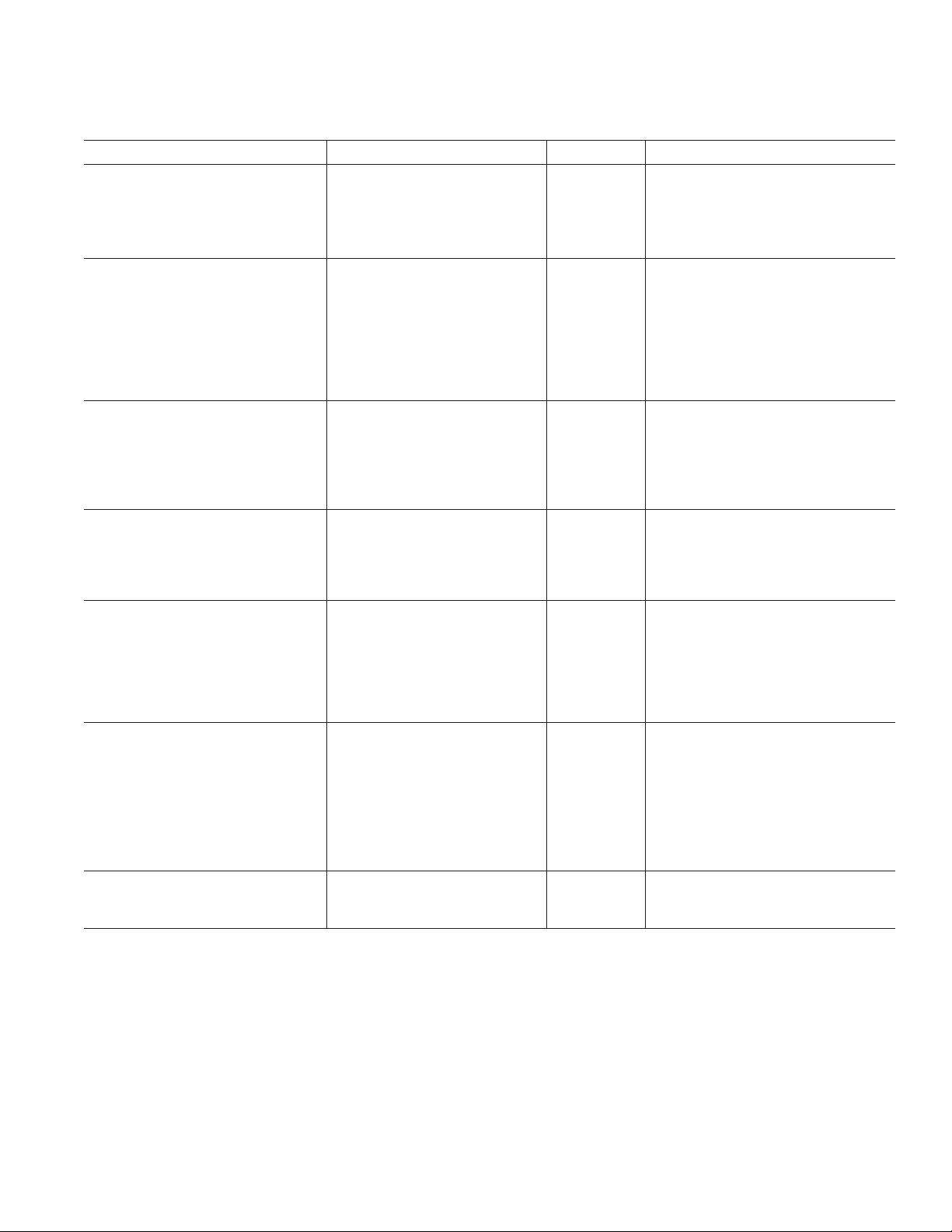

The ADV7202 is a video rate sampling Codec.

It has the capability of sampling up to five NTSC/PAL/SECAM

video I/P signals. The resolution on the front-end digitizer is

12 bits; 2 bits (12 dB) are used for gain and offset adjustment.

The digitizer has a conversion rate of 54 MHz.

It also has up to eight auxiliary inputs that can be sampled by

an 843 kHz SAR ADC for system monitoring, etc.

The back end consists of four 10-bit DACs that run at up to

54 MHz and can be used to output CVBS, S-Video, Component

YCrCb, and RGB.

This Codec also supports Picture-on-Picture with the 3-channel

I/P mux that also muxes to the DAC O/Ps.

The ADV7202 can operate at 3.3 V or 5 V. Its monolithic CMOS

construction ensures greater functionality with lower power

dissipation.

The ADV7202 is packaged in a small 64-lead LQFP package.

AIN1P

AIN1M

AIN2P

AIN2M

AIN3P

AIN3M

AIN4P

AIN4M

AIN5P

AIN5M

AIN6P

AIN6M

I/P

MUX

SHA AND

CLAMP

SHA AND

CLAMP

SHA AND

CLAMP

8-BIT 843KHz

ADV7202

FUNCTIONAL BLOCK DIAGRAM

DOUT

DAC DATA

[9:0]

12C/SPI

[9:0]

DAC

LOGIC

MUX

A/D

ADC BLOCK

12-BIT

A/D

XTAL

ADC

LOGIC

10-BIT

D/A

10-BIT

D/A

10-BIT

D/A

10-BIT

D/A

OSD I/P "S"

DAC0

DAC1

DAC2

DAC3

REV. PrB

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

PRELIMINARY TECHNICAL DATA

ADV7202–SPECIFICATIONS

5 V SPECIFICATIONS

(AVDD/DVDD = 5 V ⴞ 5%, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

1

to T

unless otherwise noted.)

MAX

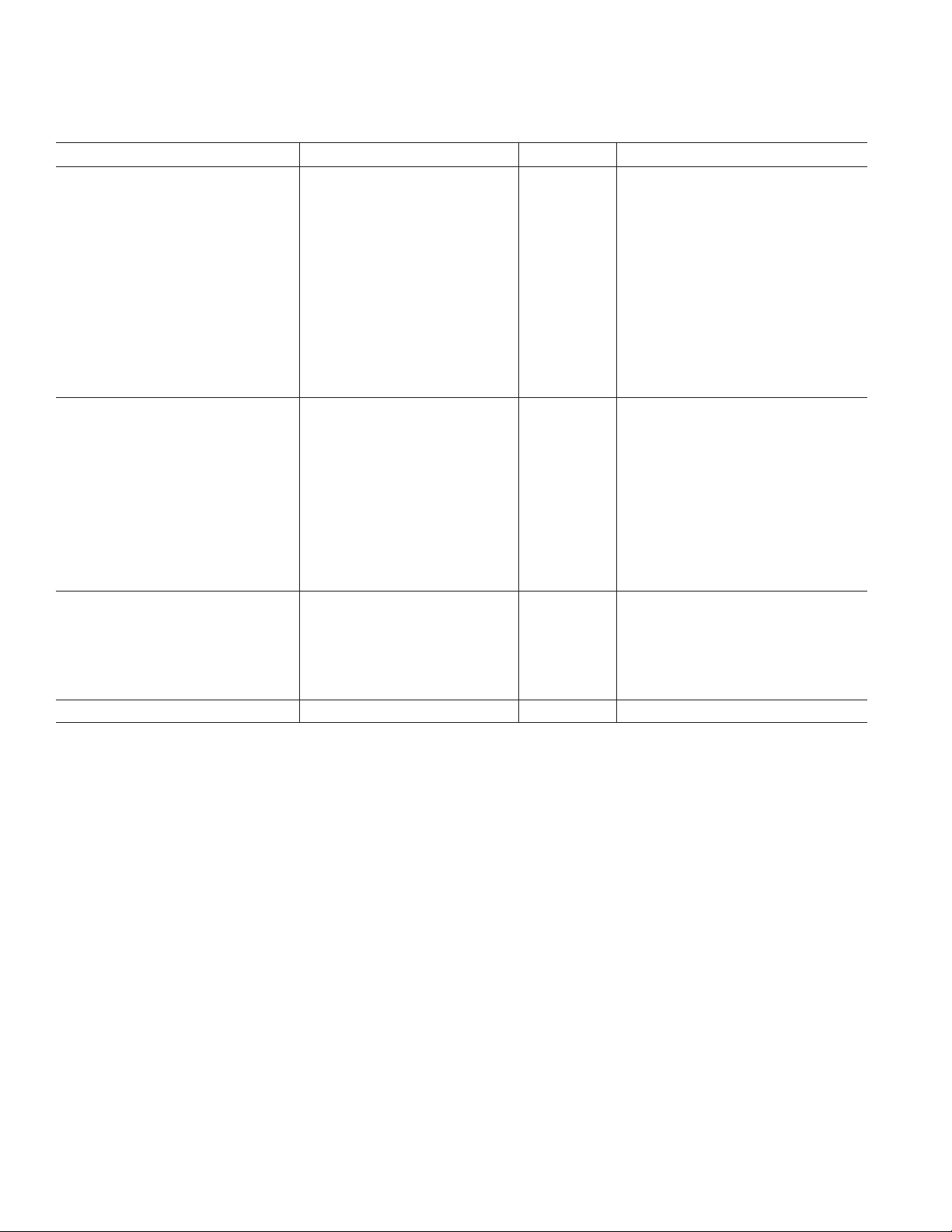

Parameter Min Typ Max Unit Test Conditions

STATIC PERFORMANCE

Resolution (Each DAC) 10 Bits

Accuracy (Each DAC) 10

Integral Nonlinearity ± 2 LSB 10-Bit Operation

Differential Nonlinearity ± 2 LSB 10-Bit Operation

VIDEO ADC

Resolution 10 Bits (plus 2-Bits for gain ranging) 2.2 V Ref.

Accuracy 10

Integral Nonlinearity ± 1 LSB 10-Bit

Differential Nonlinearity ± 0.25 LSB 10-Bit

Input Voltage Range

SNR 62 dB 27 MHz Clock, f

2

–V

REFADC

+V

REFADC

See Figure TBD

= 100 kHz

IN

50 dB 54 MHz Clock, fIN = 100 kHz

AUX ADC

Resolution 8 Bits

Differential Nonlinearity ± 1 LSB Guaranteed Monotonic

Integral Nonlinearity ± 2 LSB

SNR 44 dB 27 MHz Clock

Input Voltage Range 0 2 V

REFADC

V

DIGITAL INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

INL

IN

IN

INH

2V

0.8 V

± 1 µA

TBD pF

DIGITAL OUTPUTS

Output High Voltage, V

Output Low Voltage, V

OL

OH

2.4 V I

0.4 V I

SOURCE

= 3.2 mA

SINK

= 400 µA

Three-State Leakage Current 10 µA

Output Capacitance 10 pF

Digital Output Access Time, t

Digital Output Hold Time, t

14

15

8 ns See Figure 16

3ns

ANALOG OUTPUTS

Output Current 4.33 mA R

= 1.2 kΩ, RL = 300 Ω

SET

DAC-to-DAC Matching 2 %

Output Compliance, V

Output Impedance, R

Output Capacitance, C

Analog Output Delay

OC

OUT

3

OUT

0 +1.4 V

50 kΩ

30 pF I

7ns

OUT

= 0 mA

DAC Output Skew 0 ns

VOLTAGE REFERENCE

Reference Range, V

Reference Range, V

Reference Range, V

NOTES

1

0°C to 70°C

2

SHA gain = 1, half range for SHA gain = 2, see Table II.

3

Output Delay measured from 50% of the rising edge of the clock to the 50% point of full-scale transition.

Specifications subject to change without notice.

REFDAC

REFADC

REFADC

1.235 V

2.200 V Programmable 1.1 V or 2.2 V

1.100 V

–2–

REV. PrB

Page 3

PRELIMINARY TECHNICAL DATA

ADV7202

5 V SPECIFICATIONS

(AVDD/DVDD = 5 V ⴞ 5%, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

to T

unless otherwise noted.)

MAX

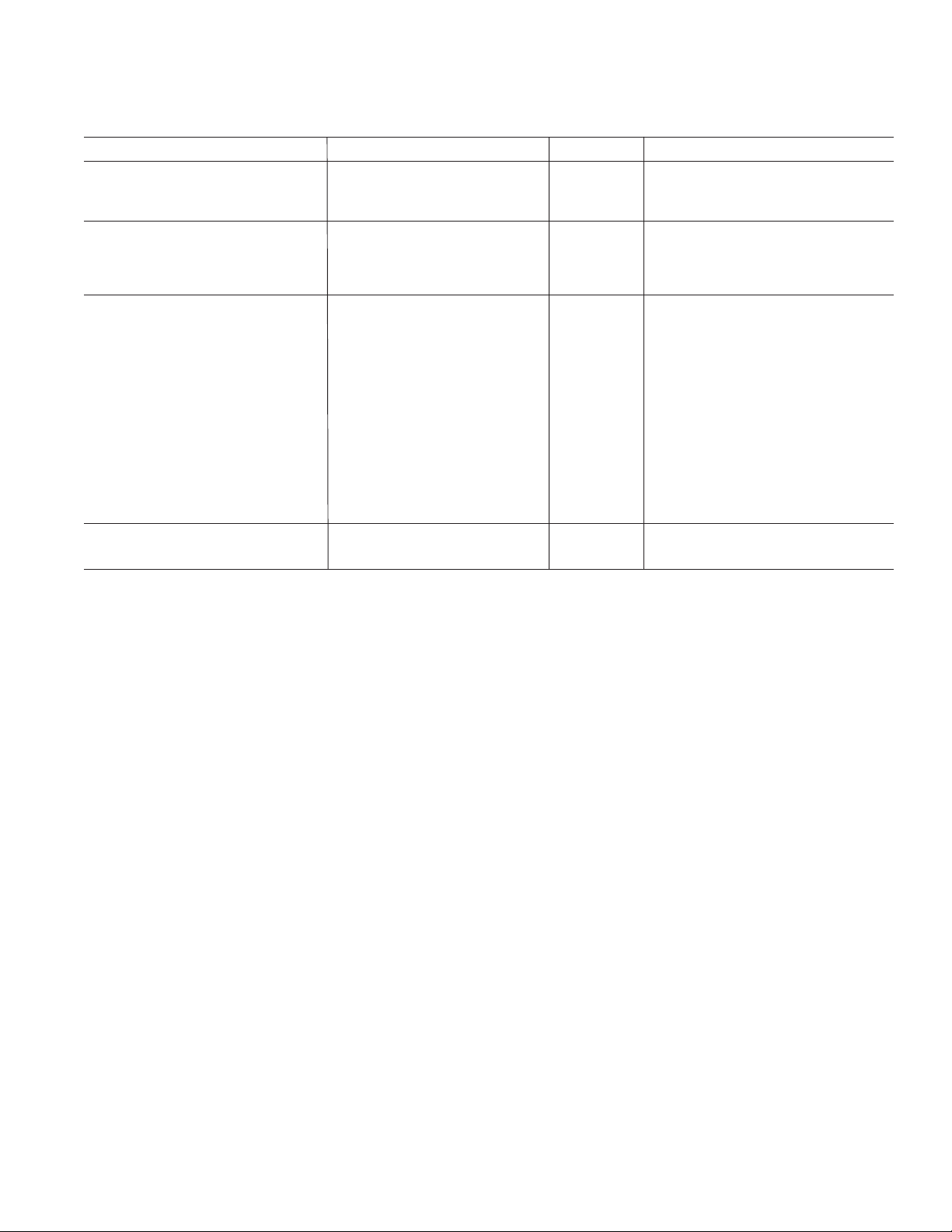

Parameter Min Typ Max Unit Test Conditions

POWER REQUIREMENTS

1

AVDD/DVDD 4.75 5 5.25 V

Normal Power Mode

I

DAC

I

DSC

I

ADC

2

3

4

4mAR

= 1.2 kΩ, RL = 300 Ω

SET

34 mA

21 mA

Sleep Mode

Current 100 µAR

= 1.2 kΩ, RL = 300 Ω

SET

PSU Rejection Ratio

DACs 0.01 0.5 %/% COMP = 0.1 µF

Video ADC 0.01 0.5 %/%

Aux ADC TBD TBD TBD TBD

Power-Up Time TBD TBD Ref. power-up time

MPU PORT—I

2C5

SCLOCK Frequency 0 400 kHz

SCLOCK High Pulsewidth, t

SCLOCK Low Pulsewidth, t

1

2

Hold Time (Start Condition), t

0.6 µs

1.3 µs

0.6 µs After this period the first clock is

3

generated.

Setup Time (Start Condition), t

Data Setup Time, t

5

SDATA, SCLOCK Rise Time, t

SDATA, SCLOCK Fall Time, t

0.6 µs Relevant for Repeated Start Condition

4

100 ns

6

7

300 ns

300 ns

Setup Time (Stop Condition), t80.6 µs

MPU PORT—SPI

5, 6

SCLOCK Frequency 0 10 MHz

SCLOCK High Pulsewidth, t

SCLOCK Low Pulsewidth, t

SI Data Setup Time, t

SI Data Hold Time, t

19

21

22

20

TBD TBD kHz

TBD TBD ns

TBD TBD ns

TBD TBD ns

RESET Low Time 100 ns

NOTES

1

All DACs and ADCs on.

2

I

is the DAC supply current.

DAC

3

I

is the digital core supply current.

DSC

4

I

is the ADC supply current.

ADC

5

TTL input values are 0 V to 3 V, with input rise/fall times

Timing reference points at 50% for inputs and outputs.

6

See SPI timing diagram Figures 10 and 11.

Specifications subject to change without notice.

≤3 ns, as measured between the 10% and 90% points.

REV. PrB

–3–

Page 4

PRELIMINARY TECHNICAL DATA

ADV7202–SPECIFICATIONS

5 V SPECIFICATIONS

(AVDD/DVDD = 4.75 – 5.25, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

Parameter Min Typ Max Unit Condition

1

to T

unless otherwise noted.)

MAX

2

PROGRAMMABLE GAIN

AMPLIFIER

Video ADC Gain –6 +6 dB Setup Conditions

CLAMP CIRCUITRY

3

Clamp Off Leakage Current TBD µA

Clamp Fine Source/Sink Current 3 µA

Clamp Coarse Source/Sink Current 0.5 mA

CLOCK CONTROL

DACCLK0/1

DACCLK1 80 MHz Single Edge Single Clock Mode

DACCLK1

8

Data Setup Time, t

Data Hold Time, t

Pipeline Delay

6, 7

4

27 MHz Dual CLK Dual Edge Mode

27 MHz 4:2:2 Mode

12

13

5

, t

18

2 ns All Input Modes

2ns

Video ADC TBD Clock Cycles

SAR TBD Clock Cycles

RESET CONTROL

RESET Low Time 10 ns

NOTES

1

Temperature range T

2

The max/min specifications are guaranteed over this range. The max/min values are typical over 4.75 V to 5.25 V range.

3

External clamp capacitor = 0.1 µF.

4

TTL input values are 0 V to 3 V, with input rise/fall times ≤3 ns, measured between the 10% and 90% points. Timing reference points at 50% for inputs and outputs.

Analog output load ≤10 pF.

5

Output delay measured from the 50% point of the rising edge of CLOCK to the 50% point of full scale transition.

6

Maximum clock speed determined by setup and hold conditions.

7

Single DAC only.

8

Guaranteed by Characterization.

Specifications subject to change without notice.

MIN

to T

: 0oC to 70oC.

MAX

–4–

REV. PrB

Page 5

PRELIMINARY TECHNICAL DATA

ADV7202

3.3 V SPECIFICATIONS

(AVDD/DVDD = 3.3 V ⴞ 5%, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

1

to T

unless otherwise noted.)

MAX

Parameter Min Typ Max Unit Test Conditions

STATIC PERFORMANCE

Resolution (Each DAC) 10 Bits

Accuracy (Each DAC) 10

Integral Nonlinearity ± 2 LSB 10-Bit Operation

Differential Nonlinearity ± 2 LSB 10-Bit Operation

VIDEO ADC

Resolution 10 10 Bits (Plus 2-Bits for gain ranging) 2.2 V Ref.

Accuracy 10

Integral Nonlinearity ± 1 LSB 10-Bit

Differential Nonlinearity ± 0.25 LSB 10-Bit

Differential Input Voltage Range

SNR 62 dB 27 MHz Clock, f

2

–V

REFADC

+V

REFADC

See Table II

= 100 kHz

IN

50 dB 54 MHz Clock, fIN = 100 kHz

AUX ADC

Resolution Bits

Differential Nonlinearity ± 1 LSB Guaranteed Monotonic

Integral Nonlinearity ± 2 LSB

SNR 44 dB 27 MHz Clock

Input Voltage Range 0 2 V

REFADC

V

DIGITAL INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

INL

IN

IN

INH

2V

0.8 V

± 1 µA

10 pF

DIGITAL OUTPUTS

Output High Voltage, V

Output Low Voltage, V

OL

OH

2.4 V I

0.4 V I

SOURCE

= 3.2 mA

SINK

= 400 µA

Three-State Leakage Current 10 µA

Output Capacitance 30 pF

Digital Output Access Time, t

Digital Output Hold Time, t

14

15

8 ns See Figure 16

3ns

ANALOG OUTPUTS

Output Current 4.33 mA R

DAC-to-DAC Matching 2 %

Output Compliance, V

Output Impedance, R

Output Capacitance, C

Analog Output Delay

OUT

3

OC

OUT

0 1.4 V

50 kΩ

30 pF I

7ns

DAC Output Skew 0 ns

VOLTAGE REFERENCE

Reference Range, V

Reference Range, V

NOTES

1

0°C to 70°C.

2

SHA gain = 1, half range for SHA gain = 2, see Table II.

3

Output delay measured from 50% of the rising edge of the clock to the 50% point of full scale transition.

Specifications subject to change without notice.

REFDAC

REFADC

1.235 V

1.100 V

= 1.2 kΩ, RL = 300 Ω

SET

= 0 mA

OUT

REV. PrB

–5–

Page 6

PRELIMINARY TECHNICAL DATA

ADV7202–SPECIFICATIONS

3.3 V SPECIFICATIONS

(AVDD/DVDD = 3.3 V ⴞ 5%, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

to T

MAX

Parameter Min Typ Max Unit Test Conditions

POWER REQUIREMENTS

1

AVDD/DVDD 3.15 3.3 3.45 V

Normal Power Mode

I

DAC

I

DSC

I

ADC

2

3

4

4mAR

= 1.2 kΩ, RL = 300 Ω

SET

34 mA

21 mA

Sleep Mode

Current 100 µAR

= 1.2 kΩ, RL = 300 Ω

SET

PSU Rejection Ratio

DACs 0.01 0.5 %/% COMP = 0.1 µF

Video ADC 0.01 0.5 %/%

Aux ADC TBD TBD TBD TBD

Power-Up Time TBD TBD TBD

MPU PORT—I

2C5

SCLOCK Frequency 0 400 kHz

SCLOCK High Pulsewidth, t

SCLOCK Low Pulsewidth, t

1

2

Hold Time (Start Condition), t

0.6 µs

1.3 µs

0.6 µs After this period the first clock is

3

generated.

Setup Time (Start Condition), t

Data Setup Time, t

5

SDATA, SCLOCK Rise Time, t

SDATA, SCLOCK Fall Time, t

0.6 µs Relevant for Repeated Start Condition

4

100 ns

6

7

300 ns

300 ns

Setup Time (Stop Condition), t80.6 µs

MPU PORT—SPI

5, 6

SCLOCK Frequency TBD TBD kHz

SCLOCK High Pulsewidth, t

SCLOCK Low Pulsewidth, t

SI Data Setup Time, t

SI Data Hold Time, t

19

21

22

20

TBD TBD kHz

TBD TBD ns

TBD TBD ns

TBD TBD ns

RESET Low Time 100 ns

NOTES

1

All DACs and ADCs on.

2

I

is the DAC supply current.

DAC

3

I

is the digital core supply current.

DSC

4

I

is the ADC supply current.

ADC

5

TTL input values are 0 V to 3 V, with input rise/fall times

6

See SPI timing diagram Figures 10 and 11.

Specifications subject to change without notice.

≤ 3 ns, as measured between the 10% and 90% points. Timing reference points at 50% for inputs and outputs.

unless otherwise noted.)

–6–

REV. PrB

Page 7

PRELIMINARY TECHNICAL DATA

ADV7202

3.3 V SPECIFICATIONS

(AVDD/DVDD = 3.3 V ⴞ 5%, V

= 1.235 V R

REF

= 1.2 k⍀, all specifications T

SET

MIN

Parameter Min Typ Max Unit Condition

1

to T

unless otherwise noted.)

MAX

2

PROGRAMMABLE GAIN

AMPLIFIER

Video ADC Gain –6 +6 dB Setup Conditions

CLAMP CIRCUITRY

3

Clamp Off Leakage Current TBD µA

Clamp Fine Source/Sink Current 3 µA

Clamp Coarse Source/Sink Current 0.5 mA

CLOCK CONTROL

4

DACCLK0/1 27 MHz Dual CLK Dual Edge Mode

DACCLK1 54 MHz Single Edge Dual Clock Mode

DACCLK1 27 MHz 4 : 2 : 2 Mode

Clock High Time, t

Clock Low Time, t

Clock High Time, t

Clock Low Time, t

Data Setup Time, t

Data Hold Time, t

Pipeline Delay

(DACCLK0) 18 ns Dual Edge Dual Clock Mode

10

(DACCLK0) 18 ns

11

(DACCLK1) 18 ns

10

(DACCLK1) 18 ns

11

12

13

5

, t

18

2 ns All Input Modes

2ns

Video ADC TBD Clock Cycles

SAR TBD Clock Cycles

RESET CONTROL

RESET Low Time 10 ns

NOTES

1

Temperature range T

2

The max/min specifications are guaranteed over this range. The max/min values are typical over 3.15 V to 3.45 V range.

3

External clamp capacitor = 0.1 µF.

4

TTL input values are 0 V to 3 V, with input rise/fall times ≤3 ns, measured between the 10% and 90% points. Timing reference points at 50% for inputs and outputs.

Analog output load ≤10 pF.

5

Output delay measured from the 50% point of the rising edge of CLOCK to the 50% point of full-scale transition.

Specifications subject to change without notice.

MIN

to T

: 0oC to 70oC.

MAX

REV. PrB

–7–

Page 8

ADV7202

WARNING!

ESD SENSITIVE DEVICE

PRELIMINARY TECHNICAL DATA

ABSOLUTE MAXIMUM RATINGS

1

AVDD to AVSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

DVDD to DVSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

Ambient Operating Temperature (T

Storage Temperature (T

Junction Temperature (T

) . . . . . . . . . . . . . . –65°C to +150°C

S

) . . . . . . . . . . . . . . . . . . . . . 150°C

J

) . . . . . . . . 0°C to 70°C

A

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . . 300°C

Vapor Phase Soldering (1 minute) . . . . . . . . . . . . . . . . 220°C

to GND2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 V to V

I

OUT

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

AA

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Analog output short circuit to any power supply or common can be of an indefinite

duration.

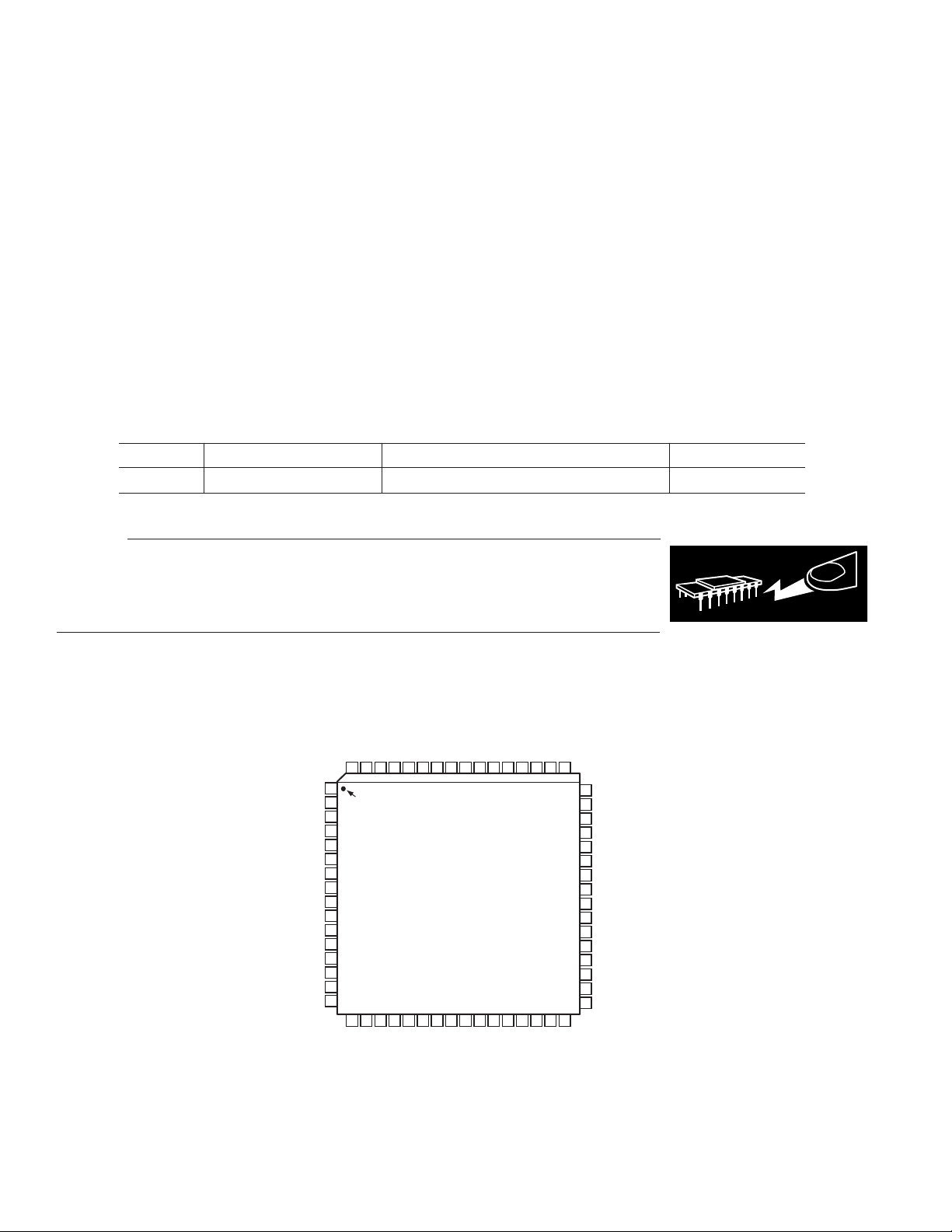

ORDERING INFORMATION

1

Model Temperature Range Package Description Package Option

ADV7202 0°C to 70°C 64-Lead Plastic Quad Flatpack (LQFP) ST-64

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADV7202 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

SYNC_IN

CLK/SCK

LE/ALSB

XTAL0

XTAL1

AVDD_ADC

AVSS_ADC

AIN1P

AIN1M

AIN2P

AIN12M

AIN3P

AIN3M

AIN4P

AIN4M

AIN5P

PIN CONFIGURATION

SYNC_OUT

DAC_DATA0

DAC_DATA1

DAC_DATA2

DAC_DATA3

DACCLK0

DACCLK1

DAC_DATA4

DAC_DATA5

CAP1

DOUT9

OSDEN

DVDD

DVSS

DOUT8

DOUT7

SI_DATA9

64 63 62 61 60 55 54 53 52 51 50 4959 58 57 56

1

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

AIN6P

AIN5M

AIN6M

SPI_SEL

REFADC

ADV7202

TOP VIEW

(Not to Scale)

CML

CAP2

DAC_DATA6

DAC_DATA7

DAC_DATA8

DAC_DATA9

DOUT6

DOUT5

DOUT3

DOUT4

48

RESET

47

RSET

46

VREFDAC

45

COMP

44

DAC0_OUT

43

DAC1_OUT

42

AVSDD_DAC

41

AVSS_DAC

40

DAC2_OUT

39

DAC3_OUT

38

OSDIN0

37

OSDIN1

36

OSDIN2

35

DOUT0

34

DOUT1

33

DOUT2

–8–

REV. PrB

Page 9

PRELIMINARY TECHNICAL DATA

ADV7202

PIN FUNCTION DESCRIPTIONS

Input/

Pin No. Mnemonic Output Function

1 SYNC_IN I This signal can be used to synchronize the updating of clamps. Polarity is pro-

grammable via I

2 CLK/SCK I MPU Port Serial Interface Clock Input. If the SPI interface is enabled, this pin is

clock input. If the I

3 LE/ALSB I If the SPI interface is enabled, this pin is Latch Enable. If the I

abled, this pin is the ALSB Address Select Pin. This signal sets up the LSB of the

MPU address. MPU address = 2cH, ALSB = 0, MPU address = 2eH, ALSB = 1.

When this pin is tied high, the I

2

I

C interface. When this pin is tied low, the input bandwidth on the I2C lines is

increased.

4 XTAL0 I Input Terminal for crystal oscillator or connection for external oscillator with

CMOS-compatible square wave clock signal.

5 XTAL1 O Second Terminal for Crystal Oscillator. Not connected if external clock source

is used.

6 AVDD_ADC P ADC Analog Supply Voltage (5 V or 3.3 V)

7 AVSS_ADC G Ground for ADC Analog Supply

8–19 AIN1–6 I Analog Signal Inputs. Can be configured differentially or single-ended.

20 SPI_SEL I A high signal on the pin selects SPI MPU port serial operation; a low signal selects

2

I

C MPU port serial operation.

21 REFADC I/O Internally generated Voltage Reference or programmable reference out.

22 CML O Common-Mode Level for ADCs

23, 24 CAP2, CAP1 I ADC Capacitor Network

25 OSDEN I Enable data from OSDIN0–2 to be switched to the outputs when set to a logic high.

26–35 DOUT[9:0] O ADC data output

36 OSDIN2 I Third Input Channel for On-Screen Display

37 OSDIN1 I Second Input Channel for On-Screen Display

38 OSDIN0 I First Input Channel for On-Screen Display

39 DAC3_OUT O General Purpose Analog Output

40 DAC2_OUT O Analog Output. Can Be Used to Output CVBS, R or U

41 AVSS_DAC G Ground for DAC Analog Supply

42 AVDD_DAC P DAC Analog Supply Voltage (5 V or 3.3 V)

43 DAC1_OUT O Analog Output. Can Be Used to Output CVBS, Y, G, or Luma.

44 DAC0_OUT O Analog Output. Can Be Used to Output CVBS, V, B, or Chroma.

45 COMP O Compensation Pin for DACs. Connect 0.1µF capacitor from COMP pin to

AVDD_DAC.

46 VREFDAC I/O DAC Voltage Reference Output Pin, Nominally 1.235 V. Can be driven by an

external voltage reference.

47 RSET I Used to control the amplitude of the DAC output current, 1200 Ω gives an I max

of 4.33 µA.

48 RESET I Master Reset (Asynchronous)

49–52, 55, 56, DAC_DATA[9:0] I DAC Input Data for Four Video Rate DACs

59–62

53 DVSS G Ground for Digital Core Supply

54 DVDD P Analog Supply Voltage for Digital Core (5 V or 3.3 V)

57, 58 DAC_CLK[1:0] I DAC Clocks

63 SYNC_OUT O Output Sync Signal, which goes to a high state while Cr data sample from a

YCrCb data stream or C data from a Y/C data stream is output on DOUT[9:0].

64 SI_SDA I/O If the SPI interface is enabled, this pin is serial data In. If the I

enabled, this pin is MPU Port Serial Data Input/Output.

2

C or SPI.

2

C interface is enabled, this pin is SCK.

2

C filter is activated, which reduces noise on the

2

C interface is en-

2

C interface is

REV. PrB

–9–

Page 10

ADV7202

PRELIMINARY TECHNICAL DATA

FUNCTIONAL DESCRIPTION

Analog Inputs

The ADV7202 has the capability of sampling up to five CVBS

video input signals, or two component YUV, or three S-Video

inputs. Eight auxiliary general-purpose inputs are also available.

Table I shows the analog signal input options available and programmable by I2C/SPI. When configured for auxiliary input

mode, the CVBS inputs are single-ended with the second differential input internally set to VREFADC. The resolution on the

front end digitizer is 12 bits; two bits (12 dB) are used for gain

and offset adjustment. The digitizer has a conversion rate of up

to 54 MHz. The eight auxiliary inputs can be used for system

monitoring, etc., and are sampled by a 843 kHz SAR ADC. The

analog input signal range will be dependent on the value of

VREFADC and the SHA gain see (Table II). Three on-screen

display inputs OSDIN[2:0] mux to the DAC outputs to enable

support for Picture-on-Picture applications.

Table I. Analog Input Signal Data

Register SHA

Setting Description Used Sync_Out

0000 CVBS in on AIN1 0 Figure 1

0001 CVBS in on AIN2 0 Figure 1

0010 CVBS in on AIN3 1 Figure 1

0011 Reserved 1

0100 CVBS in on AIN5 0 Figure 1

0101 CVBS in on AIN6 2 Figure 1

0110 Y/C, Y on AIN1, C on AIN4 0, 1 Figure 2

0111 Y/C, Y on AIN2, C on AIN3 0, 1 Figure 2

1000 YUV, Y on AIN2, U on AIN3, 0, 1, 2 Figure 3

V on AIN6

1001 CVBS on AIN1 and 8 AUX. 0, 1, 2 Figure 1

I/Ps AIN3–6*

1010 CVBS on AIN2 and 8 AUX. 0, 1, 2 Figure 1

I/Ps AIN3–6*

*AUX inputs are single-ended. All other inputs are differential.

Table II. Analog Input Signal Range

I/P SHA Input Range (V)

Mode V

(V) Gain Min Typ Max

REFOUT

Differential 2.2 1 –2.2 0 2.2

Differential 2.2 2 –1.1 0 1.1

Differential 1.1 1 –1.1 0 1.1

Differential 1.1 2 –0.55 0 0.55

Single-ended 2.2 1 0 2.2 4.4

Single-ended 2.2 2 1.1 2.2 3.3

Single-ended 1.1 1 0 1.1 2.2

Single-ended 1.1 2 0.55 1.1 1.65

NOTE

Fclk/32, 843kHz for nominal 27 Mhz

Digital Inputs

The DAC digital inputs on the ADV7202 [9:0] are TTL-compatible. Data may be latched into the device in three different

modes programmable via I

2

C or SPI.

DAC Mode 1, single clock, single edge (see Figure 13) uses only

the rising edge of DAC_CLK1 to latch data into the device.

DAC_CLK0 is a data line that goes high to indicate that the data

is for DAC0. Subsequent data words go to the next DAC in

sequence.

DAC Mode 2, dual edge, dual clock (see Figure 14) clocks data

in on both edges of DAC_CLK0 and DAC_CLK1. Using this

option, data can is latched into the device at four times the

clock speed.

DAC Mode 3, 4:2:2 mode (see Figure 15). Using this option, 4:2:2

video data is latched in using DAC_CLK1, while DAC_CLK0 is used

as a data line that is brought to a high state when Cr data is input;

hence Y will appear on DAC1, Cr on DAC2, and Cb on DAC0.

Analog Outputs

Analog Outputs [DAC0–3] consist of four 10-bit DACs that run at

up to 54 MHz or up to 108 MHz if only DAC0 is used. These outputs

can be used to output CVBS, S-Video, Component YCrCb, and RGB.

Digital Outputs

Video data will be clocked out on DOUT[9:0] during the rising

edge of XTAL0. See Figure 17. Auxiliary data can be read out

2

vial

C compatible MPU port.

I2C and SPI Control

The ADV7202 is both I2C- and SPI-compatible. It should be

noted though that only register write applications are possible

with SPI control. I

2

C operation allows both reading and writing

of system registers. Its operation is explained in detail in the MPU

Port Description section. A logic high level on the SPI_SEL line

selects SPI MPU operation. In this mode the first eight bits of

the 16-bit word on the SI data line will select the register address

and the next eight bits are the value to be programmed into the

register, i.e., the register data. See Figure 10. Latch Enable (LE)

goes low while valid address or data information is present. Figure

10 shows latch enable low for the entire 16 bits of address and

data information. As shown in Figure 11, the register eight-bit data

information does not always have to be clocked in directly after

the address. LE may go high and then low again when valid data

is available. If LE goes low for anything less than eight cycles of

SCLK, the SPI MPU will reset (not register values); hence this

method may be used to initiate a start condition.

–10–

REV. PrB

Page 11

PRELIMINARY TECHNICAL DATA

ADV7202

Video Clamping and AGC Control

When Analog signal clamping is required the input signal should

be AC coupled to the input via a capacitor, the clamping control

is via the MPU port. The AGC is implemented digitally. For

correct operation the user must program the clamp value to which

the signal has been clamped into the ADV7202 I

2

C Register. This

allows the user to specify which signal level is unaffected by the

AGC. The digital output signal will be a function of the ADC

output, the AGC Gain, and the Clamp Level, and can be represented as follows,

D Clamp Level_OUT = ADC Gain ADC – Clamp Level×

[]

()

+

(1)

D_OUT will be a 10-bit number (0–1023), the AGC Gain

defaults to 2 and can have a value between 0 to 7.99. The Clamp

Level is a 10-bit number (0–1023) although only the top eight

bits of clamp level are specified in the I

2

C Register; the ADC

value can be regarded as a 10-bit number (0–1023) for the

equation. It should be noted that the ADC resolution is 12 bits.

The above equation is used to give a basic perspective, and is

mathematically correct.

When the clamps are operational, the operation described by

Equation (1) is how the ADV7202 ensures that the level to

which the user is clamping is unaffected by the AGC loop.

When no clamps are operational, the operation should be

regarded as a straightforward gain-and-level shift.

Equation (1) maps the ADC input voltage range to its output.

AGC Gain

The AGC Gain can be set to a value from 0 to 7.9. The AGC

Gain Register holds a 12-bit number that corresponds to the

required gain. The first three MSBs hold the gain integer value

while the remaining nine bits hold the gain fractional value.

Example: The user requires a gain of 3.65.

The first three bits give the integer value 3, hence these will be

set to ‘0 1 1.’ The remaining nine bits will have to be set to give

the fractional value 0.65, 512 ⫻ 0.65 = 333 = ‘10100110 1.’

From Equation (2) it can be seen that the Clamp Level is

taken from the signal before AGC is applied and then added on

again afterwards; hence, if the AGC Gain is set to a value of

one, the result would be as follows,

(AGC Gain = 1)

D Clamp Level ADC_OUT = ADC - Clamp Level +=

FUNCTIONAL DESCRIPTION

Clamp and AGC Control

(2)

The ADV7202 has a front end 3-channel clamp control. In

order to perform an accurate AGC gain operation, it is necessary to know to what level the user is clamping the black level;

this value is programmable in Clamp Register 0 CR00–CR07.

Each channel has a fine and coarse clamp; the clamp direction

and its duration are programmable. Synchronization of the clamps

and AGC to the input signal is possible using the SYNC_IN control pin and setting mode register CR14 to Logic Level “1.” Using

this method, it is possible to ensure that AGC and clamping are

only applied outside the active video area.

Control Signals

The function and operation of the SYNC_IN signal is described

in the Clamp Control section. The SYNC_OUT will go high

while Cr data from a YCrCb data stream or C data from a Y/C

data stream has been output on DOUT[9:0]. See Figure 1 to

Figure 3.

I2C Filter

A selectable internal I2C filter allows significant noise reduction

on the I

on the I

passed to the I

input bandwidth on the I

2

C interface. In setting ALSB high, the input bandwidth

2

C lines is reduced and pulses of less than 50 ns are not

2

C controller. Setting ALSB low allows greater

2

C lines.

REV. PrB

XTAL0

DAC_DATA [9:0]

SYNC_OUT

XTAL0

DAC_DATA [9:0]

SYNC_OUT

CVBS

Figure 1. SYNC_OUT Output Timing, CVBS Input

YCYC Y CY

Figure 2. SYNC_OUT Output Timing, Y/C (S-VIDEO) Input

CVBS CVBS CVBS CVBS CVBS CVBS

–11–

Page 12

ADV7202

PRELIMINARY TECHNICAL DATA

XTAL0

DAC_DATA [9:0]

SYNC_OUT

CR Y CB Y CR Y CB

Figure 3. SYNC_OUT Output Timing, YCrCb Input

MPU PORT DESCRIPTION

The ADV7202 supports a 2-wire serial (I2C-compatible)

microprocessor bus driving multiple peripherals. Two inputs,

Serial Data (SDA) and Serial Clock (SCL), carry information

between any device connected to the bus. Each slave device is

recognized by a unique address. The ADV7202 has four possible slave addresses for both read and write operations. These

are unique addresses for each device and are illustrated in

Figure 4. The LSB sets either a read or write operation. Logic

Level “1” corresponds to a read operation, while Logic Level

“0” corresponds to a write operation. A1 is set by setting the

ALSB pin of the ADV7202 to Logic Level “0” or Logic Level

“1.” When ALSB is set to “0,” there is greater input bandwidth

on the I

bus. When ALSB is set to “1,” there is reduced input bandwidth on the I

50 ns will not pass into the I

2

C lines, which allows high-speed data transfers on this

2

C lines, which means that pulses of less than

2

C internal controller. This mode is

recommended for noisy systems.

001011A1X

ADDRESS

CONTROL

SET UP BY

ALSB

READ/WRITE

CONTROL

0 DISABLED

1 ENABLED

Figure 4. Slave Address

To control the various devices on the bus, the following protocol must be followed. First the master initiates a data transfer by

establishing a Start condition, defined by a high-to-low transition

on SDA while SCL remains high. This indicates that an address/

data stream will follow. All peripherals respond to the Start

condition and shift the next eight bits (7-bit address + R/W bit).

The bits are tranferred from MSB down to LSB. The peripheral

that recognizes the transmitted address responds by pulling the

data line low during the ninth clock pulse. This is known as an

Acknowledge Bit. All other devices withdraw from the bus at

this point and maintain an idle condition. The idle condition

is where the device monitors the SDA and SCL lines waiting for

the Start condition and the correct transmitted address. The R/W

bit determines the direction of the data.

A Logic “0” on the LSB of the first byte means that the master

will write information to the peripheral. A Logic “1” on the LSB

of the first byte means that the master will read information

from the peripheral.

The ADV7202A acts as a standard slave device on the bus. The

data on the SDA pin is eight bits long, supporting the 7-bit

addresses plus the R/W bit. It interprets the first byte as the

device address and the second byte as the starting subaddress.

The subaddresses auto-increment, allowing data to be written to

or read from the starting subaddress. A data transfer is always

terminated by a Stop condition. The user can access any unique

subaddress register on a one-by-one basis without updating all

the registers.

Stop and Start conditions can be detected at any stage during

the data transfer. If these conditions are asserted out of sequence

with normal read and write operations, they cause an immediate

jump to the idle condition. During a given SCL high period, the

user should only issue one Start condition, one Stop condition,

or a single Stop condition followed by a single Start condition. If

an invalid subaddress is issued by the user, the ADV7202 will

not issue an acknowledge and will return to the idle condition. If

in auto-increment mode, the user exceeds the highest subaddress,

the following action will be taken:

1. In Read Mode, the highest subaddress register contents

will continue to be output until the master device issues a

no-acknowledge. This indicates the end of a read. A

no-acknowledge condition is where the SDA line is not

pulled low on the ninth pulse.

2. In Write Mode, the data for the invalid byte will not be

loaded into any subaddress register, a no-acknowledge will

be issued by the ADV7202, and the part will return to the

idle condition.

Figure 5 illustrates an example of data transfer for a read

sequence and the Start and Stop conditions.

SDATA

SCLOCK

S

START ADDR R /W AC K

1–7 8 9 1–7 8 9 1–7 8 9

SUBADDRESS

ACK DATA

ACK

P

STOP

Figure 5. Bus Data Transfer

–12–

REV. PrB

Page 13

PRELIMINARY TECHNICAL DATA

Figure 6 shows bus write and read sequences.

WRITE

SEQUENCE

SEQUENCE

S SLAVE ADDR A(S) SUB ADDR A(S) DATA A(S ) DATA A(S) P

LSB = 0 LSB = 1

READ

S SLAVE ADDR A(S) SUB ADDR A(S) DATA A( M) DATA A(M) PS SLAVE ADDR A(S)

S = START BIT

P = STOP BIT

A(S) = ACKNOWLEDGE BY SLAVE

A(M) = ACKNOWLEDGE BY MASTER

Figure 6. Write and Read Sequence

t3

SDA

t6

SCL

t2

Figure 7. I2C MPU Port Timing Diagram

t1

t7

ADV7202

A

(S) = NO ACKNOWLEDGE BY SLAVE

A

(M) = NO ACKNOWLEDGE BY MASTER

t

5

t

3

t

4

t

8

DAC_CLK0

DAC_CLK1

DAC_DATA[7:0]

DAC_CLK1

DATA [9:0]

DAC_CLK0

t

12

DATA

t

10

t

13

t

11

DATA

Figure 8. Input Data Format Timing Diagram Single Clock

t

12

DATA

t

13

t

10

t

13

t

12

t

12

t

13

DATADATA

t

11

t

– SETUP TIME

12

–

t

HOLD TIME

13

t

– CLOCK HIGH TIME

10

t

– CLOCK LOW TIME

11

DATA

t

13

t

12

DATA

t

– CLOCK HIGH TIME

10

t

– CLOCK LOW TIME

11

t

– DATA SETUP TIME

12

t

– DATA HOLD TIME

13

REV. PrB

Figure 9. Input Data Format Timing Diagram Dual Clock

–13–

Page 14

ADV7202

PRELIMINARY TECHNICAL DATA

8 CLOCK CYCLES8 CLOCK CYCLES

SCLK

LE

SCLK

LE

SI

ADDRESS [7:0] DATA [7:0]

Figure 10. SPI Timing Mode 1

8 CLOCK CYCLES8 CLOCK CYCLES

SI

NOTE: TAKING LE LOW FOR < 8 CYCLES OF SCLK WILL

RESET THE SPI MPU INTERFACE.

ADDRESS [7:0]

DATA [7:0]

Figure 11. SPI Timing Mode 2

t

SCLK

t

20

19

t

21

SI/LE

Figure 12. SPI Timing Diagram

t

22

–14–

REV. PrB

Page 15

PRELIMINARY TECHNICAL DATA

DIGITAL DATA INPUT TIMING DIAGRAMS

ADV7202

A2 A3

DAC2 DAC0

At A3, NEW DAC0 DATA

IS CLOCKED IN AND A0,

A1, AND A3 ARE SENT TO

THE DACs. DATA APPEARS

AT THE OUTPUT DACs TWO

CLOCK CYCLES AFTER

BEING SENT TO THE DACs.

DAC_CLK1

DAC_CLK0

DAC_DATA [9:0]

A0

DAC0 DAC1 DAC2 DAC0 DAC1

A1

Figure 13. DAC Mode 1, Single Clock, Single Edge Input Data Format Timing Diagram. As with Mode 1, DAC_CLK0 is a

Data Line that Indicates the Data is for DAC0. Above Example Shows Three DAC Usage.

A1 A2 A3 A4

DAC_CLK0

DAC_CLK1

DAC_DATA [9:0]

DAC1 DAC2 DAC3 DAC0

DAC1 DAC2 DAC3 DAC 0

A1 DAC1 DATA CLOCKED IN.

A2 DAC2 DATA CLOCKED IN.

A3 DAC3 DATA CLOCKED IN.

A4 DAC0 DATA FOR THE NEXT

PIXEL AND THE PREVIOUS

FOUR CLOCKED OUT TO DACs.

NOTE

DATA WILL BE CLOCKED TO THE

DACs TWO CLOCK CYCLES

AFTER A4.

Figure 14. DAC Mode 2, Dual Clock, Dual Edge Input Data Format Timing Diagram

DAC_CLK1

DAC_CLK0

DAC_DATA [9:0]

ADC O/P DOUT[9:0]

SYNC_OUT, SYNC_IN

A1 A2 A3 A4

DAC0 DAC1 DAC2 DAC1 DAC0

DAC1 DAC2

Figure 15. DAC Mode 3, 4:2:2 Input Data Format Timing Diagram

t

15

DATADATA

XTAL0

OUTPUT

t

14

t

15

Figure 16. Digital O/P Timing

AT A4, PREVIOUS A0, A2,

AND A3 DATA ARE SENT

TO THE DACs. AT A2, A1

DATA APPEARS AT THE

OUTPUT DACs TWO

CLOCK CYCLES AFTER

BEING SENT T O THE DACs.

t

– ACCESS TIME

14

t

– HOLD TIME

15

REV. PrB

–15–

Page 16

ADV7202

PRELIMINARY TECHNICAL DATA

XTAL0

DATA [9:0]

DATA

DATA DATA DATA DATA DATA DATA DATA

Figure 17. Standard Mode Digital Data O/P Format

REGISTER ACCESSES

The MPU can write to or read from all of the registers of the

ADV7202 except the Subaddress Registers which are writeonly. The Subaddress Register determines which register the

next read or write operation accesses. All communications with

the part through the bus start with an access to the Subaddress

Register. A read/write operation is then performed from/to the

target address which then increments to the next address until a

Stop command on the bus is performed.

REGISTER PROGRAMMING

The following section describes the functionality of each register. All registers can be read from as well as written to.

SR4

ADV7202 SUBADDRESS REGISTER

ADDRESS SR6 SR5 SR4 SR3 SR2 SR1 SR0

00h 0000000 MODE REGISTER 0

01h 0000001 MODE REGISTER 1

02h 0000010 MODE REGISTER 2

03h 0000011 MODE REGISTER 3

04h 0000100 ACG REGISTER 0

05h 0000101 AGC REGISTER 1

06h 0000110 CLAMP REGISTER 0

07h 0000111 CLAMP REGISTER 1

08h 0001000 CLAMP REGISTER 2

09h 0001001 CLAMP REGISTER 3

0Ah 0001010 TIMING REGISTER

0Bh 0001011 V

0Ch 0001100 RESERVED

0Dh 0001101 RESERVED

0Eh 0001110 RESERVED

0Fh 0001111 RESERVED

10h 0010000 AUX REGISTER 0

11h 0010001 AUX REGISTER 1

12h 0010011 AUX REGISTER 2

13h 0010000 AUX REGISTER 3

14h 0010100 AUX REGISTER 4

15h 0010101 AUX REGISTER 5

16h 0010110 AUX REGISTER 6

17h 0010111 AUX REGISTER 7

Subaddress Register (SR7–SR0)

The Communications Register is an 8-bit write-only register.

After the part has been accessed over the bus, and a read/write

operation is selected, the subaddress is set up. The Subaddress

Register determines to/from which register the operation

takes place.

Figure 19 shows the various operations under the control of the

Subaddress Register. “0” should always be written to SR7.

Register Select (SR6–SR0)

These bits are set up to point to the required starting address.

SR3

SR2

ADJUST REGISTER

REF

SR1

SR0SR7 SR6 SR5

Figure 19. Subaddress Registers

–16–

REV. PrB

Page 17

PRELIMINARY TECHNICAL DATA

ADV7202

MODE REGISTER 0

MR0 (MR07–MR00)

(Address (SR4–SR0) = 00H)

Figure 20 shows the various operations under the control of

Mode Register 0.

MR0 BIT DESCRIPTION

ADC Reference Voltage (MR00)

This control bit is used to select the ADC reference voltage.

When this bit is set to “0,” a reference voltage of 1.1 V is

selected. When the bit is set to “1,” a reference voltage of 2.2 V

is selected.

MR7

MR7–MR5

ZERO MUST BE

WRITTEN TO

THESE BITS

MR5

POWER-DOWN

MR14

0 NORMAL

1 POWER-DOWN

MR3

0 NORMAL

1 POWER-DOWN

POWER-DOWN

External Reference Enable (MR01)

Setting this bit to “1” enables an external voltage reference for

the ADC.

Voltage Reference Power-Down (MR02)

Setting this bit to “1” causes the internal ADC voltage reference to

power down.

ADC Power-Down (MR03)

Setting this bit to “1” causes the video rate ADC to power down.

Power-Down (MR04)

Setting this bit to “1” puts the device into power-save mode.

Reserved (MR05–07)

“0” must be written to these bits.

MR2MR4MR6 MR3 MR0

POWER-DOWN

MR2

0 NORMAL

1 POWER-DOWN

ADC

V

MR1

REF

MR1

0 INTERNAL

1 EXTERNAL

EXT REF

ENABLE

ADC REF

VO LTAG E

MR0

0 1.1V

1 2.2V

Figure 20. Mode Register 0

MODE REGISTER 1

MR1 (MR17–MR10)

(Address (SR4–SR0) = 01H)

Figure 21 shows the various operations under the control of

Mode Register 1.

MR1 BIT DESCRIPTION

DAC0 Control (MR10)

Setting this bit to “0” enables DAC 0; otherwise, this DAC is

powered down.

DAC1 Control (MR11)

Setting this bit to “0” enables DAC 1; otherwise, this DAC is

powered down.

DAC2 Control (MR12)

Setting this bit to “0” enables DAC 2; otherwise, this DAC is

powered down.

DAC3 Control (MR13)

Setting this bit to “0” enables DAC 3; otherwise, this DAC is

powered down.

MR17

DAC I/P INVERT

MR17

0 DISABLE

1 ENABLE

4:2:2 MODE

MR16

0 DISABLE

1 ENABLE

MR15

DUAL EDGE CLOCK

MR14

0 SINGLE EDGE

1 DUAL EDGE

DUAL CLOCK

MR15

0 SINGLE CLK

1 DUAL CLK

Dual Edge Clock (MR14)

Setting this bit to “1” allows data to be read into the DACs on

both edges of the clock; hence, data may be read in at twice the

clock frequency. See Figure 21. If this bit is set to “0,” the data

will only be strobed on the rising edge of the clock.

Dual Clock (MR15)

Setting this bit to “1” allows the use of two clocks to strobe data

into the DACs. It is possible to clock data in with only one clock

and use the second clock to contain timing information.

4:2:2 Mode (MR16)

Setting this bit to “1” enables data to be input in 4:2:2 format

(see Figure 21). 4:2:2 mode will only work if TR14 and TR15

register bits are set to zero.

DAC Input Invert (MR17)

Setting this bit to “1” causes the input data to the DACs to be

inverted allowing for an external inverting amplifier.

MR13

MR13

0 NORMAL

1 POWER-DOWN

MR12MR14MR16

DAC2 CONTROL

MR12

0 NORMAL

1 POWER-DOWN

DAC3 CONTROL

MR11

MR10

DAC0 CONTROL

MR10

0 NORMAL

1 POWER-DOWN

DAC1 CONTROL

MR11

0 NORMAL

1 POWER-DOWN

REV. PrB

Figure 21. Mode Register 1

–17–

Page 18

ADV7202

PRELIMINARY TECHNICAL DATA

MODE REGISTER 2

MR2 (MR20–MR27)

(Address (SR4–SR0) = 02H)

Figure 22 shows the various operations under the control of

Mode Register 2.

MR1 BIT DESCRIPTION

Analog Input Configuration (MR20–MR23)

This control selects the analog input configuration, up to six

CVBS input channels, or two component YUV, or three S-Video

and eight auxiliary inputs. See Figure 22 for details.

SHA0 Control (MR24)

Setting this bit to “0” enables SHA0; otherwise, this SHA is

powered down (SHA = Sample and Hold Amplifier).

MR27

AUX CONTROL

MR27

0 NORMAL

1 POWER-DOWN

SHA2 CONTROL

MR26

0 NORMAL

1 POWER-DOWN

SHA0 CONTROL

MR24

0 NORMAL

1 POWER-DOWN

SHA1 CONTROL

MR25

0 NORMAL

1 POWER-DOWN

0 0 0 0 CVBS IN ON AIN1

0 0 0 1 CVBS IN ON AIN2

0 0 1 0 CVBS IN ON AIN3

0 0 1 1 RESERVED

0 1 0 1 CVBS IN ON AIN6

0 1 1 1 Y/C IN ON AIN2, AIN3

1 0 0 0 YUV IN ON AIN2, AIN3, AIN6

1 0 0 1 CVBS IN ON AIN1, 8 AUX INPUTS

SHA1 Control (MR25)

Setting this bit to “0” enables SHA1; otherwise, this SHA is

powered down.

SHA2 Control (MR26)

Setting this bit to “0” enables SHA2; otherwise, this SHA is

powered down.

AUX Control (MR27)

Setting this bit to “0” enables the auxiliary ADC; otherwise, this

Aux ADC is powered down.

MR22MR24MR26 MR23 MR20MR25

MR23 MR22 MR21 MR20

0 1 0 0 CVBS IN ON AIN5

0 1 1 0 Y/C IN ON AIN1, AIN4

1 0 1 0 CVBS IN ON AIN2, 8 AUX INPUTS

*

SEE FIGURE : XX

MR21

ANALOG INPUT CONFIGURATION

*

Figure 22. Mode Register 2

MODE REGISTER 3

MR3 (MR30–MR37)

(Address (SR4–SR0) = 03H)

Figure 23 shows the various operations under the control of

Mode Register 3.

MR3 BIT DESCRIPTION

Clamp Current (MR30)

Setting this bit to “1” enables the doubling of all clamp currents.

Analog Input Mode (MR31)

Setting this bit to “1” enables differential mode for the analog

inputs; otherwise, the inputs are single ended. See Figure 23.

SHA Gain (MR32)

Setting this bit to “0” enables SHA gain of 1. If the bit is set to

“1,” the SHA gain is 2. The SHA gain will limit the input signal

range, see Figure 23.

MR37

MR36–MR37

ZERO MUST BE

WRITTEN TO

THESE REGISTERS

MR35

OUTPUT ENABLE

MR34

0 NORMAL

1 HIGH Z

SYNC POLARITY

MR35

0LOW

1 HIGH

MR33

MR33

0OFF

1ON

Voltage Clamp (MR33)

Setting this bit to “1” will enable the voltage clamps.

Output Enable (MR34)

Setting this bit to “1” puts the digital outputs into high impedance.

SYNC Polarity (MR35)

This bit controls the polarity of the SYNC_IN pin. If the bit

is set to “0,” a logic low pulse corresponds to H-Sync. If the bit

is “1,” a logic high pulse corresponds to H-Sync. This sync in

pulse can then be used to control the synchronization of AGC/

Clamping, see AR12.

Reserved (MR36–MR37)

Zero must be written to both these registers.

MR32MR34MR36

SHA GAIN

MR32

01

12

VOLTAGE CLAMP

MR31

MR30

CLAMP CURRENT

MR30

0 NORMAL

1 DOUBLE

ANALOG INPUT

MR31

0 SINGLE-ENDED

1 POWER-DOWN

Figure 23. Mode Register 3

–18–

REV. PrB

Page 19

PRELIMINARY TECHNICAL DATA

ADV7202

AGC REGISTER 0

AR0 (AR00–AR07)

(Address (SR4–SR0) = 04H)

Figure 24 shows the various operations under the control of

AGC Register 0.

AR0 BIT DESCRIPTION

AGC Multiplier (AR00–AR07)

This register holds the last eight bits of the 12-bit AGC

multiplier word.

AR07

AR15

AR15–AR13

ZERO MUST BE

WRITTEN TO

THESE REGISTERS

ACG SYNC ENABLE

AR12

0OFF

1ON

AGC REGISTER 0

AR1 (AR08–AR15)

(Address (SR4–SR0) = 05H)

Figure 24 shows the various operations under the control of

AGC Register 1.

AR1 BIT DESCRIPTION

AGC Multiplier (AR08–AR11)

These registers hold the first four bits of the 12-bit AGC

multiplier word.

AGC Sync Enable (AR12)

Setting this bit to “1” forces the AGC to wait until the next sync

pulse before switching on.

Reserved (AR13–AR15)

Zero must be written to these registers.

AR02AR04AR06 AR05 AR03

AR10AR12AR14 AR13 AR11

AR09

AR08

AR01

ACG MULTIPLIER

AR11–AR00

12-BIT ACG MULTIPLIER,

HOLDS THE LSB, AR11

THE MSB

AR00

Figure 24. AGC Registers 0–1

REV. PrB

–19–

Page 20

ADV7202

PRELIMINARY TECHNICAL DATA

CLAMP REGISTER 0

CR0 (CR00–CR07)

(Address (SR4–SR0) = 06H)

Figure 25 shows the various operations under the control of

Clamp Register 0.

CR0 BIT DESCRIPTION

Clamp Level/4 (CR00–CR07)

In order to perform an accurate AGC gain operation, it is

necessary to know to what level the user is clamping the black

level. This black level is then subtracted from the 10-bit ADC

output before gaining. It is then added on again afterwards. It

should be noted that this register is eight bit and will hold the

value of Clamp Value/4.

CLAMP REGISTER 1

CR1 (CR10–CR17)

(Address (SR4–SR0) = 07H)

Figure 26 shows the various operations under the control of

Clamp Register 1.

CR07

CR05 CR03

CLAMP LEVEL

CR07–CR00

8-BIT [7:0] CLAMP

LEVEL, CR00 HOLDS THE

LSB, CR07 THE MSB

CR1 BIT DESCRIPTION

Fine Clamp On Time (CR10–CR12)

There are three fine clamp circuits on the chip. This I2C/SPI

word controls the number of clock cycles for which the fine

clamps are switched on per video line. The clamp is switched on

after a SYNC pulse is received on the SYNC_IN pin, provided

the relevant enabling bit is set (see CR16).

Coarse Clamp On Time (CR13–CR15)

There are three coarse clamp circuits on the chip. This I2C

word controls the number of clock cycles for which the fine

clamps are switched on per video line. The clamp is switched on

after a SYNC pulse is received on the SYNC_IN pin, provided

the relevant enabling bit is set (see CR16).

Synchronize Clamps (CR16)

Setting this bit to “1” forces the clamps to wait until the next

sync pulse before switching on.

Reserved (CR17)

Zero must be written to this bit.

CR02CR04CR06

CR01

CR00

CR17

CR17

ZERO MUST BE

WRITTEN TO

THIS BIT

SYNCHRONIZE

CR16

0OFF

1ON

CLAMPS

Figure 25. Clamp Register 0

CR12CR14CR15 CR13 CR10CR16

COARSE CLAMP ON TIME

CR15 CR14 CR13

0 0 0 2 CLOCK CYCLES

0 0 1 4 CLOCK CYCLES

0 1 0 8 CLOCK CYCLES

0 1 1 16 CLOCK CYCLES

1 0 0 32 CLOCK CYCLES

1 0 1 64 CLOCK CYCLES

1 1 0 128 CLOCK CYCLES

1 1 1 256 CLOCK CYCLES

Figure 26. Clamp Register 1

CR11

CR12 CR11 CR10

0 0 0 2 CLOCK CYCLES

0 0 1 4 CLOCK CYCLES

0 1 0 8 CLOCK CYCLES

0 1 1 16 CLOCK CYCLES

1 0 0 32 CLOCK CYCLES

1 0 1 64 CLOCK CYCLES

1 1 0 128 CLOCK CYCLES

1 1 1 256 CLOCK CYCLES

FINE CLAMP ON TIME

–20–

REV. PrB

Page 21

PRELIMINARY TECHNICAL DATA

ADV7202

CLAMP REGISTER 2

CR2 (CR20–CR27)

(Address (SR4–SR0) = 08H)

Figure 27 shows the various operations under the control of

Clamp Register 2.

CR2 BIT DESCRIPTION

Fine Clamp 0 Up/Down (CR20)

This bit controls the direction of fine clamp number 1, valid

only if the clamp is enabled.

Fine Clamp 0 ON/OFF (CR21)

This bit switches fine clamp number 1 on for the prescribed

number of clock cycles (CR10–CR12).

Fine Clamp 1 Up/Down (CR22)

This bit controls the direction of fine clamp number 2, valid

only if the clamp is enabled.

CR27

CR27–CR26

ZERO MUST BE

WRITTEN TO

THESE REGISTERS

FINE CLAMP 2 ON/OFF

CR25

0OFF

1ON

CR25 CR23

FINE CLAMP 2 UP/DOWN

CR24

0DOWN

1UP

FINE CLAMP 1 ON/OFF

CR23

0OFF

1ON

Fine Clamp 1 ON/OFF (CR23)

This bit switches fine clamp number 2 on for the prescribed

number of clock cycles (CR10–CR12).

Fine Clamp 2 Up/Down (CR24)

This bit controls the direction of fine clamp number 3, valid

only if the clamp is enabled.

Fine Clamp 2 ON/OFF (CR25)

This bit switches fine clamp number 3 on for the prescribed

number of clock cycles (CR10–CR12).

Reserved (CR26–CR27)

Zero must be written to these registers.

CR22CR24CR26

FINE CLAMP 1 UP/DOWN

CR22

0DOWN

1UP

FINE CLAMP 0 ON/OFF

CR21

0OFF

1ON

CR21

CR20

FINE CLAMP 0 UP/DOWN

CR20

0DOWN

1UP

Figure 27. Clamp Register 2

CLAMP REGISTER 3

CR3 (CR30–CR37)

(Address (SR4–SR0) = 09H)

Figure 28 shows the various operations under the control of

Clamp Register 3.

CR3 BIT DESCRIPTION

Coarse Clamp 0 Up/Down (CR30)

This bit controls the direction of coarse clamp number 1, valid

only if the clamp is enabled.

Coarse Clamp 0 ON/OFF (CR31)

This bit switches coarse clamp number 1 on for the prescribed

number of clock cycles (CR13–CR15).

CR37

CR37–CR36

ZERO MUST BE

WRITTEN TO

THESE REGISTERS

CR36 CR35

COARSE CLAMP 2 UP/DOWN

CR34

0DOWN

1UP

COARSE CLAMP 2 ON/OFF

CR35

0OFF

1ON

CR34

COARSE CLAMP 1 ON/OFF

CR33

0OFF

1ON

CR33

Coarse Clamp 1 Up/Down (CR32)

This bit controls the direction of coarse clamp number 2, valid

only if the clamp is enabled.

Coarse Clamp 1 ON/OFF (CR33)

This bit switches coarse clamp number 2 on for the prescribed

number of clock cycles (CR13–CR15).

Coarse Clamp 2 Up/Down (CR34)

This bit controls the direction of coarse clamp number 3, valid

only if the clamp is enabled.

Coarse Clamp 2 ON/OFF (CR35)

This bit switches coarse clamp number 3 on for the prescribed

number of clock cycles (CR13–CR15).

Reserved (CR36–CR37)

Zero must be written to these registers.

CR32

COARSE CLAMP 1 UP/DOWN

CR32

0DOWN

1UP

CR31

COARSE CLAMP 0 ON/OFF

CR31

0OFF

1ON

CR30

COARSE CLAMP 0 UP/DOWN

CR30

0DOWN

1UP

REV. PrB

Figure 28. Clamp Register 3

–21–

Page 22

ADV7202

PRELIMINARY TECHNICAL DATA

TIMING REGISTER

TR (TR00–TR07)

(Address (SR4–SR0) = 0AH)

Figure 29 shows the various operations under the control of the

Timing Register.

TR BIT DESCRIPTION

Crystal Oscillator Circuit (TR00)

If this bit is set to “0,” the internal oscillator circuit will be

disabled. Disabling the oscillator circuit is possible when an

external clock module is used, thus, saving power.

ADC Bias Currents (TR01)

If this bit is set to “1,” all analog bias currents will be doubled.

TR07

TR07

ZERO MUST BE

WRITTEN TO

THIS BIT

TR06 TR05

0 0 0ns

0 1 4ns

1 0 6ns

1 1 8ns

CLOCK DELAY

TR04 TR02

ZERO MUST BE

WRITTEN TO

THIS BIT

DUTY CYCLE

TR01

0 INACTIVE

1 ACTIVE

Duty Cycle Equalizer (TR03)

When this bit is set to “1,” the clock duty cycle equalizer circuit

is active. This will only have an effect on the ADC operation.

The digital core clock will not be affected.

Clock Delay (TR05–TR06)

Using these two bits, it is possible to insert a delay in the clock

signal to the digital core. These bits control the insertion of

the delay.

Reserved (TR02, TR04, TR07)

Zero must be written to the bits in these registers.

TR03 TR00

EQUALIZER

TR02TR04TR05TR06

ZERO MUST BE

WRITTEN TO

THIS BIT

TR01

0 NORMAL

1 DOUBLE

TR01

ADC BIAS

CURRENTS

CRYSTAL

OSC. CKT

TR00

0 DISABLE

1 ENABLE

Figure 29. Timing Register 0

VREF ADJUST REGISTER

VR (VR00–VR07)

(Address (SR4–SR0) = 0AH)

Figure 30 shows the various operations under the control of the

VREF Adjust Register.

VR BIT DESCRIPTION

Reserved (VR00)

This register is reserved and “1” must be written to this bit.

VR07

VR07

ZERO MUST BE

WRITTEN TO

THIS BIT

ADC REFERENCE VOLTAGE ADJUST

VR06 VR05 VR04

0 0 0 DEFAULT NOMINAL

0 0 1 +14mV

0 1 0 +28mV

0 1 1 +42mV

10 0 –14mV

10 1 –28mV

11 0 –42mV

11 1 –56mV

Reserved (VR01–VR03)

Zero must be written to these registers.

Reference Voltage Adjust (VR04–VR06)

By setting the value of this 3-bit word, it is possible to trim the

ADC internal voltage reference VREFADC.

Reserved (VR07)

Zero must be written to this register.

VR03 VR00

VR02VR04VR05VR06

VR03–VR01

ZERO MUST BE

WRITTEN TO

THESE BITS

VR01

VR00

ONE MUST BE

WRITTEN TO

THIS BIT

Figure 30. ADC VREF Register

–22–

REV. PrB

Page 23

PRELIMINARY TECHNICAL DATA

ADV7202

AUXILIARY MONITORING REGISTERS

AU (AU00–AU07)

(Address (SR4–SR0) = 10H)

There are eight Auxiliary Monitoring Registers. These registers

are read-only; when the device is configured for auxiliary

inputs, they will display a value corresponding to the converted

AU07

AUX REGISTER0

AU07–AU00

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX0 INPUT VALUE

Figure 31. AUX Register 0

AU15

AUX REGISTER1

AU15–AU08

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX1 INPUT VALUE

auxiliary input. Auxiliary Register “0” will contain the value of

the converted auxiliary “0” input, auxiliary register “1” the

value of the converted auxiliary “1” input, and so on to auxiliary

register 7.

AU03 AU00

AU11 AU08

AU02AU04AU05AU06

AU10AU12AU13AU14

AU01

AU09

AU23

AU31

Figure 32. AUX Register 1

AU19 AU16

AUX REGISTER2

AU23–AU16

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX2 INPUT VALUE

AU18AU20AU21AU22

Figure 33. AUX Register 2

AU27 AU24

AUX REGISTER3

AU31–AU24

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX3 INPUT VALUE

AU26AU28AU29AU30

Figure 34. AUX Register 3

AU17

AU25

REV. PrB

–23–

Page 24

ADV7202

PRELIMINARY TECHNICAL DATA

AU39

AU47

AU55

AU35 AU32

AUX REGISTER4

AU39–AU32

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX4 INPUT VALUE

AU34AU36AU37AU38

Figure 35. AUX Register 4

AU43 AU40

AUX REGISTER5

AU47–AU40

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX5 INPUT VALUE

AU42AU44AU45AU46

Figure 36. AUX Register 5

AU51 AU48

AU50AU52AU53AU54

AU33

AU41

AU49

AU63

AUX REGISTER6

AU55–AU48

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX6 INPUT VALUE

Figure 37. AUX Register 6

AU59 AU56

AUX REGISTER7

AU63–AU56

8-BIT [7:0] VALUE

CORRESPONDING TO

AUX7 INPUT VALUE

AU58AU60AU61AU62

Figure 38. AUX Register 7

AU57

–24–

REV. PrB

Page 25

PRELIMINARY TECHNICAL DATA

ADV7202

CLAMP CONTROL

The clamp control has 2 modes of operation, if the Synchronize

clamp control bit CR16 (bit-6 address 07h) is set to on the

clamps that are enabled will be switched on for the programmed

time when triggered by the Sync_in control signal, this control

signal is edge detected and its polarity can be set by MR35 (bit-5

address 03h). If the Synchronize clamp control bit is set to zero,

when enabled each clamp will switch on for the programmed time,

the enabled signal is edge detected hence the bit must first be

reset to zero before the next enable signal can be implemented.

DAC TERMINATION AND LAYOUT CONSIDERATIONS

The ADV7202 contains an on-board voltage reference. The

VREF pin is normally terminated to AVDD through a 0.1 µF

capacitor when the internal VREF is used. Alternatively, the

ADV7202 can be used with an external VREF (AD589).

Resistor RSET is connected between the RSET pin and AVSS

and is used to control the amplitude of the DAC output current.

I

= 5.196/Rset Amps

MAX

Therefore, a recommended RSET value of 1200 Ω will enable

an I

of 4.43 mA. V

MAX

value of 300 Ω.

The ADV7202 has four analog outputs—DAC0, DAC1, DAC2,

and DAC3. The DACs must be used with external buffer circuits

in order to provide sufficient current to drive an output device.

Suitable op amps are the AD8009, AD8002, AD8001, or AD8057.

PC BOARD LAYOUT CONSIDERATIONS

The ADV7202 is optimally designed for lowest noise performance,

both radiated and conducted noise. To complement the excellent noise performance of the ADV7202, it is imperative that

great care be given to the PC board layout.

The layout should be optimized for lowest noise on the ADV7202

power and ground lines. This can be achieved by shielding the

digital inputs and providing good decoupling. The lead length

between groups of AVDD, AVSS, DVDD, and DVSS pins

should be kept as short as possible to minimize inductive ringing.

It is recommended that a 4-layer printed circuit board be

used, with power and ground planes separating the layer of the

signal carrying traces of the components and solder side layer.

Placement of components should be considered to separate

noisy circuits such as crystal clocks, high-speed logic circuitry,

and analog circuitry.

There should be a separate analog ground plane (AVSS) and a

separate digital ground plane (DVSS).

= Rload × I

MAX

, Rload should have a

MAX

Power planes should encompass a digital power plane (DVDD)

and an analog power plane (AVDD). The analog power plane

should contain the DACs and all associated circuitry, VREF

circuitry. The digital power plane should contain all logic

circuitry. The analog and digital power planes should be individually

connected to the common power plane at one single point through

a suitable filtering device such as a ferrite bead.

DAC output traces on a PCB should be treated as transmission

lines. It is recommended that the DACs be placed as close as

possible to the output connector, with the analog output traces

being as short as possible (less than three inches). The DAC

termination resistors should be placed as close as possible to

the DAC outputs and should overlay the PCB’s ground plane.

As well as minimizing reflections, short analog output traces will

reduce noise pickup due to neighboring digital circuitry.

Supply Decoupling

Noise on the analog power plane can be further reduced by the

use of decoupling capacitors.

Optimum performance is achieved by the use of 0.1 µF ceramic

capacitors. Each of the group of AVDD or DVDD pins should

be individually decoupled to ground. This should be done by

placing the capacitors as close as possible to the device with the

capacitor leads as short as possible, thus minimizing lead

inductance.

Digital Signal Interconnect

The digital signal lines should be isolated as much as possible

from the analog outputs and other analog circuitry. Digital

signal lines should not overlay the analog power plane.

Due to the high clock rates used, long clock lines to the ADV7202

should be avoided to minimize noise pickup.

Any active pull-up termination resistors for the digital inputs

should be connected to the digital power plane and not the

analog power plane.

Analog Signal Interconnect

The ADV7202 should be located as close as possible to the output

connectors, thus minimizing noise pickup and reflections due to

impedance mismatch.

For optimum performance, the analog outputs should each be

source and load terminated, as shown in Figure TBD. The

termination resistors should be as close as possible to the

ADV7202 to minimize reflections.

Any unused inputs should be tied to the ground.

REV. PrB

–25–

Page 26

ADV7202

PRELIMINARY TECHNICAL DATA

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

64-Lead Thin Plastic Quad Flatpack (LQFP)

(ST-64B)

0.063 (1.60)

0.030 (0.75)

0.024 (0.60)

0.018 (0.45)

SEATING

VIEW A

MAX

49

PLANE

64

0.057 (1.45)

0.055 (1.40)

0.053 (1.35)

0.006 (0.15)

0.002 (0.05)

ROTATED 90ⴗ CCW

NOTE: CONTROLLING DIMENSIONS ARE IN MILLIMETERS.

0.472 (12.00)

48

PIN 1

1

0.020 (0.50)

BSC

0.003 (0.08)

VIEW A

BSC SQ

TOP VIEW

(PINS DOWN)

0.011 (0.27)

0.009 (0.22)

0.007 (0.17)

0.008 (0.20)

0.004 (0.09)

MAX

3.5ⴗ

7ⴗ

0ⴗ

33

32

0.394

(10.0)

BSC

SQ

17

16

C02602–0–1/02(PrA)

–26–

PRINTED IN U.S.A.

REV. PrB

Loading...

Loading...