Page 1

MicroConverter, 10-channel 24-Bit ADC

A

d

a

with Embedded 62kB FLASH MCU

Preliminary Technical Data ADuC847

FEATURES

High Resolution Sigma-Delta ADC

24-Bit Resolution

Up to 10 ADC input channels

24-Bit No Missing Codes

20-Bit rms (17.4 Bit p-p) Effective Resolution @ 60 Hz

Offset Drift 10 nV/°C, Gain Drift 0.5 ppm/°C

Memory

62 Kbytes On-Chip Flash/EE Program Memory 4 Kbytes On-Chip Flash/EE Data Memory Flash/EE, 100 Year Retention, 100 Kcycles Endurance 3 Levels of Flash/EE Program Memory Security In-Circuit Serial Download (No External Hardware) High Speed User Download (5 Seconds) 2304 Bytes On-Chip Data RAM

8051-Based Core

8051 Compatible Instruction Set

High Performance Single Cycle Core

32 kHz External Crystal

On-Chip Programmable PLL (12.58 MHz Max)

3 x 16-Bit Timer/Counter

26 Programmable I/O Lines

11 Interrupt Sources, Two Priority Levels

Dual Data Pointer, Extended 11-Bit Stack Pointer

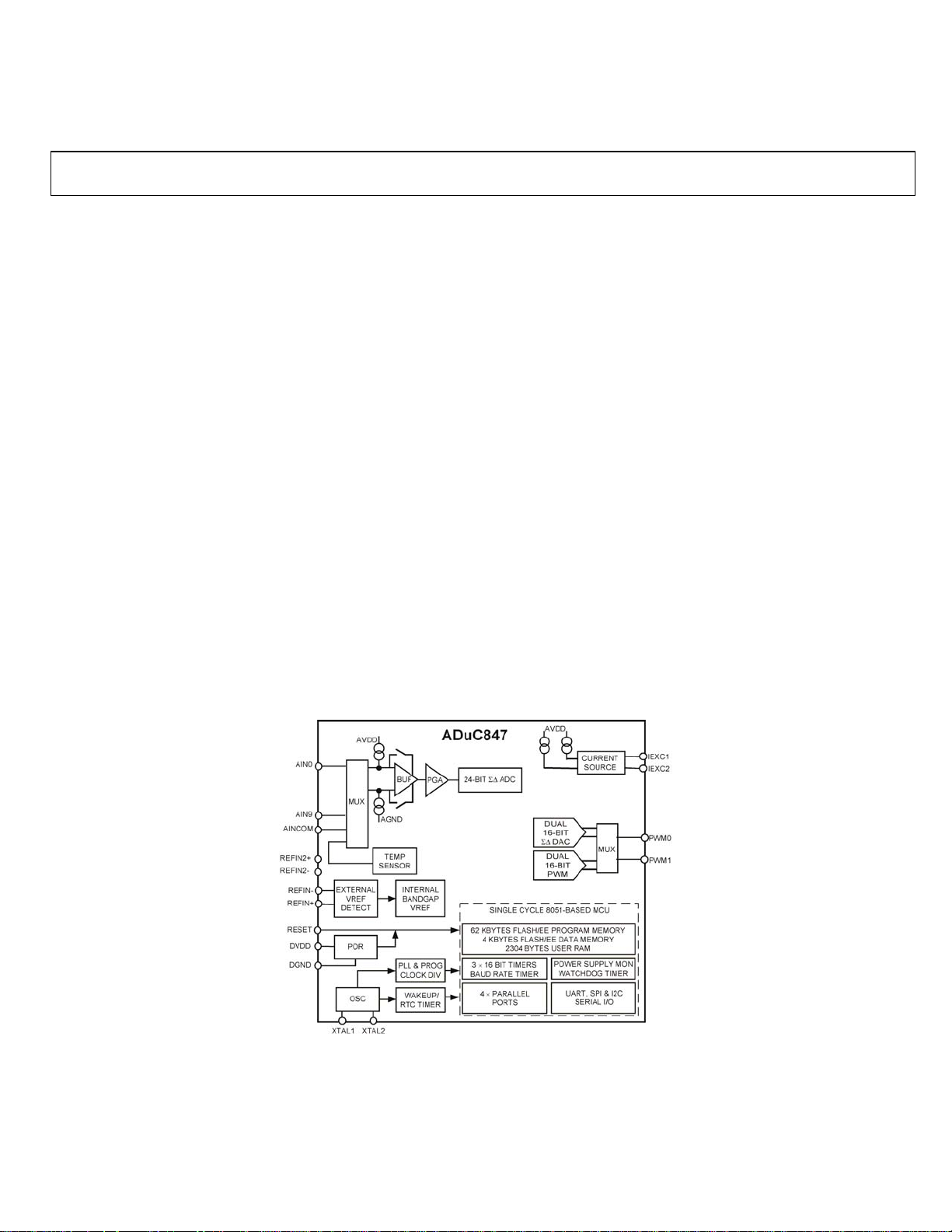

FUNCTIONAL BLOCK DIAGRAM

(Chop enabled)

On-Chip Peripherals

Internal Power on Reset Circuit

Dual 16-Bit S-D DACs/PWMs

On-Chip Temperature Sensor

Dual Excitation Current Sources

Time Interval Counter (Wakeup/RTC Timer)

UART, SPI®, and I2C® Serial I/O

High Speed Baud Rate Generator (incl 115,200)

Watchdog Timer (WDT)

Power Supply Monitor (PSM)

Power

Normal: 2.3mA Max @ 3.6 V (Core CLK = 1.57 MHz)

Power-Down: 20mA Max with Wakeup Timer Running

Specified for 3 V and 5 V Operation

Package and Temperature Range

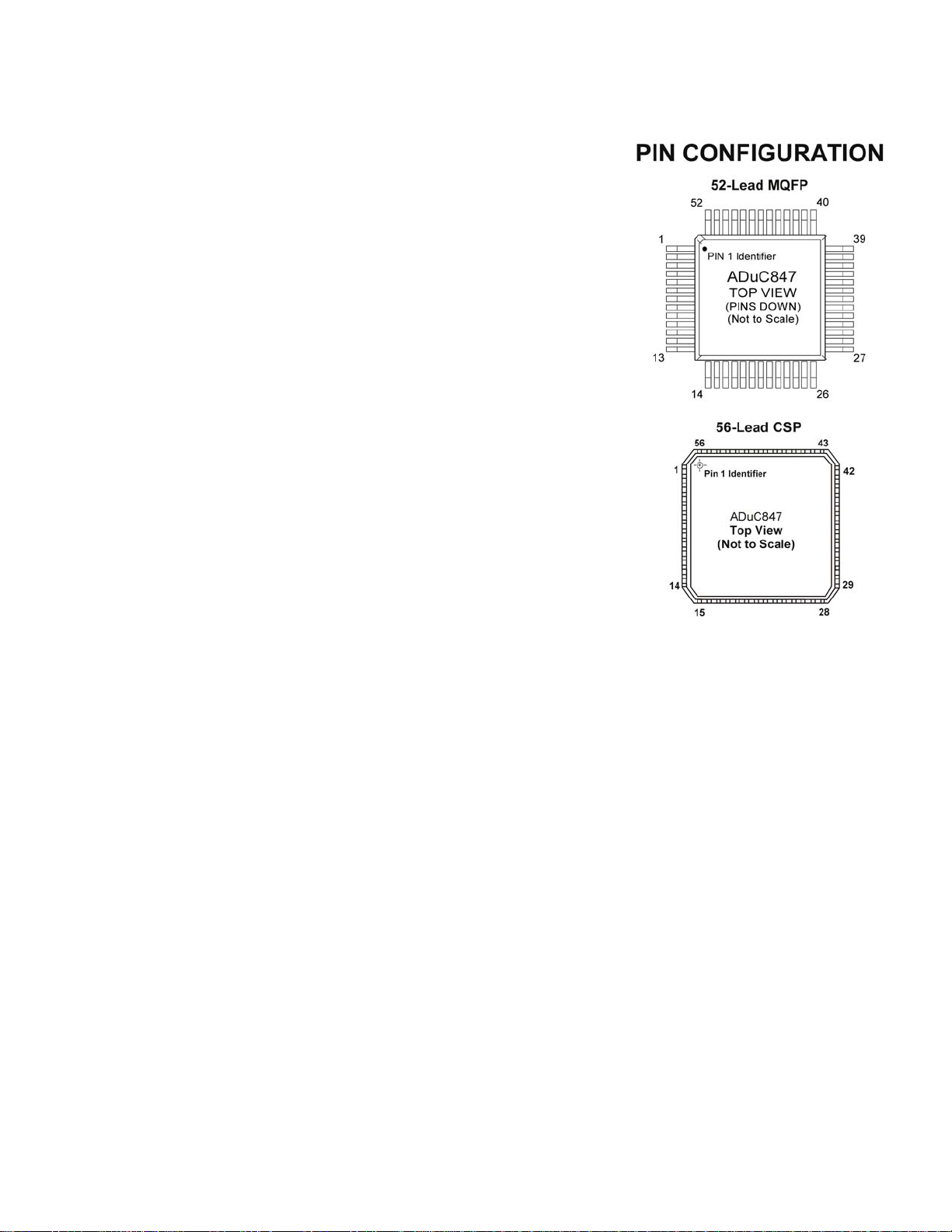

52-Lead MQFP (14 mm x 14 mm), –40°C to +125°C

56-Lead CSP (8 mm x 8 mm), –40°C to +85°C

APPLICATIONS

Multi channel Sensor monitoring

Industrial/Environmental Instrumentation

WeighScales

Portable Instrumentation, Battery Powered Systems

4-20mA Transmitters

Data Logging

Precision System Monitoring

REV. PrA 05/03

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or

other rights of third parties that may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices. Trademarks and registered

trademarks are the property of their respective companies.

Purchase of licensed I2C components of Analog Devices or one of its sublicensed

Associated Companies conveys a license for the purchaser under the Philips I

Patent Rights to use these components in an I

conforms to the I

2

C Standard Specification as defined by Philips

2

C system, provided that the system

2

C

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc.

ll rights reserve

Page 2

Preliminary Technical Data ADuC847

SPECIFICATIONS

(AVDD = 2.7 V to 3.6 V or 4.75 V to 5.25 V, DVDD = 2.85 V to 3.6 V or 4.75 V to 5.25 V, REFIN(+) = 2.5 V, REFIN(–) = AGND; AGND = DGND = 0 V; XTAL1/XTAL2 = 32.768

kHz Crystal; all specifications T

PARAMETER MIN TYP MAX UNITS CONDITION

ADC (CHOP ENABLED) 1

Conversion Rate (Chop enabled) 5.4 19.79 105 Hz CHOP = 0 (ADCMODE.3)

(Chop disabled) 16.06 59.36 1365 Hz CHOP = 1 (ADCMODE.3)

No Missing Codes2 24 Bits 19.79Hz/ 59.36Hz Update Rate

Resolution (Chop enabled) 13.5 Bits Pk-Pk Range = ± 20mV, 20Hz Update Rate

(Chop disabled) 13 Bits Pk-Pk Range = ± 20mV, 59Hz Update Rate

(Chop enabled) 18.5 Bits Pk-Pk Range = ± 2.56V, 20Hz Update Rate

(Chop disabled) 17.4 Bits Pk-Pk Range = ± 2.56V, 59.4Hz Update Rate

Output Noise See Tables IV, V VI & VII in

Integral Non Linearity ±2 ± 15 ppm of FSR 1 LSB16

Offset Error3

See tables VI & VII

Offset Error Drift vs. Temp (Chop enabled) ± 10 nV/°C Chop Enabled

Offset Error Drift vs. Temp (Chop disabled) ±200 nV/°C Chop Disabled

Full-Scale Error4

Gain Error Drift vs. Temp 5

PARAMETER MIN TYP MAX UNITS CONDITION

ADC ANALOG INPUTS

Differential Input Voltage Ranges

Bipolar Mode (ADC0CON.5 = 0)

Unipolar Mode (ADC0CON.5 = 1) 0 Æ 1.024 x Vref/GAIN V V

ADC Range Matching ± 2

Power Supply Rejection 80 dBs AIN=1V, Range=± 2.56V

113 dBs AIN=7.8mV, Range=± 20mV

Common Mode DC Rejection

On AIN 95 dBs @DC, AIN=7.8mV, Range=± 20mV

On AIN 113 dBs @DC, AIN=1V, Range=± 2.56V

Common Mode 50/60Hz Rejection 20Hz Update Rate

On AIN 95 dBs 50/60Hz ± 1Hz, AIN=7.8mV, Range=± 20mV

On AIN 90 dBs 50/60Hz ± 1Hz, AIN=1V, Range=± 2.56V

59Hz Update Rate

On AIN 95 dBs 50/60Hz ± 1Hz, AIN=7.8mV, Range=± 20mV

On AIN 90 dBs 50/60Hz ± 1Hz, AIN=1V, Range=± 2.56V

Normal Mode 50/60 Hz Rejection

On AIN 60 dBs 50/60Hz ± 1Hz, 20Hz/59Hz Update Rate

Analog Input Current2

± 5 nA T

Analog Input Current Drift ± 5 pA/°C T

± 15 pA/°C T

AINCOM Input Current ± 125 nA/V ± 2.56V Range

AINCOM Input Current Drift ± 2 pA/V/°C

Absolute AIN Voltage Limits2

Absolute AINCOM Voltage Limits A

, to T

MIN

unless otherwise noted.). Buffer On unless otherwise noted.

MAX

± 0.5 ppm/°C

9, 10

A

GND

GND

Output Noise varies with selected Update Rates

ADC Description

± 3

µV

± 10

µV

± 1.024 x V

REF

/GAIN

V

µV

± 1 nA T

+ 0.1 AV

DD

– 0.1

V Ain0-Ain9 with Buffer ON

+ 0.03 AV

– 0.03 V Buffer bypassed (ADC0CON1.6=0,

DD

and Gain Range

CHOP Enabled

Offset Error is in the order of the noise for the

programmed gain and update rate following a

calibration for CHOP disabled.

V

= REFIN(+) - REFIN(-) (or Int 1.25V Ref)

REF

GAIN = 1 to 128

= REFIN(+) - REFIN(-) GAIN=1 to 128

REF

AIN=18mV

= 85°C

MAX

= 125°C

MAX

= 85°C

MAX

= 125°C

MAX

(ADC0CON1.6 = 0 & ADC0CON1.7 = 0)

ADC0CON1.7=1)

1

REV. PrA 05/03 2

Page 3

Preliminary Technical Data ADuC847

EXTERNAL REFERENCE INPUTS

REFIN(+) to REFIN(–) Range2

Average Reference Input Current 1

Average Reference Input Current Drift +/- 0.1 nA/V/°C

‘NO Ext. REF’ Trigger Voltage 0.3 0.65 V NOXREF bit active if VREF<0.3V

NOXREF bit Inactive if VREF>0.65

Common Mode DC Rejection 125 dBs @DC, AIN=1V, Range=± 2.56V

Common Mode 50/60Hz Rejection 90 dBs 50/60Hz ± 1Hz, AIN=1V, Range=± 2.56V

Normal Mode 50/60 Hz Rejection 60 dBs 50/60Hz ± 1Hz, 20Hz/59.4Hz Update Rate

PARAMETER MIN TYP MAX UNITS CONDITION

ADC SYSTEM CALIBRATION

Full Scale Calibration Limit +1.05 x FS V

Zero Scale Calibration Limit -1.05 x FS V

Input Span 0.8 x FS 2.1 x FS V

INT REFERENCE (CHOP ENABLED)

ADC Reference

Reference Voltage 1.237 1.25 1.2625 V initial tolerance @ 25°C, VDD=5V

Power Supply Rejection 45 dBs

Reference Tempco 100 ppm/°C

TEMPERATURE SENSOR

Accuracy +/- 2 °C

Thermal Impedance 90 °C/W MQFP Package

52 °C/W CSP Package

TRANSDUCER BURNOUT CURRENT SOURCES

AIN+ Current -100 nA AIN+ is the selected positive input (Ain4 or

AIN- Current 100 nA AIN- is the selected negative input (Ain5 or

Initial Tolerance at 25°C +/- 10 %

Drift 0.03 %/°C

EXCITATION CURRENT SOURCES

Output Current -200

Initial Tolerance at 25°C +/-10 %

Drift 200 ppm/°C

Initial Current Matching at 25°C +/-1 % Matching between both Current Sources

Drift Matching 20 ppm/°C

Line Regulation (AVDD) 1

Load Regulation 0.1 V

Output Compliance A

PARAMETER MIN TYP MAX UNITS CONDITION

POWER SUPPLY MONITOR (PSM)

AVDD Trip Point Selection Range 2.63 4.63 V Four Trip Points selectable in this range

AVDD Trip Point Accuracy +/- 3.0 % T

AVDD Trip Point Accuracy +/- 3.0 % T

DVDD Trip Point Selection Range 2.63 4.63 V Four Trip Points selectable in this range

DVDD Trip Point Accuracy +/- 3.0 % T

DVDD Trip Point Accuracy +/- 3.0 % T

1 2.5 AV

V

DD

µA/V

ADC Enabled

Ain6 only) to the ADC

Ain7 only) to the ADC

µA

µA/V

AVDD-0.6 V

GND

Available from each Current Source

AVDD=5V +/- 5%

MAX

MAX

MAX

MAX

= 85°C

= 125°C

= 85°C

= 125°C

REV. PrA 05/03 -3-

Page 4

Preliminary Technical Data ADuC847

CRYSTAL OSCILLATOR (XTAL 1AND XTAL2)

Logic Inputs, XTAL1 Only2

V

, Input Low Voltage 0.8 V DVDD = 5V

INL

0.4 V DVDD = 3V

V

, Input Low Voltage 3.5 V DVDD = 5V

INH

2.5 V DVDD = 3V

XTAL1 Input Capacitance 18 pF

XTAL2 Output Capacitance 18 pF

LOGIC INPUTS

All Inputs except SCLOCK, RESET

and XTAL1

V

2

, Input Low Voltage 0.8 V DVDD = 5V

INL

0.4 V DVDD = 3V

V

SCLOCK and RESET Only

(Schmidt Triggered Inputs)

, Input Low Voltage 2.0 V

INH

2

VT+ 1.3 3.0 V DVDD = 5V

0.95 2.5 V DVDD = 3V

VT- 0.8 1.4 V DVDD = 5V

0.4 1.1 V DVDD = 3V

VT+ - VT- 0.3 0.85 V DVDD = 5V or 3V

Input Currents 2.0 V

Port 0, P1.0ÆP1.7, EA

SCLOCK, MOSI,MISO SS13

+/-10

RESET +/-10

35 105

Port 2, Port 3 +/-10

-180 -660

-20 -75

Input Capacitance 10 pF All Digital Inputs

LOGIC OUTPUTS

All Digital Outputs except XTAL22

VOH, Output High Voltage 2.4 V

2.4 V

VOL, Output Low Voltage14 0.8 V I

0.8 V I

0.8 V I

Floating State Leakage Current +/-10

Floating State Output Capacitance 10 pF

PARAMETER MIN TYP MAX UNITS CONDITION

START UP TIME

At Power On 300 ms

After External RESET in Normal Mode 3 ms

After WDT RESET in Normal Mode 3 ms Controlled via WDCON SFR

From Idle Mode 10 us

From Power-Down Mode

Oscillator Running PLLCON.7 = 0

Wakeup with INT0 Interrupt 20 us

Wakeup with SPI Interrupt 20 us

Wakeup with TIC Interrupt 20 us

Wakeup with External RESET 3 us

Oscillator Powered Down PLLCON.7 = 1

Wakeup with INT0 Interrupt 20 us

Wakeup with SPI Interrupt 20 us

Wakeup with External RESET 5 ms

+/- 10

-10 -40

µA

µA

µA

µA

µA

µA

µA

µA

V

= 0V or VDD

IN

V

= 0V, DVDD=5V, Internal Pullup

IN

VIN = DVDD, DVDD=5V

VIN = 0V, DVDD=5V

VIN = DVDD, DVDD=5V, Internal Pull-Down

VIN = DVDD, DVDD=5V

VIN = 2V, DVDD=5V

VIN = 0.45V, DVDD=5V

DV

DD

DV

DD

= 8mA, SCLOCK, MOSI/SDATA

SINK

= 10mA, P1.0, P1.1

SINK

= 1.6mA, All Other Outputs

SINK

µA

= 5V, I

= 3V, I

SOURCE

SOURCE

= 80 µA

= 20 µA

REV. PrA 05/03 4

Page 5

Preliminary Technical Data ADuC847

FLAH/EE MEMORY RELIABILITY CHARACTERISTICS

Endurance16 100,000 700,000 Cycles

Data Retention17 100 Years

POWER REQUIREMENTS

Power Supply Voltages

AVDD 3V Nominal 2.85 3.6 V

AVDD 5V Nominal 4.75 5.25 V

DVDD 3V Nominal 2.85 3.6 V

DVDD 5V Nominal 4.75 5.25 V

5V POWER CONSUMPTION

Normal Mode

18, 19

DVDD Current 4 mA core clock = 1.57MHz

13 16 mA core clock = 12.58MHz

AVDD Current 180

Power-Down Mode

18, 19

DVDD Current 53

100

DVDD Current 30

80

AVDD Current 1

3

Typical Additional Peripheral Currents (AIDD and D IDD)

Primary ADC 1 mA

Auxiliary ADC 0.5 mA

Power Supply Monitor 50

DAC 150

Dual Excitation Current Sources 400

3V POWER CONSUMPTION

Normal Mode

18, 19

DVDD Current 2.3 mA core clock = 1.57MHz

8 10 mA core clock = 12.58MHz

AVDD Current 180

Power-Down Mode

18, 19

DVDD Current 20

40

DVDD Current 10

80

AVDD Current 1

3

NOTES

1 Temperature Range for ADuC847BS (MQFP package) is –40°C to +125°C.

Temperature Range for ADuC847BCP (CSP package) is –40°C to +85°C.

2 These numbers are not production tested but are guaranteed by design and/or characterization data on production release.

3 System Zero-Scale Calibration can remove this error.

4 The ADC is factory calibrated at 25°C with AVDD = DVDD = 5 V yielding this full-scale error of 10 µV. If user power supply or temperature conditions are

significantly different from these, an Internal Full-Scale Calibration will restore this error to 10 µV. A system zero-scale and full-scale calibration will remove

this error altogether.

5 Gain Error Drift is a span drift. To calculate Full-Scale Error Drift, add the Offset Error Drift to the Gain Error Drift times the full-scale input.

6 In general terms, the bipolar input voltage range to the ADC is given by RangeADC = ±(VREF 2

VREF = REFIN(+) to REFIN(–) voltage and VREF = 1.25 V when internal ADC VREF is selected.

RN = decimal equivalent of RN2, RN1, RN0

e.g., VREF = 2.5 V and RN2, RN1, RN0 = 1, 1, 0 the RangeADC = ±1.28 V, In unipolar mode, the effective range is 0 V to 1.28 V in our example.

7 1.25 V is used as the reference voltage to the ADC when internal VREF is selected via the XREF0 and XREF 1 bits in ADC0CON2.

8 The ADuC847BCP (CSP Package) has been qualified and tested with the base of the CSP Package floating.

9 Pins configured in SPI Mode, pins configured as digital inputs during this test.

10 Pins configured in I

11 Flash/EE Memory Reliability Characteristics apply to both the Flash/EE program memory and Flash/EE data memory.

2

C Mode only.

REV. PrA 05/03 -5-

4.75V < DVDD <5.25V, AVDD= 5.25V

µA

µA

µA

µA

µA

µA

µA

µA

µA

µA

T

= 85°C; Osc ON;TIC ON

MAX

T

= 125°C; Osc ON; TIC ON

MAX

T

= 85°C; Osc OFF

MAX

T

= 125°C; Osc OFF

MAX

T

= 85°C; Osc ON or OFF

MAX

T

= 125°C; Osc ON or OFF

MAX

4.75V < DVDD <5.25V, AVDD= 5.25V

µA

µA

µA

µA

µA

µA

µA

T

MAX

T

MAX

Osc OFF

T

MAX

T

MAX

T

MAX

RN

)/125, where:

= 85°C; Osc ON;TIC ON

= 125°C; Osc ON; TIC ON

= 125°C; Osc OFF

= 85°C; Osc ON or OFF

= 125°C; Osc ON or OFF

Page 6

Preliminary Technical Data ADuC847

12 Endurance is qualified to 100 Kcycles as per JEDEC Std. 22 method A117 and measured at –40 °C, +25°C, +85°C, and +125°C. Typical endurance at 25°C is

700 Kcycles.

13 Retention lifetime equivalent at junction temperature (TJ) = 55°C as per JEDEC Std. 22, Method A117. Retention lifetime based on an activation energy of

0.6eV will derate with junction temperature.

14 Power Supply current consumption is measured in Normal, Idle, and Power-Down Modes under the following conditions:

Normal Mode: Reset = 0.4 V, Digital I/O pins = open circuit, Core Clk changed via CD bits in PLLCON, Core Executing internal software loop.

Idle Mode: Reset = 0.4 V, Digital I/O pins = open circuit, Core Clk changed via CD bits in PLLCON, PCON.0 = 1, Core Execution suspended in idle mode.

Power-Down Mode: Reset = 0.4 V, All P0 pins and P1.2–P1.7 Pins = 0.4 V, All other digital I/O pins are open circuit, Core Clk changed via CD bits in

PLLCON, PCON.1 = 1, Core Execution suspended in power-down mode, OSC turned ON or OFF via OSC_PD bit (PLLCON.7) in PLLCON SFR.

15 DVDD power supply current will increase typically by 3 mA (3 V operation) and 10 mA (5 V operation) during a Flash/EE memory program or erase cycle.

Specifications subject to change without notice

REV. PrA 05/03 6

Page 7

Preliminary Technical Data ADuC847

ABSOLUTE MAXIMUM RATINGS1

(TA = 25°C unless otherwise noted)

AVDD to AGND –0.3 V to +7 V

AVDD to DGND –0.3 V to +7 V

DVDD to AGND –0.3 V to +7 V

DVDD to DGND –0.3 V to +7 V

AGND to DGND

AVDD to DVDD –2 V to +5 V

Analog Input Voltage to AGND

Reference Input Voltage to AGND –0.3 V to AVDD +0.3 V

AIN/REFIN Current (Indefinite) 30 mA

Digital Input Voltage to DGND –0.3 V to DVDD +0.3 V

Digital Output Voltage to DGND –0.3 V to DVDD +0.3 V

Operating Temperature Range –40°C to +125°C

Storage Temperature Range –65°C to +150°C

Junction Temperature 150°C

qJA Thermal Impedance 90°C/W

Lead Temperature, Soldering Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

1

Stresses above those listed under Absolute Maximum Ratings may cause

permanent damage to the device. This is a stress rating only; functional operation

of the device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

2

AGND and DGND are shorted internally on the ADuC847.

3

Applies to P1.0 to P1.7 pins operating in analog or digital input modes

2

–0.3 V to +0.3 V

3

–0.3 V to AV

DD

+0.3 V

.

REV. PrA 05/03 -7-

Page 8

Preliminary Technical Data ADuC847

ORDERING GUIDE

MODEL Temperature Range Package Description Package Option

ADuC847BS62-5

ADuC847BS62-3

ADuC847BCP62-5

ADuC847BCP62-3

ADuC847BCP32-5

ADuC847BCP32-3

ADuC847BCP8-5

ADuC847BCP8-3

EVAL-ADuC847QS

EVAL-ADuC847QSP

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V

readily accumulate on the human body and test equipment and can discharge without

detection. Although the ADuC847 features proprietary ESD protection circuitry,

permanent damage may occur on devices subjected to high-energy electrostatic

discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

-40 Æ +125oC 52-Lead Plastic Quad Flatpack, 62kB, 5v S-52

-40 Æ +125oC 52-Lead Plastic Quad Flatpack, 62kB, 3v S-52

-40 Æ +85

-40 Æ +85oC 56-Lead Chip Scale Package, 62kB, 3v CP-56

-40 Æ +85oC 56-Lead Chip Scale Package, 32kB, 5v CP-56

-40 Æ +85oC 56-Lead Chip Scale Package, 32kB, 3v CP-56

-40 Æ +85

-40 Æ +85

o

C 56-Lead Chip Scale Package, 62kB, 5v CP-56

o

C 56-Lead Chip Scale Package, 8kB, 5v CP-56

o

C 56-Lead Chip Scale Package, 8kB, 3v CP-56

QuickStartTM Development System

QuickStart PLUS Development System

REV. PrA 05/03 8

Page 9

Preliminary Technical Data ADuC847

PIN FUNCTION DESCRIPTIONS

Pin No:

52-MQFP

1 56 P1.0/AIN0 I By power on default P1.0/AIN0 is configured as the AIN0 Analog Input.

2 1 P1.1/AIN1 I By power on default P1.1/AIN1 is configured as the AIN1 Analog Input.

3 2 P1.2/AIN2/REFIN2+ I By power on default P1.2/AIN2 is configured as the AIN2 Analog Input.

4 3 P1.3/AIN3/REFIN2- I By power on default P1.3/AIN3 is configured as the AIN3 Analog Input.

5 4 AVDD S Analog Supply Voltage

6 5 AGND S Analog Ground.

--- 6 AGND S A second Analog ground is provided with the CSP version only*

7 7 REFIN- I External Differential Reference Input, negative terminal

8 8 REFIN+ I External Differential Reference Input, positive terminal

9 9 P1.4/AIN4 I By power on default P1.4/AIN4 is configured as the AIN4 Analog Input.

10 10 P1.5/AIN5 I By power on default P1.5/AIN5 is configured as the AIN5 Analog Input.

11 11 P1.6/AIN6/IEXC1 I/O By power on default P1.6/AIN6 is configured as the AIN6 Analog Input.

*Note: This pin is provided on the CSP version only.

Pin No:

56-CSP

Pin

Mnemonic

Type* Description

AIN0 can be used as a pseudo differential input when used with AINCOM or

as the positive input of a fully differential pair when used with AIN2.

P1.0 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally.

AIN1 can be used as a pseudo differential input when used with AINCOM or

as the negative input of a fully differential pair when used with AIN0.

P1.1 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally.

AIN2 can be used as a pseudo differential input when used with AINCOM or

as the positive input of a fully differential pair when used with AIN3.

P1.2 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally. This pin also functions as a second external

differential reference input, positive terminal.

AIN3 can be used as a pseudo differential input when used with AINCOM or

as the negative input of a fully differential pair when used with AIN2.

P1.3 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally. This pin also functions as a second external

differential reference input, negative terminal.

AIN4 can be used as a pseudo differential input when used with AINCOM or

as the positive input of a fully differential pair when used with AIN5.

P1.0 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally.

AIN5 can be used as a pseudo differential input when used with AINCOM or

as the negative input of a fully differential pair when used with AIN4.

P1.1 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally.

AIN6 can be used as a pseudo differential input when used with AINCOM or

as the positive input of a fully differential pair when used with AIN7.

One or Both current sources can also be configured at this pin.

P1.0 has no digital output driver. It can function as a digital input for which

‘0’ must be written to the port bit. As a digital input, this pin must be driven

high or low externally.

REV. PrA 05/03 -9-

Page 10

Preliminary Technical Data ADuC847

Pin No:

52-MQFP

12 12 P1.7/AIN7/IEXC2 I/O By power on default P1.7/AIN7 is configured as the AIN7 Analog Input. AIN7

13 13 AINCOM I All analog inputs can be referred to this pin provided a relevant pseudo

14 14 ---- ----

---- 15 AIN8 I AIN8 can be used as a pseudo differential analog input when used with

---- 16 AIN9 I AIN9 can be used as a pseudo differential analog input when used with

15 17 RESET I Reset Input. A high level on this pin for 16 core clock cycles while the

16-19

22-25

16

17

18

19

22

23

24

25

20, 34, 48 22, 36, 51 DVDD S Digital Supply Voltage

21, 35, 47 23, 37, 38,

26 28 SCLK (I2C) I/O Serial interface clock for the I2C interface. As an input this pin is a Schmitt

27 29 SDATA I/O Serial data pin for the I2C interface. As an input this pin has a weak internal

*Note: This pin is provided on the CSP version only.

Pin No:

56-CSP

18-21

24-27

18

19

20

21

24

25

26

27

50

Pin

Mnemonic

P3.0 Æ P3.7

P3.0/RXD

P3.1/TXD

P3.2/INT0

P3.3/INT1

P3.4/T0

P3.5/T1

P3.6//WR

P3.7//RD

DGND S Digital Ground.

Type* Description

can be used as a pseudo differential input when used with AINCOM or as the

negative input of a fully differential pair when used with AIN6.

One or Both current sources can also be configured at this pin

P1.1 has no digital output driver. It can function as a digital input for which ‘0’

must be written to the port bit. As a digital input, this pin must be driven high

or low externally.

differential input mode is selected.

AINCOM or as the positive input of a fully differential pair when used with

AIN9*.

AINCOM or as the negative input of a fully differential pair when used with

AIN8*.

oscillator is running resets the device. There is an internal weak pull-down and

a Schmitt trigger input stage on this pin.

I/O P3.0–P3.7 are bi-directional port pins with internal pull-up resistors. Port 3 pins

that have 1s written to them are pulled high by the internal pull-up resistors,

and in that state can be used as inputs. As inputs, Port 3 pins being pulled

externally low will source current because of the internal pull-up resistors.

When driving a 0-to-1 output transition, a strong pull-up is active for two core

clock periods of the instruction cycle.

Port 3 pins also have various secondary functions described below.

Receiver Data for UART serial Port

Transmitter Data for UART serial Port

External Interrupt 0. This pin can also be used as a gate control input to

Timer0.

External Interrupt 1. This pin can also be used as a gate control input to

Timer1.

Timer/Counter 0 External Input

Timer/Counter 1 External Input

External Data Memory Write Strobe. Latches the data byte from Port 0 into an

external data memory.

External Data Memory Read Strobe. Enables the data from an external data

memory to Port 0.

triggered input and a weak internal pull-up is present on this pin unless it is

outputting logic low. this pin can also be controlled in software as a digital

output pin.

pull-up present unless it is outputting logic low.

REV. PrA 05/03 10

Page 11

Preliminary Technical Data ADuC847

Pin No:

52-MQFP

28 Æ 31

36 Æ 39

28

29

30

31

36

37

38

39

32 34 XTAL1

33 35 XTAL2

40 43 EA

41 44 PSEN

42 45 ALE

Pin No:

56-CSP

30 Æ 33

39 Æ 42

30

31

32

33

39

40

41

42

Pin

Mnemonic

P2.0 Æ P2.7

P2.0/SCLOCK

(SPI)

P2.1/MOSI

P2.2/MISO

P2.3/SS/T2

P2.4/T2EX

P2.5/PWM0

P2.6/PWM1

P2.7/PWMCLK

Type* Description

I/O Port 2 is a bidirectional port with internal pull-up resistors. Port 2 pins that

have 1s written to them are pulled high by the internal pull-up resistors, and in

that state can be used as inputs. As inputs, Port 2 pins being pulled externally

low will source current because of the internal pull-up resistors. Port 2 emits

the middle and high order address bytes during accesses to the 24-bit external

data memory space.

Port 2 pins also have various secondary functions described below.

Serial interface clock for the SPI interface. As an input this pin is a Schmitt

triggered input and a weak internal pull-up is present on this pin unless it is

outputting logic low.

Serial master output/slave input data for the SPI interface. A strong internal

pull-up is present on this pin when the SPI interface outputs a logic high. A

strong internal pull-down is present on this pin when the SPI interface outputs

a logic low.

Master Input/Slave Output for the SPI Interface. There is a weak pull-up on

this input pin.

Slave select input for the SPI Interface is present at this pin. A weak pull-up is

present on this pin.

On both package options this pin can also be used to provide a clock input to

Timer 2. When Enabled, counter 2 is incremented in response to a negative

transition on the T2 input pin.

This pin can be used to provide a control input to Timer 2. When Enabled, a

negative transition on the T2EX input pin will cause a Timer 2 capture or

reload event.

If the PWM is enabled then the PWM0 output will appear at this pin.

If the PWM is enabled then the PWM1 output will appear at this pin.

If the PWM is enabled then an external PWM clock can be provided at this

pin.

I Input to the crystal oscillator inverter.

O Output from the crystal oscillator inverter. (see “Hardware Design

Considerations” for description)

External Access Enable, Logic Input. When held high, this input enables the

device to fetch code from internal program memory locations 0000h to F7FFh.

No external program memory access is available on the ADuC847. To

determine the mode of code execution, the EA pin is sampled at the end of an

external RESET assertion or as part of a device power cycle.

EA may also be used as an external emulation I/O pin and therefore the

voltage level at this pin must not be changed during normal mode operation as

it may cause an emulation interrupt that will halt code execution.

Program Store Enable, Logic Output. It is active every six oscillator periods

except during external data memory accesses. This pin remains high during

internal program execution.

PSEN can also be used to enable serial download mode when pulled low

through a resistor at the end of an external RESET assertion or as part of a

device power cycle.

Address Latch Enable, Logic Output. This output is used to latch the low byte

(and page byte for 24-bit data address space accesses) of the address to

external memory during external data memory access cycles. It is activated

every six oscillator periods except during an external data memory access. It

can be disabled by setting the PCON.4 bit in the PCON SFR.

REV. PrA 05/03 -11-

Page 12

Preliminary Technical Data ADuC847

Pin No:

52-MQFP

43 Æ 46

49 Æ 52

*I = Input, O = Output, S = Supply.

Pin numbers subject to change.

Pin No:

56-CSP

46 Æ 49

52 Æ 55

Pin

Mnemonic

P0.0 Æ P0.7 I/O P0.0–P0.7, these pins are part of Port0 which is an 8-bit open-drain

DETAILED BLOCK DIAGRAM WITH PIN NUMBERS

Type* Description

bidirectional I/O port. Port 0 pins that have 1s written to them float and in that

state can be used as high impedance inputs. An external pull-up resistor will

be required on P0 outputs to force a valid logic high level externally. Port 0 is

also the multiplexed low-order address and data bus during accesses to

external data memory. In this application it uses strong internal pull-ups when

emitting 1s.

Pin numbers refer to the 52pin MQFP package.

Figure 1: Detailed Block Diagram of the ADuC847

REV. PrA 05/03 12

Page 13

Preliminary Technical Data ADuC847

COMPLETE SFR MAP

Figure 2 below shows a full SFR memory map and the SFR contents af te r RESET. NOT USED indicates unoccupied SFR locations. Un o c cupied locations

in the SFR address space are not implemented; i.e., no register exists at this location. If an unoccupied location is read, an unspecified value is

returned. SFR locations that are reserved for future use are shaded (RESERVED) and should not be accessed by user software.

Figure 2: Complete SFR Map

REV. PrA 05/03 -13-

Page 14

Preliminary Technical Data ADuC847

INTRODUCTION

The ADuC847 is a 12.58MIPs 8052 core upgrade to the ADuC834

and is very similar to the ADuC845. It includes additional analog

inputs for applications requiring more ADC channels as does the

ADuC845 but removes the DAC and Auxiliary ADC from the

ADuC845 specification. Otherwise it has all the same features as

the ADuC834, but the standard 12-cycle 8052 core has been

replaced with a 12.58MIPs single cycle core.

Since the ADuC847 and ADuC834 share the same feature set only

the differences between the two chips are documented here. For full

documentation on the ADuC834 please consult the datasheet

available at

GENERAL DESCRIPTION

The ADuC847 is a complete smart transducer front end,

integrating a high resolution sigma-delta ADC with flexible,

10/8-channel input multiplexing, a fast 8-bit MCU, and

program/data Flash/EE memory on a single chip.

The ADC includes flexible input multiplexing, a temperature

sensor and a PGA (allowing direct measurement of low level

signals). The ADC, with on-chip digital filtering and

programmable output data rates is intended for the measurement

of wide dynamic range, low frequency signals, such as those in

weigh scale, strain-gage, pressure transducer, or temperature

measurement applications.

The device operates from a 32 kHz crystal with an on-chip PLL

generating a high frequency clock of 12.58 MHz. This clock is

routed through a programmable clock divider from which the

MCU core clock operating frequency is generated. The

microcontroller core is an optimized single cycle 8052 offering

up to 12.58MIPs performance while maintaining the 8051

instruction set compatibility.

62 Kbytes of nonvolatile Flash/EE program memory, 4 Kbytes

of nonvolatile Flash/EE data memory, and 2304 bytes of data

RAM are provided on-chip. The program memory can be

configured as data memory to give up to 60 Kbytes of NV data

memory in data logging applications.

On-chip factory firmware supports in-circuit serial download and

debug modes (via UART), as well as single-pin emulation mode

via the EA pin. The ADuC847 is supported by a QuickStart™

development system featuring low cost software and hardware

development tools

8052 Instruction Set

The following pages document the number of clock cycles required

for each instruction. Most instructions are executed in one or two

clock cycles resulting in 12.6MIPs peak performance when

operating at PLLCON = 00H.

Timer Operation

Timers on a standard 8052 increment by one with each machine

cycle. On the ADuC847 one machine cycle is equal to one clock

cycle hence the timers will increment at the same rate as the core

clock.

http://www.analog.com/microconverter

ALE

The output on the ALE pin on the ADuC834 was a clock at 1/6th of

the core operating frequency. On the ADuC847 the ALE pin

operates as follows….

For a single machine cycle instruction: ALE is high for the first

half of the machine cycle and low for the second half. The ALE

output is at the core operating frequency. For a two or more

machine cycle instruction: ALE is high for the first half of the first

machine cycle and then low for the rest of the machine cycles.

External Memory Access

There is no support for external program memory access on the

ADuC847. When accessing external RAM the EWAIT register

may need to be programmed in order to give extra machine cycles

to MOVX commands. This is to account for differing external

RAM access speeds.

REV. PrA 05/03 14

Page 15

Preliminary Technical Data ADuC847

INSTRUCTION TABLE

Optimized Single Cycle 8051 Instruction Set

Mnemonic Description Bytes Cycles

Arithmetic

ADD A,Rn Add register to A 1 1

ADD A,@Ri Add indirect memory to A 1 2

ADD A,dir Add direct byte to A 2 2

ADD A,#data Add immediate to A 2 2

ADDC A,Rn Add register to A with carry 1 1

ADDC A,@Ri Add indirect memory to A with carry 1 2

ADDC A,dir Add direct byte to A with carray 2 2

ADD A,#data Add immediate to A with carry 2 2

SUBB A,Rn Subtract register from A with borrow 1 1

SUBB A,@Ri Subtract indirect memory from A with borrow 1 2

SUBB A,dir Subtract direct from A with borrow 2 2

SUBB A,#data Subtract immediate from A with borrow 2 2

INC A Increment A 1 1

INC Rn Increment register 1 1

INC @Ri Increment indirect memory 1 2

INC dir Increment direct byte 2 2

INC DPTR Increment data pointer 1 3

DEC A Decrement A 1 1

DEC Rn Decrement Register 1 1

DEC @Ri Decrement indirect memory 1 2

DEC dir Decrement direct byte 2 2

MUL AB Multiply A by B 1 9

DIV AB Divide A by B 1 9

DA A Decimal Adjust A 1 2

Logic

ANL A,Rn AND register to A 1 1

ANL A,@Ri AND indirect memory to A 1 2

ANL A,dir AND direct byte to A 2 2

ANL A,#data AND immediate to A 2 2

ANL dir,A AND A to direct byte 2 2

ANL dir,#data AND immediate data to direct byte 3 3

ORL A,Rn OR register to A 1 1

ORL A,@Ri OR indirect memory to A 1 2

ORL A,dir OR direct byte to A 2 2

ORL A,#data OR immediate to A 2 2

ORL dir,A OR A to direct byte 2 2

ORL dir,#data OR immediate data to direct byte 3 3

XRL A,Rn Exclusive-OR register to A 1 1

XRL A,@Ri Exclusive-OR indirect memory to A 2 2

XRL A,#data Exclusive-OR immediate to A 2 2

XRL dir,A Exclusive-OR A to direct byte 2 2

XRL A,dir Exclusive-OR indirect memory to A 2 2

XRL dir,#data Exclusive-OR immediate data to direct 3 3

CLR A Clear A 1 1

CPL A Complement A 1 1

SWAP A Swap Nibbles of A 1 1

RL A Rotate A left 1 1

RLC A Rotate A left through carry 1 1

RR A Rotate A right 1 1

RRC A Rotate A right through carry 1 1

Data Transfer

MOV A,Rn Move register to A 1 1

MOV A,@Ri Move indirect memory to A 1 2

MOV Rn,A Move A to register 1 1

MOV @Ri,A Move A to indirect memory 1 2

MOV A,dir Move direct byte to A 2 2

MOV A,#data Move immediate to A 2 2

MOV Rn,#data Move register to immediate 2 2

REV. PrA 05/03 -15-

Page 16

Preliminary Technical Data ADuC847

Mnemonic Description Bytes Cycles

MOV dir,A Move A to direct byte 2 2

MOV Rn, dir Mov register to direct byte 2 2

MOV dir, Rn Move direct to register 2 2

MOV @Ri,#data

MOV dir,@Ri

MOV @Ri,dir

MOV dir,dir Move direct byte to direct byte 3 3

MOV dir,#data Move immediate to direct byte 3 3

MOV DPTR,#data Move immediate to data pointer 3 3

MOVC A,@A+DPTR Move code byte relative DPTR to A 1 4

MOVC A,@A+PC Move code byte relative PC to A 1 4

MOVX A,@Ri Move external (A8) data to A 1 4

MOVX A,@DPTR Move external (A16) data to A 1 4

MOVX @Ri,A Move A to external data (A8) 1 4

MOVX @DPTR,A Move A to external data (A16) 1 4

PUSH dir Push direct byte onto stack 2 2

POP dir Pop direct byte from stack 2 2

XCH A,Rn Exchange A and register 1 1

XCH A,@Ri Exchange A and indirect memory 1 2

XCHD A,@Ri Exchange A and indirect memory nibble 1 2

XCH A,dir Exchange A and direct byte 2 2

Boolean

CLR C Clear carry 1 1

CLR bit Clear direct bit 2 2

SETB C Set Carry 1 1

SETB bit Set direct bit 2 2

CPL C Complement carry 1 1

CPL bit Complement direct bit 2 2

ANL C,bit AND direct bit and carry 2 2

ANL C,/bit AND direct bit inverse to carry 2 2

ORL C,bit OR direct bit and carry 2 2

ORL C,/bit OR direct bit inverse to carry 2 2

MOV C,bit Move direct bit to carry 2 2

MOV bit,C Move carry to direct bit 2 2

Branching

JMP @A+DPTR Jump indirect relative to DPTR 1 3

RET Return from subroutine 1 4

RETI Return from interrupt 1 4

ACALL addr11 Absolute jump to subroutine 2 3

AJMP addr11 Absolute jump unconditional 2 3

SJMP rel Short jump (relative address) 2 3

JC rel Jump on carry = 1 2 3

JNC rel Jump on carry = 0 2 3

JZ rel Jump on accumulator = 0 2 3

JNZ rel Jump on accumulator ! = 0 2 3

DJNZ Rn,rel Decrement register, jnz relative 2 3

LJMP Long jump unconditional 3 4

LCALL addr16 Long jump to subroutine 3 4

JB bit,rel Jump on direct bit = 1 3 4

JNB bit,rel Jump on direct bit = 0 3 4

JBC bit,rel Jump on direct bit = 1 and clear 3 4

CJNE A,dir,rel Compare A, direct JNE relative 3 4

CJNE A,#data,rel Compare A, immediate JNE relative 3 4

CJNE Rn,#data,rel Compare register, immediate JNE relative 3 4

CJNE @Ri,#data,rel Compare indirect, immediate JNE relative 3 4

DJNZ dir,rel Decrement direct byte, JNZ relative 3 4

Miscellaneous

NOP No operation 1 1

1. One cycle is one clock.

2. MOVX instructions are four cycles when they have 0 wait state. Cycles of MOVX instructions are 4 + n cycles when they have n wait states.

3. LCALL instruction are three cycles when the LCALL instruction comes from an interrupt.

Move immediate to indirect memory

Move indirect to direct memory

Move direct to indirect memory

2

2

2

REV. PrA 05/03 16

2

2

2

Page 17

Preliminary Technical Data ADuC847

MEMORY7 ORGANISATION

The ADuC847 contains 4 different memory blocks namely:

- 62k/30k/6k Bytes of On-Chip Flash/EE Program Memory

- 4kBytes of On-Chip Flash/EE Data Memory

- 256 Bytes of General Purpose RAM

- 2kBytes of Internal XRAM

(1) Flash/EE Program Memory

The ADuC847 provides up to 62kBytes of Flash/EE program

memory to run user code.

When EA is pulled high externally during a power cycle or a

hardware reset the part defaults to code execution from its internal

62kBytes of Flash/EE program memory. The ADuC847 does not

support the rollover from internal code space to external code

space. No external code space is available on the ADuC847.

Permanently embedded firmware allows code to be serially

downloaded to the 62kBytes of internal code space via the UART

serial port while the device is in-circuit. No external hardware is

required.

56kBytes of the program memory can be reprogrammed during

runtime hence the code space can be upgraded in the field using a

user defined protocol or it can be used as a data memory. This will

be discussed in more detail in the Flash/EE Memory section of the

datasheet.

(2) Flash/EE Data Memory

4kBytes of Flash/EE Data Memory are available to the user and

can be accessed indirectly via a group of registers mapped into the

Special Function Register (SFR) area. Access to the Flash/EE Data

memory is discussed in detail later as part of the Flash/EE memory

section in this data sheet.

(3) General Purpose RAM

The general purpose RAM is divided into two separate memories,

namely the upper and the lower 128 bytes of RAM. The lower 128

bytes of RAM can be accessed through direct or indirect addressing

while the upper 128 bytes of RAM can only be accessed through

indirect addressing as it shares the same address space as the SFR

space which can only be accessed through direct addressing.

The lower 128 bytes of internal data memory are mapped as shown

in Figure 3. The lowest 32 bytes are grouped into four banks of

eight registers addressed as R0 through R7. The next 16 bytes (128

bits), locations 20Hex through 2FHex above the register banks,

form a block of directly addressable bit locations at bit addresses

00H through 7FH. The stack can be located anywhere in the

internal memory address space, and the stack depth can be

expanded up to 2048 bytes.

Reset initializes the stack pointer to location 07 hex. Any call or

push pre-increments the SP before loading the stack. Hence

loading the stack starts from locations 08 hex which is also the first

register (R0) of register bank 1. Thus, if one is going to use more

than one register bank, the stack pointer should be initialized to an

area of RAM not used for data storage.

REV. PrA 05/03 -17-

30H

BANKS

SELECTED

VIA

BITS IN PSW

20H

11

18H

10

10H

01

08H

00

00H

Figure 3. Lower 128 Bytes of Internal Data Memory

(4) Internal XRAM

The ADuC847 contains 2kBytes of on-chip extended data memory.

This memory, although on-chip, is accessed via the MOVX

instruction. The 2kBytes of internal XRAM are mapped into the

bottom 2kBytes of the external address space if the CFG847.0 (see

Table III) bit is set, otherwise access to the external data memory

will occur just like a standard 8051.

Even with the CFG847.0 bit set access to the external XRAM will

occur once the 24 bit DPTR is greater than 0007FFH.

Figure 4: Internal and External XRAM

When accessing the internal XRAM, the P0, P2 port pins as well as

the RD and WR strobes will not be output as per a standard 8051

MOVX instruction. This allows the user to use these port pins as

standard I/O.

7FH

GENERAL-PURPOSE

AREA

2FH

BIT-ADDRESSABLE

(BIT ADDRESSES)

1FH

17H

FOUR BANKS OF EIGHT

REGISTERS

0FH

R0 R7

07H

RESET VALUE OF

STACK POINTER

Page 18

Preliminary Technical Data ADuC847

The upper 1792 bytes of the internal XRAM can be configured to

be used as an extended 11-bit stack pointer. By default the stack

will operate exactly like an 8052 in that it will rollover from FFh to

00h in the general purpose RAM. On the ADuC847 however it is

possible (by setting CFG847.7) to enable the 11-bit extended stack

pointer. In this case the stack will rollover from FFh in RAM to

0100h in XRAM.

The 11-bit stack pointer is visable in the SP and SPH SFRs. The SP

SFR is located at 81h as with a standard 8052. The SPH SFR is

located at B7h. The 3 LSBs of this SFR contain the 3 extra bits

necessary to extend the 8-bit stack pointer into an 11-bit stack

pointer.

07FFH

UPPER 1792

BYTES OF

ON-CHIP XRAM

(DATA +STACK

FOR EXSP=1,

DATA ONLY

100H

00H

FOR EXSP=0)

LOWER 25 6

BYTES OF

ON-CHIP XRAM

(DATA ONLY)

CFG845.7 = 0

FFH

256 BYTES OF

ON-CHIP DATA

(DATA + STACK)

00H

CFG845.7 = 1

RAM

Figure 4. Extended Stack Pointer Operation

External Data Memory (External XRAM)

Just like a standard 8051 compatible core the ADuC847 can access

external data memory using a MOVX instruction. The MOVX

instruction automatically outputs the various control strobes

required to access the data memory.

The ADuC847 however, can access up to 16MBytes of external

data memory. This is an enhancement of the 64kBytes external data

memory space available on a standard 8051 compatible core.

The external data memory is discussed in

more detail in the ADuC847 Hardware

Design Considerations section.

SPECIAL FUNCTION REGISTERS

(SFRs)

internal data memory space and accessed by direct addressing only.

It provides an interface between the CPU and all on chip

peripherals. A block diagram showing the programming model of

the ADuC847 via the SFR area is shown in Figure 5. All registers

except the Program Counter (PC) and the four general-purpose

register banks, reside in the SFR area. The SFR registers include

control, configuration, and data registers that provide an interface

between the CPU and all on-chip peripherals.

The SFR space is mapped into the upper 128 bytes of

Figure 5. Programming Model

Accumulator SFR (ACC)

ACC is the Accumulator register and is used for math operations

including addition, subtraction, integer multiplication and division,

and Boolean bit manipulations. The mnemonics for accumulatorspecific instructions refer to the Accumulator as A.

B SFR (B)

The B register is used with the ACC for multiplication and division

operations. For other instructions it can be treated as a generalpurpose scratchpad register.

Data Pointer (DPTR)

The Data Pointer is made up of three 8-bit registers, named DPP

(page byte), DPH (high byte) and DPL (low byte). These are used

to provide memory addresses for internal and external code access

and external data access. It may be manipulated as a 16-bit register

(DPTR = DPH, DPL), although INC DPTR instructions will

automatically carry over to DPP, or as three independent 8-bit

registers (DPP, DPH, DPL).

The ADuC847 supports dual data pointers. Refer to the Dual Data

Pointer section later in this datasheet.

Stack Pointer (SP and SPH)

The SP SFR is the stack pointer and is used to hold an internal

RAM address that is called the ‘top of the stack.’ The SP register is

incremented before data is stored during PUSH and CALL

executions. While the Stack may reside anywhere in on-chip RAM,

the SP register is initialized to 07H after a reset. This causes the

stack to begin at location 08H.

As mentioned earlier the ADuC847 offers an extended 11-bit stack

pointer. The 3 extra bits to make up the 11-bit stack pointer are the

3 LSBs of the SPH byte located at B7h. To enable the SPH SFR the

EXSP (CFG847.7) bit must be set otherwise the SPH SFR cannot

be read or written to.

REV. PrA 05/03 18

Page 19

Preliminary Technical Data ADuC847

Program Status Word (PSW)

The PSW SFR contains several bits reflecting the current status of

the CPU as detailed in Table I.

SFR Address D0H

Power ON Default Value 00H

Bit Addressable Yes

Table I. PSW SFR Bit Designations

Bit Name Description

7 CY Carry Flag

6 AC Auxiliary Carry Flag

5 F0 General-Purpose Flag

4 RS1 Register Bank Select Bits

3 RS0

2 OV Overflow Flag

1 F1 General-Purpose Flag

0 P Parity Bit

Power Control Register (PCON)

The PCON SFR contains bits for power-saving options and

general-purpose status flags as shown in Table II.

SFR Address 87H

Power ON Default Value 00H

Bit Addressable No

Table II. PCON SFR Bit Designations Bit Name Description

7 SMOD Double UART Baud Rate

6 SERIPD SPI Power-Down Interrupt

5 INT0PD INT0 Power-Down Interrupt

4 ALEOFF Disable ALE Output

3 GF1 General-Purpose Flag Bit

2 GF0 General-Purpose Flag Bit

1 PD Power-Down Mode Enable

0 IDL Idle Mode Enable

RS1 RS0 Selected Bank

0 0 0

0 1 1

1 0 2

1 1 3

Enable

Enable

847 Configuration Register (CFG847)

The CFG847 SFR contains the necessary bits to configure the

internal XRAM and the extended SP. By default it configures the

user into 8051 mode. i.e. extended SP is disabled, internal XRAM

is disabled.

SFR Address AFhH

Power ON Default Value 00H

Bit Addressable No

Table III. CFG847 SFR Bit Designations

Bit Name Description

7 EXSP Extended SP Enable.

If this bit is set to 1 then the stack will

rollover from SPH/SP = 00FFh to

0100h.

If this bit is cleared to 0 then the SPH

SFR will be disabled and the stack will rollover

from SP=FFh to SP =00h

6 ---5 ---4 ---3 ---2 ---1 ---0 XRAMEN XRAM Enable Bit

----

----

----

----

----

----

If this bit is set to 1 then the internal XRAM

will be mapped into the lower 2kBytes of the

external address space. If this bit is cleared to 0

then the internal XRAM will not be accessible

and the external data memory will be mapped

into the lower 2kBytes of external data

memory. (see figure 4).

REV. PrA 05/03 -19-

Page 20

Preliminary Technical Data ADuC847

ADC CIRCUIT INFORMATION

The ADuC847 incorporates a 10-channel (8-channel on the MQFP

package) 24-bit Σ−∆ ADC. It also includes an on-chip

programmable gain amplifier and digital filtering intended for the

measurement of wide dynamic range, low frequency signals such

as those in weigh-scale, strain-gauge, pressure transducer, or

temperature measurement applications.

The ADuC847 can be configured as four/five fully-differential

input channels or as eight/ten pseudo-differential input channels

referenced to AINCOM. The ADC is buffered and can be

programmed for one of eight input ranges from ±20 mV to ±2.56V.

Buffering the input channel means that the part can handle

significant source impedances on the analog input and that R,C

filtering (for noise rejection or RFI reduction) can be placed on the

analog inputs if required. These input channels are intended to

convert signals directly from sensors without the need for external

signal conditioning.

The ADC employs a sigma-delta conversion technique to realize up

to 24 bits of no missing codes performance (20Hz update rate, chop

enabled). The sigma-delta modulator converts the sampled input

signal into a digital pulse train whose duty cycle contains the

digital information. A Sinc

employed to decimate the modulator output data stream to give a

valid data conversion result at programmable output rates. The

signal chain has two modes of operation, CHOP enabled and

CHOP disabled. The CHOP bit in the ADCMODE register enables

and disables the chopping scheme.

Signal Chain Overview (CHOP Enabled, CHOP = 0)

With CHOP =0, chopping is enabled, this is the default and gives

optimum performance in terms of drift performance. With

chopping enabled, the available output rates vary from 5.35 Hz to

105 Hz. A block diagram of the ADC input channel with chop

enabled is shown in Figure 7.

The sampling frequency of the modulator loop is many times

higher than the bandwidth of the input signal. The integrator in the

modulator shapes the quantization noise (which results from the

analog-to-digital conversion) so that the noise is pushed toward

one-half of the modulator frequency. The output of the sigma-delta

modulator feeds directly into the digital filter. The digital filter then

band-limits the response to a frequency significantly lower than

one-half of the modulator frequency. In this manner, the 1-bit

output of the comparator is translated into a band limited, low noise

output from the ADuC847 ADC.

The ADuC847 filter is a low-pass, Sinc

primary function is to remove the quantization noise introduced at

the modulator. The cut-off frequency and decimated output data

rate of the filter are programmable via the SF word loaded in the

TABLE IV: Typical Output rms noise (µV) vs Input Range and Update Rate for the ADuC847 with chopping Enabled.

SF

Word

13 105.03 1.50 1.50 1.60 1.75 3.50 4.50 6.70 11.75

69 19.79 0.60 0.65 0.65 0.65 0.65 0.95 1.40 2.30

255 5.35 0.35 0.35 0.37 0.37 0.37 0.51 0.82 1.25

Data Update

Rate (Hz)

3

programmable low-pass filter is then

3

or (sinx/x)3 filter whose

±20 mV ±40 mV ±80 mV ±160 mV ±320 mV ±640 mV ±1.28 V ±2.56 V

filter register. The complete signal chain is chopped resulting in

excellent dc offset and offset drift specifications and is extremely

beneficial in applications where drift, noise rejection, and optimum

EMI rejection are important factors.

With chopping, the ADC repeatedly reverses its inputs. The

decimated digital output words from the Sinc

a positive offset and negative offset term included. As a result, a

final summing stage is included so that each output word from the

filter is summed and averaged with the previous filter output to

produce a new valid output result to be written to the ADC data

register. The programming of the Sinc

restricted to an 8-bit register called SF, the actual decimation factor

is the register value times 8.The decimated output rate from the

3

Sinc

filter (and the ADC conversion rate) will therefore be:

1

CHOP

1

SF

××=8

3

2

f

ADC

f ×

where

f

in the ADC conversion rate.

ADC

SF is the decimal equivalent of the word loaded to the filter

register.

f

is the modulator sampling rate of 32.768 kHz.

MOD

The chop rate of the channel is half the output data rate:

As shown in the block diagram, the Sinc

contain +V

This offset is removed by performing a running average of two.

This average by two means that the settling time to any change in

programming of the ADC will be twice the normal conversion

time, while an asynchronous step change on the analog input will

not be fully reflected until the third subsequent output.

The allowable range for SF (Chop Enabled) is 13 to 255 with a

default of 69 (45H). The corresponding conversion rates, RMS and

Pk-Pk noise performances are shown in Table IV & Table V. Note

that the conversion time increases by 0.732 ms for each increment

in SF.

With chopping enabled the ADC noise performance is the same as

that of the ADuC834.

Input Range

and –VOS, where VOS is the respective channel offset.

OS

t ×== 2

SETTLE

3

filter, therefore, have

3

decimation factor is

f

MODADC

1

ff×=2

ADC

3

filter outputs alternately

t

ADC

REV. PrA 05/03 20

Page 21

Preliminary Technical Data ADuC847

TABLE V: Peak to Peak Resolution (bits) vs Input Range and Update Rate for the ADuC847 with chopping Enabled.

Data Update

Word

13 105.03 12 13 14 15 15 15.5 16 16

69 19.79 13.5 14 15 16 17 17.5 18 18.5

255 5.35 14 15 16 17 18 18.5 19 19.5

Signal Chain Overview (CHOP Disabled, CHOP = 1)

With CHOP =1 chopping is disabled. With chopping disabled the

available output rates vary from 16.06 Hz to 1.365 kHz .The range

of applicable SF words is from 3 to 255. When switching between

channels with chop disabled, the channel throughput rate is

increased over the case where chop is enabled. The drawback with

chop disabled is that the drift performance is degraded and

calibration is required following a gain change or significant

temperature change. A block diagram of the ADC input channel

with chop disabled is shown in Figure 8. The signal chain includes

a multiplexor, buffer, PGA, sigma-delta modulator, and digital

filter. The modulator bit stream is applied to a Sinc

programming of the Sinc

register SF, the actual decimation factor is the register value times

8. The decimated output rate from the Sinc

conversion rate) will therefore be:

Rate (Hz)

±20 mV ±40 mV ±80 mV ±160 mV ±320 mV ±640 mV ±1.28 V ±2.56 V

Figure 6: ADC Circuit Diagram with Chopping Enabled

3

3

decimation factor is restricted to an 8-bit

3

filter (and the ADC

filter. The

f ×

1

×=8

where

f

is the ADC conversion rate,

ADC

SF is the decimal equivalent of the word loaded to the filter

register, valid range is from 3 to 255,

f

is the modulator sampling rate of 32.768 kHz.

MOD

The settling time to a step input is governed by the digital filter. A

synchronized step change will require a settling time of three times

the programmed update rate, a channel change can be treated as a

synchronized step change. This means that following a

synchronized step change, the ADC will require three outputs

before the result accurately reflects the new input voltage.

t ×== 3

SETTLE

f

3

ADC

SF

f

MODADC

t

ADC

Input Range SF

An unsynchronized step change will require four outputs to

accurately reflect the new analog input at its output.

The allowable range for SF is 3 to 255 with a default of 69 (45H).

The corresponding conversion rates, RMS and Pk-Pk noise

performances are shown in Table VI & Table VII. Note that the

conversion time increases by 0.244 ms for each increment in SF.

ADC NOISE PERFORMANCE WITH CHOPPING

DISABLED

Tables VII and VIII show the output rms noise and output peak-topeak resolution in bits (rounded to the nearest 0.5 LSB) for some

typical output update rates. The numbers are typical and generated

at a differential input voltage of 0V. The output update rate is

selected via the SF7–SF0 bits in the SF Filter Register. It is

important to note that the peak-to-peak resolution figures represent

the resolution for which there will be no code flicker within a sixsigma limit. The output noise comes from two sources.The first is

the electrical noise in the semiconductor devices (device noise)

used in the implementation of the modulator. Secondly, when the

analog input is converted to the digital domain, quantization noise

is added. The device noise is at a low level and is independent of

frequency. The quantization noise starts at an even lower level but

rises rapidly with increasing frequency to become the dominant

noise source. The numbers in the tables are given for the bipolar

input ranges. For the unipolar ranges the rms noise numbers will be

the same as the bipolar range, but the peak-to-peak resolution is

now based on half the signal range which effectively means losing

1 bit of resolution. Typically, the performance of the ADC with

Chop disabled will show a 1LSB degradation over the performance

with Chop enabled.

REV. PrA 05/03 -21-

Page 22

Preliminary Technical Data ADuC847

TABLE VI: Typical Output rms noise (µV) vs Input Range and Update Rate for the ADuC847 with chopping disabled.

SF

Word

3 1365.0 2.47 2.49 2.37 3.87 7.18 12.61 16.65 32.45

69 59.36 0.961 0.971 0.949 0.922 0.923 1.32 2.03 3.73

255 16.06 0.475 0.468 0.434 0.485 0.458 0.688 1.18 1.78

Data Update

Rate (Hz)

±20 mV ±40 mV ±80 mV ±160 mV ±320 mV ±640 mV ±1.28 V ±2.56 V

TABLE VII: Peak to Peak Resolution (bits) vs Input Range and Update Rate for the ADuC847 with chopping disabled.

Data Update

Word

3 1365.0 11 12 14 14 14 14 15 15

69 59.36 13 14 15 16 17 17 18 18

255 16.06 14 15 16 17 18 18 19 19

Rate (Hz)

±20 mV ±40 mV ±80 mV ±160 mV ±320 mV ±640 mV ±1.28 V ±2.56 V

Figure: 7 ADC Circuit with CHOP disabled

Reference Inputs

The ADuC847 has two separate differential reference inputs

REFIN+/- and REFIN2+/-. The common mode range for these

differential references is from AGND to AV

external reference voltage is 2.5v, with the reference select bits

configured from the ADC0CON2 and respectively.

The ADuC847 can also be configured to use the on-chip band-gap

reference, via the XREF0/1 bits in the ADC0CON2 SFR. In this

mode of operation the ADCs will see the internal reference of

1.25v, thereby halving all the input ranges. A consequence of using

the internal bandgap reference is a noticable degradation in peakto-peak resolution. For this reason operation with an external

reference is strongly recommended.

In applications where the excitation (voltage or current) for the

transducer on the analog input also drives the reference inputs for

the part, the effect of the of any low frequency noise in the

excitation source will be removed as the application is retiometric.

If the ADuC847 is not used in a ratiometric configuration then a

low noise reference should be used. Recommended references

voltage sources for the ADuC847 include ADR421, REF43,

REF192.

It should also be noted that the reference inputs provide a high

impedance, dynamic load to external connections. Because the

impedance of each reference input is dynamic, resistor/capacitor

combinations on these pins can cause dc gain errors depending on

the output impedance of the source that is driving the referenc

inputs. Reference voltage sources, like those mentioned above (e.g.

ADR421), will typically have low output impedances and therefore

. The nominal

DD

Input Range

Input Range SF

decoupling capacitors of the REFIN+/- or REFIN2+/- inputs would

be recommended. Deriving the reference voltage from an external

resistor configuration will mean that the reference input sees a

significant external source impedance. External decoupling of the

REFIN+/- and/or REFIN2+/- inputs would not be recommended in

this type of configuration.

Burnout Current Sources

The ADC on the ADuC847 incorporates two 200uA constant

current generators, one sourcing current from the AV

and one sinking current from AIN(-) to AGND. These currents are

only configurable for use on AIN4 → AIN5 and/or AIN6 → AIN7

in differential mode only, from the BO bit in the ICON SFR.

These burnout current sources are also only available with full

buffering enabled via the BUF0/BUF1 bits in the ADC0CON1

SFR. Once the burnout currents are turned on, a current will flow in

the external transducer circuit, and a measurement of the input

voltage on the analog input channel can be taken. If the resulting

voltage measured is fullscale, it indicates that the transducer has

gone open-circuit. If the voltage measured is 0v, it indicates that

the transducer has gone short circuit. The current sources work over

the normal absolute input voltage range specifications.

Reference Detect Circuit

The ADC has the option of using the internal bandgap reference or

an external reference applied to the two REFIN pins, by means of

the XREF0/1 bits in the control registers AD0CON2. A reference

detection circuit is provided to detect whether there is a valid

voltage applied to the REFIN+/- pins. This feature arose in

connection with strain gauge sensors in weigh-scales where the

reference and signal are provided via a cable from the remote

sensor. It is desirable to detect whether the cable is disconnected.

to AIN(+),

DD

REV. PrA 05/03 22

Page 23

Preliminary Technical Data ADuC847

If either of the pins is floating or if the applied voltage is below a

specified threshold then a flag (NOXREF) is set in the ADC status

register (ADCSTAT), conversion results are clamped and

calibration registers are not updated if a calibration is in progress.

Note: the reference-detect does not look at Refin2+/-.

Sinc Filter Register (SF)

The number entered into this register, when left shifted by 3 bits

sets the decimation factor of the Sinc

The range of operation of the SF word depends on whether ADC

Chop is on or off. With Chop off the minimum SF word is 3 and

the maximum is 255. This gives an ADC throughput rate from

16.06 Hz to 1.365kHz. With Chop on the minimum SF word is 13

(all values lower than 13 are clamped to 13) and the maximum is

3

Filter for the ADC.

ADC SFR INTERFACE

The ADC is controlled and configured via a number of SFRs that are mentioned here and described in more detail in the following pages.

ADCSTAT: ADC Status Register. Holds general status of the ADC.

ADCMODE: ADC Mode Register. Controls general modes of operation for ADC.

ADCCON1: ADC Control Register 1. Controls specific configuration of ADC.

ADCCON2: ADC Control Register 2. Controls specific configuration of ADC.

SF: Sinc Filter Register. Configures the decimation factor for the Sinc

ICON: Current Source Control Register. Allows user control of the various on-chip current source options.

ADCL/M/H: ADC 24-bit conversion result is held in these three 8-bit registers.

OFL/M/H: ADC 24-bit Offset Calibration Coefficient is held in these three 8-bit registers.

GNL/M/H: ADC 24-bit Gain Calibration Coefficient is held in these three 8-bit registers.

ADCSTAT—(ADC Status Register)

This SFR reflects the status of the ADC including data ready, calibration, and various (ADC-related) error and warning conditions including

Refin+/- reference detect and conversion overflow/underflow flags.

SFR Address D8H

Power-On Default Value 00H

Bit Addressable Yes

Table VIII. ADCSTAT SFR Bit Designations

Bit Name Description

7 RDY Ready Bit for Primary ADC.

Set by hardware on completion of ADC conversion or calibration cycle.

Cleared directly by the user or indirectly by write to the mode bits to start another ADC conversion or

calibration. The ADC is inhibited from writing further results to its data or calibration registers until the RDY0

bit is cleared.

6

5 CAL Calibration Status Bit.

4 NOXREF No External Reference Bit (only active if Primary or Auxiliary ADC is active).

3 ERR ADC Error Bit.

2

1

0

Reserved for Future Use

Set by hardware on completion of calibration.

Cleared indirectly by a write to the mode bits to start another ADC conversion or calibration.

Set to indicate that one or both of the REFIN pins is floating or the applied voltage is below a specified

threshold. When Set, conversion results are clamped to all ones. Only detects invalid Refin+/-, does not check

Refin2+/-.

Cleared to indicate valid VREF.

Set by hardware to indicate that the result written to the ADC data registers has been clamped to all zeros or all

ones. After a calibration, this bit also flags error conditions that caused the calibration registers not to be

written.

Cleared by a write to the mode bits to initiate a conversion or calibration.

Reserved for Future Use

Reserved for Future Use

Reserved for Future Use

255. This gives an ADC through put rate from 5.4Hz to 105Hz. See

f

equations in the ADC description section above.

adc

There is one additional feature of the Sinc

second notch filter positioned in the frequency response at 60Hz.

This gives simultaneous 50Hz & 60Hz rejection.

This 60Hz filter is enabled via the REJ60 bit in the ADCMODE

register (ADCMODE.6). This notch is only valid for SF words ≥

68, otherwise ADC errors will occur. This function is only useful

with an ADC clock of 32.768kHz.

During Calibration the current (user written) value of the SF

register is used.

3

filter and thus the ADC update rate.

3

Filter, and that is a

REV. PrA 05/03 -23-

Page 24

Preliminary Technical Data ADuC847

ADCMODE (ADC Mode Register)

Used to control the operational mode of the ADC.

SFR Address D1H

Power-On Default Value 10H

Bit Addressable No

Table IX. ADCMODE SFR Bit Designations

Bit Name Description

7 ––– Reserved for Future Use

6 REJ60 Automatic 60 Hz notch select bit. Setting this bit will place a notch in the frequency response at 60Hz, allowing simultaneous

50 & 60Hz rejection at an SF word of 82. This 60Hz notch can only be set if SF ≥ 68. This second notch is only placed at

60Hz if the ADC clock is at 32.768kHz.

5 ADCEN

4

3

CHOP

2 MD2

1 MD1

0 MD0

NOTES

1. Any change to the MD bits will immediately reset both ADCs. A write to the MD2–0 Bits with no change is also treated as a reset.

2. Once ADCMODE has been written with a calibration mode, the RDY0/1 bits (ADCSTAT) are reset and the calibration commences. On completion, the appropriate calibration

registers are written, the relevant bits in ADCSTAT are written, and the MD2–0 bits are reset to 000 to indicate the ADC is back in power-down mode.

3. Calibrations are performed at user selected SF (see SF SFR) value.

ADC Enable.

Set by the user to enable the ADC and place it in the mode selected in MD2–MD0 below.

Cleared by the user to place the ADC in power-down mode.

Reserved for Future use

Chop Mode Disable

Set by the user to disable Chop Mode on the ADC allowing greater ADC data throughput .

Cleared by the user to enable Chop Mode on the ADC.

Primary and Auxiliary ADC Mode bits. These bits select the operational mode of the enabled ADC as follows:

MD2 MD1 MD0

0 0 0 ADC Power-Down Mode (Power-On Default)

0 0 1 Idle Mode.

In Idle Mode, the ADC filter and modulator are held in a reset state although the modulator clocks

are still provided.

0 1 0 Single Conversion Mode

In Single Conversion Mode, a single conversion is performed on the enabled ADC.

On completion of a conversion, the ADC data registers (ADCH/M/L) are updated.

The relevant flags in the ADCSTAT SFR are written, and power-down is re-entered with the

MD2–MD0 accordingly being written to 000.

0 1 1 Continuous Conversion

In Continuous Conversion Mode, the ADC data registers are regularly updated at the selected update

rate (see SF Register).

1 0 0 Internal Zero-Scale Calibration

Internal short automatically connected to the enabled ADC input(s)

1 0 1 Internal Full-Scale Calibration

Internal or External REFIN+/- or REFIN2+/- VREF(as determined by XREF bits in ADCCON2)

is automatically connected to the enabled ADC input(s) for this calibration.

1 1 0 System Zero-Scale Calibration

User should connect system zero-scale input to the enabled ADC input(s) as selected by

CH3-CH0 bits in the ADCCON2 Register.

1 1 1 System Full-Scale Calibration

User should connect system full-scale input to the enabled ADC input(s) as selected by CH3-CH0

and bits in the ADCCON2 Register.

REV. PrA 05/03 24

Page 25

Preliminary Technical Data ADuC847

ADCCON1 (ADC Control Register)

ADCCON1 is used to configure the ADC for Buffer, unipolar or bipolar coding and ADC range configuration.

ADCCON1 ADC Control SFR

SFR Address D2H

Power-On Default Value 07H

Bit Addressable No

Table X. ADCCON1 SFR Bit Designations

Bit Name Description

7 BUF1

6 BUF0

5 UNI ADC Unipolar Bit.

4 ––– Reserved for Future Use

3 ––– Reserved for Future Use

2 RN2

1 RN1

0 RN0

REV. PrA 05/03 -25-

Buffer Configuration Bits

BUF1 BUF0 Buffer Configuration

0 0 ADC+ and ADC- are buffered

0 1 ADC+ only buffered

1 0 Buffer Bypass

1 1 Reserved for Future Use.

Set by user to enable unipolar coding, i.e., zero differential input will result in 0x000000 output.

Cleared by user to enable bipolar coding, zero differential input will result in 0x800000 output.

ADC Range Bits. Written by the user to select the ADC input range as follows:

RN2 RN1 RN0 Selected ADC Input Range (VREF = 2.5 V)

0 0 0 ±20 mV (0 mV–20 mV in Unipolar Mode)

0 0 1 ±40 mV (0 mV–40 mV in Unipolar Mode)

0 1 0 ±80 mV (0 mV–80 mV in Unipolar Mode)

0 1 1 ±160 mV (0 mV–160 mV in Unipolar Mode)

1 0 0 ±320 mV (0 mV–320 mV in Unipolar Mode)

1 0 1 ±640 mV (0 mV–640 mV in Unipolar Mode)

1 1 0 ±1.28 V (0 V–1.28 V in Unipolar Mode)

1 1 1 ±2.56 V (0 V–2.56 V in Unipolar Mode)

Page 26

Preliminary Technical Data ADuC847

ADCCON2 (ADC Channel Select Register)

ADCCON2 is used to select the channel for the ADC

ADCCON2 ADC Channel Select Register

SFR Address E6H

Power-On Default Value 00H

Bit Addressable No

Table XI. ADCCON2 SFR Bit Designations

Bit Name Description

7 XREF1

6 XREF0

5 ––– Reserved for Future Use

4 ––– Reserved for Future Use

3 CH3

2 CH2

1 CH1

0 CH0

ADC External Reference Select Bit.

Set by user to enable the ADC use the external reference via REFIN+/- or REFIN2+/-.

Cleared by user to enable the ADC to use the internal bandgap reference (VREF = 1.25 V).

XREF1 XREF0

0 0 Internal 1.25v Vref

0 1 Refin+/1 0 Refin2+/- (Ain2 / Ain3)

1 1 Reserved for Future Use

ADC Channel Select Bits. Written by the user to select the ADC Channel as follows

CH3 CH2 CH1 CH0 Selected ADC Input Channel.

0 0 0 0 AIN0 Æ AINCOM

0 0 0 1 AIN1 Æ AINCOM

0 0 1 0 AIN2 Æ AINCOM

0 0 1 1 AIN3 Æ AINCOM

0 1 0 0 AIN4 Æ AINCOM

0 1 0 1 AIN5 Æ AINCOM

0 1 1 0 AIN6 Æ AINCOM

0 1 1 1 AIN7 Æ AINCOM

1 0 0 0 AIN8 Æ AINCOM (CSP package only). Not a valid selection on MQFP package.

1 0 0 1 AIN9 Æ AINCOM (CSP package only). Not a valid selection on MQFP package.

1 0 1 0 AIN0 Æ AIN1

1 0 1 1 AIN2 Æ AIN3

1 1 0 0 AIN4 Æ AIN5

1 1 0 1 AIN6 Æ AIN7