Page 1

dB

Cool™ Remote Thermal

FEATURES

Controls and monitors up to 4 fans

High and low frequency fan drive signal

1 on-chip and 2 remote temperature sensors

Series resistance cancellation on the remote channel

Extended temperature measurement range, up to 191°C

Dynamic T

intelligently

Automatic fan speed control mode controls system cooling

based on measured temperature

Enhanced acoustic mode dramatically reduces user

perception of changing fan speeds

Thermal protection feature via

Monitors performance impact of Intel® Pentium™ 4

processor

Thermal control circuit via

2-wire, 3-wire, and 4-wire fan speed measurement

Limit comparison of all monitored values

Meets SMBus 2.0 electrical specifications

(fully SMBus 1.1 compliant)

control mode optimizes system acoustics

MIN

output

THERM

input

THERM

Monitor and Fan Controller

ADT7467

GENERAL DESCRIPTION

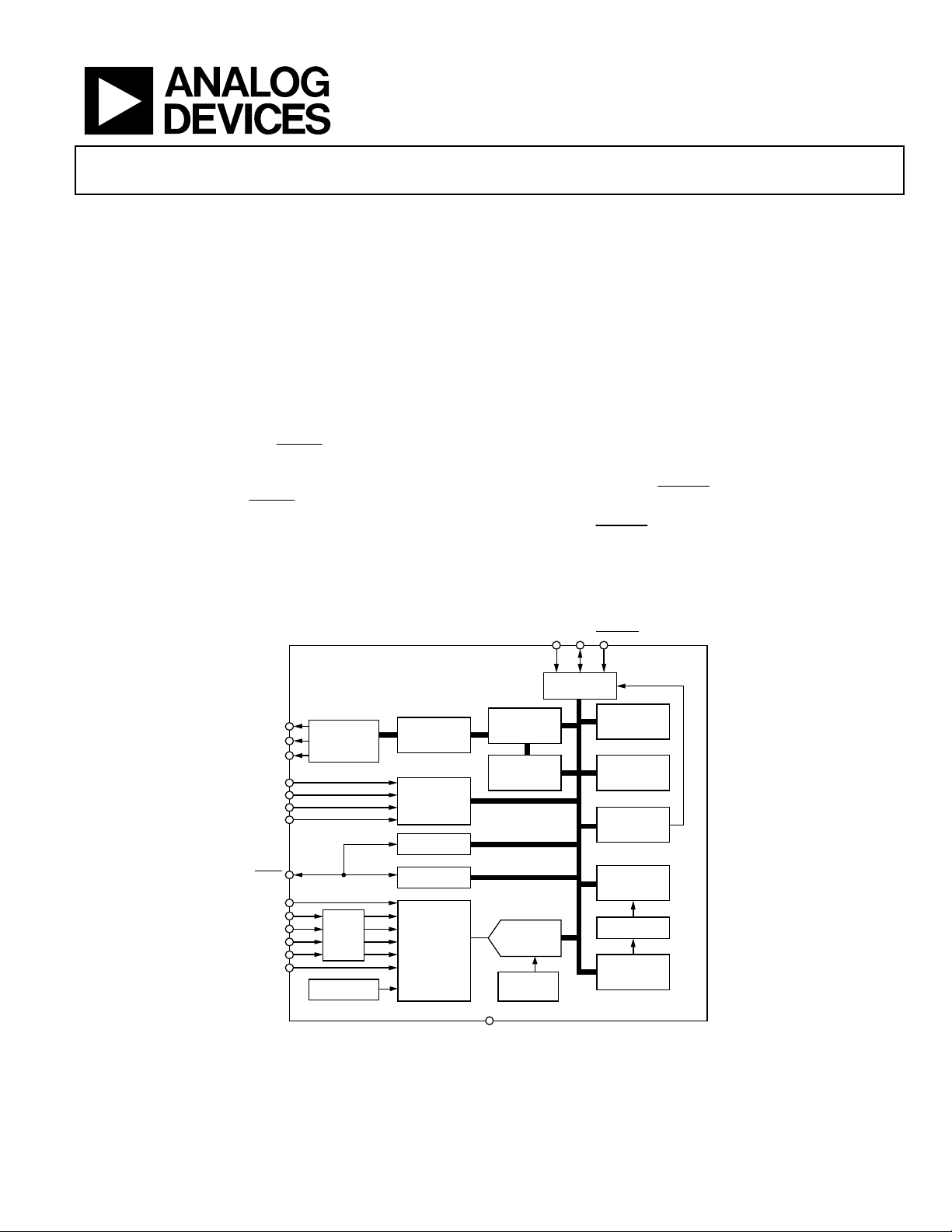

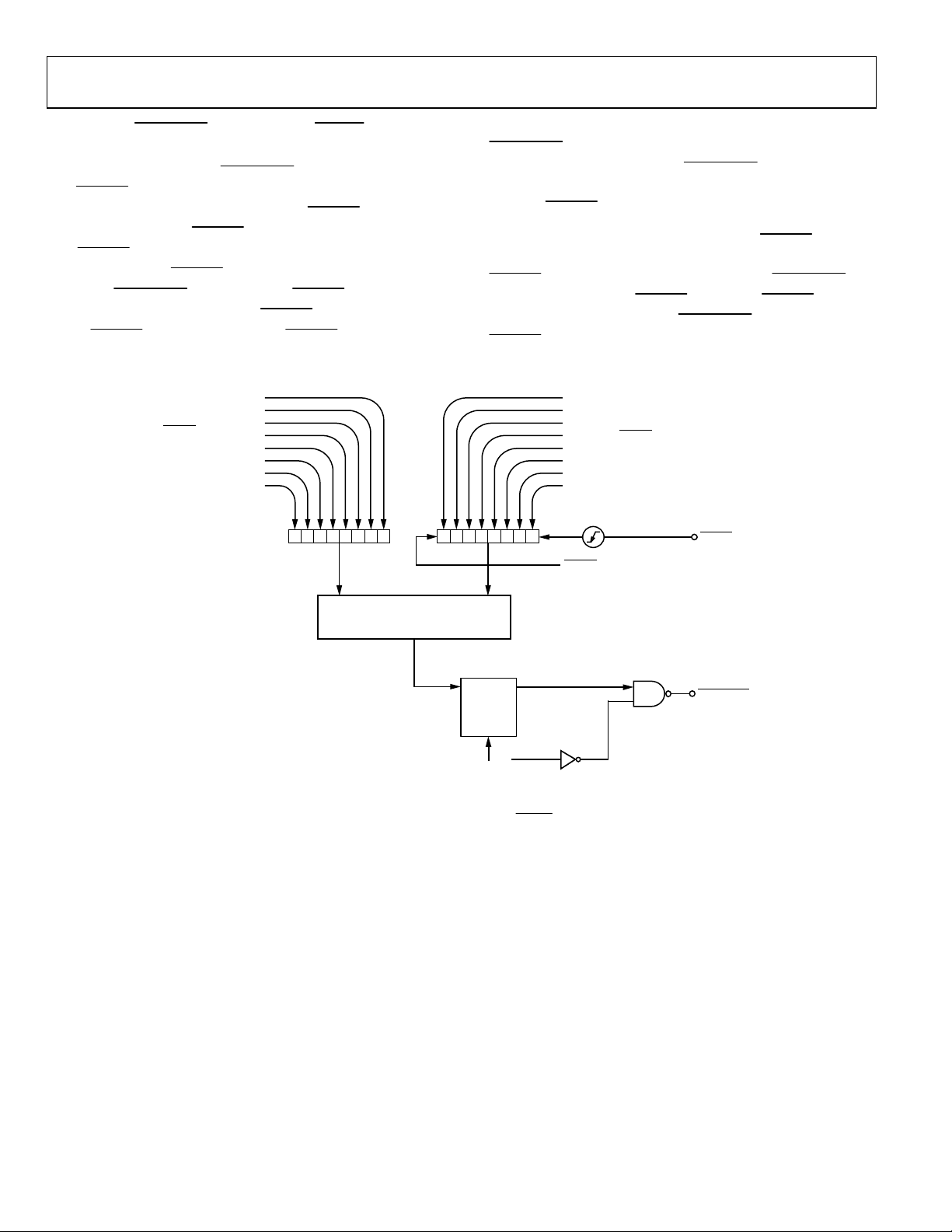

The ADT7467 dBCOOLTM controller is a thermal monitor and

multiple PWM fan controller for noise-sensitive or powersensitive applications requiring active system cooling. The

ADT7467 can drive a fan using either a low or high frequency

drive signal, monitor the temperature of up to two remote

sensor diodes plus its own internal temperature, and measure

and control the speed of up to four fans, so that they operate at

the lowest possible speed for minimum acoustic noise.

The automatic fan speed control loop optimizes fan speed for a

given temperature. A unique dynamic T

enables the system thermals/acoustics to be intelligently

managed. The effectiveness of the system's thermal solution can

be monitored using the

THERM

input. The ADT7467 also

provides critical thermal protection to the system using the

bidirectional

THERM

pin as an output to prevent system or

component overheating.

control mode

MIN

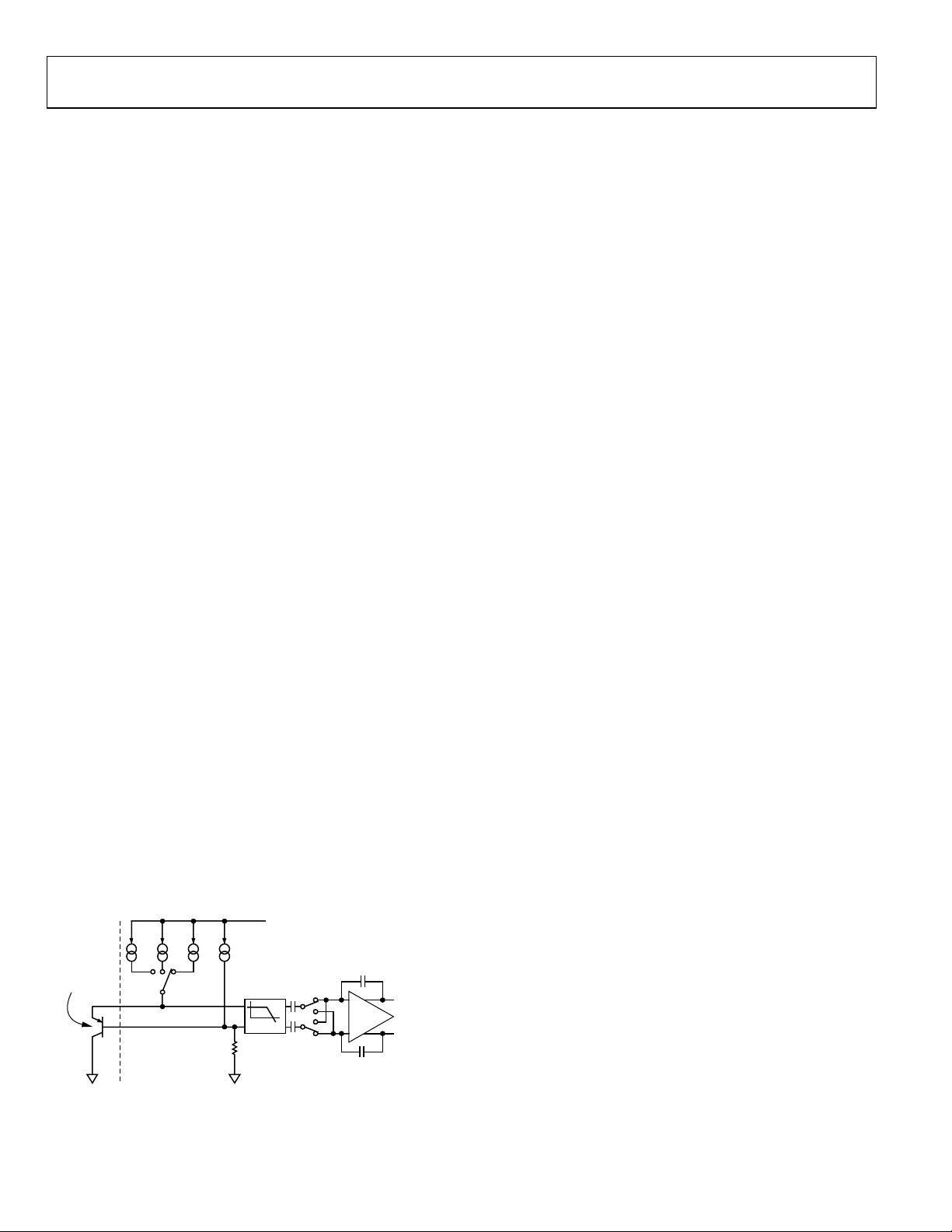

PWM1

PWM2

PWM3

TACH1

TACH2

TACH3

TACH4

THERM

V

D1+

D1–

D2+

D2–

V

CCP

CC

PWM REGISTERS

AND

CONTROLLERS

HF & LF

VCCTO ADT7467

SRC

BAND GAP

TEMP SENSOR

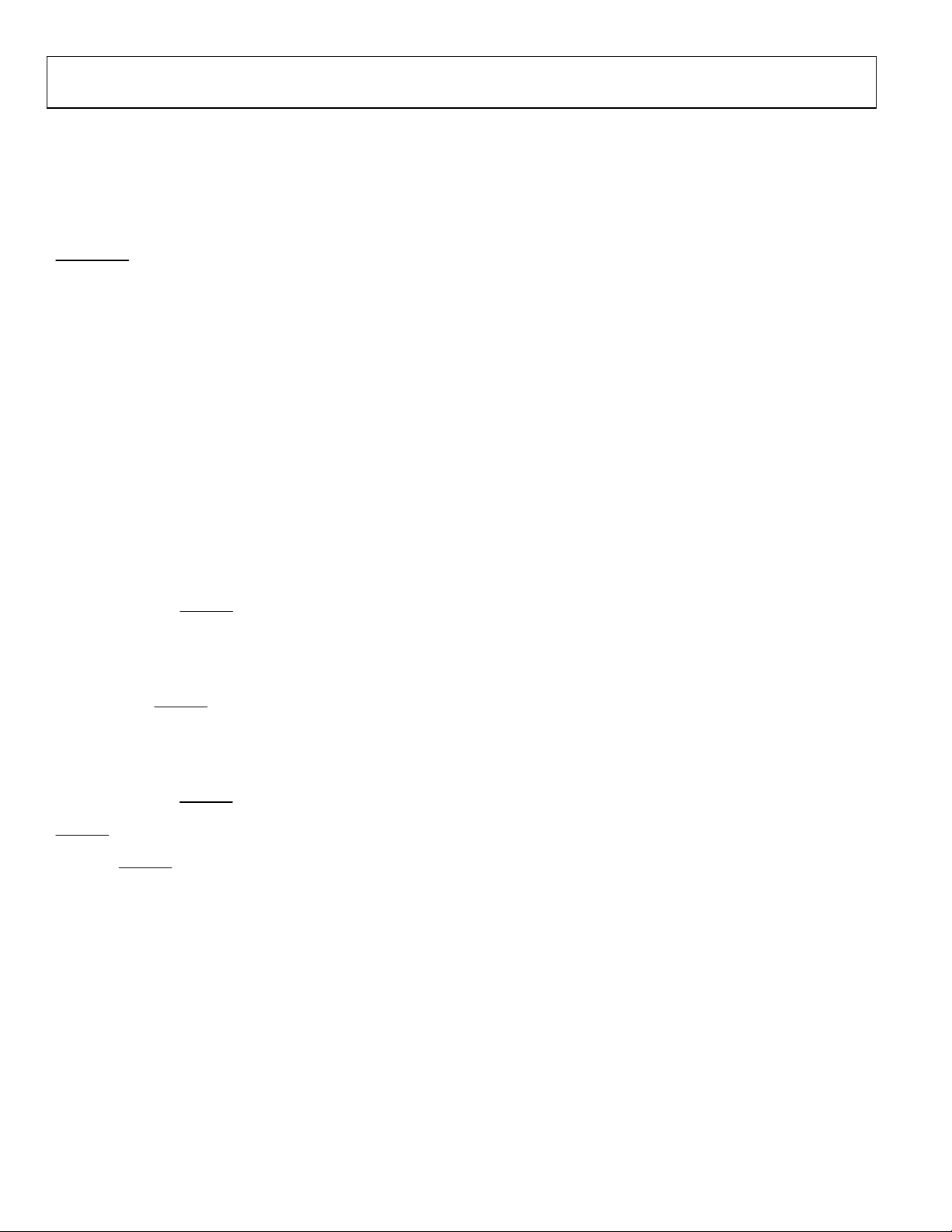

FUNCTIONAL BLOCK DIAGRAM

SCL

SDA

SMBALERT

SERIAL BUS

INTERFACE

AUTOMATIC

GND

Figure 1.

FAN SPEED

CONTROL

DYNAMIC

T

MIN

CONTROL

ADT7467

10-BIT

ADC

BAND GAP

REFERENCE

ACOUSTIC

ENHANCEMENT

CONTROL

FAN SPEED

COUNTER

PERFORMANCE

MONITORING

THERMAL

PROTECTION

INPUT

SIGNAL

CONDITIONING

AND

ANALOG

MULTIPLEXER

ADDRESS

POINTER

REGISTER

PWM

CONFIGURATION

REGISTERS

INTERRUPT

MASKING

INTERRUPT

STATUS

REGISTERS

LIMIT

COMPARATORS

VALUE AND

LIMIT

REGISTERS

04498-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

ADT7467

TABLE OF CONTENTS

Specifications..................................................................................... 3

Laying Out 2-Wire and 3-Wire Fans....................................... 28

Absolute Maximum Ratings............................................................ 5

Thermal Characteristics .............................................................. 5

ESD Caution.................................................................................. 5

Pin Configuration and Function Descriptions............................. 6

Typical Performance Characteristics ............................................. 7

Product Description......................................................................... 9

Comparison between ADT7460 and ADT7467....................... 9

Recommended Implementation............................................... 10

Serial Bus Interface..................................................................... 11

Write Operations ........................................................................ 12

Read Operations ......................................................................... 13

SMBus Timeout.......................................................................... 13

Voltage Measurement Input...................................................... 13

Analog-to-Digital Converter ....................................................13

Input Circuitry ............................................................................ 14

Operating from 3.3 V Standby.................................................. 32

XNOR Tree Test Mode .............................................................. 33

Power-On Default ...................................................................... 33

Programming the Automatic Fan Speed Control Loop ............ 34

Automatic Fan Control Overview............................................ 34

Step 1: Hardware Configuration.............................................. 35

Recommended Implementation 1 ........................................... 36

Recommended Implementation 2 ........................................... 37

Step 2: Configuring the MUX................................................... 38

Step 3: T

Step 4: PWM

Step 5: PWM

Step 6: T

Step 7: T

Step 8: T

Settings for Thermal Calibration Channels....... 40

MIN

for Each PWM (Fan) Output....................... 41

MIN

for PWM (Fan) Outputs.............................. 41

MAX

for Temperature Channels................................ 42

RANGE

for Temperature Channels ............................... 45

THERM

for Temperature Channels .................................. 46

HYST

Voltage Measurement Registers................................................ 14

V

Limit Registers ...................................................................14

CCP

Additional ADC Functions for Voltage Measurements ........14

Temperature Measurement Method ........................................ 15

Series Resistance Cancellation.................................................. 17

Factors Affecting Diode Accuracy ........................................... 17

Additional ADC Functions for Temperature Measurement. 19

Limits, Status Registers, and Interrupts ....................................... 20

Limit Values................................................................................. 20

Status Registers ........................................................................... 21

THERM

Timer............................................................................ 23

REVISION HISTORY

Revision 0: Initial Version

Dynamic T

Control Mode ................................................... 48

MIN

Step 9: Operating Points for Temperature Channels............. 50

Step 10: High and Low Limits for Temperature Channels ... 51

Step 11: Monitoring

THERM

................................................... 53

Enhancing System Acoustics .................................................... 54

Step 12: Ramp Rate for Acoustic Enhancement..................... 56

Register Tables ................................................................................ 59

ADT7467 Programming Block Diagram.................................... 77

Outline Dimensions....................................................................... 78

Ordering Guide .......................................................................... 78

Rev. 0 | Page 2 of 80

Page 3

ADT7467

SPECIFICATIONS

TA = T

All voltages are measured with respect to GND, unless otherwise specified. Typicals are at T

norm. Logic inputs accept input high voltages up to V

logic levels of V

not production tested.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

POWER SUPPLY

20 µA Standby mode

TEMP-TO-DIGITAL CONVERTER

36 µΑ Second current

96 µΑ Third current

ANALOG-TO-DIGITAL CONVERTER (INCLUDING MUX AND ATTENUATORS)

FAN RPM-TO-DIGITAL CONVERTER

MIN

to T

, VCC = V

MAX

= 0.8 V for a falling edge and VIH = 2.0 V for a rising edge. SMBus timing specifications are guaranteed by design and are

IL

MIN

to V

, unless otherwise noted.

MAX

MAX

= 25°C and represent most likely parametric

A

even when device is operating down to V

. Timing specifications are tested at

MIN

Supply Voltage 3.0 3.3 5.5 V

Supply Current, ICC 3 mA Interface inactive, ADC active

Local Sensor Accuracy ±1.5 °C 0°C ≤ TA ≤ 70°C

−3.5 +2 °C −40°C ≤ TA ≤ +100°C

−4 +2 °C −40°C ≤ TA ≤ +120°C

Resolution 0.25 °C

Remote Diode Sensor Accuracy ±0.5 ±1.5 °C 0°C ≤ TA ≤ 70°C; 0°C ≤ TD ≤ 120°C

−3.5 +2 °C 0°C ≤ TA ≤ 105°C; 0°C ≤ TD ≤ 120°C

−4.5 +2 °C −40°C ≤ TA ≤ +120°C; 0°C ≤ TD ≤ +120°C

Resolution 0.25 °C

Remote Sensor Source Current 6 µA First current

Total Unadjusted Error (TUE) ±1.5 %

Differential Nonlinearity (DNL) ±1 LSB 8 bits

Power Supply Sensitivity ±0.1 %/V

Conversion Time (Voltage Input) 11 ms Averaging enabled

Conversion Time (Local Temperature) 12 ms Averaging enabled

Conversion Time (Remote Temperature) 38 ms Averaging enabled

Total Monitoring Cycle Time 145 ms Averaging enabled

Total Monitoring Cycle Time 19 ms Averaging disabled

Input Resistance 40 80 100 kΩ For V

channel

CC

80 140 200 kΩ For all other channels

Accuracy ±5 % 0°C ≤ TA ≤ 70°C, 3.3 V

±7 % −40°C ≤ TA ≤ +120°C, 3.3 V

±10 % −40°C ≤ TA ≤ +120°C, 5.5 V

Full-Scale Count 65,535

Nominal Input RPM 109 RPM Fan count = 0xBFFF

329 RPM Fan count = 0x3FFF

5000 RPM Fan count = 0x0438

10000 RPM Fan count = 0x021C

Internal Clock Frequency 85.5 90 94.5 kHz 0°C ≤ TA ≤ 70°C, V

83.7 90 96.3 kHz −40°C ≤ TA ≤ +120°C, V

81 90 99 kHz −40°C ≤ TA ≤ +120°C, V

= 3.3V

cc

= 3.3 V

CC

= 5.5 V

CC

Rev. 0| Page 3 of 80

Page 4

ADT7467

A

Parameter Min Typ Max Unit Test Conditions/Comments

OPEN-DRAIN DIGITAL OUTPUTS, PWM1 to PWM3, XTO

Current Sink, IOL 8.0 mA

Output Low Voltage, VOL 0.4 V I

High Level Output Current, IOH 0.1 1.0 µA V

OPEN-DRAIN SERIAL DATA BUS OUTPUT (SDA)

Output Low Voltage, VOL 0.4 V I

High Level Output Current, IOH 0.1 1.0 µA V

SMBUS DIGITAL INPUTS (SCL, SDA)

Input High Voltage, VIH 2.0 V

Input Low Voltage, V

0.4 V

IL

Hysteresis 500 mV

DIGITAL INPUT LOGIC LEVELS (TACH INPUTS)

Input High Voltage, VIH 2.0 V

5.5 V Maximum input voltage

Input Low Voltage, VIL 0.8 V

−0.3 V Minimum input voltage

Hysteresis 0.5 V p-p

DIGITAL INPUT LOGIC LEVELS (THERM) ADTL+

Input High Voltage, V

Input Low Voltage, V

0.75 × V

IH

0.4 V

IL

V

CCP

DIGITAL INPUT CURRENT

Input High Current, IIH −1 µA VIN = VCC

Input Low Current, IIL 1 µA VIN = 0

Input Capacitance, CIN 5 pF

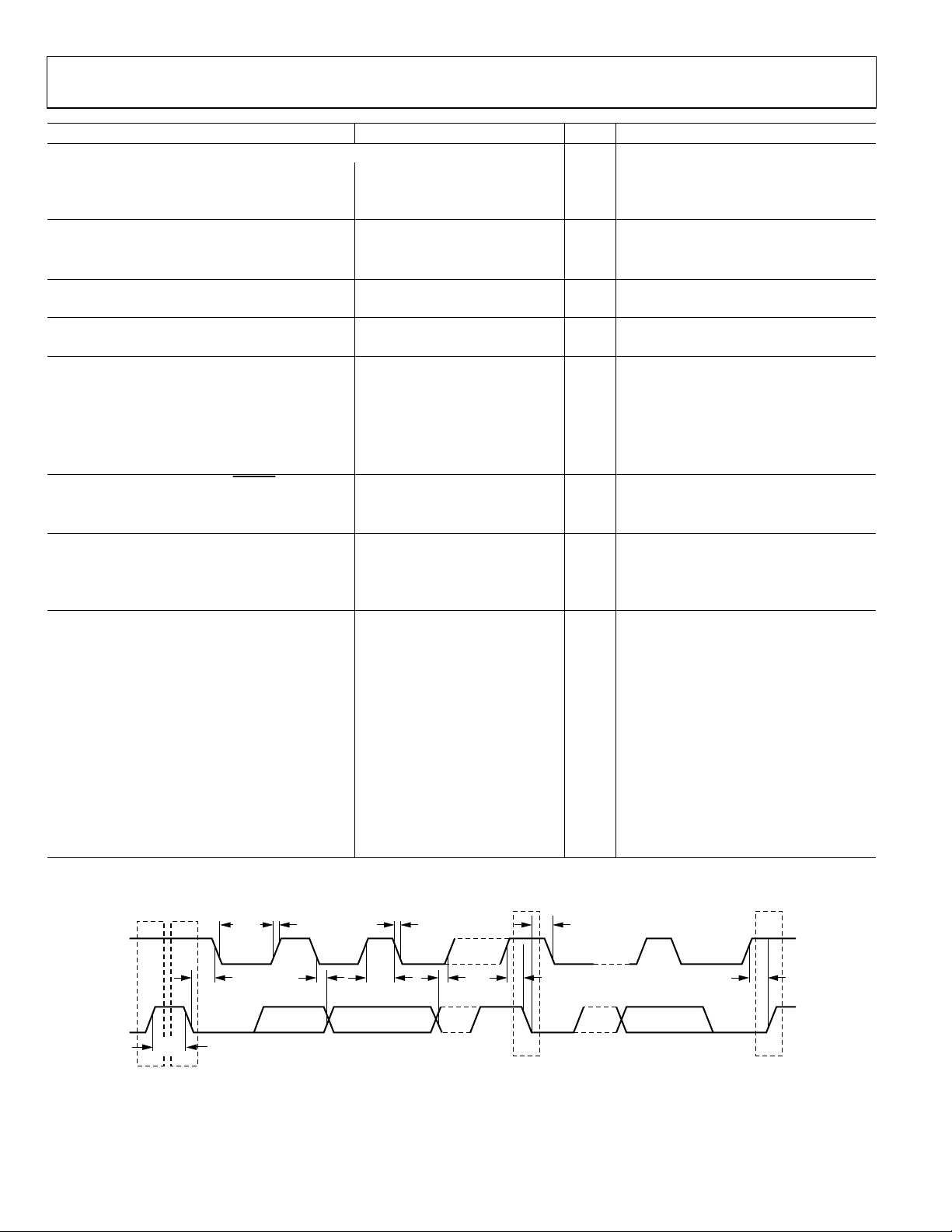

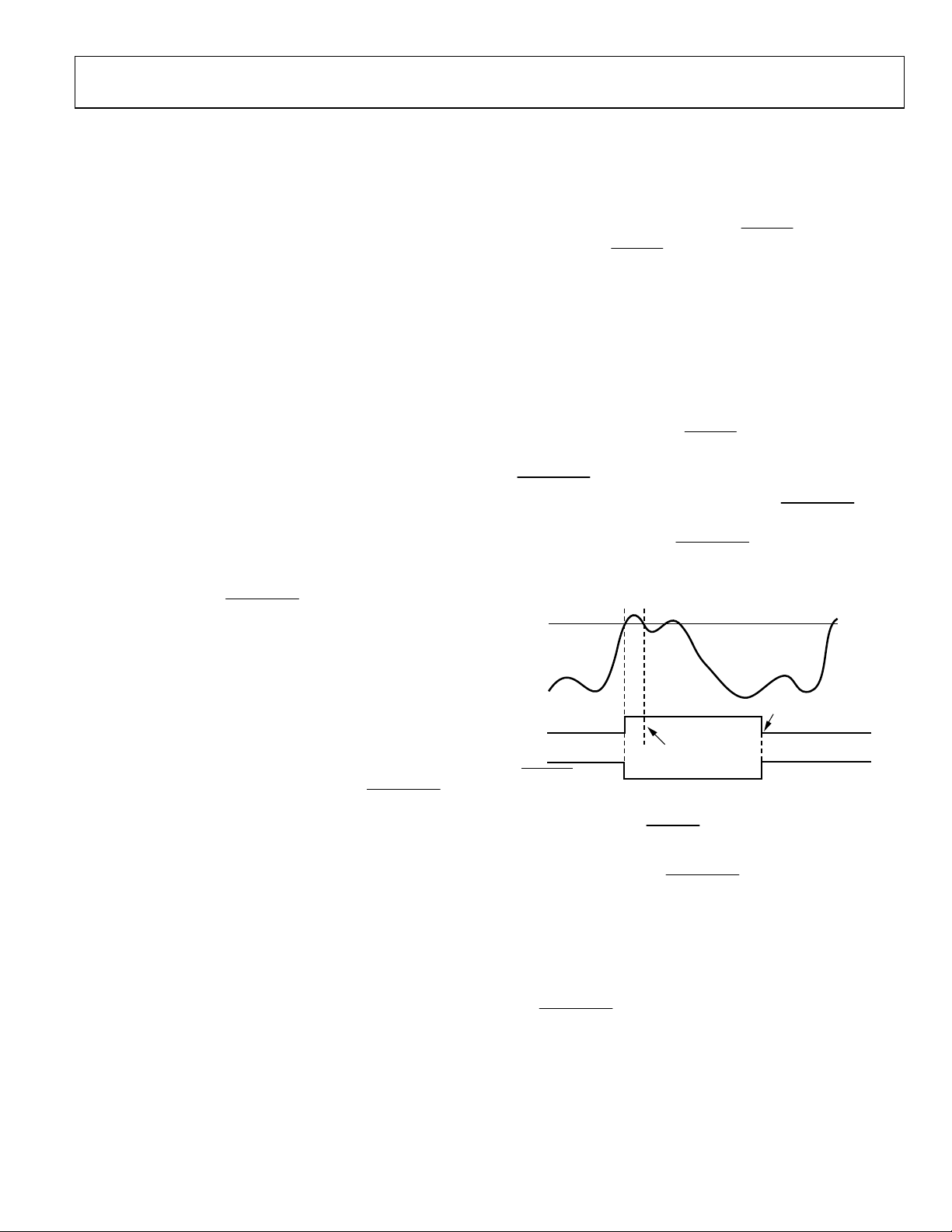

SERIAL BUS TIMING

Clock Frequency, f

5

See Figure 2

10 400 kHz

SCLK

Glitch Immunity, tSW 50 ns

Bus Free Time, t

Start Setup Time, t

Start Hold Time, t

SCL Low Time, t

SCL High Time, t

4.7 µs

BUF

4.7 µs

SU;STA

4.0 µs

HD;STA

4.7 µs

LOW

4.0 50 µs

HIGH

SCL, SDA Rise Time, tR 1000 ns

SCL, SDA Fall Time, t

Data Setup Time, t

Data Hold Time, t

Detect Clock Low Timeout, t

300 µs

F

250 ns

SU;DAT

300 ns

HD;DAT

15 35 ms Can be optionally disabled

TIMEOUT

= −8.0 mA, VCC = +3.3 V

OUT

= VCC

OUT

= −4.0 mA, VCC = +3.3 V

OUT

= VCC

OUT

t

F

t

HIGH

t

SU; DAT

SP

Figure 2. Serial Bus Timing Diagram

t

SU; STA

t

HD; STA

t

SU; STO

04498-0-002

SCL

SD

t

BUF

PS

t

HD; STA

t

LOW

t

R

t

HD; DAT

Rev. 0 | Page 4 of 80

Page 5

ADT7467

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Positive Supply Voltage (VCC) 5.5 V

Voltage on Any Input or Output Pin −0.3 V to +6.5 V

Input Current at Any Pin ±5 mA

Package Input Current ±20 mA

Maximum Junction Temperature (T

Storage Temperature Range −65°C to +150°C

Lead Temperature, Soldering

IR Reflow Peak Temperature 220°C

Lead Temperature (Soldering 10 s) 300°C

ESD Rating 1000 V

) 150°C

JMAX

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL CHARACTERISTICS

16-lead QSOP package:

= 150°C/W

θ

JA

= 39°C/W

θ

JC

Rev. 0| Page 5 of 80

Page 6

ADT7467

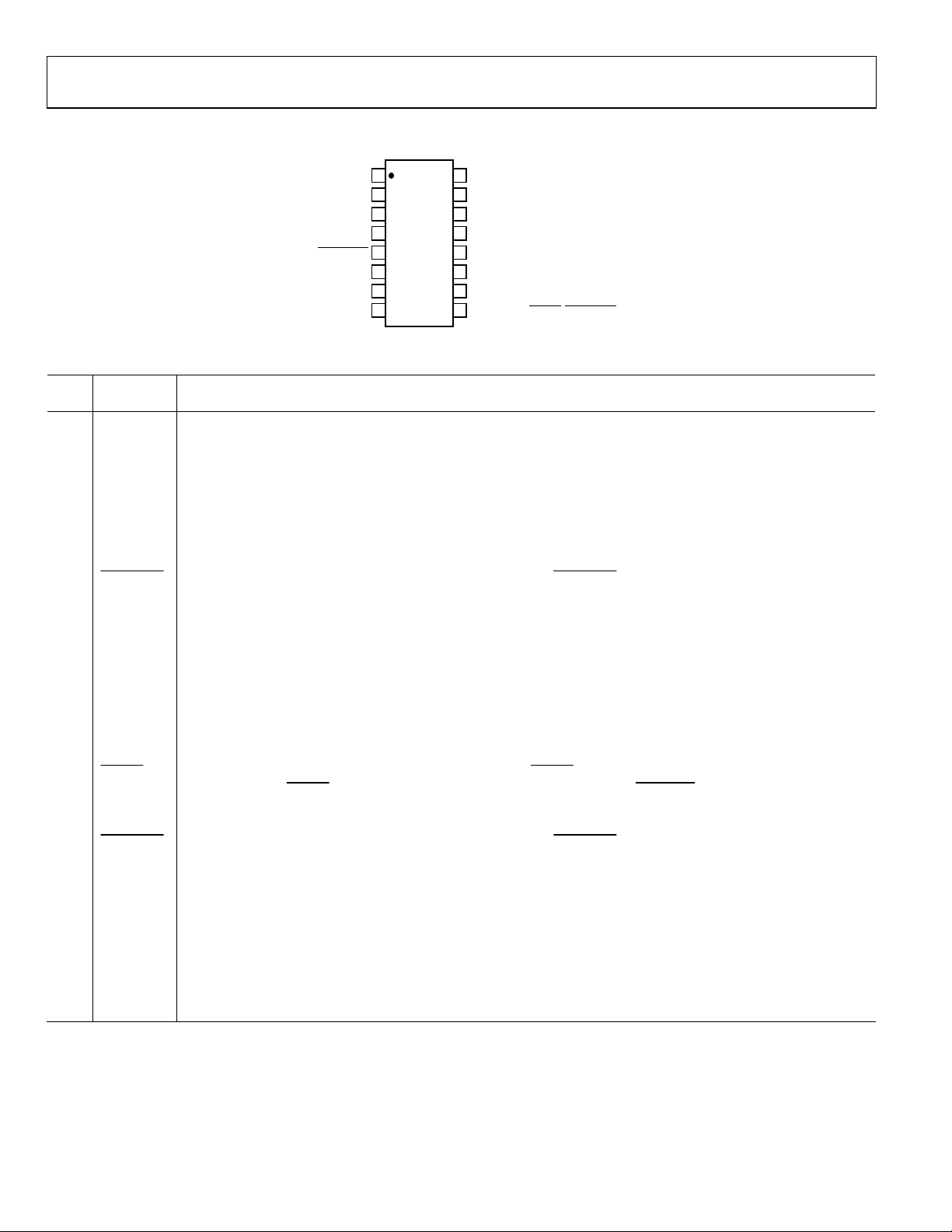

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

16

SCL

1

GND

2

V

3

CC

ADT7467

4

TACH3

PWM2/SMBALERT

TACH1

TACH2

PWM3

TOP VIEW

(NOT TO SCALE)

5

6

7

8

Figure 3. Pin Configuration

Table 3. Pin Function Descriptions

Pin

No. Mnemonic Description

1 SCL Digital Input (Open Drain). SMBus serial clock input. Requires SMBus pull-up.

2 GND Ground Pin for the ADT7467.

3 VCC

Power Supply. Can be powered by 3.3 V standby, if monitoring in low power states is required. V

through this pin. The ADT7467 can also be powered from a 5 V supply. Setting Bit 7 of Configuration Register 1 (Reg.

0x40) rescales the VCC input attenuators to correctly measure a 5 V supply.

4 TACH3

Digital Input (Open Drain). Fan tachometer input to measure speed of Fan 3. Can be reconfigured as an analog input

(AIN3) to measure the speed of 2-wire fans (low frequency mode only).

5 PWM2

Digital Output (Open Drain). Requires 10 kΩ typical pull-up. Pulse width modulated output to control Fan 2 speed.

Can be configured as a high or low frequency drive.

SMBALERT

Digital Output (Open Drain). This pin can be reconfigured as an SMBALERT interrupt output to signal out-of-limit

conditions.

6 TACH1

Digital Input (Open Drain). Fan tachometer input to measure speed of Fan 1. Can be reconfigured as an analog input

(AIN1) to measure the speed of 2-wire fans (low frequency mode only).

7 TACH2

Digital Input (Open Drain). Fan tachometer input to measure speed of Fan 2. Can be reconfigured as an analog input

(AIN2) to measure the speed of 2-wire fans (low frequency mode only).

8 PWM3

Digital I/O (Open Drain). Pulse width modulated output to control the speed of Fan 3 and Fan 4. Requires 10 kΩ

typical pull-up. Can be configured as a high or low frequency drive.

9 TACH4

Digital Input (Open Drain). Fan tachometer input to measure speed of Fan 4. Can be reconfigured as an analog input

(AIN4) to measure the speed of 2-wire fans (low frequency mode only).

GPIO General Purpose Open Drain Digital I/O.

Alternatively, the pin can be reconfigured as a bidirectional THERM pin, which can be used to time and monitor

THERM

assertions on the THERM

input. For example, the pin can be connected to the PROCHOT output of an Intel Pentium 4

processor or to the output of a trip point temperature sensor. This pin can be used as an output to signal

overtemperature conditions.

SMBALERT

Digital Output (Open Drain). This pin can be reconfigured as an SMBALERT interrupt output to signal out-of-limit

conditions.

10 D2− Cathode Connection to Second Thermal Diode.

11 D2+ Anode Connection to Second Thermal Diode.

12 D1− Cathode Connection to First Thermal Diode.

13 D1+ Anode Connection to First Thermal Diode.

14 V

Analog Input. Monitors processor core voltage (0 V − 3 V).

CCP

15 PWM1 Digital Output (Open Drain). Pulse-width modulated output to control Fan 1 speed. Requires 10 kΩ typical pull-up.

XTO Also functions as the output from the XNOR tree in XNOR test mode.

16 SDA Digital I/O (Open Drain). SMBus bidirectional serial data. Requires 10 kΩ typical pull-up.

SDA

PWM1/XTO

15

V

14

CCP

13

D1+

12

D1–

11

D2+

10

D2–

9

TACH4/GPIO/THERM/SMBALERT

04498-0-003

is also monitored

CC

Rev. 0 | Page 6 of 80

Page 7

ADT7467

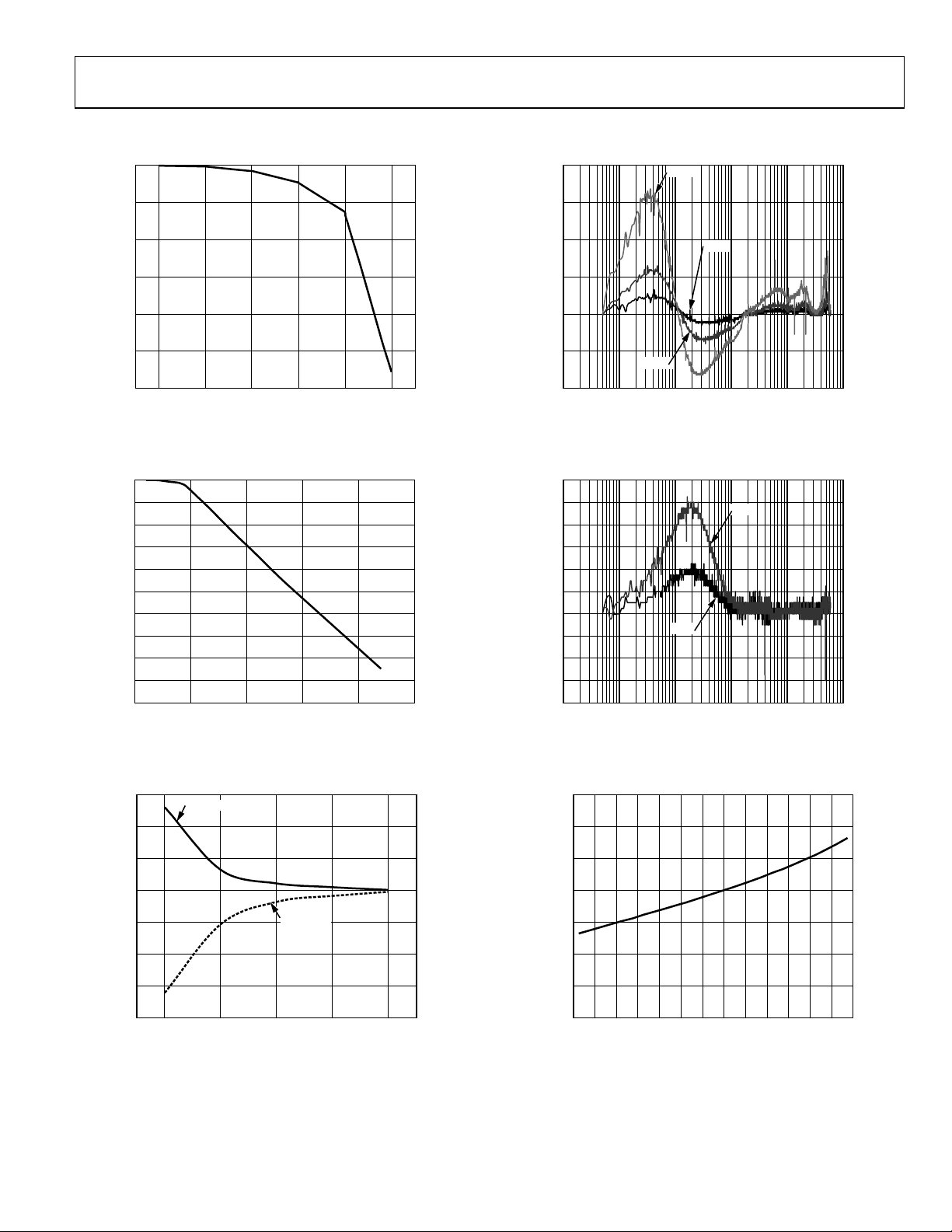

TYPICAL PERFORMANCE CHARACTERISTICS

0

20

100mV

–10

–20

–30

–40

TEMPERATURE ERROR (°C)

–50

–60

1 4.73.3 100 2.2

CAPACITANCE (nF)

Figure 4. Temperature Error vs. Capacitance between D+ and D−

0

–10

–20

–30

–40

–50

–60

–70

TEMPERATURE ERROR (°C)

–80

–90

–100

CAPACITANCE (nF)

Figure 5. External Temperature Error vs. D+/D− Capacitance

60

40

D+ TO GND

15

04498-0-045

10

5

0

TEMPERATURE ERROR (°C)

–5

–10

60mV

40mV

FREQUENCY (kHz)

1G10 100 1M 10M 100M

04498-0-048

Figure 7. Remote Temperature Error vs. Common Mode Noise Frequency

6

5

4

3

2

1

0

–1

TEMPERATURE ERROR (°C)

–2

–3

2501020515

04498-0-046

–4

10mV

FREQUENCY (kHz)

20mV

1G10 100 1M 10M 100M

04498-0-049

Figure 8. Remote Temperature Error vs. Differential Mode Noise Frequency

1.40

1.35

20

0

D+ TO V

–20

–40

TEMPERATURE ERROR (°C)

–60

–80

RESISTANCE (MΩ)

CC

1000 3.3 20110

04498-0-047

Figure 6. Temperature Error vs. PCB Resistance

1.30

1.25

(mA)

1.20

DD

I

1.15

1.10

1.05

3.0 3.8 5.23.4 4.43.6 4.83.2 4.0 5.44.6 5.04.2

POWER SUPPLY VOLTAGE (V)

Figure 9. Normal I

vs. Power Supply

DD

04498-0-050

Rev. 0| Page 7 of 80

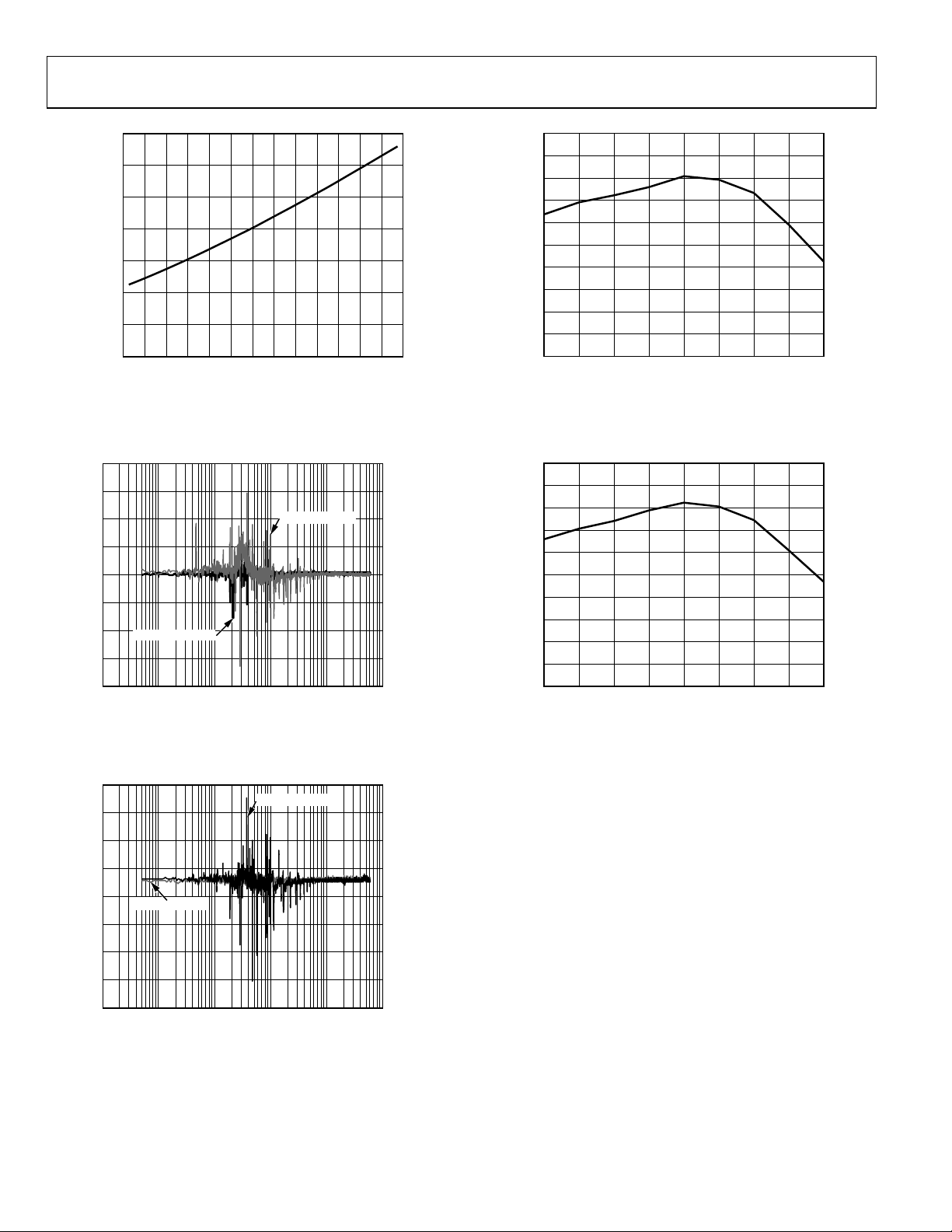

Page 8

ADT7467

7

6

5

4

(µA)

3

DD

I

2

1

0

3.0 3.8 5.23.4 4.43.6 4.83.2 4.0 5.44.6 5.04.2

POWER SUPPLY VOLTAGE (V)

04498-0-051

1.0

0.5

0

–0.5

–1.0

–1.5

–2.0

–2.5

TEMPERATURE ERROR (°C)

–3.0

–3.5

–4.0

TEMPERATURE (°C)

120–40 –20 0 20 40 60 80 100

04498-0-091

Figure 10. Shutdown I

vs. Power Supply

DD

20

15

10

5

0

–5

–10

TEMPERATURE ERROR (°C)

–15

–20

INT ERROR, 100mV

POWER SUPPLY NOISE FREQUENCY (kHz)

INT ERROR, 250mV

Figure 11. Internal Temperature Error vs. Power Supply

20

15

10

5

EXT ERROR, 250mV

Figure 13. Internal Temperature Error vs. ADT7467 Temperature

1.0

0.5

0

–0.5

–1.0

–1.5

–2.0

–2.5

TEMPERATURE ERROR (°C)

–3.0

–3.5

1G10 100 1M 10M 100M

04498-0-052

–4.0

TEMPERATURE (°C)

120–40 –20 0 20 40 60 80 100

04498-0-092

Figure 14. Remote Temperature Error vs. ADT7467 Temperature

0

EXT ERROR, 100mV

–5

–10

TEMPERATURE ERROR (°C)

–15

–20

POWER SUPPLY NOISE FREQUENCY (kHz)

1G10 100 1M 10M 100M

Figure 12. Remote Temperature Error vs. Power Supply Noise Frequency

04498-0-053

Rev. 0 | Page 8 of 80

Page 9

ADT7467

PRODUCT DESCRIPTION

The ADT7467 is a complete thermal monitor and multiple fan

controller for any system requiring thermal monitoring and

cooling. The device communicates with the system via a serial

system management bus. The serial bus controller has a serial

data line for reading and writing addresses and data (Pin 16),

and an input line for the serial clock (Pin 1). All control and

programming functions for the ADT7467 are performed over

the serial bus. In addition, a pin can be reconfigured as an

SMBALERT

output to signal out-of-limit conditions.

COMPARISON BETWEEN ADT7460 AND ADT7467

The ADT7467 is an upgrade to the ADT7460. The ADT7467

and ADT7460 are almost pin and register map compatible. The

ADT7467 and ADT7460 have the following differences:

1. On the ADT7467, the PWM drive signals can be config-

ured as either high frequency or low frequency drives. The

low frequency option is programmable between 10 Hz and

100 Hz. The high frequency option is 22.5 kHz. On the

ADT7460, only the low frequency option is available.

2. Once V

fan speeds is enabled on the ADT7467 when V

powered up, or if V

SMBus transaction with the ADT7467 is completed. On the

ADT7460, the STRT bit in Configuration Register 1 must

be set to enable monitoring.

3. The fans are switched off by default on power-up on the

ADT7467. On the ADT7460, the fans run at full speed on

power-up.

Fail-safe cooling is provided on the ADT7467 in that, if the

measured temperature exceeds the

the fans run at full speed.

is powered up, monitoring of temperature and

CC

is

CCP

is never powered up, when the first

CCP

THERM

limit (100°C),

5. The ADT7467 has an extended temperature measurement

range. The measurement range goes from–64°C to +191°C.

On the ADT7460, the measurement range is from −127°C

to +127°C. This means that the ADT7467 can measure

higher temperatures. The ADT7467 also includes the

ADT7460 temperature range; the temperature measurement range can be switched by setting Bit 0 of

Configuration Register 5.

6. The ADT7467 maximum fan speed (% duty cycle) in the

automatic fan speed control loop can be programmed. The

maximum fan speed is 100% duty cycle on the ADT7460

and is not programmable.

7. The offset register in the ADT7467 is programmable up to

±64°C with 0.50°C resolution. The offset register of the

ADT7460 is programmable up to ±32°C with 0.25°C

resolution.

8. V

is monitored on Pin 14 of the ADT7467 and can be

CCP

used to set the threshold for

V

). 2.5 V is monitored on Pin 14 of the ADT7460. The

CCP

threshold for

and V

THERM

= 0.8 V on the ADT7460.

IL

THERM

PROCHOT

(

PROCHOT

(

) is set at VIH = 1.7 V

) (2/3 of

9. On the ADT7460, Pin 14 could be reconfigured as SMBus

ALERT. This is not available on the ADT7467. SMBus

ALERT can be enabled instead on Pin 9.

10. A GPIO can also be made available on Pin 9 on the

ADT7467. This is not available on the ADT7460. Set the

GPIO polarity and direction in Configuration Register 5.

The GPIO status bit is Bit 5 of Status Register 2 (shared

with TACH4 and

THERM

, because only one can be

enabled at a time).

Fail-safe cooling is also provided 4.6 s after V

is powered

CCP

up. The fans go to full speed, if the ADT7467 has not been

addressed via the SMBus within 4.6 s of when the V

CCP

powered up. This protects the system in the event that the

SMBus fails. The ADT7467 can be programmed at any

time, either before or after the 4.6 s has elapsed, and it

behaves as programmed. If V

safe cooling is effectively disabled. If V

is never powered up, fail-

CCP

is disabled,

CCP

writing to the ADT7467 at any time causes the ADT7467 to

operate normally.

4. Series resistance cancellation (SRC) is provided on the

remote temperature channels on the ADT7467, but not on

the ADT7460. SRC automatically cancels linear offset

introduced by a series resistance between the thermal

diode and the sensor.

is

Rev. 0| Page 9 of 80

11. The ADT7460 has three possible SMBus addresses, which

are selectable using the address select and address enable

pins. The ADT7467 has one SMBus address available at

Address 0x2E.

Due to the inclusion of extra functionality, the register map has

changed, including an additional configuration register:

Configuration Register 5 at Address 0x7C.

Page 10

ADT7467

Configuration Register 5

Bit 0: If Bit 0 is set to 1, the ADT7467 is backward compatible

temperature-wise with the ADT7460. Measurements, T

calibration circuit, fan control, etc., work in the range −127°C to

+127°C. Also, care should be taken in reprogramming the

temperature limits (T

, operating point,

MIN

THERM

their desired twos complement value, because the power-on

default for them is at Offset 64. The extended temperature range

is −64°C to 191°C. The default is 1, which is in the −64°C to

+191°C temperature range.

Bit 1 = 0 is the high frequency (22.5 kHz) fan drive signal.

Bit 1 = 1 switches the fan drive to low frequency PWM,

programmable between 10 Hz and 100 Hz, the same as the

ADT7460. The default = 0 = HF PWM.

Bit 2 sets the direction for the GPIO: 0 = input, 1 = output.

Bit 3 sets the GPIO polarity: 0 = active low, 1 = active high.

How to Set the Functionality of Pin 9

Pin 9 on the ADT7467 has four possible functions:

THERM

, GPIO, and TACH4. The user chooses the required

functionality by setting Bit 0 and Bit 1 of Configuration

Register 4 at Address 0x7D.

MIN

limits) to

SMBALERT

Table 4. Pin 9 Settings

Bit 0 Bit 1 Function

00 TACH4

01

10

THERM

SMBALERT

11 GPIO

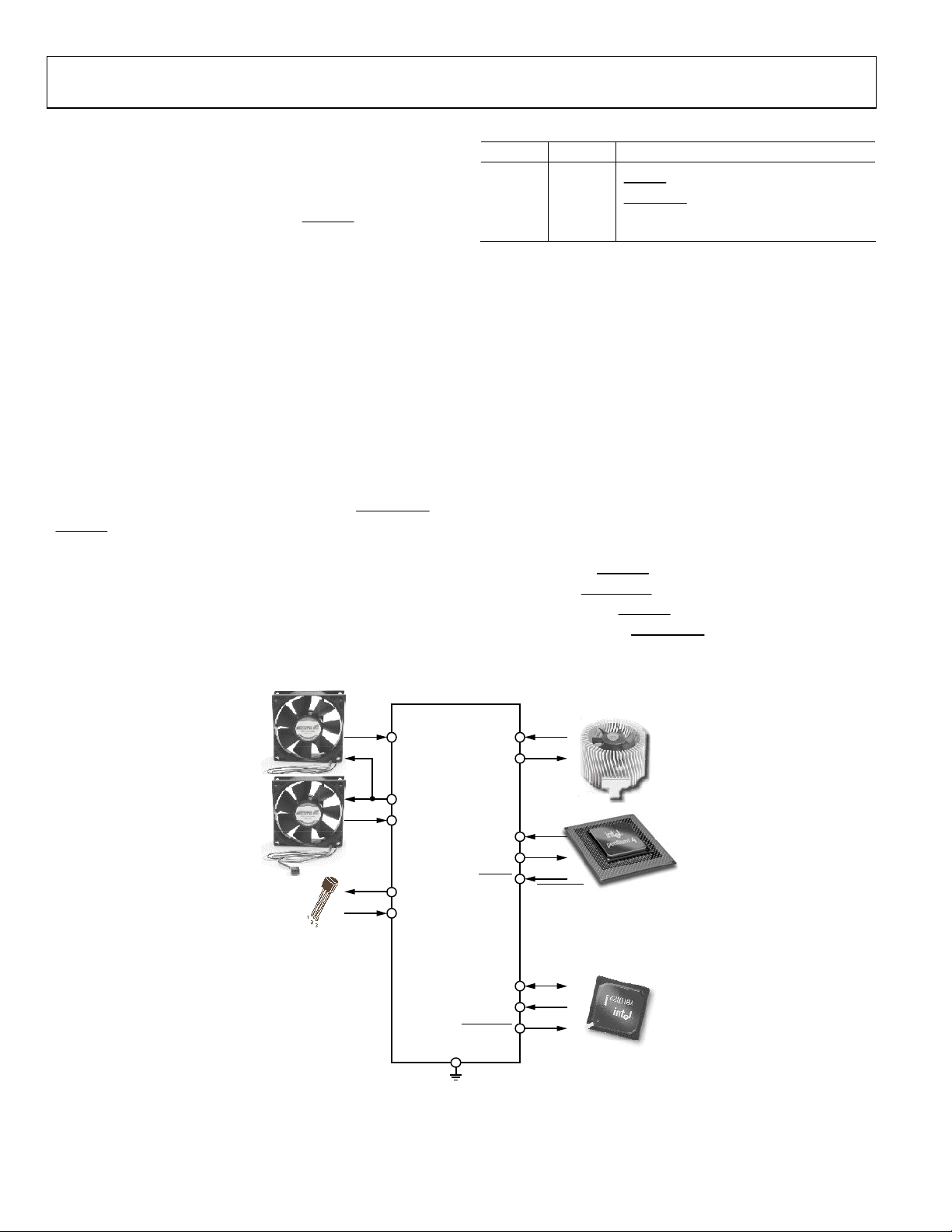

RECOMMENDED IMPLEMENTATION

Configuring the ADT7467 as in Figure 15 allows the system

designer to use the following features:

• Two PWM outputs for fan control of up to three fans (the

front and rear chassis fans are connected in parallel).

• Three TACH fan speed measurement inputs.

• V

• CPU temperature measured using Remote 1 temperature

,

• Ambient temperature measured through Remote 2

• Bidirectional

measured internally through Pin 3.

CC

channel.

temperature channel.

THERM

Pentium 4

PROCHOT

overtemperature

programmed as an

pin. This feature allows Intel

monitoring and can function as an

THERM

output. It can alternatively be

SMBALERT

system interrupt output.

FRONT

CHASSIS

FAN

REAR

CHASSIS

FAN

AMBIENT

TEMPERATURE

ADT7467

TACH2

PWM3

TACH3

D1+

D1–

Figure 15. ADT7467 Configuration

PWM1

TACH1

D2+

D2–

THERM

SDA

SCL

SMBALERT

GND

PROCHOT

CPU FAN

CPU

ICH

04498-0-004

Rev. 0 | Page 10 of 80

Page 11

ADT7467

SERIAL BUS INTERFACE

On PCs and servers, control of the ADT7467 is carried out

using the serial system management bus (SMBus). The

ADT7467 is connected to this bus as a slave device, under the

control of a master controller, which is usually (but not

necessarily) the ICH.

The ADT7467 has a fixed 7-bit serial bus address of 0101110 or

0x2E. The read/write bit must be added to get the 8-bit address

(01011100 or 0x5C). Data is sent over the serial bus in

sequences of nine clock pulses: eight bits of data followed by an

acknowledge bit from the slave device. Transitions on the data

line must occur during the low period of the clock signal and

remain stable during the high period, because a low-to-high

transition when the clock is high might be interpreted as a stop

signal. The number of data bytes that can be transmitted over

the serial bus in a single read or write operation is limited only

by what the master and slave devices can handle.

When all data bytes have been read or written, stop conditions

are established. In write mode, the master pulls the data line

high during the tenth clock pulse to assert a stop condition. In

read mode, the master device overrides the acknowledge bit by

pulling the data line high during the low period before the

ninth clock pulse. This is known as No Acknowledge. The

master then takes the data line low during the low period before

the tenth clock pulse, and then high during the tenth clock

pulse to assert a stop condition.

Any number of bytes of data can be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined at

the beginning and cannot subsequently be changed without

starting a new operation.

In the ADT7467, write operations contain either one or two

bytes, and read operations contain one byte and perform the

following functions. To write data to one of the device data

registers or read data from it, the address pointer register must

be set so that the correct data register is addressed, then data

can be written into that register or read from it. The first byte of

a write operation always contains an address that is stored in the

address pointer register. If data is to be written to the device,

then the write operation contains a second data byte that is

written to the register selected by the address pointer register.

This write operation is illustrated in Figure 16. The device

W

address is sent over the bus, and then R/

is set to 0. This is

followed by two data bytes. The first data byte is the address of

the internal data register to be written to, which is stored in the

address pointer register. The second data byte is the data to be

written to the internal data register.

When reading data from a register, there are two possibilities:

• If the ADT7467’s address pointer register value is unknown

or not the desired value, it must first be set to the correct

value before data can be read from the desired data register.

This is done by performing a write to the ADT7467 as

before, but only the data byte containing the register

address is sent, because no data is written to the register.

This is shown in Figure 17.

A read operation is then performed consisting of the serial

W

bus address, R/

bit set to 1, followed by the data byte read

from the data register. This is shown in Figure 18.

• If the address pointer register is known to be already at the

desired address, data can be read from the corresponding

data register without first writing to the address pointer

register, as shown in Figure 18.

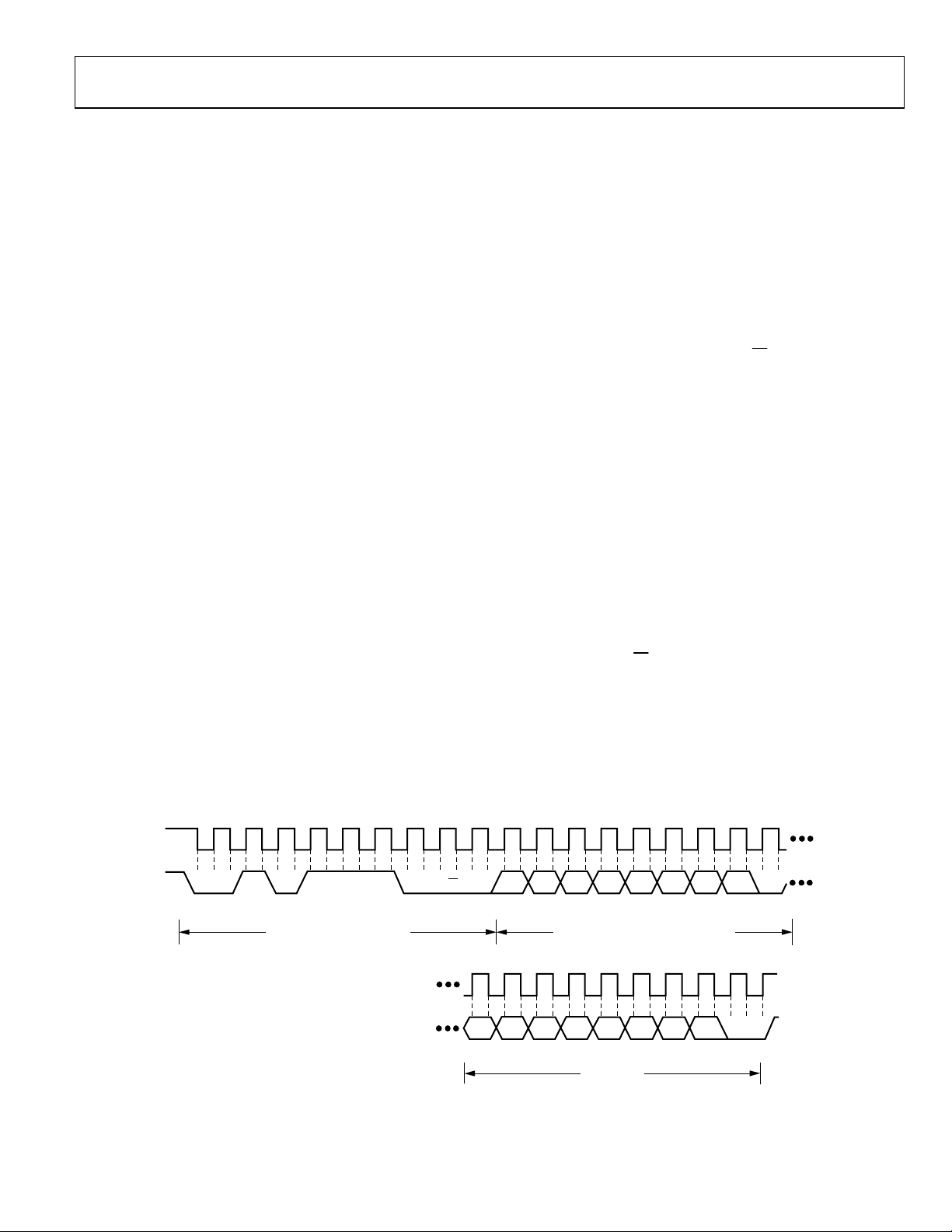

SCL

SDA

START BY

MASTER

19

0

1011

FRAME 1

SERIAL BUS ADDRESS BYTE

SCL (CONTINUED)

SDA (CONTINUED)

Figure 16. Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

0

1

R/W

ACK. BY

ADT7467

Rev. 0| Page 11 of 80

1

D6

D7

1

D7

D5

D6

D4

D5

ADDRESS POINTER REGISTER BYTE

D4

D3

FRAME 3

DATA BYTE

D3

FRAME 2

D2

D2

D1

D0

9

D1

D0

ACK. BY

ADT7467

9

ACK. BY

ADT7467

STOP BY

MASTER

04498-0-005

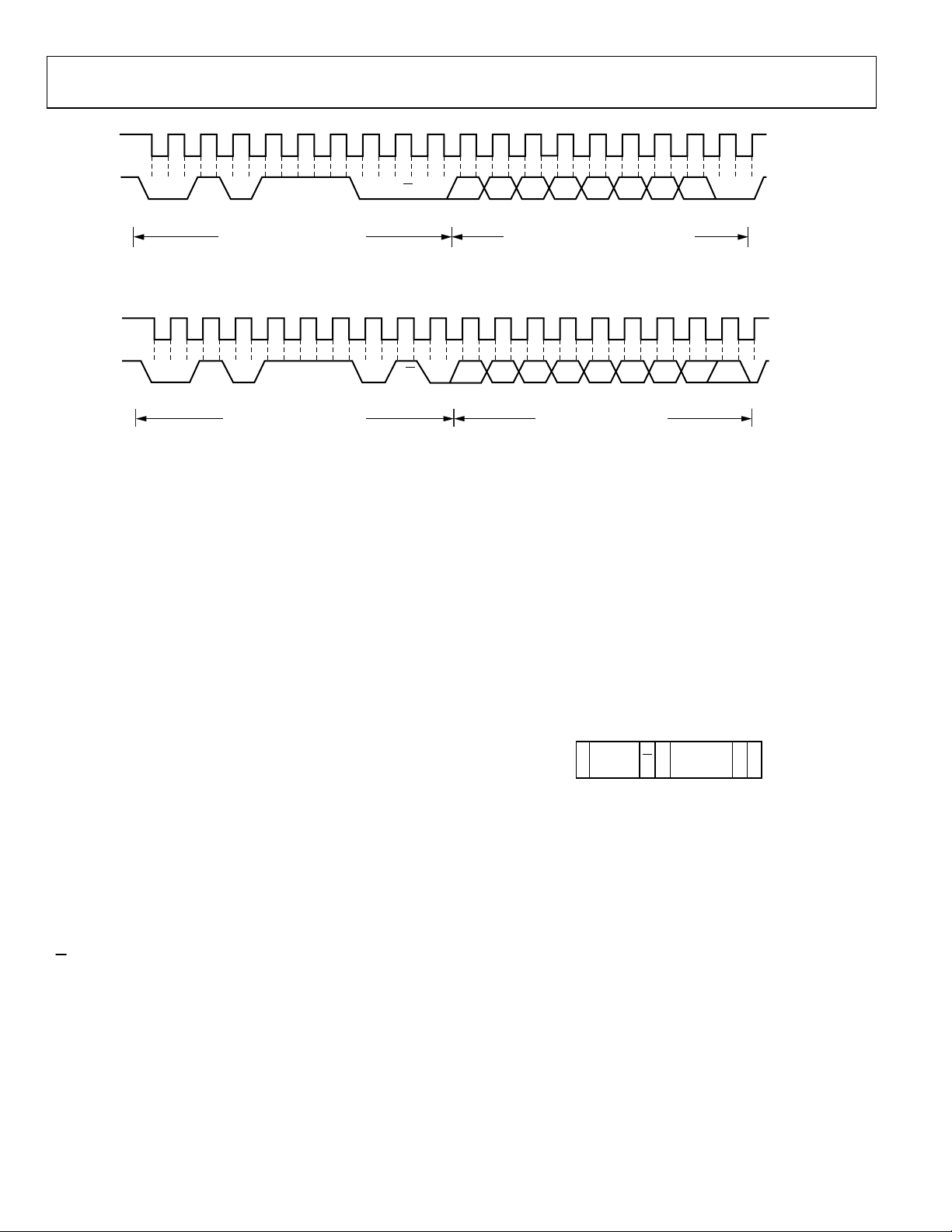

Page 12

ADT7467

SDA

SCL

SDA

START BY

MASTER

1

0

10

1

FRAME 1

SERIAL BUS ADDRESS BYTE

1

0

1

R/W

ACK. BY

ADT7467

Figure 17. Writing to the Address Pointer Register Only

1

SCL

0

START BY

MASTER

10

SERIAL BUS ADDRESS BYTE

1

FRAME 1

1

0

1

R/W

ACK. BY

ADT7467

Figure 18. Reading Data from a Previously Selected Register

It is possible to read a data byte from a data register without

first writing to the address pointer register, if the address

pointer register is already at the correct value. However, it is not

possible to write data to a register without writing to the address

pointer register, because the first data byte of a write is always

written to the address pointer register.

In addition to supporting the send byte and receive byte

protocols, the ADT7467 also supports the read byte protocol.

(See System Management Bus Specifications Rev. 2 for more

information. This document is available from Intel.)

If several read or write operations must be performed in

succession, the master can send a repeat start condition instead

of a stop condition to begin a new operation.

WRITE OPERATIONS

The SMBus specification defines several protocols for different

types of read and write operations. The ones used in the

ADT7467 are discussed below. The following abbreviations are

used in the diagrams:

S – START

P – STOP

R – READ

W – WRITE

A – ACKNOWLEDGE

A

– NO ACKNOWLEDGE

D0

9

ACK. BY

ADT7467

STOP BY

MASTER

19

D6

D7

D4

D5

ADDRESS POINTER REGISTER BYTE

D3

FRAME 2

D2

D1

19

D6

D7

D4

D5

DATA BYTE FROM ADT7467

D3

FRAME 2

D2

D1

9

D0

NO ACK. BY

MASTER

STOP BY

MASTER

2. The master sends the 7-bit slave address followed by the

write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

5. The slave asserts ACK on SDA.

6. The master asserts a stop condition on SDA and the

transaction ends.

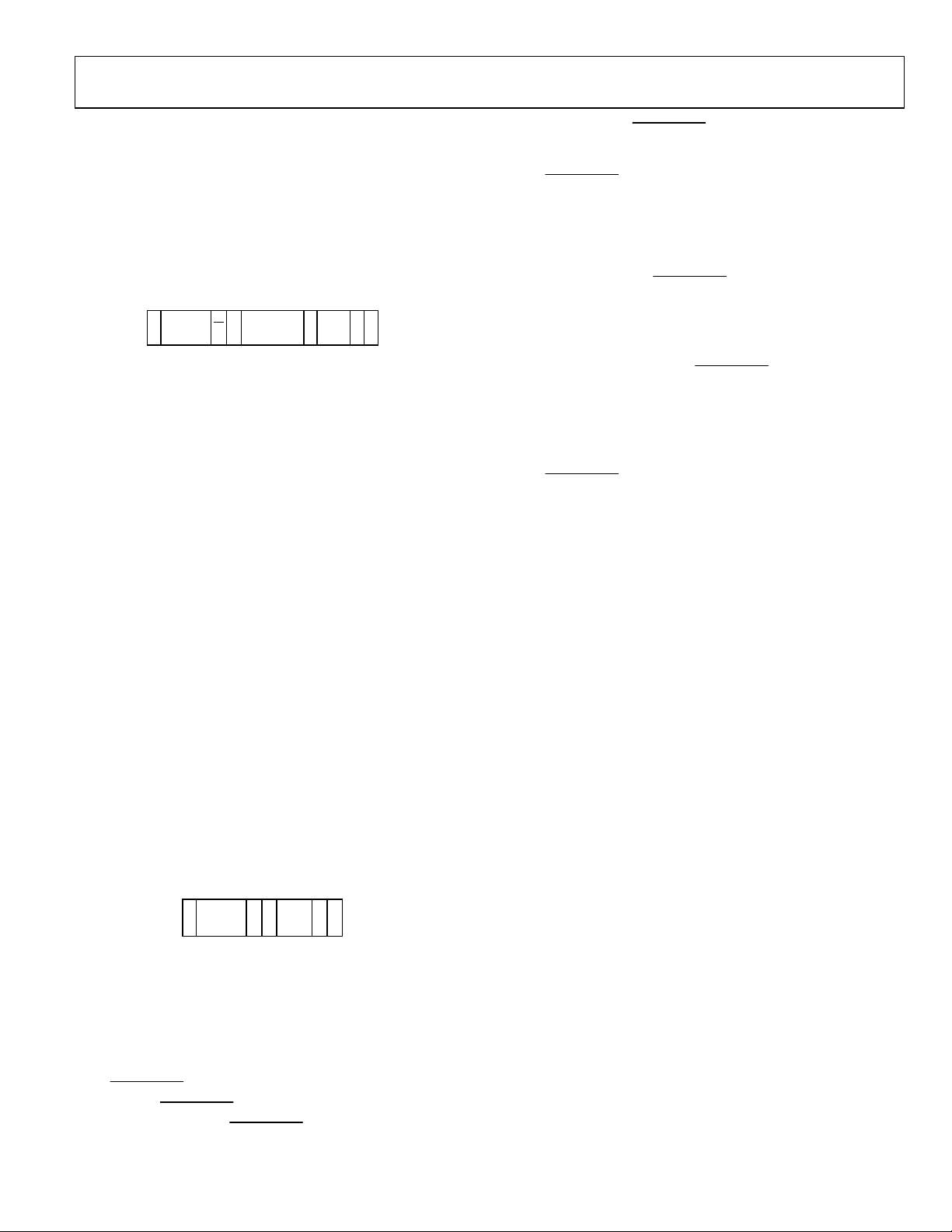

For the ADT7467, the send byte protocol is used to write a

register address to RAM for a subsequent single byte read from

the same address. This operation is illustrated in Figure 19.

231564

SLAVE

ADDRESS

REGISTER

WASAP

ADDRESS

04498-0-008

Figure 19. Setting a Register Address for Subsequent Read

If the master is required to read data from the register

immediately after setting up the address, it can assert a repeat

start condition immediately after the final ACK and carry out a

single byte read without asserting an intermediate stop

condition.

Write Byte

In this operation, the master device sends a command byte and

one data byte to the slave device, as follows:

04498-0-006

04498-0-007

The ADT7467 uses the following SMBus write protocols.

Send Byte

In this operation, the master device sends a single command

byte to a slave device as follows:

1. The master device asserts a start condition on SDA.

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by the

write bit (low).

3. The addressed slave device asserts ACK on SDA.

4. The master sends a command code.

Rev. 0 | Page 12 of 80

Page 13

ADT7467

5. The slave asserts ACK on SDA.

6. The master sends a data byte.

7. The slave asserts ACK on SDA.

8. The master asserts a stop condition on SDA to end the

transaction.

This operation is illustrated in Figure 20.

24653178

SLAVE

ADDRESS

Figure 20. Single Byte Write to a Register

SLAVE

ADDRESS

DATAAAWSAP

04498-0-009

READ OPERATIONS

The ADT7467 uses the following SMBus read protocols.

Receive Byte

This operation is useful when repeatedly reading a single

register. The register address must have been set up previously.

In this operation, the master device receives a single byte from a

slave device, as follows:

1. The master device asserts a start condition on SDA.

2. The master sends the 7-bit slave address followed by the

read bit (high).

3. The addressed slave device asserts ACK on SDA.

4. The master receives a data byte.

5. The master asserts NO ACK on SDA.

6. The master asserts a stop condition on SDA and the

transaction ends.

In the ADT7467, the receive byte protocol is used to read a

single byte of data from a register whose address has previously

been set by a send byte or write byte operation. This operation

is illustrated in Figure 21.

213564

SLAVE

SRAAPDATA

ADDRESS

Figure 21. Single Byte Read from a Register

Alert Response Address

Alert response address (ARA) is a feature of SMBus devices that

allows an interrupting device to identify itself to the host when

multiple devices exist on the same bus.

SMBALERT

The

output or an

connected to a common

output can be used as either an interrupt

SMBALERT

. One or more outputs can be

SMBALERT

line connected to the

04498-0-010

master. If a device’s

procedure occurs:

SMBALERT

1.

2. The master initiates a read operation and sends the alert

response address (ARA = 0001 100). This is a general call

address that must not be used as a specific device address.

3. The device whose

the alert response address, and the master reads its device

address. The address of the device is now known and can

be interrogated in the usual way.

4. If more than one device’s

one with the lowest device address has priority in accordance with normal SMBus arbitration.

5. Once the ADT7467 has responded to the alert response

address, the master must read the status registers and the

SMBALERT

away.

SMBUS TIMEOUT

The ADT7467 includes an SMBus timeout feature. If there is no

SMBus activity for 35 ms, the ADT7467 assumes that the bus is

locked and releases the bus. This prevents the device from

locking or holding the SMBus expecting data. Some SMBus

controllers cannot handle the SMBus timeout feature, so it can

be disabled.

Configuration Register 1(Reg. 0x40)

<6> TODIS = 0, SMBus timeout enabled (default).

<6> TODIS = 1, SMBus timeout disabled.

VOLTAGE MEASUREMENT INPUT

The ADT7467 has one external voltage measurement channel. It

can also measure its own supply voltage, V

ure V

. The VCC supply voltage measurement is carried out

CCP

through the V

Register 1 (Reg. 0x40) allows a 5 V supply to power the

ADT7467 and be measured without overranging the V

measurement channel. The V

chipset supply voltage in computer systems.

ANALOG-TO-DIGITAL CONVERTER

All analog inputs are multiplexed into the on-chip, successive

approximation, analog-to-digital converter. This has a resolution of 10 bits. The basic input range is 0 V to 2.25 V, but the

input has built-in attenuators to allow measurement of V

without any external components. To allow for the tolerance of

the supply voltage, the ADC produces an output of 3/4 full scale

(decimal 768 or 300 hex) for the nominal input voltage and so

has adequate headroom to deal with overvoltages.

SMBALERT

line goes low, the following

is pulled low.

SMBALERT

output is low responds to

SMBALERT

output is low, the

is cleared only if the error condition has gone

. Pin 14 can meas-

CC

pin (Pin 3). Setting Bit 7 of Configuration

CC

CC

input can be used to monitor a

CCP

CCP

Rev. 0| Page 13 of 80

Page 14

ADT7467

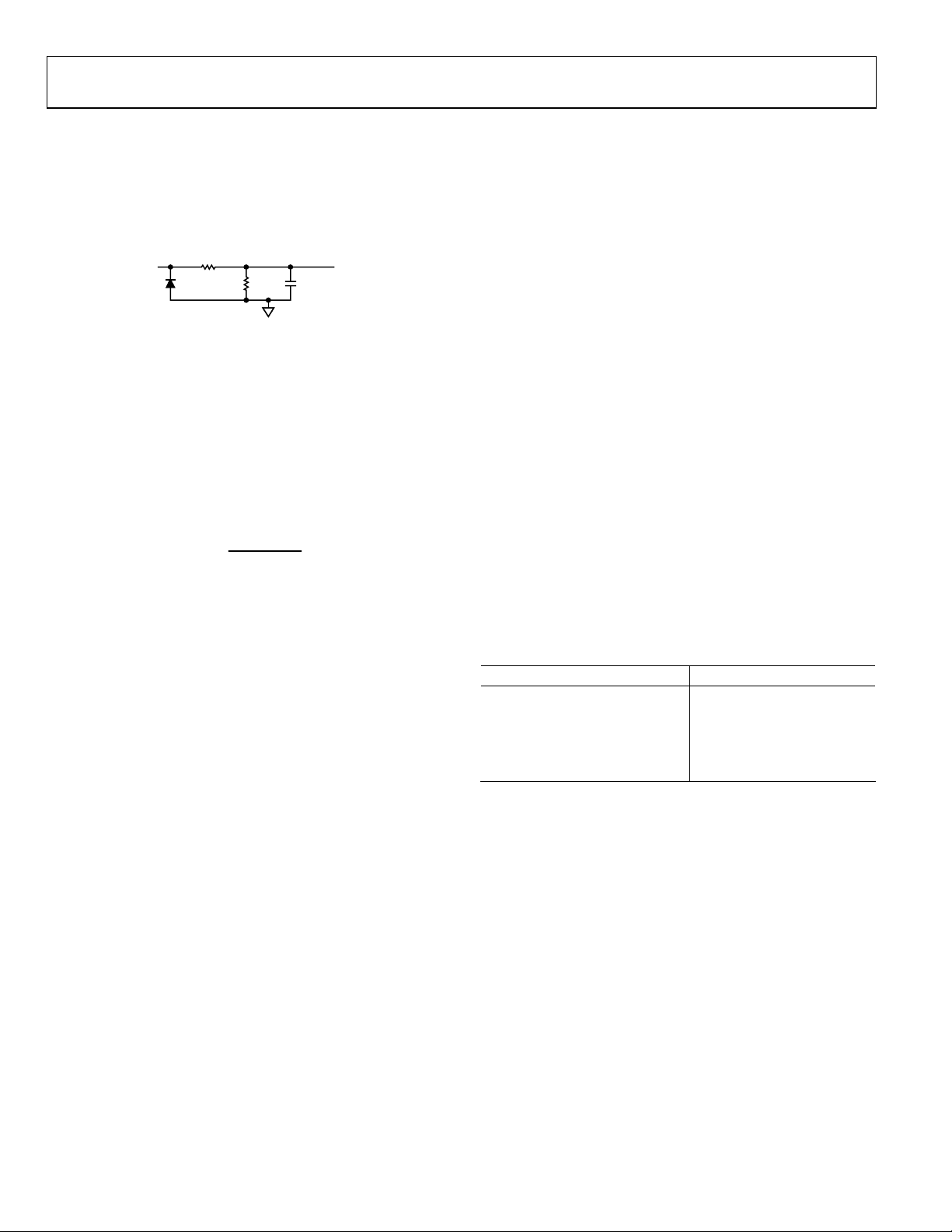

INPUT CIRCUITRY

The internal structure for the V

Figure 22. The input circuit consists of an input protection

diode, an attenuator, plus a capacitor to form a first-order lowpass filter that gives the input immunity to high frequency

noise.

V

CCP

17.5kΩ

Figure 22. Structure of Analog Inputs

VOLTAGE MEASUREMENT REGISTERS

Reg. 0x21 V

Reg. 0x22 V

V

LIMIT REGISTERS

CCP

Associated with the V

high and low limit register. Exceeding the programmed high or

low limit causes the appropriate status bit to be set. Exceeding

either limit can also generate

Reg. 0x46 V

Reg. 0x47 V

Reg. 0x48 VCC Low Limit = 0x00 default

Reg. 0x49 VCC High Limit = 0xFF default

Table 5 shows the input ranges of the analog inputs and output

codes of the 10-bit ADC.

When the ADC is running, it samples and converts a voltage

input in 0.7 ms and averages 16 conversions to reduce noise; a

measurement takes nominally 11 ms.

Reading = 0x00 default

CCP

Reading = 0x00 default

CC

and VCC measurement channels is a

CCP

Low Limit = 0x00 default

CCP

High Limit = 0xFF default

CCP

analog input is shown in

CCP

52.5kΩ 35pF

SMBALERT

interrupts.

04498-0-011

ADDITIONAL ADC FUNCTIONS FOR VOLTAGE MEASUREMENTS

A number of other functions are available on the ADT7467 to

offer the system designer increased flexibility.

Turn-Off Averaging

For each voltage measurement read from a value register,

16 readings have actually been made internally and the results

averaged before being placed into the value register. For

instances where faster conversions are needed, setting Bit 4 of

Configuration Register 2 (Reg. 0x73) turns averaging off. This

effectively gives a reading 16 times faster (0.7 ms), but the

reading may be noisier.

Bypass Voltage Input Attenuator

Setting Bit 5 of Configuration Register 2 (Reg. 0x73) removes

the attenuation circuitry from the V

user to directly connect external sensors or to rescale the analog

voltage measurement inputs for other applications. The input

range of the ADC without the attenuators is 0 V to 2.25 V.

Single-Channel ADC Conversion

Setting Bit 6 of Configuration Register 2 (Reg. 0x73) places the

ADT7467 into single-channel ADC conversion mode. In this

mode, the ADT7467 can be made to read a single voltage

channel only. If the internal ADT7467 clock is used, the selected

input is read every 0.7 ms. The appropriate ADC channel is

selected by writing to Bits <7:5> of the TACH1 minimum high

byte register (0x55).

Bits <7:5> Reg. 0x55 Channel Selected

001 V

010 V

101 Remote 1 Temperature

110 Local Temperature

111 Remote 2 Temperature

Configuration Register 2 (Reg. 0x73)

<4> = 1, averaging off.

input. This allows the

CCP

CCP

CC

<5> = 1, bypass input attenuators.

<6> = 1, single-channel convert mode.

TACH1 Minimum High Byte (Reg. 0x55)

<7:5> selects ADC channel for single-channel convert mode.

Rev. 0 | Page 14 of 80

Page 15

ADT7467

Table 5. 10-Bit A/D Output Code vs. VIN

Input Voltage A/D Output

VCC (+5 VIN) V

<0.0065 <0.0042 <0.00293 0 00000000 00

0.0065–0.0130 0.0042–0.0085 0.0293–0.0058 1 00000000 01

0.0130–0.0195 0.0085–0.0128 0.0058–0.0087 2 00000000 10

0.0195–0.0260 0.0128–0.0171 0.0087–0.0117 3 00000000 11

0.0260–0.0325 0.0171–0.0214 0.0117–0.0146 4 00000001 00

0.0325–0.0390 0.0214–0.0257 0.0146–0.0175 5 00000001 01

0.0390–0.0455 0.0257–0.0300 0.0175–0.0205 6 00000001 10

0.0455–0.0521 0.0300–0.0343 0.0205–0.0234 7 00000001 11

0.0521–0.0586 0.0343–0.0386 0.0234–0.0263 8 00000010 00

•

•

•

1.6675–1.6740 1.100–1.1042 0.7500–0.7529 256 (1/4-scale) 01000000 00

•

•

•

3.330–3.3415 2.200–2.2042 1.5000–1.5029 512 (1/2-scale) 10000000 00

•

•

•

5.0025–5.0090 3.300–3.3042 2.2500–2.2529 768 (3/4 scale) 11000000 00

•

•

•

6.5983–6.6048 4.3527–4.3570 2.9677–2.9707 1013 11111101 01

6.6048–6.6113 4.3570–4.3613 2.9707–2.9736 1014 11111101 10

6.6113–6.6178 4.3613–4.3656 2.9736–2.9765 1015 11111101 11

6.6178–6.6244 4.3656–4.3699 2.9765–2.9794 1016 11111110 00

6.6244–6.6309 4.3699–4.3742 2.9794–2.9824 1017 11111110 01

6.6309–6.6374 4.3742–4.3785 2.9824–2.9853 1018 11111110 10

6.6374–6.4390 4.3785–4.3828 2.9853–2.9882 1019 11111110 11

6.6439–6.6504 4.3828–4.3871 2.9882–2.9912 1020 11111111 00

6.6504–6.6569 4.3871–4.3914 2.9912–2.9941 1021 11111111 01

6.6569–6.6634 4.3914–4.3957 2.9941–2.9970 1022 11111111 10

>6.6634 >4.3957 >2.9970 1023 11111111 11

(3.3 VIN) V

CC

Decimal Binary (10 Bits)

CCP

TEMPERATURE MEASUREMENT METHOD

A simple method of measuring temperature is to exploit the

negative temperature coefficient of a diode, measuring the baseemitter voltage (V

current. Unfortunately, this technique requires calibration to

null out the effect of the absolute value of V

from device to device.

The technique used in the ADT7467 is to measure the change in

when the device is operated at three different currents.

V

BE

Previous devices have used only two operating currents, but the

use of a third current allows automatic cancellation of

resistances in series with the external temperature sensor.

) of a transistor, operated at constant

BE

, which varies

BE

Rev. 0| Page 15 of 80

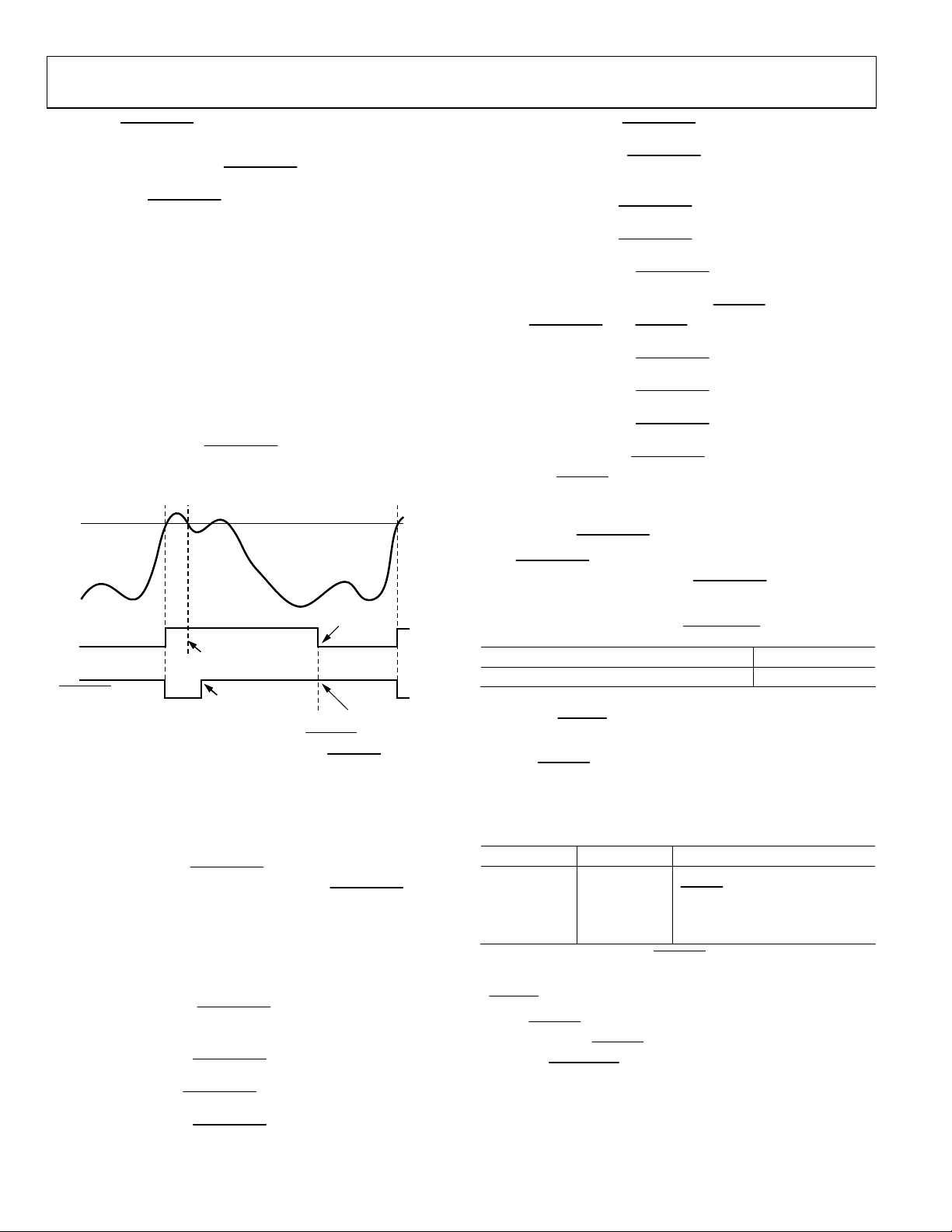

Figure 24 shows the input signal conditioning used to measure

the output of an external temperature sensor. This figure shows

the external sensor as a substrate transistor, but it could equally

be a discrete transistor. If a discrete transistor is used, the

collector is not grounded and should be linked to the base. To

prevent ground noise from interfering with the measurement,

the more negative terminal of the sensor is not referenced to

ground, but is biased above ground by an internal diode at the

D− input. C1 can optionally be added as a noise filter

(recommended maximum value 1000 pF). However, a better

option in noisy environments is to add a filter, as described in

the Noise Filtering section.

Page 16

ADT7467

Local Temperature Measurement

The ADT7467 contains an on-chip band gap temperature

sensor whose output is digitized by the on-chip 10-bit ADC.

The 8-bit MSB temperature data is stored in the local temperature register (Address 26h). Because both positive and negative

temperatures can be measured, the temperature data is stored in

Offset 64 format or twos complement format, as shown in

Table 6 and Table 7. Theoretically, the temperature sensor and

ADC can measure temperatures from −128°C to +127°C (or

−61°C to +191°C in the extended temperature range) with a

resolution of 0.25°C. However, this exceeds the operating

temperature range of the device, so local temperature

measurements outside the ADT7467 operating temperature

range are not possible.

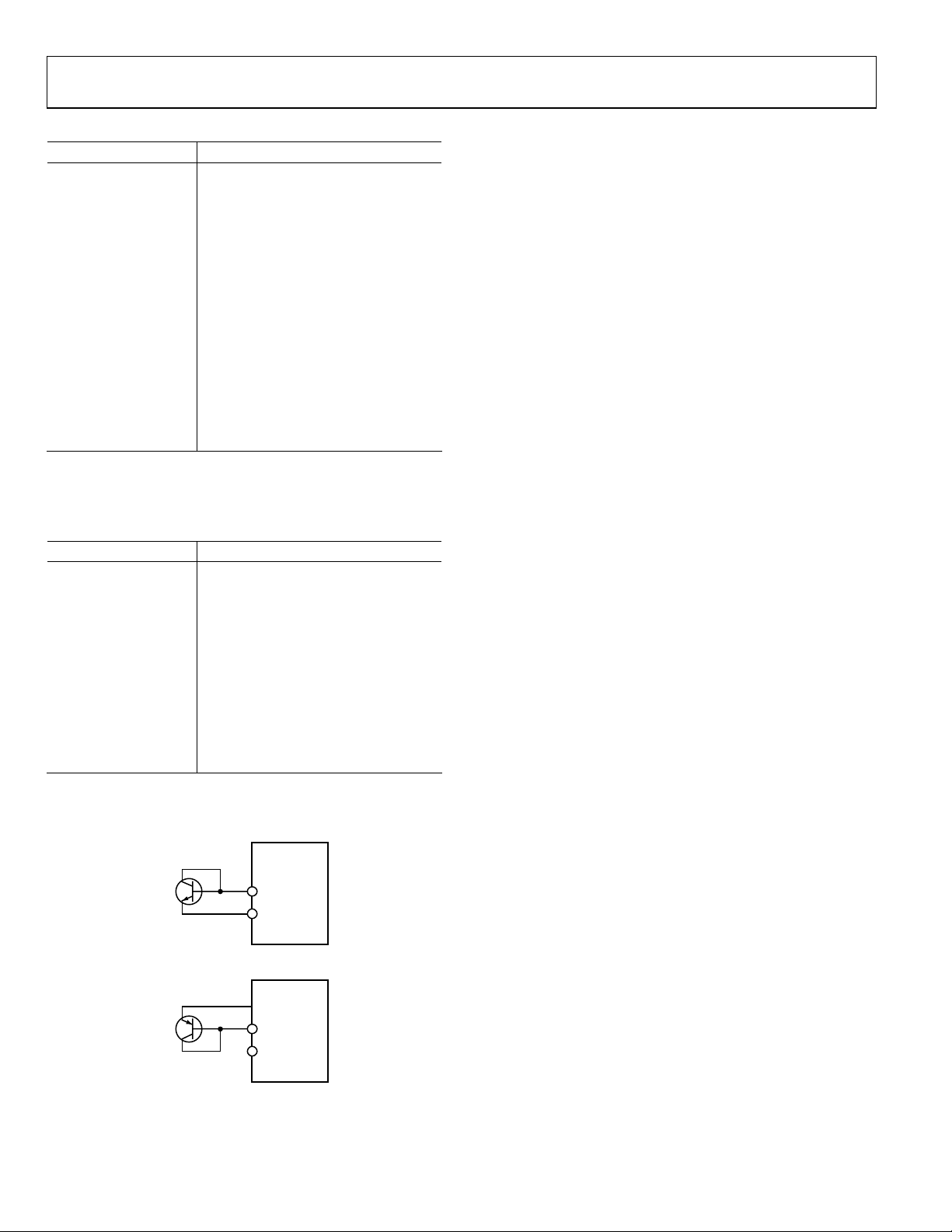

Remote Temperature Measurement

The ADT7467 can measure the temperature of two remote

diode sensors or diode-connected transistors connected to

Pins 10 and 11, or 12 and 13.

If a discrete transistor is used, the collector is not grounded and

should be linked to the base. If a PNP transistor is used, the base

is connected to the D– input and the emitter to the D+ input. If

an NPN transistor is used, the emitter is connected to the D–

input and the base to the D+ input. Figure 25 and Figure 26

show how to connect the ADT7467 to an NPN or PNP

transistor for temperature measurement. To prevent ground

noise from interfering with the measurement, the more negative

terminal of the sensor is not referenced to ground, but is biased

above ground by an internal diode at the D– input.

To m e as u re

V

, the operating current through the sensor is

BE

switched among three related currents. Shown in Figure 23,

N1 × I and N2 × I are different multiples of the current I. The

currents through the temperature diode are switched between

I and N1 × I, giving

giving

V

BE2

V

two

measurements. This method can also cancel the effect

BE

V

, and then between I and N2 × I,

BE1

. The temperature can then be calculated using the

of any series resistance on the temperature measurement.

The forward voltage of a diode or diode-connected transistor

operated at a constant current exhibits a negative temperature

coefficient of about –2 mV/°C. Unfortunately, the absolute value

varies from device to device and individual calibration is

of V

BE

required to null this out, so the technique is unsuitable for mass

production. The technique used in the ADT7467 is to measure

the change in V

when the device is operated at three different

BE

currents. This is given by

()

NnqKTV

BE

1/ ×=∆

where:

K is Boltzmann’s constant.

q is the charge on the carrier.

T is the absolute temperature in Kelvin.

N is the ratio of the two currents.

Figure 23 shows the input signal conditioning used to measure

the output of a remote temperature sensor. This figure shows

the external sensor as a substrate transistor, provided for

temperature monitoring on some microprocessors. It could also

be a discrete transistor such as a 2N3904/2N3906.

V

N2 × IIN1× II

BIAS

DD

The resulting ∆V

waveforms are passed through a 65 kHz

BE

low-pass filter to remove noise and then to a chopper-stabilized

amplifier. This amplifies and rectifies the waveform to produce

a dc voltage proportional to ∆V

. The ADC digitizes this

BE

voltage, and a temperature measurement is produced. To reduce

the effects of noise, digital filtering is performed by averaging

the results of 16 measurement cycles.

The results of remote temperature measurements are stored in

10-bit, twos complement format, as listed in Table 6. The extra

resolution for the temperature measurements is held in the

Extended Resolution Register 2 (Reg. 0x77). This gives

temperature readings with a resolution of 0.25°C.

Noise Filtering

For temperature sensors operating in noisy environments,

previous practice was to place a capacitor across the D+ and D−

pins to help combat the effects of noise. However, large capacitances affect the accuracy of the temperature measurement,

leading to a recommended maximum capacitor value of 1000 pF.

This capacitor reduces the noise, but does not eliminate it, making

use of the sensor difficult in a very noisy environment.

REMOTE

SENSING

TRANSISTOR

D+

D–

Figure 23. Signal Conditioning for Remote Diode Temperature Sensors

LPF

fC = 65kHz

V

OUT+

TO ADC

V

OUT–

04498-0-012

Rev. 0 | Page 16 of 80

Page 17

ADT7467

T

The ADT7467 has a major advantage over other devices for

eliminating the effects of noise on the external sensor. Using the

series resistance cancellation feature, a filter can be constructed

between the external temperature sensor and the part. The effect

of any filter resistance seen in series with the remote sensor is

automatically canceled from the temperature result.

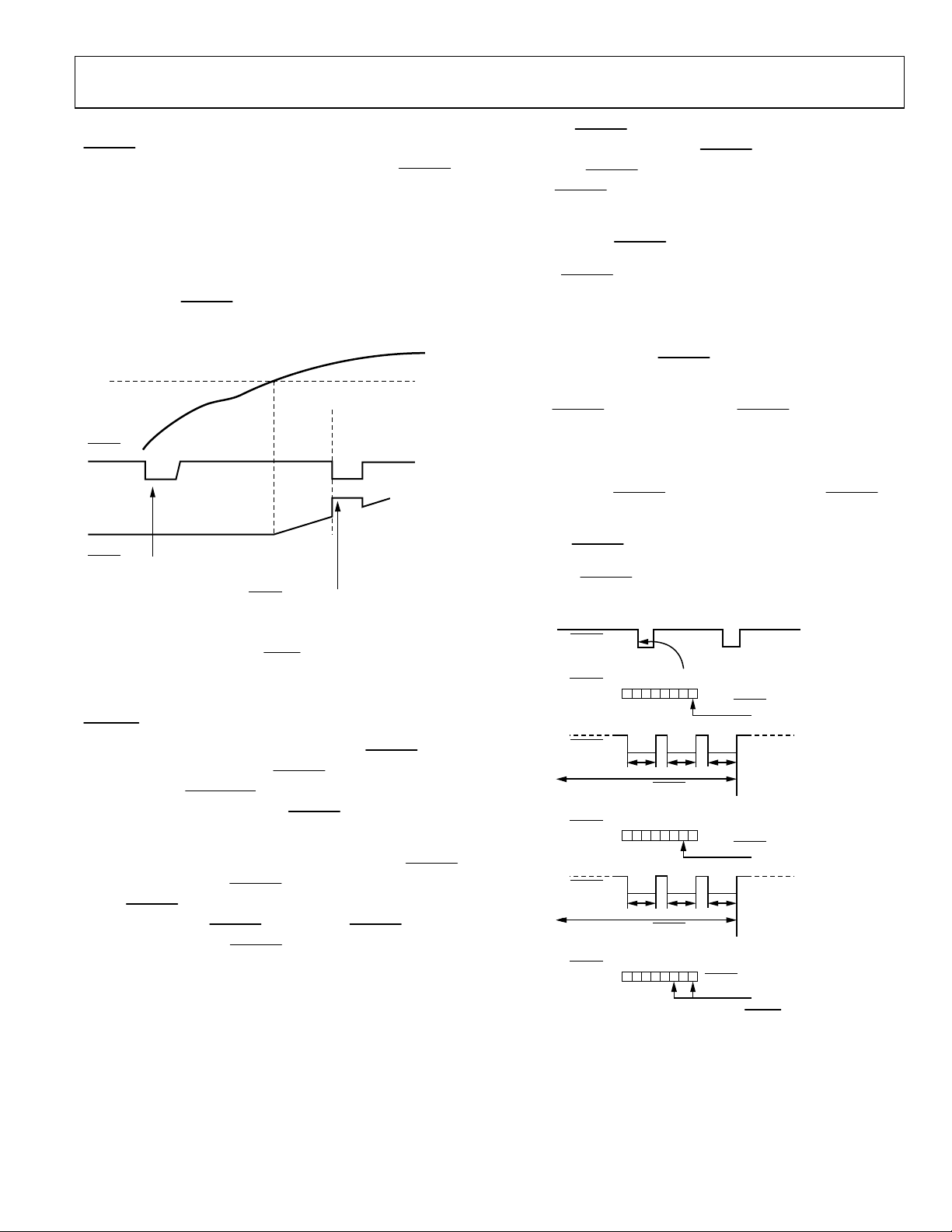

The construction of a filter allows the ADT7467 and the remote

temperature sensor to operate in noisy environments. Figure 24

shows a low-pass R-C-R filter, with the following values:

R = 100 Ω, C = 1 nF

This filtering reduces both common-mode noise and

differential noise.

100Ω

REMOTE

EMPERATURE

SENSOR

Figure 24. Filter between Remote Sensor and ADT7467

100Ω

1nF

D+

D–

04498-0-093

SERIES RESISTANCE CANCELLATION

Parasitic resistance to the ADT7467 D+ and D− inputs (seen in

series with the remote diode) is caused by a variety of factors

including PCB track resistance and track length. This series

resistance appears as a temperature offset in the remote sensor’s

temperature measurement. This error typically causes a 0.5°C

offset per 1 Ω of parasitic resistance in series with the remote

diode.

The ADT7467 automatically cancels out the effect of this series

resistance on the temperature reading, giving a more accurate

result without the need for user characterization of this

resistance. The ADT7467 is designed to automatically cancel,

typically, up to 3 kΩ of resistance. By using an advanced

temperature measurement method, this is transparent to the

user. This feature allows resistances to be added to the sensor

path to produce a filter, allowing the part to be used in noisy

environments. See the Noise Filtering section for details.

FACTORS AFFECTING DIODE ACCURACY

Remote Sensing Diode

The ADT7467 is designed to work with either substrate

transistors built into processors or discrete transistors. Substrate

transistors are generally PNP types with the collector connected

to the substrate. Discrete types can be either PNP or NPN

transistors connected as a diode (base-shorted to the collector).

If an NPN transistor is used, the collector and base are

connected to D+ and the emitter is connected to D−. If a PNP

transistor is used, the collector and base are connected to D−

and the emitter is connected to D+.

To reduce the error due to variations in both substrate and

discrete transistors, a number of factors should be taken into

consideration:

The ideality factor, n

•

, of the transistor is a measure of the

f

deviation of the thermal diode from ideal behavior. The

ADT7467 is trimmed for an n

value of 1.008. Use the

f

following equation to calculate the error introduced at a

temperature T (°C), when using a transistor whose n

not equal 1.008. See the processor data sheet for the n

does

f

f

values.

T = (n

− 1.008)/1.008 × (273.15 K + T)

f

To factor this in, the user can write the ∆T value to the

offset register. The ADT7467 then automatically adds it to

or subtracts it from the temperature measurement.

Some CPU manufacturers specify the high and low current

•

levels of the substrate transistors. The high current level of

the ADT7467, I

, is 96 µA and the low level current, I

HIGH

LOW

is 6 µA. If the ADT7467 current levels do not match the

current levels specified by the CPU manufacturer, it might

be necessary to remove an offset. The CPU’s data sheet

advises whether this offset needs to be removed and how to

calculate it. This offset can be programmed to the offset

register. It is important to note that, if more than one offset

must be considered, the algebraic sum of these offsets must

be programmed to the offset register.

If a discrete transistor is used with the ADT7467, the best

accuracy is obtained by choosing devices according to the

following criteria:

•

Base-emitter voltage greater than 0.25 V at 6 µA, at the

highest operating temperature.

Base-emitter voltage less than 0.95 V at 100 µA, at the

•

lowest operating temperature.

•

Base resistance less than 100 Ω.

Small variation in h

•

control of V

BE

(say 50 to 150) that indicates tight

FE

characteristics.

Transistors, such as 2N3904, 2N3906, or equivalents in SOT-23

packages, are suitable devices to use.

,

Rev. 0| Page 17 of 80

Page 18

ADT7467

Table 6. Temperature Data Format

Temperature Digital Output (10-Bit)1

–128°C

–125°C

–100°C

–75°C

–50°C

–25°C

–10°C

0°C

10.25°C

25.5°C

50.75°C

75°C

100°C

125°C

127°C

1

Bold numbers denote 2 LSB of measurement in Extended Resolution

Register 2 (Reg. 0x77) with 0.25°C resolution.

Table 7. Extended Range, Temperature Data Format

Temperature Digital Output (10-Bit)1

–64°C

–1°C

0°C

1°C

10°C

25°C

50°C

75°C

100°C

125°C

191°C

1

Bold numbers denote 2 LSB of measurement in Extended Resolution

Register 2 (Reg. 0x77) with 0.25°C resolution.

2N3904

NPN

Figure 25. Measuring Temperature Using an NPN Transistor

2N3906

PNP

Figure 26. Measuring Temperature Using a PNP Transistor

1000 0000 00

1000 0011 00

1001 1100 00

1011 0101 00

1100 1110 00

1110 0111 00

1111 0110 00

0000 0000 00

0000 1010 01

0001 1001 10

0011 0010 11

0100 1011 00

0110 0100 00

0111 1101 00

0111 1111 00

0000 0000 00

0011 1111 00

0100 0000 00

0100 0001 00

0100 1010 00

0101 1001 00

0111 0010 00

1000 1001 00

1010 0100 00

1011 1101 00

1111 1111 00

ADT7467

D+

D–

ADT7467

D+

D–

04498-0-013

04498-0-014

Nulling Out Temperature Errors

As CPUs run faster, it is getting more difficult to avoid high

frequency clocks when routing the D+/D– traces around a

system board. Even when recommended layout guidelines are

followed, some temperature errors may still be attributable to

noise coupled onto the D+/D– lines. Constant high frequency

noise usually attenuates or increases temperature measurements

by a linear, constant value.

The ADT7467 has temperature offset registers at Addresses

0x70, 0x72 for the Remote 1 and Remote 2 temperature

channels. By doing a one-time calibration of the system, the

user can determine the offset caused by system board noise and

null it out using the offset registers. The offset registers automatically add an Offset 64/twos complement 8-bit reading to

every temperature measurement. The LSBs add 0.5°C offset to

the temperature reading so the 8-bit register effectively allows

temperature offsets of up to ±64°C with a resolution of 0.5°C.

This ensures that the readings in the temperature measurement

registers are as accurate as possible.

Temperature Offset Registers

Reg. 0x70 Remote 1 Temperature Offset = 0x00 (0°C default)

Reg. 0x71

Reg. 0x72

Local Temperature Offset = 0x00 (0°C default)

Remote 2 Temperature Offset = 0x00 (0°C default)

ADT7460/ADT7467 Backwards Compatible Mode

By setting Bit 1 of Configuration Register 5 (0x7C), all temperature measurements are stored in the Zone Temp value registers

(0x25, 0x26, and 0x27) in twos complement in the range −64°C

to +127°C. (The ADT7468 still makes calculations based on the

Offset64 extended range and clamps the results, if necessary.)

The temperature limits must be reprogrammed in twos complement. If a twos complement temperature below −63°C is

entered, the temperature is clamped to −63°C. In this mode, the

diode fault condition remains −128°C = 1000 0000, while in the

extended temperature range (−64°C to +191°C), the fault

condition is represented by −64°C = 0000 0000.

Temperature Measurement Registers

Reg. 0x25 Remote 1 Temperature

Reg. 0x26

Reg. 0x27

Reg. 0x77

Local Temperature

Remote 2 Temperature

Extended Resolution 2 = 0x00 default

<7:6> TDM2, Remote 2 temperature LSBs.

<5:4> LTMP, local temperature LSBs.

<3:2> TDM1, Remote 1 temperature LSBs.

Rev. 0 | Page 18 of 80

Page 19

ADT7467

Temperature Measurement Limit Registers

Associated with each temperature measurement channel are

high and low limit registers. Exceeding the programmed high or

low limit causes the appropriate status bit to be set. Exceeding

either limit can also generate

Reg. 0x4E

Reg. 0x4F

Reg. 0x50

Reg. 0x51

Reg. 0x52

Reg. 0x53

Remote 1 Temperature Low Limit = 0x01 default

Remote 1 Temperature High Limit = 0x7F default

Local Temperature Low Limit = 0x01 default

Local Temperature High Limit = 0x7F default

Remote 2 Temperature Low Limit = 0x01 default

Remote 2 Temperature High Limit = 0x7F default

SMBALERT

interrupts.

Reading Temperature from the ADT7467

It is important to note that temperature can be read from the

ADT7467 as an 8-bit value (with 1°C resolution) or as a 10-bit

value (with 0.25°C resolution). If only 1°C resolution is

required, the temperature readings can be read back at any time

and in no particular order.

If the 10-bit measurement is required, this involves a 2-register

read for each measurement. The extended resolution register

(Reg. 0x77) should be read first. This causes all temperature

reading registers to be frozen until all temperature reading

registers have been read from. This prevents an MSB reading

from being updated while its two LSBs are being read and vice

versa.

ADDITIONAL ADC FUNCTIONS FOR TEMPERATURE MEASUREMENT

A number of other functions are available on the ADT7467 to

offer the system designer increased flexibility.

Turn-Off Averaging

For each temperature measurement read from a value register,

16 readings have actually been made internally and the results

averaged before being placed into the value register. Sometimes

it is necessary to take a very fast measurement. Setting Bit 4 of

Configuration Register 2 (Reg. 0x73) turns averaging off.

Table 8. Conversion Time with Averaging Disabled

Channel Measurement Time

Voltage Channel 0.7 ms

Remote Temperature 1 7 ms

Remote Temperature 2 7 ms

Local Temperature 1.3 ms

Table 9. Conversion Time with Averaging Enabled

Channel Measurement Time

Voltage Channels 11 ms

Remote Temperature 39 ms

Local Temperature 12 ms

Single-Channel ADC Conversions

Setting Bit 6 of Configuration Register 2 (Reg. 0x73) places the

ADT7467 into single-channel ADC conversion mode. In this

mode, the ADT7467 can be made to read a single temperature

channel only. The appropriate ADC channel is selected by

writing to Bits <7:5> of the TACH1 minimum high byte register

(0x55).

Table 10. Channel Selection

Bits <7:5> Reg. 0x55 Channel Selected

101 Remote 1 temperature

110 Local temperature

111 Remote 2 temperature

Configuration Register 2 (Reg. 0x73)

<4> = 1, averaging off.

<6> = 1, single-channel convert mode,

TACH1 Minimum High Byte (Reg. 0x55)

<7:5> selects ADC channel for single-channel convert mode.

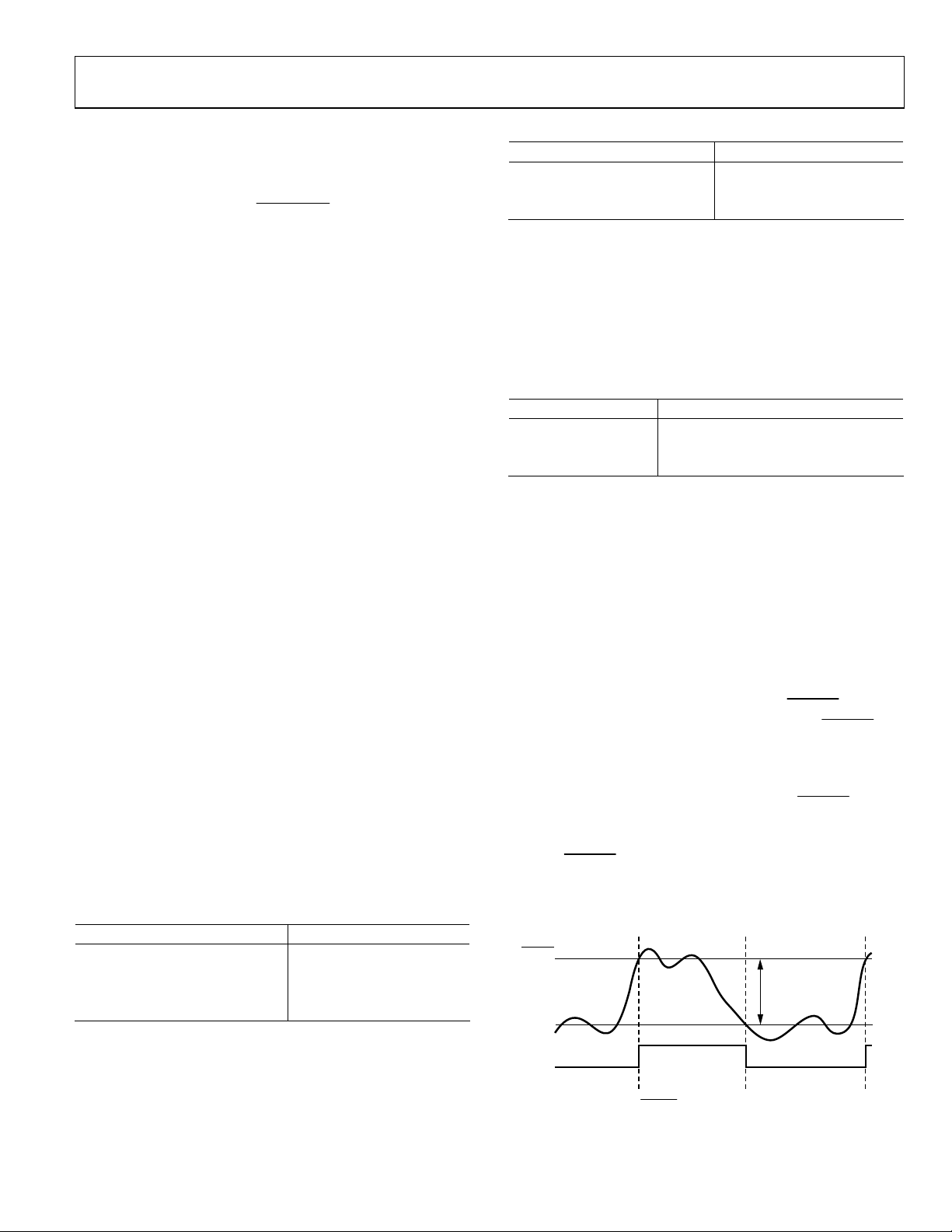

Overtemperature Events

Overtemperature events on any of the temperature channels can

be detected and dealt with automatically in automatic fan speed

control mode. Reg. 0x6A to Reg. 0x6C are the

THERM

temperature limits. When a temperature exceeds its

THERM

temperature limit, all PWM outputs run at the maximum PWM

duty cycle (Reg. 0x38, Reg. 0x39, Reg. 0x3A). This effectively

runs the fans at the fastest allowed speed. The fans stay running

at this speed until the temperature drops below

THERM

minus

hysteresis. (This can be disabled by setting the boost bit in

Configuration Register 3, Bit 2, Reg. 0x78.) The hysteresis value

for that

THERM

temperature limit is the value programmed

into Reg. 0x6D and Reg. 0x6E (hysteresis registers). The default

hysteresis value is 4°C.

THERM LIMIT

HYSTERESIS (°C)

TEMPERATURE

FANS

Figure 27.

100%

THERM

Temperature Limit Operation

04498-0-015

Rev. 0| Page 19 of 80

Page 20

ADT7467

LIMITS, STATUS REGISTERS, AND INTERRUPTS

LIMIT VALUES

Associated with each measurement channel on the ADT7467

are high and low limits. These can form the basis of system

status monitoring; a status bit can be set for any out-of-limit

condition and detected by polling the device. Alternatively,

SMBALERT

microcontroller of out-of-limit conditions.

8-Bit Limits

The following is a list of 8-bit limits on the ADT7467.

Volt ag e Li mi t Re g is t er s

Reg. 0x46 V

Reg. 0x47

Reg. 0x48

Reg. 0x49

Temperature Limit Registers

Reg. 0x4E Remote 1 Temperature Low Limit = 0x01 default

Reg. 0x4F

Reg. 0x6A

Reg. 0x50

Reg. 0x51

Reg. 0x6B

Reg. 0x52

Reg. 0x53

Reg. 0x6C

THERM

Reg. 0x7A

16-Bit Limits

The fan TACH measurements are 16-bit results. The fan TACH

limits are also 16 bits, consisting of a high byte and low byte.

Because fans running under speed or stalled are normally the

only conditions of interest, only high limits exist for fan TACHs.

Because the fan TACH period is actually being measured,

exceeding the limit indicates a slow or stalled fan.

Fan Limit Registers

Reg. 0x54 TACH 1 Min i mum L ow Byte = 0x00 default

Reg. 0x55

Reg. 0x56

interrupts can be generated to flag a processor or

Low Limit = 0x00 default

CCP

V

High Limit = 0xFF default

CCP

VCC Low Limit = 0x00 default

VCC High Limit = 0xFF default

Remote 1 Temperature High Limit = 0x7F default

Remote 1

Local Temperature Low Limit = 0x01 default

Local Temperature High Limit = 0x7F default

Local

Remote 2 Temperature Low Limit = 0x01 default

Remote 2 Temperature High Limit = 0x7F default

Remote 2

Limit Register

THERM

TAC H1 M ini m u m Hi g h B y te = 0x00 default

TAC H2 M ini m u m L ow B y te = 0x00 default

THERM

THERM

THERM

Limit = 0x00 default

Limit = 0x64 default

Limit = 0x64 default

Limit = 0x64 default

Reg. 0x57

Reg. 0x58

Reg. 0x59

Reg. 0x5A

Reg. 0x5B

TAC H2 M ini m u m Hi g h B y te = 0x00 default

TAC H3 M ini m u m L ow B y te = 0x00 default

TAC H3 M ini m u m Hi g h B y te = 0x00 default

TAC H4 M ini m u m L ow B y te = 0x00 default

TAC H4 M ini m u m Hi g h B y te = 0x00 default

Out-of-Limit Comparisons

Once all limits have been programmed, the ADT7467 can be

enabled for monitoring. The ADT7467 measures all voltage and

temperature measurements in round-robin format and sets the

appropriate status bit for out-of-limit conditions. TACH

measurements are not part of this round-robin cycle. Comparisons are done differently depending on whether the measured

value is being compared to a high or low limit.

High Limit: > Comparison Performed

Low Limit: ≤ Comparison Performed

Voltage and temperature channels use a window comparator for

error detecting and, therefore, have high and low limits. Fan

speed measurements use only a low limit. This fan limit is

needed only in manual fan control mode.

Analog Monitoring Cycle Time

The analog monitoring cycle begins when a 1 is written to the

start bit (Bit 0) of Configuration Register 1 (Reg. 0x40). By

default, the ADT7463 powers up with this bit set. The ADC

measures each analog input in turn and, as each measurement is

completed, the result is automatically stored in the appropriate

value register. This round-robin monitoring cycle continues

unless disabled by writing a 0 to Bit 0 of Configuration

Register 1.

As the ADC is normally left to free-run in this manner, the time

taken to monitor all the analog inputs is normally not of

interest, because the most recently measured value of any input

can be read out at any time.

For applications where the monitoring cycle time is important,

it can easily be calculated. The total number of channels

measured is

•

One dedicated supply voltage input (V

•

Supply voltage (V

•

Local temperature

•

Two remote temperatures

CC

pin)

CCP

)

Rev. 0 | Page 20 of 80

Page 21

ADT7467

T

As mentioned previously, the ADC performs round-robin

conversions . The total monitoring cycle time for averaged

voltage and temperature monitoring is 145 ms. The total

monitoring cycle time for voltage and temperature monitoring

with averaging disabled is 19 ms. The ADT7467 is a derivative

of the ADT7468. As a result, the total conversion time in the

ADT7467 is the same as the total conversion time of the

ADT7468, even though the ADT7467 has less monitored

channels.

Fan TACH measurements are made in parallel and are not

synchronized with the analog measurements in any way.

STATUS REGISTERS

The results of limit comparisons are stored in Status Registers 1

and 2. The status register bit for each channel reflects the status

of the last measurement and limit comparison on that channel.

If a measurement is within limits, the corresponding status

register bit is cleared to 0. If the measurement is out-of-limits,

the corresponding status register bit is set to 1.

The state of the various measurement channels can be polled by

reading the status registers over the serial bus. In Bit 7 (OOL) of

Status Register 1 (Reg. 0x41), 1 means that an out-of-limit event

has been flagged in Status Register 2. This means that the user

also needs to read Status Register 2. Alternatively, Pin 5 or Pin 9

can be configured as an

interrupt automatically notifies the system supervisor of an outof-limit condition. Reading the status registers clears the

appropriate status bit as long as the error condition that caused

the interrupt has cleared. Status register bits are “sticky.”

Whenever a status bit is set, indicating an out-of-limit

condition, it remains set even if the event that caused it has

gone away (until read). The only way to clear the status bit is to

read the status register after the event has gone away. Interrupt

status mask registers (Reg. 0x74, 0x75) allow individual

interrupt sources to be masked from causing an

However, if one of these masked interrupt sources goes out-oflimit, its associated status bit is set in the interrupt status

registers.

Status Register 1 (Reg. 0x41)

Bit 7 (OOL) = 1, denotes a bit in Status Register 2 is set and

Status Register 2 should be read.

Bit 6 (R2T) = 1, Remote 2 temperature high or low limit has

been exceeded.

Bit 5 (LT) = 1, local temperature high or low limit has been

exceeded.

Bit 4 (R1T) = 1, Remote 1 temperature high or low limit has

been exceeded.

SMBALERT

output. This hardware

SMBALERT

.

Status Register 2 (Reg. 0x42)

Bit 7 (D2) = 1, indicates an open or short on D2+/D2– inputs.

Bit 6 (D1) = 1, indicates an open or short on D1+/D1– inputs.

Bit 5 (F4P) = 1, indicates Fan 4 has dropped below minimum

speed. Alternatively, indicates that the

exceeded, if the

THERM

function is used.

THERM

limit has been

Bit 4 (FAN3) = 1, indicates Fan 3 has dropped below minimum

speed.

Bit 3 (FAN2) = 1, indicates Fan 2 has dropped below minimum

speed.

Bit 2 (FAN1) = 1, indicates Fan 1 has dropped below minimum

speed.

Bit 1 (OVT) = 1, indicates a

THERM

overtemperature limit has

been exceeded.

SMBALERT

The ADT7467 can be polled for status, or an

Interrupt Behavior

SMBALERT

interrupt can be generated for out-of-limit conditions. It is

important to note how the

SMBALERT

output and status bits

behave when writing interrupt handler software.

HIGH LIMIT

TEMPERATURE

CLEARED ON READ

“STICKY”

STATUS BI

TEMP BACK IN LIMIT

SMBALERT

Figure 28.

(STATUS BIT STAYS SET)

SMBALERT

Figure 28 shows how the

and Status Bit Behavior

SMBALERT

(TEMP BELOW LIMIT)

output and “sticky” status

bits behave. Once a limit is exceeded, the corresponding status

bit is set to 1. The status bit remains set until the error condition

subsides and the status register is read. The status bits are

referred to as “sticky,” because they remain set until read by

software. This ensures that an out-of-limit event cannot be

missed, if software is polling the device periodically. Note that

SMBALERT

the

output remains low for the entire duration that

a reading is out-of-limit and until the status register has been

read. This has implications on how software handles the

interrupt.

04498-0-022

Bit 2 (VCC) = 1, V

Bit 1 (V

CCP

) = 1, V

high or low limit has been exceeded.

CC

high or low limit has been exceeded.

CCP

Rev. 0| Page 21 of 80

Page 22

ADT7467

Handling

To prevent the system from being tied up servicing interrupts, it

is recommend to handle the

Detect the

1.

2.

Enter the interrupt handler.

3.

Read the status registers to identify the interrupt source.

4.

Mask the interrupt source by setting the appropriate mask

5.

Take the appropriate action for a given interrupt source.

6.

Exit the interrupt handler.

7.

Periodically poll the status registers. If the interrupt status

SMBALERT

Interrupts

SMBALERT

SMBALERT

assertion.

interrupt as follows:

bit in the interrupt mask registers (Reg. 0x74, Reg. 0x75).

bit has cleared, reset the corresponding interrupt mask bit

to 0. This causes the

SMBALERT

output and status bits to

behave as shown in Figure 29.

Bit 2 (VCC) = 1, masks

Bit 0 (V

) = 1, masks

CCP

SMBALERT

SMBALERT

for VCC channel.

for V

Interrupt Mask Register 2 (Reg. 0x75)

Bit 7 (D2) = 1, masks

Bit 6 (D1) = 1, masks

Bit 5 (FAN4) = 1, masks

If the TACH4 pin is being used as the

SMBALERT

masks

Bit 4 (FAN3) = 1, masks

Bit 3 (FAN2) = 1, masks

Bit 2 (FAN1) = 1, masks

Bit 1 (OVT) = 1, masks

(exceeding

THERM

SMBALERT

SMBALERT

SMBALERT

THERM

for a

SMBALERT

SMBALERT

SMBALERT

SMBALERT