Page 1

SALEM® Three-Phase

a

FEATURES

IEC 687, Class 0.5 and Class 0.2 Accuracy

ANSI C12.1

IEC 1268, Requirements for Reactive Power

Configurable as Import/Export or Import Only

Simultaneous Measurement of:

Active Power and Energy—Import and Export

Reactive Power and Energy

Apparent Power

Power Factor for Individual Phases and Total Frequency

RMS Voltage for All Phases

RMS Current for All Phases

Harmonic Analysis for Voltage and Current

All Odd Harmonics up to 21st Order

Interface with a General Purpose Microcontroller

User-Friendly Calibration of Gain Offset and Phase and

Nonlinearity Compensation on CTs (Patent Pending)

Two Programmable Output E-Pulses

Programmable E-Pulse Constant from 1,000 Pulses/kWh

to 20,000 Pulses/kWh

15 kHz Sampling Frequency

Tamper-Proof Metering

Single 5 V Supply

SMPS

RESISTOR

BLOCK

CT

CT

CT

Electronic Energy Meter

ADSST-EM-3035

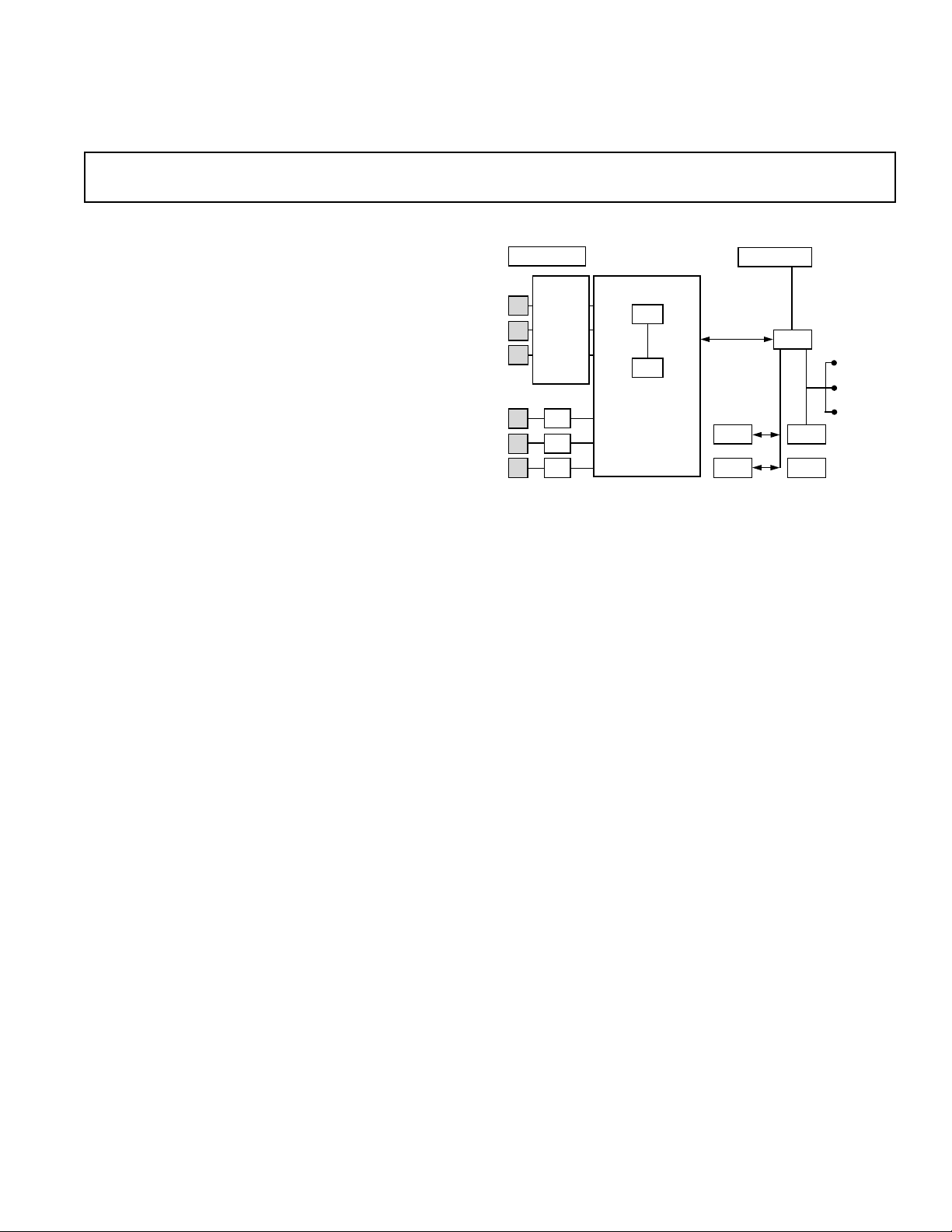

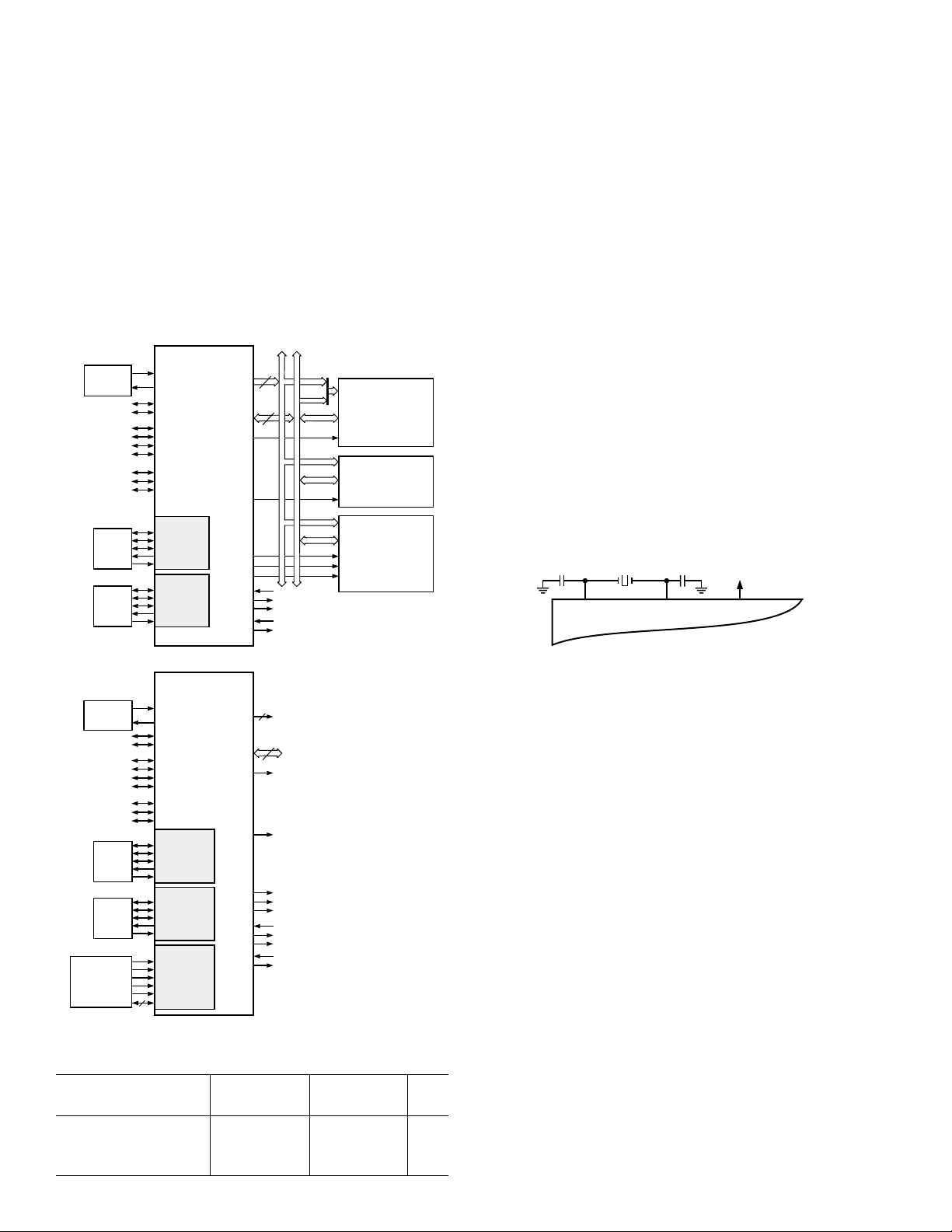

FUNCTIONAL BLOCK DIAGRAM

LCD DISPLAY

DSP

ADC

ADSST-EM-3035

CHIPSET

SPI BUS

FLASH

RTC

C

BUTTONS

OPTO

RS-232

GENERAL DESCRIPTION

The ADSST-EM-3035 Chipset consists of a fast and accurate

6 channel, 16-bit sigma-delta analog-to-digital converter

ADSST-73360AR (ADC), an efficient digital signal processor

ADSST-2185KST-133 (DSP), and Metering Software. The

ADC and DSP are interfaced together to simultaneously acquire

voltage and current samples on all the three phases and perform

mathematically intensive computations to accurately

calculate

the Powers, Energies, Instantaneous Quantities, and Harmonics.

The chipset could be interfaced to any general-purpose microprocessor to develop state of the art polyphase or Tri-vector energy

metering solution in accordance with IEC 1036, IEC 687, or

ANSI C12.1.

All calibrations are done in digital domain and no trimming

potentiometers are required.

SALEM is a registered trademark of Analog Devices, Inc.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

ADSST-EM-3035

ADSST-2185KST-133 (DSP) SPECIFICATION

FEATURES

30 ns Instruction Cycle 33 MIPS Sustained Performance

Single-Cycle Instruction Execution

Single-Cycle Context Switch

Three-Bus Architecture Allows Dual Operand Fetches

in Every Instruction Cycle

Multifunction Instructions

Power-Down Mode Featuring Low CMOS Standby Power

Dissipation with 100 Cycle Recovery from Power-Down

Condition

Low Power Dissipation in Idle Mode

ADSP-2100 Family Code Compatible, with Instruction

Set Extensions

40 kBytes of On-Chip RAM, Configured as

8 KWords On-Chip Program Memory RAM and

8 KWords On-Chip Data Memory RAM

Dual Purpose Program Memory for Both Instruction

and Data Storage

Independent ALU, Multiplier/Accumulator, and Barrel

Shifter Computational Units

Two Independent Data Address Generators

Powerful Program Sequencer Provides Zero Overhead

Looping Conditional Instruction Execution

Programmable 16-Bit Interval Timer with Prescaler

100-Lead TQFP

16-Bit Internal DMA Port for High Speed Access to On-

Chip Memory (Mode Selectable)

4 MBytes Byte Memory Interface for Storage of Data

Tables and Program Overlays

8-Bit DMA to Byte Memory for Transparent Program and

Data Memory Transfers (Mode Selectable)

I/O Memory Interface with 2048 Locations Supports

Parallel Peripherals (Mode Selectable)

Programmable Memory Strobe and Separate I/O

Memory Space Permits Glueless System Design

(Mode Selectable)

Programmable Wait State Generation

Two Double-Buffered Serial Ports with Companding

GENERAL DESCRIPTION

The ADSST-2185KST-133 is a single-chip microcomputer

optimized for digital signal processing (DSP) and other high

speed numeric processing applications.

The ADSST-2185KST-133 combines the ADSP-2100 family

base architecture (three computational units, data address

generators, and a program sequencer) with two serial ports, a

16-bit internal DMA port, a byte DMA port, a programmable

timer, Flag I/O, extensive interrupt capabilities, and on-chip

program and data memory.

The ADSST-2185KST-133 integrates 40 kBytes of on-chip

memory configured as 8 Kwords (24-bit) of program RAM and

8 Kwords (16-bit) of data RAM. Power-down circuitry is also

provided to meet the low power needs of battery operated portable

equipment. The ADSST-2185KST-133 is available in a 100-lead

TQFP package.

In addition, the ADSST-2185KST-133 supports instructions

that include bit manipulations, bit set, bit clear, bit toggle, bit

test new ALU constants, new multiplication instruction (x squared),

biased rounding, result free ALU operations, I/O memory transfers, and global interrupt masking for increased flexibility.

Fabricated in a high speed, double metal, low power, CMOS

process, the ADSST-2185KST-133 operates with a 25 ns

instruction cycle time. Every instruction can execute in a single

processor cycle.

The ADSST-2185KST-133’s flexible architecture and comprehensive instruction set allow the processor to perform

multiple operations in parallel. In one processor cycle, the

ADSST-2185KST-133 can:

•

•

•

•

•

•

Hardware and Automatic Data Buffering

Automatic Booting of On-Chip Program Memory from

Byte-Wide External Memory, e.g., EPROM, or through

Internal DMA Port

Six External Interrupts

13 Programmable Flag Pins Provide Flexible System Signaling

UART Emulation through Software SPORT Reconfiguration

ICE-Port Emulator Interface Supports Debugging in Final Systems

Generate the next program address

Fetch the next instruction

Perform one or two data moves

Update one or two data address pointers

Perform a computational operation

This takes place while the processor continues to:

Receive and transmit data through the two serial ports

Receive and/or transmit data through the internal DMA port

Receive and/or transmit data through the byte DMA port

Decrement timer

POWER-DOWN

DATA ADDRESS

GENERATORS

DAG 2

DAG 1

ARITHMETIC UNITS

ALU

MAC

ADSP-2100 BASE

ARCHITECTURE

PROGRAM

SEQUENCER

PROGRAM MEMORY ADDRESS

DATA MEMORY ADDRESS

PROGRAM MEMORY DATA

DATA MEMORY DATA

SHIFTER

CONTROL

MEMORY

16K 24

PROGRAM

MEMORY

SERIAL PORTS

16K 16

DATA

MEMORY

SPORT 1SPORT 0

PROGRAMMABLE

I/O

AND

FLAGS

TIMER

FULL MEMORY

MODE

EXTERNAL

ADDRESS

BUS

EXTERNAL

DATA

BUS

BYTE DMA

CONTROLLER

OR

EXTERNAL

DATA

BUS

INTERNAL

DMA

PORT

HOST MODE

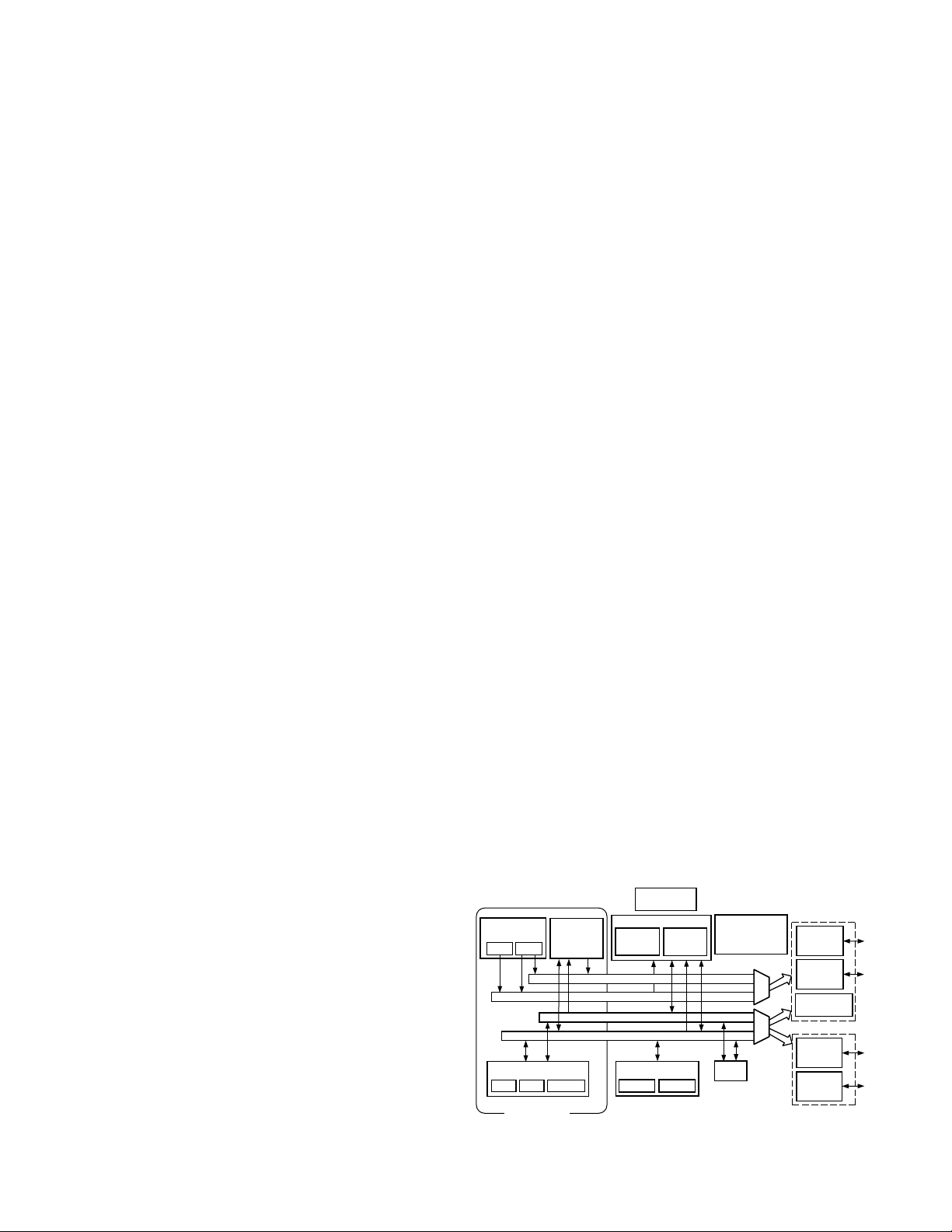

Figure 1. Functional Block Diagram

–2–

REV. 0

Page 3

ADSST-EM-3035

ARCHITECTURE OVERVIEW

The ADSST-2185KST-133 instruction set provides flexible

data moves and multifunction (one or two data moves with a

computation) instructions. Every instruction can be executed in

a single processor cycle. The ADSST-2185KST-133 assembly

language uses an algebraic syntax for ease of coding and readability. A comprehensive set of development tools supports

program development.

Figure 1 is an overall block diagram of the ADSST-2185KST-133.

The processor contains three independent computational units:

the ALU, the multiplier/accumulator (MAC), and the shifter.

The computational units process 16-bit data directly and have

provisions

performs a standard set of arithmetic and logic operations; division

primitives are also supported. The MAC performs single-cycle

multiply, multiply/add and multiply/subtract operations with 40

bits of accumulation. The shifter performs logical and arithmetic

shifts, normalization, denormalization and derive exponent

operations.

The shifter can be used to efficiently implement numeric format

control including multiword and block floating-point representations.

The internal result (R) bus connects the computational units

so the output of any unit may be the input of any unit on the

next cycle.

A powerful program sequencer and two dedicated data address

generators ensure efficient delivery of operands to these computational units. The sequencer supports conditional jumps,

subroutine calls, and returns in a single cycle. With internal loop

counters and loop stacks, the ADSST-2185KST-133 executes

looped code with zero overhead. No explicit jump instructions

are required to maintain loops.

Two data address generators (DAGs) provide addresses for simultaneous dual operand fetches from data memory and program memory.

Each DAG maintains and updates four address pointers. Whenever

the pointer is used to access data (indirect addressing),

modified by the value of one of four possible modify registers. A

length value may be associated with each pointer to implement

automatic modulo addressing for circular buffers.

Efficient data transfer is achieved with the use of five internal buses:

•

•

•

•

•

The two address buses (PMA and DMA) share a single external

address bus, allowing memory to be expanded off-chip, and the two

data buses (PMD and DMD) share a single external data bus.

memory space and I/O memory space also share the external buses.

Program memory can store both instructions and data, permitting

the ADSST-2185KST-133 to fetch two operands in a single cycle,

one from program memory and one from data memory. The

ADSST-2185KST-133 can fetch an operand from program

memory and the next instruction in the same cycle.

When configured in host mode, the ADSST-2185KST-133 has

a 16-bit Internal DMA port (IDMA port) for connection to

external systems. The IDMA port is made up of 16 data/address

pins and five control pins. The IDMA port provides transparent,

direct access to the DSP’s on-chip program and data RAM.

REV. 0

to support multiprecision computations. The ALU

it is post-

Program Memory Address (PMA) Bus

Program Memory Data (PMD) Bus

Data Memory Address (DMA) Bus

Data Memory Data (DMD) Bus

Result (R) Bus

Byte

An interface to low cost byte-wide memory is provided by the

Byte DMA port (BDMA port). The BDMA port is bidirectional

and can directly address up to four megabytes of external RAM

or ROM for off-chip storage of program overlays or data tables.

The byte memory and I/O memory space interface supports slow

memories and I/O memory-mapped peripherals with programmable

wait state generation. External devices can gain control of external

buses with bus request/grant signals (BR, BGH, and BG). One

execution mode (Go Mode) allows the ADSST-2185KST-133

to continue running from on-chip memory. Normal execution

mode requires the processor to halt while buses are granted.

The ADSST-2185KST-133 can respond to 11 interrupts.

There are up to six external interrupts (one edge-sensitive, two

level-sensitive, and three configurable) and seven internal interrupts generated by the timer, the serial ports (SPORTs), the

Byte DMA port, and the power-down circuitry. There is also a

master RESET signal. The two serial ports provide a complete

synchronous serial interface with optional companding in hardware and a wide variety of framed or frameless data transmit

and receive modes of operation.

Each port can generate an internal programmable serial clock or

accept an external serial clock.

The ADSST-2185KST-133 provides up to 13 general purpose

flag pins. The data input and output pins on SPORT1 can be

alternatively configured as an input flag and an output flag. In

addition, eight flags are programmable as inputs or outputs, and

three flags are always outputs.

A programmable interval timer generates periodic interrupts. A

16-bit count register (TCOUNT) decrements every n processor

cycle, where n is a scaling value stored in an 8-bit register (TSCALE).

When the value of the count register reaches zero, an interrupt is

generated and the count register is reloaded from a 16-bit period

register (TPERIOD).

Serial Ports

The ADSST-2185KST-133 incorporates two complete synchronous

serial ports (SPORT0 and SPORT1) for serial communications

and multiprocessor communication.

Here is a brief list of the capabilities of the ADSST-2185KST-133

SPORTs. For additional information on Serial Ports, refer to

the ADSP-2100 Family User’s Manual, Third Edition.

•

SPORTs are bidirectional and have a separate, double-buffered

transmit and receive section.

•

SPORTs can use an external serial clock or generate their own

serial clock internally.

•

SPORTs have independent framing for the receive and transmit

sections. Sections run in a frameless mode or with frame synchronization signals internally or externally generated. Frame

sync signals are active high or inverted, with either of two

pulsewidths and timings.

•

SPORTs support serial data word lengths from 3 to 16 bits and

provide optional A-law and M-law companding according to

CCITT recommendation G.711.

•

SPORT receive and transmit sections can generate unique

interrupts on completing a data-word transfer.

•

SPORTs can receive and transmit an entire circular buffer of

data with only one overhead cycle per data-word. An interrupt

is generated after a data buffer transfer.

–3–

Page 4

ADSST-EM-3035

•

SPORT0 has a multichannel interface to selectively receive and

transmit a 24- or 32-word, time-division multiplexed, serial

bitstream.

•

SPORT1 can be configured to have two external interrupts

(IRQ0 and IRQ1) and the Flag In and Flag Out signals. The

internally generated serial clock may still be used in this

configuration.

Table I. Common-Mode Pins

Pin Descriptions

The ADSST-2185KST-133 is available in a 100-lead TQFP

package. To maintain maximum functionality and reduce package size and pin count, some serial ports, programmable flags,

interrupt and external bus pins have dual, multiplexed functionality. The external bus pins are configured during RESET only,

while serial port pins are software configurable during program

execution. Flag and interrupt functionality is retained concurrently on multiplexed pins. In cases where pin functionality is

reconfigurable, the default state is shown in plain text; alternate

functionality is shown in italics.

Pin Number Input/

Name(s) of Pins Output Function

RESET 1IProcessor Reset Input

BR 1IBus Request Input

BG 1OBus Grant Output

BGH 1OBus Grant Hung Output

DMS 1OData Memory Select Output

PMS 1O

Program Memory Select Output

IOMS 1OMemory Select Output

BMS 1OByte Memory Select Output

CMS 1OCombined Memory

Select Output

RD 1OMemory Read Enable Output

WR 1OMemory Read Enable Output

IRQ2+PF7

IRQL0+PF5 1 I Level-Sensitive

IRQL1+PF6

IRQE+PF4

1IEdge- or Level-Sensitive

Interrupt Request

Interrupt Requests

1ILevel-Sensitive

Interrupt

Requests

1IEdge-Sensitive

Interrupt Requests

1

1

1

1

PF3 1 I/O Programmable I/O Pin

PF2 (Mode C)

1IProgrammable I/O Pin Mode

Select Input-Checked only

During RESET

PF1 (Mode B)

1IMode Select Input-Checked

only During RESET

Pin Number Input/

Name(s) of Pins Output Function

PF0 (Mode A) 1 I Mode Select Input-Checked

only During RESET

CLKIN, 2 I Clock or Quartz Crystal Input

XTAL

CLKOUT 1 O Processor Clock Output

SPORT0 5 I/O Serial Port I/O Pins

SPORT1 5 I/O Serial Port I/O Pins

IRQ1:0 Edge- or Level-Sensitive

Interrupts

F1, F0 Flag In, Flag Out

2

PWD 1IPower-Down Control Input

PWDACK 1 O Power-Down Control Output

FL0, FL1, 3 O Output Flags

FL2

VDD 16 I VDD and GND

AND

GND

EX-Port 9 I/O For Emulation Use

NOTES

1

Interrupt/Flag pins retain both functions concurrently. If IMASK is set to enable

the corresponding interrupts, the DSP will vector to the appropriate interrupt

vector address when the pin is asserted, either by external devices or set as a

programmable flag.

2

SPORT configuration determined by the DSP System Control Register. Software

configurable.

–4–

REV. 0

Page 5

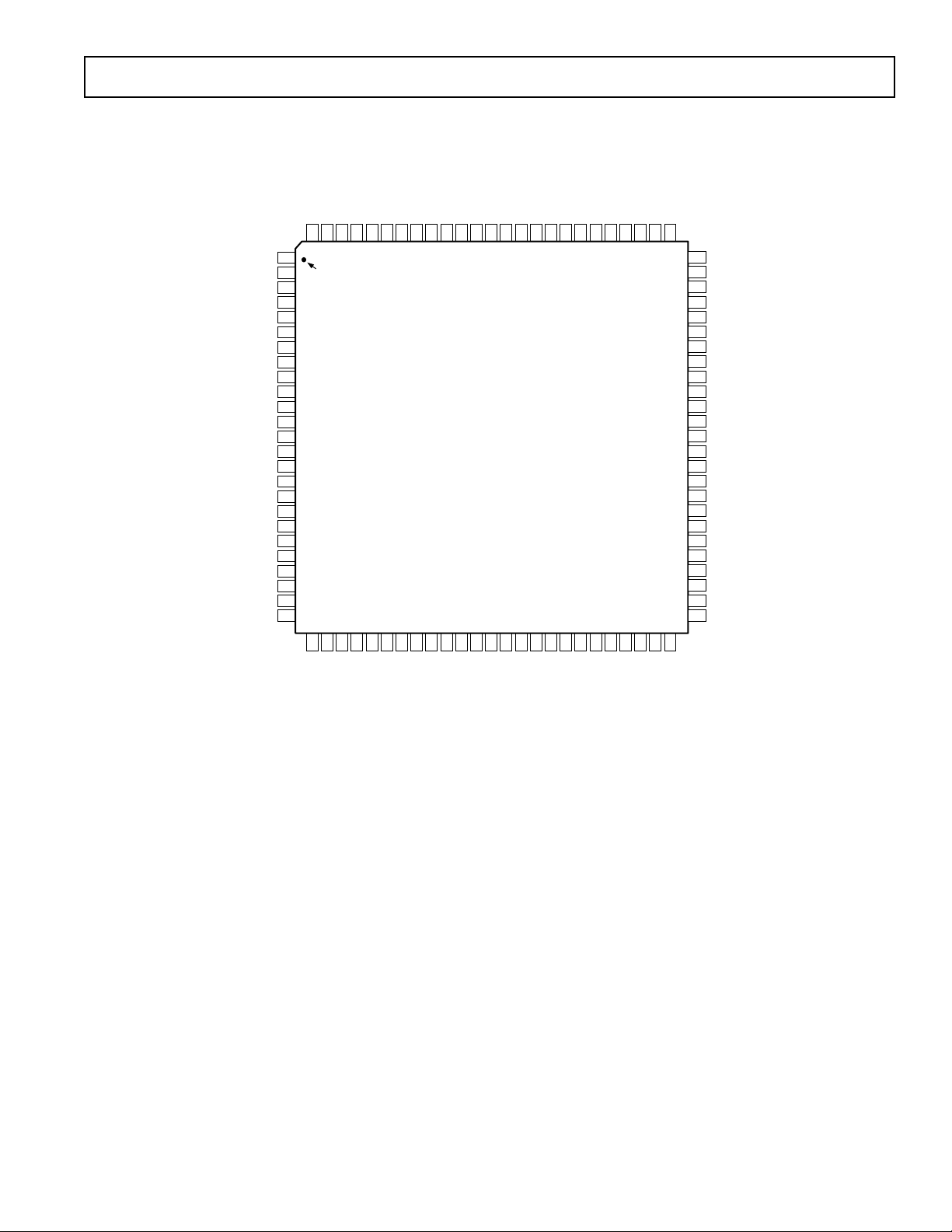

100-Lead TQFP Package Pinout

ADSST-EM-3035

A4/IAD3

A5/IAD4

GND

A6/IAD5

A7/IAD6

A8/IAD7

A9/IAD8

A10/IAD9

A11/IAD10

A12/IAD11

A13/IAD12

GND

CLKIN

XTAL

VDD

CLKOUT

GND

VDD

WR

RD

BMS

DMS

PMS

IOMS

CMS

A0

A3/IAD2

A2/IAD1

A1/IAD0

PWDACK

BGH

9998979695949392919089888786858483828180797877

100

1

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2728293031323334353637383940414243444546474849

26

DT0

GND

IRQL0+PF5

IRQL1+PF6

IRQ2+PF7

IRQE+PF4

PWD

GND

PF1 [MODE B]

PF0 [MODE A]

PF2 [MODE C]

VDD

ADSST-2185KST-133

TOP VIEW

(Not to Scale)

DR0

RFS0

VDD

SCLK0

DT1/FO

TFS0

PF3

TFS1/IRQ1

FL0

RFS1/IRQ0

FL1

FL2

GND

DR1/FI

D23

D22

SCLK1

ERESET

D20

D21

EMS

RESET

GND

EE

D19

ECLK

D18

D17

ELIN

ELOUT

D16

76

50

EINT

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

D15

D14

D13

D12

GND

D11

D10

D9

VDD

GND

D8

D7/IWR

D6/IRD

D5/IAL

D4/IS

GND

VDD

D3/IACK

D2/IAD15

D1/IAD14

D0/IAD13

BG

EBG

BR

EBR

REV. 0

–5–

Page 6

ADSST-EM-3035

System Interface

Figure 2 shows typical basic system configurations with the

ADSST-2185KST-133, two serial devices, a byte-wide EPROM

and optional external program and data overlay memories (mode

selectable). Programmable wait state generation allows the processor to connect easily to slow peripheral devices. The ADSST2185KST-133 also provides four external interrupts and two serial

ports, or six external interrupts and one serial port. Host Memory

Mode allows access to the full external data bus, but limits addressing to a single address bit (A0). Additional system peripherals can

be added in this mode through the use of external hardware to

generate and latch address signals.

FULL MEMORY MODE

ADSST-2185

1/2x CLOCK

OR

CRYSTAL

SERIAL

DEVICE

SERIAL

DEVICE

KST-133

CLKIN

XTAL

FL0–2

PF3

IRQ2/PF7

IRQE/PF4

IRQL0/PF5

IRQL1/PF6

MODE C/PF2

MODE B/PF1

MODE A/PF0

SPORT1

SCLK1

RFS1 OR IRQ0

TFS1 OR IRQ1

DT1 OR FO

DR1 OR FI

SPORT0

SCLK0

RFS0

TFS0

DT0

DR0

ADDR13–0

DATA23–0

BMS

IOMS

PMS

DMS

CMS

BGH

PWD

PWDACK

BR

BG

A

14

13–0

A0–A21

D

23–16

D

24

15–8

A

10–0

D

23–8

A

13–0

D

23–0

DATA

CS

ADDR

DATA

(PERIPHERALS)

2048 LOCATIONS

CS

ADDR

OVERLAY

MEMORY

DATA

PM SEGMENTS

DM SEGMENTS

BYTE

MEMORY

I/O SPACE

TWO 8K

TWO 8K

Clock Signals

Either a crystal or a TTL-compatible clock signal can clock the

ADSST-2185KST-133.

The CLKIN input cannot be halted, changed during operation,

or operated below the specified frequency during normal

operation. The only exception is while the processor is in the

power-down state. For additional information, refer to Chapter 9,

ADSP-2100 Family User’s Manual, Third Edition, for detailed

information on this power-down feature.

If an external clock is used, it should be a TTL-compatible signal

running at half the instruction rate. The signal is connected to the

processor's CLKIN input. When an external clock is used, the

XTAL input must be left unconnected.

The ADSST-2185KST-133 uses an input clock with a frequency

equal to half the instruction rate; a 20.00 MHz input clock

yields a 25 ns processor cycle (which is equivalent to 40 MHz).

Normally, instructions are executed in a single processor cycle.

All device timing is relative to the internal instruction clock rate,

which is indicated by the CLKOUT signal when enabled.

Because the ADSST-2185KST-133 includes an on-chip oscillator

circuit, an external crystal may be used. The crystal should be

connected across the CLKIN and XTAL pins, with two capacitors

connected as shown in Figure 3. Capacitor values are dependent

on crystal type and should be specified by the crystal manufacturer.

A parallel-resonant, fundamental frequency,

microprocessor-

grade crystal should be used.

CLKIN XTAL CLKOUT

DSP

HOST MEMORY MODE

ADSST-2185

1/2x CLOCK

OR

CRYSTAL

SERIAL

DEVICE

SERIAL

DEVICE

SYSTEM

INTERFACE

OR

CONTROLLER

CLKIN

XTAL

FL0–2

PF3

IRQ2/PF7

IRQE/PF4

IRQL0/PF5

IRQL1/PF6

MODE C/PF2

MODE B/PF1

MODE A/PF0

SCLK1

RFS1 OR IRQ0

TFS1 OR IRQ1

DT1 OR FO

DR1 OR FI

SCLK0

RFS0

TFS0

DT0

DR0

IRD/D6

IWR/D7

IS/D4

IAL/D5

IACK/D3

IAD15–0

16

KST-133

SPORT1

SPORT0

IDMA PORT

ADDR0

DATA23–8

BMS

IOMS

PMS

DMS

CMS

BGH

PWD

PWDACK

1

16

BR

BG

Figure 2. Basic System Interface

Recommended Operating Conditions

A Grade B Grade

Parameters Min Max Min Max Unit

Supply Voltage 4.5 5.5 4.5 5.5 V

V

DD

T

Ambient 0 +70 –40 +85 °C

AMB

Operating Temperature

Figure 3. External Crystal Connections

A clock output (CLKOUT) signal is generated by the processor

at the processor’s cycle rate. This can be enabled and disabled by

the CLKODIS bit in the SPORT0 Autobuffer Control Register.

Reset

The RESET signal initiates a master reset of the ADSST2185KST-133. The RESET signal must be asserted during the

power-up sequence to assure proper initialization. RESET dur-

ing initial power-up must be held long enough to allow the

internal clock to stabilize. If RESET is activated any time after

power-up, the clock continues to run and does not require stabilization time.

The power-up sequence is defined as the total time required for

the crystal oscillator circuit to stabilize after a valid VDD is

applied to the processor, and for the internal phase-locked loop

(PLL) to lock onto the specific crystal frequency. A minimum of

2000 CLKIN cycles ensures that the PLL has locked, but does

not include the crystal oscillator start-up time. During this powerup sequence, the RESET signal should be held low. On any

subsequent resets, the RESET signal must meet the minimum

pulsewidth specification, t

RSP

.

The RESET input contains some hysteresis; however, if you use

an RC circuit to generate your RESET signal, the use of an

external Schmidt trigger is recommended. The master reset sets

all internal stack pointers to the empty stack condition, masks

all interrupts and clears the MSTAT register. When RESET is

released, if there is no pending bus request and the chip is configured for booting, the boot-loading sequence is performed.

The first instruction is fetched from on-chip program memory

location 0x0000 once boot loading completes.

–6–

REV. 0

Page 7

ADSST-EM-3035

ELECTRICAL CHARACTERISTICS

K/B Grade

Parameters Test Conditions Min Typ Max Unit

V

IH

V

IH

V

IL

V

OH

V

OL

I

IH

I

IL

I

OZH

I

OZL

I

DD

I

DD

C

I

C

O

NOTES

1

Bidirectional pins: D0–D23, RFS0, RFS1, SCLK0, SCLK1, TFS0, TFS1, A1–A13, PF0–PF7.

2

Input only pins: RESET, BR, DR0, DR1, PWD.

3

Input only pins: CLKIN, RESET, BR, DR0, DR1, PWD .

4

Output pins: BG, PMS, DMS, BMS, IOMS, CMS, RD, WR, PWDACK, A0, DT0, DT1, CLKOUT, FL2-0, BGH.

5

Although specified for TTL outputs, all ADSST-2185KST-133 outputs are CMOS-compatible and will drive to VDD and GND, assuming no dc loads.

6

Guaranteed but not tested.

7

Three-statable pins: A0–A13, D0, D23, PMS, DMS, BMS, IOMS, CMS, RD, WR, DT0, DT1, SCLK0, SCLK1, TFS0, TFS1, RFS0, RFS1, PF0, PF7.

8

0 V on BR, CLKIN inactive.

9

Idle refers to ADSST-2185KST-133 state of operation during execution of IDLE instruction. Deasserted pins are driven to either VDD or GND.

10

IDD measurement taken with all instructions executing from internal memory. 50% of the instructions are multifunction (types 1, 4, 5, 12, 13, 14), 30% are type 2

and type 6, and 20% are idle instructions.

11

VIN = 0 V and 3 V. For typical figures for supply currents, refer to Power Dissipation section.

12

Applies to TQFP package type

13

Output pin capacitance is the capacitive load for any three-stated output pin.

Specifications subject to change without notice.

High-Level Input Voltage

High-Level CLKIN Voltage @ VDD = max 2.2 V

Low-Level Input Voltage

High-Level Output Voltage

Low-Level Output Voltage

High-Level Input Current

Low-Level Input Current

Three-State Leakage Current

Three-State Leakage Current

Supply Current (Idle)

Supply Current @ V

(Dynamic)

Input Pin @ VIN = 2.5 V,

Capacitance

Output Pin @ VIN = 2.5 V,

Capacitance

10, 11

3, 6, 12

6, 7, 12, 13

1, 2

1, 3

1, 4, 5

1, 4, 5

3

3

7

7

9

@ V

= max 2.0 V

DD

@ VDD = min 0.8 V

@ VDD = min

I

= –0.5 max 2.4 V

OH

@ V

= min

DD

= –100 µA

I

OH

6

VDD – 0.3 V

@ VDD = min 0.4 V

I

= 2 mA

OL

@ VDD = max

V

= VDD max 10 µA

IN

@ VDD = max

= 0 V 10 µA

V

IN

@ VDD = max

V

= VDD max 10 µA

IN

@ VDD = max

V

IN

= 0 V

8

10 µA

@ VDD = 5.0 12.4 mA

= 5.0

DDINT

T

= 25°C

AMB

t

= 30 ns

CK

= 25 ns

t

CK

f

= 1.0 MHz,

IN

T

AMB

11

11

55 mA

[65] mA

= 25°C8pF

fIN = 1.0 MHz,

T

= 25°C8pF

AMB

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Output Voltage Swing . . . . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

+ 0.3 V

DD

Operating Temperature Range (Ambient) . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) TQFP . . . . . . . . . . . . . . . . 280°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

REV. 0

–7–

ENVIRONMENTAL CONDITIONS

Ambient Temperature Rating:

T

= T

AMB

= Case Temperature in °C

T

CASE

– (PD ⫻ CA)

CASE

PD = Power Dissipation in W

= Thermal Resistance (Junction-to-Ambient)

JA

= Thermal Resistance (Junction-to-Case)

JC

= Thermal Resistance (Case-to-Ambient)

CA

Package

JA

JC

CA

TQFP 50°C/W 2°C/W 48°C/W

Page 8

ADSST-EM-3035

ADSST-73360AR (ADC)

FEATURES

Six 16-Bit A/D Converters

Programmable Input Sample Rate

Simultaneous Sampling

76 dB SNR

64 kS/s Maximum Sample Rate

–83 dB Crosstalk

Low Group Delay (125 s Typ per ADC Channel)

Programmable Input Gain

Flexible Serial Port which Allows Multiple Devices to

be Connected in Cascade

Single (2.7 V to 5.5 V) Supply Operation

80 mW Max Power Consumption at 2.7 V

On-Chip Reference

28-Lead SOIC

VINP1

VINN1

VINP2

VINN2

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

0/38dB

PGA

0/38dB

PGA

CONDITIONING

CONDITIONING

GENERAL DESCRIPTION

The ADSST-73360AR is a six-input channel analog front-end

processor for power metering. It features six 16-bit A/D conversion provide 76 dB signal-to-noise ratio over a dc to 4 kHz

signal bandwidth. Each channel also features a programmable

input gain amplifier (PGA) with gain settings in eight stages

from 0 dB to 38 dB.

The ADSST-73360AR is particularly suitable for industrial

power metering as each channel samples synchronously, ensuring that there is no (phase) delay between the conversions. The

ADSST-73360AR also features low group delay conversions on

all channels.

An on-chip reference voltage is included with a nominal value

of 1.2 V.

The sampling rate of the device is programmable with four

separate settings offering 64 kHz, 32 kHz, 16 kHz, and 8 kHz

sampling rates (from a master clock of 16.384 MHz).

A serial port (SPORT) allows easy interfacing of single or cascaded devices to industry standard DSP engines. The SPORT

transfer rate is programmable to allow interfacing to both fast

and slow DSP engines.

The ADSST-73360AR is available in 28-lead SOIC.

ANALOG

-

ANALOG

-

DECIMATOR

DECIMATOR

SDI

SDIFS

SCLK

VINP3

VINN3

REFCAP

REFOUT

VINP4

VINN4

VINP5

VINN5

VINP6

VINN6

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

0/38dB

PGA

REFERENCE

0/38dB

PGA

0/38dB

PGA

0/38dB

PGA

ANALOG

-

CONDITIONING

ADSST-73360AR

ANALOG

-

CONDITIONING

ANALOG

-

CONDITIONING

ANALOG

-

CONDITIONING

DECIMATOR

DECIMATOR

DECIMATOR

DECIMATOR

Figure 4. Functional Block Diagram

SERIAL

I/O

PORT

RESET

MCLK

SE

SDO

SDOFS

–8–

REV. 0

Page 9

ADSST-EM-3035

SPECIFICATIONS

ADSST-73360AR

(AVDD = 5 V 10%; DVDD = 5 V 10%; DGND = AGND = 0 V, f

Parameter Min Typ Max Unit Test Conditions/Comments

REFERENCE

REFCAP

Absolute Voltage, V

REFCAP TC 50 ppm/°C 0.1 µF Capacitor Required from, REFCAP to AGND2

REFOUT

Typical Output Impedance 130 Ω

Absolute Voltage, V

Minimum Load Resistance 2 kΩ 5 VEN = 1

Maximum Load Capacitance 100 pF

ADC SPECIFICATIONS

Maximum Input Range at VIN

Nominal Reference Level at VIN 2.1908 V p-p 5 VEN = 1, Measured Differentially

(0 dBm0) 0 dBm

Absolute Gain

PGA = 0 dB +0.1 dB 1.0 kHz

PGA = 38 dB –0.5 dB 1.0 kHz

Gain Tracking Error ± 0.1 dB 1.0 kHz, +3 dBm0 to –50 dBm0

Signal to (Noise + Distortion)

PGA = 0 dB 76 dB 0 Hz to fS/2; fS = 8 kHz

PGA = 38 dB 70 dB 0 Hz to 4 kHz; fS = 64 kHz

Total Harmonic Distortion

PGA = 0 dB –86 dB

PGA = 38 dB –80 dB

Intermodulation Distortion –79 dB PGA = 0 dB

Idle Channel Noise –76 dB PGA = 0 dB

Crosstalk ADC-to-ADC –85 dB ADC1 Input Signal Level: 1 kHz, 0 dBm0

DC Offset 20 mV PGA = 0 dB

Power Supply Rejection –55 dB Input Signal Level at AVDD and DVDD

Wave Group Delay

Input Resistance at VIN

FREQUENCY RESPONSE

(ADC)7 Typical Output

Frequency (Normalized to fS)

0 0dB

0.03125 –0.1 dB

0.0625 –0.25 dB

0.125 –0.6 dB

0.1875 –1.4 dB

0.25 –2.8 dB

0.3125 –4.5 dB

0.375 –7.0 dB

0.4375 –9.5 dB

> 0.5 < –12.5 dB

REFCAP

REFOUT

2, 3

4, 5

2, 4

1.25 V 5 VEN = 0

2.5 V 5 VEN = 1

1.25 V 5 VEN = 0, Unloaded

2.5 V 5 VEN = 1, Unloaded

3.156 V p-p 5 VEN = 1, Measured Differentially

3.17 dBm

25 µs 64 kHz Output Sample Rate

50 µs 32 kHz Output Sample Rate

95 µs 16 kHz Output Sample Rate

190 µs8 kHz Output Sample Rate

25 kΩ

= 16.384 MHz, f

MCLK

= 8.192 MHz, fS = 8 kHz; TA = T

SCLK

ADC2 Input at Idle

Pins 1.0 kHz, 100 mV p-p Sine

6

DMCLK = 16.384 MHz

MIN

to T

, unless otherwise noted1.)

MAX

REV. 0

–9–

Page 10

ADSST-EM-3035

WARNING!

ESD SENSITIVE DEVICE

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC INPUTS

V

, Input High Voltage VDD – 0.8 V

INH

V

, Input Low Voltage 0 0.8 V

INL

, Input Current –0.5 µA

I

IH

, Input Capacitance 10 pF

C

IN

LOGIC OUTPUT

V

, Output High Voltage VDD – 0.4 V

OH

, Output Low Voltage 0 0.4 V |IOUT| < 100 A

V

OL

Three-State Leakage Current –0.3 A

POWER SUPPLIES

AV

DV

I

NOTES

1

2

3

4

5

6

7

8

Specifications subject to change without notice.

1, AVDD2 4.5 5.5 V

DD

DD

8

DD

Operating temperature range is as follows: –40°C to +85°C. Therefore, T

Test conditions: Input PGA set for 0 dB gain (unless otherwise noted).

At input to sigma-delta modulator of ADC.

Guaranteed by design.

Overall group delay will be affected by the sample rate and the external digital filtering.

The ADCs input impedance is inversely proportional to DMCLK and is approximated by: (4 ∞10”)/DMCLK.

Frequency response of ADC measured with input at audio reference level (the input level that produces an output level of –10 dBm0), with 38 dB preamplifier

bypassed and input gain of 0 dB.

Test Conditions: no load on digital inputs, analog inputs ac coupled to ground.

4.5 5.5 V

DD

DD

= –40°C and T

MIN

V

V |IOUT| < 100 A

See Table II

= +85°C.

MAX

Table II. Current Summary (AVDD = DVDD = 3.3 V)

Analog Digital Total MCLKON

Conditions Current Current Current (Max) SE ON Comments

ADCs Only On 16 16 32 1 YES REFOUT Disabled

REFCAP Only On 0.8 0 0.8 0 NO REFOUT Disabled

REFCAP and REFOUT Only On 3.5 0 3.5 0 NO

All Sections Off 0.1 1.9 2.0 0 YES

MCLK Active Levels

Equal to 0 V and DV

All Sections Off 0 0.05 0.06 0 NO

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C unless otherwise noted.)

AVDD, DVDD to GND . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

AGND to DGND . . . . . . . . . . . . . . . . . . . . . –0.3 V to +0.3 V

Digital I/O Voltage to DGND . . . . . . –0.3 V to DV

Analog I/O Voltage to AGND . . . . . . –0.3 V to AV

+ 0.3 V

DD

+ 0.3 V

DD

Operating Temperature Range Industrial (A Version)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 150°C

SOIC,

Thermal Impedance . . . . . . . . . . . . . . . . . . 75°C/W

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Digital Inputs Static and

Equal to

0 V and DV

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADSST-EM-3035 features proprietary ESD protection circuitry, permanent damage may occur

on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

DD

DD

–10–

REV. 0

Page 11

PIN CONFIGURATION

ADSST-EM-3035

VINP2

1

2

VINN2

3

VINP1

4

VINN1

AV

DD

AGND2

DGND

DV

DD

RESET

SCLK

MCLK

SDO

5

6

7

2

8

9

10

11

12

13

14

REFOUT

REFCAP

PIN FUNCTION DESCRIPTIONS

Mnemonic Function

VINP1 Analog Input to the Positive Terminal of Input

Channel 1

VINN1 Analog Input to the Negative Terminal of Input

Channel 1

VINP2 Analog Input to the Positive Terminal of Input

Channel 2

VINN2 Analog Input to the Negative Terminal of Input

Channel 2

VINP3 Analog Input to the Positive Terminal of Input

Channel 3

VINN3 Analog Input to the Negative Terminal of Input

Channel 3

VINP4 Analog Input to the Positive Terminal of Input

Channel 4

VINN4 Analog Input to the Negative Terminal of Input

Channel 4

VINP5 Analog Input to the Positive Terminal of Input

Channel 5

VINN5 Analog Input to the Negative Terminal of Input

Channel 5

VINP6 Analog Input to the Positive Terminal of Input

Channel 6

VINN6 Analog Input to the Negative Terminal of Input

Channel 6

REFOUT Buffered Reference Output, which has a nominal value

of 1.2 V or 2.4 V, the value being dependent on the

status of Bit 5 VEN (CRC:7). This pin can be overdriven

by an external reference if required.

REFCAP A Bypass Capacitor to AGND2 of 0.1 µF is required

for the on-chip reference. The capacitor should be

fixed to this pin.

AVDD2 Analog Power Supply Connection

AGND2 Analog Ground/Substrate Connection

DGND Digital Ground/Substrate Connection

DV

DD

Digital Power Supply Connection

VINN3

28

VINP3

27

VINN4

26

VINP4

25

VINN5

ADSST-

73360AR

TOP VIEW

(Not to Scale)

24

23

22

21

20

19

18

17

16

15

VINP5

VINN6

VINP6

AV

DD

AGND1

SE

SDI

SDIFS

SDOFS

1

Mnemonic Function

RESET Active Low Reset Signal. This input resets the entire chip,

resetting the control registers and clearing the digital

circuitry.

SCLK Output Serial Clock whose rate determines the serial trans-

fer rate to/from the ADSST73360AR. It is used to clock

data or control information to and from the serial port

(SPORT). The frequency of SCLK is equal to the frequency

of the master clock (MCLK) divided by an integer number

This integer number being the product of the external

master clock rate divider and the serial clock rate divider.

MCLK Master Clock Input. MCLK is driven from an external

clock signal.

SDO Serial Data Output of the ADSST-73360AR. Both data

and control information may be output on this pin and are

clocked on the positive edge of SCLK. SDO is in threestate when no information is being transmitted and when

SE is low.

SDOFS Framing Signal Output for SDO Serial Transfers. The

frame sync is one bit wide and it is active one SCLK period

before the first bit (MSB) of each output word. SDOFS

is referenced to the positive edge of SCLK. SDOFS is

in three-state when SE is low.

SDIFS Framing Signal Input for SDI Serial Transfers. The frame

sync is one bit wide and it is valid one SCLK period

before the first bit (MSB) of each input word. SDIFS is

sampled on the negative edge of SCLK and is ignored

when SE is low.

SDI Serial Data Input of the ADSST-73360AR. Both data

and control information may be input on this pin and are

clocked on the negative edge of SCLK. SDI is ignored

when SE is low.

SE SPORT Enable. Asynchronous input enable pin for the

SPORT. When SE is set low by the DSP, the output pins

of the SPORT are three-stated and the input pins are

ignored. SCLK is also disabled internally in order to decrease

power dissipation. When SE is brought high, the control

and data registers of the SPORT are at their original values

(before SE was brought low. However, the timing counters

and other internal registers are at their reset values.

AGND1 Analog Ground Connection

AVDD1 Analog Power Supply Connection

REV. 0

–11–

Page 12

ADSST-EM-3035

Grounding and Layout

ANALOG GROUND

DIGITAL GROUND

Figure 5. Grounding and Layout

Since the analog inputs to the ADSST-73360AR are differential,

most of the voltages in the analog modulator are common-mode

voltages. The excellent common-mode rejection of the part will

remove common-mode noise on these inputs. The analog and

digital supplies of the ADSST-73360AR are independent and

separately pinned out to minimize coupling between analog and

digital sections of the device. The digital filters on the encoder

section will provide rejection of broadband noise on the power

supplies, except at integer multiples of the modulator sampling

frequency. The digital filters also remove noise from the analog

inputs provided the noise source does not saturate the analog

modulator. However, because the resolution of the ADSST73360LAR ADC is high, and the noise levels from the

ADSST-73360AR are so low, care must be taken with regard to

grounding and layout.

The printed circuit board that houses the ADSST-73360AR

should be designed so the analog and digital sections are separated and confined to certain sections of the board. The

ADSST-73360AR pin configuration offers a major advantage in

that its analog and digital interfaces are connected on opposite

sides of the package. This facilitates the use of ground planes

that can be easily separated, as shown in Figure 5. A minimum

etch technique is generally best for ground planes as it gives the

best shielding. Digital and analog ground planes should be

joined in only one place. If this connection is close to the device,

it is recommended to use a ferrite bead inductor as shown in

Figure 5.

Avoid running digital lines under the device for they will couple

noise onto the die. The analog ground plane should be allowed

to run under the ADSST-73360AR to avoid noise coupling.

The power supply lines to the ADSST-73360AR should use as

large a trace as possible to provide low impedance paths and

reduce the effects of glitches on the power supply lines. Fast

switching signals such as clocks should be shielded with digital

ground to avoid radiating noise to other sections of the board,

and clock signals should never be run near the analog inputs.

Traces on opposite sides of the board should run at right angles

to each other. This will reduce the effects of feedthrough

through the board. A micro-strip technique is by far the best but

is not always possible with a double-sided board. In this technique, the component side of the board is dedicated to ground

planes while signals are placed on the other side.

Good decoupling is important when using high speed devices.

All analog and digital supplies should be decoupled to AGND

and DGND respectively, with 0.1 µF ceramic capacitors in

parallel with 10 µF tantalum capacitors. To achieve the best

from these decoupling capacitors, they should be placed as close

as possible to the device, ideally right up against it. In systems

where a common supply voltage drives both the AVDD and

DVDD of the ADSST-73360AR, it is recommended that the

system’s AVDD supply be used. This supply should have the

recommended analog supply decoupling between the AVDD

pins of the ADSST-73360AR and AGND and the recommended

digital supply decoupling capacitors between the DVDD pin

and DGND.

NOTE: FOR MORE DETAILS ON ADSST-73360AR, PLEASE

REFER TO DATA SHEET OF AD73360

Interfaces between ADSST-EM-3035 and Microcontroller Overview

The following paragraphs describe the interface between the

ADSST-EM-3035 chipset and the microcontroller. The sequence

of operations is a critical issue for proper functioning of the two

processors on the board. The DSP processor is primarily used to

compute various parameters, provide the impulse outputs on the

external LEDs and provide automatic gain switching inside the

ADC. The microcontroller can collect the data from the chipset

for data management for further processing. There are two basic

functions that the microcontroller performs in a handshaking

mode with the DSP processor:

•

Boot loading the DSP with metering software on power up

(for non-ROM coded version only)

•

Communication with the DSP on SPI to:

Send Initialization data on power up after boot loading the

DSP with metering software

Receive data from DSP during normal operation

Receive and send data during calibration

This section describes the Boot loading and SPI operations.

BOOT LOADING THE DSP PROCESSOR FROM THE MICROCONTROLLER

The DSP processor has an internal program memory RAM that

supports boot loading. With boot loading, the processor reads

instructions from a byte-wide data bus connected to the microcontroller and stores the instructions in the 24-bit wide internal

program memory. The host microcontroller, is the source of

bytes to be loaded into on-chip memory. The choice of which

technique to use depends upon the I/O structure of the host

microcontroller, availability of I/O port lines, and the amount

of address decoding logic already available in the system. The

description here is one of the many ways that this could be

configured. However, the software on the microcontroller has

been written in way to make optimum use of the configuration.

Figure 6 illustrates the system implementation to allow a

microcontroller to boot the DSP processor. The only hardware

required is a D-type flip-flop and a 5 kΩ resistor. The resistor

is used to pull the DSP processor’s BMS pin (Boot Memory

Select) high.

The DSP processor boots using the BDMA option. The BDMA

option can be used when pins Mode A, Mode B, and Mode C on

the DSP are tied low. With these pins tied low the DSP automatically enters its boot sequence after the processor is reset.

–12–

REV. 0

Page 13

ADSST-EM-3035

In the sequence of booting the DSP, it has to be loaded with an

object code into the internal program memory. The byte wide

memory boot code file has the following structure:

a) 32 words or 96 bytes of the initial header,

b)81 words or 243 bytes for initializing BDMA and associated

registers,

c) 6712 words or 20136 bytes of program code.

V

74L574

5k

PR

O

D0–D7

FLASH

DD

DSP

BMS

BR

RESET

D8–D15

C

PX

PY

PZ

D0–D7

D

CLK

D0–D7

CLOCK

Figure 6. System Architecture for Boot Loading DSP

Processor From Microcontroller

When the DSP is reset with the pins Mode A, Mode B, and

Mode C tied low, it enters into the byte wide memory data

access mode. The boot loading process will consist of the DSP

reading the first 32 words, a small delay, say one millisecond for

it execute these 32 words of program. The DSP will then read

the next 81 words. After which a small delay, of say one millisecond, will be required for it to execute these 81 words. The

DSP will now (with BDMA registers initialized) read the code

length also initialized in the previous process. It should be noted

that when the DSP reads the 20136 bytes from its port of the

program code, it will overwrite the first 113 words (i.e., 339

bytes). After reading 20136 bytes, it will start execution automatically.

The process of loading the code to the DSP is as follows:

•

After the microcontroller is reset, hold DSP in reset by bringing

reset pin low.

•

Make PX high and clock PY (low to high transition). This will

make BR low. In effect, the DSP will not read because it has

granted its buses since BR is asserted.

•

Put the first byte of the program code on the DSP bus D8 to

D15 and deassert BR, which is done by taking PX low and

clocking a transition on PY (low to high). Since the DSP buses

have been released, it will read the byte and assert BMS. The

assertion of BMS will cause the flip-flop to preset (PR on 74LS74)

itself and therefore BR is again asserted.

•

Continue this process byte by byte for 96 bytes and give a

small delay.

•

After the delay continue the byte loading process for the next

243 bytes and give a small delay again.

•

Continue the byte loading process for 20136 bytes.

•

Soon after the last program byte is loaded, the DSP starts

execution of the code.

At the start of execution, the DSP waits for uploading of 154

bytes of data consisting of calibration constants (gain & dc offsets),

E-pulse constants and filter coefficients. This data has to be sent

to the DSP processor on the SPI port. Until the DSP receives

the 154 bytes, the actual process of executing the metering code

on the DSP does not start. Soon after receiving all the constants

(i.e. 154 bytes) the metering process starts. Four dummy bytes

have to be sent after the start of execution for the DSP to send

back the check sum of its internal code. The microcontroller can

use this to verify that the complete metering code has been

loaded on the DSP processor properly. The DSP is now ready

to provide the computed data on the SPI port.

REV. 0

DATA

D0–D7

PIN BOOT 1

PIN BOOT 2

BR

BMS

ST

BYTE OF DATA

1

T1

MINIMUM 6 DSP

CLOCK CYCLES

Figure 7. Timing Diagram for Boot Loading the DSP Processor

–13–

Page 14

ADSST-EM-3035

SERIAL PERIPHERAL INTERFACE (SPI) AND CONTROL

The DSP and the microcontroller are interfaced through Serial

Peripheral Interface (SPI). The microcontroller is always configured as a master and the DSP as a slave.

FRAMING SIGNAL

RFS

TF

DR

DT

SCLK

FL2

DSP

DSP

CONTROL

SPI

TRANSMIT

SPI

RECEIVE

CLK

INTERRUPT

MICROCONTROLLER

Figure 8. Serial Peripheral Interface and Control

SPI OPERATION

There are two modes of communication between DSP and

microcontroller.

•

Microcontroller to DSP (while uploading the initial data of

154 bytes, including four bytes to read checksum of code

from DSP, and sending a command)

Bring the DSP_control pin low, i.e., give a high to low

transition. This informs the DSP that the data after this

transition is a valid data.

Send the data byte on the microcontroller’s SPI port. Since

the microcontroller is configured as a master, the clock

signal will be generated by the microcontroller and the

DSP being a slave will read the data byte in sync with the

clock signal. Bring DSP_control signal back to high state.

•

DSP to Microcontroller (while transmitting computed data

to the microcontroller)

The DSP during its metering code execution, is ready to

give the computed parameters to the microcontroller after

every 32 cycles of power line.

To request data from the DSP, the microcontroller sends a

request code 45h on the SPI bus.

The DSP then sends a high to low transition on Pin FL2

soon after it completes the next 32 cycles of computation as

an indication to the microcontroller that it is ready to

transmit most recent data.

Since the microcontroller is a master, it has to now send

clock signal to the DSP on the SPI to receive data. For the

clock signal to be generated, the microcontroller has to

send a dummy byte. The dummy byte (say, 0xFF) should

be one that is not recognized by the DSP as a command.

The microcontroller may send as many dummy bytes as it

requires up to a maximum of 522 bytes for the complete

data train. The data received from the DSP will be in the

same sequence as described in Table IV. If the microcontroller does not require all the parameters then it may

stop sending dummy bytes at any time.

The diagram below shows the sequence of operation.

FRAMING SIGNAL

CLOCK

DATA

Figure 9. SPI Sequence of Operation

Quadrant and Other Conventions

The data sent by the DSP is based on the following convention:

•

Figure 10 gives the quadrant convention used by the chipset.

•

Import means delivered from the utility to the user.

•

Export means delivered by the user to the utility.

•

Total means total of all three phases.

– REACTIVE

ACTIVE EXPORT

CAPACITIVE

Q2

Q3 Q4

+ REACTIVE

ACT IVE IMPORT

Q1

INDUCTIVE

Figure 10.

Power Up Initialization

To reduce the component count, cost and to give designer a

greater flexibility in designing, ADSST-EM-3035 has not been

provided with any Nonvolatile Memory to store the calibration

constants and initialization data. On power up, after the boot

loading of the DSP software, the microcontroller provides the

DSP with all the initialization data. After receiving the initialization data the DSP starts the metering. The table below list outs

the data that has to be transferred to the DSP on power up.

–14–

REV. 0

Page 15

ADSST-EM-3035

Table III. Data Transfer to DSP on Power-Up

Initialization Gain Constants

and DC Offsets Value

R Phase Voltage Gain 2 4000h

Y Phase Voltage Gain 2 4000h

B Phase Voltage Gain 2 4000h

R Phase Current Low Gain 2 4000h

Y Phase Current Low Gain 2 4000h

B Phase Current Low Gain 2 4000h

R Phase Current High Gain 2 4000h

Y Phase Current High Gain 2 4000h

B Phase Current High Gain 2 4000h

R Phase Voltage DC Offset 2 0

Y Phase Voltage DC Offset 2 0

B Phase Voltage DC Offset 2 0

R Phase Current Low Gain DC Offset 2 0

Y Phase Current Low Gain DC Offset 2 0

B Phase Current Low Gain DC Offset 2 0

R Phase Current High Gain DC Offset 2 0

Y Phase Current High Gain DC Offset 2 0

B Phase Current High Gain DC Offset 2 0

E-pulse (Type)*

Energy Pulse eφ = active

e1 = Apparent 1 1

Pulse E-pulse Constant

Range from 1,000–20,000 Impulse Constant 1 2 2000

(pulses/kWh)

Pulse E-pulse Constant Range from 1,000–20,000

PHASE COMPENSATION VARIABLES

R Phase Coeff for High Current Range 12 0000,

R Phase Coeff for Middle Current Range 12 -DoR Phase Coeff for Low Current Range 12 -DoY Phase Coeff for High Current Range 12 -DoY Phase Coeff for Middle Current Range 12 -DoY Phase Coeff for Low Current Range 12 -DoB Phase Coeff for High Current Range 12 -DoB Phase Coeff for Middle Current Range 12 -DoB Phase Coeff for Low Current Range 12 -Do-

*The first byte to be sent for initialization is 45h followed by all the above tabled

parameters in the same sequence.

Phase Compensation Coefficients

Three sets of filter coefficients have been provided which will be

automatically selected by the DSP during execution based on

the maximum current (Imax). In the ADSST-EM-3035, the

Imax is fixed at 20 Amps. Therefore the current ranges have

been grouped as:

•

High current range: From 20 Amps to 7 Amps

•

Middle current range: 7 Amps to 1.5 Amps

•

Low current range: 1.5 Amps to 0 Amps

Defaults

2 2000

0000,

7FFF,

0000,

0000,

0000

Data from DSP to Microcontroller

To facilitate easy of operation, the data transfer form DSP to

microcontroller has been segregated into multiple blocks.

Table IV lists the various data blocks:

Table IV. Data Transfer Sequence from DSP to Microcontroller

DATA from DSP on SPI BUS Byte(s)

REQUEST CODE 45h 1

R Phase Voltage 2

R Phase Current 2

R Phase Active Power 4

R Phase Apparent Power 4

R Phase Inductive Power 4

R Phase Capacitive Power 4

R Phase Power Factor 2

R Phase Active Energy Import 4

R Phase Apparent Energy 4

R Phase Inductive Energy 4

R Phase Active Energy Export 4

R Phase Capacitive Energy 4

Y Phase Voltage 2

Y Phase Current 2

Y Phase Active Power 4

Y Phase Apparent Power 4

Y Phase Inductive Power 4

Y Phase Capacitive Power 4

Y Phase Power Factor 2

Y Phase Active Energy Import 4

Y Phase Apparent Energy 4

Y Phase Inductive Energy 4

Y Phase Active Energy Export 4

Y Phase Capacitive Energy 4

B Phase Voltage 2

B Phase Current 2

B Phase Active Power 4

B Phase Apparent Power 4

B Phase Inductive Power 4

B Phase Capacitive Power 4

B Phase Power Factor 2

B Phase Active Energy Import 4

B Phase Apparent Energy 4

B Phase Inductive Energy 4

B Phase Active Energy Export 4

B Phase Capacitive Energy 4

Total Active Power 4

Total Apparent Power 4

Total Inductive Power 4

Total Capacitive Power 4

Average Power Factor 2

Total Active Energy Import 4

Total Apparent Energy 4

Total Inductive Energy 4

Total Active Energy Export 4

Total Capacitive Energy 4

Frequency 2

R Phase Channel_Present 1

Y Phase Channel_Present 1

REV. 0

–15–

Page 16

ADSST-EM-3035

DATA from DSP on SPI BUS Byte(s)

B Phase Channel_Present 1

R Phase Current Division FlagUnits_flag_R 1

Y Phase Current Division FlagUnits_flag_Y 1

B Phase Current Division FlagUnits_flag_B 1

R Phase Negative Power Flag 1

Y Phase Negative Power Flag 1

B Phase Negative Power Flag 1

R Phase (INDUC/CAP POWER Flag) 1

Y Phase (INDUC/CAP POWER Flag) 1

B Phase (INDUC/CAP POWER Flag) 1

GAIN CONTRASTS AND DC OFFSETS

R Phase Voltage Gain 2

Y Phase Voltage Gain 2

B Phase Voltage Gain 2

R Phase Current Low Gain 2

Y Phase Current Low Gain 2

B Phase Current Low Gain 2

R Phase Current High Gain 2

Y Phase Current High Gain 2

B Phase Current High Gain 2

R Phase Voltage DC Offset 2

Y Phase Voltage DC Offset 2

B Phase Voltage DC Offset 2

R Phase Current Low Gain DC Offset 2

Y Phase Current Low Gain DC Offset 2

B Phase Current Low Gain DC Offset 2

R Phase Current High Gain DC Offset 2

Y Phase Current High Gain DC Offset 2

B Phase Current High Gain DC Offset 2

DC_Offset Calibration Done (EFh) 1

Total Negative Power Flag 1

Total Inductive Capacitive Flag 1

HARMONIC ANALYSIS DATA

(All odd harmonics sequenced from fundamental

to 21st order, total 11 harmonics of 2 bytes each)

R Phase Voltage Components Magnitude

R Phase Current Components Magnitude 22

R Phase Voltage Components Phase 22

R Phase Current Components Phase 22

Y Phase Voltage Components Magnitude 22

Y Phase Current Components Magnitude 22

Y Phase Voltage Components Phase 22

Y Phase Current Components Phase 22

B Phase Voltage Components Magnitude 22

B Phase Current Components Magnitude 22

B Phase Voltage Components Phase 22

B Phase Current Components Phase 22

2 ⫻ 11 = 22

Table V. Interpretation of the Voltage Data

Phase Voltage Data

from DSP

Hex (2 byte) Decimal

5A10h 23056 230.56 V

Table VI. Interpretation of the Current Data

Line Current Data Unit

from DSP flag_X

Hex (2 Byte) Decimal (X = R/Y/B) Current

278Bh 10123 1 1.0123 A

278Bh 10123 0 10.123 A

Frequency Data from DSP

The frequency data is with two decimal places. This means that

the value has to be divided by 100 to get the frequency. For

example, if DSP data = 139Fh (decimal value = 5023), then the

frequency is 50.23 Hz

Interpretation of the Power Data

As in the case of current and voltages, described above, all the

power data supplied by DSP has to be interpreted, as shown in

Table VII.

The data received from the DSP is in a 4-byte format. The least

significant word comes first and the most significant word

comes last, e.g., 000D1C4A will come as 1C4A000D and this

word reversal has to be performed by the controller.

Table VII. Interpretation of the Power Data

Power Data from DSP

Hex (4-Byte) Decimal Power

000D1C4A 859210

Interpretation of the Power Factor Data

The DSP data for power factor has a resolution up to four decimal places. To get the value of Power Factor the DSP data has

to be divided by 10,000.

Table VIII. Interpretation of the Power Factor Data

Power Factor Data

from DSP

Hex (2-Byte) Decimal Power Factor

1388h 5000 0.5

Interpretation of the Energy Data

The DSP data for energy has a resolution up to four decimal

places. To get the value of Energy the DSP data has to be

divided by 10,000.

Voltage

859.210 W

–16–

Table IX. Interpretation of the Energy Data

Energy Data

from DSP

Hex (4-Byte) Decimal Energy

000D1C4Ah 859210

85.9210 kWh

REV. 0

Page 17

ADSST-EM-3035

Interpretation of Harmonics Data

Each harmonic data from DSP is two byte wide. The voltage

and phase angle values have a resolution of up to second decimal place and the current has up to third decimal place.

The reference design has a CT with turn ratio of 1:2500 and

burden resistance of 82 Ω. This generates 0.656 V rms or 0.928 V

(0–pk) at 20 amps current. This leaves enough margins

rent pulses or low crest factor loads, such as electronic loads

such as SMPS.

INPUT SECTION

PHASE VOLTAGE

1M

GND

TO ADC

TO ADC

V

CC

100

NEUTRAL

LINE CURRENT

3.3k

*VALUE MAY CHANGE ACCORDING

0.001F

82

GND PDSP

100

0.01F

Figure 11. Input Section

ADSST-73360AR has an input range of V

to V

– (V

REF

). This limit defines the resistance network on the potential

V

REF

0.6525) V p-p (0.856 V to 4.14 V

REF

REF

+ (V

0.6525)

REF

for 2.5 V

The maximum current can be up to 32.767 amps.

CALIBRATION

ADSST-EM-3035 Chipset has a highly advance calibration

routines embedded into the software. Easy of calibration is the

philosophy in ADSST-EM-3035 Chipset. ADSST-EM-3035

chipset enables dc offset and gain computation on the voltage

and current channels and also performs phase and nonlinearity

compensation on the current transformer. Calibrations for

power is done internally and no extra procedure is required for

it. This section describes the calibration procedure required.

Voltage Gain Calibration

To calibrate voltage channel:

•

•

•

•

circuits and the burden resistance on the secondary side of the

CT. ADSST-73360AR being a unipolar ADC the ac, potential, and current have to be offset by a desired dc level. The

reference design has a dc offset of 2.5 V. This limits the p-p

signal range of potential and current to ±1.64 V peak or

1.16 V rms.

For details please refer to the data sheet of AD73360.

Potential Section

The selection of potential divider circuit should be such that it can:

•

Handle high surge voltages

•

Should have minimum VA burden

•

Give approximately 0.656 V rms output at nominal voltage

•

•

Current Gain Calibration

The Current Gain calibration is performed at two current settings to compute two current gain coefficients, namely current

high gain and current low gain coefficients. In all six current

gain coefficients are calculated for all the three phase currents.

The gains are calculated at:

•

•

such that it sufficiently takes care of over voltage.

•

The reference design has 1 MΩ and 3.3 kΩ resistance

network.

Current Section

The selection of CT ratio and burden resistance should be such

that it can

•

Handle the complete dynamic range for the current signal input.

•

Give around 1 V(0–pk) output at maximum current such that

it sufficiently takes of loads with low crest factors and

current surges.

DC Offset Calibration for Voltage and Current

Writing EFh to DSP on SPI initiates the dc offset calibration in

the DSP. After 32 cycles the DSP returns back the offset values

and sends FEh as a mark of completion on the SPI. The

microcontroller has to store the dc offset constants for uploading

during power up.

for cur-

Inject a known voltage (VI ) to the meter based on ADSSTEM-3035

Note the voltage read by meter say VM

Voltage gain coefficient = (VI/VM) 0x4000.

The calculated coefficients are to be communicated to the

microcontroller for storage.

Repeat the same procedure for all the three channels

Note: Where 0x4000 is default coefficient in hex

I1 = 20 A

I2 = 5 A

Inject the meter with current value I

1

Note the value of the current sent by meter (IM)

Current low gain coefficient = (I

Inject the meter with I

current

2

Note the value of the current sent by meter (I

Current high gain coefficient = (I

) 0x4000

1/IM

) 0x4000

2/IM

)

M

The calculated coefficients are to be communicated to the

microcontroller for storage

Repeat the procedure for other Phases

REV. 0

–17–

Page 18

ADSST-EM-3035

Table X. DC Offset Calibration Data

Command from Setup Input

DC-Offset Microcontrolled Voltage and

Calibration in Hex Current

Offset 0xEF V = Nominal

Calibration Voltage

(All Three Phases) I = 0

The microcontroller now issues 0x45H command on SPI to the

DSP. The DSP sends back Table IV. This table will contain

new dc-offset coefficients. The microcontroller should store

these coefficients.

Procedure

•

Power up the meter with nominal voltage

•

Give command for calculation of the coefficient (EFh) to

DSP on SPI.

•

Receive the coefficient by sending Ox45 on SPI after waiting

at least 1s.

•

Store the coefficient

Phase Compensation

The ADSST-EM-3035 employs a patent pending algorithm for

phase compensation and non-linearity. This also reduces the

cost of the end product by reducing the cost of the sensing elements i.e., CT. To compensate for the phase non-linearity in

CTs, the compensation is performed at three current ranges.

The three current ranges for calibration are:

•

20 A > I1 > 7 A

•

7 A > I2 > 1.5 A

•

1.5 A > I3 > 0 A

Procedure

•

The ADSSTCOMP.EXE supplied with the chipset is an

executable file for calculation of the phase compensation

coefficients.

•

Set the voltage equal to 230 V which is the nominal voltage at

all phases.

•

Inject I1 current at 0.5 inductive (60° lagging) in all phases.

•

The chipset performs the harmonic analysis by providing

information about the magnitude and phase angle for all odd

harmonics sequenced from fundamental to 21st order. The

DSP sends the phase angle information along with other data

as described in Table IV after sending the command 0x45.

•

The value of the phase angle for line current A, B, and C is

available at the locations 283, 371, and 459 respectively (say

, PB, PC) in the data stream sent by the DSP.

P

A

•

Calculate the normalized lag value (LA, LB, LC) for each phase

as under :

P

°+60

–

L

=

A

L

=

B

L

=

C

•

Run ADSSTCOMP.EXE on PC

•

Feed the normalized lag value during the execution of

ADSSTCOMP.EXE.

•

The ADSSTCOMP.EXE will provide six coefficients for each

phase and the size of each coefficient is 2 bytes.

•

The phase compensation should be performed for the three

currents on each phase. These coefficients must be stored in a

suitable location such that DSP can get these coefficients on

power up in the same sequence as shown in Table III.

Configuration of Output E-pulses

The ADSST-EM-3035 Chipset provides two pulse outputs

•

Configurable for Active energy or Apparent energy

•

Reactive energy

•

Table III gives the default conditions and configuration for

first E-pulse.

•

The E-pulse constant is variable from 1,000 pulses/kWh to

20,000 pulses/kWh.

•

Example: To set 1,500 pulses/kWh, the new E-pulse constant will be 1,500

Inaccuracy of the E-pulse

Higher E-pulse constant is always desirable as it reduces the

testing time. However, increase in pulses/kWh may increases the

error at higher power. The error can be calculated by the

given formula.

General Note About Calibration

•

It should be noted that ADSST-EM-3035 does not have any

permanent memory and hence all the calibration data are to

be stored by the microcontroller and provided to the DSP at

the time of power up.

•

Before starting the calibration the meter should be supplied with

the default calibration constants as specified in the Table III.

120

.

°+60

–

120

.

°+60

–

120

.

A

2

P

B

2

P

C

2

(1)

(2)

(3)

–18–

REV. 0

Page 19

•

The whole calibration can be done in very few steps as shown

in the example below.

Start meter with nominal voltage and calculate dc offset

Set current at 20 A and calculate voltage gain and

low

current gain for all channels

Set current at 5 A and calculate low current gain for

all chan

nels

Set current at 20 A < I < 7 A and perform phase compensation

for all channels

Set current at 1.5 A < I < 7 A and perform phase compensation

for all channels

Set current at 1.5 A < I < 0

for all channels

tion

A

and perform phase compensa-

Table XII. Maximum Error (Power and Energies)

Current Voltage PF Min Typ Max Unit

0.01 In

0.05 In

0.02 In

< I < 0.05 In V

< I < I

MAX

< I < 0.1 In V

N

V

N

N

1.0 ± 0.1 ± 0.2 %

1.0 ± 0.1 ± 0.2 %

0.5 Lagging ± 0.15 ± 0.35 %

0.8 Leading ± 0.15 ± 0.35 %

0.1 In

< I < I

MAX

V

N

0.5 Lagging ± 0.1 ± 0.2 %

0.8 Leading ± 0.1 ± 0.2 %

ADSST-EM-3035

MEASUREMENT ACCURACY

Overall Accuracy, Power and Energy Measurement

The accuracy figures are measured in nominal conditions

unless otherwise indicated. The measurement are taken on the

reference design with the given below nominal values.

Reference Design with Metal CT (0.5 Class)

Table XI. Nominal Value: Reference Design Parameters

Parameters Nominal Value

Nominal Voltage (Neutral to Line) V

NVN

Max Voltage (Neutral to Line) 300 V

Max Current I

MAX

Base Current In = 5 A

Frequency

Power Factor 1

THD of Voltage < 2%

Temperature 23 ± 2°C

= 230 V ± 1%

I

= 20 A

MAX

FN = 50

Hz/60 Hz ± 10%

Table XIII. Unbalanced Load Error

Current Voltage PF Min Typ Max Unit

0.05 In

< I < I

0.1 In < I < I

MAX

MAX

V

N

V

N

1.0 ± 0.15 ± 0.2 %

0.5 Lagging ± 0.15 ± 0.2 %

Table XIV. Voltage Variation Error

Voltage Current PF Min Typ Max Unit

± 10% 0.05 In < I < I

V

N

VN ± 10% 0.1 In < I < I

MAX

MAX

1.0 ± 0.05 ± 0.1 %

0.5 Lagging ± 0.05 ± 0.1 %

Table XV. Frequency Variation Errors

Frequency Current PF Min Typ Max Unit

± 10% 0.05 In < I < I

V

N

VN ± 10% 0.1 In < I < I

MAX

MAX

1.0 ± 0.05 ± 0.1 %

0.5 Lagging ± 0.05 ± 0.1 %

REV. 0

–19–

Page 20

ADSST-EM-3035

Table XVI. Harmonic Distortion Error

Current Current Min Typ Max Unit

10% of Third

0.05 In < I < I

MAX

± 0.05 ± 0.1 %

Harmonic

Table XVII. Reverse Phase Sequence Error

Current Voltage Min Typ Max Unit

0.1 In V

N

± 0.05 %

ELECTRICAL CHARACTERISTICS OF ADSST-EM-3035

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 V to 7 V

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.3 V to V