Page 1

a

TigerSHARC

®

Embedded Processor

ADSP-TS101S

KEY FEATURES

300 MHz, 3.3 ns instruction cycle rate

6M bits of internal—on-chip—SRAM memory

19 mm × 19 mm (484-ball) or 27 mm × 27 mm

(625-ball) PBGA package

Dual computation blocks—each containing an ALU, a multi-

plier, a shifter, and a register file

Dual integer ALUs, providing data addressing and pointer

manipulation

Integrated I/O includes 14-channel DMA controller, external

port, four link ports, SDRAM controller, programmable

flag pins, two timers, and timer expired pin for system

integration

1149.1 IEEE compliant JTAG test access port for on-chip

emulation

On-chip arbitration for glueless multiprocessing with up to

eight TigerSHARC processors on a bus

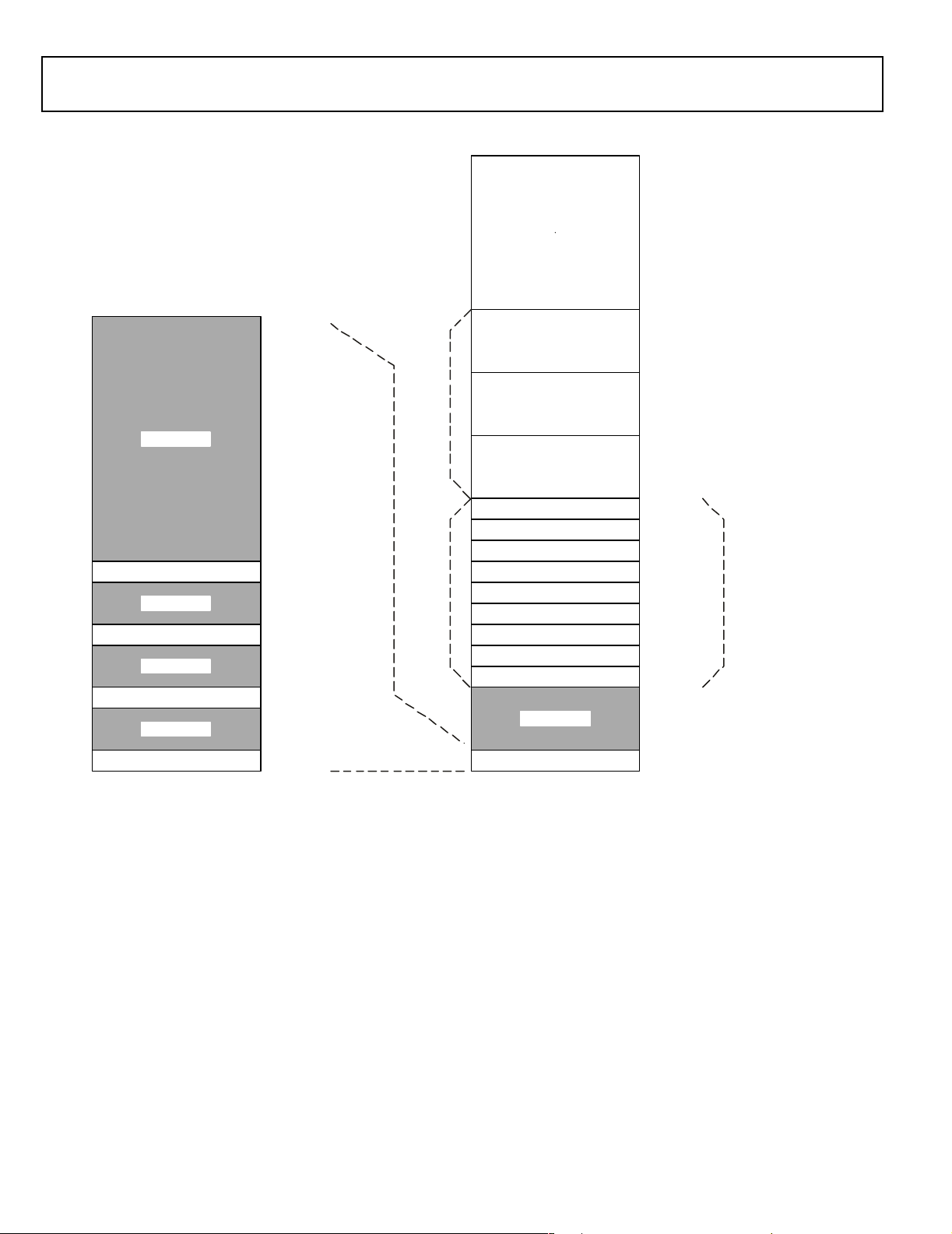

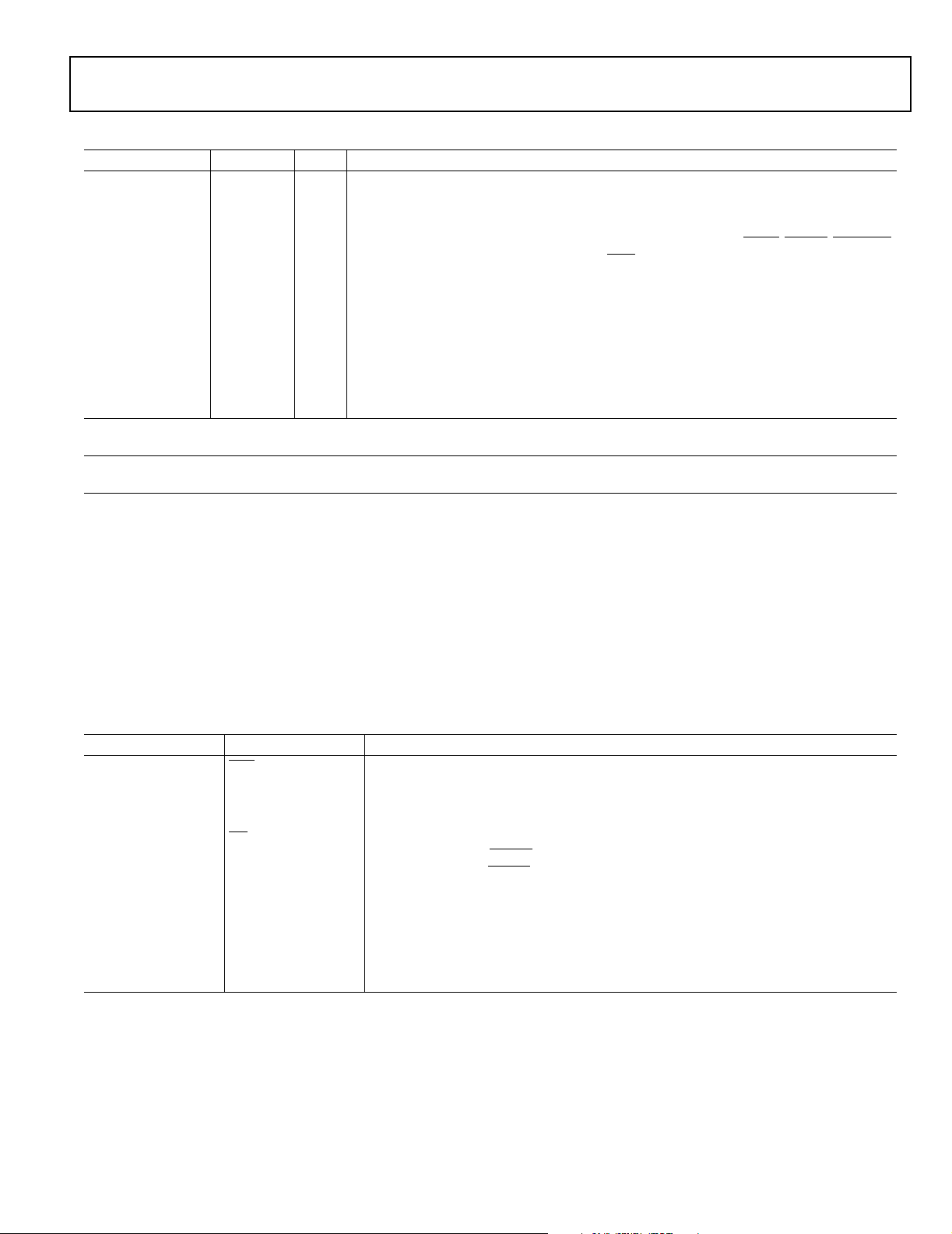

COMPUTATIONAL BLOCKS

SHIFTER

ALU

MULTIPLIER

X

REGISTER

FILE

32 × 32

128 128

DAB

DAB

128 128

Y

REGISTER

FILE

32 × 32

MULTIPLIER

ALU

SHIFTER

PROGRAM SEQUENCER

PC BTB IRQ

ADDR

IAB

FETCH

DATA ADDRESS GENERATION

INTEGER

32

128

32

128

32

128

I/O PROCESSOR

CONTROLLER

CONTROL/

STATUS/

TCBs

32

JALU

32 × 32 32 × 32

DMA

DMA ADDRESS

32

INTEGER

KALU

DMA DATA

KEY BENEFITS

Provides high performance Static Superscalar DSP opera-

tions, optimized for telecommunications infrastructure

and other large, demanding multiprocessor DSP

applications

Performs exceptionally well on DSP algorithm and I/O bench-

marks (see benchmarks in Table 1 and Table 2)

Supports low overhead DMA transfers between internal

memory, external memory, memory-mapped peripherals,

link ports, other DSPs (multiprocessor), and host

processors

Eases DSP programming through extremely flexible instruc-

tion set and high level language friendly DSP architecture

Enables scalable multiprocessing systems with low commu-

nications overhead

INTERNAL MEMORY

MEMORY

M0

64K × 32

AD

32 256

MEMORY

M1

64K × 3 2

AD

256

MEMORY

M2

64K × 32

AD

I/O ADDRESS

LINK DATA

M0 ADDR

M0 DATA

M1 ADDR

M1 DATA

M2 ADDR

M2 DATA

32

CONTROLLER

SDRAM CONTROLLER

EXTERNAL PORT

MULTIPROCESSOR

INTERFACE

HOST INTERFACE

INPUT FIFO

OUTPUT BUFFER

OUTPUT FIFO

CLUSTER BUS

ARBITER

LINK PORT

CONTROL/

STATUS/

BUFFERS

JTAG PORT

LINK

PORTS

6

32

ADDR

64

DATA

CNTRL

3

L0

8

3

L1

8

3

8

L2

3

8

L3

TigerSHARC and the TigerSHARC logo are registered trademarks of Analog Devices, Inc.

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

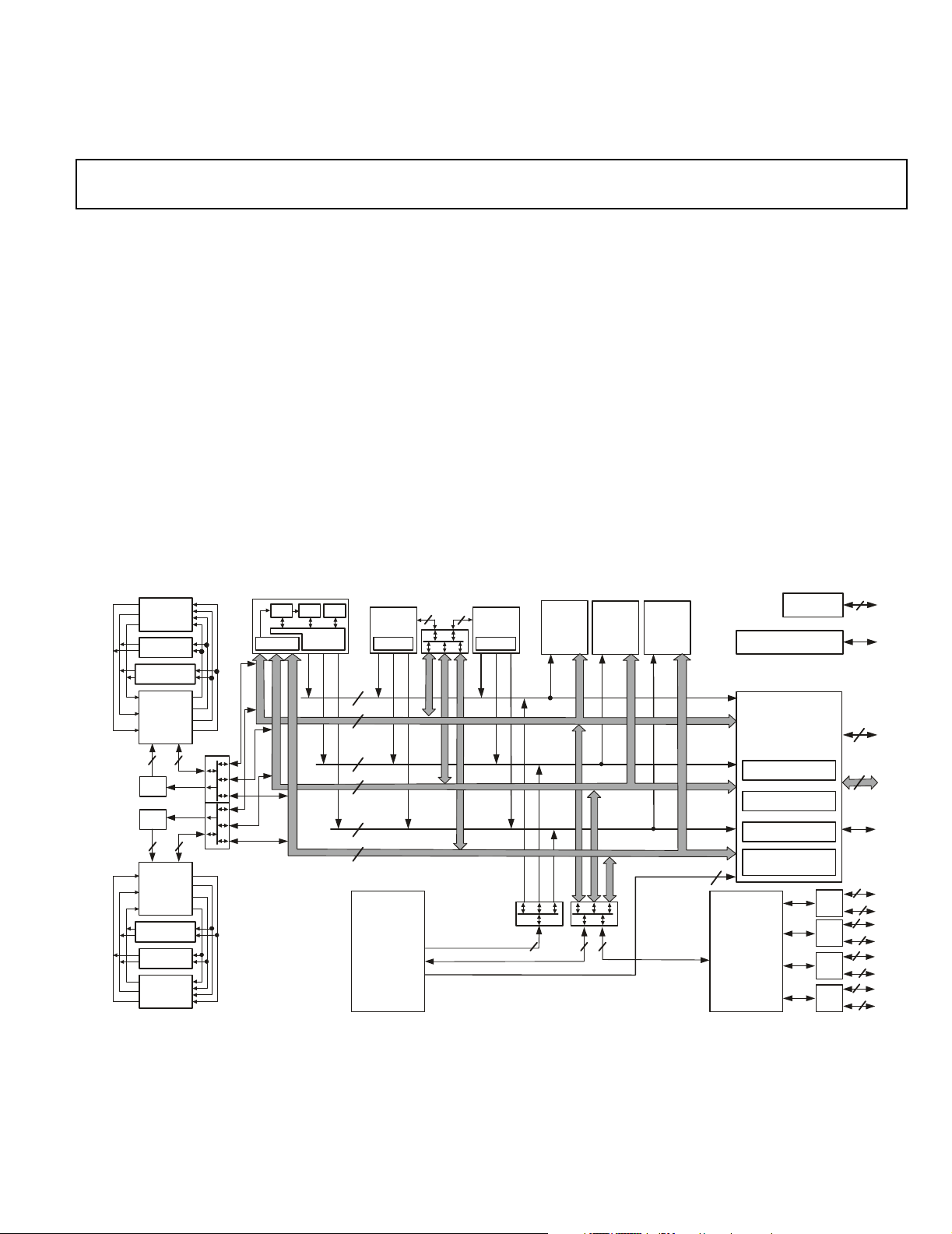

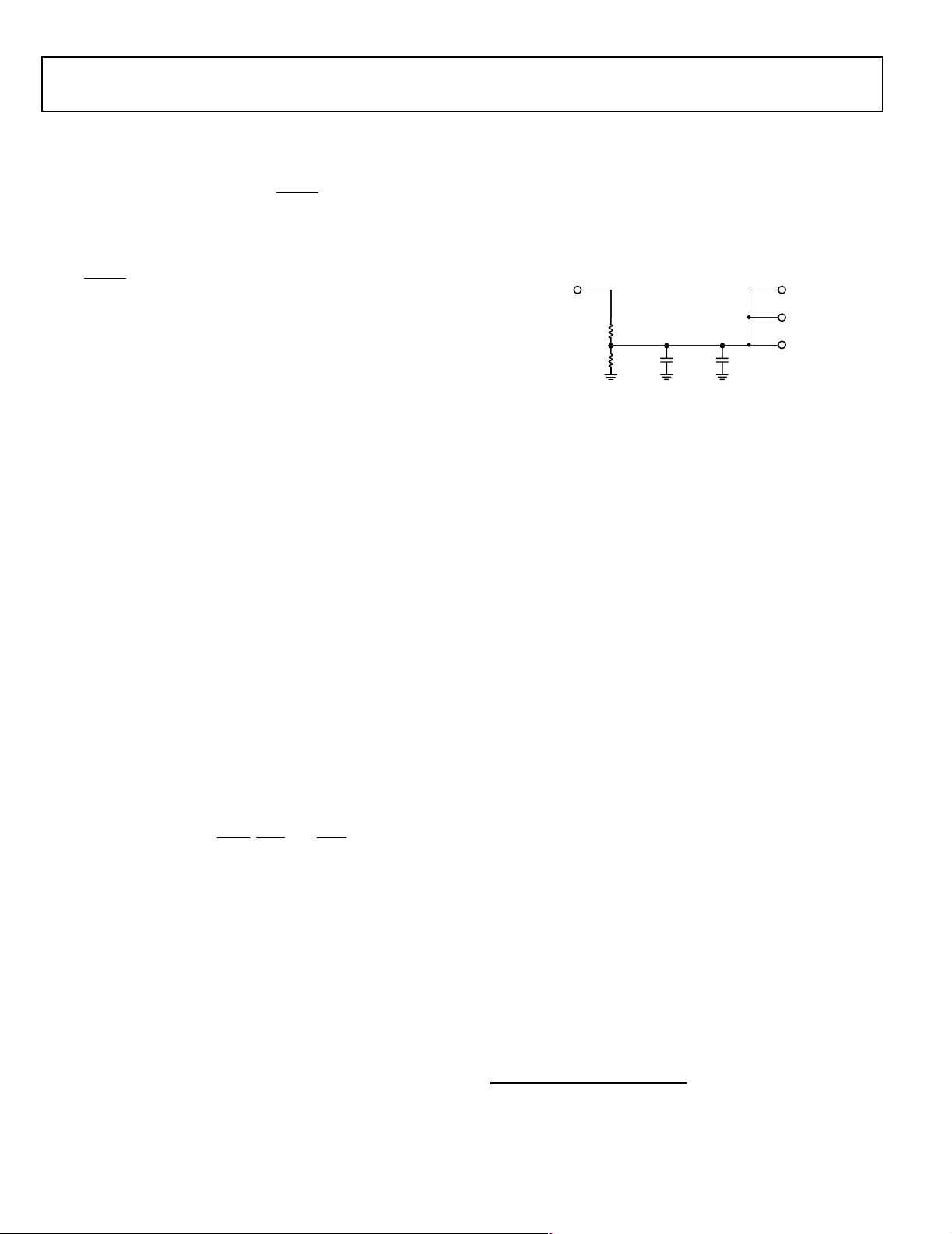

Figure 1. Functional Block Diagram

One Technology Way, P.O.Box 9106, Norwood, MA 02062-9106 U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

ADSP-TS101S

TABLE OF CONTENTS

General Description ................................................. 3

Dual Compute Blocks ............................................ 4

Data Alignment Buffer (DAB) .................................. 4

Dual Integer ALUs (IALUs) .................................... 4

Program Sequencer ............................................... 5

Interrupt Controller ........................................... 5

Flexible Instruction Set ........................................ 5

On-Chip SRAM Memory ........................................ 5

External Port

(Off-Chip Memory/Peripherals Interface) ................ 6

Host Interface ................................................... 6

Multiprocessor Interface ...................................... 7

SDRAM Controller ............................................ 7

EPROM Interface .............................................. 7

DMA Controller ................................................... 7

Link Ports ........................................................... 8

Timer and General-Purpose I/O ............................... 9

Reset and Booting ................................................. 9

Low Power Operation ............................................ 9

Clock Domains .................................................... 9

Output Pin Drive Strength Control ......................... 10

Power Supplies ................................................... 10

Filtering Reference Voltage and Clocks .................... 10

Development Tools ............................................. 10

Designing an Emulator-

Compatible DSP Board (Target) .......................... 11

Additional Information ........................................ 11

Pin Function Descriptions ....................................... 12

Pin States at Reset ............................................... 12

Pin Definitions ................................................... 12

Strap Pin Function Descriptions ................................ 19

Specifications ........................................................ 20

Recommended Operating Conditions ...................... 20

Electrical Characteristics ....................................... 20

Absolute Maximum Ratings .................................. 21

ESD Sensitivity ................................................... 21

Timing Specifications .......................................... 21

General AC Timing .......................................... 21

Link Ports Data Transfer

and Token Switch Timing ............................... 29

Output Drive Currents ......................................... 32

Test Conditions .................................................. 34

Output Disable Time ......................................... 34

Output Enable Time ......................................... 34

Capacitive Loading ........................................... 34

Environmental Conditions .................................... 36

Thermal Characteristics ..................................... 36

PBGA Pin Configurations ........................................ 36

Outline Dimensions ................................................ 43

Ordering Guide ..................................................... 44

REVISION HISTORY

12/04—Rev. A to Rev. B

Provides more information on clock signals (including a usable

jitter specification) in:

Reference Clocks—Core Clock (CCLK) Cycle Time ..... 22

Reference Clocks—Local Clock (LCLK) Cycle Time .... 22

Reference Clocks—System Clock (SCLK) Cycle Time . . 23

Reference Clocks—Test Clock (TCK) Cycle Time ....... 23

Updates input setup times for external port pins in:

AC Signal Specifications (for SCLK <16.7 ns) ............. 25

Rev. B | Page 2 of 44 | December 2004

Page 3

GENERAL DESCRIPTION

ADSP-TS101S

The ADSP-TS101S TigerSHARC processor is an ultrahigh performance, static superscalar processor optimized for large signal

processing tasks and communications infrastructure. The DSP

combines very wide memory widths with dual computation

blocks—supporting 32- and 40-bit floating-point and 8-, 16-,

32-, and 64-bit fixed-point processing—to set a new standard of

performance for digital signal processors. The TigerSHARC

processor’s static superscalar architecture lets the processor execute up to four instructions each cycle, performing 24 fixedpoint (16-bit) operations or six floating-point operations.

Three independent 128-bit wide internal data buses, each

connecting to one of the three 2M bit memory banks, enable

quad word data, instruction, and I/O accesses and provide

14.4G bytes per second of internal memory bandwidth. Operat-

ing at 300 MHz, the ADSP-TS101S processor’s core has a 3.3 ns

instruction cycle time. Using its Single-Instruction, MultipleData (SIMD) features, the ADSP-TS101S can perform 2.4 billion 40-bit MACs or 600 million 80-bit MACs per second.

Table 1 and Table 2 show the DSP’s performance benchmarks.

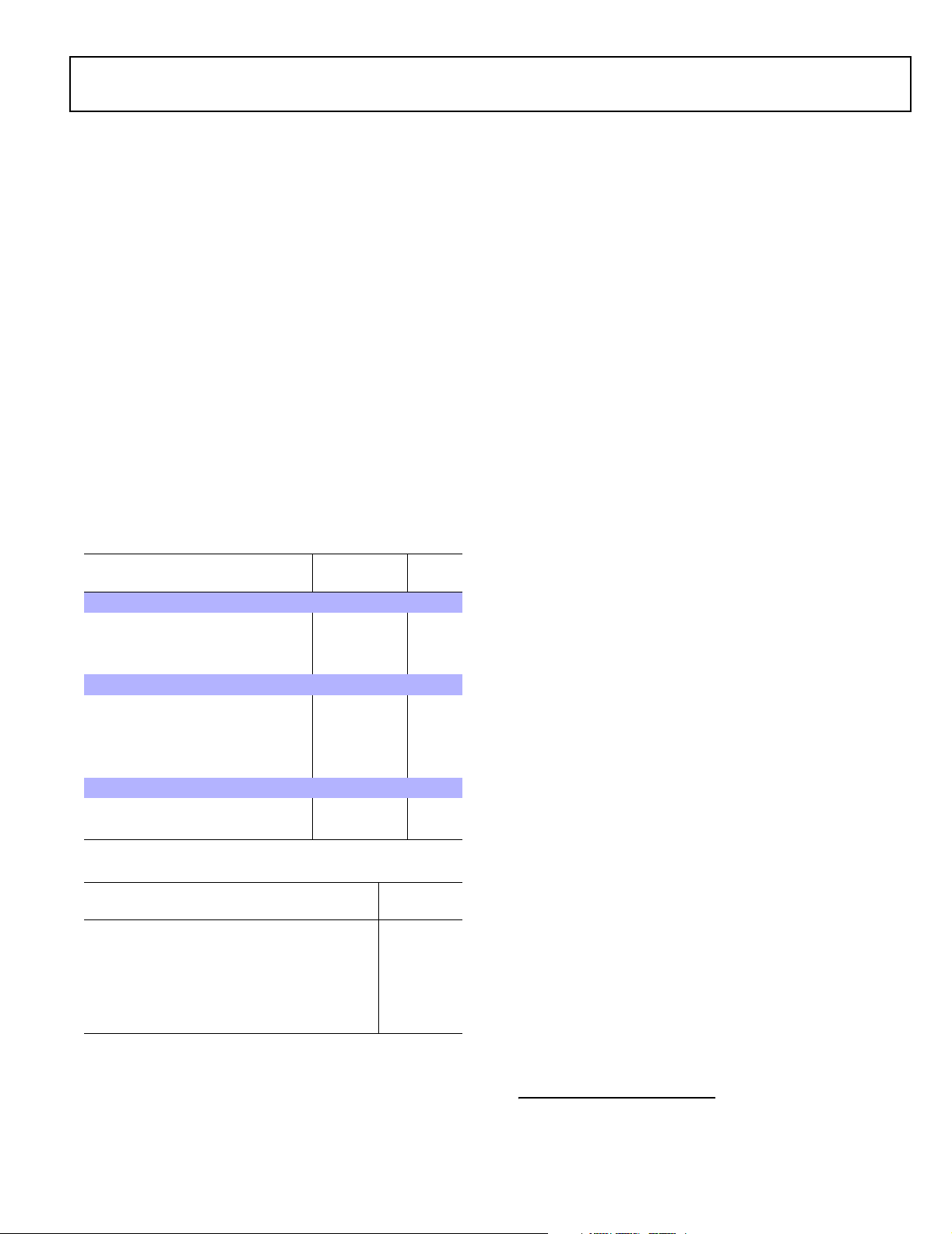

Table 1. General-Purpose Algorithm Benchmarks

at 300 MHz

Clock

Benchmark Speed

32-bit algorithm, 600 million MACs/s peak performance

1024 point complex FFT (Radix 2) 32.78 µs 9,835

50-tap FIR on 1024 input 91.67 µs 27,500

Single FIR MAC 1.83 ns 0.55

16-bit algorithm, 2.4 billion MACs/s peak performance

256 point complex FFT (Radix 2) 3.67 µs 1,100

50-tap FIR on 1024 input 24.0 µs 7,200

Single FIR MAC 0.47 ns 0.14

Single complex FIR MAC 1.9 ns 0.57

I/O DMA transfer rate

External port 800M bytes/s n/a

Link ports (each) 250M bytes/s n/a

Cycles

Table 2. 3G Wireless Algorithm Benchmarks

Execution

Benchmark

Turbo decode

384 kbps data channel

Viterbi decode

12.2 kbps AMR

Complex correlation

3.84 Mcps4 with a spreading factor of 256

1

The execution speed is in instruction cycles per second.

2

This value is for six iterations of the algorithm. For eight iterations of the turbo

decoder, this benchmark is 67 MIPS.

3

Adaptive multi rate (AMR)

4

Megachips per second (Mcps)

3

voice channel

1

(MIPS)

51 MIPS

0.86 MIPS

0.27 MIPS

2

The ADSP-TS101S is code compatible with the other

TigerSHARC processors.

The Functional Block Diagram on Page 1 shows the ADSPTS101S processor’s architectural blocks. These blocks include:

• Dual compute blocks, each consisting of an ALU, multiplier, 64-bit shifter, and 32-word register file and associated

data alignment buffers (DABs)

•Dual integer ALUs (IALUs), each with its own 31-word

register file for data addressing

• A program sequencer with instruction alignment buffer

(IAB), branch target buffer (BTB), and interrupt controller

• Three 128-bit internal data buses, each connecting to one

of three 2M bit memory banks

•On-chip SRAM (6Mbit)

• An external port that provides the interface to host processors, multiprocessing space (DSPs), off-chip memory

mapped peripherals, and external SRAM and SDRAM

• A 14-channel DMA controller

• Four link ports

• Two 64-bit interval timers and timer expired pin

• A 1149.1 IEEE compliant JTAG test access port for on-chip

emulation

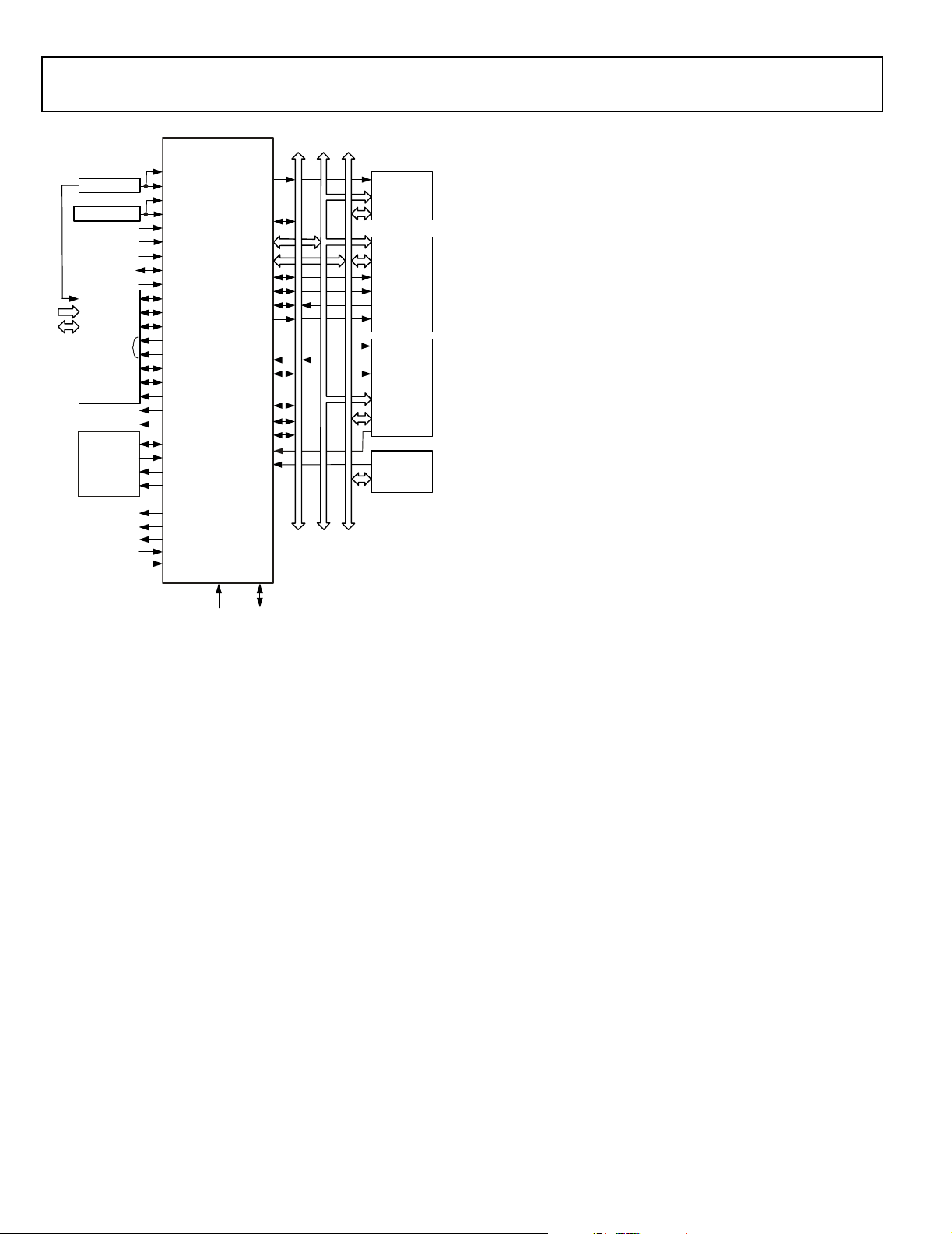

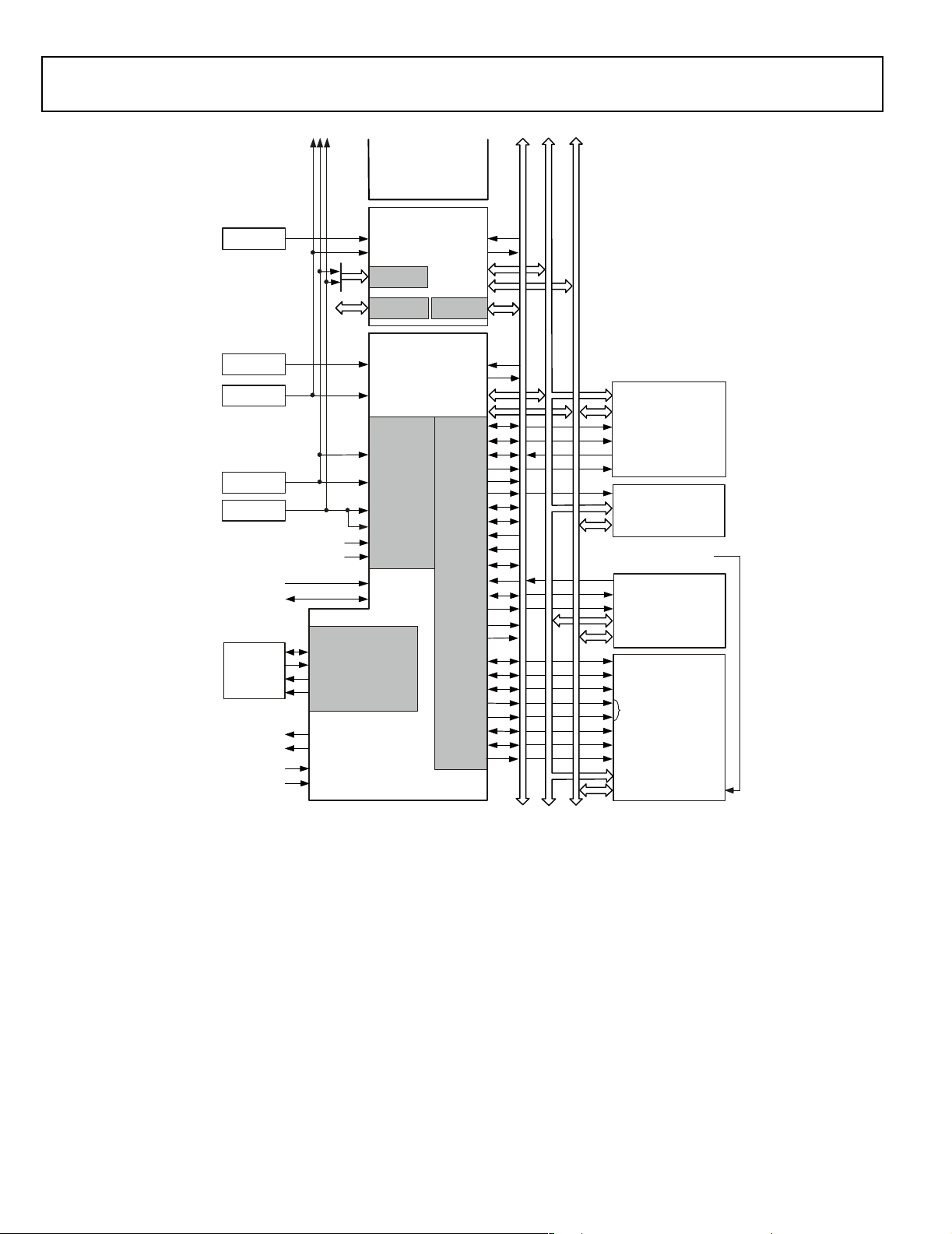

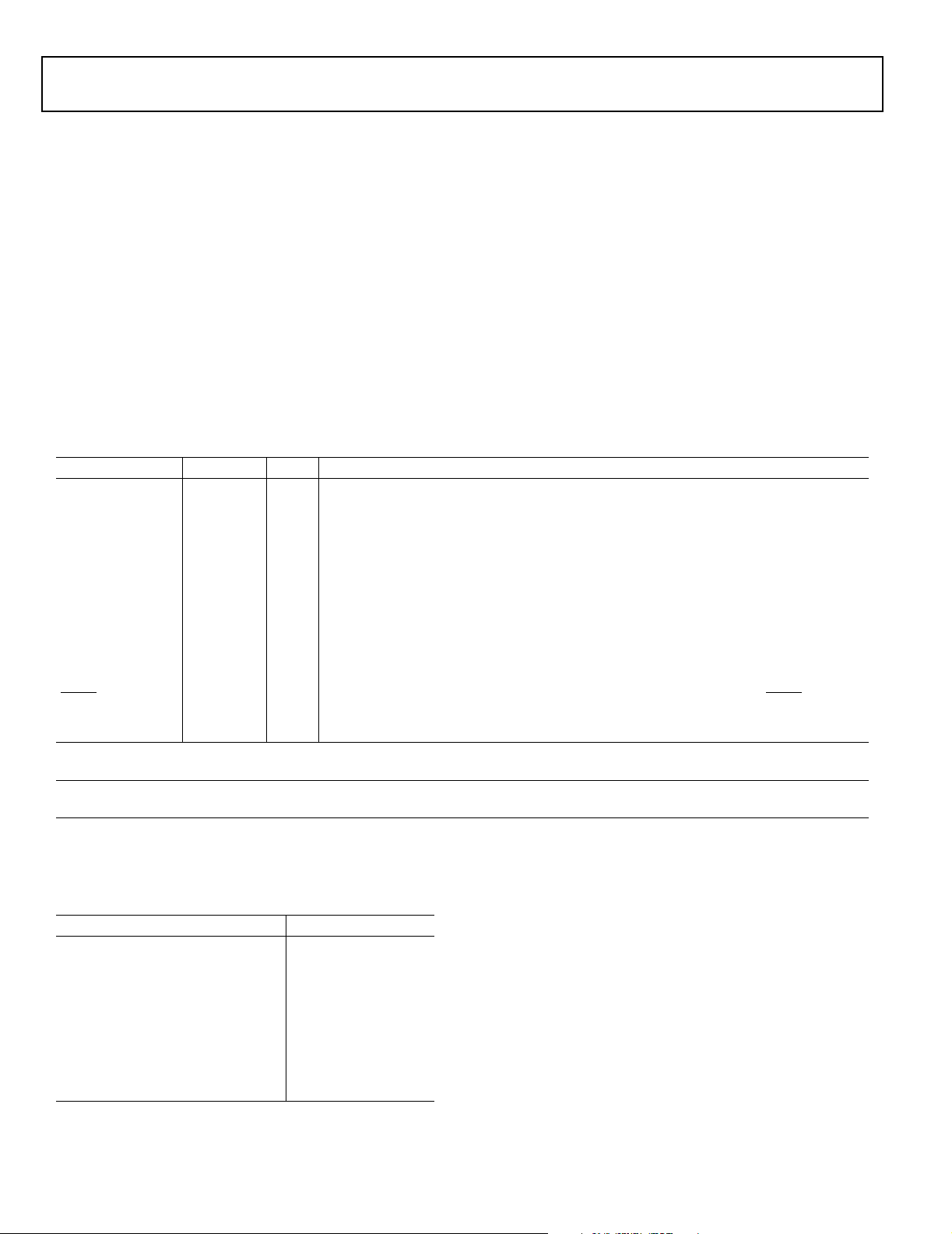

Figure 2 shows a typical single processor system with external

SDRAM. Figure 4 on Page 8 shows a typical multiprocessor

system.

TM

†

The TigerSHARC processor uses a Static Superscalar

architecture. This architecture is superscalar in that the ADSP-TS101S

processor’s core can execute simultaneously from one to four

32-bit instructions encoded in a very large instruction word

(VLIW) instruction line using the DSP’s dual compute blocks.

Because the DSP does not perform instruction reordering at

run-time—the programmer selects which operations will execute in parallel prior to run-time—the order of instructions is

static.

With few exceptions, an instruction line, whether it contains

one, two, three, or four 32-bit instructions, executes with a

throughput of one cycle in an eight-deep processor pipeline.

For optimal DSP program execution, programmers must follow

the DSP’s set of instruction parallelism rules when encoding an

instruction line. In general, the selection of instructions that the

DSP can execute in parallel each cycle depends on the instruction line resources each instruction requires and on the source

and destination registers used in the instructions. The programmer has direct control of three core components—the IALUs,

the compute blocks, and the program sequencer.

The ADSP-TS101S, in most cases, has a two-cycle arithmetic

execution pipeline that is fully interlocked, so whenever a computation result is unavailable for another operation dependent

†

Static Superscalar is a trademark of Analog Devices, Inc.

Rev. B | Page 3 of 44 | December 2004

Page 4

ADSP-TS101S

CLOCK

REFERENCE

SDRAM

MEMORY

(OPTIONAL)

CS

CLK

ADDR

RAS

CAS

DATA

DQM

WE

CKE

A10

LINK

DEVICES

(4 MAX)

(OPTIONAL)

ADSP-TS101S

LCLK_P

SCLK_P

S/LCLK_N

V

REF

LCLKRAT2–0

SCLKFREQ

IRQ3–0

FLAG3–0

ID2–0

MSSD

RAS

CAS

LDQM

HDQM

SDWE

SDCKE

SDA10

FLYBY

IOEN

LXDAT7–0

LXCLKIN

LXCLKOUT

LXDIR

TMR0E

BM

BUSLOCK

CONTROLIMP2–0

DS2–0

ADDR31–0

DATA63–0

WRH/WRL

MS1–0

BR7–0

BOFF

DMAR3–0

RESET JTAG

BMS

BRST

ACK

MSH

HBR

HBG

CPA

DPA

RD

BOOT

EPROM

(OPTIONAL)

CS

ADDR

DATA

MEMORY

(OPTIONAL)

ADDR

DATA

OE

WE

ACK

CS

HOST

PROCESSOR

INTERFACE

(OPTIONAL)

ADDR

DATA

DMA DEVICE

(OPTIONAL)

DATA

registers in the register file individually (word aligned), or

in sets of two (dual aligned) or four (quad aligned).

• ALU—the ALU performs a standard set of arithmetic operations in both fixed- and floating-point formats. It also

performs logic operations.

• Multiplier—the multiplier performs both fixed- and floating-point multiplication and fixed-point multiply and

accumulate.

• Shifter—the 64-bit shifter performs logical and arithmetic

shifts, bit and bit stream manipulation, and field deposit

and extraction operations.

• Accelerator—128-bit unit for trellis decoding (for example,

Viterbi and turbo decoders) and complex correlations for

communication applications.

Using these features, the compute blocks can:

• Provide 8 MACs per cycle peak and 7.1 MACs per cycle

sustained 16-bit performance and provide 2 MACs per

cycle peak and 1.8 MACs per cycle sustained 32-bit performance (based on FIR)

• Execute six single precision floating-point or execute 24

storing intermediate results. Instructions can access the

L

S

A

T

S

O

E

R

T

N

O

C

A

R

D

D

D

A

fixed-point (16-bit) operations per cycle, providing

1,800 MFLOPS or 7.3 GOPS performance

• Perform two complex 16-bit MACs per cycle

• Execute eight trellis butterflies in one cycle

Figure 2. Single Processor System with External SDRAM

on it, the DSP automatically inserts one or more stall cycles as

needed. Efficient programming with dependency-free instructions can eliminate most computational and memory transfer

data dependencies.

In addition, the ADSP-TS101S supports SIMD operations two

ways—SIMD compute blocks and SIMD computations.The

programmer can direct both compute blocks to operate on the

same data (broadcast distribution) or on different data (merged

distribution). In addition, each compute block can execute four

16-bit or eight 8-bit SIMD computations in parallel.

DUAL COMPUTE BLOCKS

The ADSP-TS101S has compute blocks that can execute computations either independently or together as a SIMD engine.

The DSP can issue up to two compute instructions per compute

block each cycle, instructing the ALU, multiplier, or shifter to

perform independent, simultaneous operations.

The compute blocks are referred to as X and Y in assembly syntax, and each block contains three computational units—an

ALU, a multiplier, a 64-bit shifter—and a 32-word register file.

• Register file—each compute block has a multiported

32-word, fully orthogonal register file used for transferring

data between the computation units and data buses and for

DATA ALIGNMENT BUFFER (DAB)

The DAB is a quad word FIFO that enables loading of quad

word data from nonaligned addresses. Normally, load instructions must be aligned to their data size so that quad words are

loaded from a quad aligned address. Using the DAB significantly improves the efficiency of some applications, such as FIR

filters.

DUAL INTEGER ALUS (IALUS)

The ADSP-TS101S has two IALUs that provide powerful

address generation capabilities and perform many general-purpose integer operations. Each of the IALUs:

• Provides memory addresses for data and update pointers

• Supports circular buffering and bit-reverse addressing

• Performs general-purpose integer operations, increasing

programming flexibility

• Includes a 31-word register file for each IALU

As address generators, the IALUs perform immediate or indirect (pre- and post-modify) addressing. They perform modulus

and bit-reverse operations with no constraints placed on memory addresses for the modulus data buffer placement. Each

IALU can specify either a single, dual, or quad word access from

memory.

The IALUs have hardware support for circular buffers, bit

reverse, and zero-overhead looping. Circular buffers facilitate

efficient programming of delay lines and other data structures

required in digital signal processing, and they are commonly

Rev. B | Page 4 of 44 | December 2004

Page 5

ADSP-TS101S

used in digital filters and Fourier transforms. Each IALU provides registers for four circular buffers, so applications can set

up a total of eight circular buffers. The IALUs handle address

pointer wraparound automatically, reducing overhead, increasing performance, and simplifying implementation. Circular

buffers can start and end at any memory location.

Because the IALU’s computational pipeline is one cycle deep, in

most cases, integer results are available in the next cycle. Hardware (register dependency check) causes a stall if a result is

unavailable in a given cycle.

PROGRAM SEQUENCER

The ADSP-TS101S processor’s program sequencer supports:

• A fully interruptible programming model with flexible programming in assembly and C/C++ languages; handles

hardware interrupts with high throughput and no aborted

instruction cycles.

• An eight-cycle instruction pipeline—three-cycle fetch pipe

and five-cycle execution pipe—with computation results

available two cycles after operands are available.

• The supply of instruction fetch memory addresses; the

sequencer’s instruction alignment buffer (IAB) caches up

to five fetched instruction lines waiting to execute; the program sequencer extracts an instruction line from the IAB

and distributes it to the appropriate core component for

execution.

• The management of program structures and determination

of program flow according to JUMP, CALL, RTI, RTS

instructions, loop structures, conditions, interrupts, and

software exceptions.

• Branch prediction and a 128-entry branch target buffer

(BTB) to reduce branch delays for efficient execution of

conditional and unconditional branch instructions and

zero-overhead looping; correctly predicted branches that

are taken occur with zero-to-two overhead cycles, overcoming the three-to-six stage branch penalty.

• Compact code without the requirement to align code in

memory; the IAB handles alignment.

Interrupt Controller

The DSP supports nested and non-nested interrupts. Each

interrupt type has a register in the interrupt vector table. Also,

each has a bit in both the interrupt latch register and the interrupt mask register. All interrupts are fixed as either level

sensitive or edge sensitive, except the IRQ3–0

rupts, which are programmable.

The DSP distinguishes between hardware interrupts and software exceptions, handling them differently. When a software

exception occurs, the DSP aborts all other instructions in the

instruction pipe. When a hardware interrupt occurs, the DSP

continues to execute instructions already in the instruction pipe.

hardware inter-

Flexible Instruction Set

The 128-bit instruction line, which can contain up to four 32-bit

instructions, accommodates a variety of parallel operations for

concise programming. For example, one instruction line can

direct the DSP to conditionally execute a multiply, an add, and a

subtract in both computation blocks while it also branches to

another location in the program. Some key features of the

instruction set include:

• Enhanced instructions for communications infrastructure

to govern trellis decoding (for example, Viterbi and turbo

decoders) and despreading via complex correlations

• Algebraic assembly language syntax

• Direct support for all DSP, imaging, and video arithmetic

types, eliminating hardware modes

• Branch prediction encoded in instruction, enables zerooverhead loops

• Parallelism encoded in instruction line

• Conditional execution optional for all instructions

• User-defined, programmable partitioning between program and data memory

ON-CHIP SRAM MEMORY

The ADSP-TS101S has 6M bits of on-chip SRAM memory,

divided into three blocks of 2M bits (64K words × 32 bits). Each

block—M0, M1, and M2—can store program, data, or both, so

applications can configure memory to suit specific needs. Placing program instructions and data in different memory blocks,

however, enables the DSP to access data while performing an

instruction fetch.

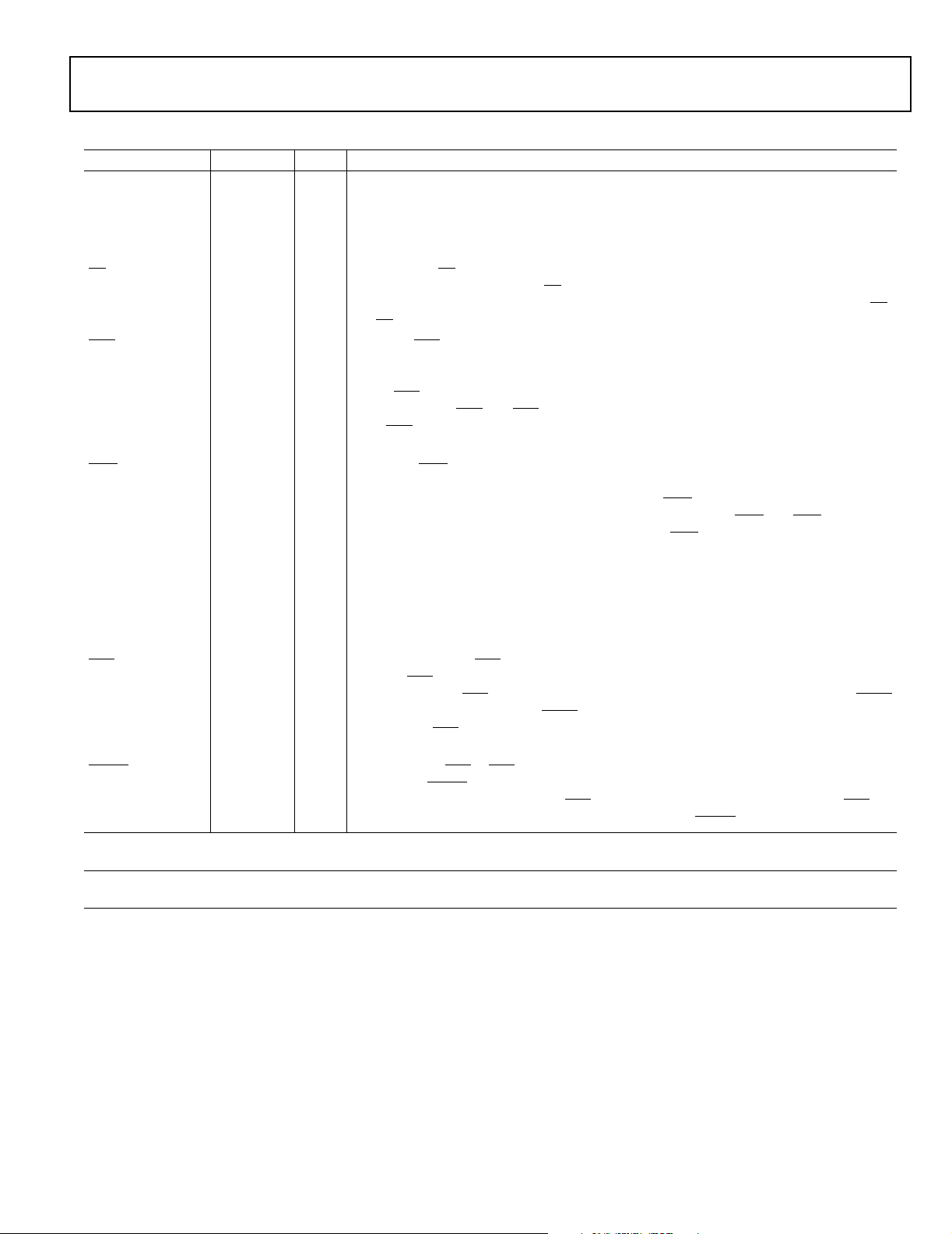

The DSP’s internal and external memory (Figure 3) is organized

into a unified memory map, which defines the location

(address) of all elements in the system.

The memory map is divided into four memory areas—host

space, external memory, multiprocessor space, and internal

memory—and each memory space, except host memory, is subdivided into smaller memory spaces.

Each internal memory block connects to one of the 128-bit wide

internal buses—block M0 to bus MD0, block M1 to bus MD1,

and block M2 to bus MD2—enabling the DSP to perform three

memory transfers in the same cycle. The DSP’s internal bus

architecture provides a total memory bandwidth of 14.4G bytes

per second, enabling the core and I/O to access eight 32-bit data

words (256 bits) and four 32-bit instructions each cycle. The

DSP’s flexible memory structure enables:

• DSP core and I/O access of different memory blocks in the

same cycle

• DSP core access of all three memory blocks in parallel—

one instruction and two data accesses

• Programmable partitioning of program and data memory

• Program access of all memory as 32-, 64-, or 128-bit

words—16-bit words with the DAB

• Complete context switch in less than 20 cycles (66 ns)

Rev. B | Page 5 of 44 | December 2004

Page 6

ADSP-TS101S

INTERNAL SPACE

RE SER VE D

INTERNAL REGISTERS (UREGS)

RE SER VE D

INTERNAL MEMORY 2

RE SER VE D

INTERNAL MEMORY 1

RE SE RV E D

INTERNAL MEMORY 0

0x 003FF FFF

0x00300000

0x00280000

0x00200000

0x 00180 7FF

0x00180000

0x0010FFFF

0x00100000

0x0008FFFF

0x00080000

0x0000FFFF

0x00000000

GLOBAL SPACE

HOST

(MSH)

E

C

A

P

S

Y

R

O

M

E

M

L

A

N

R

E

T

X

E

E

C

A

P

S

Y

R

O

M

E

M

R

O

S

S

E

C

O

R

P

I

T

L

U

M

BANK 1

(MS1)

BANK 0

(MS0)

SDRAM

(MSSD)

PROC ESSOR I D 7

PROC ESSOR I D 6

PROC ESSOR I D 5

PROC ESSOR I D 4

PROC ESSOR I D 3

PROC ESSOR I D 2

PROC ESSOR I D 1

PROC ESSOR I D 0

BROADCAST

RESERVED

INTER NAL ME MORY

0xFFFFFFFF

0 x100 00000

0 x0C 0000 00

0 x080 00000

0 x040 00000

0 x03C 000 00

0 x038 00000

0 x034 00000

0 x030 00000

0 x02C 000 00

0 x028 00000

0 x024 00000

0 x020 00000

0 x01C 000 00

0x003FFFFF

0 x000 00000

EACH IS A COPY

OF INTERNAL SPACE

Figure 3. Memory Map

EXTERNAL PORT (OFF-CHIP MEMORY/PERIPHERALS INTERFACE)

The ADSP-TS101S processor’s external port provides the processor’s interface to off-chip memory and peripherals. The

4G word address space is included in the DSP’s unified address

space. The separate on-chip buses—three 128-bit data buses and

three 32-bit address buses—are multiplexed at the external port

to create an external system bus with a single 64-bit data bus

and a single 32-bit address bus. The external port supports data

transfer rates of 800M bytes per second over external bus.

The external bus can be configured for 32- or 64-bit operation.

When the system bus is configured for 64-bit operation, the

lower 32 bits of the external data bus connect to even addresses,

and the upper 32 bits connect to odd addresses.

Rev. B | Page 6 of 44 | December 2004

The external port supports pipelined, slow, and SDRAM protocols. Addressing of external memory devices and memory

mapped peripherals is facilitated by on-chip decoding of high

order address lines to generate memory bank select signals.

The ADSP-TS101S provides programmable memory, pipeline

depth, and idle cycle for synchronous accesses, and external

acknowledge controls to support interfacing to pipelined or

slow devices, host processors, and other memory-mapped

peripherals with variable access, hold, and disable time

requirements.

Host Interface

The ADSP-TS101S provides an easy and configurable interface

between its external bus and host processors through the external port. To accommodate a variety of host processors, the host

Page 7

ADSP-TS101S

interface supports pipelined or slow protocols for accesses of the

host as slave. Each protocol has programmable transmission

parameters, such as idle cycles, pipe depth, and internal

wait cycles.

The host interface supports burst transactions initiated by a host

processor. After the host issues the starting address of the burst

and asserts the BRST

internally while the host continues to assert BRST

The host interface provides a deadlock recovery mechanism that

enables a host to recover from deadlock situations involving the

DSP. The BOFF

nism. When the host asserts BOFF

current transaction and asserts HBG

nal bus.

The host can directly read or write the internal memory of the

ADSP-TS101S, and it can access most of the DSP registers,

including DMA control (TCB) registers. Vector interrupts support efficient execution of host commands.

signal, the DSP increments the address

.

signal provides the deadlock recovery mecha-

, the DSP backs off the

and relinquishes the exter-

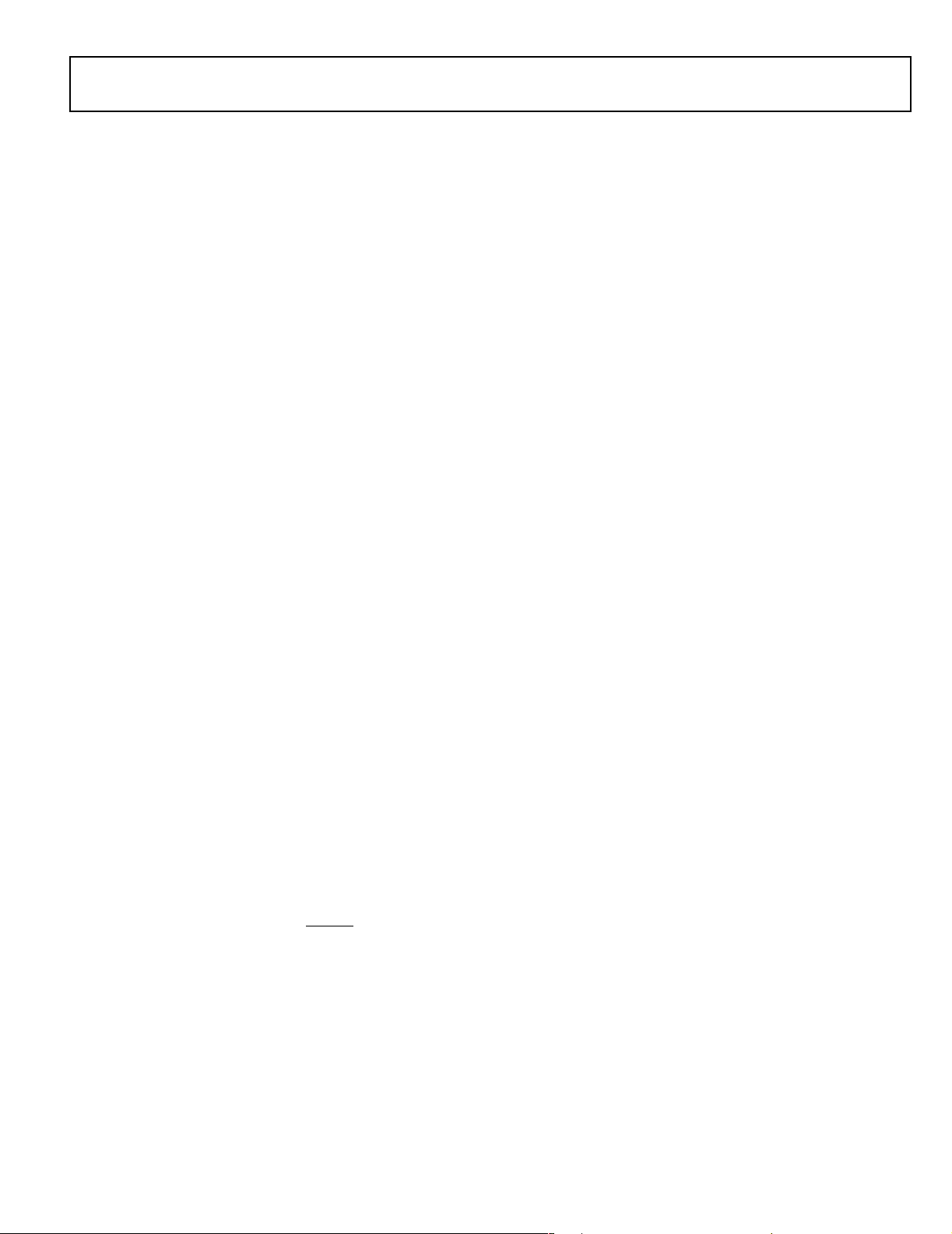

Multiprocessor Interface

The ADSP-TS101S offers powerful features tailored to multiprocessing DSP systems through the external port and link

ports. This multiprocessing capability provides highest bandwidth for interprocessor communication, including:

• Up to eight DSPs on a common bus

• On-chip arbitration for glueless multiprocessing

• Link ports for point-to-point communication

The external port and link ports provide integrated, glueless

multiprocessing support.

The external port supports a unified address space (see Figure 3)

that enables direct interprocessor accesses of each ADSPTS101S processor’s internal memory and registers. The DSP’s

on-chip distributed bus arbitration logic provides simple, glueless connection for systems containing up to eight ADSPTS101S processors and a host processor. Bus arbitration has a

rotating priority. Bus lock supports indivisible read-modifywrite sequences for semaphores. A bus fairness feature prevents

one DSP from holding the external bus too long.

The DSP’s four link ports provide a second path for interprocessor communications with throughput of 1G bytes per second.

The cluster bus provides 800M bytes per second throughput—

with a total of 1.8G bytes per second interprocessor bandwidth.

SDRAM Controller

The SDRAM controller controls the ADSP-TS101S processor’s

transfers of data to and from synchronous DRAM (SDRAM).

The throughput is 32 or 64 bits per SCLK cycle using the external port and SDRAM control pins.

The SDRAM interface provides a glueless interface with standard SDRAMs—16M bit, 64M bit, 128M bit, and 256M bit. The

DSP directly supports a maximum of 64M words × 32 bits of

SDRAM. The SDRAM interface is mapped in external memory

in the DSP’s unified memory map.

EPROM Interface

The ADSP-TS101S can be configured to boot from external

8-bit EPROM at reset through the external port. An automatic

process (which follows reset) loads a program from the EPROM

into internal memory. This process uses 16 wait cycles for each

read access. During booting, the BMS

EPROM chip select signal. The EPROM boot procedure uses

DMA Channel 0, which packs the bytes into 32-bit instructions.

Applications can also access the EPROM (write flash memories)

during normal operation through DMA.

The EPROM or flash memory interface is not mapped in the

DSP’s unified memory map. It is a byte address space limited to

a maximum of 16M bytes (24 address bits). The EPROM or

flash memory interface can be used after boot via a DMA.

pin functions as the

DMA CONTROLLER

The ADSP-TS101S processor’s on-chip DMA controller, with

14 DMA channels, provides zero-overhead data transfers without processor intervention. The DMA controller operates

independently and invisibly to the DSP’s core, enabling DMA

operations to occur while the DSP’s core continues to execute

program instructions. The DMA controller performs DMA

transfers between:

• Internal memory and external memory and memorymapped peripherals

• Internal memory of other DSPs on a common bus, a host

processor, or link port I/O

• External memory and external peripherals or link port I/O

• External bus master and internal memory or link port I/O

The DMA controller provides a number of additional features.

The DMA controller supports flyby transfers. Flyby operations

only occur through the external port (DMA Channel 0) and do

not involve the DSP’s core. The DMA controller acts as a conduit to transfer data from one external device to another

through external memory. During a transaction, the DSP:

• Relinquishes the external data bus

• Outputs addresses, memory selects (MS1–0

, and SDWE) and the FLYBY, IOEN, and RD/WR

CAS

strobes

•Responds to ACK

DMA chaining is also supported by the DMA controller. DMA

chaining operations enable applications to automatically link

one DMA transfer sequence to another for continuous transmission. The sequences can occur over different DMA channels

and have different transmission attributes.

The DMA controller also supports two-dimensional transfers.

The DMA controller can access and transfer two-dimensional

memory arrays on any DMA transmit or receive channel. These

transfers are implemented with index, count, and modify registers for both the X and Y dimensions.

, MSSD, RAS,

Rev. B | Page 7 of 44 | December 2004

Page 8

ADSP-TS101S

001

000

RESET

CLOCK

REFERENCE

VOLTAGE

LINK

DEVICES

(4 MAX)

(OPTIONAL)

ID2–0

RESET

CLKS/REFS

ID2–0

RESET

CLKS/REFS

SCLK_P

LCLK_P

S/LCLK_N

V

REF

LCLKRAT2–0

SCLKFREQ

IRQ3–0

FLAG3–0

LINK

LXDAT7–0

LXCLKIN

LXCLKOUT

LXDIR

TMR0E

BM

CONTROLIMP2–0

DS2–0

ADSP-TS101 #7

ADSP-TS101 #6

ADSP-TS101 #5

ADSP-TS101 #4

ADSP-TS101 #3

ADSP-TS101 #2

ADSP-TS101 #1

ADDR31–0

DATA63–0

CONTROL

LINK

ADSP-TS101 #0

ADDR31–0

DATA63–0

BUSLOCK

DMAR3–0

CONTROL

BR7–2,0

BR1

BR7–1

BR0

RD

WRH/L

ACK

MS1–0

BMS

CPA

DPA

BOFF

BRST

HBR

HBG

MSH

FLYBY

IOEN

MSSD

RAS

CAS

LDQM

HDQM

SDWE

SDCKE

SDA10

L

S

S

O

R

T

N

O

C

L

O

R

T

N

O

C

A

E

T

R

A

D

D

D

A

S

S

A

E

T

R

A

D

D

D

A

ADDR

DATA

OE

WE

ACK

CS

CS

ADDR

DATA

ADDR

DATA

CS

RAS

CAS

DQM

WE

CKE

A10

ADDR

DATA

GLOBAL

MEMORY

AND

PERIPHERALS

(OPTIONAL)

BOOT

EPROM

(OPTIONAL)

CLOCK

HOST

PROCESSOR

INTERFACE

(OPTIONAL)

SDRAM

MEMORY

(OPTIONAL)

CLK

Figure 4. Shared Memory Multiprocessing System

The DMA controller performs the following DMA operations:

• External port block transfers. Four dedicated bidirectional

DMA channels transfer blocks of data between the DSP’s

internal memory and any external memory or memorymapped peripheral on the external bus. These transfers

support master mode and handshake mode protocols.

• Link port transfers. Eight dedicated DMA channels (four

transmit and four receive) transfer quad word data only

between link ports and between a link port and internal or

Rev. B | Page 8 of 44 | December 2004

external memory. These transfers only use handshake

mode protocol. DMA priority rotates between the four

receive channels.

• AutoDMA transfers. Two dedicated unidirectional DMA

channels transfer data received from an external bus master

to internal memory or to link port I/O. These transfers only

use slave mode protocol, and an external bus master must

initiate the transfer.

LINK PORTS

The DSP’s four link ports provide additional 8-bit bidirectional

I/O capability. With the ability to operate at a double data rate—

latching data on both the rising and falling edges of the clock—

Page 9

ADSP-TS101S

running at 125 MHz, each link port can support up to

250M bytes per second, for a combined maximum throughput

of 1G bytes per second.

The link ports provide an optional communications channel

that is useful in multiprocessor systems for implementing point

to point interprocessor communications. Applications can also

use the link ports for booting.

Each link port has its own double-buffered input and output

registers. The DSP’s core can write directly to a link port’s transmit register and read from a receive register, or the DMA

controller can perform DMA transfers through eight (four

transmit and four receive) dedicated link port DMA channels.

Each link port has three signals that control its operation.

LxCLKOUT and LxCLKIN implement clock/acknowledge

handshaking. LxDIR indicates the direction of transfer and is

used only when buffering the LxDAT signals. An example application would be using differential low-swing buffers for long

twisted-pair wires. LxDAT provides the 8-bit data bus

input/output.

Applications can program separate error detection mechanisms

for transmit and receive operations (applications can use the

checksum mechanism to implement consecutive link port

transfers), the size of data packets, and the speed at which bytes

are transmitted.

Under certain conditions, the link port receiver can initiate a

token switch to reverse the direction of transfer; the transmitter

becomes the receiver and vice versa.

TIMER AND GENERAL-PURPOSE I/O

The ADSP-TS101S has a timer pin (TMR0E) that generates output when a programmed timer counter has expired. Also, the

DSP has four programmable general-purpose I/O pins

(FLAG3–0) that can function as either single bit input or output. As outputs, these pins can signal peripheral devices; as

inputs, they can provide the test for conditional branching.

RESET AND BOOTING

The ADSP-TS101S has two levels of reset (see reset specifications on Page 24):

• Power-up reset—after power-up of the system, and strap

options are stable, the RESET

• Normal reset—for any resets following the power-up reset

sequence, the RESET

pin must be asserted.

The DSP can be reset internally (core reset) by setting the

SWRST bit in SQCTL. The core is reset, but not the external

port or I/O.

pin must be asserted (low).

After reset, the ADSP-TS101S has four boot options for beginning operation:

• Boot from EPROM. The DSP defaults to EPROM booting

when the BMS

pin strap option is set low. See Strap Pin

Function Descriptions on Page 19.

• Boot by an external master (host or another ADSPTS101S). Any master on the cluster bus can boot the

ADSP-TS101S through writes to its internal memory or

through autoDMA.

• Boot by link port. All four receive link DMA channels are

initialized after reset to transfer a 256-word block to internal memory address 0 to 255, and to issue an interrupt at

the end of the block (similar to EP DMA). The corresponding DMA interrupts are set to address zero (0).

• No boot—Start running from an external memory. Using

the “no boot” option, the ADSP-TS101S must start running

from an external memory, caused by asserting one of the

IRQ3–0

interrupt signals.

The ADSP-TS101S core always exits from reset in the idle state

and waits for an interrupt. Some of the interrupts in the interrupt vector table are initialized and enabled after reset.

LOW POWER OPERATION

The ADSP-TS101S can enter a low power sleep mode in which

its core does not execute instructions, reducing power consumption to a minimum. The ADSP-TS101S exits sleep mode

when it senses a falling edge on any of its IRQ3–0

interrupt

inputs. The interrupt, if enabled, causes the ADSP-TS101S to

execute the corresponding interrupt service routine. This feature is useful for systems that require a low power standby

mode.

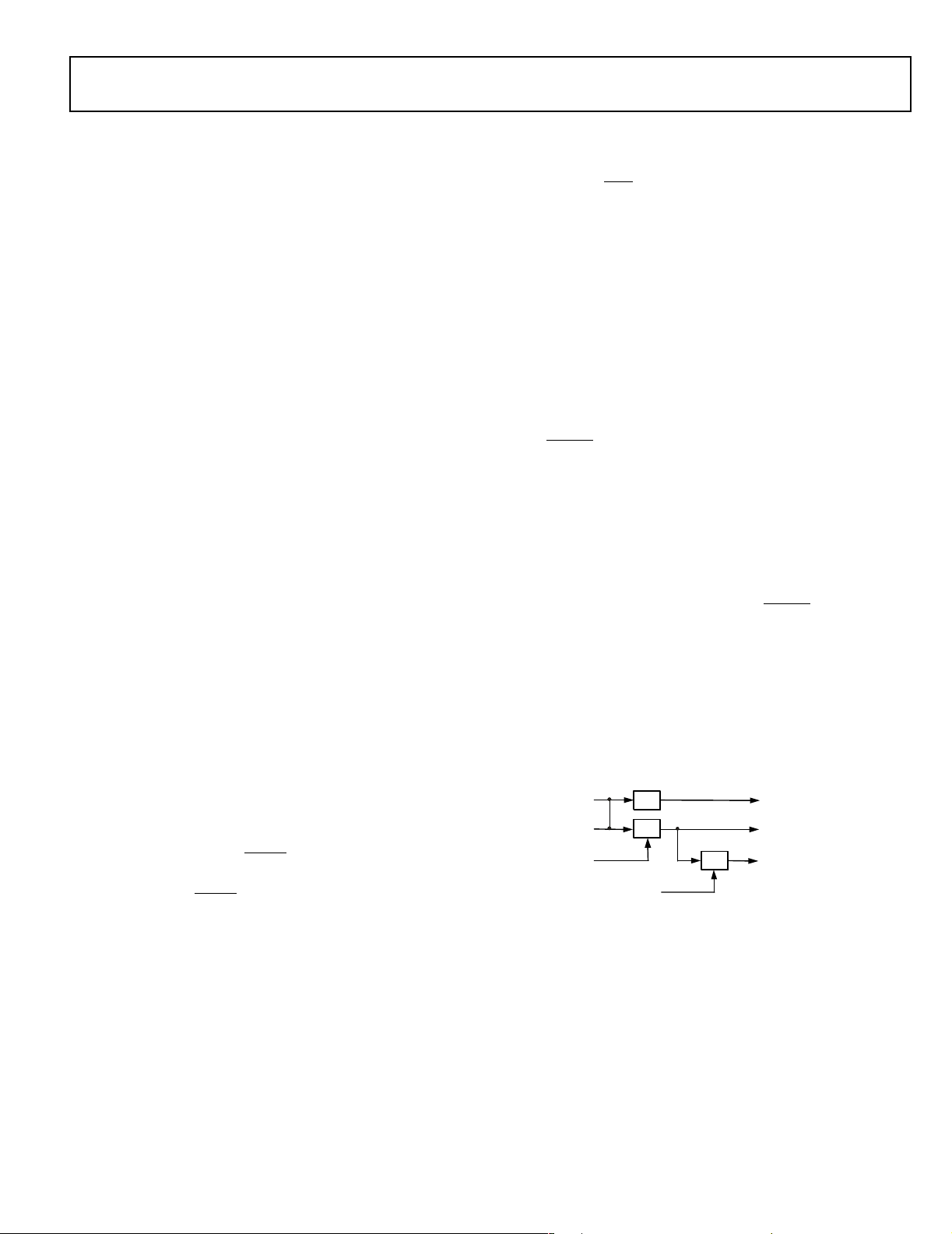

CLOCK DOMAINS

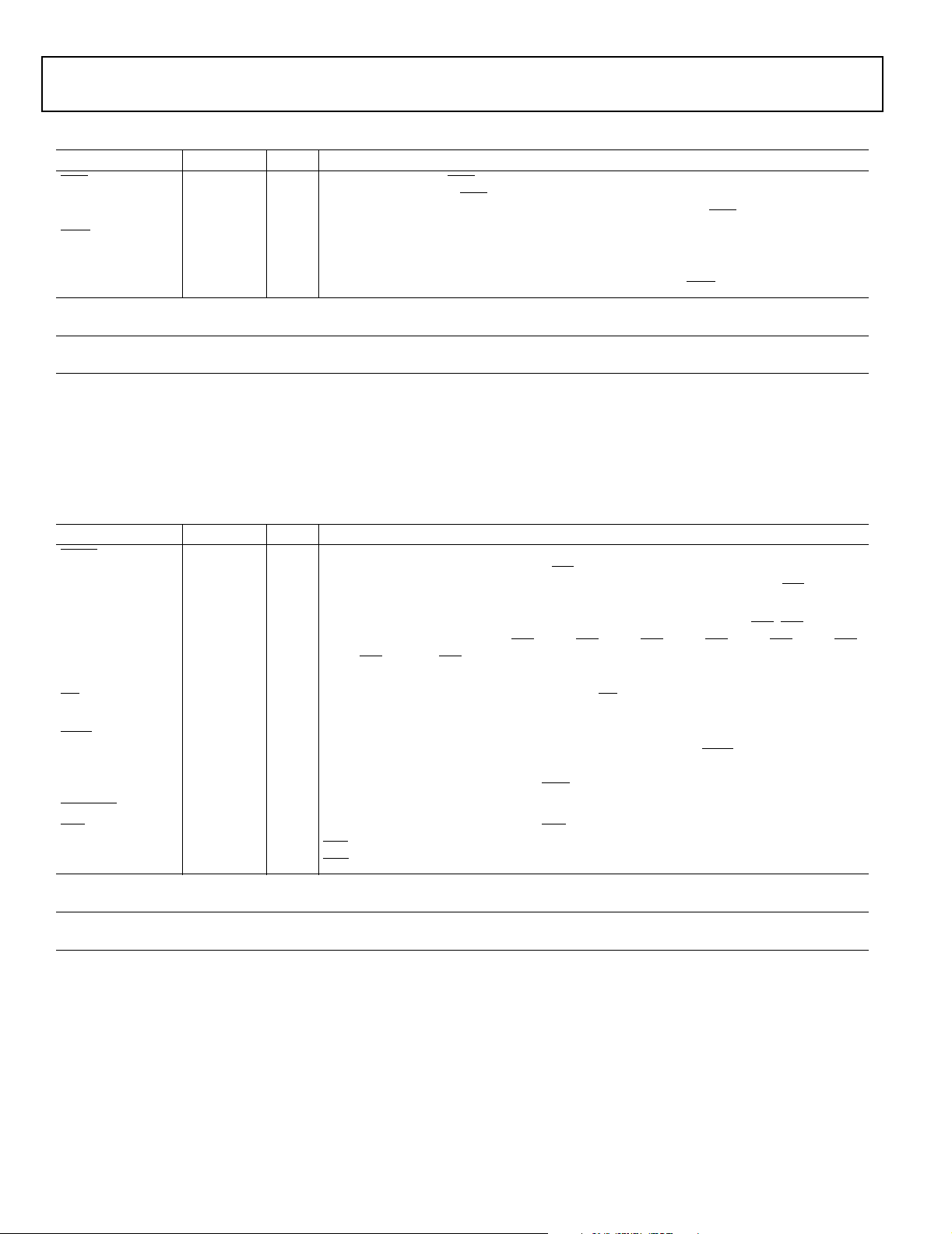

As shown in Figure 5, the ADSP-TS101S has two clock inputs,

SCLK (system clock) and LCLK (local clock).

SCLK_P

LCLK_P

LCLKRATx

LCTLx REGISTER

DLL

DLL

PLL

DLL

SPD BITS,

Figure 5. Clock Domains

/LR

DLL

These inputs drive its two major clock domains:

• SCLK (system clock). Provides clock input for the external

bus interface and defines the ac specification reference for

the external bus signals. The external bus interface runs at

1× the SCLK frequency. A DLL locks internal SCLK to

SCLK input.

• LCLK (local clock). Provides clock input to the internal

clock driver, CCLK, which is the internal clock for the core,

internal buses, memory, and link ports. The instruction

EXTERNAL INTERFACE

CCLK

(INSTRUCTION RATE)

LxCLKOUT/LxCLKIN

(LINK PORT RATE)

Rev. B | Page 9 of 44 | December 2004

Page 10

ADSP-TS101S

execution rate is equal to CCLK. A PLL from LCLK generates CCLK which is phase-locked. The LCLKRAT pins

define the clock multiplication of LCLK to CCLK (see

Table 4). The link port clock is generated from CCLK via a

software programmable divisor. RESET

must be asserted

until LCLK is stable and within specification for at least

2 ms. This applies to power-up as well as any dynamic

modification of LCLK after power-up. Dynamic modification may include LCLK going out of specification as long as

RESET

is asserted.

Connecting SCLK and LCLK to the same clock source is a

requirement for the device. Using an integer clock multiplication value provides predictable cycle-by-cycle operation, a

requirement of fault-tolerant systems and some multiprocessing systems.

Noninteger values are completely functional and acceptable for

applications that do not require predictable cycle-by-cycle

operation.

OUTPUT PIN DRIVE STRENGTH CONTROL

Pins CONTROLIMP2-0 and DS2-0 work together to control

the output drive strength of two groups of pins, the

Address/Data/Control pin group and the Link pin group.

CONTROLIMP2-0 independently configures the two pin

groups to the maximum drive strength or to a digitally controlled drive strength that is selectable by the DS2-0 pins (see

Table 13 on Page 18). If the digitally controlled drive strength is

selected for a pin group, the DS2-0 pins determine one of eight

strength levels for that group (see Table 14 on Page 18). The

drive strength selected varies the slew rate of the driver. Drive

strength 0 (DS2-0 = 000) is the weakest and slowest slew rate.

Drive strength 7 (DS2-0 = 111) is the strongest and fastest slew

rate.

The stronger drive strengths are useful for high frequency

switching while the lower strengths may allow use of a relaxed

design methodology. The strongest drive strengths have a larger

di/dt and thus require more attention to signal integrity issues

such a ringing, reflections and coupling. Also a larger di/dt can

increase external supply rail noise, which impacts power supply

and power distribution design.

The drive strengths for the EMU

, CPA, and DPA pins are not

controllable and are fixed to the maximum level.

For drive strength calculation, see Output Drive Currents on

Page 32.

POWER SUPPLIES

The ADSP-TS101S has separate power supply connections for

internal logic (V

) power supply. The internal (VDD) and analog (V

(V

DD_IO

supplies must meet the 1.2 V requirement. The I/O buffer

(V

) supply must meet the 3.3 V requirement.

DD_IO

The analog supply (V

produce a stable clock, systems must provide a clean power supply to power input V

bypassing the V

), analog circuits (V

DD

) powers the clock generator PLLs. To

DD_A

. Designs must pay critical attention to

DD_A

supply.

DD_A

), and I/O buffer

DD_A

DD_A

)

The required power-on sequence for the DSP is to provide V

(and V

) before V

DD_A

DD_IO

.

DD

FILTERING REFERENCE VOLTAGE AND CLOCKS

Figure 6 shows a possible circuit for filtering V

LCLK_N. This circuit provides the reference voltage for the

switching voltage, system clock, and local clock references.

V

DD_IO

R1

R2 C1 C2

V

SS

R1: 2k⍀ SERIES RESISTOR

R2: 1.67k⍀ SERIES RESIST OR

C1: 1F CAPACITOR (SMD)

C2: 1nF CAPACITOR (HF SMD) PLACED CLOSE TO DSP’S PINS

Figure 6. V

, SCLK_N, and LCLK_N Filter

REF

, SCLK_N, and

REF

V

REF

SCLK_N

LCLK_N

DEVELOPMENT TOOLS

The ADSP-TS101S is supported with a complete set of

CROSSCORE

including Analog Devices emulators and VisualDSP++

opment environment. The same emulator hardware that

supports other TigerSHARC processors also fully emulates the

ADSP-TS101S.

The VisualDSP++ project management environment lets programmers develop and debug an application. This environment

includes an easy to use assembler (which is based on an algebraic syntax), an archiver (librarian/library builder), a linker, a

loader, a cycle-accurate instruction-level simulator, a C/C++

compiler, and a C/C++ run-time library that includes DSP and

mathematical functions. A key point for these tools is C/C++

code efficiency. The compiler has been developed for efficient

translation of C/C++ code to DSP assembly. The DSP has architectural features that improve the efficiency of compiled C/C++

code.

The VisualDSP++ debugger has a number of important features. Data visualization is enhanced by a plotting package that

offers a significant level of flexibility. This graphical representation of user data enables the programmer to quickly determine

the performance of an algorithm. As algorithms grow in complexity, this capability can have increasing significance on the

designer’s development schedule, increasing productivity. Statistical profiling enables the programmer to nonintrusively poll

the processor as it is running the program. This feature, unique

to VisualDSP++, enables the software developer to passively

gather important code execution metrics without interrupting

the real-time characteristics of the program. Essentially, the

developer can identify bottlenecks in software quickly and

†

CROSSCORE is a registered trademark of Analog Devices, Inc.

‡

VisualDSP++ is a registered trademark of Analog Devices, Inc.

®

†

software and hardware development tools,

®

‡

devel-

Rev. B | Page 10 of 44 | December 2004

Page 11

ADSP-TS101S

efficiently. By using the profiler, the programmer can focus on

those areas in the program that impact performance and take

corrective action.

Debugging both C/C++ and assembly programs with the

VisualDSP++ debugger, programmers can:

• View mixed C/C++ and assembly code (interleaved source

and object information)

• Insert breakpoints

• Set conditional breakpoints on registers, memory,

and stacks

• Trace instruction execution

• Perform linear or statistical profiling of program execution

• Fill, dump, and graphically plot the contents of memory

• Perform source level debugging

• Create custom debugger windows

The VisualDSP++ IDDE lets programmers define and manage

DSP software development. Its dialog boxes and property pages

let programmers configure and manage all of the TigerSHARC

development tools, including the color syntax highlighting in

the VisualDSP++ editor. This capability permits programmers

to:

• Control how the development tools process inputs and

generate outputs

• Maintain a one-to-one correspondence with the tool’s

command line switches

The VisualDSP++ Kernel (VDK) incorporates scheduling and

resource management tailored specifically to address the memory and timing constraints of DSP programming. These

capabilities enable engineers to develop code more effectively,

eliminating the need to start from the very beginning, when

developing new application code. The VDK features include

threads, critical and unscheduled regions, semaphores, events,

and device flags. The VDK also supports priority-based, preemptive, cooperative, and time-sliced scheduling approaches. In

addition, the VDK was designed to be scalable. If the application

does not use a specific feature, the support code for that feature

is excluded from the target system.

Because the VDK is a library, a developer can decide whether to

use it or not. The VDK is integrated into the VisualDSP++

development environment, but can also be used via standard

command line tools. When the VDK is used, the development

environment assists the developer with many error-prone tasks

and assists in managing system resources, automating the generation of various VDK-based objects, and visualizing the

system state, when debugging an application that uses the VDK.

VCSE is Analog Devices technology for creating, using, and

reusing software components (independent modules of substantial functionality) to quickly and reliably assemble software

applications. It is also used for downloading components from

the Web, dropping them into the application, and publishing

component archives from within VisualDSP++. VCSE supports

component implementation in C/C++ or assembly language.

Use the expert linker to visually manipulate the placement of

code and data on the embedded system. View memory utilization in a color-coded graphical form, easily move code and data

to different areas of the DSP or external memory with a drag of

the mouse, examine run-time stack and heap usage. The expert

linker is fully compatible with existing linker definition file

(LDF), allowing the developer to move between the graphical

and textual environments.

Analog Devices DSP emulators use the IEEE 1149.1 JTAG Test

Access Port of the ADSP-TS101S processor to monitor and control the target board processor during emulation. The emulator

provides full speed emulation, allowing inspection and modification of memory, registers, and processor stacks. Nonintrusive

in-circuit emulation is assured by the use of the processor’s

JTAG interface—the emulator does not affect target system

loading or timing.

In addition to the software and hardware development tools

available from Analog Devices, third parties provide a wide

range of tools supporting the TigerSHARC processor family.

Hardware tools include TigerSHARC processor PC plug-in

cards. Third party software tools include DSP libraries, realtime operating systems, and block diagram design tools.

DESIGNING AN EMULATORCOMPATIBLE DSP BOARD (TARGET)

The Analog Devices family of emulators are tools that every

DSP developer needs to test and debug hardware and software

systems. Analog Devices has supplied an IEEE 1149.1 JTAG test

access port (TAP) on each JTAG DSP. The emulator uses the

TAP to access the internal features of the DSP, allowing the

developer to load code, set breakpoints, observe variables,

observe memory, and examine registers. The DSP must be

halted to send data and commands, but once an operation has

been completed by the emulator, the DSP system is set running

at full speed with no impact on system timing.

To use these emulators, the target board must include a header

that connects the DSP’s JTAG port to the emulator.

For details on target board design issues including mechanical

layout, single processor connections, multiprocessor scan

chains, signal buffering, signal termination, and emulator pod

logic, see the EE-68: Analog Devices JTAG Emulation Technical

Reference on the Analog Devices website (www.analog.com)—

use site search on “EE-68.” This document is updated regularly

to keep pace with improvements to emulator support.

ADDITIONAL INFORMATION

This data sheet provides a general overview of the ADSPTS101S processor’s architecture and functionality. For detailed

information on the ADSP-TS101S processor’s core architecture

and instruction set, see the ADSP-TS101 TigerSHARC Processor

Programming Reference and the ADSP-TS101 TigerSHARC Processor Hardware Reference. For detailed information on the

development tools for this processor, see the VisualDSP++

User’s Guide for TigerSHARC Processors.

Rev. B | Page 11 of 44 | December 2004

Page 12

ADSP-TS101S

PIN FUNCTION DESCRIPTIONS

While most of the ADSP-TS101S processor’s input pins are normally synchronous—tied to a specific clock—a few are

asynchronous. For these asynchronous signals, an on-chip synchronization circuit prevents metastability problems. The

synchronous ac specification for asynchronous signals is used

only when predictable cycle-by-cycle behavior is required.

All inputs are sampled by a clock reference, therefore input

PIN STATES AT RESET

The output pins can be three-stated during normal operation.

The DSP three-states all outputs during reset, allowing these

pins to get to their internal pull-up or pull-down state. Some

output pins (control signals) have a pull-up or pull-down that

maintains a known value during transitions between different

drivers.

specifications (asynchronous minimum pulse widths or synchronous input setup and hold) must be met to guarantee

recognition.

PIN DEFINITIONS

The Type column in the following pin definitions tables

describes the pin type, when the pin is used in the system. The

Term (for termination) column describes the pin termination

type if the pin is not used by the system. Note that some pins are

always used (indicated with au symbol).

Table 3. Pin Definitions—Clocks and Reset

Signal Type Term Description

LCLK_N I au Local Clock Reference. Connect this pin to V

as shown in Figure 6.

REF

LCLK_P I au Local Clock Input. DSP clock input. The instruction cycle rate = n × LCLK, where n is user-

programmable to 2, 2.5, 3, 3.5, 4, 5, or 6. For more information, see Clock Domains on Page 9.

LCLKRAT2–0

1

I (pd2) au LCLK Ratio. The DSP’s core clock (instruction cycle rate) = n × LCLK, where n is user-program-

mable to 2, 2.5, 3, 3.5, 4, 5, or 6 as shown in Table 4. These pins must have a constant value while

the DSP is powered.

SCLK_N I au System Clock Reference. Connect this pin to V

as shown in Figure 6.

REF

SCLK_P I au System Clock Input. The DSP’s system input clock for cluster bus. This pin must be connected

to the same clock source as LCLK_P. For more information, see Clock Domains on Page 9.

SCLKFREQ

3

I (pu2) au SCLK Frequency. SCLKFREQ = 1 is required. The SCLKFREQ pin must have a constant value while

the DSP is powered.

RESET

I/A au Reset. Sets the DSP to a known state and causes program to be in idle state. RESET must be

asserted at specified time according to the type of reset operation. For details, see Reset and

Booting on Page 9.

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

1

The internal pull-down may not be sufficient. A stronger pull-down may be necessary.

2

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

3

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Table 4. LCLK Ratio

LCLKRAT2–0 Ratio

000 (default) 2

001 2.5

010 3

011 3.5

100 4

101 5

110 6

111 Reserved

Rev. B | Page 12 of 44 | December 2004

Page 13

Table 5. Pin Definitions—External Port Bus Controls

ADSP-TS101S

Signal Type Term Description

ADDR31–0

1

I/O/T nc Address Bus. The DSP issues addresses for accessing memory and peripherals on these pins. In

a multiprocessor system, the bus master drives addresses for accessing internal memory or I/O

processor registers of other ADSP-TS101S processors. The DSP inputs addresses when a host or

another DSP accesses its internal memory or I/O processor registers.

DATA63–0

RD

1

2

I/O/T nc External Data Bus. Data and instructions are received, and driven by the DSP, on these pins.

I/O/T (pu3)nc Memory Read. RD is asserted whenever the DSP reads from any slave in the system, excluding

SDRAM. When the DSP is a slave, RD is an input and indicates read transactions that access its

internal memory or universal registers. In a multiprocessor system, the bus master drives RD.

pin changes concurrently with ADDR pins.

The RD

WRL

2

I/O/T (pu3) nc Write Low. WRL is asserted in two cases: When the ADSP-TS101S writes to an even address word

of external memory or to another external bus agent; and when the ADSP-TS101S writes to a

32-bit zone (host, memory, or DSP programmed to 32-bit bus). An external master (host or DSP)

asserts WRL

bus master drives WRL

slave, WRL

for writing to a DSP’s low word of internal memory. In a multiprocessor system, the

. The WRL pin changes concurrently with ADDR pins. When the DSP is a

is an input and indicates write transactions that access its internal memory or

universal registers.

2

WRH

I/O/T (pu3) nc Write High. WRH is asserted when the ADSP-TS101S writes a long word (64 bits) or writes to an

odd address word of external memory or to another external bus agent on a 64-bit data bus.

An external master (host or another DSP) must assert WRH

for writing to a DSP’s high word of

64-bit data bus. In a multiprocessing system, the bus master drives WRH. The WRH pin changes

concurrently with ADDR pins. When the DSP is a slave, WRH

is an input and indicates write

transactions that access its internal memory or universal registers.

ACK I/O/T epu Acknowledge. External slave devices can deassert ACK to add wait states to external memory

accesses. ACK is used by I/O devices, memory controllers, and other peripherals on the data

phase. The DSP can deassert ACK to add wait states to read accesses of its internal memory. The

ADSP-TS101S does not drive ACK during slave writes. Therefore, an external (approximately

10 kΩ) pull-up is required.

2, 4

BMS

O/T

(pu/pd3)

au Boot Memory Select. BMS is the chip select for boot EPROM or flash memory. During reset, the

DSP uses BMS as a strap pin (EBOOT) for EPROM boot mode. When the DSP is configured to

boot from EPROM, BMS

is active during the boot sequence. Pull-down enabled during RESET

(asserted); pull-up enabled after RESET (deasserted). In a multiprocessor system, the DSP bus

master drives BMS. For details see Reset and Booting on Page 9 and the EBOOT signal

description in Table 16 on Page 19.

MS1–0

2

O/T (pu3)nc Memory Select. MS0 or MS1 is asserted whenever the DSP accesses memory banks 0 or 1,

respectively. MS1–0 are decoded memory address pins that change concurrently with ADDR

pins. When ADDR31:26 = 0b000010, MS0 is asserted. When ADDR31:26 = 0b000011, MS1 is

asserted. In multiprocessor systems, the master DSP drives MS1–0

.

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Rev. B | Page 13 of 44 | December 2004

Page 14

ADSP-TS101S

Table 5. Pin Definitions—External Port Bus Controls (Continued)

Signal Type Term Description

2

MSH

2

BRST

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

1

The address and data buses may float for several cycles during bus mastership transitions between a TigerSHARC processor and a host. Floating in this case means that these

inputs are not driven by any source and that dc-biased terminations are not present. It is not necessary to add pull-ups as there are no reliability issues and the worst-case

power consumption for these floating inputs is negligible. Unconnected address pins may require pull-ups or pull-downs to avoid erroneous slave accesses, depending on

the system. Unconnected data pins may be left floating.

2

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

3

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

4

The internal pull-down may not be sufficient. A stronger pull-down may be necessary.

Table 6. Pin Definitions—External Port Arbitration

Signal Type Term Description

BR7–0

1

ID2–0

1

BM

BOFF

BUSLOCK

3

HBR

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

O/T (pu3) nc Memory Select Host. MSH is asserted whenever the DSP accesses the host address space

(ADDR31:28 ≠ 0b0000). MSH is a decoded memory address pin that changes concurrently with

ADDR pins. In a multiprocessor system, the bus master DSP drives MSH.

I/O/T (pu3) nc Burst. The current bus master (DSP or host) asserts this pin to indicate that it is reading or writing

data associated with consecutive addresses. A slave device can ignore addresses after the first

one and increment an internal address counter after each transfer. For host-to-DSP burst

accesses, the DSP increments the address automatically while BRST

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

is asserted.

I/O epu Multiprocessing Bus Request Pins. Used by the DSPs in a multiprocessor system to arbitrate for

bus mastership. Each DSP drives its own BRx line (corresponding to the value of its ID2–0 inputs)

and monitors all others. In systems with fewer than eight DSPs, set the unused BRx

pins high.

I (pd2) au Multiprocessor ID. Indicates the DSP’s ID. From the ID, the DSP determines its order in a multi-

processor system. These pins also indicate to the DSP which bus request (BR0–BR7) to assert

when requesting the bus: 000 = BR0, 001 = BR1, 010 = BR2, 011 = BR3, 100 = BR4, 101 = BR5,

110 = BR6

, or 111 = BR7. ID2–0 must have a constant value during system operation and can

change during reset only.

O (pd2) au Bus Master. The current bus master DSP asserts BM. For debugging only. At reset this is a strap

pin. For more information, see Table 16 on Page 19.

I epu Back Off. A deadlock situation can occur when the host and a DSP try to read from each other’s

bus at the same time. When deadlock occurs, the host can assert BOFF to force the DSP to

relinquish the bus before completing its outstanding transaction, but only if the outstanding

transaction is to host memory space (MSH

).

O/T (pu2) nc Bus Lock Indication. Provides an indication that the current bus master has locked the bus.

I epu Host Bus Request. A host must assert HBR to request control of the DSP’s external bus. When

HBR

is asserted in a multiprocessing system, the bus master relinquishes the bus and asserts

once the outstanding transaction is finished.

HBG

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Rev. B | Page 14 of 44 | December 2004

Page 15

ADSP-TS101S

Table 6. Pin Definitions—External Port Arbitration (Continued)

Signal Type Term Description

3

HBG

CPA

DPA I/O (o/d) See

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

to V

, nc = not connected; au = always used.

DD-IO

1

The internal pull-down may not be sufficient. A stronger pull-down may be necessary.

2

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

3

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

I/O/T (pu2) nc Host Bus Grant. Acknowledges HBR and indicates that the host can take control of the external

bus. When relinquishing the bus, the master DSP three -states the ADDR31–0, DATA63–0, MSH,

MSSD, MS1–0, RD, WRL, WRH, BMS, BRST, FLYBY, IOEN, RAS, CAS, SDWE, SDA10, SDCKE, LDQM

and HDQM pins, and the DSP puts the SDRAM in self-refresh mode. The DSP asserts HBG

the host deasserts HBR. In multiprocessor systems, the current bus master DSP drives HBG, and

.

is an open drain output, connected to all DSPs

I/O (o/d) See

next

column

all slave DSPs monitor HBG

Core Priority Access. Asserted while the DSP’s core accesses external memory. This pin enables

a slave DSP to interrupt a master DSP’s background DMA transfers and gain control of the

external bus for core-initiated transactions. CPA

in the system. The CPA pin has an internal 500 Ω pull-up resistor, which is only enabled on the

DSP with ID2–0 = 0. If ID0 is not used, terminate this pin as either epu or nc. If ID7–1 is not used,

terminate this pin as epu.

DMA Priority Access. Asserted while a high priority DSP DMA channel accesses external

next

column

memory. This pin enables a high priority DMA channel on a slave DSP to interrupt transfers of

a normal priority DMA channel on a master DSP and gain control of the external bus for DMA-

initiated transactions. DPA

is an open drain output, connected to all DSPs in the system. The

DPA pin has an internal 500 Ω pull-up resistor, which is only enabled on the DSP with ID2–0 = 0.

If ID0 is not used, terminate this pin as either epu or nc. If ID7–1 is not used, terminate this pin

as epu.

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

until

Table 7. Pin Definitions—External Port DMA/Flyby

Signal Type Term Description

DMAR3–0

I/A epu DMA Request Pins. Enable external I/O devices to request DMA services from the DSP. In

response to DMARx

, the DSP performs DMA transfers according to the DMA channel’s initial-

ization. The DSP ignores DMA requests from uninitialized channels.

1

FLYBY

O/T (pu2) nc Flyby Mode. When a DSP DMA channel is initiated in FLYBY mode, it generates flyby transac tions

on the external bus. During flyby transactions, the DSP asserts FLYBY, which signals the source

or destination I/O device to latch the next data or strobe the current data, respectively, and to

prepare for the next data on the next cycle.

1

IOEN

O/T (pu2) nc I/O Device Output Enable. Enables the output buffers of an external I/O device for flyby trans-

actions between the device and external memory. Active on flyby transactions.

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

1

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

2

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Rev. B | Page 15 of 44 | December 2004

Page 16

ADSP-TS101S

Table 8. Pin Definitions—External Port SDRAM Controller

Signal Type Term Description

1

MSSD

1

RAS

1

CAS

1

LDQM

1

HDQM

1

SDA10

1, 3

SDCKE

1

SDWE

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

1

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

2

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

3

The internal pull-down may not be sufficient. A stronger pull-down may be necessary.

I/O/T (pu2) nc Memory Select SDRAM. MSSD is asserted whenever the DSP accesses SDRAM memory space.

MSSD is a decoded memory address pin that is asserted whenever the DSP issues an SDRAM

command cycle (access to ADDR31:26 = 0b000001). MSSD in a multiprocessor system is driven

by the master DSP.

I/O/T (pu2) nc Row Address Select. When sampled low, RAS indicates that a row address is valid in a read or

write of SDRAM. In other SDRAM accesses, RAS defines the type of operation to execute

according to SDRAM specification.

I/O/T (pu2) nc Column Address Select. When sampled low, CAS indicates that a column address is valid in a

read or write of SDRAM. In other SDRAM accesses, CAS defines the type of operation to execute

according to the SDRAM specification.

O/T (pu2) nc Low Word SDRAM Data Mask. When LDQM is sampled high, the DSP three-states the SDRAM

DQ buffers. LDQM is valid on SDRAM transactions when CAS is asserted and is inactive on read

transactions. On write transactions, LDQM is active when accessing an odd address word on a

64-bit memory bus to disable the write of the low word.

O/T (pu2) nc High Word SDRAM Data Mask. When HDQM is sampled high, the DSP three-states the SDRAM

DQ buf fers . HD QM i s va lid o n SD RAM t ran sac ti ons whe n CA S is asserted and is inactive on read

transactions. On write transactions, HDQM is active when accessing an even address in word

accesses or is active when memory is configured for a 32-bit bus to disable the write of the high

word.

O/T (pu2) nc SDRAM Address bit 10 pin. Separate A10 signals enable SDRAM refresh operation while the DSP

executes non-SDRAM transactions.

I/O/T

(pu/pd2)

nc SDRAM Clock Enable. Activates the SDRAM clock for SDRAM self-refresh or suspend modes. A

slave DSP in a multiprocessor system does not have the pull-up or pull-down. A master DSP (or

ID = 0 in a single processor system) has a 100 kΩ pull-up before granting the bus to the host,

except when the SDRAM is put in self-refresh mode. In self-refresh mode, the master has a

100 kΩ pull-down before granting the bus to the host.

I/O/T (pu2) nc SDRAM Write Enable. When sampled low while CAS is active, SDWE indicates an SDRAM write

access. When sampled high while CAS

is active, SDWE indicates an SDRAM read access. In other

SDRAM accesses, SDWE defines the type of operation to execute according to SDRAM

specification.

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Rev. B | Page 16 of 44 | December 2004

Page 17

Table 9. Pin Definitions—JTAG Port

ADSP-TS101S

Signal Type Term Description

epu

1

Emulation. Connected only to the DSP’s JTAG emulator target board connector.

Test Clock (JTAG). Provides an asynchronous clock for JTAG scan.

1

1

Test Data Output (JTAG). A serial data output of the scan path.

EMU

O (o/d) nc

TCK I epd or

2

TDI

I (pu3)nc1Test Data Input (JTAG). A serial data input of the scan path.

TDO O/T nc

2

TMS

TRST

2

I (pu3)nc1Test Mode Select (JTAG). Used to control the test state machine.

I/A (pu3) au Test Reset (JTAG). Resets the test state machine. TRST must be asserted or pulsed low after

power-up for proper device operation.

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 kΩ; pu = internal pull-up approximately 100 kΩ; T = three-state

Term (for termination) column symbols: epd = external pull-down approximately 10 k

to V

, nc = not connected; au = always used.

DD-IO

1

See the reference on Page 11 to the JTAG emulation technical reference EE-68.

2

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

3

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Table 10. Pin Definitions—Flags, Interrupts, and Timer

Signal Type Term Description

FLAG3–0

1

I/O/A (pd2) nc FLAG pins. Bidirectional input/output pins can be used as program conditions. Each pin can be

configured individually for input or for output. FLAG3–0 are inputs after power-up and reset.

3

IRQ3–0

I/A (pu2) nc Interrupt Request. When asserted, the DSP generates an interrupt. Each of the IRQ3–0 pins can

be independently set for edge triggered or level sensitive operation. After reset, these pins are

strap option is initialized for booting.

TMR0E

1

O (pd2) au Timer 0 expires. This output pulses for four SCLK cycles whenever timer 0 expires. At reset this

disabled unless the IRQ3–0

is a strap pin. For additional information, see Table 16 on Page 19.

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO

1

The internal pull-down may not be sufficient. A stronger pull-down may be necessary.

2

See Electrical Characteristics on Page 20 for maximum and minimum current consumption for pull-up and pull-down resistances.

3

The internal pull-up may not be sufficient. A stronger pull-up may be necessary.

Ω; pu = internal pull-up approximately 100 kΩ; T = three-state

Ω to V

; epu = external pull-up approximately 10 kΩ

SS

Table 11. Pin Definitions—Link Ports

Signal Type Term Description

L0DAT7–0

L1DAT7–0

L2DAT7–0

L3DAT7–0

1

1

1

1

I/O nc Link0 Data 7–0

I/O nc Link1 Data 7–0

I/O nc Link2 Data 7–0

I/O nc Link3 Data 7–0

L0CLKOUT O nc Link0 Clock/Acknowledge Output

L1CLKOUT O nc Link1 Clock/Acknowledge Output

L2CLKOUT O nc Link2 Clock/Acknowledge Output

L3CLKOUT O nc Link3 Clock/Acknowledge Output

L0CLKIN I/A epu Link0 Clock/Acknowledge Input

L1CLKIN I/A epu Link1 Clock/Acknowledge Input

Type column symbols: A = asynchronous; G = ground; I = input; O = output; o/d = open drain output; P = power supply;

pd = internal pull-down approximately 100 k

Term (for termination) column symbols: epd = external pull-down approximately 10 k

, nc = not connected; au = always used.

to V

DD-IO